Enhanced Crystal Quality of AlxIn1-xAsySb1-y for Terahertz Quantum Cascade Lasers

Abstract

:1. Introduction

2. Experiment Section

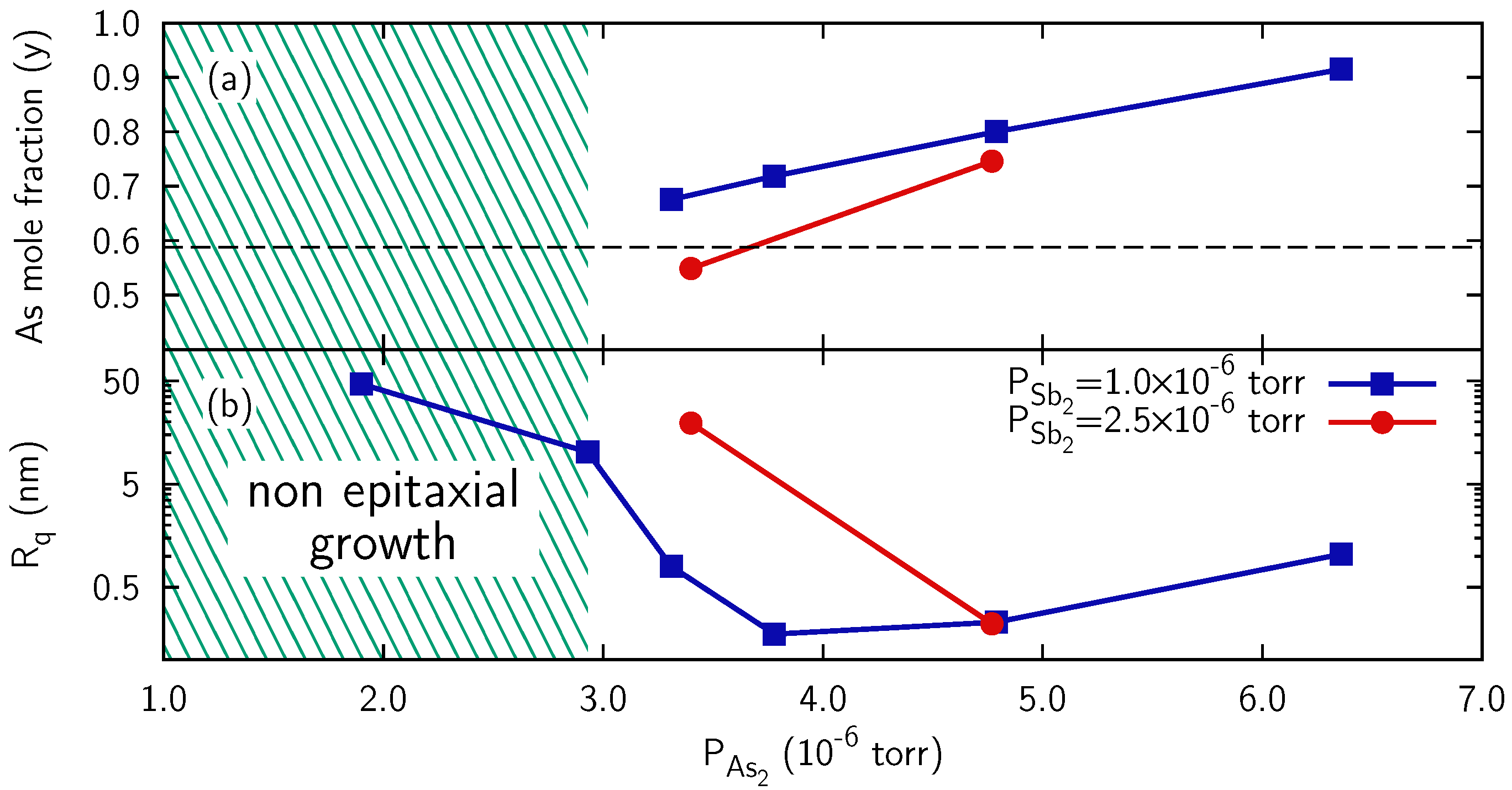

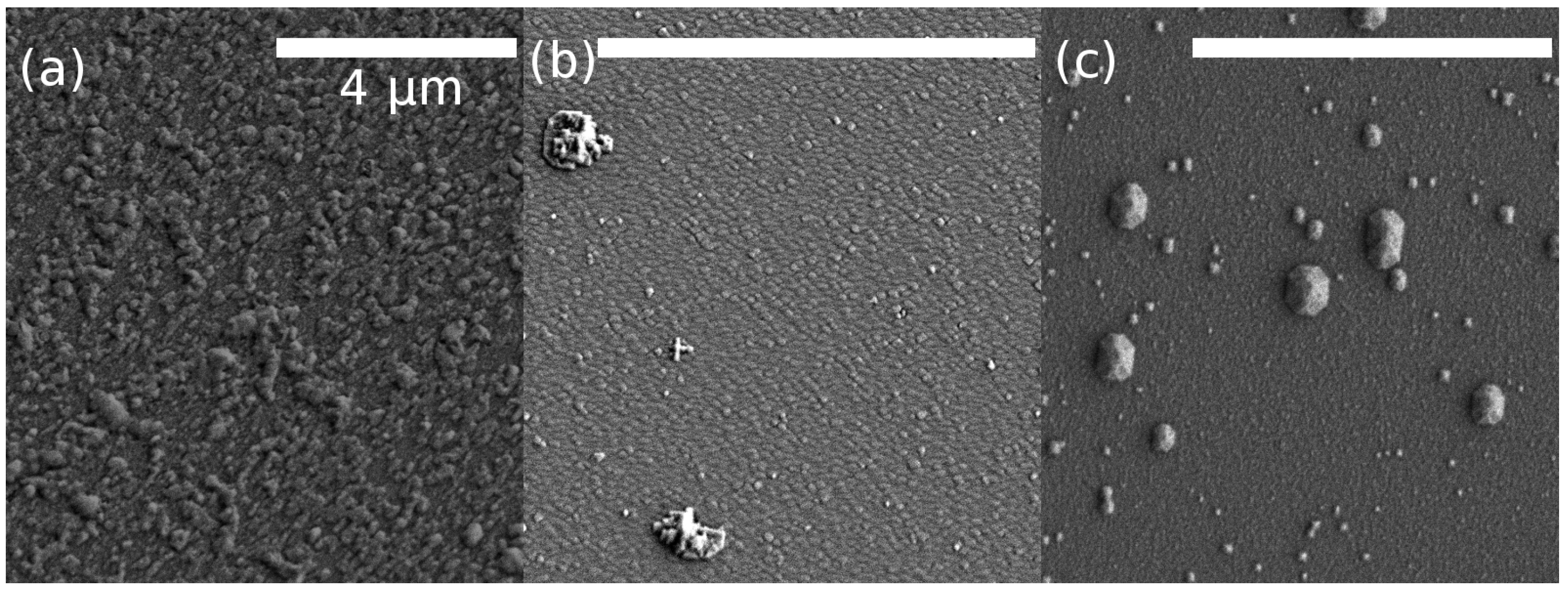

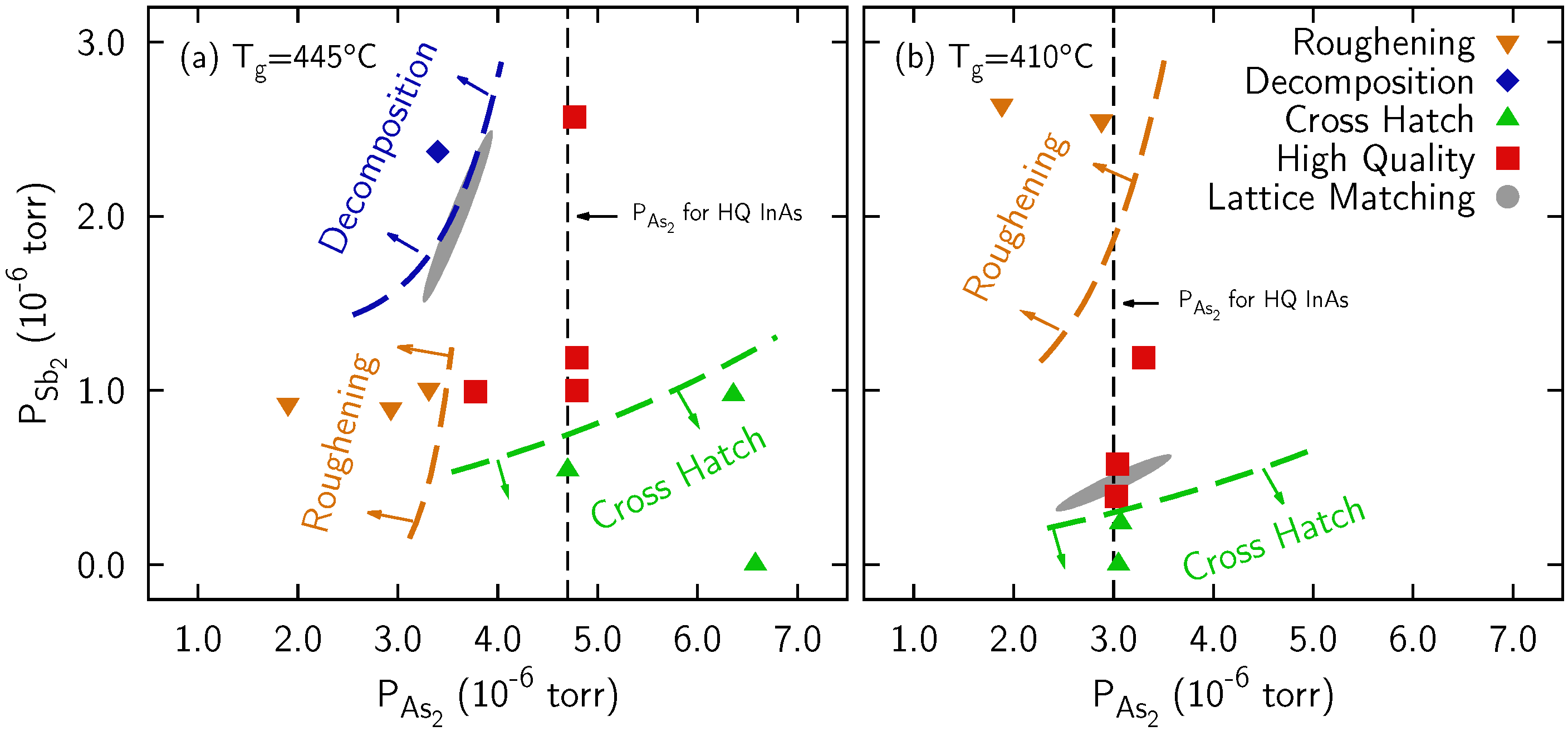

2.1. Growth Optimization of AlxIn1-xAsySb1-y

2.2. Low Temperature Growth of InAs Based Inter-Subband Devices

3. Discussions

4. Conclusions

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ohtani, K.; Ohno, H. InAs/AlSb quantum cascade lasers operating at 10 μm. Appl. Phys. Lett. 2003, 82, 1003–1005. [Google Scholar] [CrossRef]

- Teissier, R.; Barate, D.; Vicet, A.; Alibert, C.; Baranov, A.; Marcadet, X.; Renard, C.; Garcia, M.; Sirtori, C.; Revin, D.; Cockburn, J. Room temperature operation of InAs/AlSb quantum cascade lasers. Appl. Phys. Lett. 2004, 85, 167–169. [Google Scholar] [CrossRef]

- Devenson, J.; Teissier, R.; Cathabard, O.; Baranov, A. InAs/AlSb quantum cascade lasers emitting below 3 μm. Appl. Phys. Lett. 2007, 90. [Google Scholar] [CrossRef]

- Devenson, J.; Cathabard, O.; Teissier, R.; Baranov, A. InAsAlSb quantum cascade lasers emitting at 2.75–2.97 μm. Appl. Phys. Lett. 2007, 91. [Google Scholar] [CrossRef]

- Marcadet, X.; Renard, C.; Carras, M.; Garcia, M.; Massies, J. InAs/AlAsSb based quantum cascade lasers. Appl. Phys. Lett. 2007. [Google Scholar] [CrossRef]

- Turner, G.W.; Choi, H.K.; Le, H.Q. Growth of InAsSb quantum wells for long-wavelength (∼4 μm) lasers. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1995, 13, 699. [Google Scholar] [CrossRef]

- Wilk, A.; Fraisse, B.; Christol, P.; Boissier, G.; Grech, P.; El Gazouli, M.; Rouillard, Y.; Baranov, A.; Joullié, A. MBE growth of InAs/InAsSb/InAlAsSb “W” quantum well laser diodes emitting near 3 μm. J. Cryst. Growth 2001, 227–228, 586–590. [Google Scholar] [CrossRef]

- Semenov, A.; Solov’ev, V.; Meltser, B.; Terent’ev, Y.; Prokopova, L.; Ivanov, S. Molecular beam epitaxy of AlInAsSb alloys near the miscibility gap boundary. J. Cryst. Growth 2005, 278, 203–208. [Google Scholar] [CrossRef]

- Kudo, M.; Mishima, T. MBE growth of Si-doped InAlAsSb layers lattice-matched with InAs. J. Cryst. Growth 1997, 175–176, 844–848. [Google Scholar] [CrossRef]

- Washington-Stokes, D.; Hogan, T.; Chow, P.; Golding, T.; Kirschbaum, U.; Littler, C.; Lukic, R. AlxIn1-xAs1-ySby/GaSb effective mass superlattices grown by molecular beam epitaxy. J. Cryst. Growth 1999, 201–202, 854–857. [Google Scholar] [CrossRef]

- Ye, H.; Li, L.; Hinkey, R.; Yang, R.; Mishima, T.; Keay, J.; Santos, M.; Johnson, M. MBE growth optimization of InAs (001) homoepitaxy. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. 2013, 31. [Google Scholar] [CrossRef]

- Rojas-Ramirez, J.; Wang, S.; Contreras-Guerrero, R.; Caro, M.; Bhatnagar, K.; Holland, M.; Oxland, R.; Doornbos, G.; Passlack, M.; Diaz, C.; et al. AlxIn1-xAsySb1-y alloys lattice matched to InAs(100) grown by molecular beam epitaxy. J. Cryst. Growth 2015, 425, 33–38. [Google Scholar] [CrossRef]

- Sarney, W.; Svensson, S.; Wang, D.; Donetsky, D.; Kipshidze, G.; Shterengas, L.; Lin, Y.; Belenky, G. AlInAsSb for M-LWIR detectors. J. Cryst. Growth 2015, 425, 357–359. [Google Scholar] [CrossRef]

- Losurdo, M.; Capezzuto, P.; Bruno, G.; Brown, A.S.; Brown, T.; May, G. Fundamental reactions controlling anion exchange during mixed anion heterojunction formation: Chemistry of As-for-Sb and Sb-for-As exchange reactions. J. Appl. Phys. 2006, 100. [Google Scholar] [CrossRef]

- Reininger, P.; Zederbauer, T.; Schwarz, B.; Detz, H.; MacFarland, D.; Andrews, A.M.; Schrenk, W.; Strasser, G. InAs/AlAsSb based quantum cascade detector. Appl. Phys. Lett. 2015, 107. [Google Scholar] [CrossRef]

- Brandstetter, M.; Kainz, A.M.; Zederbauer, T.; Krall, M.; Schönhuber, S.; Detz, H.; Schrenk, W.; Andrews, A.M.; Strasser, G.; Unterrainer, K. InAs based terahertz quantum cascade lasers. Appl. Phys. Lett. 2016, 108. [Google Scholar] [CrossRef]

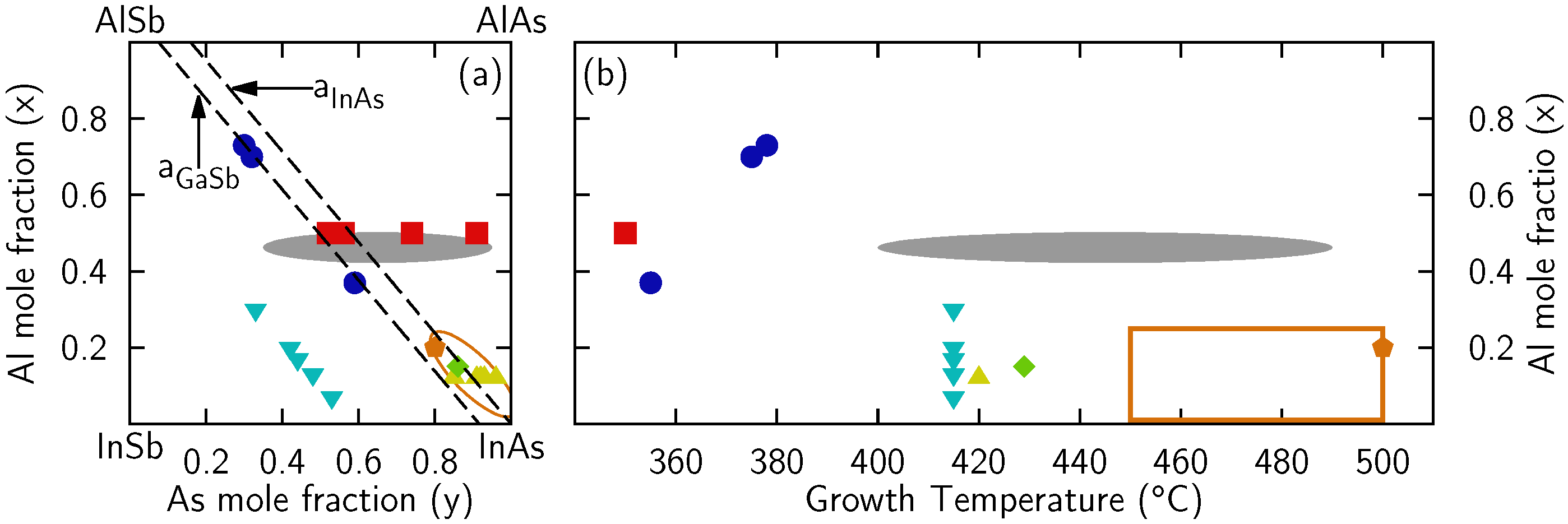

condition explicitly mentioned; the range studied is indicated by the outlined areas) Semenov et al. [8] grown on InAs; similar results were obtained by Rojas-Ramirez et al. [12]; () Washington-Stokes et al. [10] grown on GaSb; () Turner et al. [6] grown on GaSb; () Kudo et al. [9] grown on GaAs; () Wilk et al. [7] grown on InAs; () Sarney et al. [13] grown on a lattice-constant shifting AlGaInSb buffer on GaSb; The regions of temperature and composition studied within this work are indicated by the gray shaded areas.

condition explicitly mentioned; the range studied is indicated by the outlined areas) Semenov et al. [8] grown on InAs; similar results were obtained by Rojas-Ramirez et al. [12]; () Washington-Stokes et al. [10] grown on GaSb; () Turner et al. [6] grown on GaSb; () Kudo et al. [9] grown on GaAs; () Wilk et al. [7] grown on InAs; () Sarney et al. [13] grown on a lattice-constant shifting AlGaInSb buffer on GaSb; The regions of temperature and composition studied within this work are indicated by the gray shaded areas.

condition explicitly mentioned; the range studied is indicated by the outlined areas) Semenov et al. [8] grown on InAs; similar results were obtained by Rojas-Ramirez et al. [12]; () Washington-Stokes et al. [10] grown on GaSb; () Turner et al. [6] grown on GaSb; () Kudo et al. [9] grown on GaAs; () Wilk et al. [7] grown on InAs; () Sarney et al. [13] grown on a lattice-constant shifting AlGaInSb buffer on GaSb; The regions of temperature and composition studied within this work are indicated by the gray shaded areas.

condition explicitly mentioned; the range studied is indicated by the outlined areas) Semenov et al. [8] grown on InAs; similar results were obtained by Rojas-Ramirez et al. [12]; () Washington-Stokes et al. [10] grown on GaSb; () Turner et al. [6] grown on GaSb; () Kudo et al. [9] grown on GaAs; () Wilk et al. [7] grown on InAs; () Sarney et al. [13] grown on a lattice-constant shifting AlGaInSb buffer on GaSb; The regions of temperature and composition studied within this work are indicated by the gray shaded areas.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zederbauer, T.; Andrews, A.M.; MacFarland, D.; Detz, H.; Schrenk, W.; Strasser, G. Enhanced Crystal Quality of AlxIn1-xAsySb1-y for Terahertz Quantum Cascade Lasers. Photonics 2016, 3, 20. https://doi.org/10.3390/photonics3020020

Zederbauer T, Andrews AM, MacFarland D, Detz H, Schrenk W, Strasser G. Enhanced Crystal Quality of AlxIn1-xAsySb1-y for Terahertz Quantum Cascade Lasers. Photonics. 2016; 3(2):20. https://doi.org/10.3390/photonics3020020

Chicago/Turabian StyleZederbauer, Tobias, Aaron Maxwell Andrews, Donald MacFarland, Hermann Detz, Werner Schrenk, and Gottfried Strasser. 2016. "Enhanced Crystal Quality of AlxIn1-xAsySb1-y for Terahertz Quantum Cascade Lasers" Photonics 3, no. 2: 20. https://doi.org/10.3390/photonics3020020

APA StyleZederbauer, T., Andrews, A. M., MacFarland, D., Detz, H., Schrenk, W., & Strasser, G. (2016). Enhanced Crystal Quality of AlxIn1-xAsySb1-y for Terahertz Quantum Cascade Lasers. Photonics, 3(2), 20. https://doi.org/10.3390/photonics3020020