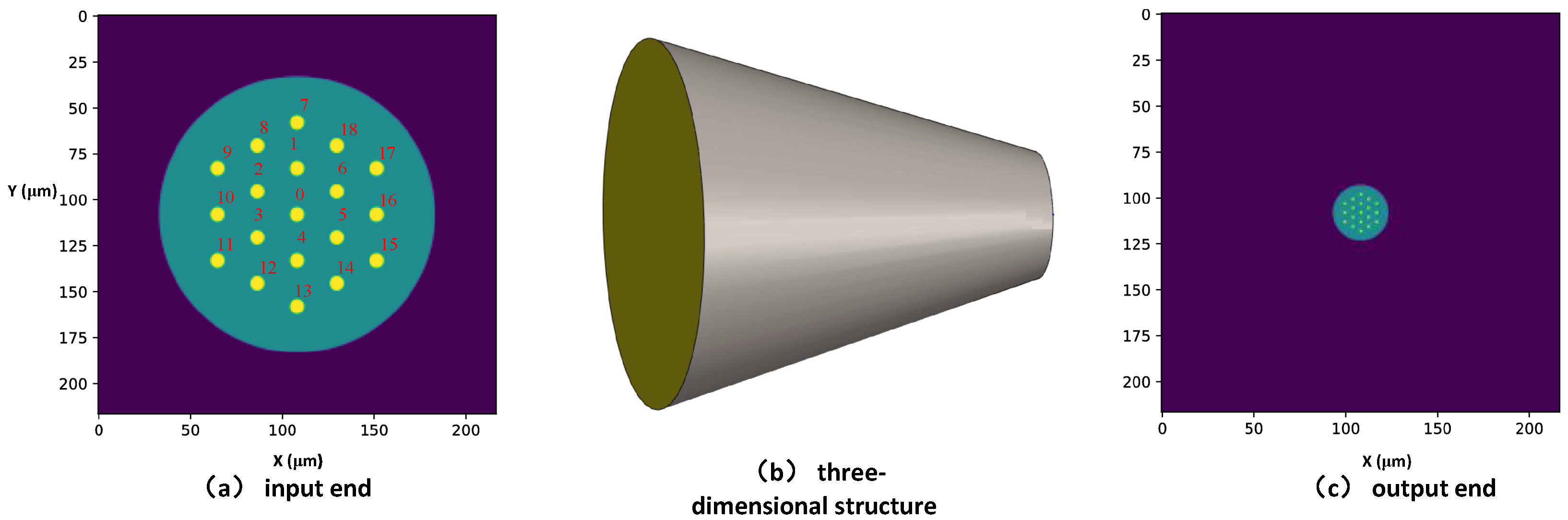

3.1. Design and Performance Simulation of Photonic Lanterns

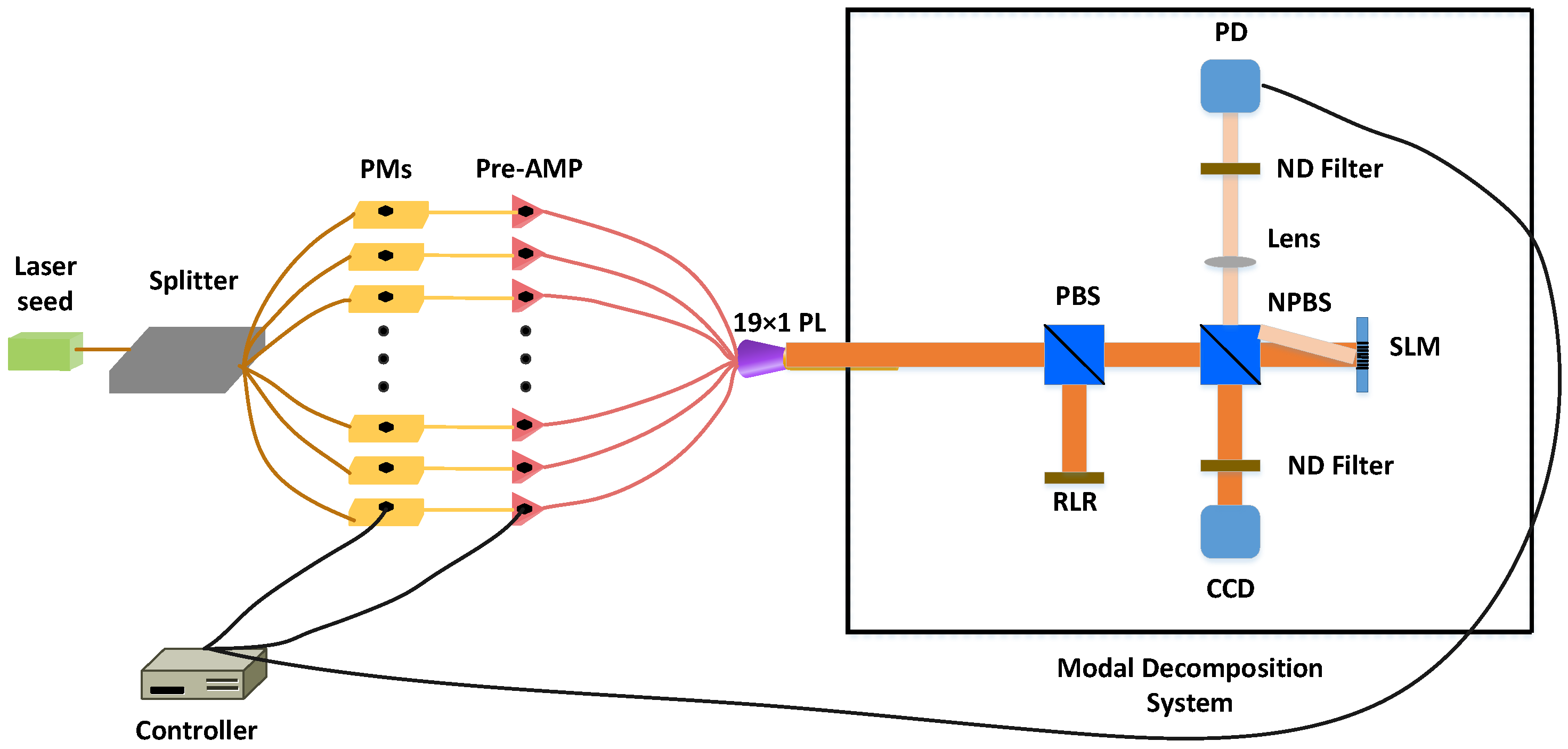

The proposed photonic lantern is schematically depicted in

Figure 3. Specifically,

Figure 3a provides a cross-sectional view of the single-mode end of the PL. In this figure, the numbers indicate the indices of the SMFs, which are arranged in a three-layer circularly symmetric configuration. When designing photonic lanterns, it is crucial to arrange the SMFs as compactly as possible to ensure efficient coupling of light fields, and the geometric arrangement of the SMF cores should match the modal structure supported by the multimode end because theoretical studies have shown that matching these structures can effectively reduce device loss. Following these design principles, the optimal configuration for a 19 × 1 photonic lantern is arranged in a three-layer circularly symmetric configuration: the innermost layer contains 1 SMF, the middle layer contains 6 SMFs, and the outermost layer contains 12 SMFs, ensuring efficient light coupling and minimizing losses by matching the modal structures between the single-mode and multimode ends. The parameters exploited in the design and simulation of this 19 ×1 photonic lantern are shown in

Table 1. The core diameters of the single-mode fibers are 8 µm, and these fibers are arranged in a three-layer circular configuration forming a bundle having a diameter of 150 µm, which is surrounded by a low-refractive-index jacket. Based on our preliminary research, we found that the core-to-cladding ratio of the input single-mode fibers is a critical factor influencing mode evolution results in photonic lanterns. The results show that a larger core-to-cladding ratio can lead to purer mode output. To achieve better output beam quality, photonic lanterns with larger output core diameters require larger core-to-cladding ratios of the SMFs. Therefore, in designing this photonic lantern, we selected commercially available single-mode fibers having the largest core-to-cladding ratio (8/80) and corroded their cladding diameter to 30 µm, rather than using the commonly employed 10/125 single-mode fibers.

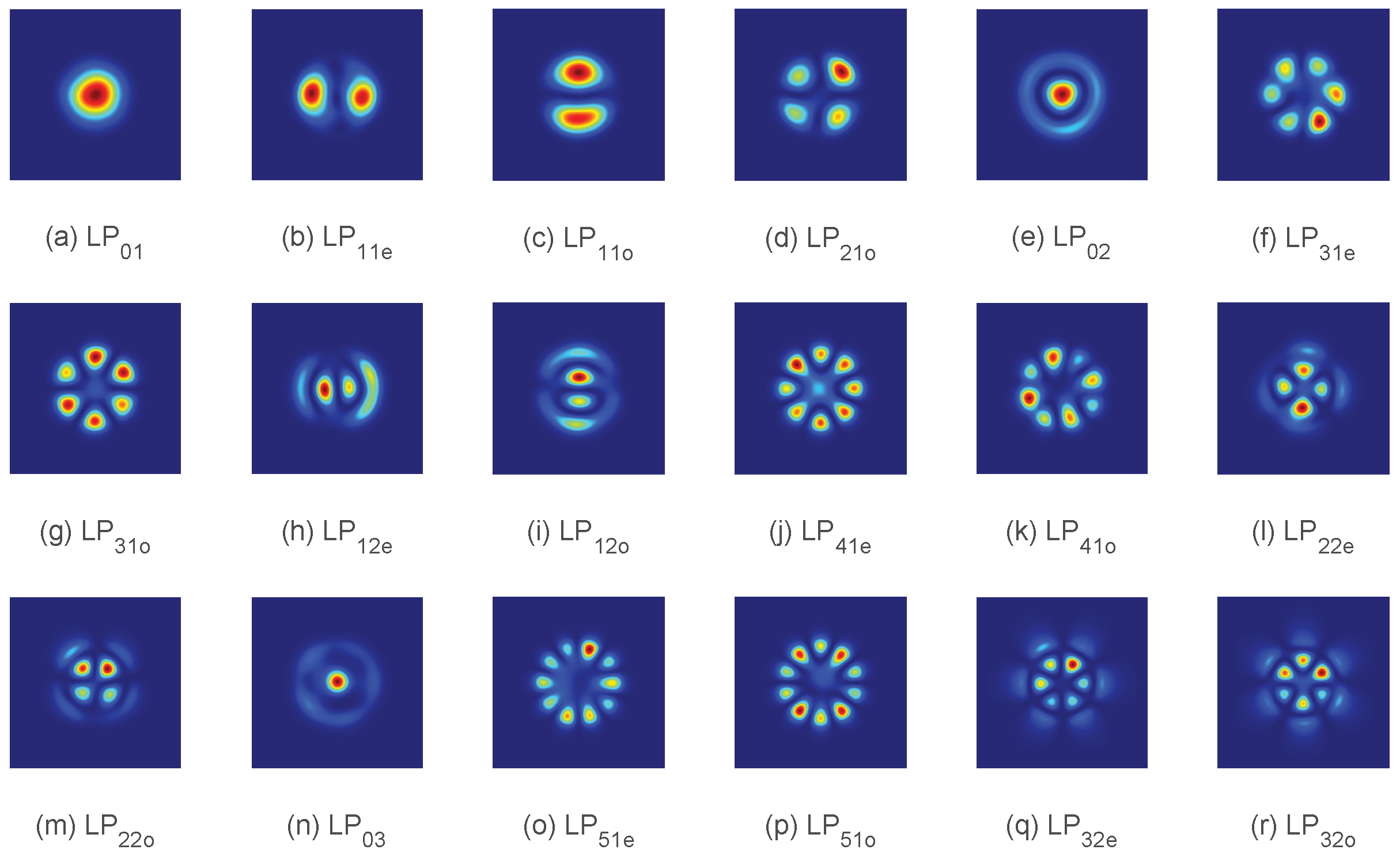

The single-mode fiber bundle undergoes linear adiabatic tapering to form a gradually tapered transition zone, having a length of 3 cm, where the tapering ratio is 1:5. The taper ratio and taper length have an effect on the output performance of such a photonic lantern. The taper ratio directly determines the core diameter of the multimode output end of the photonic lantern and thus determines the number of modes that the output end can support. As the taper diameter gradually becomes finer, the single-mode fiber bundle turns into the core of a multimode fiber, while the jacket becomes the cladding of the multimode fiber. An excessively large taper ratio would result in the multimode output end supporting more than 19 modes, which would require more input arms to control the output modes. On the other hand, an overly small taper ratio would lead to the multimode output end supporting fewer than 19 modes. Taking the above into account, a taper ratio of 1:5 is a suitable value. While the taper length affects energy loss during the process of mode coupling, adiabatic transition requires that the change in the transverse dimensions of the single-mode fiber bundle within the tapering region must occur sufficiently slowly. This ensures that the mode coupling is minimized and energy loss is reduced during the transition process. A taper region that is too short fails to satisfy the adiabatic approximation, causing some light to leak out of the photonic lantern and increasing its loss. Conversely, a longer taper region ensures excellent mode coupling and low loss but increases fabrication difficulty. Considering both the insertion loss and the practical constraints of the manufacturing process, a taper length of 3 cm is deemed appropriate. The output end is spliced to a multi-mode fiber with dimensions and numerical aperture (NA = 0.095) matched to ensure optimal performance. Nineteen distinct modes can be supported by the multi-mode fiber, matching the number of input arms at the input end, which are LP01, LP02, LP03, LP11e, LP11o, LP12e, LP12o, LP21e, LP21o, LP22e, LP22o, LP31e, LP31o, LP32e, LP32o, LP41e, LP41o, LP51e, and LP51o, respectively.

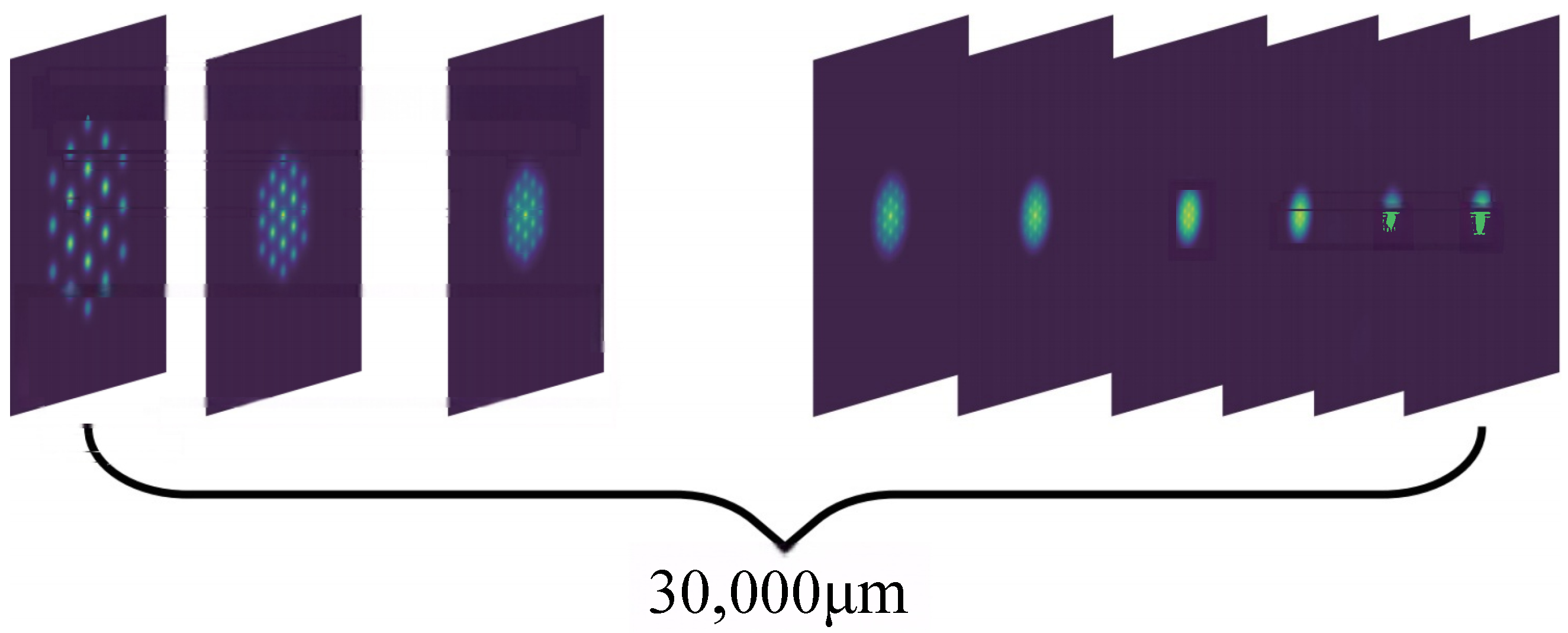

As the taper diameter decreases, the confined optical fields within the single-mode fibers progressively converge and merge into supermodes.

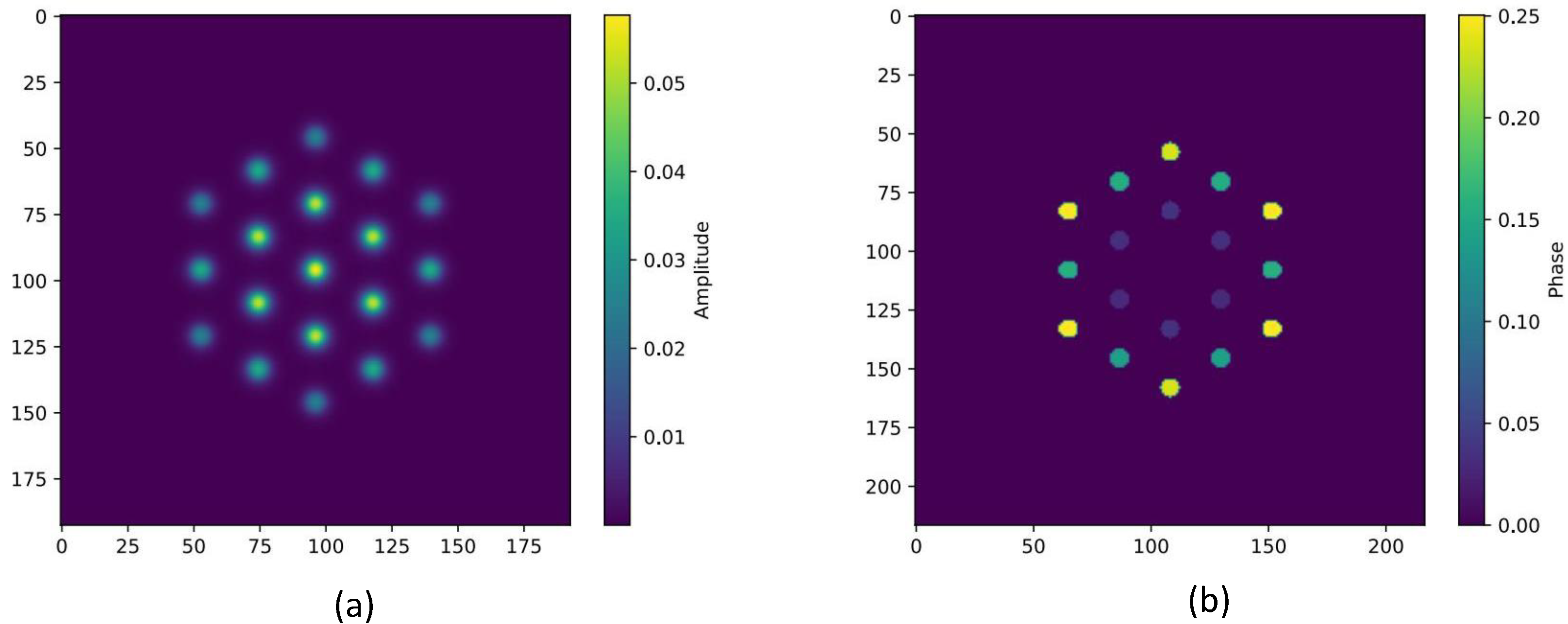

Figure 4 depicts the transformation process of the photonic lantern, starting from the input end where individual single-mode fibers propagate light independently, to the output end where these fields coalesce into the fundamental mode of a multi-mode fiber. At the initial stage, due to the relatively large spacing between the cores of the single-mode fibers, the optical fields propagate separately within each fiber. As the single-mode fibers taper down, they can no longer confine the optical fields, leading to leakage and gradual merging of the light fields. Although the Gaussian beam is circularly symmetric, the input configuration of the photonic lantern does not exhibit this symmetry. Instead, it shows

symmetry, as evident in

Figure 5. The amplitude decreases from the center outward, following a Gaussian-like distribution of the fundamental mode. The amplitude and phase differences among the single-mode fiber bundles in the second layer are relatively minor, while those in the third layer are more significant, which can be observed from the transmission matrix in the

Supplementary Material File S1.

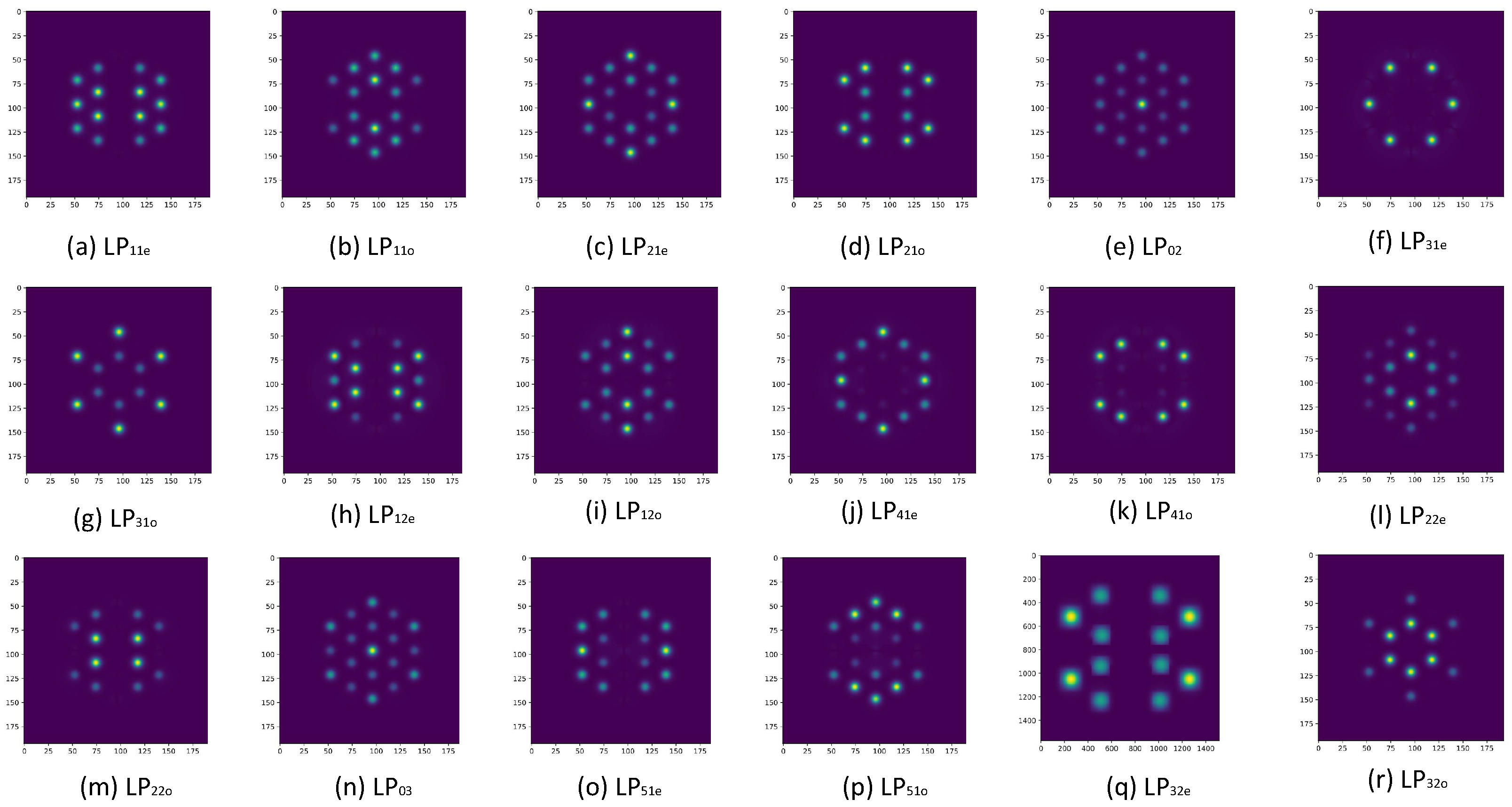

The amplitude at the single-mode input end of the photonic lantern, which can output the other 18 high-order LP modes, is illustrated in

Figure 6. One can observe that the light intensity at the single-mode input end shares some similarities with the distribution of the corresponding high-order mode fields. However, there are also notable differences in the distribution patterns. Furthermore, when comparing the same o and e degenerate states, the input end lacks 90° symmetry. This is due to the fact that the o and e degenerate states have

symmetry, while the photonic lantern structure has

symmetry.

These observations highlight the complex interplay between the input field distribution and the modal properties of the photonic lantern. Insertion loss (IL) is a critical parameter for characterizing the photonic lantern’s ability to output the desired modes. Before calculating the insertion loss for various output modes of the photonic lantern, it is first necessary to obtain its transmission matrix. Using this matrix, the required optical parameters (amplitudes and phases) at the input arms for generating the corresponding output modes can be deduced. The detailed steps are as follows: first, inject laser light individually into each single-mode (SM) input port. Next, perform mode decomposition at the multimode (MM) output port to measure the normalized mode decomposition coefficients

for each SM input. Using these coefficients, construct the transmission matrix

M of the photonic lantern, which is

Once the transmission matrix M is determined, apply the corresponding input vectors by injecting laser light with the appropriate intensity and phase differences into the SM input ports. For example, to generate the fundamental mode at the output, the input power for each SM fiber should be proportional to the square of the modulus of the corresponding element in the first row of the transmission matrix M, and the phase difference should match the phase of the corresponding element in the first row. Finally, measure the total output power at the MMF output port to validate the performance. , where is the power of the corresponding output mode, and is the power at each input arm. Since this work focuses on the design and simulation of a 19 × 1 photonic lantern, the calculated insertion losses represent ideal conditions. These losses only account for the leakage of the optical field during the mode evolution process. Other practical losses, such as Fresnel reflection losses introduced during the actual fabrication process, have not been considered in these calculations.

This photonic lantern demonstrates high-efficiency output of LP modes, as evidenced by the insertion efficiencies listed in

Table 2. Overall, all the modes exhibit insertion efficiencies exceeding 98%, with a trend indicating that higher-order modes (corresponding to lower effective refractive indices) tend to have slightly lower efficiencies. Specifically, the lowest insertion efficiency observed is 98.43% for the

mode, equating to an insertion loss of approximately 0.07 dB. In summary, the photonic lantern achieves excellent performance across various modes, ensuring minimal signal loss even for higher-order modes, despite the noted symmetry differences.

A phase vortex beam carrying orbital angular momentum can be generated by the linear superposition of the two degenerate states of the

mode (where

) with equal amplitudes and a phase difference of

. Therefore, the photonic lantern can similarly evolve efficiently and effectively into OAM modes. As illustrated in

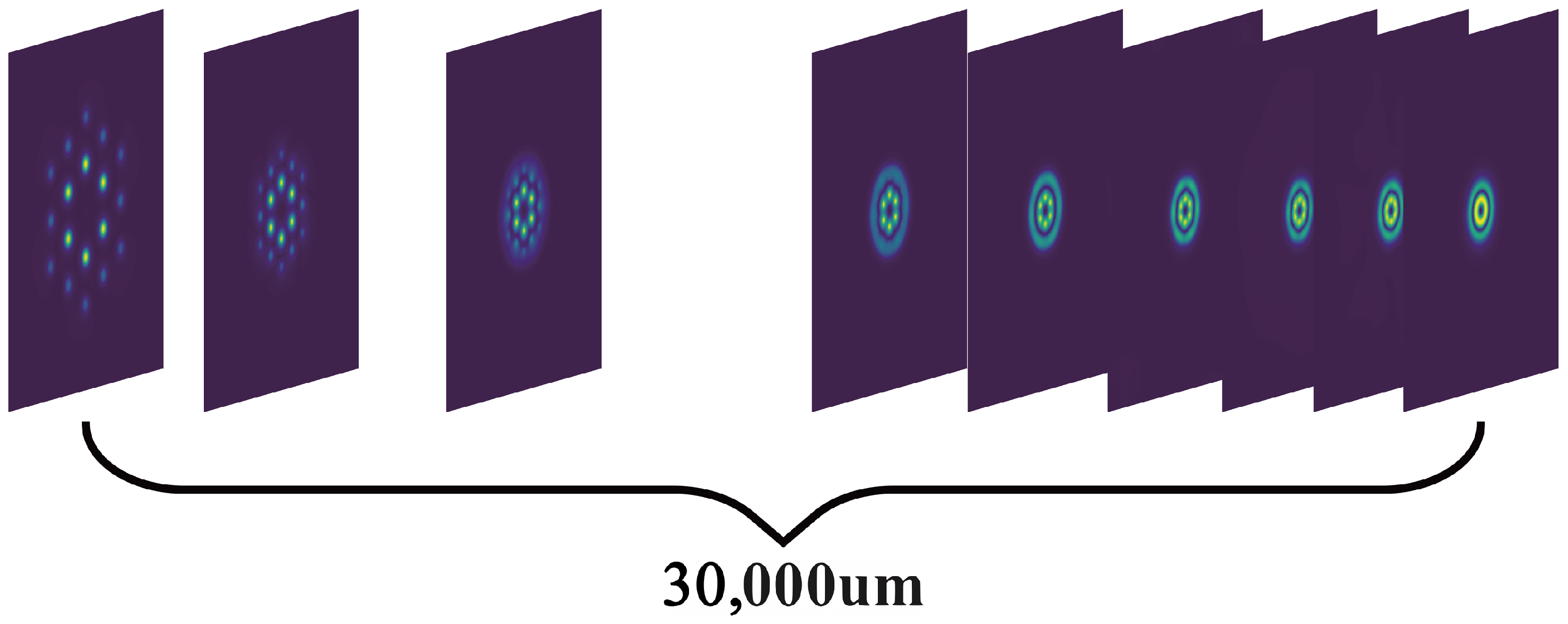

Figure 7, which uses the

mode as an example, the photonic lantern transitions from a single-mode input to a phase vortex beam within the taper region. Similar to the evolution of the fundamental mode, at the initial stage, the beams are tightly confined within the cores of the SMFs due to their large core-to-core distances, propagating independently. As the taper diameter decreases, the beams begin to leak out of the SMFs and gradually merge. By the output end, the beams have fully coalesced, forming a new core from the SMF bundle, with the jacket serving as the new cladding. The beams ultimately evolve into the

eigenmode of a new multi-mode fiber.

Given that OAM modes are hollow beams, the intensity at the center SMF (SMF-0) is nearly zero. Although the OAM beam’s intensity distribution is circularly symmetric, the intensity distribution at the single-mode input end lacks this symmetry. This is due to the fact that OAM modes carry orbital angular momentum, leading to asymmetric inputs among SMFs at the same layer. These properties can be understood through the transmission matrix of the OAM modes, as detailed in

Supplementary Materials File S2. Given that this multimode fiber supports 16 LP high-order modes (with

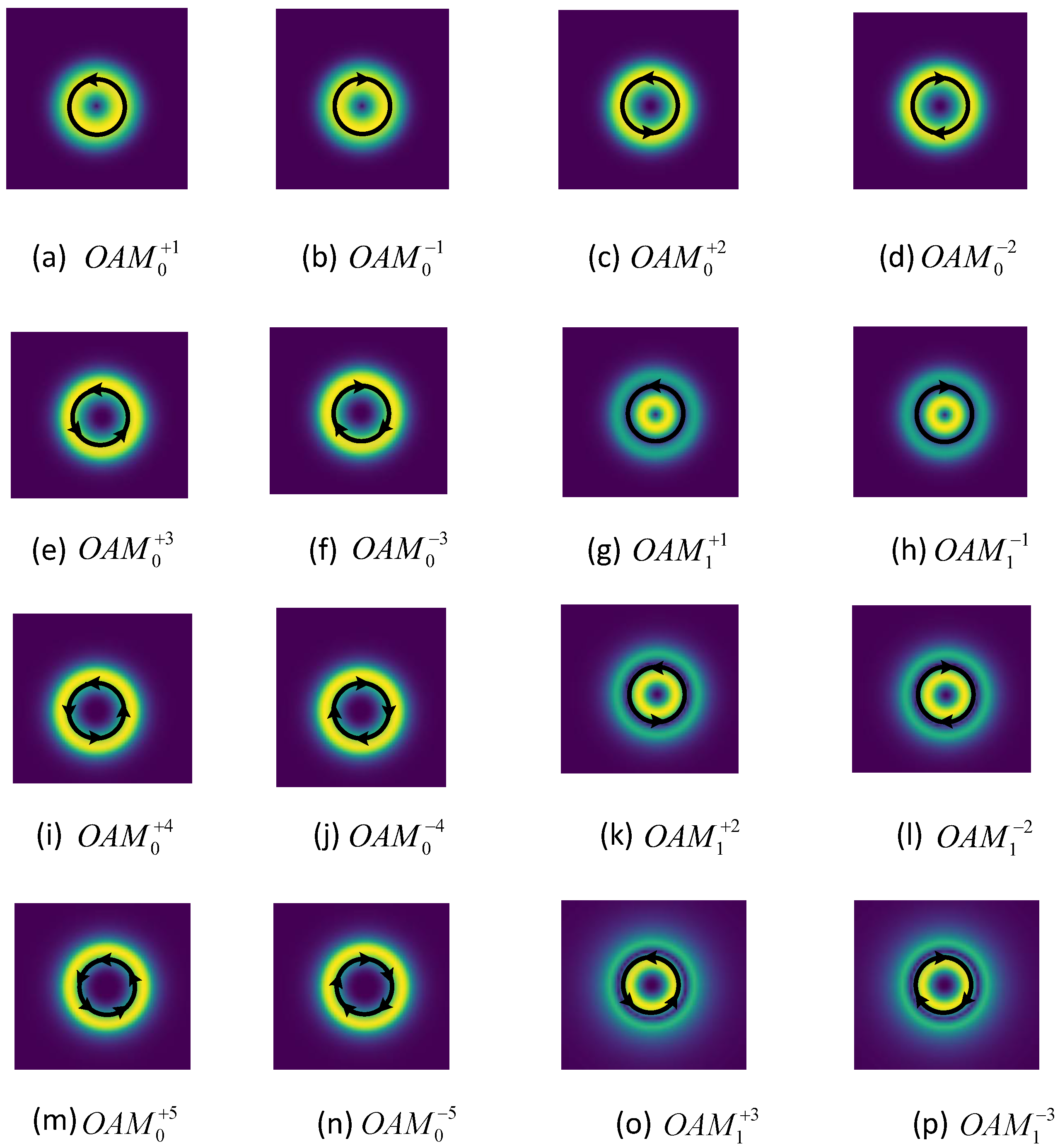

), it is capable of generating a total of 16 OAM modes.

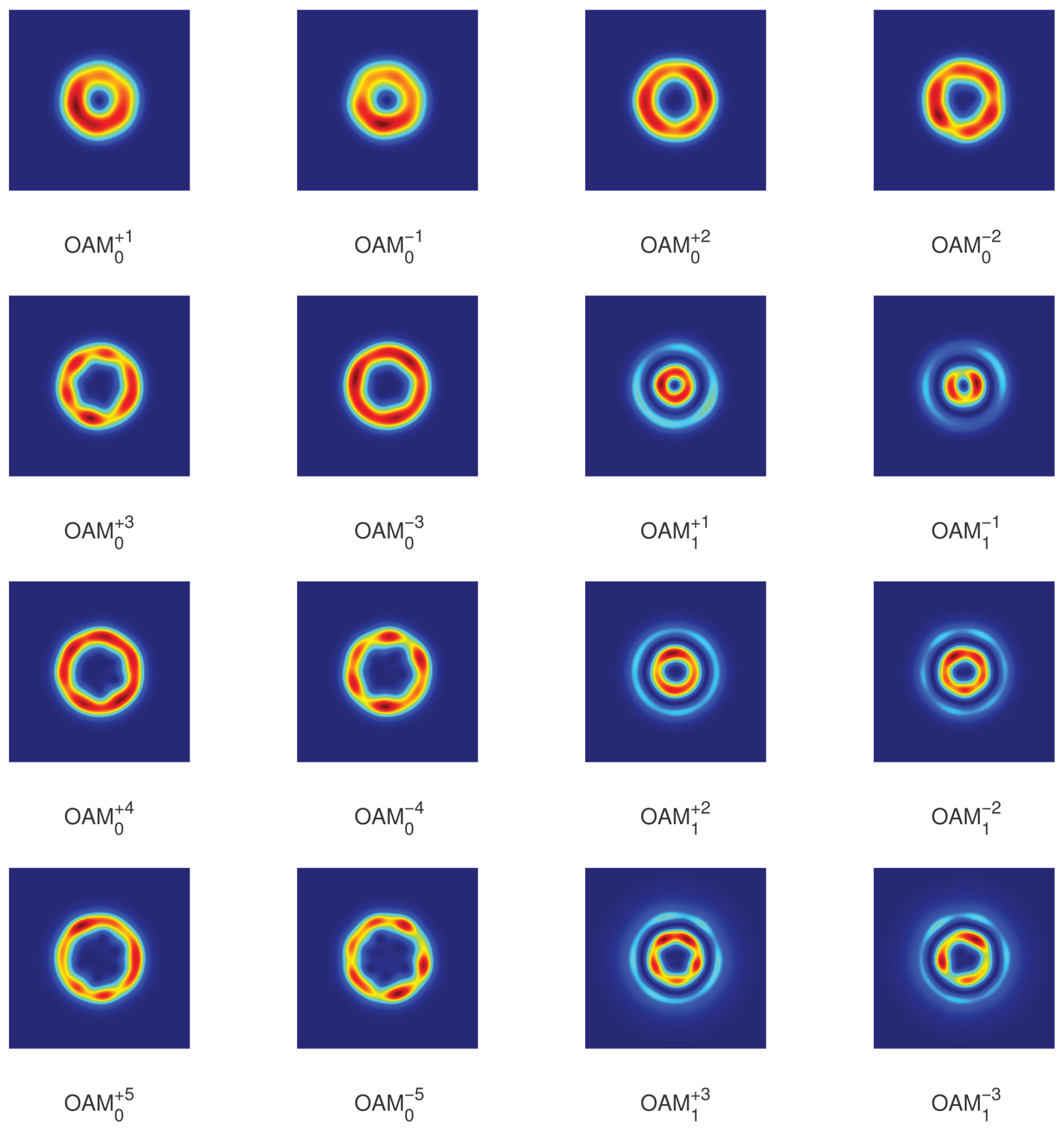

Figure 8 shows the 16 OAM modes that can be generated by the photonic lantern. The orientation of the arrows signifies the rotational direction of the beam (clockwise or counterclockwise), whereas the number of arrows represents the absolute value of the topological charge

l. As shown in the figure, the photonic lantern can output ultra-pure OAM modes. Given that the 19 × 1 photonic lantern efficiently outputs

modes (where

), and OAM modes are coherent superpositions of these

modes, the photonic lantern can also efficiently generate OAM modes. The transmission efficiency of these OAM modes falls between the efficiencies of the

and

modes (where

).

A good design is fundamental to achieving high-quality photonic lanterns, but precise fabrication is equally critical for their performance. Although the fabrication and control of the 19 × 1 photonic lantern are not the primary focus of this study, we can briefly introduce some of the most critical aspects of the design process.

Cleanliness: Cleanliness of both the optical fibers and the glass tubes is crucial throughout the entire process. Any dirt or liquid residue can cause intense burning during the fusion and tapering stages, significantly reducing the yield. Even tiny contaminants can become the primary source of loss in the final photonic lantern.

Bundling Techniques: Precise control over the inner diameter of the pre-tapered glass sleeve is essential to ensure that the fiber bundle is tightly and uniformly arranged. Custom molds may be required to achieve specific geometric arrangements, ensuring optimal packing density and alignment.

Fusion Tapering Parameters: The choice of flame size and tapering speed during the fusion process affects the collapse effect, which alters the size of air holes between single-mode fibers or determines whether the glass sleeve and fiber bundle shrink proportionally. Ensuring proportional shrinking is critical for the success of the splicing step. Therefore, selecting appropriate fusion tapering parameters is vital for achieving high-quality results.

3.2. Mode Adaptive Output Control Based on the 19 × 1 Photonic Lantern

Although, as previously mentioned, photonic lanterns can achieve efficient and high-purity mode outputs, this goal is challenging to attain in practical applications. The primary reasons are the following. Firstly, it is difficult to precisely control the amplitude and phase parameters of the input arms of the photonic lantern; secondly, minor environmental disturbances can alter the optical parameters of the input arms, leading to instability in the output modal field. Environmental disturbances, such as air flow and base vibrations causing fiber jitter, can affect the amplitudes and phases of the input arms of the PL. The fiber output is highly sensitive to these disturbances, impacting signal stability. Additionally, instabilities in optical components, such as laser seeds and splitters, also contribute to these perturbations. Our preliminary measurements in the laboratory indicate that phase jitter occurs at frequencies ranging from approximately 1 kHz to 10 kHz, while amplitude jitter occurs at frequencies ranging from about 1 Hz to 10 Hz. To simulate these disturbances, we modeled all jitter as a combination of a 10 kHz random phase jitter and a 10 Hz random amplitude jitter applied to the input arms of the photonic lantern. In simulations, we modeled amplitude perturbations with a variation of up to 20% and phase perturbations with variations up to

radians. The controller bandwidth was designed to be 10 MHz to effectively correct these environmental perturbations. Previously, we have implemented adaptive control systems for 3 × 1, 5 × 1, and 6 × 1 photonic lanterns [

22,

25,

26,

27,

28,

29]. On this basis, we will expand the control channels to 19 and introduce a high-speed mode decomposition system into the control system. In the previous work, we used PMs which are lithium niobate phase modulators with a 10 GHz bandwidth and control accuracy of 0.1 mrad, and a Pre-AMP with an output of the 10 W level and control accuracy in mW, whose precision has far exceeded the required control accuracy of

.

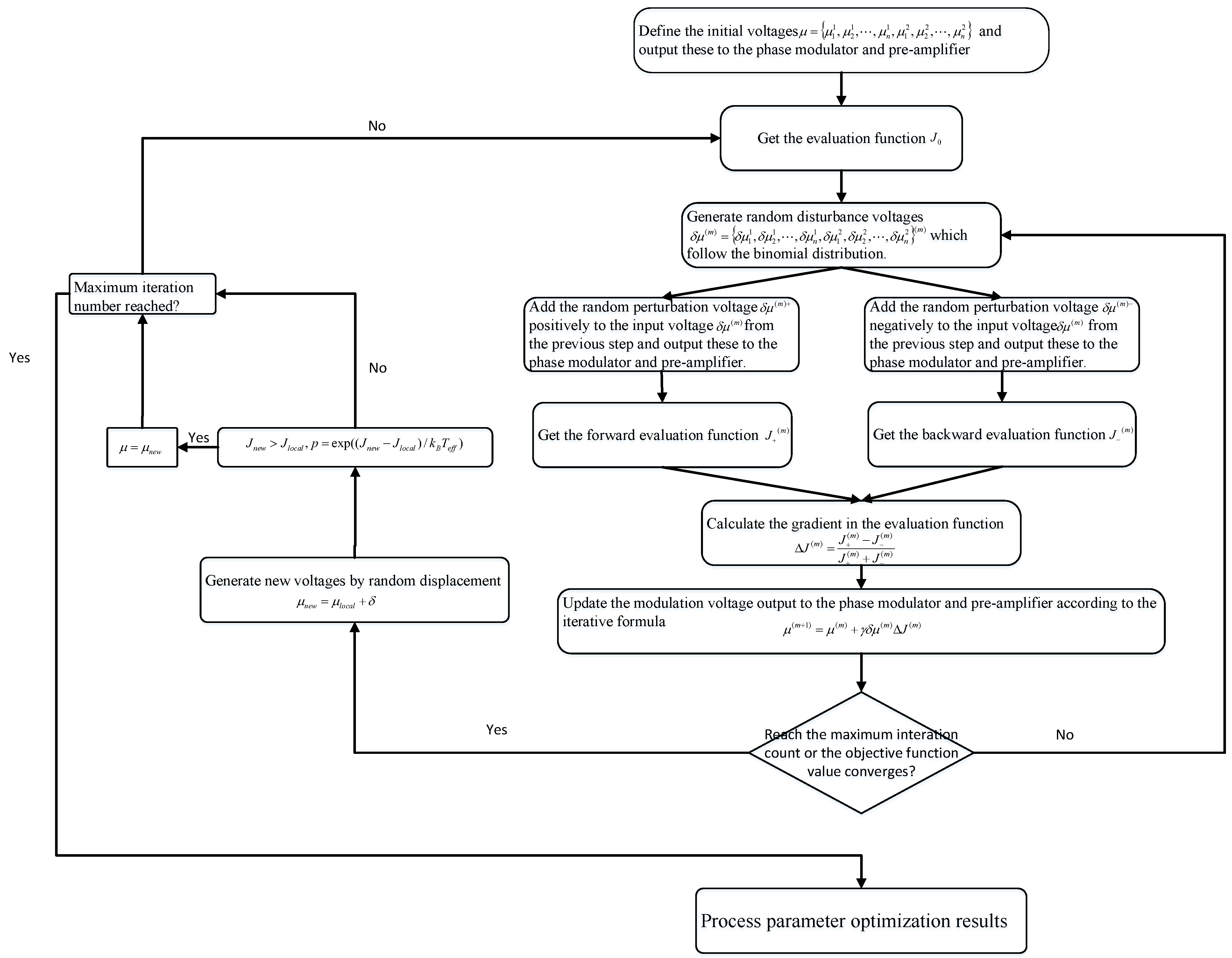

In this simulation, the transmission matrix of the PL needs to be determined in advance because we rely on it to obtain the mode information at the multimode output of the PL. However, in actual experiments, it is not necessary to know the transmission matrix beforehand. The SPGD algorithm can adaptively search for the optimal solution as long as there is a one-to-one correspondence between the input and output, without requiring explicit knowledge of their specific relationship. During operation, the mode decomposition device is continuously required because perturbations are not static. Real-time adaptive control is necessary based on the results of mode decomposition to maintain optimal performance.

These difficulties are particularly pronounced for the 19 × 1 photonic lantern due to its higher control complexity. Therefore, an adaptive control system is essential to achieve stable, high-purity mode outputs. Here, we employ the SPGD algorithm augmented with basin hopping for adaptive control, the processes of which are detailed in

Section 2.2. The phase and amplitude of the input arms are adjusted using the adaptive control algorithm, while polarization is controlled by a polarization controller to align the polarization direction consistently. Although the system appears linear in the optical field, directly inverting the PL transmission matrix combined with output mode measurements is challenging. Firstly, direct inversion of the PL transmission matrix requires high-speed and precise measurement of the amplitude and phase information at the input arms of the photonic lantern. Secondly, accurately obtaining the transmission matrix of a photonic lantern is extremely difficult due to manufacturing defects, which cause the actual transmission matrix to deviate from the designed one. Lastly, in high-power applications, we typically connect a fiber amplifier after the photonic lantern. Mode decomposition for control is performed after the amplifier, where the SPGD adaptive control algorithm can also account for mode competition within the fiber amplifier. Given these challenges, the SPGD combined with the basin hopping algorithm is a more suitable control strategy for managing the modes in photonic lanterns.

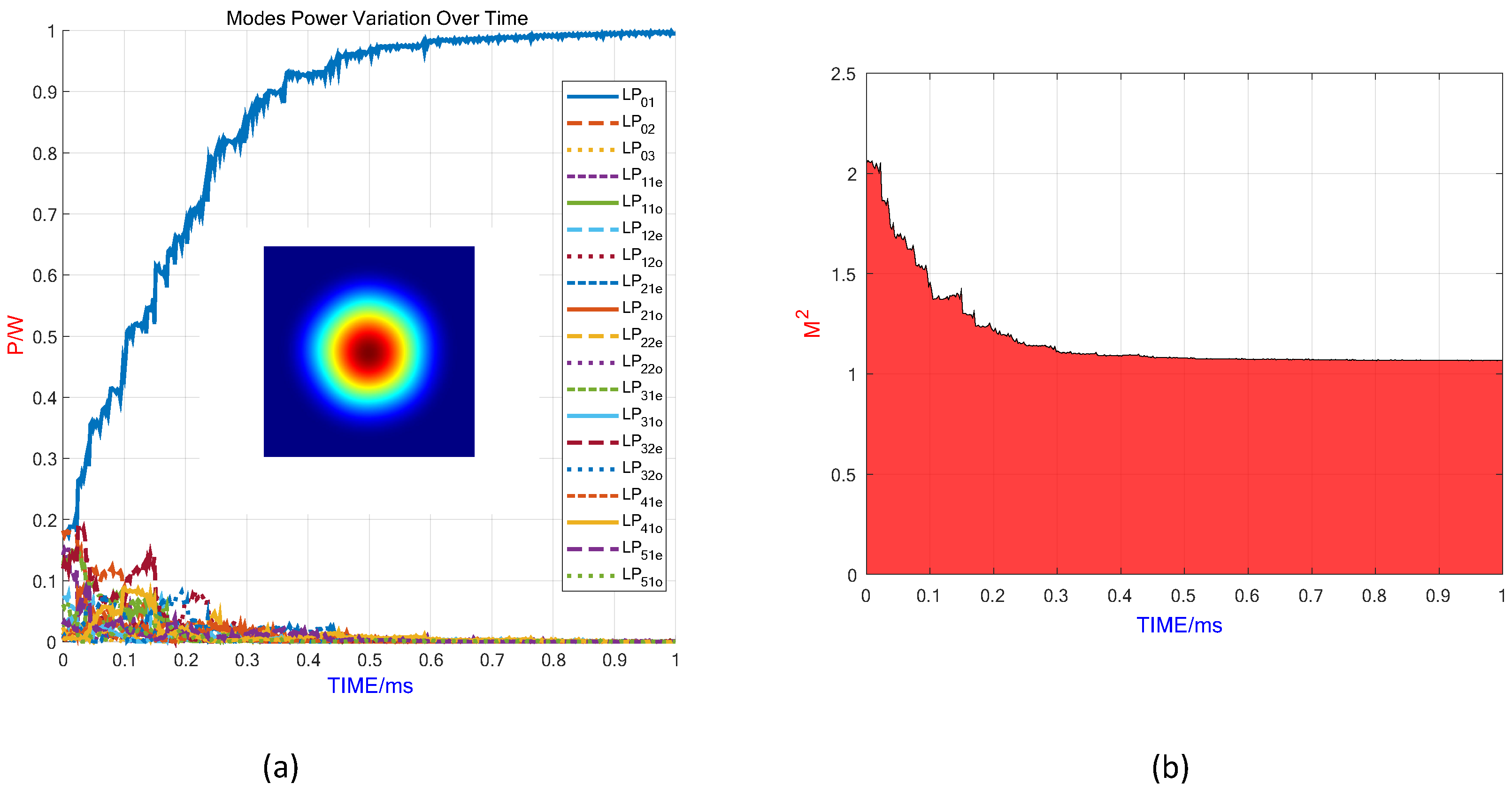

The fundamental mode of fiber lasers, owing to its superior beam quality and high energy concentration, has found widespread application in various fields, such as the industrial and medical sectors. Therefore, we first applied this control system to achieve stable, high-purity fundamental mode control through simulation.

Figure 9a illustrates the mode content evolution and the final output beam generated by the 19 × 1 photonic lantern during the adaptive control process, specifically targeting the fundamental mode output.

Figure 9b shows how the M

2 value varies with process time for the fundamental mode. These figures clearly demonstrate that the application of the active control algorithm results in a gradual increase in the fundamental mode content and a progressive decrease in the M

2 factor. Ultimately, the output fundamental mode content surpasses 99%, achieving an M

2 value better than 1.07, indicating excellent beam quality.

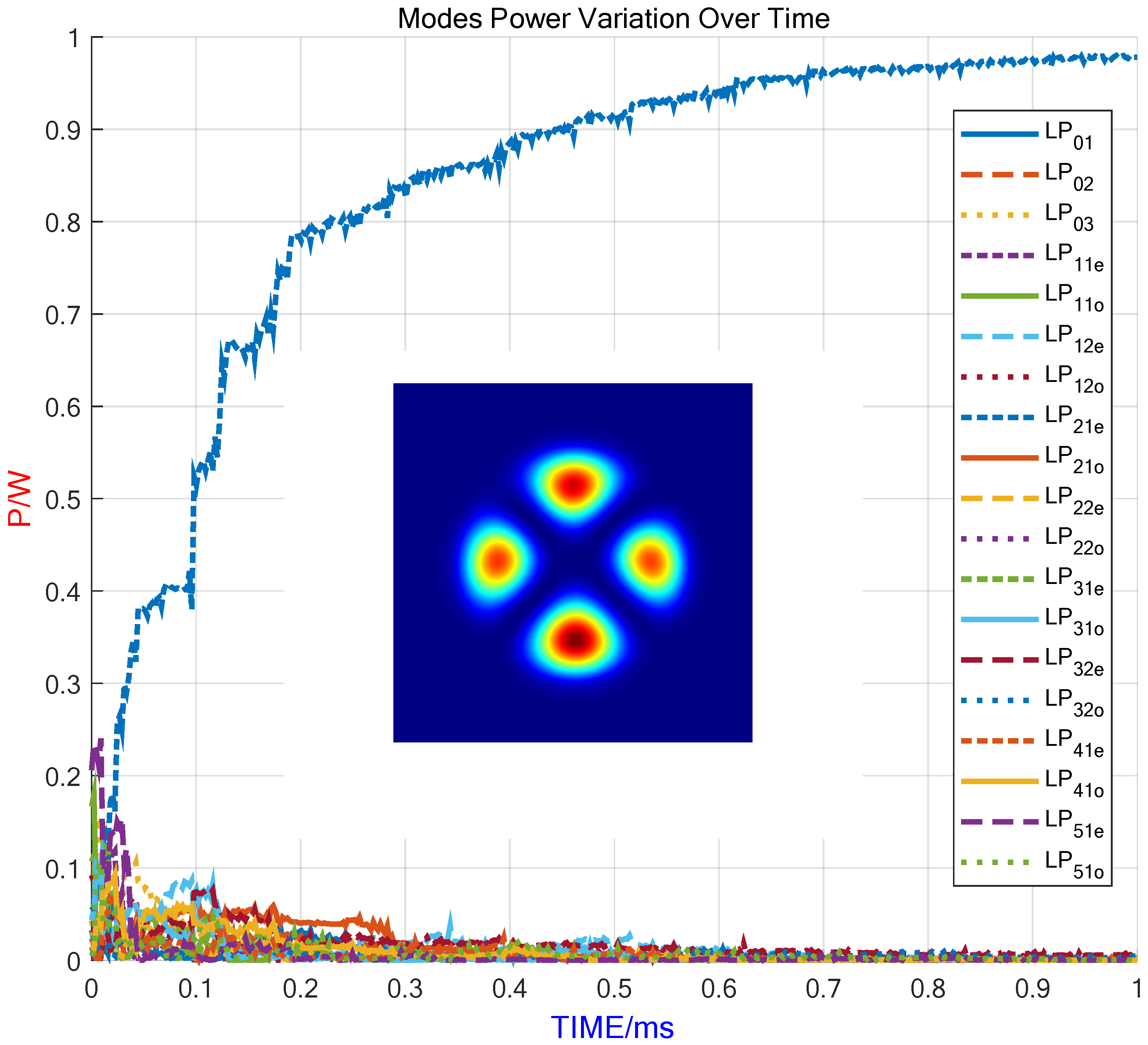

For high-order LP modes, we selected the LP

21e mode as an example to study the mode control process and its control effect.

Figure 10 illustrates the mode content evolution and the final output beam generated by the 19 × 1 photonic lantern during the adaptive control process, with the objective of achieving LP

21e mode output. At the outset, environmental disturbances cause the optical parameters of the photonic lantern’s input arms to deviate from their optimal settings. As a result, the output beam contains a substantial number of unwanted modes, leading to a highly disordered beam profile. This initial state underscores the necessity of adaptive control mechanisms to stabilize and optimize the output. Through the adaptive control algorithm, the system effectively adjusts the phase and amplitude of the input arms, thereby producing the desired high-purity mode stably. The final output achieves a purity of over 95% for the LP

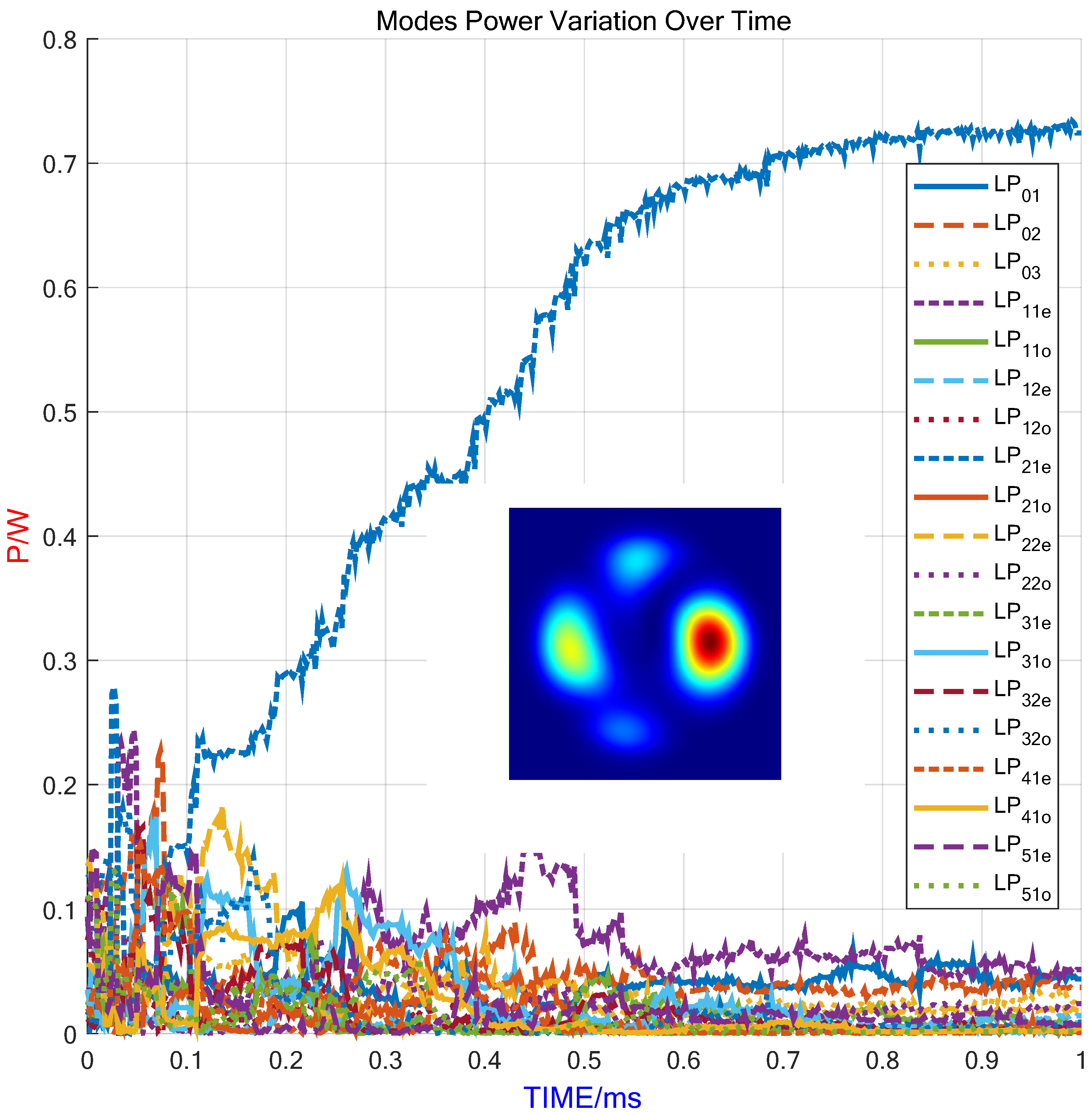

21e mode. This result demonstrates the effectiveness of the proposed adaptive control strategy in managing high-order mode transitions. By dynamically adjusting the phase and amplitude of the input arms, the system successfully stabilizes the desired mode, even in the presence of environmental disturbances. The key to effective control lies in the ability to quickly find the global optimum rather than getting trapped in a local optimum. Here, we present simulation results using only the SPGD algorithm, as shown in

Figure 11. The results indicate that the controlled output of the LP

21e mode content reached only 72%, which is significantly lower compared to the >95% mode content achieved in

Figure 10. This discrepancy is due to the SPGD algorithm converging to a local optimum rather than the global solution.

Figure 12 and

Figure 13 illustrate the generation of the additional 18 LP modes and 16 OAM modes by the 19 × 1 photonic lantern within the adaptive control system. As evident from the figures, the LP and OAM modes generated by the adaptive control system show a high degree of similarity to their corresponding standard mode field patterns. This close resemblance indicates that the generated modes possess a high level of purity.

Table 3 presents the final output mode purity of the target modes obtained from this simulation. From the table, it is evident that for all controlled modes, the final output mode purity is ≥90%. Despite the inherent randomness in each simulation run, the results consistently show that the output modes maintain a purity exceeding 90%. Additionally, it is observed that the purity of lower-order modes is generally higher compared to that of higher-order modes. This suggests that lower-order modes are more easily controlled and maintained at higher purities. The results highlight the system’s capability to produce stable and high-fidelity modes, even under varying environmental conditions. In summary, the adaptive control system effectively ensures the generation of high-purity LP and OAM modes, validating its practical utility in advanced optical applications.

In our previous simulations using a 19 × 1 photonic lantern with an adaptive control system, we achieved dynamic switching between 19 LP modes and 16 OAM modes, ensuring high-quality output with over 90% mode purity. However, despite these promising simulation results, the actual fabricated photonic lanterns still exhibit differences from their simulated counterparts. During the fused tapering process of PLs, factors such as flame stability, uniformity of flame temperature, and taper speed stability can lead to discrepancies between the actual fabricated PLs and simulated PLs. These inconsistencies primarily manifest in two ways: (1) transmission matrix mismatch; (2) increased insertion loss. The transmission matrix mismatch does not affect control performance, as the SPGD algorithm can adaptively search for the optimal solution as long as there is a one-to-one correspondence between the input and output, without requiring explicit knowledge of their specific relationship, while for increased insertion loss, it exacerbates the thermal effect, which leads to reduced mode coupling efficiency and changes in modal field shape. To mitigate the thermal effect, first, select PLs with low insertion loss, and second, place the PLs in a water-cooled environment to minimize the adverse effects caused by thermal effects. Through these improvements, we aim to achieve a robust and highly efficient experimental setup that closely matches the theoretical predictions, thereby validating the feasibility of our proposed approach.