Femtosecond-Laser Direct Writing of Double-Line and Tubular Depressed-Cladding Waveguides in Ultra-Low-Expansion Glass

Abstract

1. Introduction

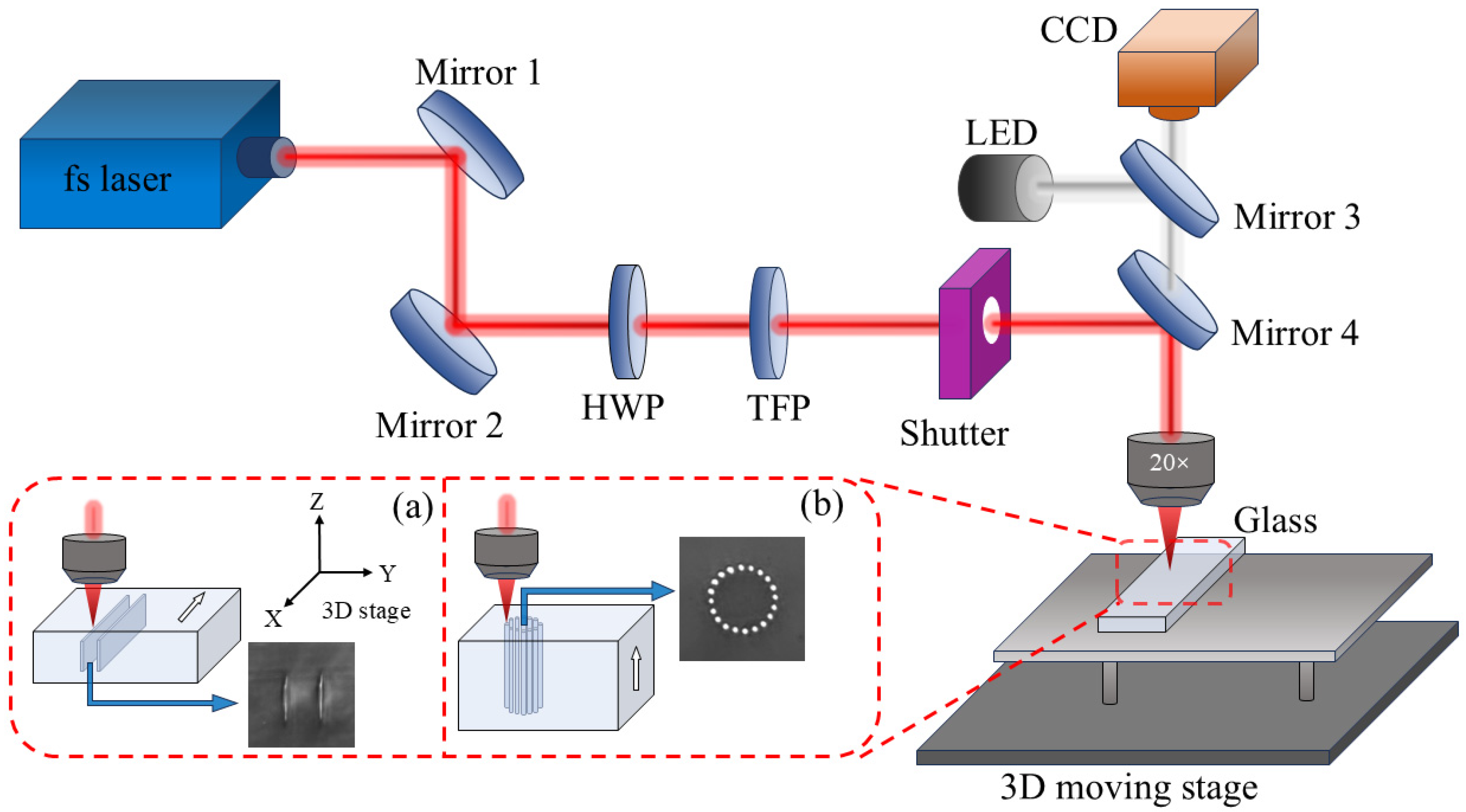

2. Materials and Methods

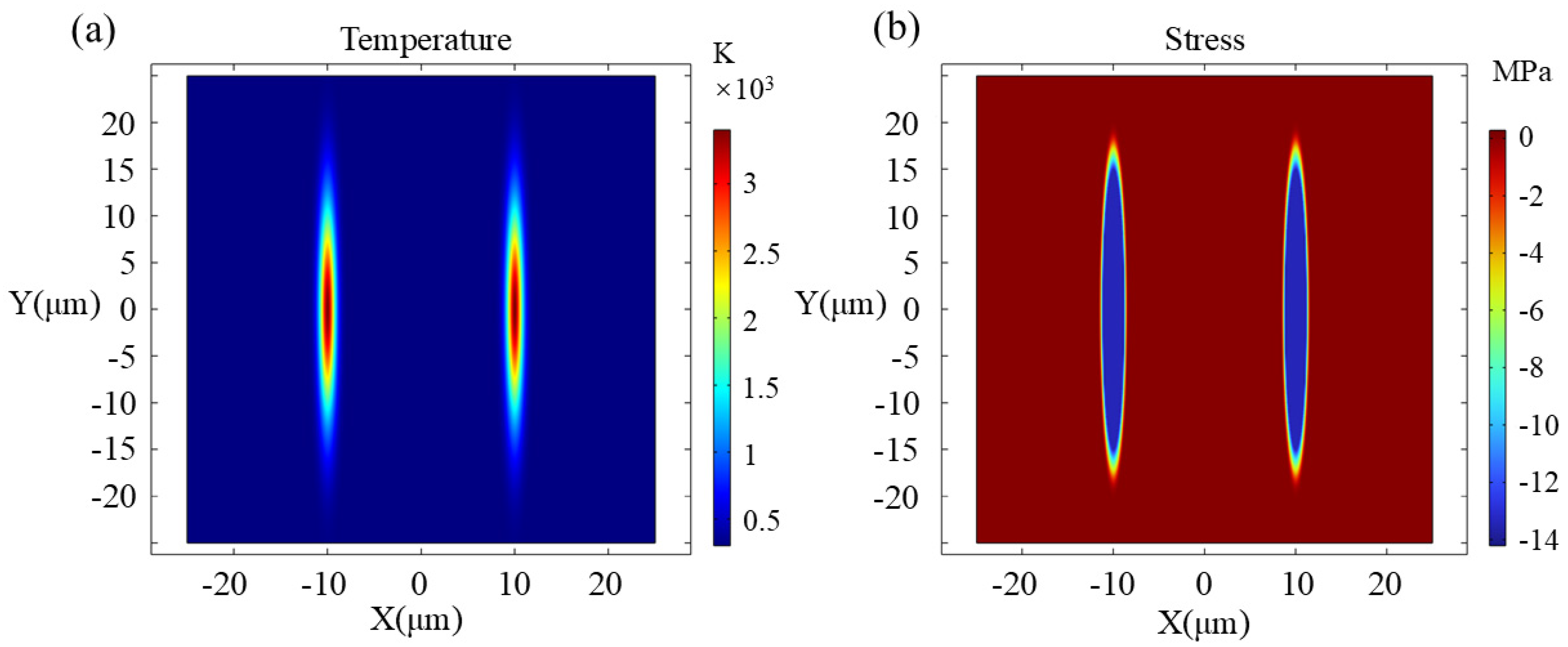

2.1. Simulation

2.2. Experimental Setup

3. Results and Discussion

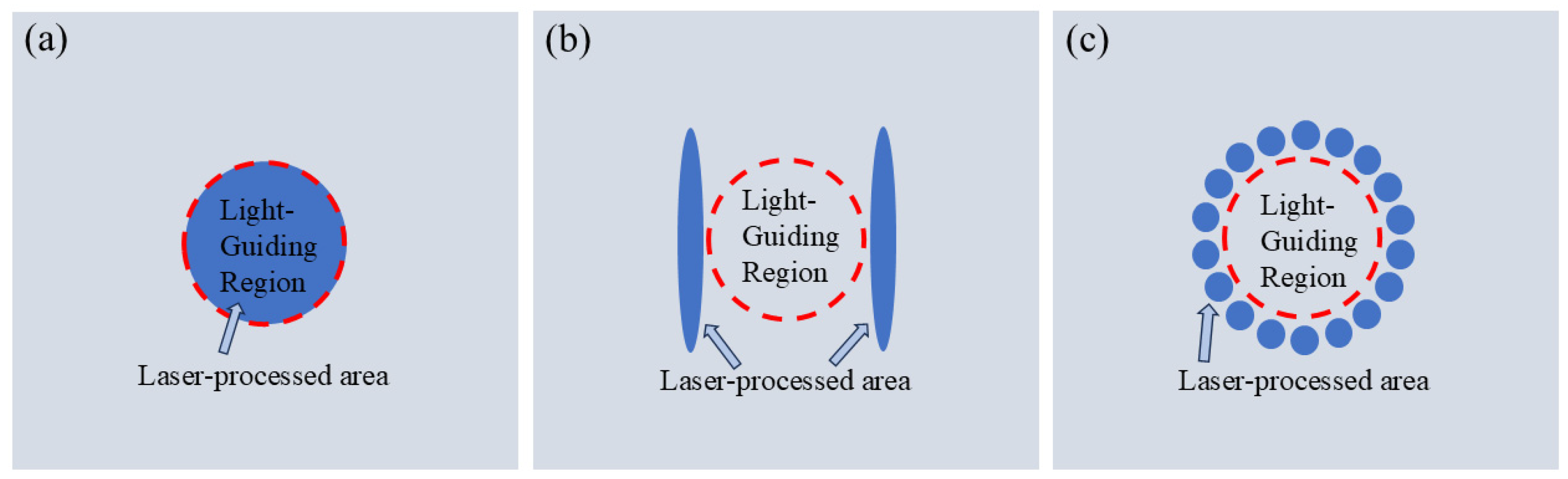

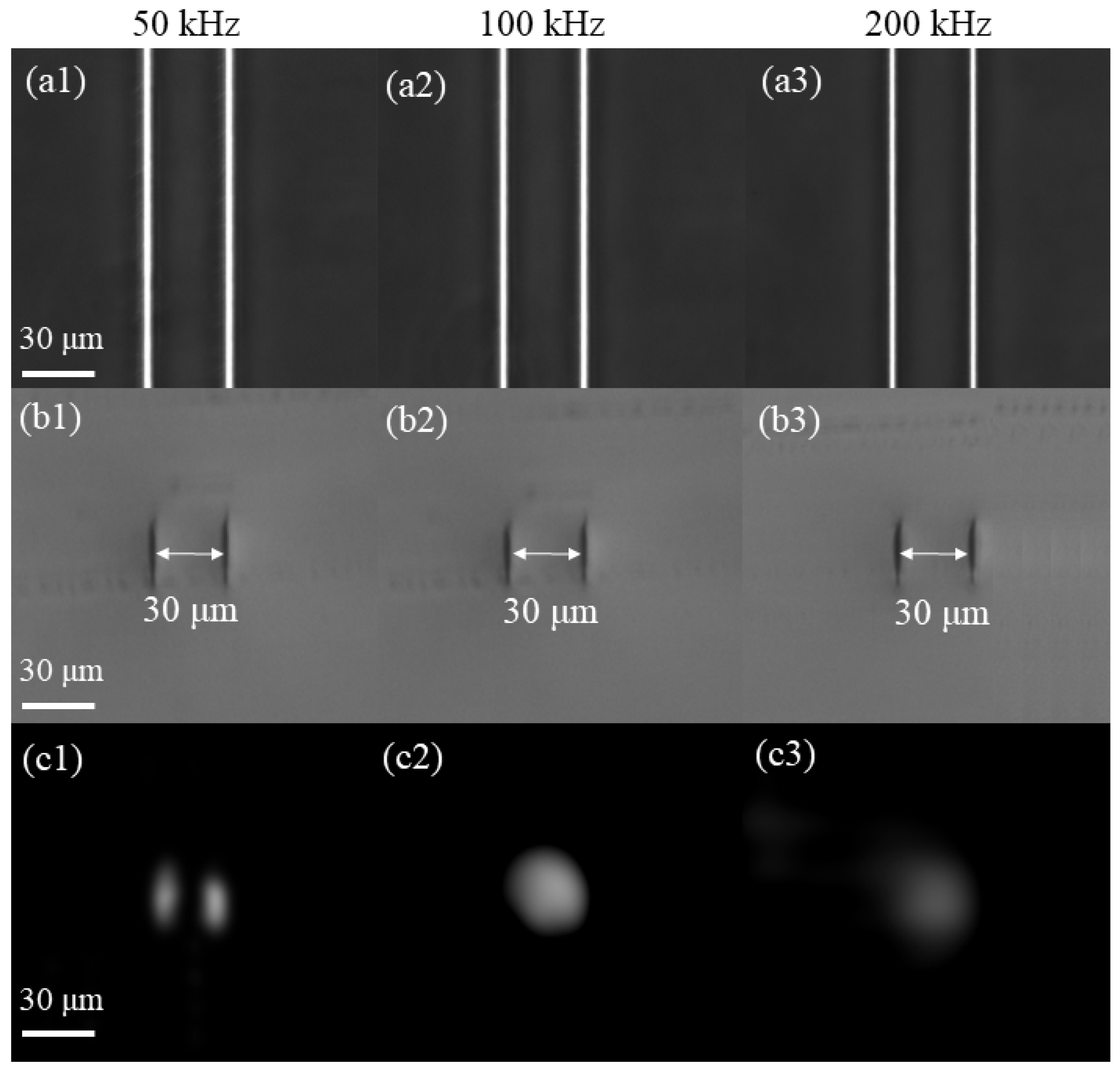

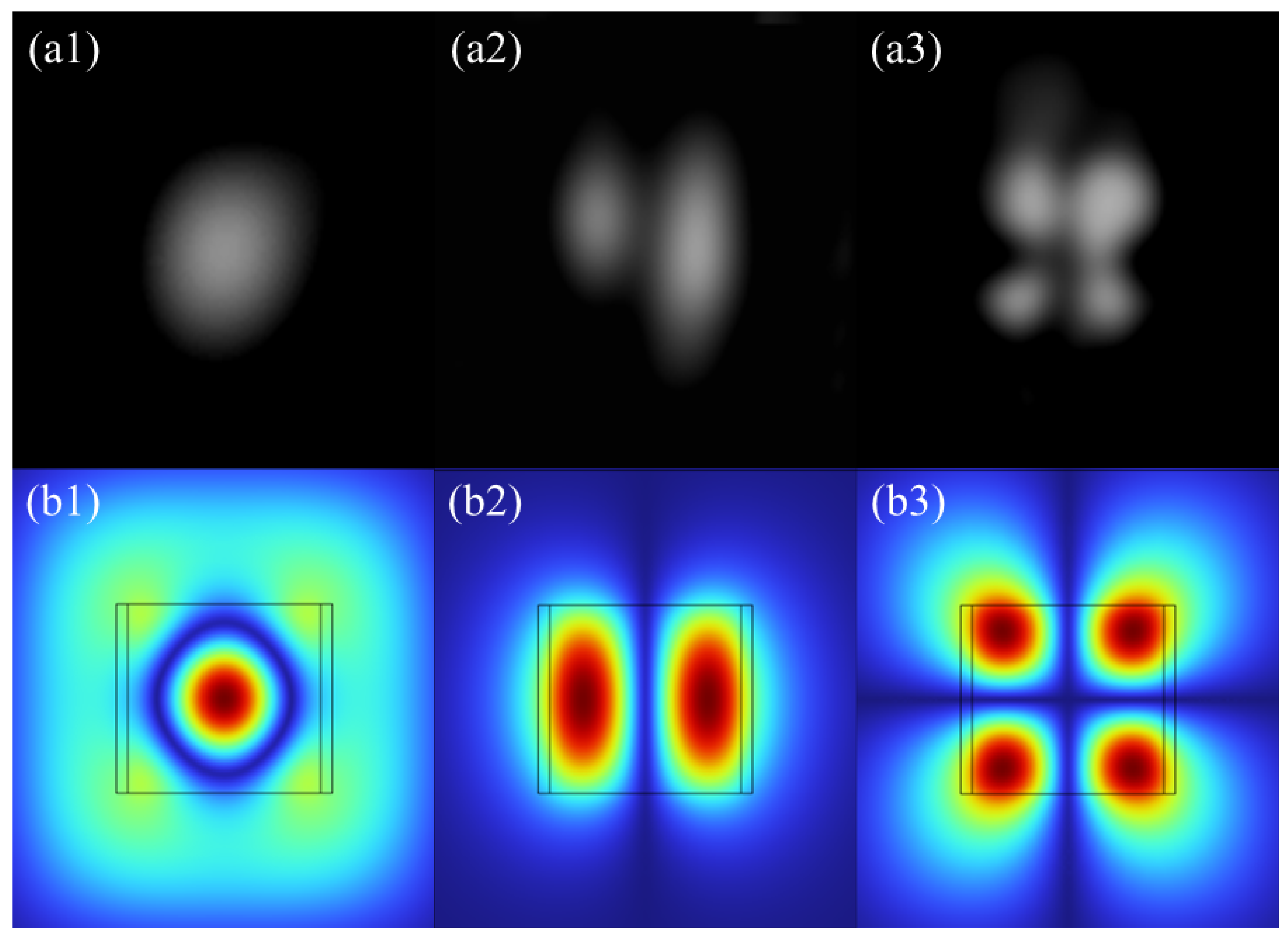

3.1. Double-Line Waveguide

3.2. Depressed-Cladding Tubular Waveguide

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, B.; Zhang, B.; Liu, W.; Lu, Q.; Wang, L.; Chen, F. Recoverable and rewritable waveguide beam splitters fabricated by tailored femtosecond laser writing of lithium tantalate crystal. Opt. Laser Technol. 2022, 145, 107500. [Google Scholar] [CrossRef]

- Selvaraja, S.K.; Sethi, P. Review on optical waveguides. Emerg. Waveguide Technol. 2018, 95, 458. [Google Scholar]

- Lutpi, H.A.; Mohamad, H.; Abdullah, T.K.; Ismail, H. Effect of isothermal treatment on the structural, microstructure, and physio-mechanical properties of Li2O-Al2O3-SiO2 glass–ceramic. J. Aust. Ceram. Soc. 2022, 58, 9–20. [Google Scholar] [CrossRef]

- Xiong, S.; Wang, R.; Tao, H. Ultrafast laser micromachining the ultra-low expansion glass-ceramic: Optimization of processing parameters and physical mechanism. J. Eur. Ceram. Soc. 2021, 41, 5990–5999. [Google Scholar] [CrossRef]

- Chunxia, Z.; Xinzhao, J.; Wei, Z.; Jie, L.; Shigang, F.; Can, H. Development Status and Application of Ultra-Low Expansion Glass-Ceramics. J. Synth. Cryst. 2023, 52, 2135. [Google Scholar]

- Hartmann, P.; Jedamzik, R.; Carré, A.; Krieg, J.; Westerhoff, T. Glass ceramic ZERODUR®: Even closer to zero thermal expansion: A review, part 1. J. Astron. Telesc. Instrum. Syst. 2021, 7, 020901. [Google Scholar]

- Dymshits, O.; Shepilov, M.; Zhilin, A. Transparent glass-ceramics for optical applications. MRS Bull. 2017, 42, 200–205. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Dong, L.; Zhang, J.; Li, C.; Yu, G.; Chen, J. The application and development of ultra low expansion glass-ceramic in aerospace area. In Proceedings of the AOPC 2017: Space Optics and Earth Imaging and Space Navigation, Beijing, China, 24 October 2017; pp. 87–92. [Google Scholar]

- Zhang, Y.; Wu, J.; Wang, L.; Chen, F. Femtosecond laser direct writing of Nd: YAG waveguide with Type I modification: Positive refractive index change in track. Opt. Mater. 2021, 113, 110844. [Google Scholar] [CrossRef]

- Burghoff, J.; Nolte, S.; Tünnermann, A. Origins of waveguiding in femtosecond laser-structured LiNbO3. Appl. Phys. A 2007, 89, 127–132. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, S.; Chen, F. Femtosecond laser direct writing of flexibly configured waveguide geometries in optical crystals: Fabrication and application. Opto-Electron. Adv. 2020, 3, 190042-1–190042-12. [Google Scholar] [CrossRef]

- Chen, F.; de Aldana, J.R.V. Direct femtosecond laser writing of optical waveguides in dielectrics. In Laser Micro-Nano-Manufacturing and 3D Microprinting; Springer: Berlin/Heidelberg, Germany, 2020; pp. 185–210. [Google Scholar]

- Li, L.; Kong, W.; Chen, F. Femtosecond laser-inscribed optical waveguides in dielectric crystals: A concise review and recent advances. Adv. Photonics 2022, 4, 024002. [Google Scholar] [CrossRef]

- Lihachev, A.I.; Nashchekin, A.; Sokolov, R.V.; Konnikov, S.G. Determination of the thicknesses and visualization of ion-exchange waveguides in glasses by scanning electron microscopy. Tech. Phys. 2019, 64, 418–421. [Google Scholar] [CrossRef]

- Qi, Y.; Li, Y. Integrated lithium niobate photonics. Nanophotonics 2020, 9, 1287–1320. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Y.; Peng, Y.; Lv, R.-q.; Zhao, Q. Review of femtosecond laser direct writing fiber-optic structures based on refractive index modification and their applications. Opt. Laser Technol. 2022, 146, 107473. [Google Scholar] [CrossRef]

- Wang, S.; Yang, J.; Deng, G.; Zhou, S. Femtosecond laser direct writing of flexible electronic devices: A mini review. Materials 2024, 17, 557. [Google Scholar] [CrossRef]

- Zhang, X.-L.; Yu, F.; Chen, Z.-G.; Tian, Z.-N.; Chen, Q.-D.; Sun, H.-B.; Ma, G. Non-Abelian braiding on photonic chips. Nat. Photonics 2022, 16, 390–395. [Google Scholar] [CrossRef]

- Wang, J.; Cai, C.; Cui, F.; Yang, M.; Liang, Y.; Wang, J. Tailoring light on three-dimensional photonic chips: A platform for versatile OAM mode optical interconnects. Adv. Photonics 2023, 5, 036004. [Google Scholar] [CrossRef]

- Tang, H.; Lin, X.-F.; Feng, Z.; Chen, J.-Y.; Gao, J.; Sun, K.; Wang, C.-Y.; Lai, P.-C.; Xu, X.-Y.; Wang, Y. Experimental two-dimensional quantum walk on a photonic chip. Sci. Adv. 2018, 4, eaat3174. [Google Scholar] [CrossRef]

- Ehrhardt, M.; Keil, R.; Maczewsky, L.J.; Dittel, C.; Heinrich, M.; Szameit, A. Exploring complex graphs using three-dimensional quantum walks of correlated photons. Sci. Adv. 2021, 7, eabc5266. [Google Scholar] [CrossRef]

- Liang, Y.; Cai, C.; Wang, K.; Lian, X.; Wang, J.; Liu, J.; Shen, L.; Wang, J. Low-insertion-loss femtosecond laser-inscribed three-dimensional high-density mux/demux devices. Adv. Photonics Nexus 2023, 2, 036002. [Google Scholar] [CrossRef]

- Thomson, R.; Harris, R.; Birks, T.; Brown, G.; Allington-Smith, J.; Bland-Hawthorn, J. Ultrafast laser inscription of a 121-waveguide fan-out for astrophotonics. Opt. Lett. 2012, 37, 2331–2333. [Google Scholar] [CrossRef]

- Gross, S.; Riesen, N.; Love, J.D.; Withford, M.J. Three-dimensional ultra-broadband integrated tapered mode multiplexers. Laser Photonics Rev. 2014, 8, L81–L85. [Google Scholar] [CrossRef]

- Li, Z.-Z.; Ouyang, Y.; Li, Z.-T.; Tian, Z.-N.; Zhang, X.-L.; Chen, Q.-D.; Sun, H.-B. Three-dimensional on-chip mode converter. Opt. Lett. 2023, 48, 1140–1143. [Google Scholar] [CrossRef] [PubMed]

- Waltermann, C.; Doering, A.; Köhring, M.; Angelmahr, M.; Schade, W. Cladding waveguide gratings in standard single-mode fiber for 3D shape sensing. Opt. Lett. 2015, 40, 3109–3112. [Google Scholar] [CrossRef] [PubMed]

- He, J.; He, J.; Xu, X.; Du, B.; Xu, B.; Liao, C.; Bai, Z.; Wang, Y. Single-mode helical Bragg grating waveguide created in a multimode coreless fiber by femtosecond laser direct writing. Photonics Res. 2021, 9, 2052–2059. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, J.; Wang, X.-x.; Peng, Y.; Hu, X.-g. Femtosecond laser-inscribed fiber-optic sensor for seawater salinity and temperature measurements. Sens. Actuators B Chem. 2022, 353, 131134. [Google Scholar] [CrossRef]

- Khalil, A.A.; Lalanne, P.; Bérubé, J.-P.; Petit, Y.; Vallée, R.; Canioni, L. Femtosecond laser writing of near-surface waveguides for refractive-index sensing. Opt. Express 2019, 27, 31130–31143. [Google Scholar] [CrossRef]

- Singhal, A.; Dalmiya, A.; Lynch, P.T.; Paprotny, I. 2-photon polymerized IP-DIP 3D photonic crystals for Mid IR spectroscopic applications. IEEE Photonics Technol. Lett. 2023, 35, 410–413. [Google Scholar] [CrossRef]

- Stinson, V.P.; Park, S.; McLamb, M.; Boreman, G.; Hofmann, T. Photonic crystals with a defect fabricated by two-photon polymerization for the infrared spectral range. Optics 2021, 2, 284–291. [Google Scholar] [CrossRef]

- Ostendorf, A.; Chichkov, B.N. Two-photon polymerization: A new approach to micromachining. Photonics Spectra 2006, 40, 72. [Google Scholar]

- Zhang, Y.; Zhang, G.; Bai, J.; Chen, C.; Stoian, R.; Cheng, G. Double line and tubular depressed cladding waveguides written by femtosecond laser irradiation in PTR glass. Opt. Mater. Express 2017, 7, 2626–2635. [Google Scholar] [CrossRef]

- Lipatiev, A.; Fedotov, S.; Lotarev, S.; Naumov, A.; Lipateva, T.; Savinkov, V.; Shakhgildyan, G.; Sigaev, V. Direct laser writing of depressed-cladding waveguides in extremely low expansion lithium aluminosilicate glass-ceramics. Opt. Laser Technol. 2021, 138, 106846. [Google Scholar] [CrossRef]

- Kongsuwan, P.; Wang, H.; Vukelic, S.; Yao, Y.L. Characterization of morphology and mechanical properties of glass interior irradiated by femtosecond laser. J. Manuf. Sci. Eng. 2010, 132, 041009. [Google Scholar] [CrossRef]

- Müller, G.; Pannhorst, W.; Schiffner, U. The Scientific Basis. In Low Thermal Expansion Glass Ceramics; Bach, H., Ed.; Springer: Berlin/Heidelberg, Germany, 1995; pp. 13–49. [Google Scholar]

- Glezer, E.N.; Mazur, E. Ultrafast-laser driven micro-explosions in transparent materials. Appl. Phys. Lett. 1997, 71, 882–884. [Google Scholar] [CrossRef]

- Juodkazis, S.; Nishimura, K.; Tanaka, S.; Misawa, H.; Gamaly, E.G.; Luther-Davies, B.; Hallo, L.; Nicolai, P.; Tikhonchuk, V.T. Laser-Induced Microexplosion Confined in the Bulk of a Sapphire Crystal: Evidence of Multimegabar Pressures. Phys. Rev. Lett. 2006, 96, 166101. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Juodkazis, S.; Nishimura, K.; Misawa, H.; Luther-Davies, B.; Hallo, L.; Nicolai, P.; Tikhonchuk, V.T. Laser-matter interaction in the bulk of a transparent solid: Confined microexplosion and void formation. Phys. Rev. B—Condens. Matter Mater. Phys. 2006, 73, 214101. [Google Scholar] [CrossRef]

- Juodkazis, S.; Misawa, H.; Hashimoto, T.; Gamaly, E.G.; Luther-Davies, B. Laser-induced microexplosion confined in a bulk of silica: Formation of nanovoids. Appl. Phys. Lett. 2006, 88, 201909. [Google Scholar] [CrossRef]

- Mansour, I.; Caccavale, F. An improved procedure to calculate the refractive index profile from the measured near-field intensity. J. Light. Technol. 2002, 14, 423–428. [Google Scholar] [CrossRef]

- Morikawa, J.; Orie, A.; Hashimoto, T.; Juodkazis, S. Thermal and optical properties of the femtosecond-laser-structured and stress-induced birefringent regions in sapphire. Opt. Express 2010, 18, 8300–8310. [Google Scholar] [CrossRef]

- Hu, H.; Gan, Q.; Zhan, Q. Generation of a nondiffracting superchiral optical needle for circular dichroism imaging of sparse subdiffraction objects. Phys. Rev. Lett. 2019, 122, 223901. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, X.; He, B.; Chen, H.; Ren, Z.; Bai, J. Size-variable dark-hollow beam generation using cross-phase modulation. Opt. Laser Technol. 2019, 119, 105582. [Google Scholar] [CrossRef]

- Lv, J.; Wang, K.; Cheng, G. Filament damage and channel waveguide fabrication in Yb-doped phosphate glass. Mod. Phys. Lett. B 2020, 34, 2050325. [Google Scholar] [CrossRef]

- Zhang, G.; Cheng, G.; Bhuyan, M.K.; D’amico, C.; Wang, Y.; Stoian, R. Ultrashort Bessel beam photoinscription of Bragg grating waveguides and their application as temperature sensors. Photonics Res. 2019, 7, 806–814. [Google Scholar] [CrossRef]

- Ai, S.; Yang, Q.; Jia, Y.; Ren, Y.; Lv, J.; Liu, H. Ultrafast laser inscription of 2D confinement MMI-based beam splitters with tunable splitting ratio in Nd: YAG crystal. Opt. Laser Technol. 2024, 176, 111013. [Google Scholar] [CrossRef]

- Yu, M.; Ai, S.; Chen, Y.; Chen, F.; Liu, H. Compact 1 × 3 waveguide beam splitters with variable splitting ratios in LiNbO3 crystal fabricated by femtosecond laser direct writing. Chin. Opt. Lett. 2024, 22, 090008. [Google Scholar]

| Property | Parameters |

|---|---|

| Thermal conductivity @20 °C [W/(m · K)] | 1.483 |

| Specific heat @20 °C [J/(g · K)] | 0.75 |

| Young’s modulus @20 °C [GPa] | 90 |

| Poisson’s ratio | 0.245 |

| Density [g/cm3] | 2.53 |

| Refractive index | 1.543 |

| Thermal diffusivity @20 °C [10−6 m2/s] | 0.786 |

| Thermal expansion coefficient α0/50 °C [10−8/K] | 0 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Guo, S.; Cheng, G.; Wang, F.; Wang, X.; Zhang, Y. Femtosecond-Laser Direct Writing of Double-Line and Tubular Depressed-Cladding Waveguides in Ultra-Low-Expansion Glass. Photonics 2025, 12, 797. https://doi.org/10.3390/photonics12080797

Wu Y, Guo S, Cheng G, Wang F, Wang X, Zhang Y. Femtosecond-Laser Direct Writing of Double-Line and Tubular Depressed-Cladding Waveguides in Ultra-Low-Expansion Glass. Photonics. 2025; 12(8):797. https://doi.org/10.3390/photonics12080797

Chicago/Turabian StyleWu, Yuhao, Sixuan Guo, Guanghua Cheng, Feiran Wang, Xu Wang, and Yunjie Zhang. 2025. "Femtosecond-Laser Direct Writing of Double-Line and Tubular Depressed-Cladding Waveguides in Ultra-Low-Expansion Glass" Photonics 12, no. 8: 797. https://doi.org/10.3390/photonics12080797

APA StyleWu, Y., Guo, S., Cheng, G., Wang, F., Wang, X., & Zhang, Y. (2025). Femtosecond-Laser Direct Writing of Double-Line and Tubular Depressed-Cladding Waveguides in Ultra-Low-Expansion Glass. Photonics, 12(8), 797. https://doi.org/10.3390/photonics12080797