Improved Tunneling Property of p+Si Nanomembrane/n+GaAs Heterostructures through Ultraviolet/Ozone Interface Treatment

Abstract

1. Introduction

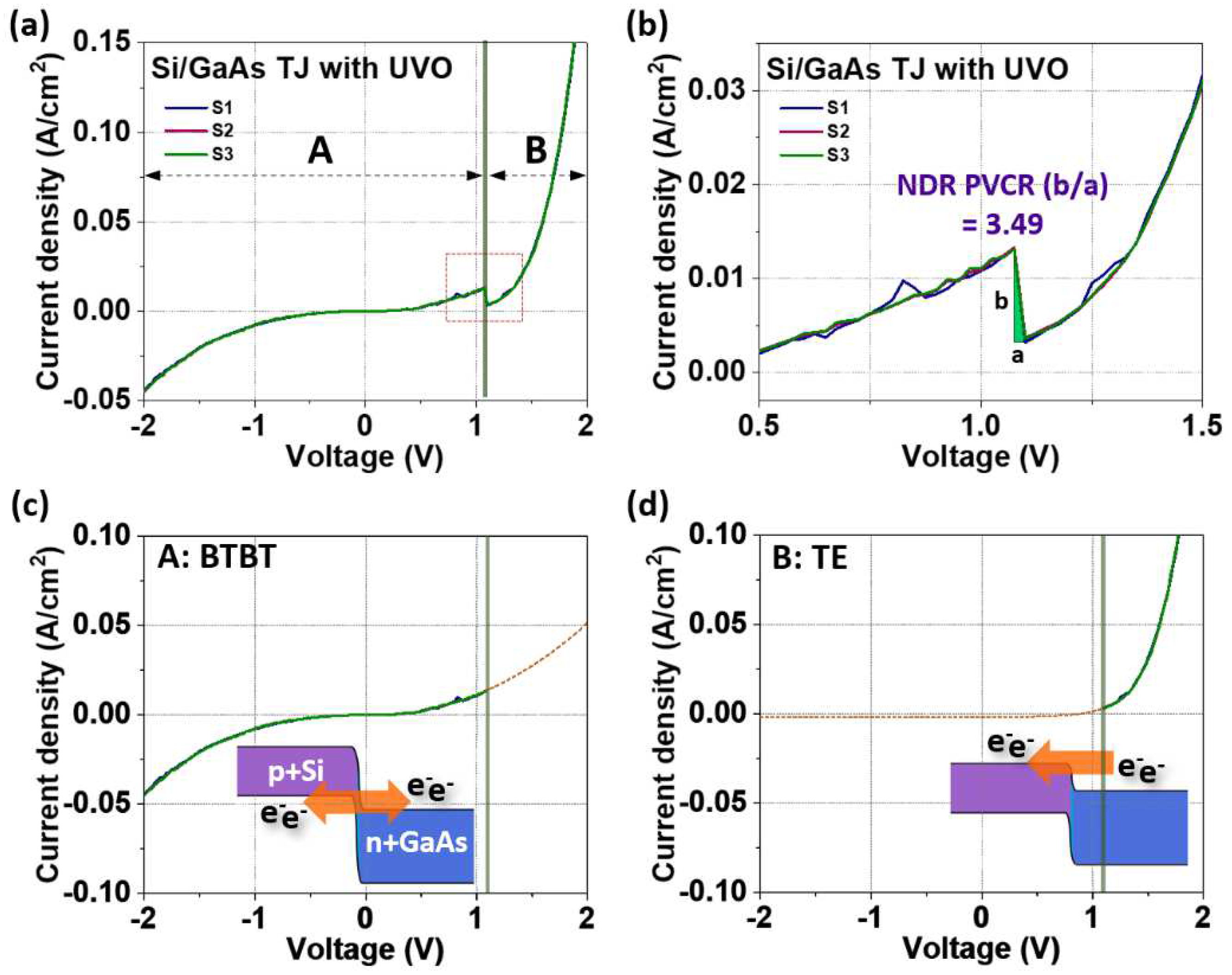

2. Results and Discussion

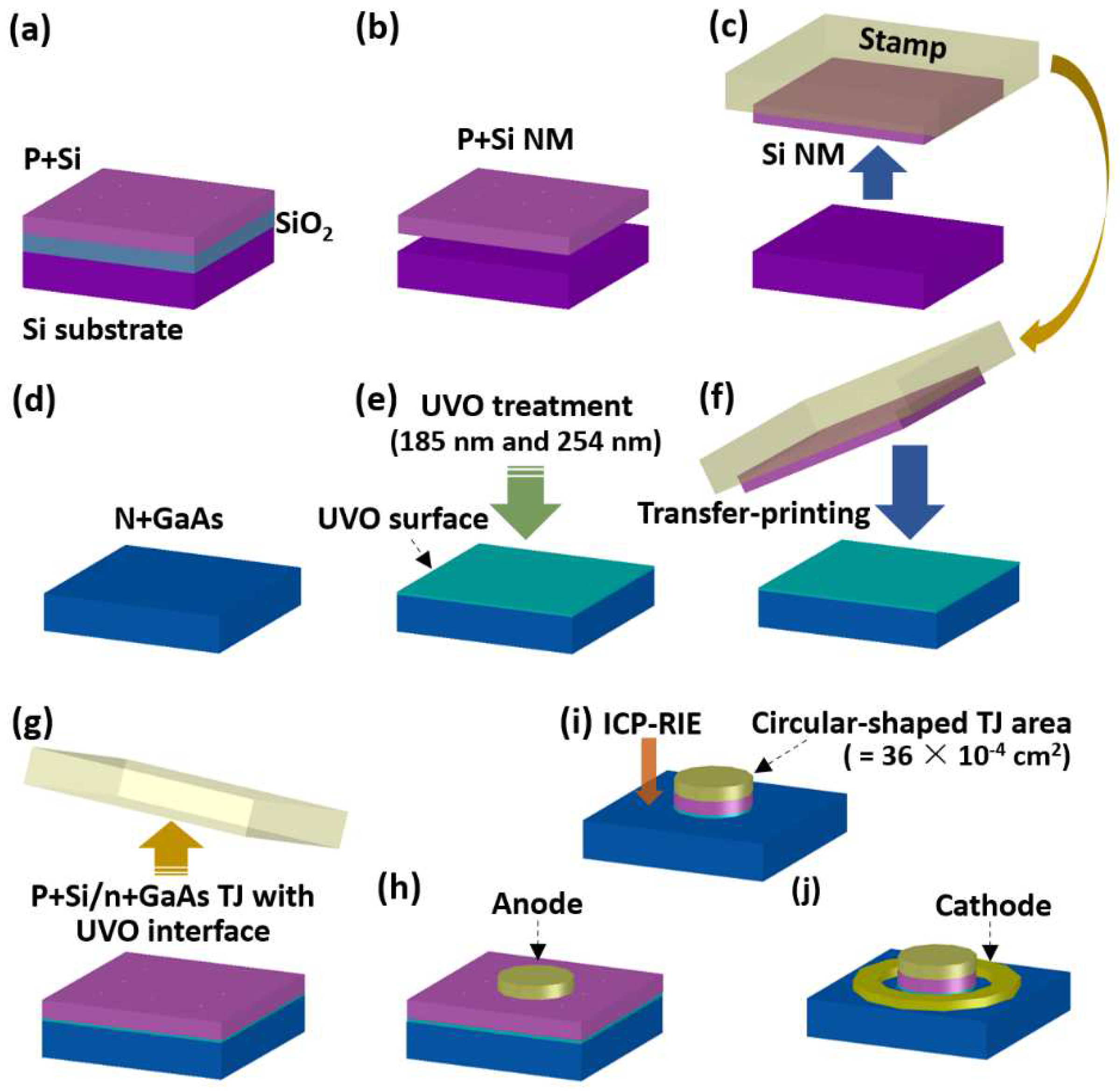

3. Materials and Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, X.; Wang, J. Ferroelectric tunnel junctions with high tunnelling electroresistance. Nat. Electron. 2020, 3, 440. [Google Scholar] [CrossRef]

- Hase, Y.; Komori, Y.; Kusumoto, T.; Harada, T.; Seki, J.; Shiga, T.; Kamiya, K.; Nakanishi, S. Negative differential resistance as a critical indicator for the discharge capacity of lithium-oxygen batteries. Nat. Commun. 2019, 10, 596. [Google Scholar] [CrossRef]

- Shim, J.; Oh, S.; Kang, D.-H.; Jo, S.-H.; Ali, M.H.; Choi, W.-Y.; Heo, K.; Jeon, J.; Lee, S.; Kim, M.; et al. Phosphorene/rhenium disulfide heterojunction-based negative differential resistance device for multi-valued logic. Nat. Commun. 2016, 7, 13413. [Google Scholar] [CrossRef] [PubMed]

- Yan, R.; Fathipour, S.; Han, Y.; Song, B.; Xiao, S.; Li, M.; Ma, N.; Protasenko, V.; Muller, D.A.; Jena, D.; et al. Esaki diodes in van der Waals heterojunctions with broken-gap energy band alignment. Nano Lett. 2015, 15, 5791. [Google Scholar] [CrossRef]

- Liu, X.; Qu, D.; Li, H.-M.; Moon, I.; Ahmed, F.; Kim, C.; Lee, M.; Choi, Y.; Cho, J.H.; Hone, J.C.; et al. Modulation of quantum tunneling via a vertical two-dimensional black phosphorus and molybdenum disulfide p-n junction. ACS Nano 2017, 11, 9143. [Google Scholar] [CrossRef]

- Kim, K.; Jang, J.; Kim, H. Negative differential resistance in Si/GaAs tunnel junction formed by single crystalline nanomembrane transfer method. Results Phys. 2021, 25, 104279. [Google Scholar] [CrossRef]

- Liang, J.; Miyazaki, T.; Morimoto, M.; Nishida, S.; Watanabe, N.; Shigekawa, N. Electrical properties of Si/Si interfaces by using surface-activated bonding. Appl. Phys. Express 2013, 6, 021801. [Google Scholar] [CrossRef]

- Zhao, Y.; Bao, W.L.; Yang, F.; Wang, X. Plasma-activated GaAs/Si wafer bonding with high mechanical strength and electrical conductivity. Mater. Sci. Semicond. 2022, 143, 106481. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Zhu, Z.H.; Crouse, D.; Lo, Y.H. Electrical properties of wafer-bonded GaAs/Si heterojunctions. Appl. Phys. Lett. 1998, 73, 2337. [Google Scholar] [CrossRef]

- Kiefer, A.M.; Paskiewicz, D.M.; Clausen, A.M.; Buchwald, W.R.; Soref, R.A.; Lagally, M.G. Si/Ge Junctions Formed by Nanomembrane Bonding. ACS Nano 2011, 5, 1179. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.C.; Kabuyanagi, S.; Nishimura, T.; Yajima, T.; Toriumi, A. n+Si/pGe heterojunctions fabricated by low temperature ribbon bonding with passivating interlayer. IEEE Electron. Device Lett. 2017, 38, 716. [Google Scholar] [CrossRef]

- Schroeder, D.P.; Aksamija, Z.; Rath, A.; Voyles, P.M.; Lagally, M.G.; Eriksson, M.A. Thermal resistance of transferred-silicon-nanomembrane interfaces. Phys. Rev. Lett. 2015, 115, 256101. [Google Scholar] [CrossRef]

- Hwang, S.-W.; Lee, C.H.; Cheng, H.; Jeong, J.-W.; Kang, S.-K.; Kim, J.-H.; Shin, J.; Yang, J.; Liu, Z.; Ameer, G.A.; et al. Biodegradable elastomers and silicon nanomembranes/nanoribbons for stretchable, transient electronics, and biosensors. Nano Lett. 2015, 15, 2801. [Google Scholar] [CrossRef]

- Tai, Y.-C.; Yeh, P.-L.; An, S.; Cheng, H.-H.; Kim, M.; Chang, G.-E. Strain-free GeSn nanomembranes enabled by transfer-printing techniques for advanced optoelectronic applications. Nanotechnology 2020, 31, 445301. [Google Scholar] [CrossRef]

- Kim, K.; Kim, T.J.; Zhang, H.; Liu, D.; Jung, Y.H.; Gong, J.; Ma, Z. AlGaN/GaN Schottky-Gate HEMTs with UV/O3-Treated Gate Interface. IEEE Electron. Device Lett. 2020, 41, 1488. [Google Scholar] [CrossRef]

- Kim, K.; Liu, D.; Gong, J.; Ma, Z. Reduction of leakage current in GaN Schottky diodes through ultraviolet/ozone plasma treatment. IEEE Electron. Device Lett. 2019, 40, 1796. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Gong, J.; Liu, D.; Ma, Z. Metal-Al2O3-GaN capacitors with an ultraviolet/ozone plasma-treated interface. Jpn. J. Appl. Phys. 2020, 59, 030908. [Google Scholar] [CrossRef]

- Gao, J.; Xiao, C.; Feng, C.; Wu, L.; Yu, B.; Qian, L.; Kim, S.H. Oxidation-induced changes of mechanochemical reactions at GaAs-SiO2 interface: The competitive roles of water adsorption, mechanical property, and oxidized structure. Appl. Surf. Sci. 2021, 548, 149205. [Google Scholar] [CrossRef]

- Aksamija, Z.; Knezevic, I. Thermal conductivity of Si1-xGex/Si1-yGey superlattices: Competition between interfacial and internal scattering. Phys. Rev. B 2013, 88, 155318. [Google Scholar] [CrossRef]

- Prasher, R. Acoustic mismatch model for thermal contact resistance of van der Waals contacts. Appl. Phys. Lett. 2009, 94, 041905. [Google Scholar] [CrossRef]

- El-Basit, W.A.; Awad, Z.I.M.; Kamh, S.A.; Soliman, F.A.S. Temperature dependence of backward tunnel diode oscillator circuit. Microelectron. J. 2020, 99, 104756. [Google Scholar] [CrossRef]

- Wilson, A.A.; Jankowski, N.R.; Nouketcha, F.; Tompkins, R. Kapitza Resistance at the Two-Dimensional Electron Gas Interface. In Proceedings of the Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 28–30 May 2019. [Google Scholar]

- Lee, J.; Choi, S.; Yang, K. Temperature dependence characteristics of InP RTD based CML-mobile D-flip flop IC. In Proceedings of the 2009 IEEE International Conference on Indium Phosphide & Related Materials, Newport Beach, CA, USA, 10–14 May 2009. [Google Scholar]

- Dashiell, M.W.; Troeger, R.T.; Rommel, S.L.; Adam, T.N.; Berger, P.R.; Guedj, C.; Kolodzey, J.; Seabaugh, A.C. Current-voltage characteristics of high current density silicon Esaki diodes grown by molecular beam epitaxy and the influence of thermal annealing. IEEE Trans. Electron. Devices 2000, 47, 1707. [Google Scholar] [CrossRef]

- Growden, T.A.; Zhang, W.; Brown, E.R.; Storm, D.F.; Hansen, K.; Fakhimi, P.; Meyer, D.J.; Berger, P.R. 431 kA/cm2 peak tunneling current density in GaN/AlN resonant tunneling diodes. Appl. Phys. Lett. 2018, 112, 033508. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Jang, J. Improved Tunneling Property of p+Si Nanomembrane/n+GaAs Heterostructures through Ultraviolet/Ozone Interface Treatment. Inorganics 2022, 10, 228. https://doi.org/10.3390/inorganics10120228

Kim K, Jang J. Improved Tunneling Property of p+Si Nanomembrane/n+GaAs Heterostructures through Ultraviolet/Ozone Interface Treatment. Inorganics. 2022; 10(12):228. https://doi.org/10.3390/inorganics10120228

Chicago/Turabian StyleKim, Kwangeun, and Jaewon Jang. 2022. "Improved Tunneling Property of p+Si Nanomembrane/n+GaAs Heterostructures through Ultraviolet/Ozone Interface Treatment" Inorganics 10, no. 12: 228. https://doi.org/10.3390/inorganics10120228

APA StyleKim, K., & Jang, J. (2022). Improved Tunneling Property of p+Si Nanomembrane/n+GaAs Heterostructures through Ultraviolet/Ozone Interface Treatment. Inorganics, 10(12), 228. https://doi.org/10.3390/inorganics10120228