Dual-Parameter Surface Plasmon Resonance Photonic Crystal Fiber Sensor for Simultaneous Magnetic Field and Temperature Detection with Potential SERS Applications

Abstract

1. Introduction

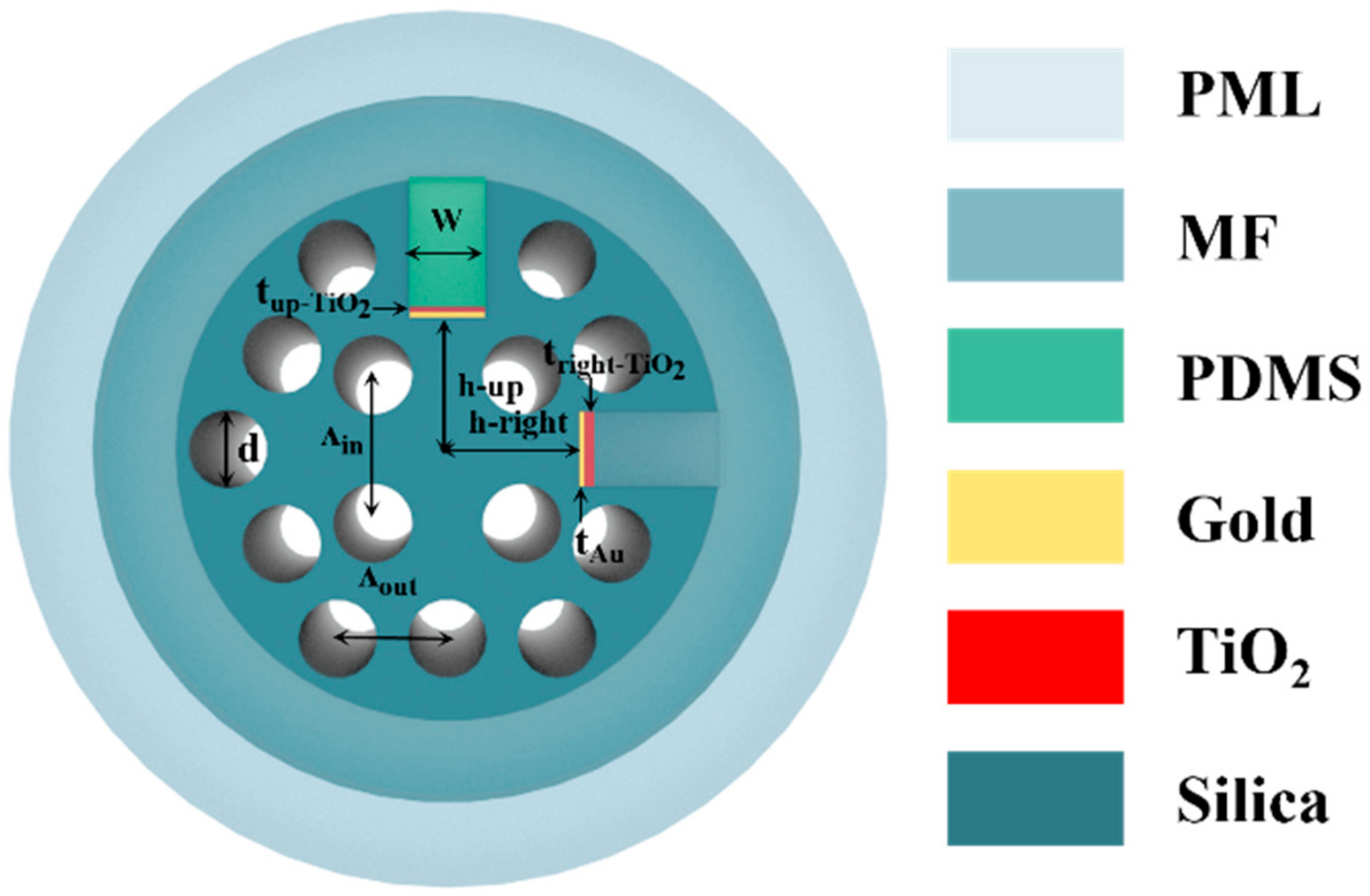

2. Structure Design and Theoretical Analysis

2.1. Structure Design

2.2. Theoretical Analysis

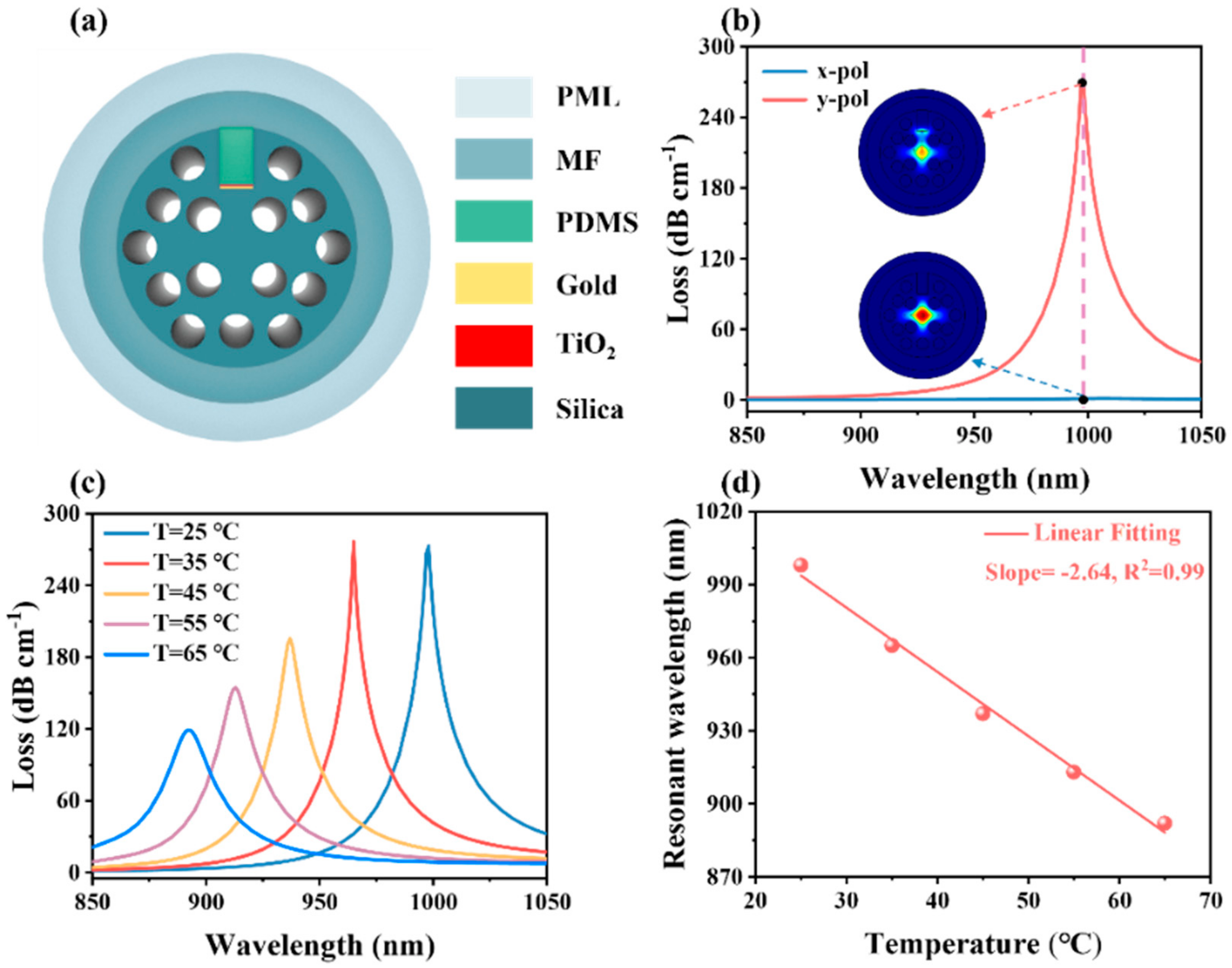

2.3. Single-Parameter Magnetic Field Sensing of the SPR-PCF Sensor

2.4. Single-Parameter Temperature Sensing of the SPR-PCF Sensor

3. Results

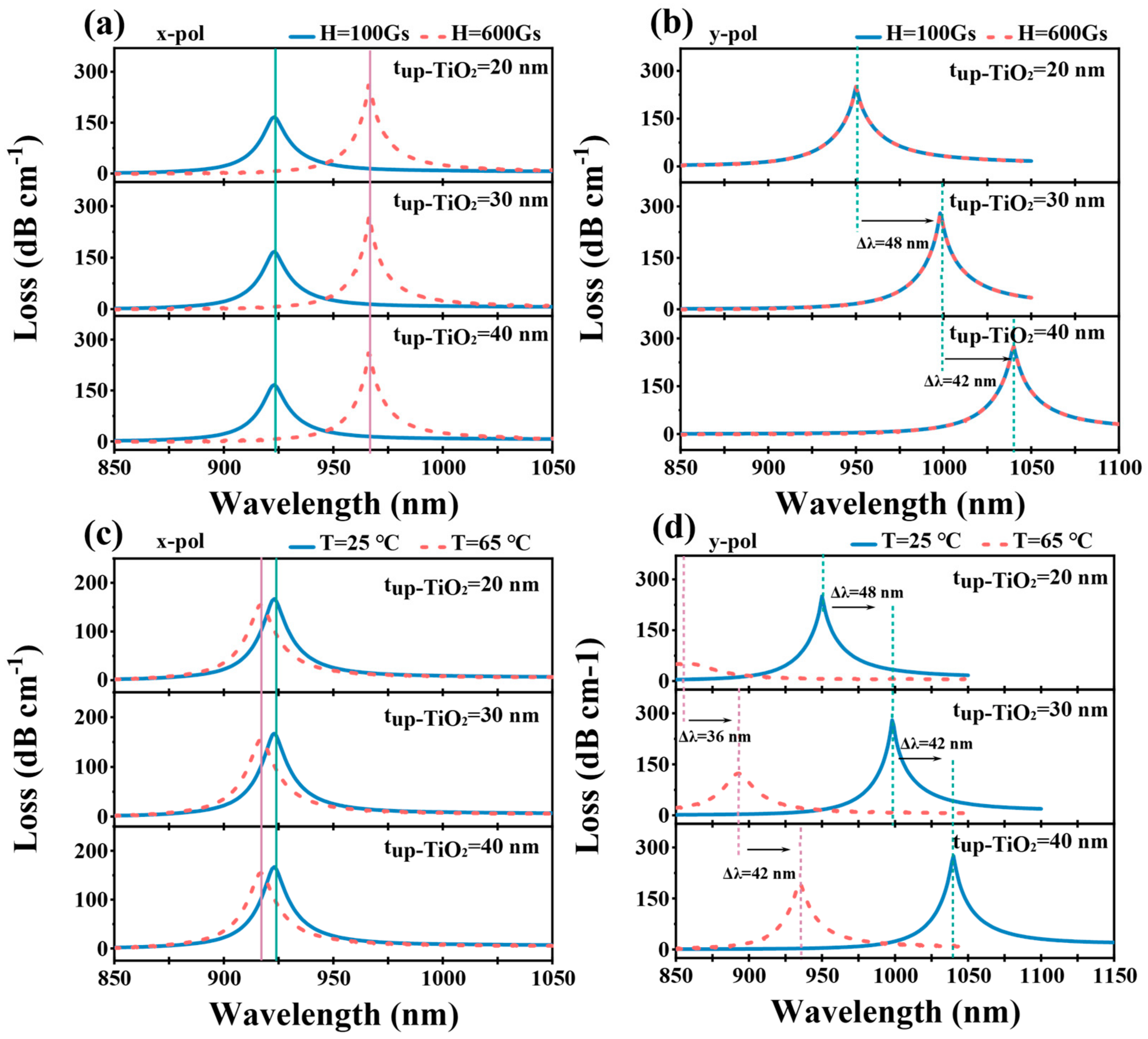

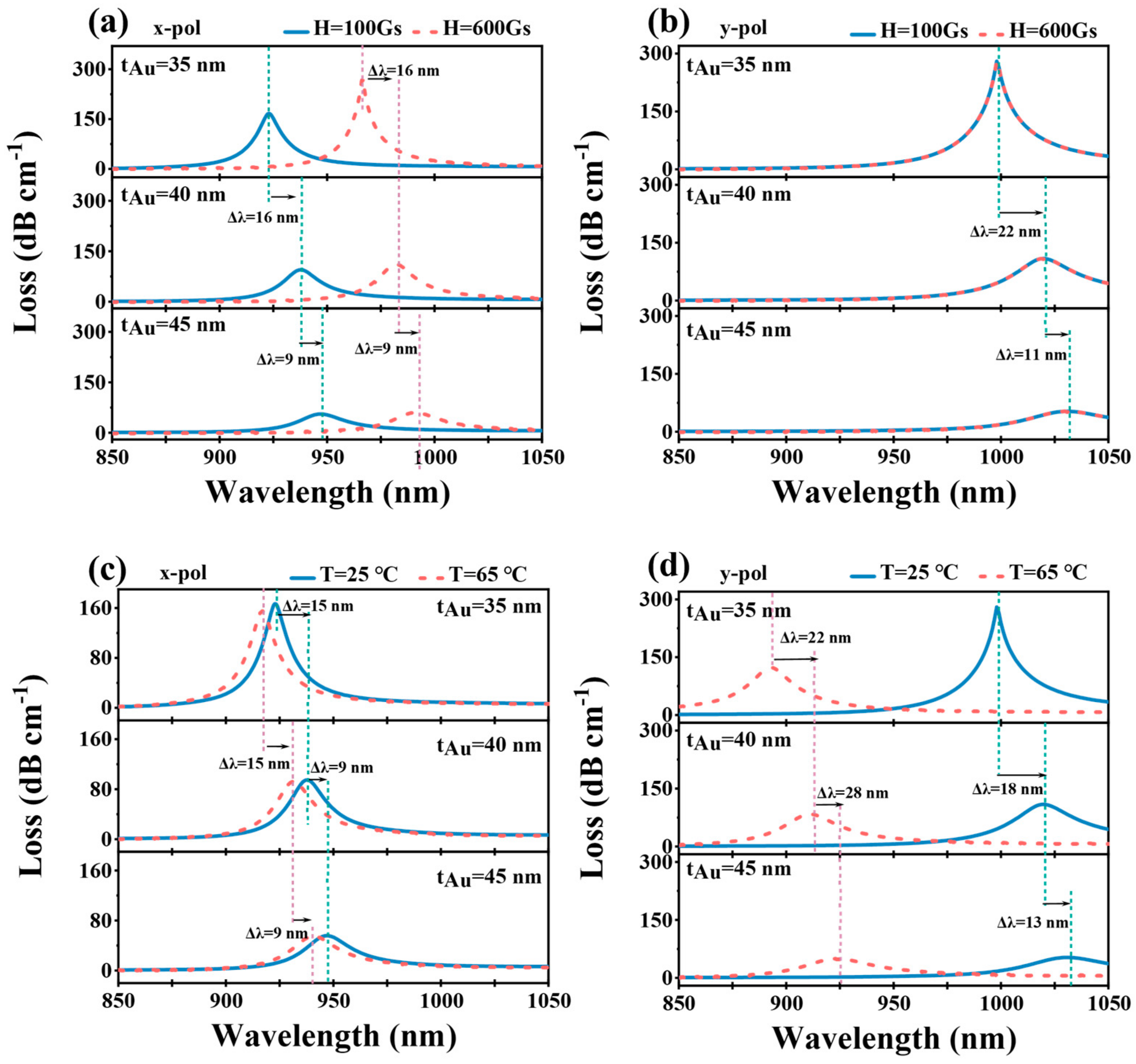

3.1. Effect of TiO2 and Au Film Thicknesses on Sensing Performance

3.2. Effect of Variation of Structural Parameters on the Spectral Response

3.3. Dual-Parameter Sensing of Magnetic Field and Temperature

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, X.; Li, X.G.; Li, S.G.; An, G.W.; Cheng, T.L. Magnetic Field Sensing Based on SPR Optical Fiber Sensor Interacting with Magnetic Fluid. IEEE Trans. Instrum. Meas. 2019, 68, 234–239. [Google Scholar] [CrossRef]

- Dai, T.T.; Yi, Y.T.; Yi, Z.; Tang, Y.J.; Yi, Y.G.; Cheng, S.B.; Hao, Z.Q.; Tang, C.J.; Wu, P.H.; Zeng, Q.D. Photonic Crystal Fiber Based on Surface Plasmon Resonance Used for Two Parameter Sensing for Magnetic Field and Temperature. Photonics 2024, 11, 784. [Google Scholar] [CrossRef]

- Ji, Y.; Pu, S.L.; Liu, W.A.; Zhang, C.C.; Fu, J.Q.; Han, S.F.; Duan, S.M.; Huang, S.Y.; Lahoubi, M. High-sensitivity vector magnetic field sensor based on a V-shaped multimode-no-core-multimode fiber structure. Opt. Lett. 2024, 49, 2813–2816. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Schwendtner, E.; Navarrete, M.C.; Díaz-Herrera, N.; González-Cano, A.; Esteban, O. Advanced Plasmonic Fiber-Optic Sensor for High Sensitivity Measurement of Magnetic Field. IEEE Sens. J. 2019, 19, 7355–7364. [Google Scholar] [CrossRef]

- Zhang, X.X.; Qian, J.X.; Wang, W.; Lu, K.F.; Li, X.H.; Chen, H.B.; Zhang, J.Y. Fiber-Optic Vector Magnetic Field Sensors Based on Magnetic Fluid: Progress and Prospect. IEEE Trans. Instrum. Meas. 2024, 73, 6010213. [Google Scholar] [CrossRef]

- Su, C.B.; Yang, W.J.; Tong, D.; Zhu, Q.F.; Ma, Y.W.; Geng, T.; Yuan, L.B. A Highly Sensitive Sensor Based on Combination of Magnetostrictive Material and Vernier Effect for Magnetic Field Measurement. J. Light. Technol. 2024, 42, 485–492. [Google Scholar] [CrossRef]

- Sun, L.; Jiang, S.; Marciante, J.R. All-fiber optical magnetic-field sensor based on Faraday rotation in highly terbium-doped fiber. Opt. Express 2010, 18, 5407–5412. [Google Scholar] [CrossRef]

- Tian, P.X.; Guan, C.Y.; Ye, P.; Cheng, T.L.; Yang, J.; Zhu, Z.; Shi, J.H.; Yang, J.; Yuan, L.B. Dual Mode Interference Magnetic-Field Sensor Based on Hollow Suspended-Core Fiber. IEEE Photon. Technol. Lett. 2022, 34, 43–46. [Google Scholar] [CrossRef]

- Gu, S.F.; Feng, D.Q.; Zhang, T.H.; Deng, S.D.; Li, M.; Hu, Y.W.; Sun, W.; Deng, M. Highly Sensitive Magnetic Field Measurement with Taper-Based In-Line Mach-Zehnder Interferometer and Vernier Effect. J. Light. Technol. 2022, 40, 909–917. [Google Scholar] [CrossRef]

- Tian, H.; Tian, K.; Zhang, H.Y.; Shao, L.P.; Wang, Y.M.; Lu, H.L.; Shao, W.J.; Tang, J.; Hu, J.H. Vector magnetic field sensor based on coreless D-shaped fiber and magnetic fluid. Opt. Express 2024, 32, 25508–25518. [Google Scholar] [CrossRef]

- Zhang, F.; Li, B.; Chen, X.Y.; Gao, Y.H.; Yan, X.; Zhang, X.N.; Wang, F.; Suzuki, T.; Ohishi, Y.; Cheng, T.L. A Magnetic Field Sensor Based on Birefringence Effect in Asymmetric Four-Hole Fiber. J. Light. Technol. 2022, 40, 2594–2600. [Google Scholar] [CrossRef]

- Bilal, M.M.; Lopez-Aguayo, S.; Thottoli, A. Numerical Analysis of Solid-Core Photonic Crystal Fiber Based on Plasmonic Materials for Analyte Refractive Index Sensing. Photonics 2023, 10, 1070. [Google Scholar] [CrossRef]

- You, E.M.; Wang, H.L.; Zheng, J.R.; Meng, Z.D.; Zhang, M.X.; Ding, S.Y.; Tian, Z.Q. Attenuated total reflection-cascading nanostructure-enhanced Raman spectroscopy on flat surfaces: A nano-optical design. J. Raman Spectrosc. 2021, 52, 446–457. [Google Scholar] [CrossRef]

- Yao, S.Y.; Yu, Y.; Qin, S.P.; Wang, D.Y.; Yan, P.G.; Zhang, Z.R. Research on optimization of magnetic field sensing characteristics of PCF sensor based on SPR. Opt. Express 2022, 30, 16405–16418. [Google Scholar] [CrossRef]

- Wang, D.Y.; Yu, Y.; Lu, Z.C.; Yang, J.B.; Yi, Z.; Bian, Q.; Zhang, J.F.; Qin, S.P.; Weng, J.J.; Yao, S.Y.; et al. Design of photonic crystal fiber to excite surface plasmon resonance for highly sensitive magnetic field sensing. Opt. Express 2022, 30, 29271–29286. [Google Scholar] [CrossRef]

- Yao, S.Y.; Wang, D.Y.; Yu, Y.; Zhang, Z.R.; Wei, L.Y.; Yang, J.B. Design of an Er-doped surface plasmon resonance-photonic crystal fiber to improve magnetic field sensitivity. Opt. Express 2022, 30, 41240–41254. [Google Scholar] [CrossRef]

- Fan, Z.K.; Chu, S.C.; Zhang, X.Q.; Meng, J.H.; Fan, Y.Q.; Zhang, Y.P. Two Kinds of Liquid Crystal Filled PCFs Temperature and RI Sensors Based on SPR. IEEE Sens. J. 2023, 23, 5766–5772. [Google Scholar] [CrossRef]

- Danlard, I.; Akowuah, E.K. Design and Theoretical Analysis of a Dual-Polarized Quasi D-Shaped Plasmonic PCF Microsensor for Back-to-Back Measurement of Refractive Index and Temperature. IEEE Sens. J. 2021, 21, 9860–9868. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhu, W.L.; Yi, Z.; Ma, G.L.; Gao, X.; Dai, B.; Yu, Y.; Zhou, G.R.; Wu, P.H.; Liu, C. Highly sensitive sensing of a magnetic field and temperature based on two open ring channels SPR-PCF. Opt. Express 2022, 30, 39055–39067. [Google Scholar] [CrossRef]

- Liu, T.G.; Jiang, J.F.; Liu, K.; Wang, S.; Zhang, X.Z.; Hu, H.F.; Ding, Z.Y.; Guo, H.R.; Li, Y.F.; Zhang, W.L. Review of Fiber Mechanical and Thermal Multi-Parameter Measurement Technologies and Instrumentation. J. Light. Technol. 2021, 39, 3724–3739. [Google Scholar] [CrossRef]

- Liu, H.; Tan, C.; Zhu, C.H.; Wang, Y.; Gao, Y.; Ma, H.L.; Cheng, D.Q. Simultaneous measurement of temperature and magnetic field based on directional resonance coupling in photonic crystal fibers. Opt. Commun. 2017, 391, 111–115. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, D.; Lv, R.Q.; Ying, Y. Tunable Characteristics and Mechanism Analysis of the Magnetic Fluid Refractive Index with Applied Magnetic Field. IEEE Trans. Magn. 2014, 50, 4600205. [Google Scholar] [CrossRef]

- Zhu, Z.D.; Liu, L.; Liu, Z.H.; Zhang, Y.; Zhang, Y.X. Surface-plasmon-resonance-based optical-fiber temperature sensor with high sensitivity and high figure of merit. Opt. Lett. 2017, 42, 2948–2951. [Google Scholar] [CrossRef]

- Liu, Q.; Li, S.G.; Chen, H.L.; Fan, Z.K.; Li, J.S. Photonic Crystal Fiber Temperature Sensor Based on Coupling Between Liquid-Core Mode and Defect Mode. IEEE Photon. J. 2015, 7, 4500509. [Google Scholar] [CrossRef]

- Rifat, A.A.; Mandiraji, G.A.; Sua, Y.M.; Ahmed, R.; Shee, Y.G.; Adikan, F.R.M. Highly sensitive multi-core flat fiber surface plasmon resonance refractive index sensor. Opt. Express 2016, 24, 2485–2495. [Google Scholar] [CrossRef]

- Vial, A.; Grimault, A.S.; Macías, D.; Barchiesi, D.; de la Chapelle, M.L. Improved analytical fit of gold dispersion: Application to the modeling of extinction spectra with a finite-difference time-domain method. Phys. Rev. B 2005, 71, 085416. [Google Scholar] [CrossRef]

- Yang, X.C.; Zhu, L.Q.; Lu, Y.; Yao, J.Q. Ultrasharp LSPR Temperature Sensor Based on Grapefruit Fiber Filled with a Silver Nanoshell and Liquid. J. Light. Technol. 2020, 38, 2015–2021. [Google Scholar] [CrossRef]

- Liu, Q.; Li, S.G.; Chen, H.L.; Li, J.S.; Fan, Z.K. High-sensitivity plasmonic temperature sensor based on photonic crystal fiber coated with nanoscale gold film. Appl. Phys. Express 2015, 8, 046701. [Google Scholar] [CrossRef]

- Russell, P. Photonic crystal fibers. Science 2003, 299, 358–362. [Google Scholar] [CrossRef]

- Cregan, R.F.; Mangan, B.J.; Knight, J.C.; Birks, T.A.; Russell, P.S.; Roberts, P.J.; Allan, D.C. Single-mode photonic band gap guidance of light in air. Science 1999, 285, 1537–1539. [Google Scholar] [CrossRef]

- van Brakel, A.; Grivas, C.; Petrovich, M.N.; Richardson, D.J. Micro-channels machined in microstructured optical fibers by femtosecond laser. Opt. Express 2007, 15, 8731–8736. [Google Scholar] [CrossRef]

- Wang, H.R.; Wu, M.Y.; Zhou, J.; Zheng, S.C.; Xie, T.T.; Dai, W.Y.; Fu, H.Y.; Lv, W.L.; Chen, N.; Bu, Y.K. SPR Sensor Based on Cascaded NCF and U-Shaped Multimode Fibers for Simultaneous Detection of Refractive Index and Temperature. IEEE Sens. J. 2023, 23, 16851–16858. [Google Scholar] [CrossRef]

- Wang, Y.J.; Li, S.G.; Li, J.S.; Chen, H.L. High-Sensitivity Refractive Index Sensing and Broadband Tunable Polarization Filtering Characteristics of D-Shaped Micro-Structured Fiber with Single-Layer Air-Holes and Gold Film Based on SPR. J. Light. Technol. 2022, 40, 863–871. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.H.; Zhang, Y.; Li, S.; Zhang, Y.X.; Yang, X.H.; Zhang, J.Z.; Yuan, L.B. Specialty optical fibers and 2D materials for sensitivity enhancement of fiber optic SPR sensors: A review. Opt. Laser Technol. 2022, 152, 108167. [Google Scholar] [CrossRef]

- Singh, S.; Chaudhary, B.; Kumar, R.; Upadhyay, A.; Kumar, S. A Numerical Analysis of Rectangular Open Channel Embedded TiO2-Au-MXene Employed PCF Biosensor for Brain Tumor Diagnosis. IEEE Sens. J. 2024, 24, 16047–16054. [Google Scholar] [CrossRef]

- Yi, J.; You, E.M.; Hu, R.; Wu, D.Y.; Liu, G.K.; Yang, Z.L.; Zhang, H.; Gu, Y.; Wang, Y.H.; Wang, X.; et al. Surface-enhanced Raman spectroscopy: A half-century historical perspective. Chem. Soc. Rev. 2025, 54, 1453–1551. [Google Scholar] [CrossRef]

- Jing, J.Y.; Wang, Q.; Zhao, W.M.; Wang, B.T. Long-range surface plasmon resonance and its sensing applications: A review. Opt. Lasers Eng. 2019, 112, 103–118. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Li, L.; Yin, H. Long-Range Spoof Surface Plasmons (LRSSP) on the Asymmetric Double Metal Gratings. IEEE Photon. J. 2021, 13, 4800209. [Google Scholar] [CrossRef]

- Mo, X.W.; Lv, J.T.; Liu, Q.; Jiang, X.X.; Si, G.Y. A Magnetic Field SPR Sensor Based on Temperature Self-Reference. Sensors 2021, 21, 6130. [Google Scholar] [CrossRef]

- Fan, Y.Y.; Pu, S.L.; Li, D.H.; Zhao, Y.L.; Yuan, M.; Wang, J.; Liu, W.N. Bilaterally Polished Photonic Crystal Fiber Magnetic Field Sensor Based on Lossy Mode Resonance. IEEE Sens. J. 2022, 22, 23786–23792. [Google Scholar] [CrossRef]

| Ref. | Structure | Magnetic Field Sensitivity (pm/Oe) | Temperature Sensitivity (pm/°C) | Number of Simultaneously Detectable Parameters | Result Type |

|---|---|---|---|---|---|

| [14] | D-shaped PCF | 190 | −29.7 | 1 | Simulation |

| [15] | D-shaped PCF | 2175 | Simulation | ||

| [16] | D-shaped PCF | 5 | 0 | 1 | Simulation |

| [19] | Two opening ring PCF | 308 | −6520 | 2 | Simulation |

| [39] | D-shaped PCF | 143 | −229 | 2 | Simulation |

| [40] | Symmetrically side-polished PCF | 467 | 0 | 1 | Simulation |

| Our work | Multi-channel PCF | 860 | −2628 | 2 | Simulation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Liu, S.; Liu, W.; Wang, S. Dual-Parameter Surface Plasmon Resonance Photonic Crystal Fiber Sensor for Simultaneous Magnetic Field and Temperature Detection with Potential SERS Applications. Photonics 2025, 12, 355. https://doi.org/10.3390/photonics12040355

Wang H, Liu S, Liu W, Wang S. Dual-Parameter Surface Plasmon Resonance Photonic Crystal Fiber Sensor for Simultaneous Magnetic Field and Temperature Detection with Potential SERS Applications. Photonics. 2025; 12(4):355. https://doi.org/10.3390/photonics12040355

Chicago/Turabian StyleWang, Haoran, Shiwei Liu, Wenzhao Liu, and Shuai Wang. 2025. "Dual-Parameter Surface Plasmon Resonance Photonic Crystal Fiber Sensor for Simultaneous Magnetic Field and Temperature Detection with Potential SERS Applications" Photonics 12, no. 4: 355. https://doi.org/10.3390/photonics12040355

APA StyleWang, H., Liu, S., Liu, W., & Wang, S. (2025). Dual-Parameter Surface Plasmon Resonance Photonic Crystal Fiber Sensor for Simultaneous Magnetic Field and Temperature Detection with Potential SERS Applications. Photonics, 12(4), 355. https://doi.org/10.3390/photonics12040355