Investigation of the Dislocation Behavior of 6- and 8-Inch AlGaN/GaN HEMT Structures with a Thin AlGaN Buffer Layer Grown on Si Substrates

Abstract

1. Introduction

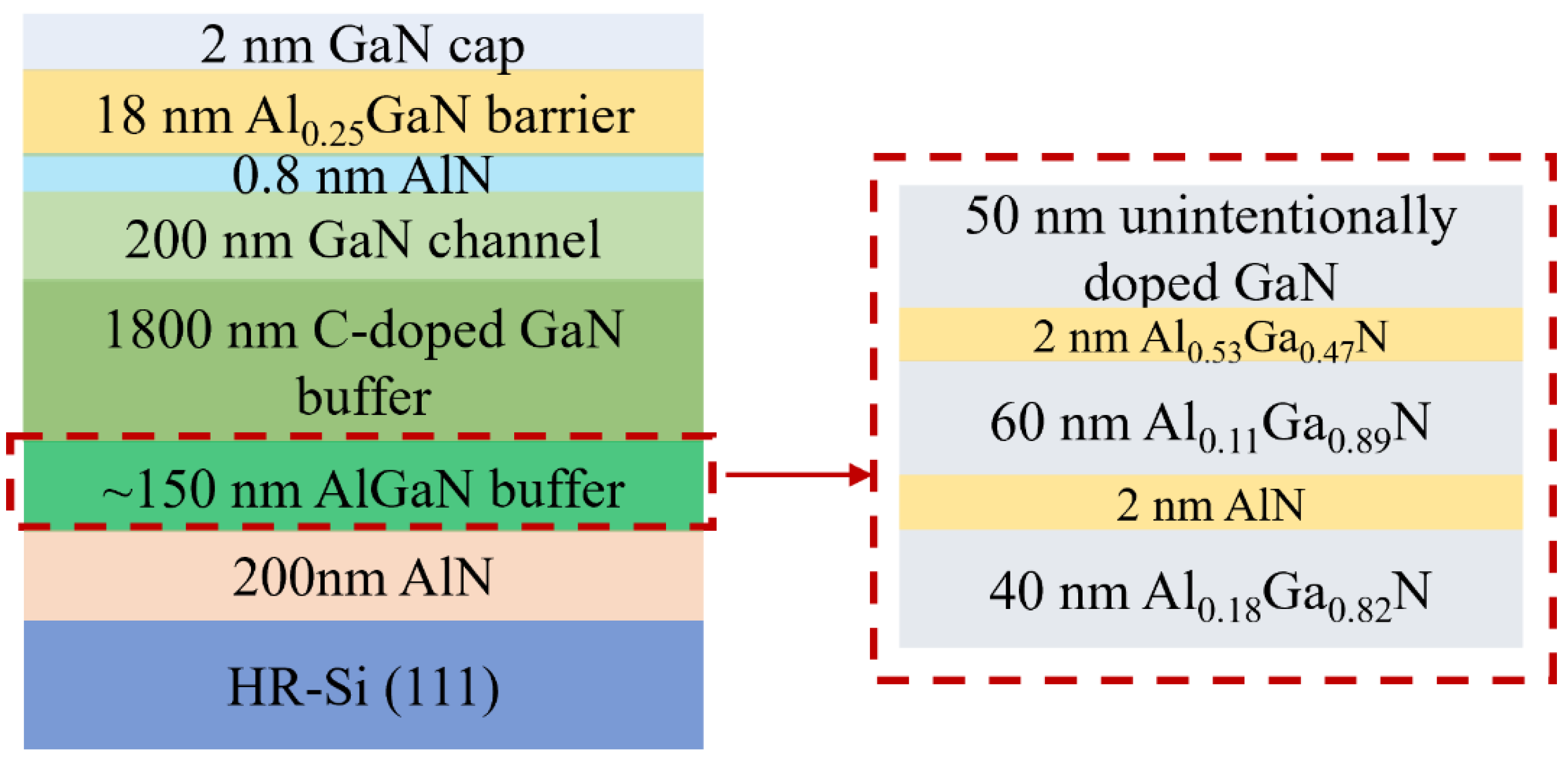

2. Experimental Details

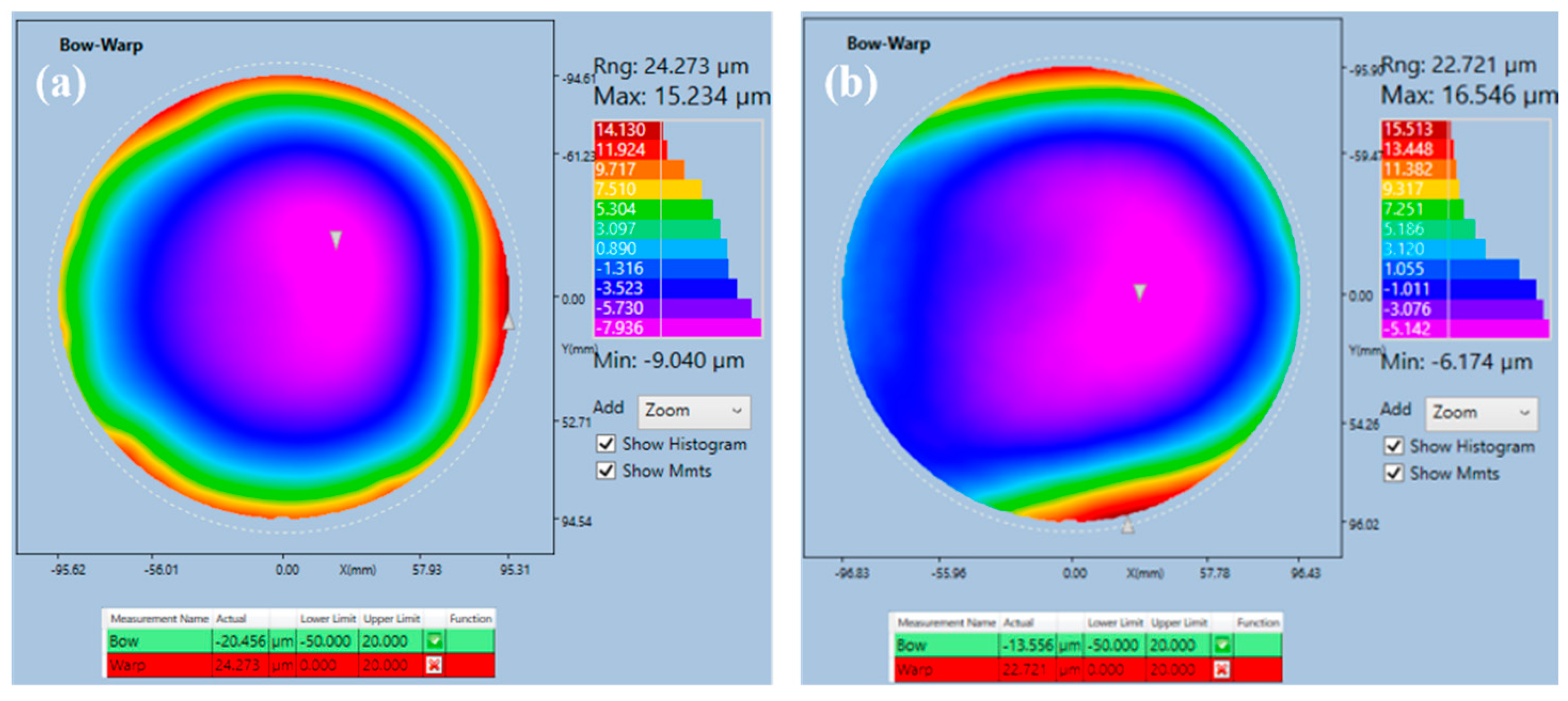

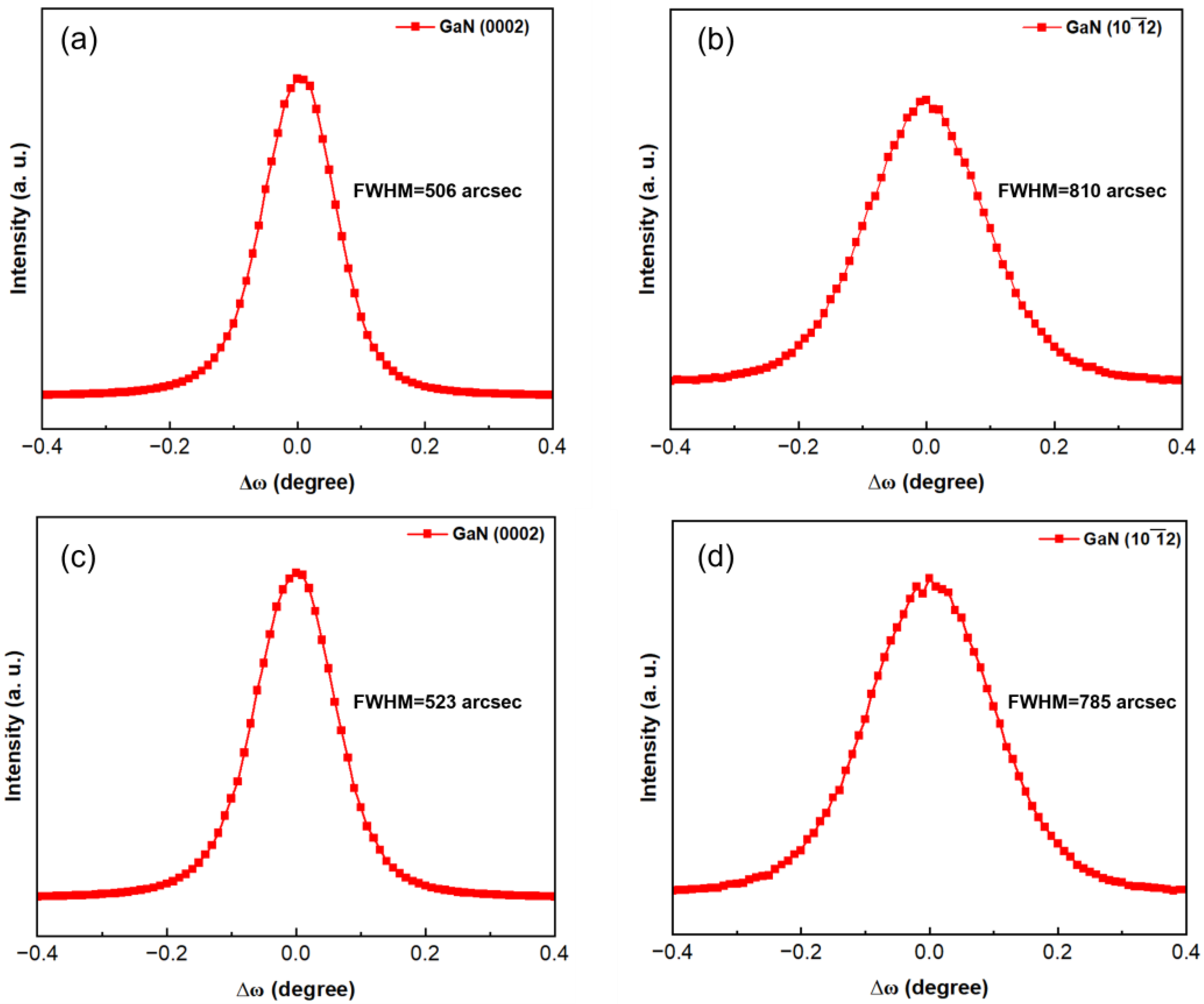

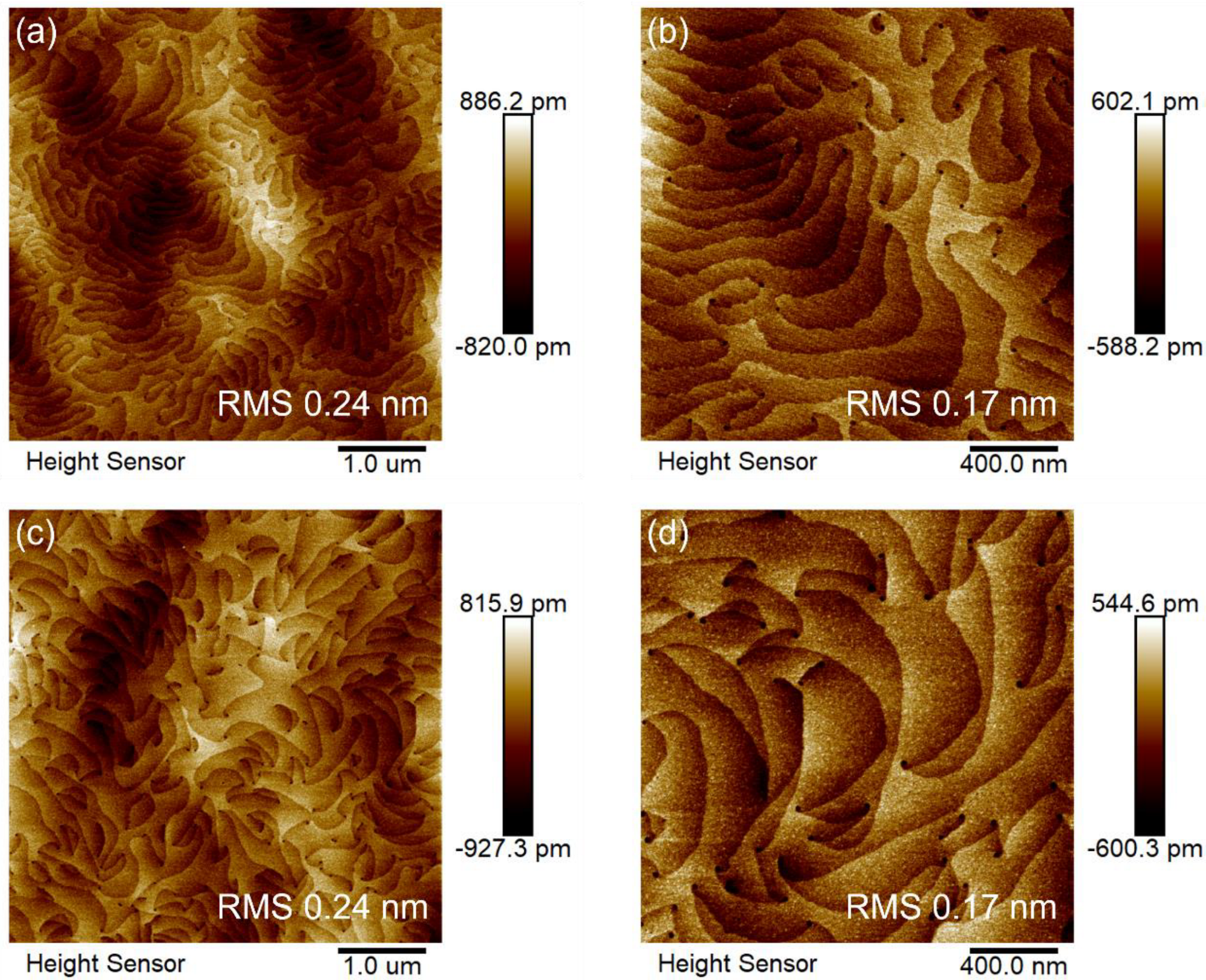

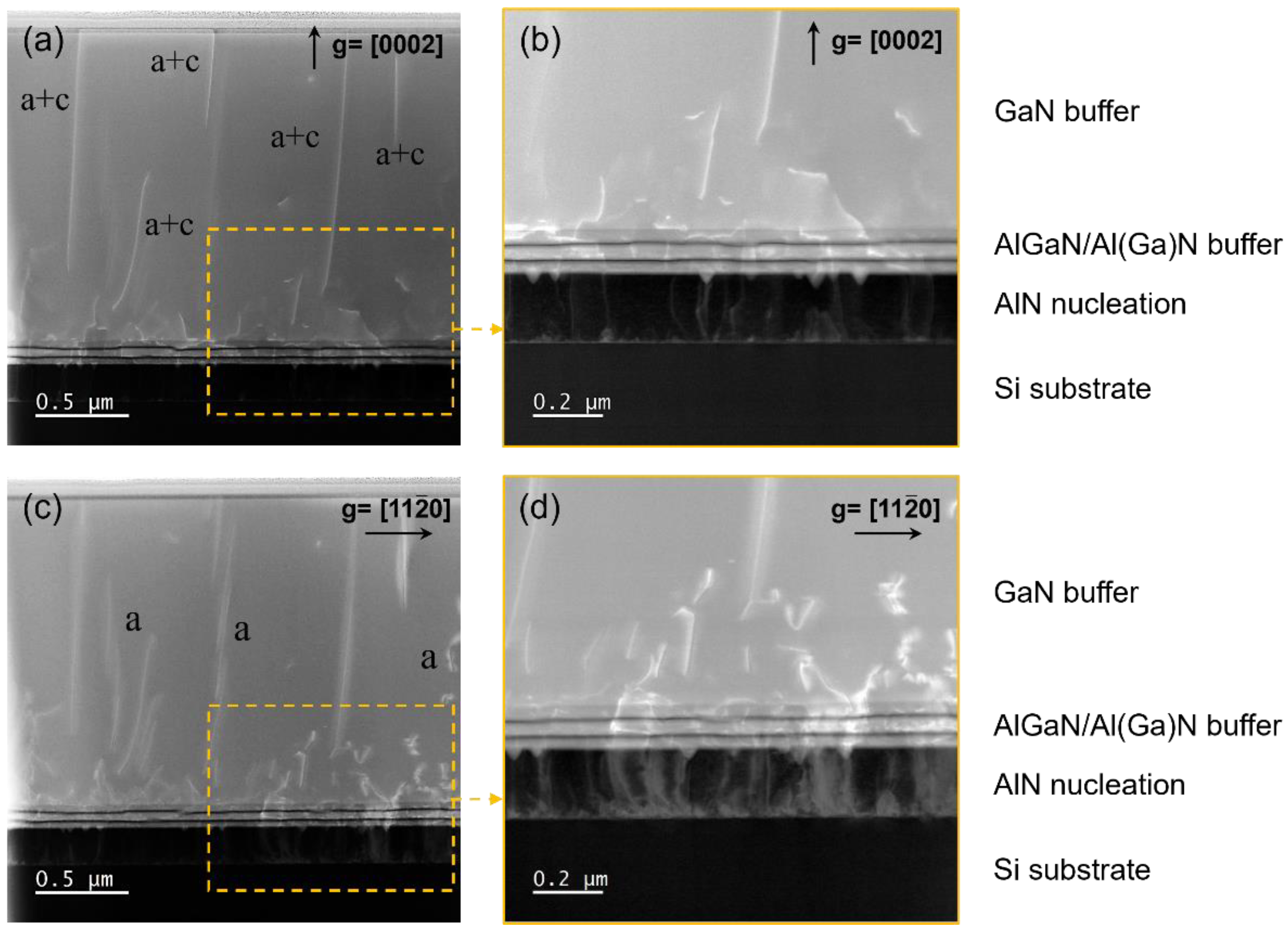

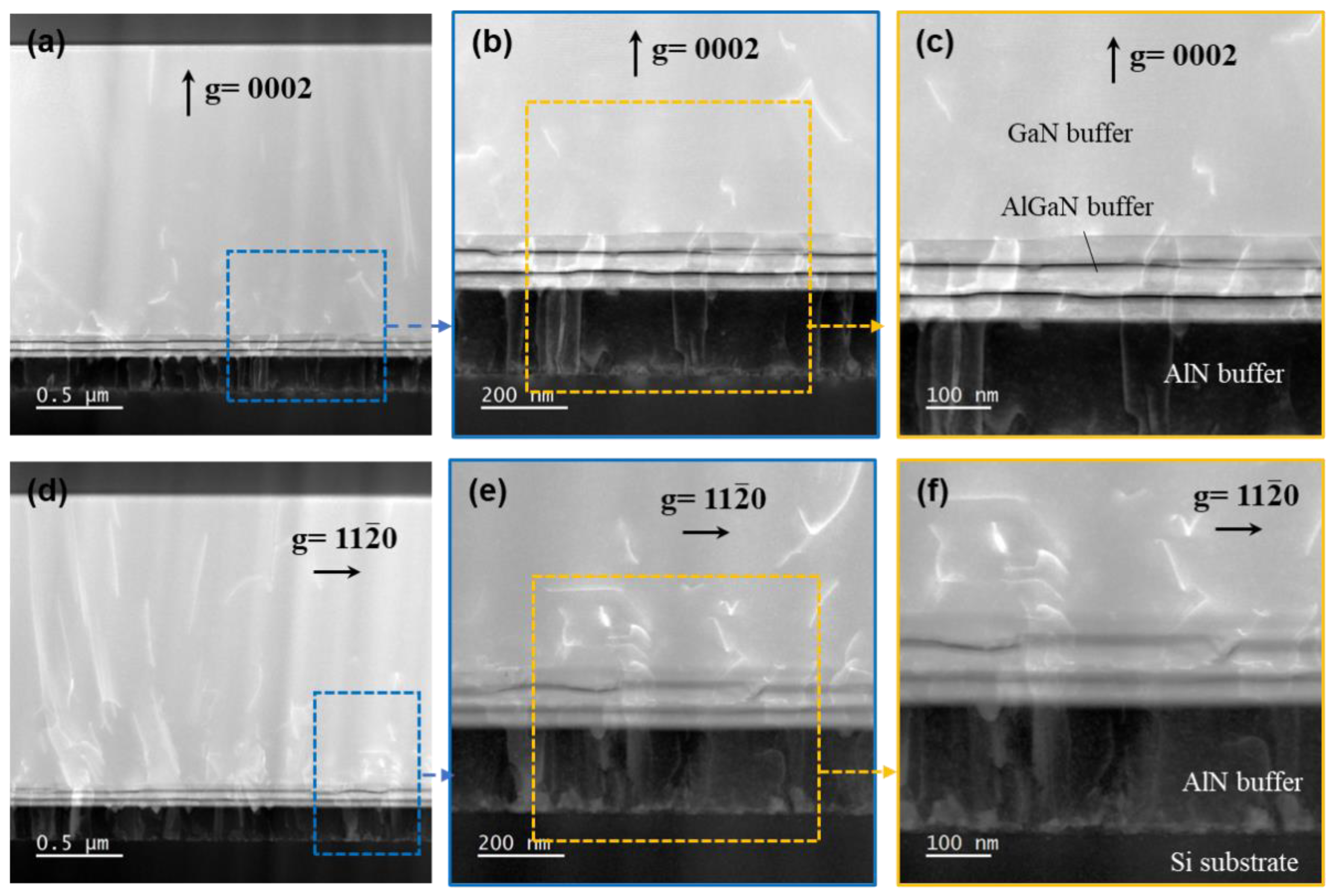

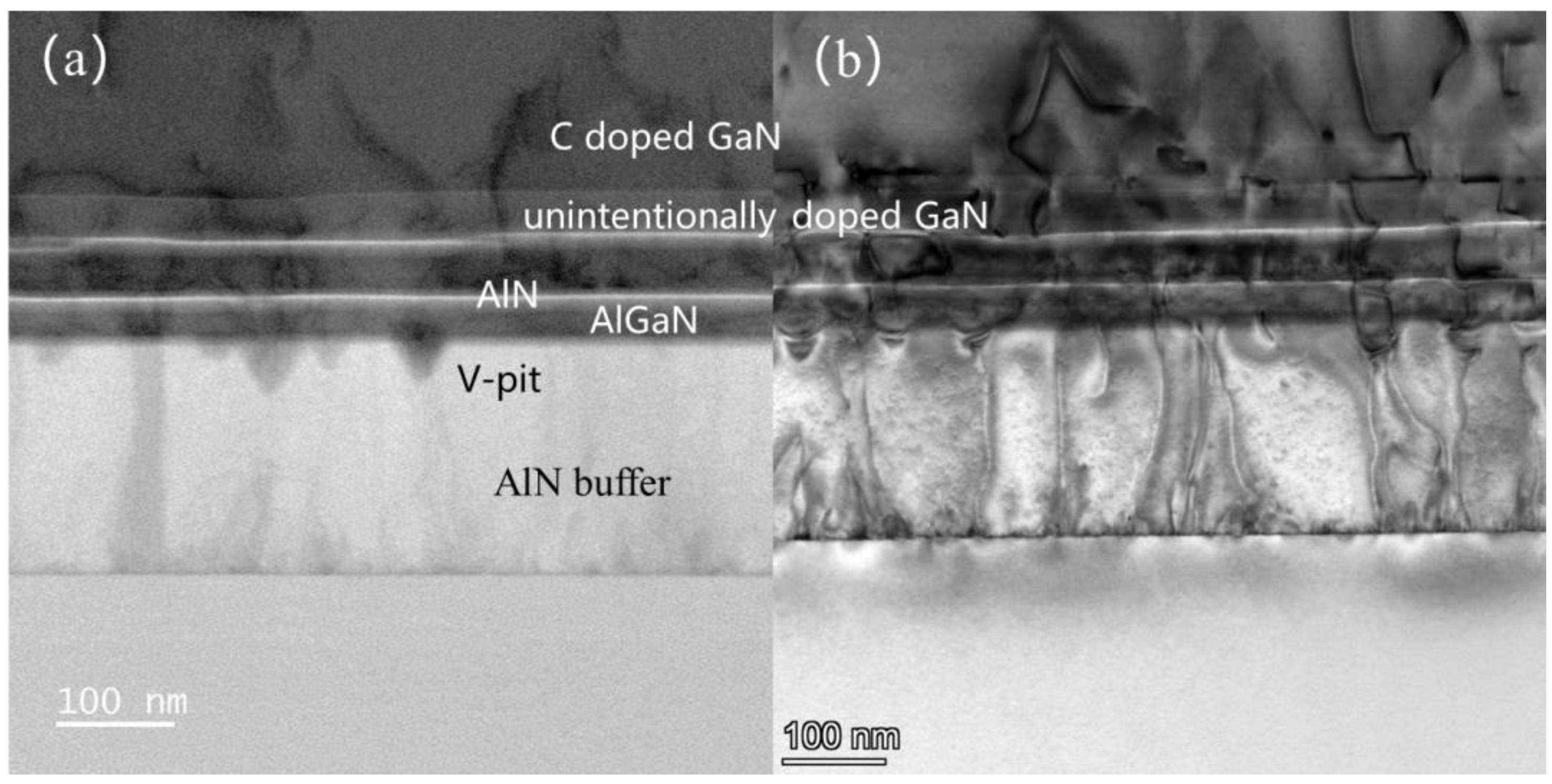

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, N.T.; Xing, Z.H.; Li, S.J.; Luo, L.; Zeng, F.Y.; Li, G.Q. GaN-based power high-electron-mobility transistors on Si substrates: From materials to devices. Semicond. Sci. Technol. 2023, 38, 063002. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, J.; Wu, S.; Jia, L.; Yang, X.; Liu, Y.; Zhang, Y.; Sun, Q. A review on the GaN-on-Si power electronic devices. Fundam. Res. 2022, 2, 462–475. [Google Scholar] [CrossRef] [PubMed]

- Haziq, M.; Falina, S.; Manaf, A.A.; Kawarada, H.; Syamsul, M. Challenges and Opportunities for High-Power and High-Frequency AlGaN/GaN High-Electron-Mobility Transistor (HEMT) Applications: A Review. Micromachines 2022, 13, 2133. [Google Scholar] [CrossRef] [PubMed]

- Ajayan, J.; Nirmal, D.; Mohankumar, P.; Mounika, B.; Bhattacharya, S.; Tayal, S.; Fletcher, A.S.A. Challenges in material processing and reliability issues in AlGaN/GaN HEMTs on silicon wafers for future RF power electronics & switching applications: A critical review. Mater. Sci. Semicond. Process. 2022, 151, 106982. [Google Scholar] [CrossRef]

- Hsu, L.H.; Lai, Y.Y.; Tu, P.T.; Langpoklakpam, C.; Chang, Y.T.; Huang, Y.W.; Lee, W.C.; Tzou, A.J.; Cheng, Y.J.; Lin, C.H.; et al. Development of GaN HEMTs Fabricated on Silicon, Silicon-on-Insulator, and Engineered Substrates and the Heterogeneous Integration. Micromachines 2021, 12, 1159. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Nomoto, K.; Pan, M.; Li, W.S.; Hickman, A.; Miller, J.; Lee, K.; Hu, Z.Y.; Bader, S.J.; Lee, S.M.; et al. GaN HEMTs on Si with Regrown Contacts and Cutoff/Maximum Oscillation Frequencies of 250/204 GHz. IEEE Electron. Device Lett. 2020, 41, 689–692. [Google Scholar] [CrossRef]

- Teo, K.H.; Zhang, Y.H.; Chowdhury, N.; Rakheja, S.; Ma, R.; Xie, Q.Y.; Yagyu, E.; Yamanaka, K.; Li, K.X.; Palacios, T. Emerging GaN technologies for power, RF, digital, and quantum computing applications: Recent advances and prospects. J. Appl. Phys. 2021, 130, 160902. [Google Scholar] [CrossRef]

- Lai, Y.J.; Liu, Y.C.; Hsu, Y.F.; Wu, M.C. Characteristics Comparison of Nanochannel GaN-on-Si and GaN-on-SiC HEMTs. ECS J. Solid State Sci. Technol. 2023, 12, 075002. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Y.; Song, K.; Xing, C.; Yang, L.; Wang, D.; Yu, H.; Xiang, X.; Gao, N.; Xu, G.; et al. Demonstration of AlGaN/GaN HEMTs on vicinal sapphire substrates with large misoriented angles. Appl. Phys. Lett. 2021, 119, 072104. [Google Scholar] [CrossRef]

- Yeh, P.C.; Tu, P.T.; Liu, H.H.; Hsu, C.H.; Yang, H.Y.; Fu, Y.K.; Lee, L.H.; Tzeng, P.J.; Wu, Y.R.; Sheu, S.S.; et al. CMOS-compatible GaN HEMT on 200 mm Si-substrate for RF application. In Proceedings of the International Symposium on VLSI Technology, Systems and Applications (VLSI-TSA), Hsinchu, Taiwan, 19–22 April 2021. [Google Scholar]

- Xie, H.L.; Liu, Z.H.; Gao, Y.; Ranjan, K.; Lee, K.E.; Ng, G.I. CMOS-compatible GaN-on-Si HEMTs with cut-off frequency of 210 GHz and high Johnson’s figure-of-merit of 8.8 THz V. Appl. Phys. Express 2020, 13, 026503. [Google Scholar] [CrossRef]

- Peralagu, U.; Alian, A.; Putcha, V.; Khaled, A.; Rodriguez, R.; Sibaja-Hernandez, A.; Chang, S.; Simoen, E.; Zhao, S.E.; Jaeger, B.D.; et al. CMOS-compatible GaN-based devices on 200 mm-Si for RF applications: Integration and Performance. In Proceedings of the 2019 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 7–11 December 2019; pp. 17.12.11–17.12.14. [Google Scholar]

- Zhang, L.; Hong Lee, K.; Riko, I.M.; Huang, C.-C.; Kadir, A.; Lee, K.E.; Jin Chua, S.; Fitzgerald, E.A. MOCVD growth of GaN on SEMI-spec 200 mm Si. Semicond. Sci. Technol. 2017, 32, 065001. [Google Scholar] [CrossRef]

- Cheng, J.P.; Yang, X.L.; Sang, L.; Guo, L.; Hu, A.Q.; Xu, F.J.; Tang, N.; Wang, X.Q.; Shen, B. High mobility AlGaN/GaN heterostructures grown on Si substrates using a large lattice-mismatch induced stress control technology. Appl. Phys. Lett. 2015, 106, 142106. [Google Scholar] [CrossRef]

- Su, J.; Armour, E.A.; Krishnan, B.; Lee, S.M.; Papasouliotis, G.D. Stress engineering with AlN/GaN superlattices for epitaxial GaN on 200 mm silicon substrates using a single wafer rotating disk MOCVD reactor. J. Mater. Res. 2015, 30, 2846–2858. [Google Scholar] [CrossRef]

- Meneghini, M.; De Santi, C.; Abid, I.; Buffolo, M.; Cioni, M.; Khadar, R.A.; Nela, L.; Zagni, N.; Chini, A.; Medjdoub, F.; et al. GaN-based power devices: Physics, reliability, and perspectives. J. Appl. Phys. 2021, 130, 181101. [Google Scholar] [CrossRef]

- Zhang, Y.; Dadgar, A.; Palacios, T. Gallium nitride vertical power devices on foreign substrates: A review and outlook. J. Phys. D Appl. Phys. 2018, 51, 273001. [Google Scholar] [CrossRef]

- Feng, M.X.; Liu, J.X.; Sun, Q.; Yang, H. III-nitride semiconductor lasers grown on Si. Prog. Quantum Electron. 2021, 77, 100323. [Google Scholar] [CrossRef]

- Zhan, X.; Liu, J.; Sun, X.; Huang, Y.; Gao, H.; Zhou, Y.; Li, Q.; Sun, Q.; Yang, H. Crack-free 2.2 μm-thick GaN grown on Si with a single-layer AlN buffer for RF device applications. J. Phys. D Appl. Phys. 2023, 56, 015104. [Google Scholar] [CrossRef]

- Lee, J.H.; Im, K.S. Growth of High Quality GaN on Si (111) Substrate by Using Two-Step Growth Method for Vertical Power Devices Application. Crystals 2021, 11, 234. [Google Scholar] [CrossRef]

- He, X.; Feng, Y.; Yang, X.; Wu, S.; Cai, Z.; Wei, J.; Shen, J.; Huang, H.; Liu, D.; Chen, Z.; et al. Step-Graded AlGaN vs superlattice: Role of strain relief layer in dynamic on-resistance degradation. Appl. Phys. Express 2021, 15, 011001. [Google Scholar] [CrossRef]

- Umeda, H. GaN on Si: Epitaxy and Devices. In Wide Bandgap Semiconductors for Power Electronics; Wiley: Hoboken, NJ, USA, 2021; pp. 555–582. [Google Scholar] [CrossRef]

- Kim, J.G.; Cho, C.; Kim, E.; Hwang, J.S.; Park, K.H.; Lee, J.H. High Breakdown Voltage and Low-Current Dispersion in AlGaN/GaN HEMTs with High-Quality AlN Buffer Layer. IEEE Trans. Electron Devices 2021, 68, 1513–1517. [Google Scholar] [CrossRef]

- Wang, K.; Li, M.; Yang, Z.; Wu, J.; Yu, T. Stress control and dislocation reduction in the initial growth of GaN on Si (111) substrates by using a thin GaN transition layer. CrystEngComm 2019, 21, 4792–4797. [Google Scholar] [CrossRef]

- Zhang, Z.-Z.; Yang, J.; Zhao, D.-G.; Liang, F.; Chen, P.; Liu, Z.-S. Influence of the lattice parameter of the AlN buffer layer on the stress state of GaN film grown on (111) Si. Chin. Phys. B 2023, 32, 028101. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, X.L.; Feng, Y.X.; Li, Y.; Wang, M.J.; Shen, J.F.; Wei, L.; Liu, D.S.; Wu, S.; Cai, Z.D.; et al. Vacancy-engineering-induced dislocation inclination in III-nitrides on Si substrates. Phys. Rev. Mater. 2020, 4, 073402. [Google Scholar] [CrossRef]

- Besendörfer, S.; Meissner, E.; Lesnik, A.; Friedrich, J.; Dadgar, A.; Erlbacher, T. Methodology for the investigation of threading dislocations as a source of vertical leakage in AlGaN/GaN-HEMT heterostructures for power devices. J. Appl. Phys. 2019, 125, 095704. [Google Scholar] [CrossRef]

- Sasangka, W.A.; Syaranamual, G.J.; Made, R.I.; Thompson, C.V.; Gan, C.L. Threading dislocation movement in AlGaN/GaN-on-Si high electron mobility transistors under high temperature reverse bias stressing. Aip Adv. 2016, 6, 095102. [Google Scholar] [CrossRef]

- Liu, J.X.; Huang, Y.N.; Sun, X.J.; Zhan, X.N.; Sun, Q.; Gao, H.W.; Feng, M.X.; Zhou, Y.; Ikeda, M.; Yang, H. Wafer-scale crack-free 10 mu m-thick GaN with a dislocation density of 5.8 × 107 cm−2 grown on Si. J. Phys. D-Appl. Phys. 2019, 52, 425102. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, X.; Ma, H.; Zhang, Q.; Shen, B. Effects of Al doping on dislocation inclinations and strain of GaN films on Si substrates. AIP Adv. 2023, 13, 025250. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Huang, J.; Pan, L.; Meng, B.; Wei, Q.; Yang, B. Investigation of the Dislocation Behavior of 6- and 8-Inch AlGaN/GaN HEMT Structures with a Thin AlGaN Buffer Layer Grown on Si Substrates. Inorganics 2024, 12, 207. https://doi.org/10.3390/inorganics12080207

Yan Y, Huang J, Pan L, Meng B, Wei Q, Yang B. Investigation of the Dislocation Behavior of 6- and 8-Inch AlGaN/GaN HEMT Structures with a Thin AlGaN Buffer Layer Grown on Si Substrates. Inorganics. 2024; 12(8):207. https://doi.org/10.3390/inorganics12080207

Chicago/Turabian StyleYan, Yujie, Jun Huang, Lei Pan, Biao Meng, Qiangmin Wei, and Bing Yang. 2024. "Investigation of the Dislocation Behavior of 6- and 8-Inch AlGaN/GaN HEMT Structures with a Thin AlGaN Buffer Layer Grown on Si Substrates" Inorganics 12, no. 8: 207. https://doi.org/10.3390/inorganics12080207

APA StyleYan, Y., Huang, J., Pan, L., Meng, B., Wei, Q., & Yang, B. (2024). Investigation of the Dislocation Behavior of 6- and 8-Inch AlGaN/GaN HEMT Structures with a Thin AlGaN Buffer Layer Grown on Si Substrates. Inorganics, 12(8), 207. https://doi.org/10.3390/inorganics12080207