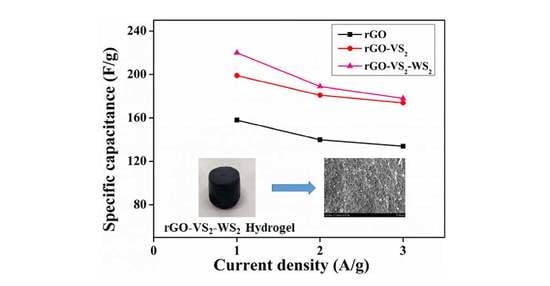

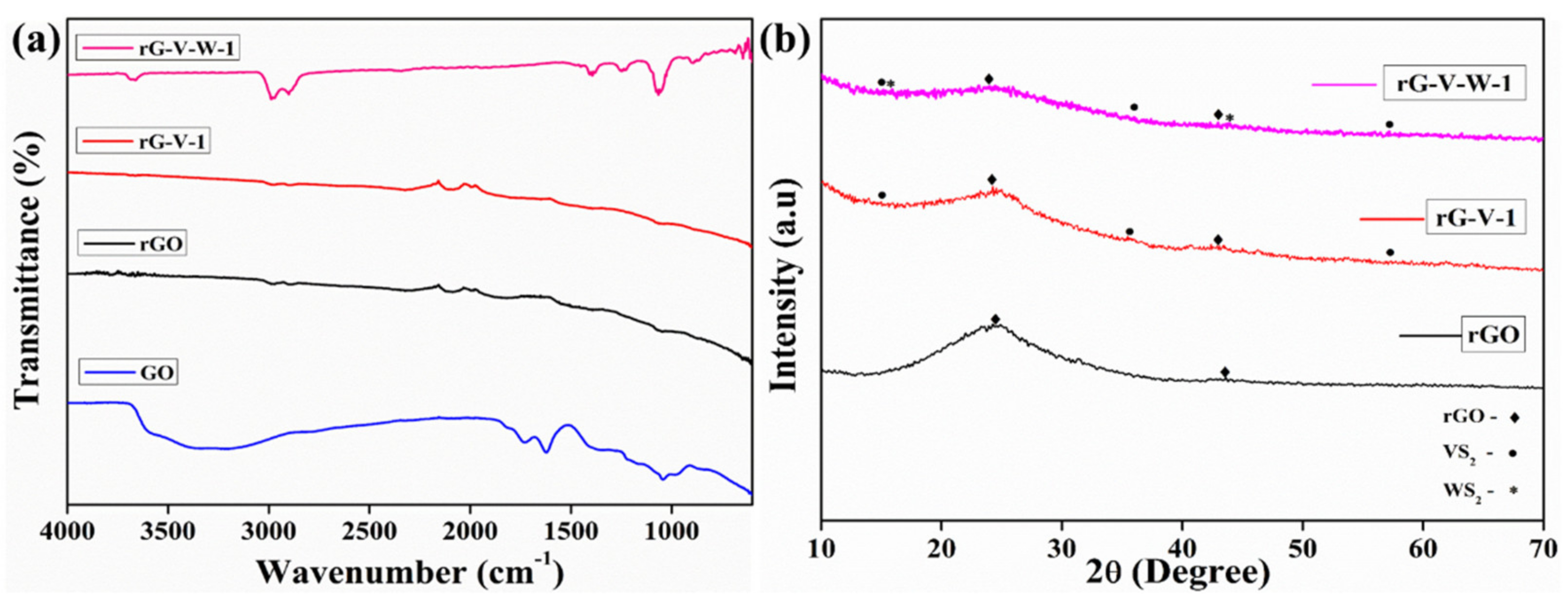

Three-Dimensional Ternary rGO/VS2/WS2 Composite Hydrogel for Supercapacitor Applications

Abstract

1. Introduction

2. Experimental Section

2.1. Chemicals

2.2. Synthesis of Graphene Oxide and Preparation of Vanadium Disulfide (VS2)

2.3. Development of rGO Hydrogels

2.4. Binary Composite Hydrogel (rGO-VS2 (rG-V)) Preparation

2.5. Preparation of rG-V-W Hydrogel

2.6. Structural/Microstructural Characterization and Electrochemical Measurements

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, J.; Luo, Q.; Hou, Q.; Chen, H.; Liu, T.; He, H.; Wang, J.; Shao, Q.; Dong, M.; Wu, S.; et al. Suppressing Charge Recombination and Ultraviolet Light Degradation of Perovskite Solar Cells Using Silicon Oxide Passivation. ChemElectroChem 2019, 6, 3167–3174. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, X.; Lu, J.; Geng, X.; Wan, Y.; Wu, M.; Yang, P. Substrate effects on the CVD growth of MoS2 and WS2. J. Mater. Sci. 2019, 55, 990–996. [Google Scholar] [CrossRef]

- Liu, M.; Meng, Q.; Yang, Z.; Zhao, X.; Liu, T. Ultra-long-term cycling stability of an integrated carbon–sulfur membrane with dual shuttle-inhibiting layers of graphene “nets” and a porous carbon skin. Chem. Commun. 2018, 54, 5090–5093. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Qin, J.; Hu, Q.; Wang, D.; Wang, F.; Zhong, Y.; Zhang, J.; Zhou, H.; Dong, M.; Hu, C. Theoretical investigation of molybdenum/tungsten-vanadium solid solution alloy membranes: Thermodynamic stability and hydrogen permeation. J. Membr. Sci. 2020, 608, 118200. [Google Scholar] [CrossRef]

- Wei, H.G.; Wang, H.; Li, A.; Cui, D.P.; Zhao, Z.N.; Chu, L.Q.; Wei, X.; Wang, L.; Pan, D.; Fan, J.C.; et al. Multifunctions of Polymer Nanocomposites: Environmental Remediation, Electromagnetic Interference Shielding, And Sensing Applications. ChemNanoMat 2020, 6, 174–184. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, H.; Su, W.; Wang, T.; Wang, X.; Chen, T.; Huo, T.; Dang, F.; Dong, M.; Wang, C.; et al. Trace bismuth and iodine co-doping enhanced thermoelectric performance of PbTe alloys. J. Phys. D Appl. Phys. 2020, 53, 245501. [Google Scholar] [CrossRef]

- Tan, J.; Li, D.; Liu, Y.; Zhang, P.; Qu, Z.; Yan, Y.; Hu, H.; Cheng, H.; Zhang, J.; Dong, M. A self-supported 3D aerogel network lithium–sulfur battery cathode: Sulfur spheres wrapped with phosphorus doped graphene and bridged with carbon nanofibers. J. Mater. Chem. A 2020, 8, 7980–7990. [Google Scholar] [CrossRef]

- Li, X.; Zhao, W.; Yin, R.; Huang, L.; Qian, X. A highly porous polyaniline-graphene composite used for electrochemical supercapacitors. Eng. Sci. 2018, 3, 89–95. [Google Scholar] [CrossRef]

- Dong, H.; Li, Y.; Chai, H.; Cao, Y.; Chen, X. Hydrothermal Synthesis of CuCo S Nano-structure and N-Doped Graphene for High- 2 4 Performance Aqueous Asymmetric Supercapacitors. ES Energy Environ. 2019, 4, 19–26. [Google Scholar] [CrossRef]

- Ma, Y.; Ma, M.; Yin, X.; Shao, Q.; Lu, N.; Feng, Y.; Lu, Y.; Wujcik, E.K.; Mai, X.; Wang, C.; et al. Tuning polyaniline nanostructures via end group substitutions and their morphology dependent electrochemical performances. Polymer 2018, 156, 128–135. [Google Scholar] [CrossRef]

- Yang, L.; Guo, X.; Jin, Z.; Guo, W.; Duan, G.; Liu, X.; Li, Y. Emergence of melanin-inspired supercapacitors. Nano Today 2021, 37, 101075. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Hou, H.; Xu, W.; Duan, G.; He, S.; Liu, K.; Jiang, S. Recent progress in carbon-based materials for supercapacitor electrodes: A review. J. Mater. Sci. 2021, 56, 173–200. [Google Scholar] [CrossRef]

- Duan, G.; Zhao, L.; Zhang, C.; Chen, L.; Zhang, Q.; Liu, K.; Wang, F. Pyrolysis of zinc salt-treated flax fiber: Hierarchically porous carbon electrode for supercapacitor. Diam. Relat. Mater. 2022, 129, 109339. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Chen, Y.; Cheng, K.; Yan, J.; Zhu, K.; Ye, K.; Wang, G.; Zhou, L.; Cao, D. Freestanding 3D Polypyrrole@ reduced graphene oxide hydrogels as binder-free electrode materials for flexible asymmetric supercapacitors. J. Colloid Interface Sci. 2019, 536, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Wang, H.; Li, A.; Li, H.; Cui, D.; Dong, M.; Lin, J.; Fan, J.; Zhang, J.; Hou, H. Advanced porous hierarchical activated carbon derived from agricultural wastes toward high performance supercapacitors. J. Alloy. Compd. 2020, 820, 153111. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, J.; Xu, L.; Liu, H.; Zhou, B.; Tang, Y.; Zhu, L.; Jiang, X.; Jiang, X. Facile synthesis of a graphene/nickel-cobalt hydroxide ternary hydrogel for high-performance supercapacitors. J. Colloid Interface Sci. 2018, 531, 593–601. [Google Scholar] [CrossRef]

- Zheng, S.; Zhang, J.; Deng, H.; Du, Y.; Shi, X. Chitin derived nitrogen-doped porous carbons with ultrahigh specific surface area and tailored hierarchical porosity for high performance supercapacitors. J. Bioresour. Bioprod. 2021, 6, 142–151. [Google Scholar] [CrossRef]

- Cao, L.; Li, H.; Xu, Z.; Zhang, H.; Ding, L.; Wang, S.; Zhang, G.; Hou, H.; Xu, W.; Yang, F.; et al. Comparison of the heteroatoms-doped biomass-derived carbon prepared by one-step nitrogen-containing activator for high performance supercapacitor. Diam. Relat. Mater. 2021, 114, 108316. [Google Scholar] [CrossRef]

- Wang, F.; Cheong, J.Y.; He, Q.; Duan, G.; He, S.; Zhang, L.; Zhao, Y.; Kim, I.-D.; Jiang, S. Phosphorus-doped thick carbon electrode for high-energy density and long-life supercapacitors. Chem. Eng. J. 2021, 414, 128767. [Google Scholar] [CrossRef]

- Duan, G.; Zhao, L.; Chen, L.; Wang, F.; He, S.; Jiang, S.; Zhang, Q. ZnCl 2 regulated flax-based porous carbon fibers for supercapacitors with good cycling stability. New J. Chem. 2021, 45, 22602–22609. [Google Scholar] [CrossRef]

- Cao, L.; Li, H.; Liu, X.; Liu, S.; Zhang, L.; Xu, W.; Yang, H.; Hou, H.; He, S.; Zhao, Y. Nitrogen, sulfur co-doped hierarchical carbon encapsulated in graphene with “sphere-in-layer” interconnection for high-performance supercapacitor. J. Colloid Interface Sci. 2021, 599, 443–452. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Yang, L.; Wang, T.; Zhang, M.; Duan, G.; Liu, X.; Li, Y. Synthetic melanin facilitates MnO supercapacitors with high specific capacitance and wide operation potential window. Polymer 2021, 235, 124276. [Google Scholar] [CrossRef]

- Han, X.; Xiao, G.; Wang, Y.; Chen, X.; Duan, G.; Wu, Y.; Gong, X.; Wang, H. Design and fabrication of conductive polymer hydrogels and their applications in flexible supercapacitors. J. Mater. Chem. A 2020, 8, 23059–23095. [Google Scholar] [CrossRef]

- Wang, F.; Jiang, C.; Tang, C.; Bi, S.; Wang, Q.; Du, D.; Song, J. High output nano-energy cell with piezoelectric nanogenerator and porous supercapacitor dual functions—A technique to provide sustaining power by harvesting intermittent mechanical energy from surroundings. Nano Energy 2016, 21, 209–216. [Google Scholar] [CrossRef]

- EMeyer, E.; Bede, A.; Mutukwa, D.; Taziwa, R.; Zingwe, N. Optimization, and analysis of carbon supported VS2 nanocomposites as potential electrodes in supercapacitors. J. Energy Storage 2019, 27, 101074. [Google Scholar]

- Murugan, A.V.; Quintin, M.; Delville, M.-H.; Campet, G.; Vijayamohanan, K. Entrapment of poly (3, 4-ethylenedioxythiophene) between VS 2 layers to form a new organic–inorganic intercalative nanocomposite. J. Mater. Chem. A 2005, 15, 902–909. [Google Scholar] [CrossRef]

- Huang, Z.; Han, X.; Cui, X.; He, C.; Zhang, J.; Wang, X.; Lin, Z.; Yang, Y. Vertically aligned VS 2 on graphene as a 3D heteroarchitectured anode material with capacitance-dominated lithium storage. J. Mater. Chem. A 2020, 8, 5882–5889. [Google Scholar] [CrossRef]

- Torad, N.L.; Hu, M.; Kamachi, Y.; Takai, K.; Imura, M.; Naito, M.; Yamauchi, Y. Facile synthesis of nanoporous carbons with controlled particle sizes by direct carbonization of monodispersed ZIF-8 crystals. Chem. Commun. 2013, 49, 2521–2523. [Google Scholar] [CrossRef]

- Pang, S.; Tsao, H.N.; Feng, X.; Müllen, K. Patterned graphene electrodes from solution-processed graphite oxide films for organic field-effect transistors. Adv. Mater. 2009, 21, 3488–3491. [Google Scholar] [CrossRef]

- Li, N.; Su, J.; Xu, Z.; Li, D.-P.; Liu, Z.-T. Theoretical and experimental investigation on structural and electronic properties of Al/O/Al, O-doped WS 2. J. Phys. Chem. Solids 2016, 89, 84–88. [Google Scholar] [CrossRef]

- Abbas, O.A.; Lewis, A.H.; Aspiotis, N.; Huang, C.-C.; Zeimpekis, I.; Hewak, D.W.; Sazio, P.; Mailis, S. Laser printed two-dimensional transition metal dichalcogenides. Sci. Rep. 2021, 11, 5211. [Google Scholar] [CrossRef] [PubMed]

- Coehoorn, R.; Haas, C.; Dijkstra, J.; Flipse, C.J.F.; de Groot, R.A.; Wold, A. Electronic structure of MoSe2, MoS2, and WSe2. I. Band-structure calculations and photoelectron spectroscopy. Phys. Rev. B 1987, 35, 6195–6202. [Google Scholar] [CrossRef]

- Perea-López, N.; Elías, A.L.; Berkdemir, A.; Castro-Beltran, A.; Gutiérrez, H.R.; Feng, S.; Lv, R.; Hayashi, T.; López-Urías, F.; Ghosh, S. Photosensor device based on few-layered WS2 films. Adv. Funct. Mater. 2013, 23, 5511–5517. [Google Scholar] [CrossRef]

- Berkdemir, A.; Gutiérrez, H.R.; Botello-Méndez, A.R.; Perea-López, N.; Elías, A.L.; Chia, C.-I.; Wang, B.; Crespi, V.H.; López-Urías, F.; Charlier, J.-C. Identification of individual and few layers of WS2 using Raman Spectroscopy. Sci. Rep. 2013, 3, 1755. [Google Scholar] [CrossRef]

- Cesano, F.; Bertarione, S.; Piovano, A.; Agostini, G.; Rahman, M.M.; Groppo, E.; Bonino, F.; Scarano, D.; Lamberti, C.; Bordiga, S.; et al. Model oxide supported MoS2 HDS catalysts: Structure and surface properties. Catal. Sci. Technol. 2011, 1, 123–136. [Google Scholar] [CrossRef]

- Gutiérrez, H.R.; Perea-López, N.; Elías, A.L.; Berkdemir, A.; Wang, B.; Lv, R.; López-Urías, F.; Crespi, V.H.; Terrones, H.; Terrones, M. Extraordinary room-temperature photoluminescence in triangular WS2 monolayers. Nano Lett. 2013, 13, 3447–3454. [Google Scholar] [CrossRef] [PubMed]

- Bhat, K.S.; Nagaraja, H. Effect of isoelectronic tungsten doping on molybdenum selenide nanostructures and their graphene hybrids for supercapacitors. Electrochim. Acta 2019, 302, 459–471. [Google Scholar] [CrossRef]

- Wu, X.; Li, H.; Yang, X.; Wang, X.; Miao, Z.; Zhou, P.; Zhao, J.; Zhou, J.; Zhuo, S. Reduced Graphene Oxide Hydrogel for High Energy Density Symmetric Supercapacitor with High Operation Potential in Aqueous Electrolyte. ChemElectroChem 2021, 8, 4353–4359. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, T.; Qian, F.; Han, T.Y.-J.; Duoss, E.B.; Kuntz, J.D.; Spadaccini, C.M.; Worsley, M.A.; Li, Y. Supercapacitors Based on Three-Dimensional Hierarchical Graphene Aerogels with Periodic Macropores. Nano Lett. 2016, 16, 3448–3456. [Google Scholar] [CrossRef]

- Meng, X.; Lu, L.; Sun, C. Green synthesis of three-dimensional MnO2/graphene hydrogel composites as a high-performance electrode material for supercapacitors. ACS Appl. Mater. Interfaces 2018, 10, 16474–16481. [Google Scholar] [CrossRef]

- Kang, S.H.; Lee, G.Y.; Lim, J.; Kim, S.O. CNT–rGO Hydrogel-Integrated Fabric Composite Synthesized via an Interfacial Gelation Process for Wearable Supercapacitor Electrodes. ACS Omega 2021, 6, 19578–19585. [Google Scholar] [CrossRef] [PubMed]

- Chi, H.Z.; Wu, Y.Q.; Shen, Y.K.; Zhang, C.; Xiong, Q.; Qin, H. Electrodepositing manganese oxide into a graphene hydrogel to fabricate an asymmetric supercapacitor. Electrochim. Acta 2018, 289, 158–167. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved synthesis of graphene oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef] [PubMed]

- Tian, Q.; Li, N.; Liu, J.; Wang, M.; Deng, J.; Zhou, J.; Ma, Q. Catalytic hydrogenation of alkali lignin to bio-oil using fullerene-like vanadium sulfide. Energy Fuels 2015, 29, 255–261. [Google Scholar] [CrossRef]

- Gong, Y.; Li, D.; Fu, Q.; Pan, C. Influence of graphene microstructures on electrochemical performance for supercapacitors. Prog. Nat. Sci. 2015, 25, 379–385. [Google Scholar] [CrossRef]

- Khataee, A.; Eghbali, P.; Irani-Nezhad, M.H.; Hassani, A. Sonochemical synthesis of WS2 nanosheets and its application in sonocatalytic removal of organic dyes from water solution. Ultrason. Sonochemistry 2018, 48, 329–339. [Google Scholar] [CrossRef]

- Vattikuti, S.V.P.; Nagajyothi, P.C.; Devarayapalli, K.C.; Shim, J. Depositing reduced graphene oxide onto tungsten disulfide nanosheets via microwave irradiation: Confirmation of four-electron transfer-assisted oxygen reduction and methanol oxidation reaction. New J. Chem. 2020, 44, 10638–10647. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, N.; Tang, Z.-R.; Xu, Y.-J. Graphene Transforms Wide Band Gap ZnS to a Visible Light Photocatalyst. The New Role of Graphene as a Macromolecular Photosensitizer. ACS Nano 2012, 6, 9777–9789. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhu, Y.; Yu, B.; Fang, C.; Zhang, J. Metallic 1T-VS2 nanosheets featuring V2+ self-doping and mesopores towards an efficient hydrogen evolution reaction. Inorg. Chem. Front. 2019, 6, 3510–3517. [Google Scholar] [CrossRef]

- Fang, W.; Zhao, H.; Xie, Y.; Fang, J.; Xu, J.; Chen, Z. Facile hydrothermal synthesis of VS2/graphene nanocomposites with superior high-rate capability as lithium-ion battery cathodes. ACS Appl. Mater. Interfaces 2015, 7, 13044–13052. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Sun, X.; Wu, C.; Peng, L.; Lin, C.; Hu, S.; Yang, J.; Xie, Y. Metallic Few-Layered VS2 Ultrathin Nanosheets: High Two-Dimensional Conductivity for In-Plane Supercapacitors. J. Am. Chem. Soc. 2011, 133, 17832–17838. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, S.; Kundu, M. Carbon Free Nanostructured Plate like WS2 with Excellent Lithium Storage Properties. ChemistrySelect 2020, 5, 14183–14189. [Google Scholar] [CrossRef]

- Zhang, H.; Xie, A.; Wang, C.; Wang, H.; Shen, Y.; Tian, X. Bifunctional reduced graphene oxide/V2O5 composite hydrogel: Fabrication, high performance as electromagnetic wave absorbent and supercapacitor. ChemPhysChem 2014, 15, 366–373. [Google Scholar] [CrossRef]

- Zhang, S.; Pan, N. Supercapacitors Performance Evaluation. Adv. Energy Mater. 2014, 5, 1401401. [Google Scholar] [CrossRef]

- Ratha, S.; Rout, C.S. Supercapacitor electrodes based on layered tungsten disulfide-reduced graphene oxide hybrids synthesized by a facile hydrothermal method. ACS Appl. Mater. Interfaces 2013, 5, 11427–11433. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Wang, J.; Liu, F.; Chang, X.; Chen, H.; Lin, H.; Han, S. Graphene-constructed flower-like porous Co(OH)2 with tunable hierarchical morphologies for supercapacitors. RSC Adv. 2016, 6, 16745–16750. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magdum, S.S.; Thangarasu, S.; Oh, T.H. Three-Dimensional Ternary rGO/VS2/WS2 Composite Hydrogel for Supercapacitor Applications. Inorganics 2022, 10, 229. https://doi.org/10.3390/inorganics10120229

Magdum SS, Thangarasu S, Oh TH. Three-Dimensional Ternary rGO/VS2/WS2 Composite Hydrogel for Supercapacitor Applications. Inorganics. 2022; 10(12):229. https://doi.org/10.3390/inorganics10120229

Chicago/Turabian StyleMagdum, Sahil S., Sadhasivam Thangarasu, and Tae Hwan Oh. 2022. "Three-Dimensional Ternary rGO/VS2/WS2 Composite Hydrogel for Supercapacitor Applications" Inorganics 10, no. 12: 229. https://doi.org/10.3390/inorganics10120229

APA StyleMagdum, S. S., Thangarasu, S., & Oh, T. H. (2022). Three-Dimensional Ternary rGO/VS2/WS2 Composite Hydrogel for Supercapacitor Applications. Inorganics, 10(12), 229. https://doi.org/10.3390/inorganics10120229