Real-Time Depth Monitoring of Air-Film Cooling Holes in Turbine Blades via Coherent Imaging During Femtosecond Laser Machining

Abstract

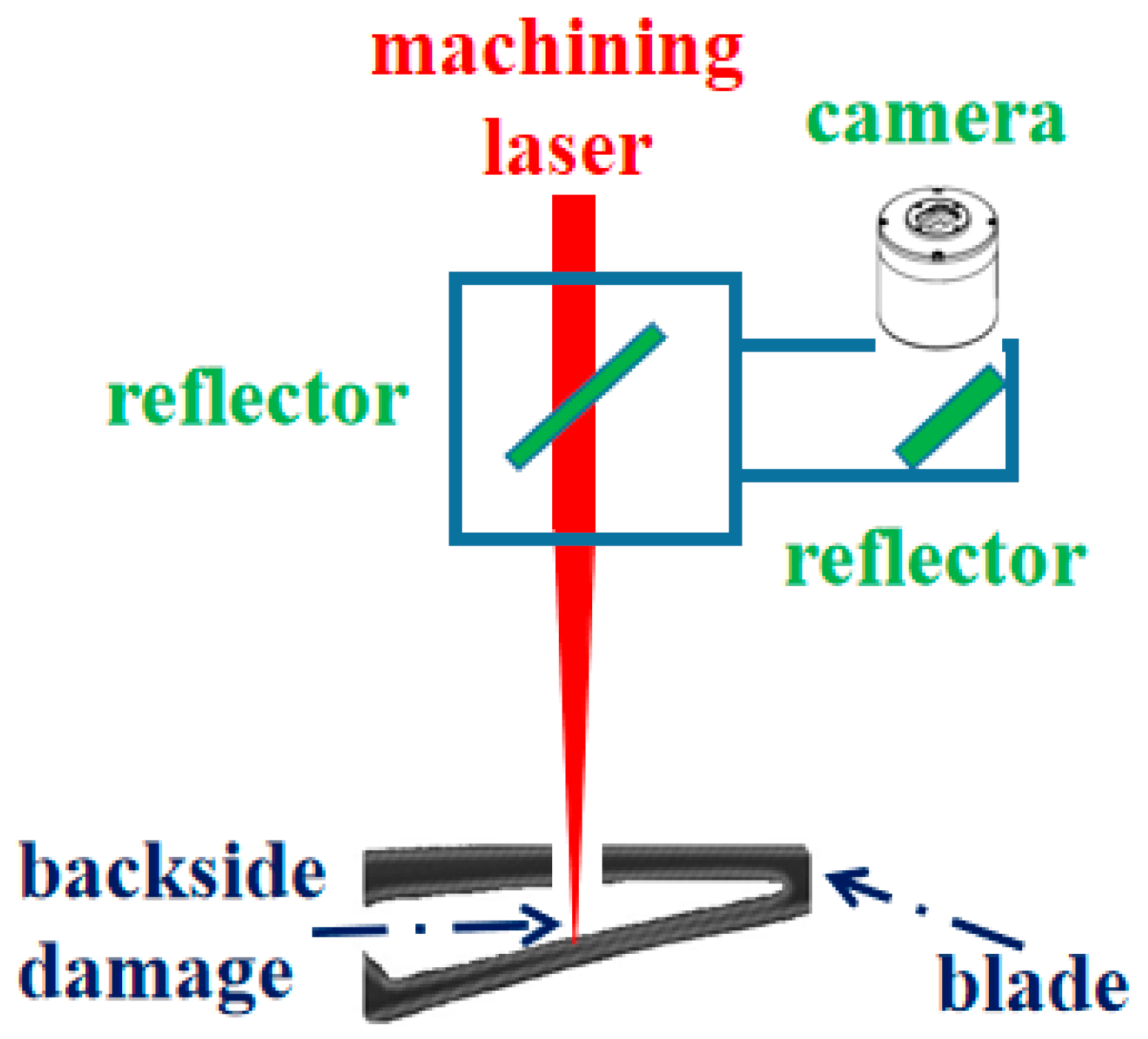

1. Introduction

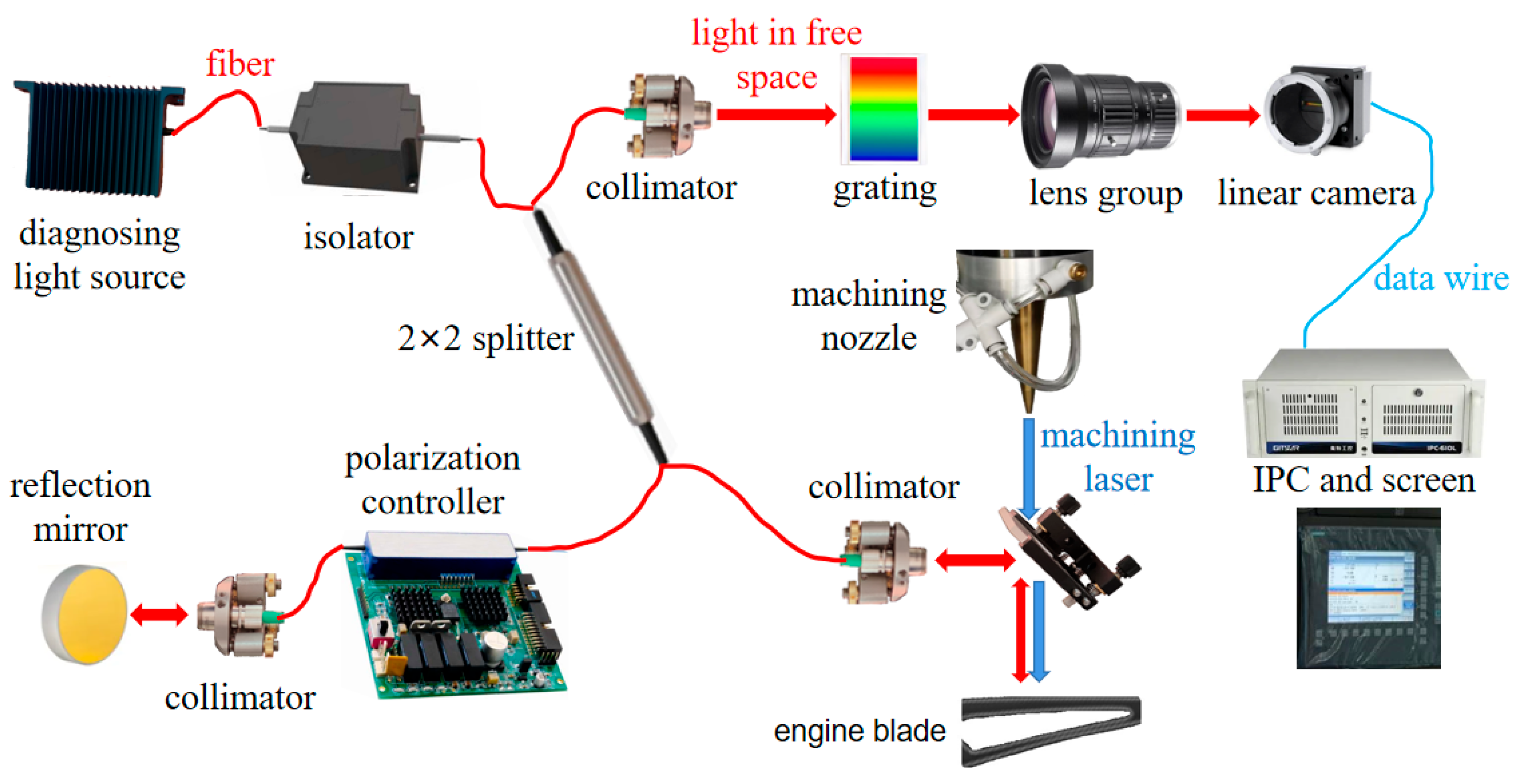

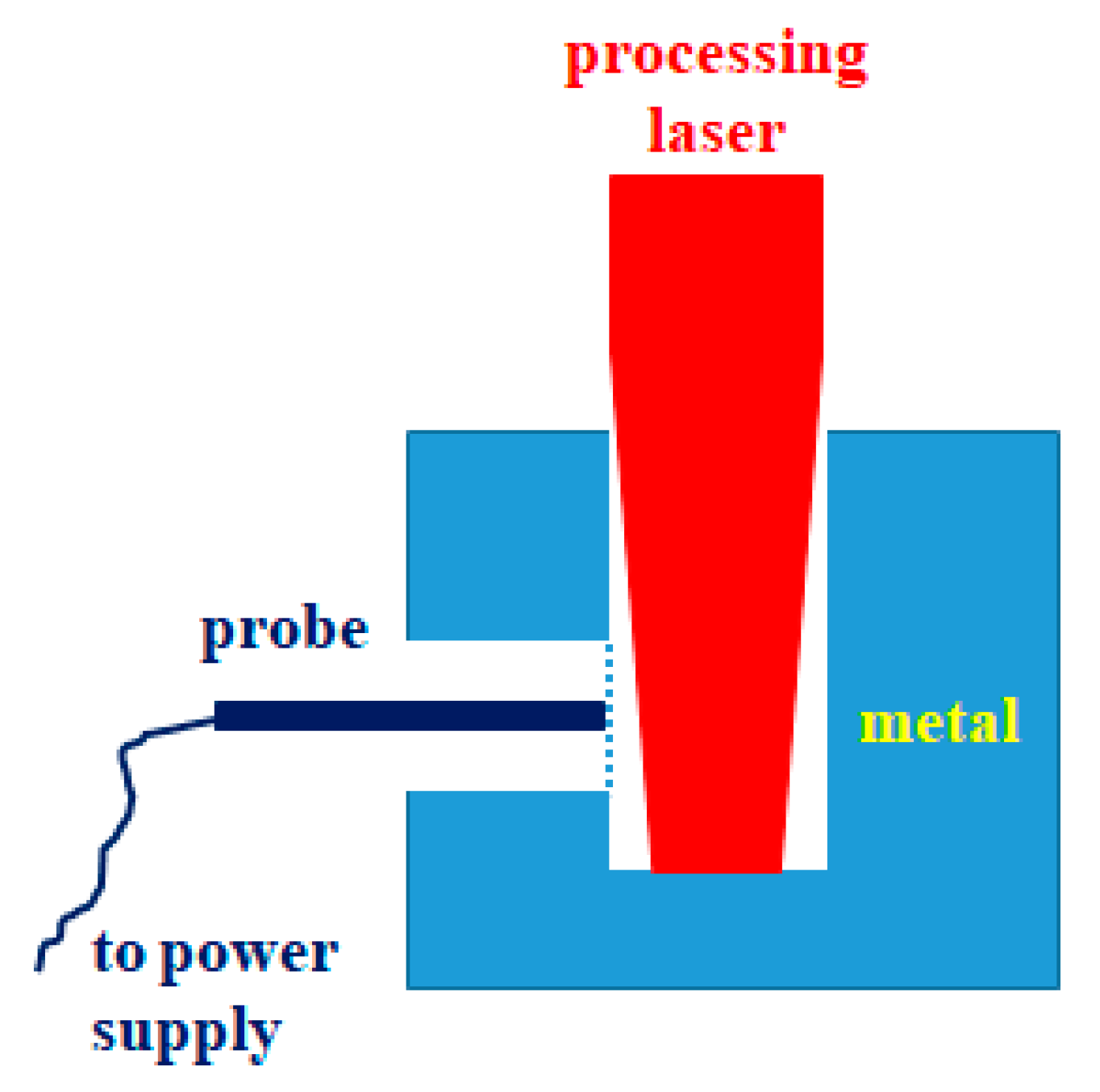

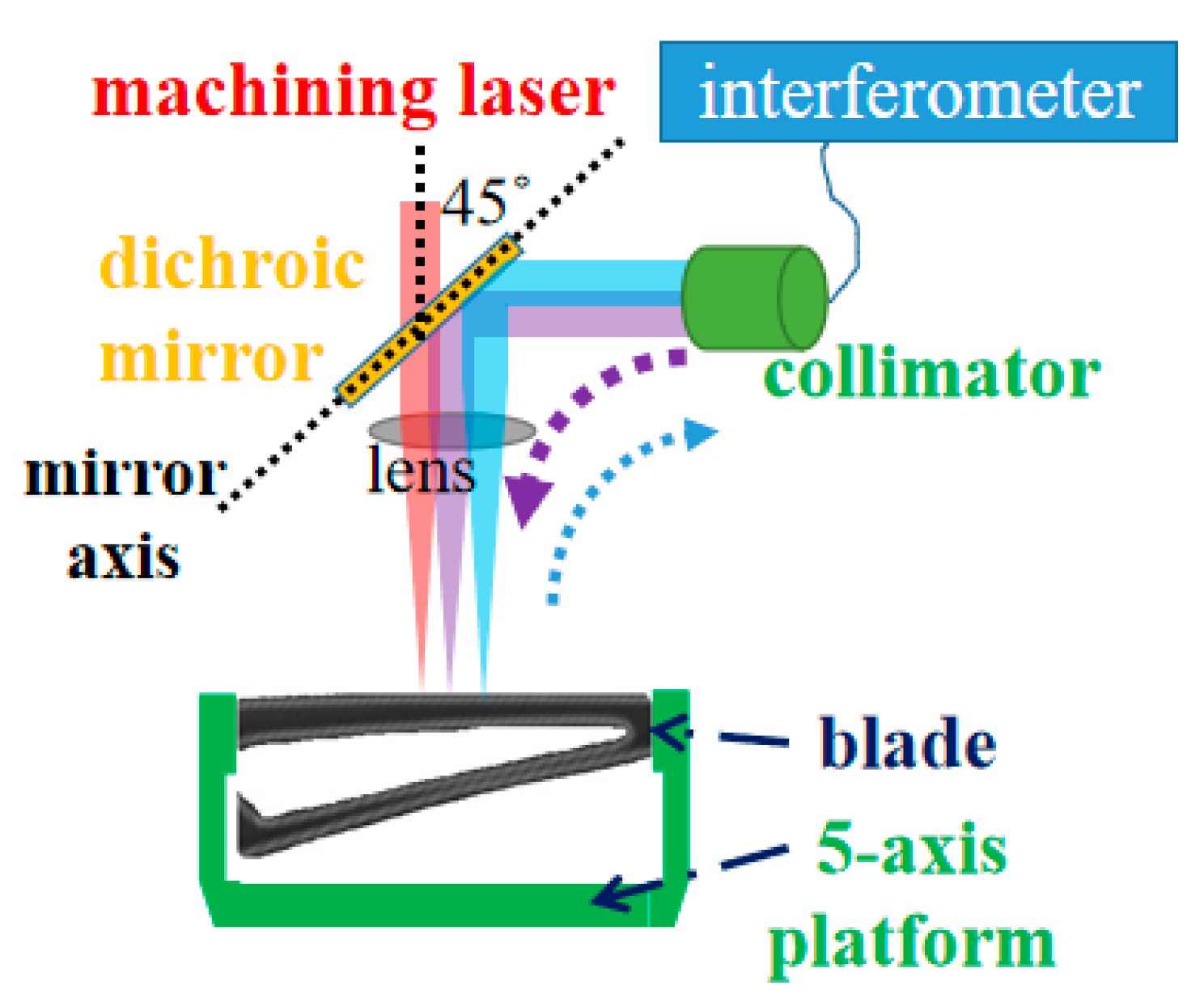

2. Materials and Methods

2.1. Diagnostics Methods

- Adjustable path configuration:The fiber length can be precisely tuned to achieve an optimal optical path difference between interferometer arms, fulfilling the fundamental interference precondition.

- Spectral filtering capability:During machining operations, plasma generation within the processing hole emits intense broadband radiation. Our system employs HI780 fiber (core diameter: 780 μm) for dual functionality: ① efficient transmission of the 830 nm probe beam; ② effective suppression of plasma emissions, back-reflected processing laser (1064 nm), and ambient light interference. This inherent filtering eliminates the need for darkroom conditions, significantly enhancing practical deployment feasibility.

- Vibration immunity:The fiber architecture demonstrates exceptional mechanical decoupling, effectively isolating the interferometer from laser cooling system vibrations, workshop floor oscillations, and machining-induced mechanical disturbances.

- Dynamic z-axis compatibility:The flexible fiber configuration enables seamless vertical synchronization between the machining head and sample arm collimator, maintaining optical alignment during depth progression without performance degradation.

2.2. Physics for Algorithm

- When , , as both beams originate from the same coherent source;

- When , , resulting in the disappearance of interference fringes.

3. Results

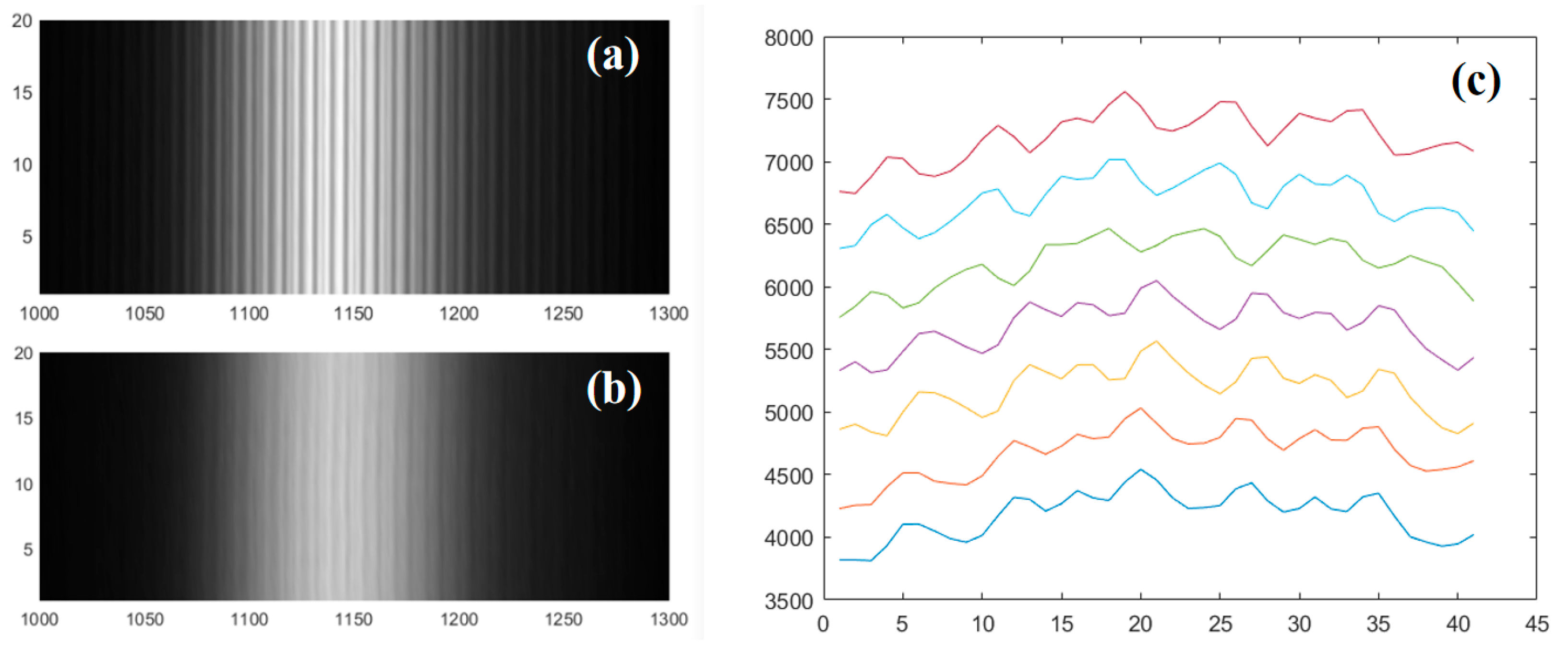

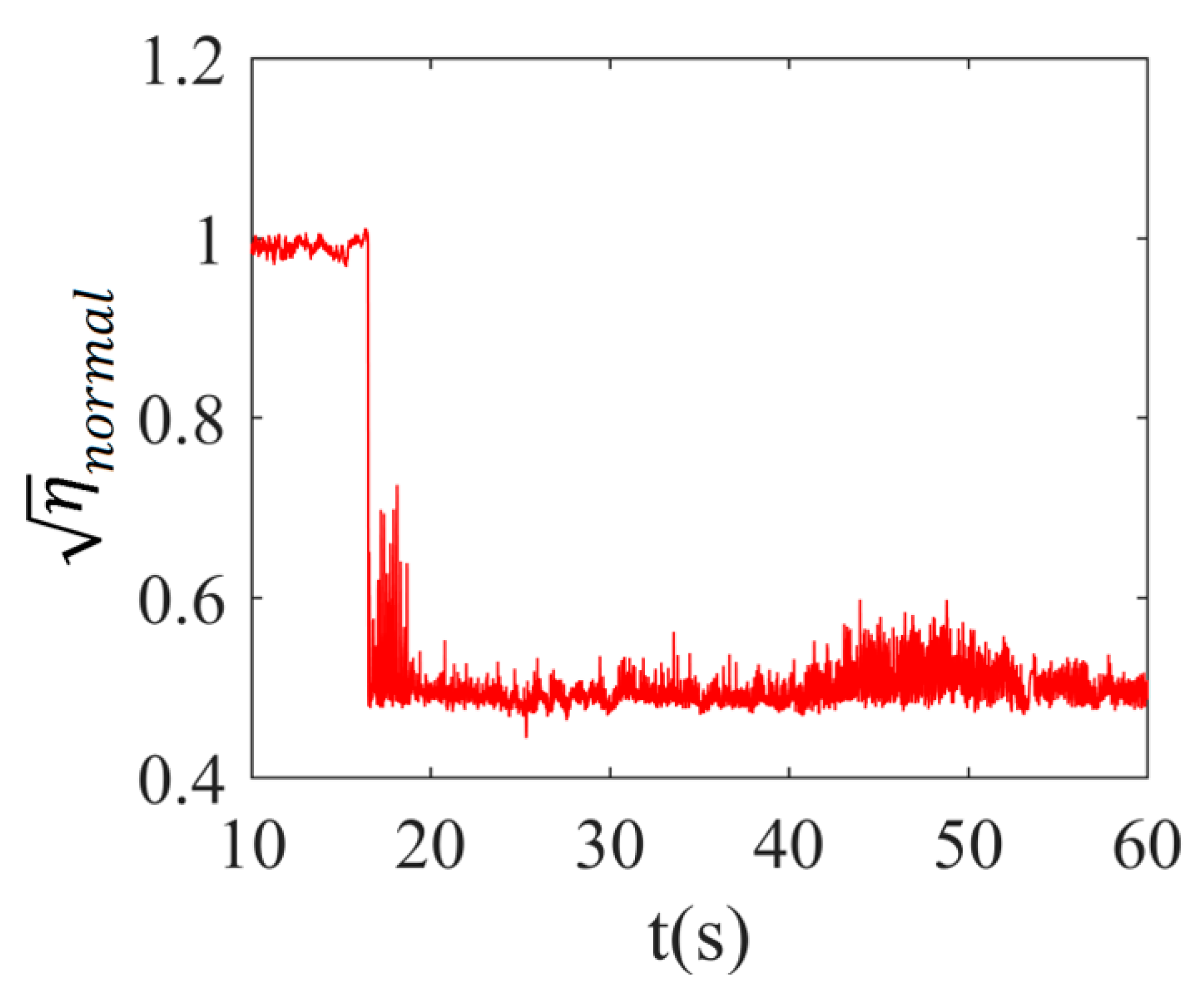

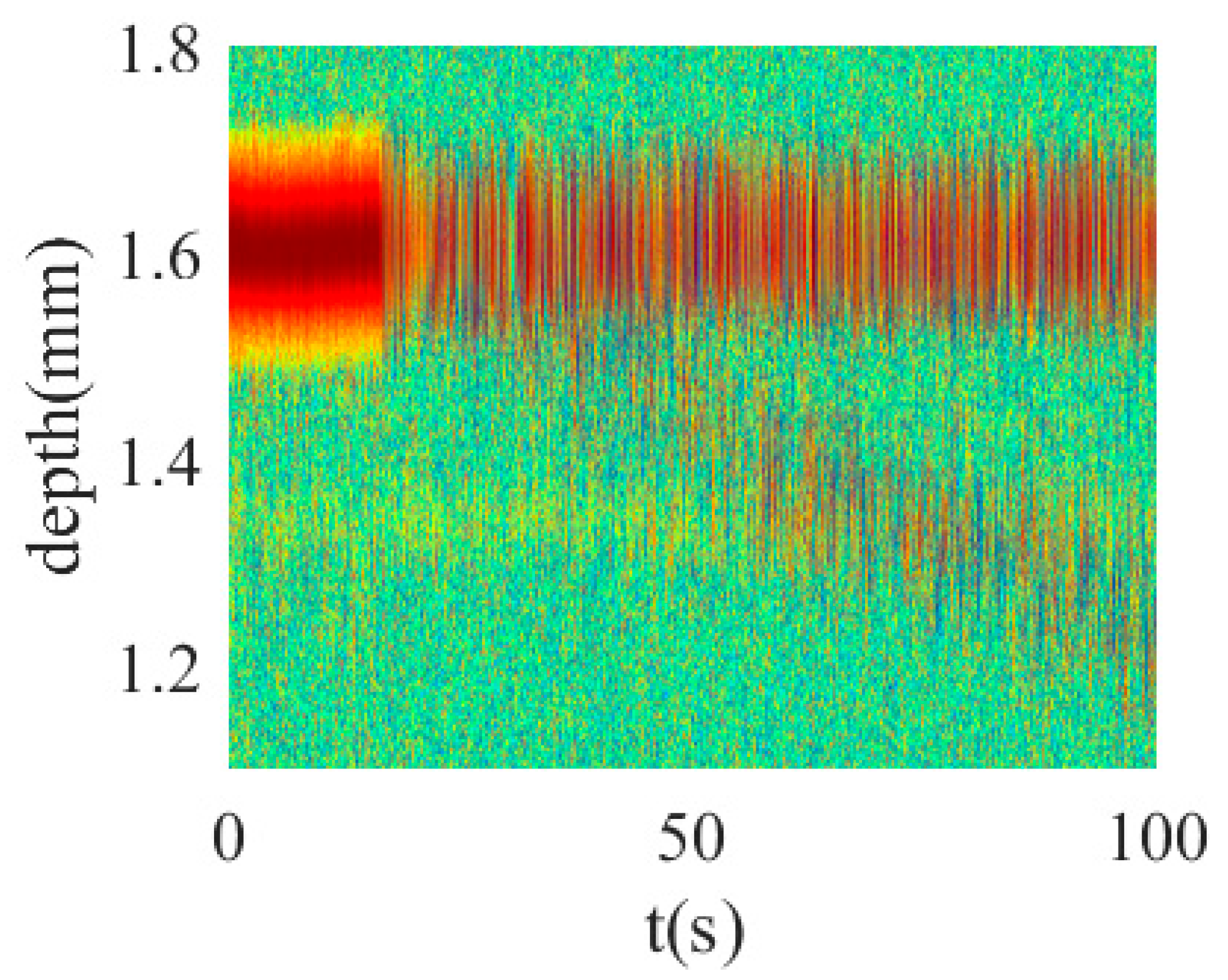

3.1. Plasma Compensation

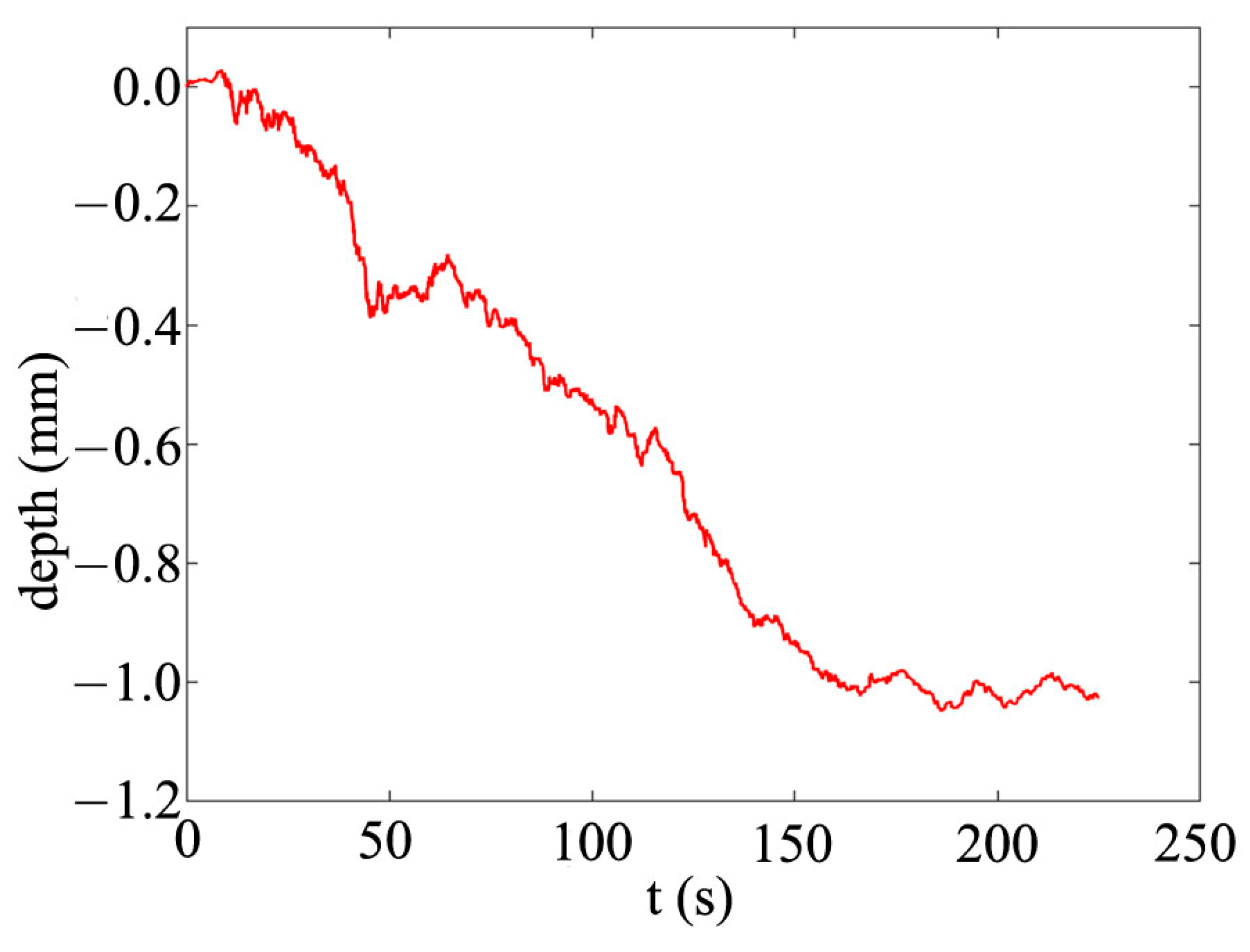

3.2. Real-Time Test Results

4. Discussion

- Depth measurement error:The accumulated measurement error in depth quantification reaches several micrometers—a magnitude comparable to the system’s 11.7 μm depth resolution. We implemented plasma compensation in the CHE software-derived depth calculations using experimentally determined plasma density values. While this correction assumes uniform plasma density distribution (a simplification requiring refinement), it can mitigate a great part of the measurement discrepancy

- Motion-tracking degradation:The depth measurement error induces erroneous movement judgments of the machining head, as previously described. Such miscalculations may trigger inappropriate sample arm length adjustments. The resulting optical path mismatch between sample and reference arms may violate the fundamental coherence condition, causing immediate loss of imaging functionality.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| OCT | Optical Coherence Tomography |

| ICI | Inline Coherent Imaging |

| SLD | Super-Luminescent Diode |

| FWHM | Full Width at Half Maximum |

| IPC | Industrial-grade Personal Computing |

| CHE | Coherent-imaging for Hole drilling in Engine blade |

References

- Ashcom, J.B. The Role of Focusing in the Interaction of Femtosecond Laser Pulses with Transparent Materials; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Schulz, W.; Eppelt, U.; Poprawe, R. Review on laser drilling I. Fundamentals, modeling, and simulation. J. Laser Appl. 2013, 25, 012006. [Google Scholar] [CrossRef]

- Jia, X.; Chen, Y.; Liu, L.; Wang, C.; Duan, J. Advances in laser drilling of structural ceramics. Nanomaterials 2022, 12, 230. [Google Scholar] [CrossRef] [PubMed]

- Calabrese, L.; Azzolini, M.; Bassi, F.; Gallus, E.; Bocchi, S.; Maccarini, G.; Pellegrini, G.; Ravasio, C. Micro-milling process of metals: A comparison between femtosecond laser and EDM techniques. J. Manuf. Mater. Proc. 2021, 5, 125. [Google Scholar] [CrossRef]

- Rethfeld, B.; Ivanov, D.S.; Garcia, M.E.; Anisimov, S.I. Modelling ultrafast laser ablation. J. Phys. D Appl. Phys. 2017, 50, 193001. [Google Scholar] [CrossRef]

- Zhigilei, L.V.; Lin, Z.; Ivanov, D.S. Atomistic modeling of short pulse laser ablabtion of metals: Connections between melting, spallation, and phase explosion. J. Phys. Chem. C 2009, 113, 11892–11906. [Google Scholar] [CrossRef]

- Smirnov, N.A.; Kudryashov, S.I.; Rudenko, A.A.; Zayarny, D.A.; Ionin, A.A. Pulsewidth and ambient medium effects during ultrashort-pulse laser ablation of silicon in air and water. Appl. Surf. Sci. 2021, 562, 150243. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Hennig, G. Surface structuring with ultra-short laser pulses: Basics, limitations and needs for high throughput. Phys. Proc. 2014, 56, 1047–1058. [Google Scholar] [CrossRef]

- Lei, S.; Zhao, X.; Yu, X.; Hu, A.; Vukelic, S.; Jun, M.B.G.; Joe, H.; Yao, Y.L.; Shin, Y.C. Ultrafast laser applications in manufactruing processes: A state-of-the-art review. J. Manuf. Sci. Eng. 2020, 142, 031005. [Google Scholar]

- Li, X.; Guan, Y. Theoretical fundamentals of short pulse laser-metal interaction: A review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

- Momma, C.; Chichkov, B.N.; Nolte, S.; von Alvensleben, F.; Tunnermann, A.; Welling, H.; Wellegehausen, B. Short-pulse laser ablation of solid targets. Opt. Commun. 1996, 129, 134–142. [Google Scholar] [CrossRef]

- Nolte, S.; Momma, C.; Hacobs, H.; Tunnermann, A. Ablation of metals by ultrashort laser pulses. J. Opt. Soc. Am. B 1997, 14, 2716–2722. [Google Scholar] [CrossRef]

- Sokolowski-Tinten, K.; von der Linde, D. Generation of dense electron-hole plasmas in silicon. Phys. Rev. B 2000, 61, 2643–2650. [Google Scholar] [CrossRef]

- Hu, Y.; Jiang, R.S.; Huang, C.X.; Chen, C.L.; Wang, S.J. Simulation and experimental study of femtosecong laser ablation mechanisms of NiCoCrAlY coating. Surf. Coat. Technol. 2024, 494, 131469. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Yang, Z.; Wang, C. Femtosecond laser-induced evolution of surface micro-structure in depth direction of nickel-based alloy. Appl. Sci. 2022, 12, 8464. [Google Scholar] [CrossRef]

- Li, M.; Wen, Z.; Wang, P.; Liu, Y.; Li, Z.; Yue, Z. Femtosecond laser high-quality drilling of film cooling holes in nickel-based single superalloy for turbine blades with a two-step helical drilling method. J. Mater. Proc. Technol. 2023, 312, 117827. [Google Scholar] [CrossRef]

- Randall, G.J.; Rhoades, L.J. Laser Back Wall Protection by Particulate Shading. U.S. Patent US20070175872A1, 2 August 2007. [Google Scholar]

- Cuttell, M. Method of Drilling Through a Wall of Hollow Component. U.S. Patent EP2567775, 7 March 2013. [Google Scholar]

- Knowles, M.R.H.; Kearsley, A.J.; Andrews, A.J.; Bell, A.I.; Rutterford, G.; Foster-Turner, G.J. Laser-drilling. U.S. Patent 6365871, 2 April 2002. [Google Scholar]

- Kreutz, E.W.; Trippe, L.; Walther, K.; Poprawe, R. Process Development and Control of Laser Drilled and Shaped Holes in Turbine Components. J. Laser Micro 2007, 2, 123–127. [Google Scholar] [CrossRef]

- Anabitarte, F.; Cobo, A.; Lopezhiguera, J.M. Laser-induced breakdown spectroscopy: Fundamentals, applications, and challenges. ISRN Spectrosc. 2014, 2012, 285240. [Google Scholar] [CrossRef]

- Cao, Z.T.; Jiang, L.; Wang, S.M.; Wang, M.M.; Liu, L.; Yang, F.; Lu, Y.F. Influence of electron dynamics on the enhancement of double-pulse femtosecond laser-induced breakdown spectroscopy of fused silica. Spectrochim. Acta Part B At. Spectrosc. 2018, 141, 63–69. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, L.; Wang, S.; Sun, J.; Zhan, J.; Zhu, W. An accurate interface detection of TBCs coated blades by double pulse femtosecond laser-induced breakdown spectroscopy. Spectrochim. Acta Part B At. Spectrosc. 2025, 224, 107088. [Google Scholar] [CrossRef]

- Temnov, V.V.; Tinten, K.S.; Zhou, P.; von Linde, D.D. Femtosecond time-resolved interferometric microscopy. Appl. Phys. A 2004, 78, 483. [Google Scholar] [CrossRef]

- Bouma, B.E.; Tearney, G.J. Handbook of Optical Coherence Tomography; Marcel Dekker: New York, NY, USA, 2002. [Google Scholar]

- Fercher, A.F.; Drexler, W.; Hitzenberger, C.K.; Lasser, T. Optical coherence tomography—Principles and applications. Rep. Prog. Phys. 2003, 66, 239–303. [Google Scholar] [CrossRef]

- Swanson, E.A.; Izatt, J.A.; Hee, M.R.; Huang, D.; Lin, C.P.; Schuman, J.S.; Puliafifito, C.A.; Fujimoto, J.G. In vivo retinal imaging by optical coherence tomography. Opt. Lett. 1993, 18, 1864–1866. [Google Scholar] [CrossRef] [PubMed]

- Bagayev, S.N.; Gelikonov, V.M.; Gelikonov, G.V.; Kargapoltsev, E.S.; Kuranov, R.V.; Razhev, A.M.; Tuchin, I.V.; Zhupikov, A.A. Optical coherence tomography for in situ monitoring of laser corneal ablation. J. Biomed. Opt. 2002, 7, 633–642. [Google Scholar] [CrossRef]

- Wojtkowski, M.; Leitgeb, R.; Kowalczyk, A.; Bajraszewski, T.; Fercher, A.F. In vivo human retinal imaging by Fourier domain optical coherence tomography. J. Biomed. Opt. 2002, 7, 457–463. [Google Scholar] [CrossRef] [PubMed]

- Tearney, G.J.; Bouma, B.E.; Boppart, S.A.; Golubovic, B.; Swanson, E.A.; Fujimoto, J.G. Rapid acquisition of in vivo biological images by use of optical coherence tomography. Opt. Lett. 1996, 21, 1408–1410. [Google Scholar] [CrossRef]

- Tearney, G.J.; Brezinski, M.E.; Bouma, B.E.; Boppart, S.A.; Pitris, C.; Southern, J.F.; Fujimoto, J.G. In vivo endoscopic optical biopsy with optical coherence tomography. Science 1997, 276, 2037–2039. [Google Scholar] [CrossRef]

- Colston, B.W.; Sathyam, U.S.; DaSilva, L.B.; Everett, M.J.; Stroeve, P.; Otis, L.L. Dental OCT. Opt Express 1998, 3, 230–238. [Google Scholar] [CrossRef]

- Amaechi, B.T.; Higham, S.M.; Podoleanu, A.G.; Rogers, J.A.; Jackson, D.A. Use of optical coherence tomography for assessment of dental caries: Quantitative procedure. J. Oral Rehabil. 2001, 28, 1092–1093. [Google Scholar] [CrossRef]

- Xu, F.; Pudavar, H.E.; Prasad, P.N. Confocal enhanced optical coherence tomography for nondestructive evaluation of paints and coatings. Opt. Lett. 1999, 24, 1808–1810. [Google Scholar] [CrossRef]

- Li, T.; Wang, A.; Murphy, K.; Claus, R. White-light scanning fiber Michelson interferometer for absolute position-distance measurement. Opt. Lett. 1995, 20, 785–787. [Google Scholar] [CrossRef]

- Webster, P.J.L.; Yu, J.X.Z.; Leung, B.Y.C.; Anderson, M.D.; Yang, V.X.D.; Fraser, J.M. In situ 24 kHz coherent imaging of morphology change in laser percussion drilling. Opt. Lett. 2010, 35, 646–648. [Google Scholar] [CrossRef]

- Webster, P.J.L.; Wright, L.G.; Mortimer, K.D.; Leung, B.Y.; Yu, J.X.Z.; Fraser, J.M. Automatic real-time guidance of laser machining with inline coherent imaging. J. Laser Appl. 2011, 23, 022001. [Google Scholar] [CrossRef]

- Webster, P.J.L.; Wright, L.G.; Ji, Y.; Galbraith, C.M.; Kinross, A.W.; van Vlack, C.; Fraser, J.M. Automatic laser welding and milling with in situ inline coherent imaging. Opt. Lett. 2014, 39, 6217–6220. [Google Scholar] [CrossRef] [PubMed]

- Sokolov, M.; Franciosa, P.; Botros, R.A.; Ceglarek, D. Keyhole mapping to enable closed-loop weld penetration depth control for remote laser welding of aluminum components using optical coherence tomography. J. Laser Appl. 2020, 32, 032004. [Google Scholar] [CrossRef]

- Fleming, T.G.; Clark, S.J.; Fan, X.; Fezzaa, K.; Lun, C.; Leung, A.; Lee, P.D.; Fraser, J.M. Synchrotron validation of niline coherent imaging for tracking laser keyhole depth. Addit. Manuf. 2023, 77, 103798. [Google Scholar]

- Hsu, L.W.; Salminen, A. Laser welding monitoring with multisensory data fusion: A brief review. Mater. Sci. Eng. 2023, 1296, 012014. [Google Scholar] [CrossRef]

- Boley, M.; Fetzer, F.; Weber, R.; Graf, T. Statistical evaluation method to determine the laser welding depth by optical coherence tomography. Opt. Lasers Eng. 2019, 119, 56–64. [Google Scholar] [CrossRef]

- Fleming, T.G.; Rees, D.T.; Marussi, S.; Connolley, T.; Atwood, R.C.; Jones, M.A.; Fraser, J.M.; Leung, C.L.; Lee, P.D. In situ correlative observation of humping-induced cracking in directed energy deposition of nickel-based superalloys. Addit. Manuf. 2023, 71, 103579. [Google Scholar] [CrossRef]

- Fleming, T.G.; Nestor, S.G.L.; Allen, T.R.; Boukhaled, M.A.; Smith, N.J.; Fraser, J.M. Tracking and controlling the morphology evolution of 3D powder-bed fusion using inline coherent imaging. Addit. Manuf. 2020, 32, 100978. [Google Scholar] [CrossRef]

- Mandel, L.; Wolf, E. Optical Coherence and Quantum Optics; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Hutchinson, I.H. Principles of Plasma Diagnostics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2002. [Google Scholar]

- Langmuir, I.; Mott-Smith, H. Studies of electric discharges in gases at low pressures. Gen. Electr. Rev. 1924, 27, 449–455. [Google Scholar]

- Yang, J. Inline Coherent Imaging Applied to Laser Micromachining; Queen’s University Press: Kingston, ON, Canada, 2014. [Google Scholar]

| Parameters | Units | Model: Y15-F04 (Guoshen Ltd., Shanghai, China) |

|---|---|---|

| Central wavelength | nm | 1027–1040 |

| Pulse width | fs | 400 |

| Repetitive frequency | KHz | 50–200 |

| Polarization direction | Horizontal polarization | |

| Single pulse power (maximum) | μJ | 100 |

| Output power (maximum) | W | 20@200K |

| Beam circularity | % | >85 |

| Beam diameter | mm | 2.5 ± 0.2 |

| Power stability | % | <3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Liu, R.; Xiao, C.; Xu, P. Real-Time Depth Monitoring of Air-Film Cooling Holes in Turbine Blades via Coherent Imaging During Femtosecond Laser Machining. Photonics 2025, 12, 668. https://doi.org/10.3390/photonics12070668

Yu Y, Liu R, Xiao C, Xu P. Real-Time Depth Monitoring of Air-Film Cooling Holes in Turbine Blades via Coherent Imaging During Femtosecond Laser Machining. Photonics. 2025; 12(7):668. https://doi.org/10.3390/photonics12070668

Chicago/Turabian StyleYu, Yi, Ruijia Liu, Chenyu Xiao, and Ping Xu. 2025. "Real-Time Depth Monitoring of Air-Film Cooling Holes in Turbine Blades via Coherent Imaging During Femtosecond Laser Machining" Photonics 12, no. 7: 668. https://doi.org/10.3390/photonics12070668

APA StyleYu, Y., Liu, R., Xiao, C., & Xu, P. (2025). Real-Time Depth Monitoring of Air-Film Cooling Holes in Turbine Blades via Coherent Imaging During Femtosecond Laser Machining. Photonics, 12(7), 668. https://doi.org/10.3390/photonics12070668