Equivalent Measurement and Real-Time Compensation of Error Caused by Intensity Change in Deep Sub-Nanometer Displacement Measuring Interferometry

Abstract

1. Introduction

2. Displacement Measuring Error and Compensation Method

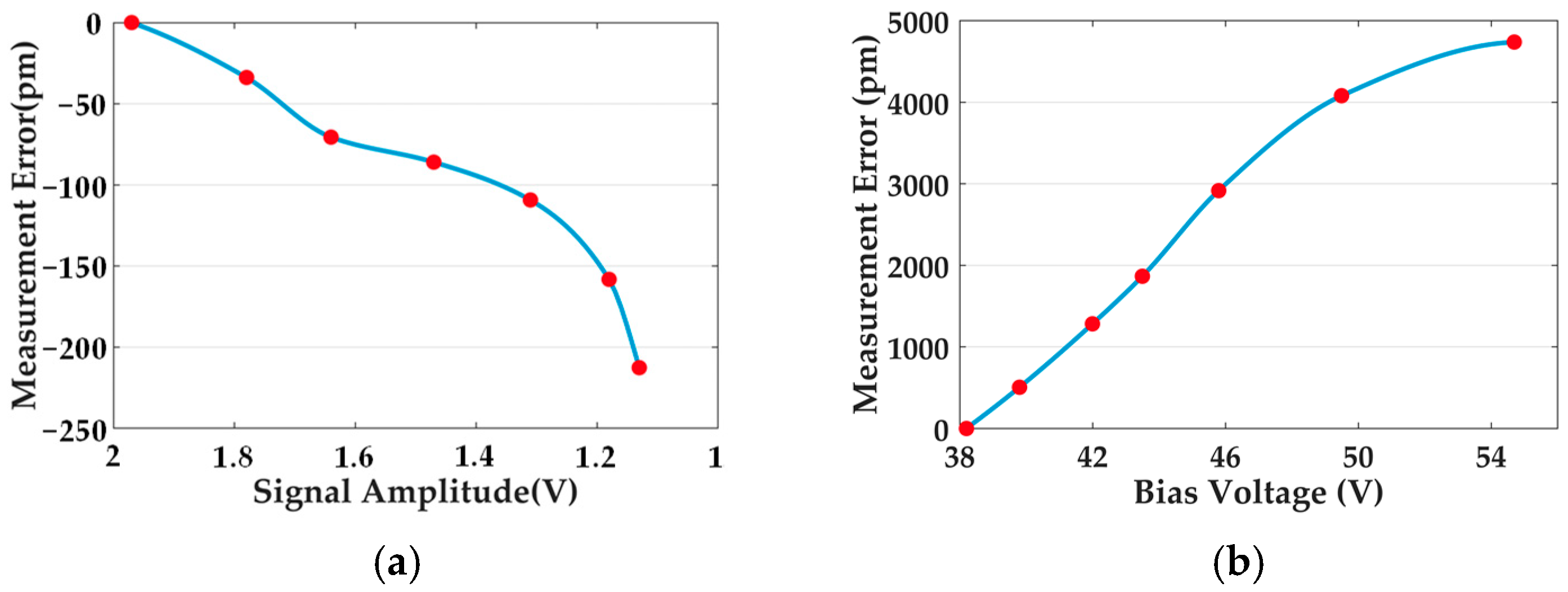

2.1. Displacement Measuring Error Caused by Intensity Changes

- Differences. The gain, noise, and delay of the APD are all related to its internal structure and materials. Even when different APDs exist in the same batch, the characteristics are not the same.

- Nonlinearity. There is a serious nonlinearity between the delay and the input light intensity.

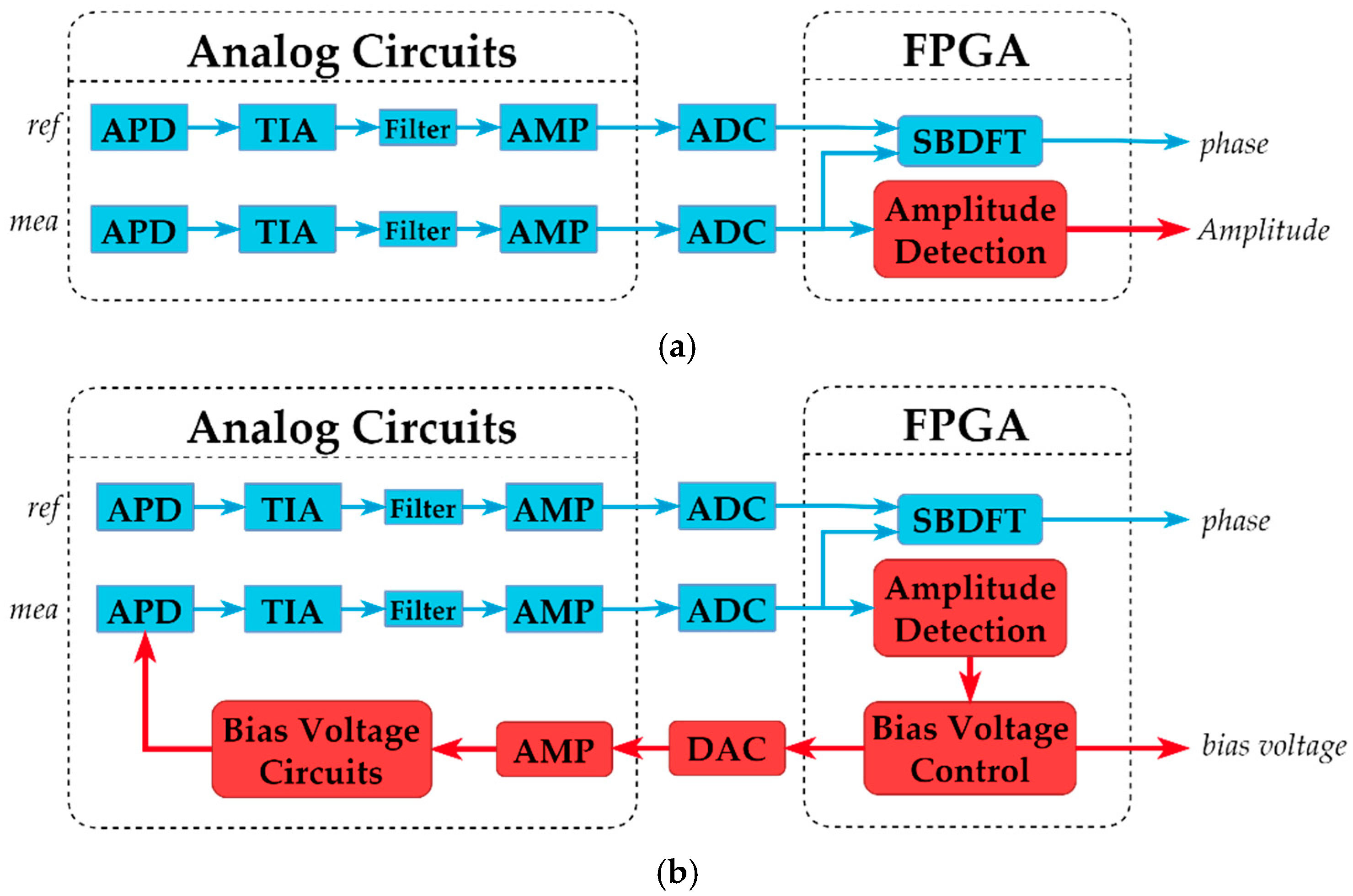

2.2. Compensation Method

3. Experiments and Results

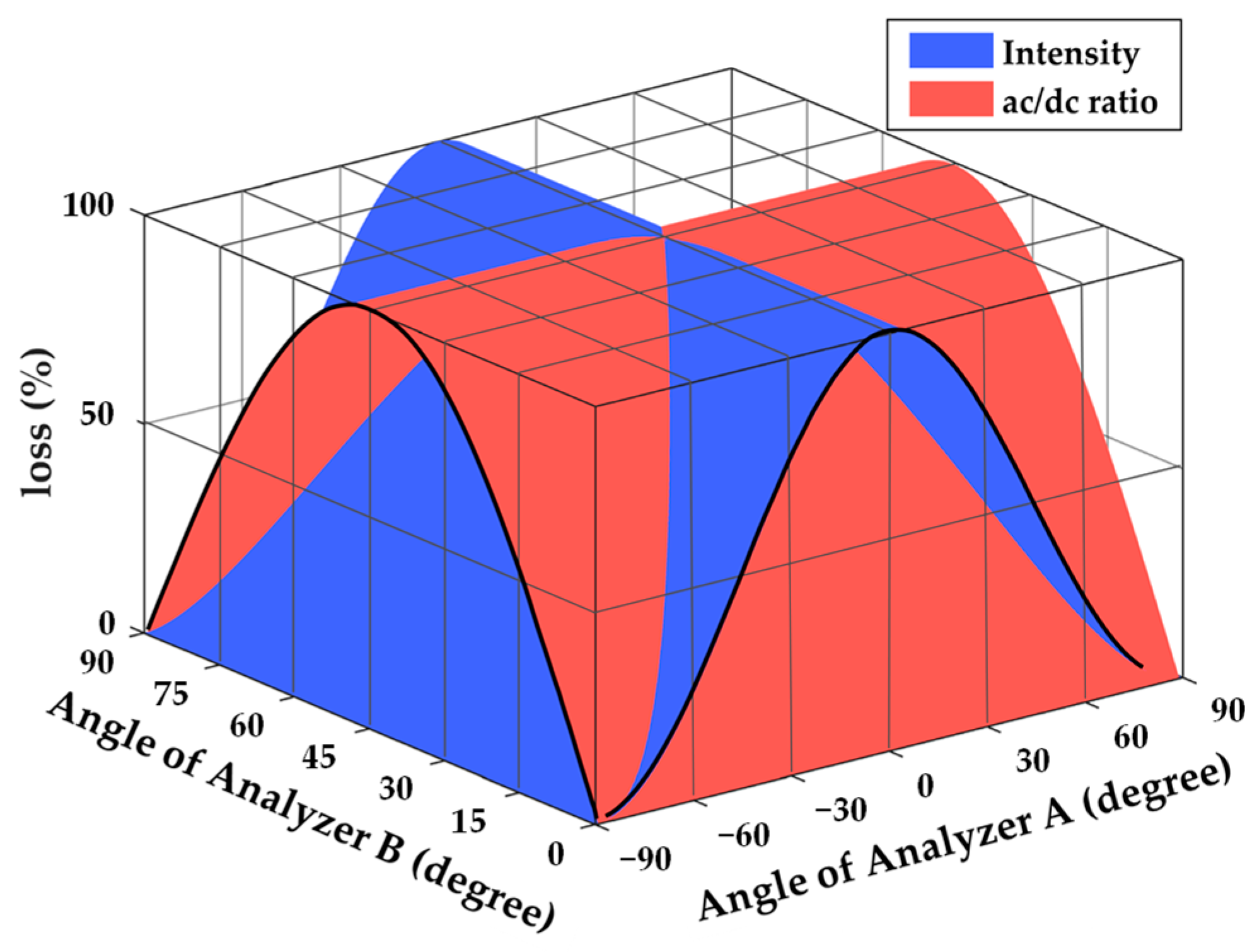

3.1. Attenuation Calculation

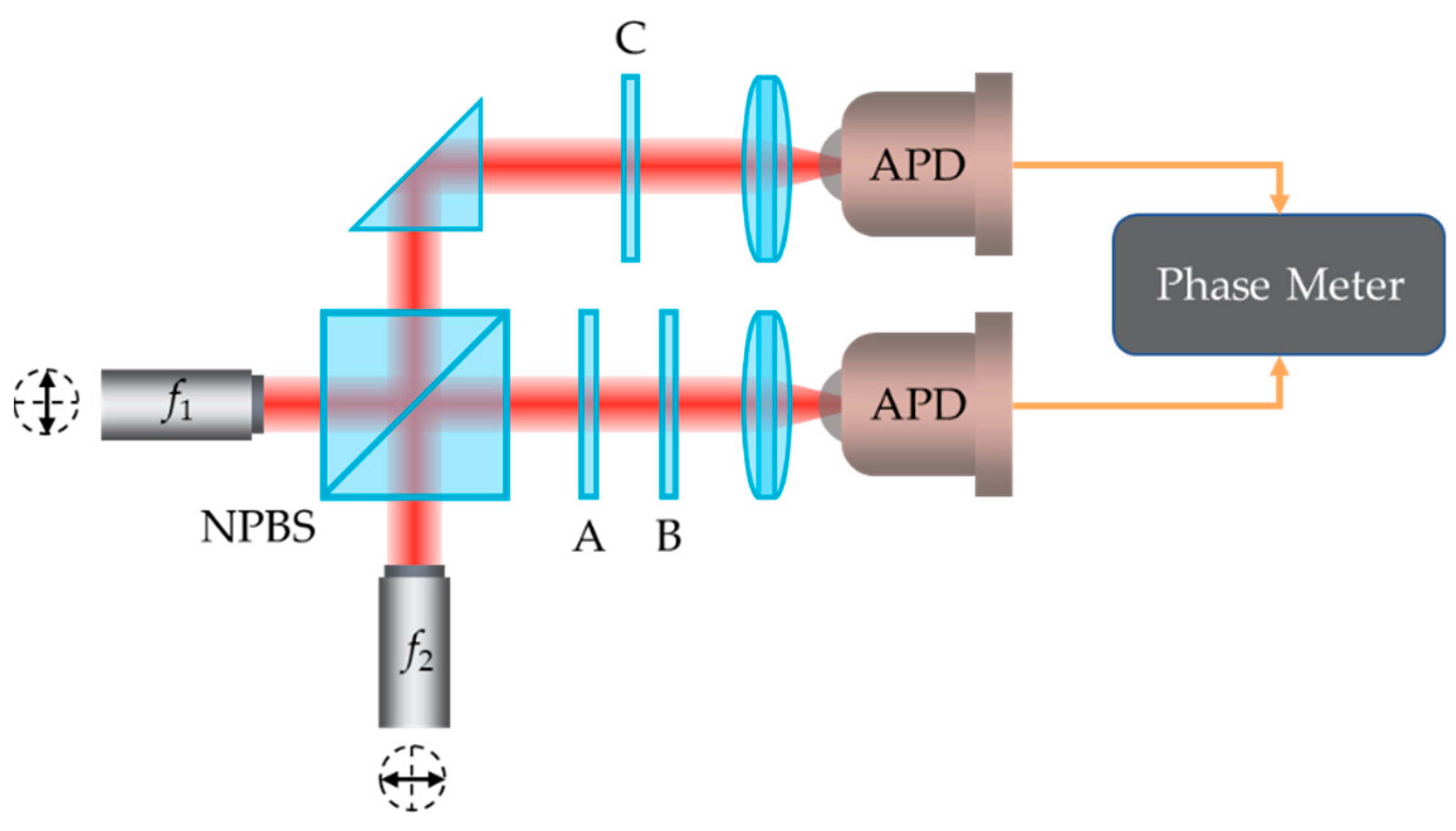

3.2. Experimental Principle and Device

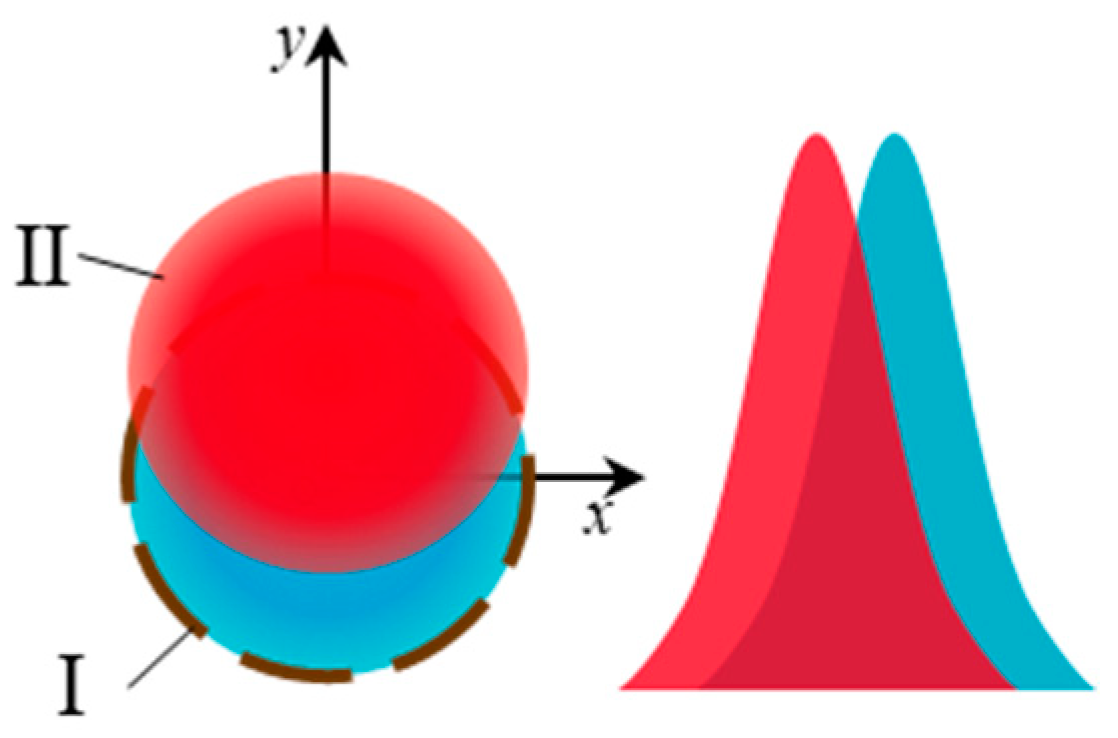

3.3. Equivalent Measurement of the Error

3.4. Verification of the Error Compensation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lawall, J. Interferometry for Accurate Displacement Metrology. Opt. Photon. News 2004, 15, 40–45. [Google Scholar] [CrossRef]

- Weichert, C.; Köchert, P.; Köning, R.; Flügge, J.; Andreas, B.; Kuetgens, U.; Yacoot, A. A heterodyne interferometer with periodic nonlinearities smaller than ±10 pm. Meas. Sci. Technol. 2012, 23, 094005. [Google Scholar] [CrossRef]

- Abbott, B.P.; Abbott, R.; Abbott, T.D.; Abernathy, M.R.; Acernese, F.; Ackley, K.; Adams, C.; Adams, T.; Addesso, P.; Adhikari, R.X.; et al. Observation of Gravitational Waves from a Binary Black Hole Merger. Phys. Rev. Lett. 2016, 116, 061102. [Google Scholar] [CrossRef] [PubMed]

- Pisani, M.; Yacoot, A.; Balling, P.; Bancone, N.; Birlikseven, C.; Celik, M.; Flugge, J.; Hamid, R.; Kochert, P.; Kren, P.; et al. Comparison of the performance of the next generation of optical interferometers. Metrologia 2012, 49, 455–467. [Google Scholar] [CrossRef]

- Pease, R.F.; Chou, S.Y. Lithography and Other Patterning Techniques for Future Electronics. Proc. IEEE 2008, 96, 248–270. [Google Scholar] [CrossRef]

- Kochert, P.; Flugge, J.; Weichert, C.; Koning, R.; Manske, E. Phase measurement of various commercial heterodyne He-Ne-laser interferometers with stability in the picometer regime. Meas. Sci. Technol. 2012, 23, 6. [Google Scholar] [CrossRef]

- Manske, E.; Jager, G.; Hausotte, T.; Fussl, R. Recent developments and challenges of nanopositioning and nanomeasuring technology. Meas. Sci. Technol. 2012, 23, 10. [Google Scholar] [CrossRef]

- Lou, Y.T.; Yan, L.P.; Chen, B.Y.; Zhang, S.H. Laser homodyne straightness interferometer with simultaneous measurement of six degrees of freedom motion errors for precision linear stage metrology. Opt. Express 2017, 25, 6805–6821. [Google Scholar] [CrossRef] [PubMed]

- Rowley, W.R.C. Signal Strength in Two-beam Interferometers with Laser Illumination. Opt. Acta Int. J. Opt. 1969, 16, 159–168. [Google Scholar] [CrossRef]

- Huang, J.J.S.; Chang, H.S.; Jan, Y.H.; Ni, C.J.; Chen, H.S.; Chou, E. Temperature Dependence Study of Mesa-Type InGaAs/InAlAs Avalanche Photodiode Characteristics. Adv. Optoelectron. 2017, 2017, 5. [Google Scholar] [CrossRef]

- Kharraz, O.; Forsyth, D. Performance comparisons between PIN and APD photodetectors for use in optical communication systems. Optik 2013, 124, 1493–1498. [Google Scholar] [CrossRef]

- Yan, L.P.; Yan, Y.C.; Chen, B.Y.; Lou, Y.T. A Differential Phase-Modulated Interferometer with Rotational Error Compensation for Precision Displacement Measurement. Appl. Sci. 2022, 12, 5002. [Google Scholar] [CrossRef]

- Su, Z.; Liang, X.; Bi, S. Noise analysis and determination method of optimum multiplication rate for APD sensor. In Proceedings of the International Conference on Automatic Control and Artificial Intelligence (ACAI 2012), Xiamen, China, 3–5 March 2012; pp. 1403–1406. [Google Scholar]

- Wu, X.Y.; Cui, J.Y.; Xu, C.X.; Zheng, W.; Zheng, Y.C. The design of laser detection circuit with high reliability and large dynamic range based on APD. In Proceedings of the Conference on Optical Sensing and Imaging Technologies and Applications/International Symposium on Optoelectronic Technology and Application (OTA)/Annual Conference of the Chinese-Society-for-Optical-Engineering (CSOE), Beijing, China, 22–24 May 2018. [Google Scholar]

- Yu, X.N.; Tong, S.F.; Dong, Y.; Song, Y.S.; Hao, S.C.; Lu, J. Design and performance testing of an avalanche photodiode receiver with multiplication gain control algorithm for intersatellite laser communication. Opt. Eng. 2016, 55, 5. [Google Scholar] [CrossRef]

- Cao, Y.H.; Bu, X.Z.; Xu, M.M.; Han, W. APD optimal bias voltage compensation method based on machine learning. ISA Trans. 2020, 97, 230–240. [Google Scholar] [CrossRef]

- Budzyn, G.; Podzorny, T. Study on avalanche photodiode influence on heterodyne laser interferometer linearity. In Proceedings of the 12th International AIVELA Conference on Vibration Measurements by Laser and Noncontact Techniques—Advances and Applications, Ancona, Italy, 29 June–1 July 2016. [Google Scholar]

- Wang, B.H.; Huang, Z.H.; Zeng, X.G.; Sorin, W.V.; Liang, L.; Fiorentino, M.; Beausoleil, R.G. A Compact Model for Si-Ge Avalanche Photodiodes Over a Wide Range of Multiplication Gain. J. Lightwave Technol. 2019, 37, 3229–3235. [Google Scholar] [CrossRef]

- Bielecki, Z.; Achtenberg, K.; Kopytko, M.; Mikolajczyk, J.; Wojtas, J.; Rogalski, A. Review of photodetectors characterization methods. Bull. Pol. Acad. Sci. Tech. Sci. 2022, 70, 26. [Google Scholar] [CrossRef]

- Campbell, J.C.; Demiguel, S.; Ma, F.; Beck, A.; Guo, X.Y.; Wang, S.L.; Zheng, X.G.; Li, X.W.; Beck, J.D.; Kinch, M.A.; et al. Recent advances in avalanche photodiodes (vol 10, pg 777, 2004). IEEE J. Sel. Top. Quantum Electron. 2004, 10, 1446–1447. [Google Scholar] [CrossRef]

- Merhav, N. Optimal Correlators for Detection and Estimation in Optical Receivers. In Proceedings of the IEEE International Symposium on Information Theory (ISIT), Electr Network, Melbourne, Australia, 12–20 July 2021; pp. 3097–3102. [Google Scholar]

- Ray, S.; Hella, M.M.; Hossain, M.M.; Zarkesh-Ha, P.; Hayat, M.M. Speed Optimized Large Area Avalanche Photodetector in Standard CMOS Technology for Visible Light Communication. In Proceedings of the 13th IEEE Sensors Conference, Valencia, Spain, 2–5 November 2014; pp. 2147–2150. [Google Scholar]

- Yokoyama, S.; Okamoto, A.; Araki, T.; Suzuki, N. Examination to eliminate undesirable phase delay of an avalanche photodiode (APD) for intensity-modulated light. Rev. Sci. Instrum. 1995, 66, 5331–5336. [Google Scholar] [CrossRef]

- Yokoyama, S.; Suzuki, N.; Araki, T. Correction of intensity-dependent phase delay in avalanche photodiodes for high-frequency modulation-light. Rev. Sci. Instrum. 1995, 66, 4391–4392. [Google Scholar] [CrossRef]

- Miyata, T.; Araki, T.; Iwata, T. Correction of the intensity-dependent phase delay in a silicon avalanche photodiode by controlling its reverse bias voltage. IEEE J. Quantum Electron. 2003, 39, 919–923. [Google Scholar] [CrossRef]

- Chang, D.; Wang, J.N.; Hu, P.C.; Tan, J.B. Zoom into picometer: A picoscale equivalent phase-difference-generating method for testing heterodyne interferometers without ultraprecision stages. Opt. Eng. 2019, 58, 8. [Google Scholar] [CrossRef]

- Demarest, F.C. High-resolution, high-speed, low data age uncertainty, heterodyne displacement measuring interferometer electronics. Meas. Sci. Technol. 1998, 9, 1024–1030. [Google Scholar] [CrossRef]

| Times | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| AC/DC ratio (%) | 100 | 98 | 93 | 88 | 83 | 78 | 73 |

| Light intensity (μW) | 25 | 24.6 | 23.8 | 23.0 | 22.2 | 21.4 | 20.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Sun, Y.; Xing, X.; Hu, P.; Chang, D.; Tan, J. Equivalent Measurement and Real-Time Compensation of Error Caused by Intensity Change in Deep Sub-Nanometer Displacement Measuring Interferometry. Photonics 2022, 9, 714. https://doi.org/10.3390/photonics9100714

Wang J, Sun Y, Xing X, Hu P, Chang D, Tan J. Equivalent Measurement and Real-Time Compensation of Error Caused by Intensity Change in Deep Sub-Nanometer Displacement Measuring Interferometry. Photonics. 2022; 9(10):714. https://doi.org/10.3390/photonics9100714

Chicago/Turabian StyleWang, Jianing, Yunke Sun, Xu Xing, Pengcheng Hu, Di Chang, and Jiubin Tan. 2022. "Equivalent Measurement and Real-Time Compensation of Error Caused by Intensity Change in Deep Sub-Nanometer Displacement Measuring Interferometry" Photonics 9, no. 10: 714. https://doi.org/10.3390/photonics9100714

APA StyleWang, J., Sun, Y., Xing, X., Hu, P., Chang, D., & Tan, J. (2022). Equivalent Measurement and Real-Time Compensation of Error Caused by Intensity Change in Deep Sub-Nanometer Displacement Measuring Interferometry. Photonics, 9(10), 714. https://doi.org/10.3390/photonics9100714