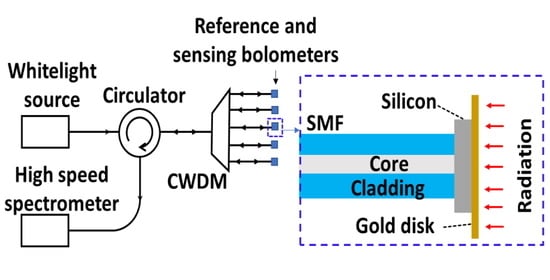

This section is divided into four parts. Parts 1–3 concern the noise performance and describe, respectively, the effects of the optical power distribution, the choice of fringe peaks or valleys for wavelength tracking, and the mechanical vibration on the temperature resolution of the fiber-optic bolometers. The results justify the use of the attenuator and polarization scrambler in the final setup. Part 4 concerns the characterization of the NEPD performance and the time constants of the fiber-optic bolometers.

3.1. Optical Power Management

One of the key components in the fiber-optic bolometer system that determines the noise performance of the system is the high-speed spectrometer. We found that the peak intensity of the signal output from the spectrometer and the exposure time set for the spectrometer can affect the noise performance of each of the channels. The exposure time of the spectrometer is the integration time of the on-chip charge amplifier in the photodiode array of the spectrometer that integrates the photodiode current from each pixel. Our results justify the use of attenuators to equalize the peak intensity of the spectrometer for the five channels for optimized overall noise performance.

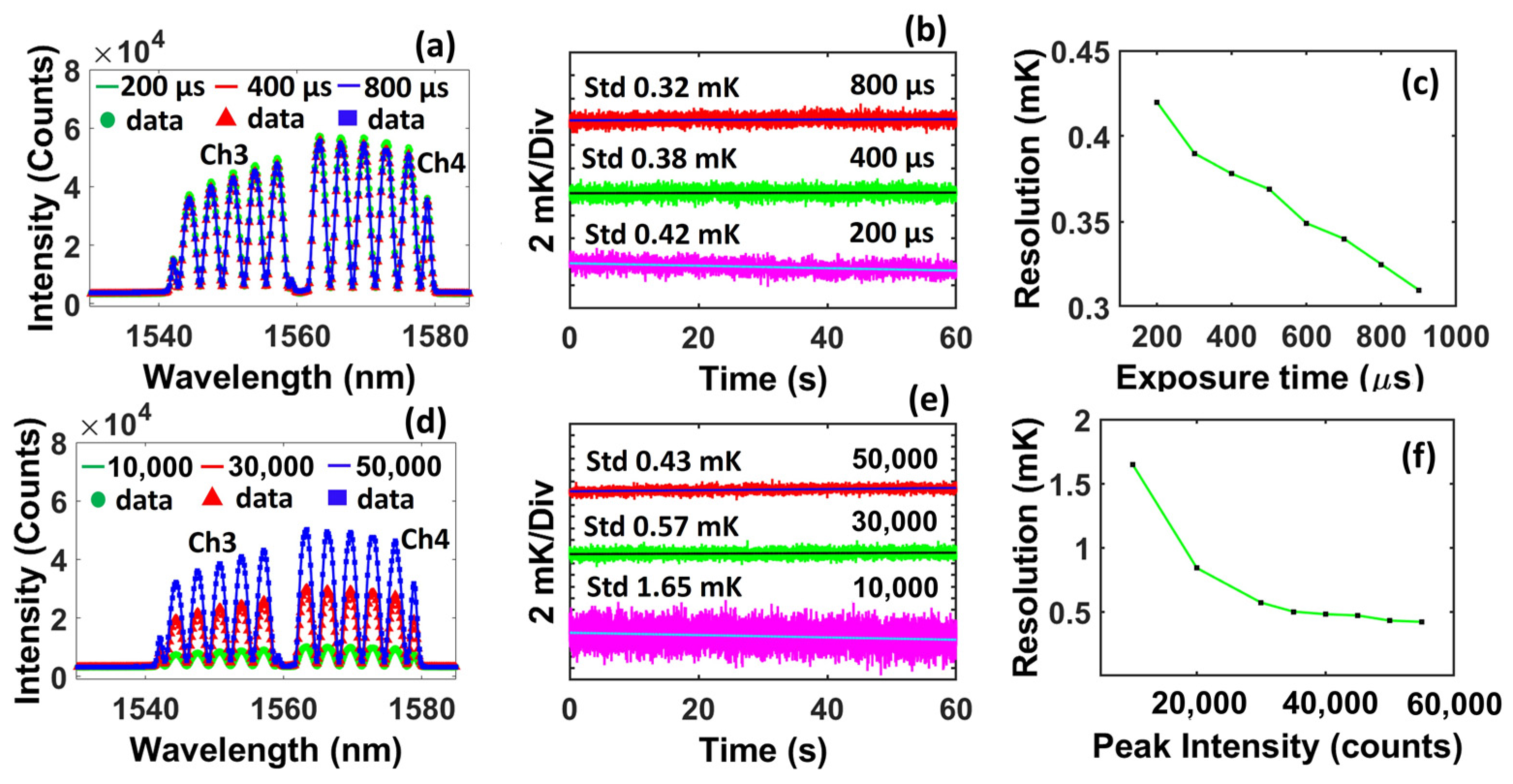

Specifically, we first studied the effect of the exposure time on the measurement resolution using Ch. 3 as an example. In this case, we increased the exposure time of the spectrometer from 200 to 900 μs in steps of 100 μs. Note that increasing the exposure time results in a larger gain of the on-chip charge amplifier that amplifies the photodiode current, leading to increased peak intensity of the spectrometer output. For each value of the exposure time, the peak intensity of the spectrum recorded by the spectrometer was maintained at a constant level of ~55,000 counts (close to the maximum output value of the spectrometer) by adjusting the attenuator on the channel.

Figure 3a shows the reflection spectra measured by the spectrometer at three different exposure time values (200, 400, and 800 μs). For each measured spectrum, the wavelength position of each of the fringe valleys was found by fitting the data points around the valley with a sinusoidal function. Then, the shift of the average of the wavelength position of the five valleys within the wavelength range of the CWDM channel was found and converted to temperature variations using a responsivity of 84 pm/K at 1550 nm [

10] (the responsivity was corrected using the center wavelength of the channel). To obtain the noise performance, the reflection spectrum was continuously recorded by the spectrometer for around 60 s at a frame rate of 1 kHz while the bolometer was kept in a sealed glass tube without applying radiation from a 405 nm laser. To remove the drift generated by the environmental temperature variation, the moving average with an averaging window size of 100 data points (corresponding to 0.1 s in time) of the temperature reading from the reference bolometer was subtracted from the reading of the sensing bolometer. Residual drift was removed by subtracting the linear temperature variation from the actual temperature variation in the fiber-optic bolometer. The standard deviation of the relative temperature variation was used to specify the resolution of the bolometer. The relative temperature variation in the fiber-optic bolometer connected to Ch. 4 is shown in

Figure 3b when the exposure time of the spectrometer was set at 200, 400, and 800 μs. A resolution of 0.42, 0.38, and 0.32 mK was found for the exposure time of 200, 400, and 800 μs, respectively.

Figure 3c shows the resolution of the fiber-optic bolometer vs. different exposure times of the spectrometer. It is seen that the value of the resolution reduced as the exposure time increased, which is expected as an increased exposure time corresponds to an increased integration time of the charge amplifier for each of the detector pixels in the photodetector array, resulting in reduced noise from the pixel output. In practice, the maximum exposure time that can be used is determined by the required measurement speed. We also noticed that the improvement in noise performance by increasing the exposure time was moderate. The value of resolution reduced from 0.42 to 0.31 mK when the exposure time increased from 200 to 900 μs.

Next, we studied the effect of the peak intensity from the spectrum output on the noise performance of the bolometer. In this case, the exposure time was set at 200 μs and maintained at this value during the experiment. The peak intensity of the spectrometer output was increased from 10,000 to 55,000 counts by adjusting the attenuation using an attenuator connected to the light source.

Figure 3d shows the reflection spectra measured by the spectrometer with three different peak intensity levels (10,000, 30,000, and 50,000 counts). The resolution of the bolometer was characterized following the same process described above. The relative temperature variation measured by the bolometers connected to the Ch. 4 is shown for three different peak intensities in

Figure 3e. A noise of 1.65, 0.57, and 0.43 mK was found when the maximum peak intensity counts were set to 10,000, 30,000, and 50,000, respectively.

Figure 3f shows the bolometer resolution as a function of peak intensity. It shows that the value of resolution exponentially increased as the peak intensity reduced, and the resolution was strongly influenced by the peak intensity when the peak intensity was below ~35,000 counts. To achieve optimized measurement resolution, the peak intensity should be maintained at >35,000 counts.

The light source and the spectrometer were shared by all five channels through the CWDM. Because of the non-uniform spectral profile of the light source and the variations in the reflection spectra of individual bolometers, the power spectral densities of the reflected light had large variations among the five channels without the attenuators.

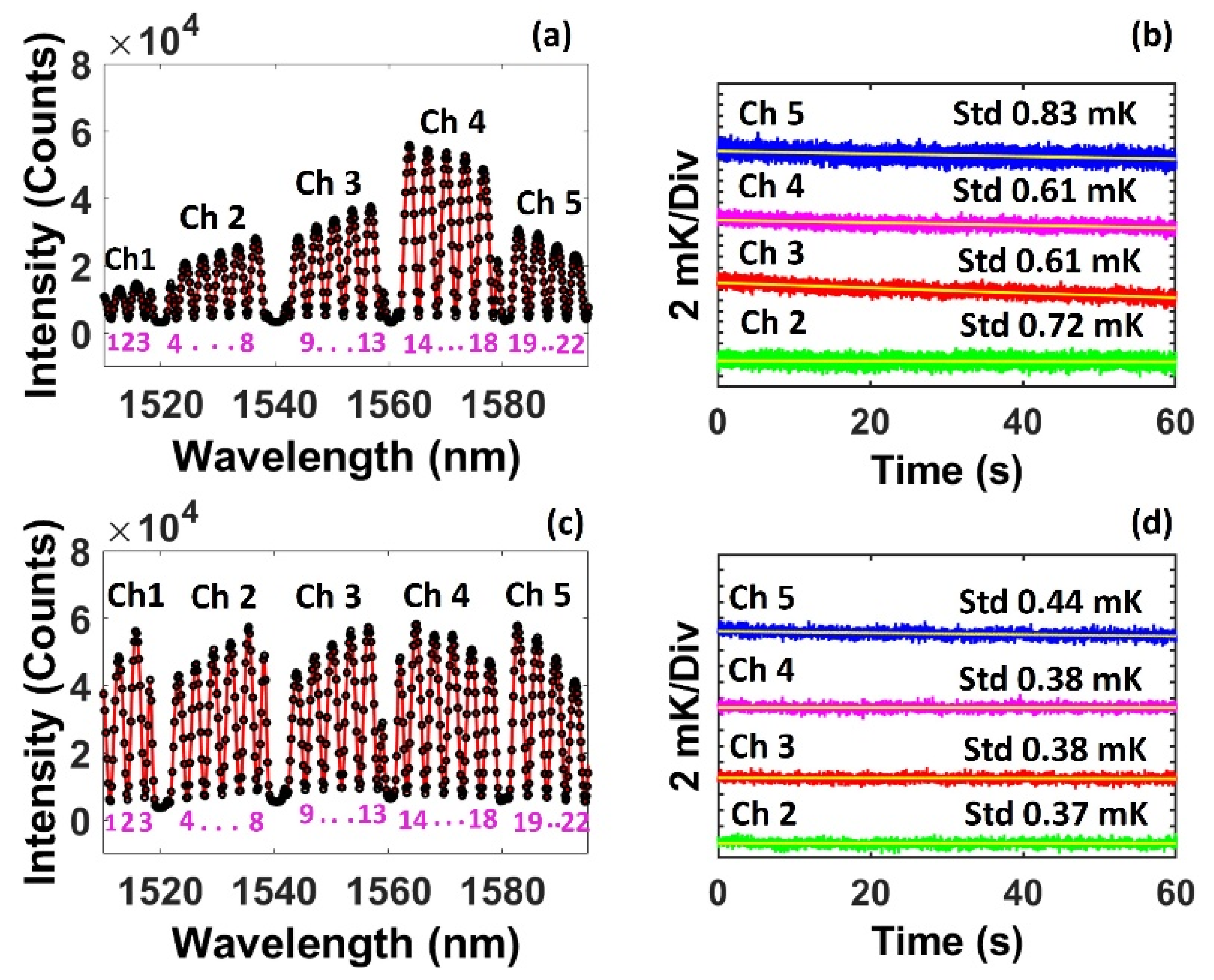

Figure 4a shows a spectral frame containing the signal from all five bolometers. The exposure time was set at ~50 μs to prevent the saturation of the spectrometer output for Ch. 4, which had the largest peak intensity at ~55,000 counts. The fringe valleys used for signal processing are also indicated by the numbers in the figure. The spectrum shows large discrepancies in the peak intensity among the five channels with average peak intensities below 35,000, the threshold above which the measurement resolution was not sensitive to the peak intensity, for Chs. 1, 2, and 5 and above the threshold for Chs. 3 and 4.

Figure 4b shows the resolution of the four sensing bolometer channels (Chs. 2–5) after compensating for the environmental drift from the reference bolometer channel (Ch. 1). The result shows that Chs. 3 and 4 had similar resolutions of 0.61 mK. Although the peak intensity for Ch. 4 was higher than that for Ch. 3, they exhibited similar resolutions because the intensity of both channels exceeded the threshold of 35,000 counts, as shown in

Figure 3d. The resolution increased to 0.72 mK for Ch. 2 and 0.83 mK for Ch. 5 due to the reduced peak intensity below 35,000 counts for these channels. It is worth noting that the number of fringe valleys available for signal processing for Ch. 5 was less than that for other channels connected to the sensing bolometers because of the limited wavelength range of the spectrometer. Five fringe valleys were used for Ch. 2, while only four valleys were available for Ch. 5. Thus, Ch. 5 showed a worse resolution despite its stronger peak intensity compared with Ch. 2.

Using the attenuators in the five channels, we adjusted the peak intensity of each of the channels and the exposure time of the spectrometer, which brought the peak intensities for the five channels to a similar level of 55,000 counts, as shown in

Figure 4c. Reaching this maximum peak intensity for all the channels required a larger exposure time set for the spectrometer, which offered additional enhancement to the noise performance.

Figure 4d shows the noise performance for this power-balanced configuration. The four sensing bolometers showed a similar measurement resolution around 0.4 mK (ranging between 0.37 and 0.44 mK), which was smaller than the case without attenuators shown in

Figure 4b. The variation in the resolution is attributed to the difference in the power variations within each channel that cannot be balanced by the attenuator.

3.3. Effect of Mechanical Vibration

Large mechanical vibration can be present in a magnetic-confinement fusion system that may contaminate the signal from an optical diagnostic system. For example, it has been shown that mechanical vibration can cause movements up to 1 cm at frequencies of a few hertz for the interferometry measurement system on tokamaks [

11,

12]. Signal contamination from mechanical vibration is also a concern for the fiber-optic bolometer system. Silicon pillars that form the FP cavity in a bolometer may have a small birefringence due to the thermal stress and elastic strains of the silicon wafer from which the pillars are manufactured [

13]. The birefringence makes the bolometer sensitive to light polarizations. Previously, we demonstrated that fiber-optic bolometers interrogated using linearly polarized light from a DFB laser show significant noise degradation from mechanical vibration that induces birefringence to the fiber and subsequently changes the polarization of the light in the fiber [

14]. The light source used here is a SLED, which may have non-negligible degree of polarization. Therefore, it is important to study the effect of mechanical vibration on the noise performance of the system.

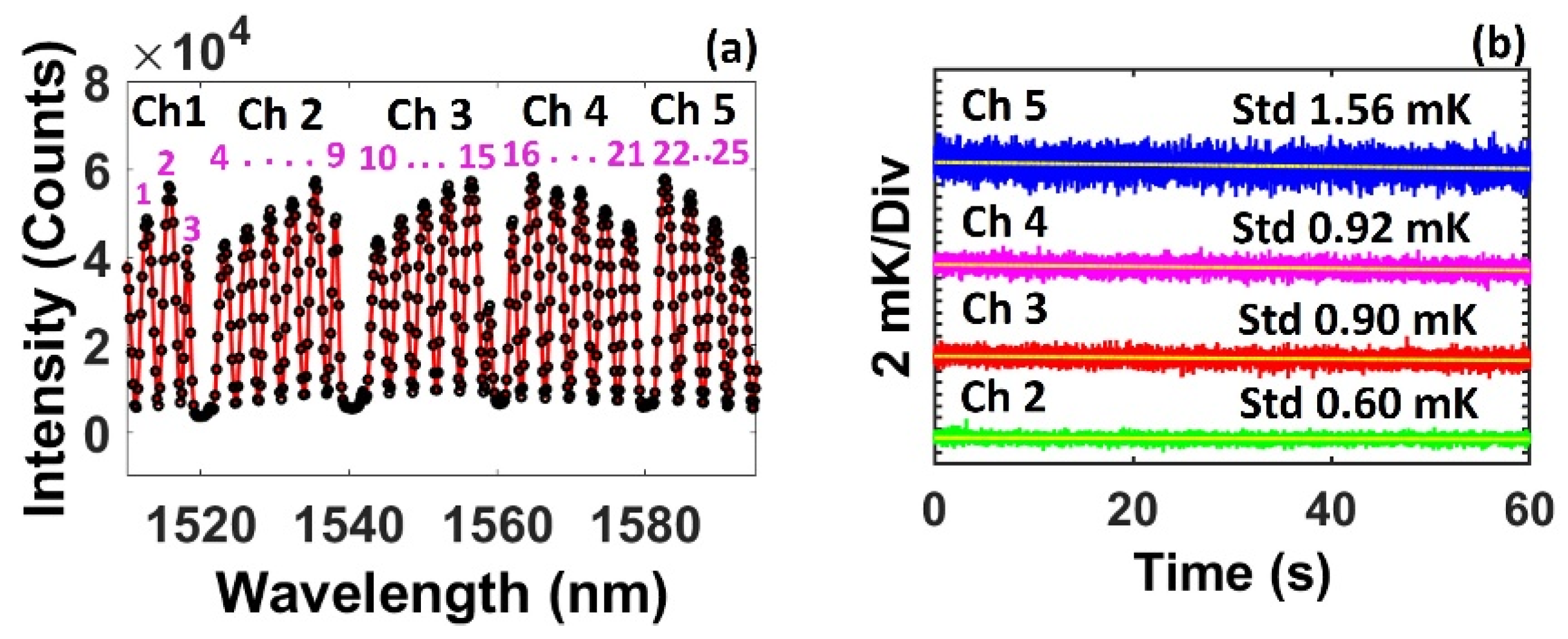

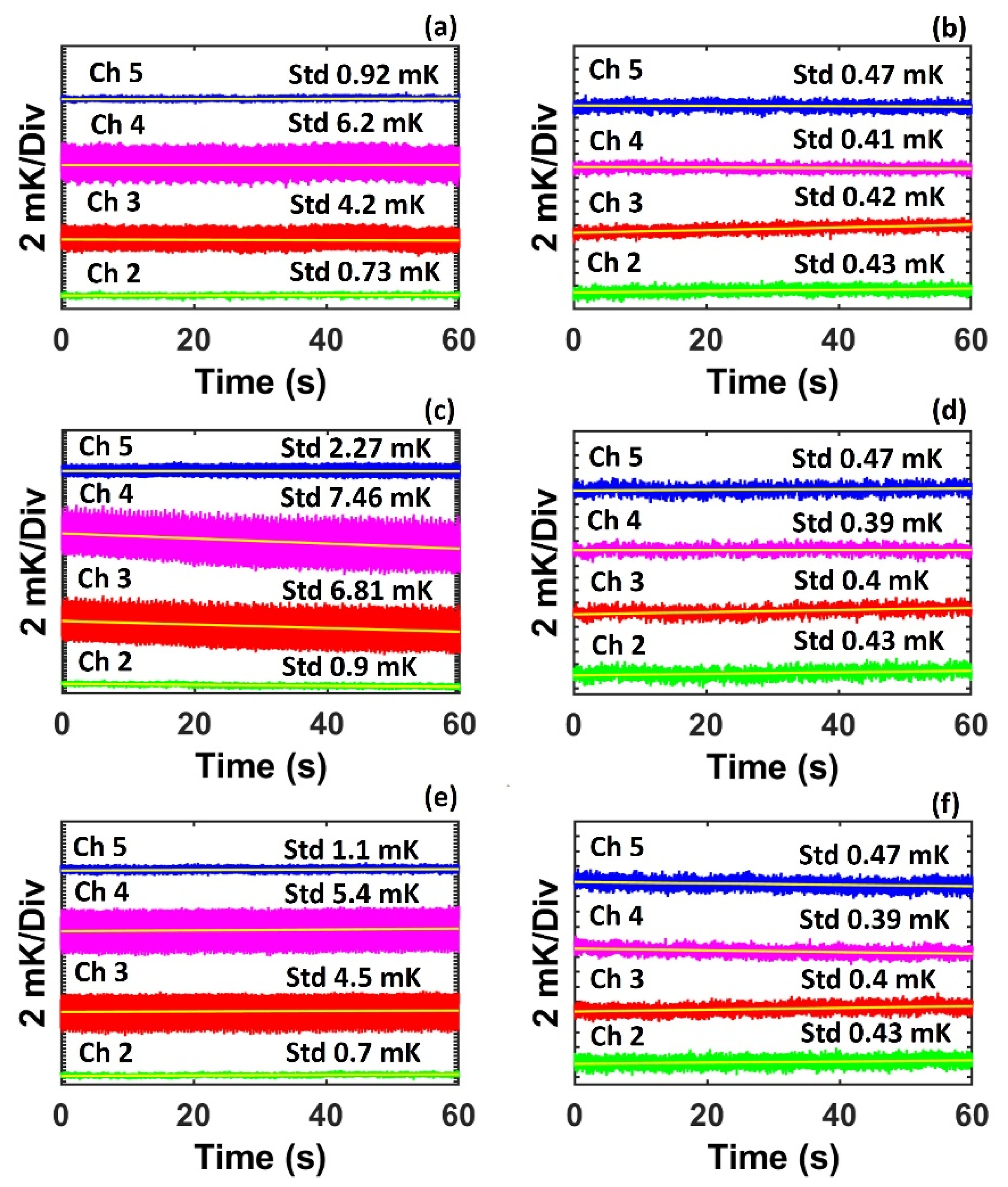

After optimizing the experimental setup with an attenuator to balance the peak intensity of the channels and using fringe valley tracking for signal processing, mechanical vibration was applied by using an electromagnetic shaker in the fiber before the CWDM. The vibration was applied using frequencies of 5, 10, and 100 Hz with peak-to-peak sinusoidal displacements of ~7, ~5, and ~1 mm, respectively.

Figure 6a shows the relative temperature variation for the sensing bolometers in Chs. 2–5 in the case of the 5 Hz vibration applied on the fiber. It is seen that the vibration significantly degraded the noise performance with the temperature resolution being 0.73, 4.2, 6.2, and 0.92 mK for Chs. 2–5, respectively. It is believed that the degradation of noise performance is determined by the birefringence of the silicon pillars and the orientation of the light polarization relative to the principal axes of the birefringence, both of which are uncontrolled during the construction of the bolometer and during the operation of the bolometer system. Therefore, the level of performance degradation shows a great variation among the four sensing bolometers.

To mitigate the effect of the mechanical vibration, a polarization scrambler was used after the SLED to randomize the polarization state at a speed (5 MHz) much higher than the frame rate (1 kHz) of the spectrometer. Therefore, the light injected into the bolometer can be considered as unpolarized, which is insensitive to the changes in the birefringence induced by the mechanical vibration.

Figure 6b shows the resolution after the polarization scrambler was applied when the fiber was experiencing the 5 Hz mechanical vibration. The results show that Chs. 2–5 had a much lower and similar noise level of ~0.43 mK (ranging between 0.41 and 0.47 mK), which is comparable to the noise performance when there was no vibration, as shown in

Figure 4d.

A similar effect was found when vibration was applied at a frequency of 10 and 100 Hz. Noise levels were higher and non-uniform among the sensing bolometers with the application of vibration and without polarization scrambling; the noise levels reduced to ~0.42 mK, relatively uniformly for all bolometers after the use of the polarization scrambler, as shown in

Figure 6c–f. The results show that the polarization scrambler is effective for mitigating the degradation from mechanical vibration.

3.4. NEPDs and Time Constants

The responsivities and time constants of the four sensing bolometers (Chs. 2–5) were characterized by exposing the bolometers to radiation from a 405 nm laser modulated by a square wave of 0.1 Hz with different levels of amplitude.

Figure 7a–d shows the relative temperature changes of the bolometer when radiation with a power density amplitude of 74 W/m

2 impinged on to the bolometers. The average temperature rise when the bolometers reached a steady state was 272 mK (range: 222–312 mK), corresponding to an average responsivity of 3.68 mK/(W/m

2) (range: 3.0–4.2 mK/(W/m

2)). The insets of

Figure 6a–d show the close-up views of the responses at the transient in response to the step changes of the radiation. The time constant of each bolometer, which is a measure of the measurement speed of the bolometer, was found by the time it took for the temperature to fall to 63% of the overall temperature change during the cycle when the laser was switched off. The average time constant of the bolometer was 223 ms (range: 192–235 ms). The variations in the responsivity and the time constant among the four bolometers are believed to arise from different amounts of glue and/or from the variation in the gold disk sizes used to fabricate each of the bolometers that affect the thermal mass of the bolometers and the heat transfer process between the bolometers and the ambient air.

To characterize the NEPD for each bolometer, we exposed the bolometer with radiation of different levels of amplitude and calculated the signal-to-noise ratio (SNR) at each radiation level. The SNR was found by dividing the temperature rise from the radiation when the bolometer reached a steady state by

, where

is the temperature resolution of the bolometer defined in

Section 3.1,

Section 3.2,

Section 3.3 and

Section 3.4.

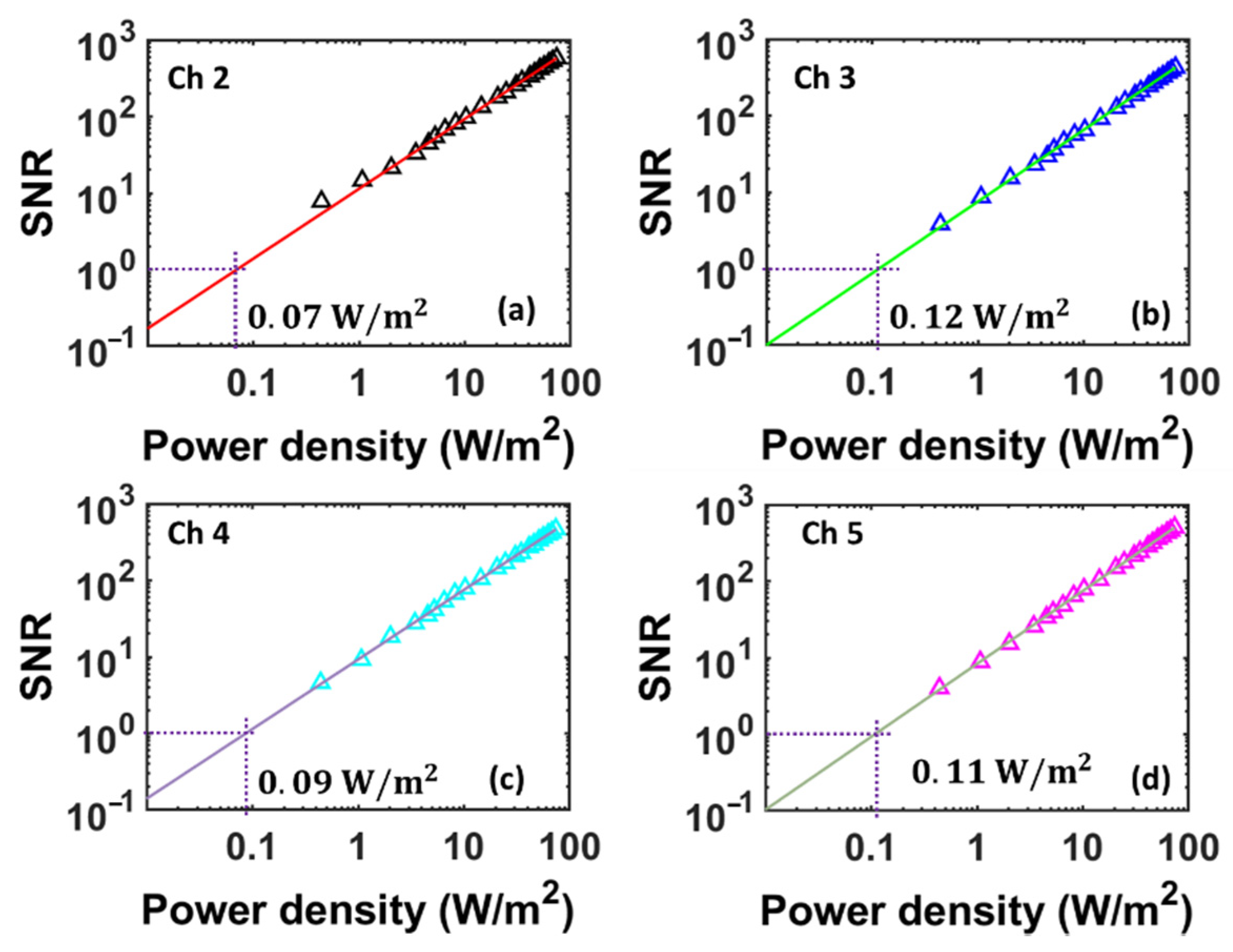

Figure 8a–d shows the SNR vs. power density for the four sensing bolometers. The NEPD is the power density level corresponding to a unity SNR, which can be found from the linear fitting line shown in

Figure 8. The average NEPD for the four bolometers was 0.10 W/m

2 (range: 0.07–0.12 W/m

2), which is similar to the NEPD of the fiber-optic bolometer based on a high-finesse silicon FPI interrogated using a wavelength-scanning DFB laser [

7]. Again, the variation in the NEPD among the sensing bolometers is attributed to the fabrication variations resulting in different thermal masses of bolometers.