Linear Fiber Laser Configurations for Optical Concentration Sensing in Liquid Solutions

Abstract

1. Introduction

2. Experimental Setup

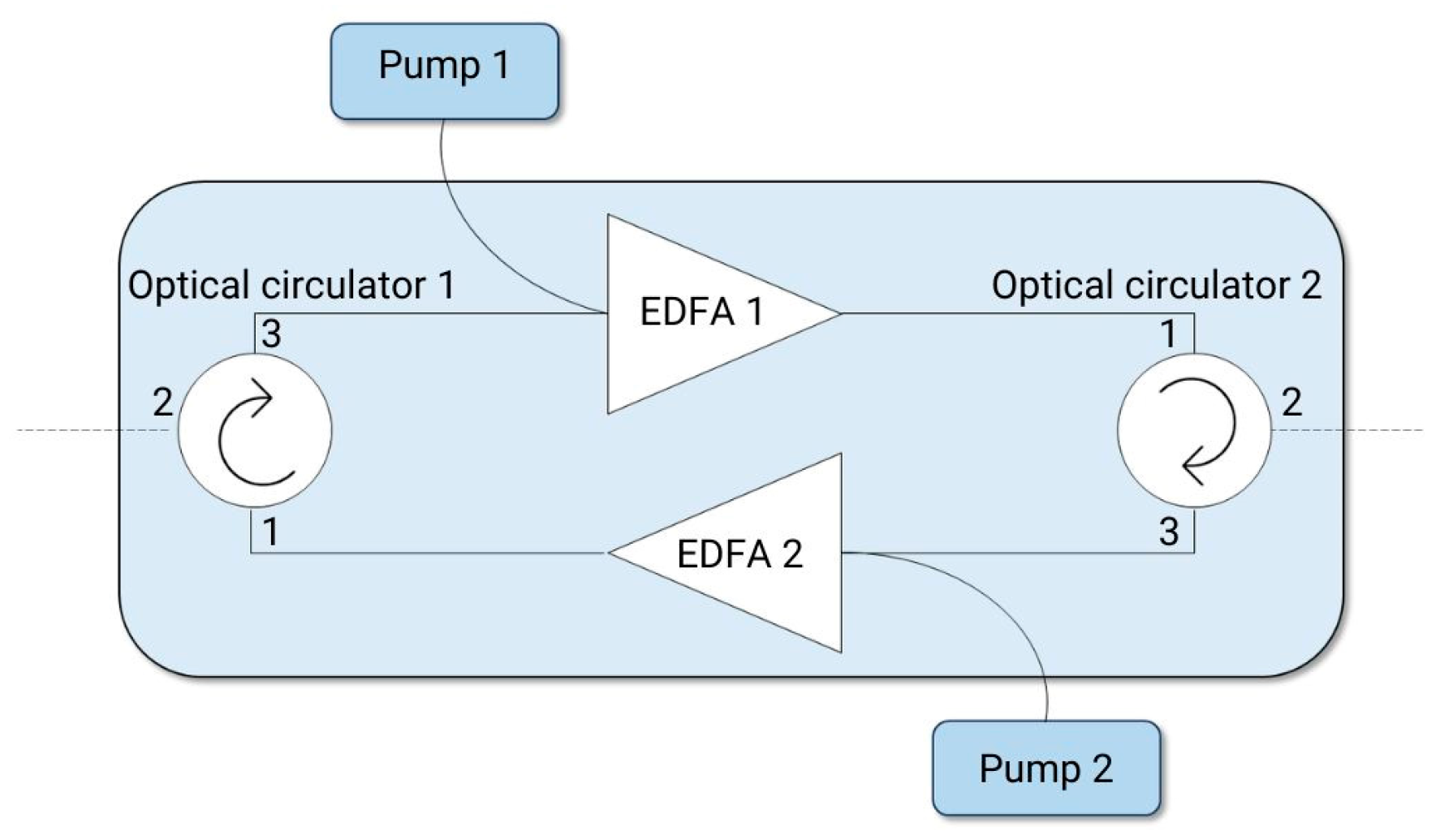

2.1. Laser Gain

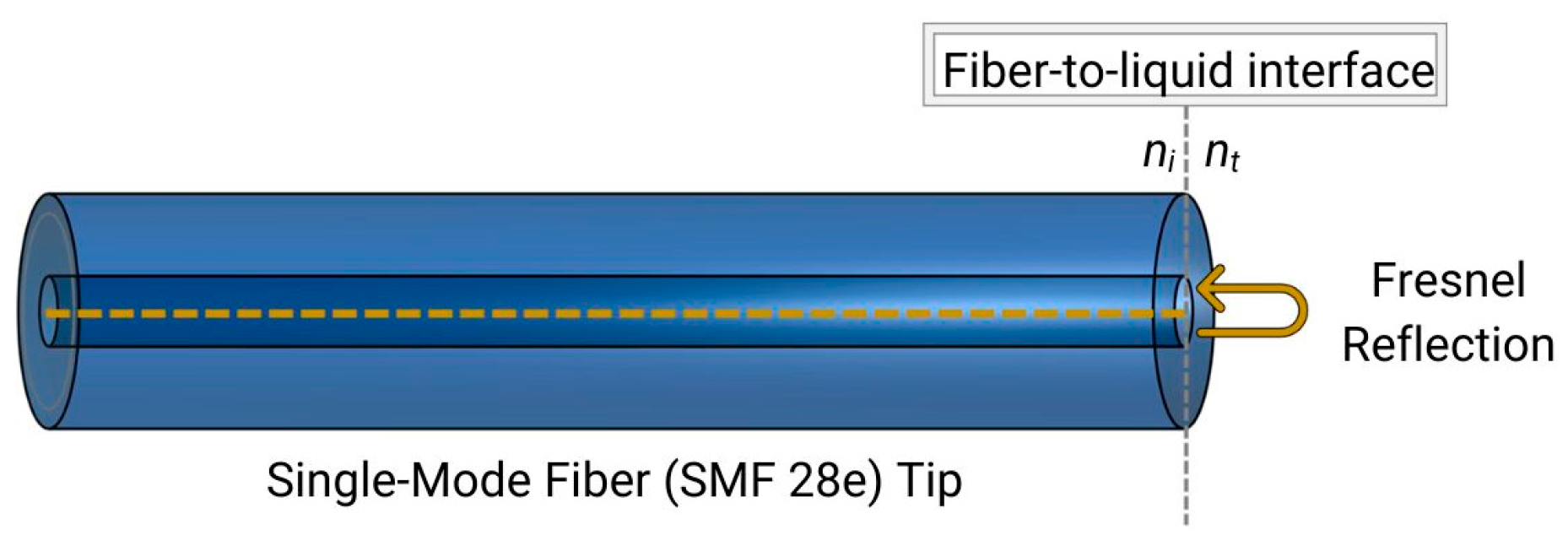

2.2. Sensing Head and Its Operation Mechanism

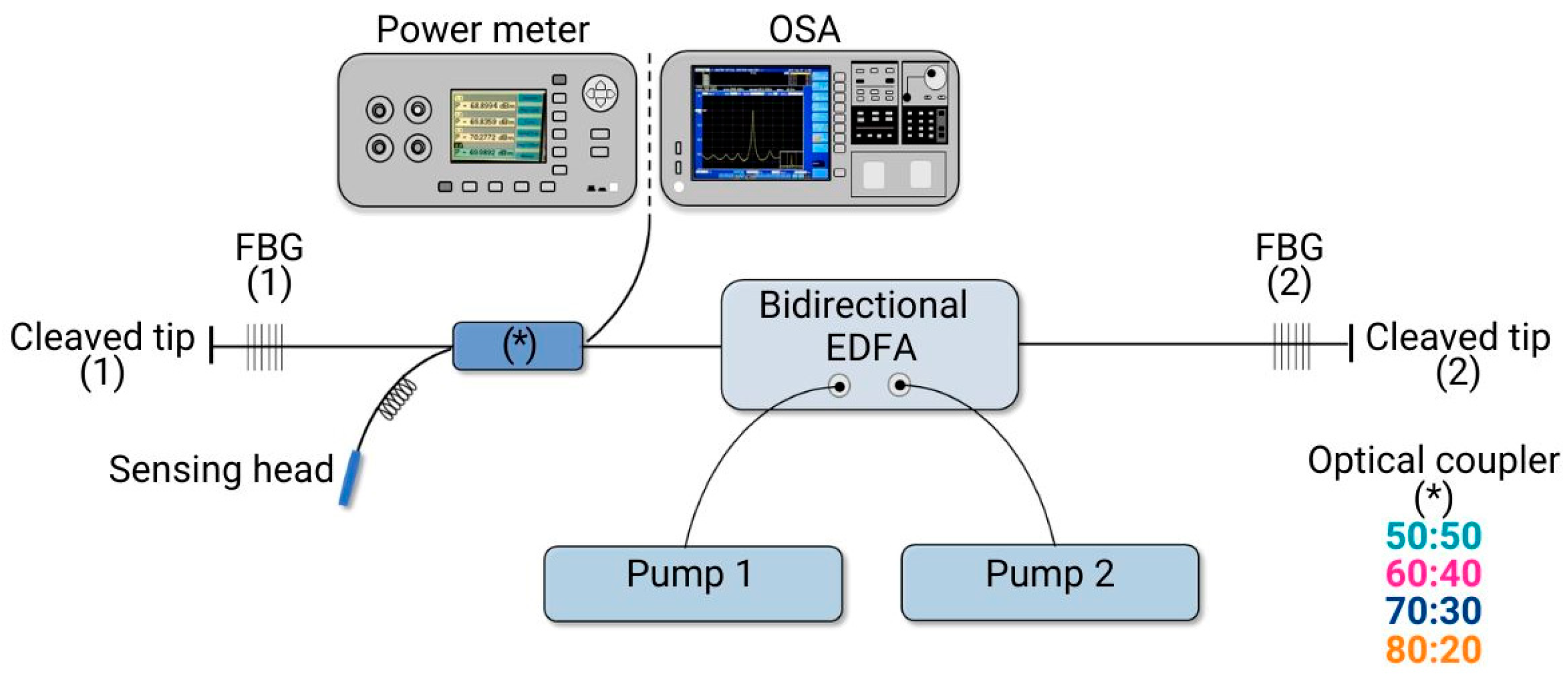

2.3. Experimental Configuration

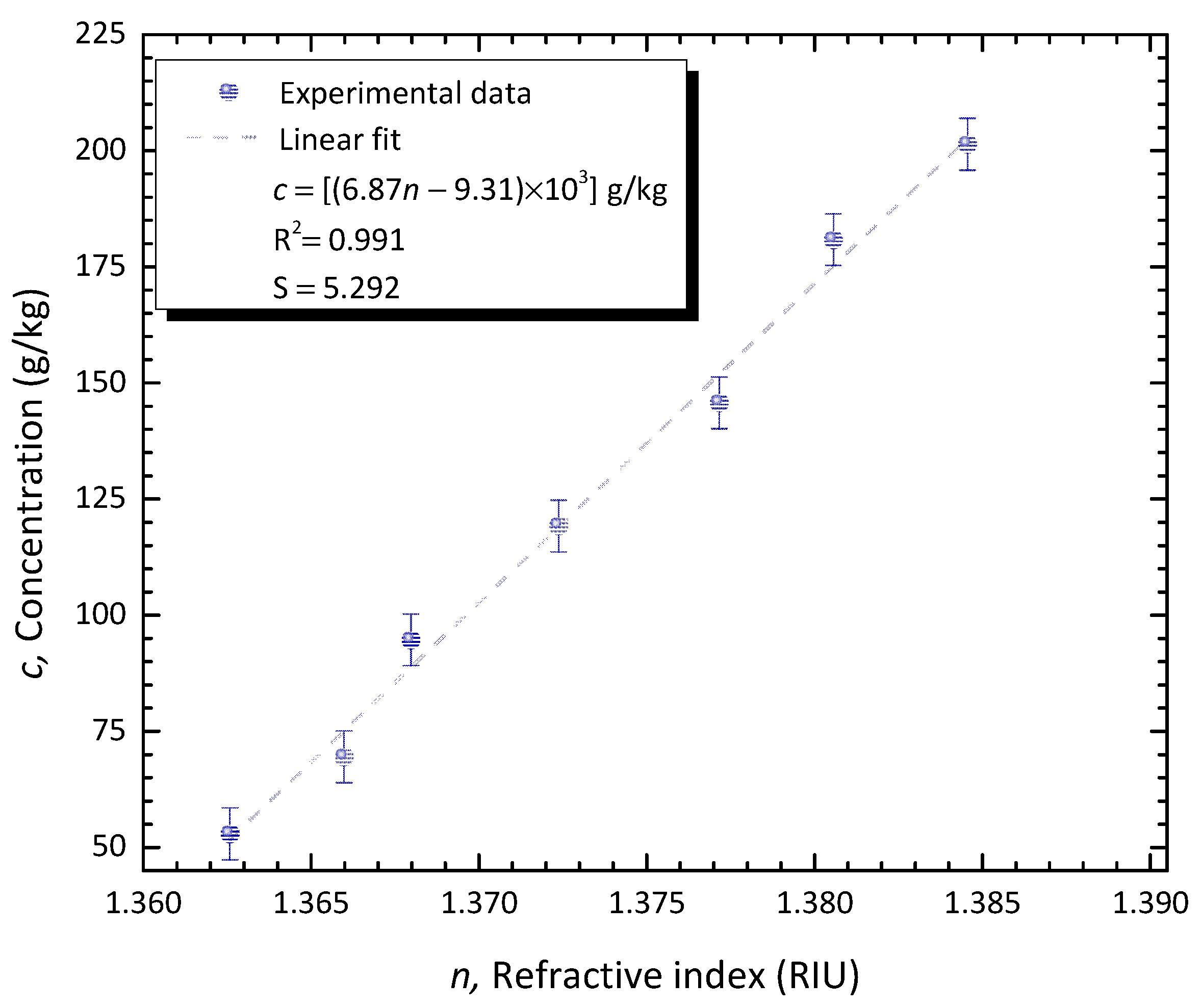

2.4. Optical Characterization of Liquid Solutions

3. Results and Discussion

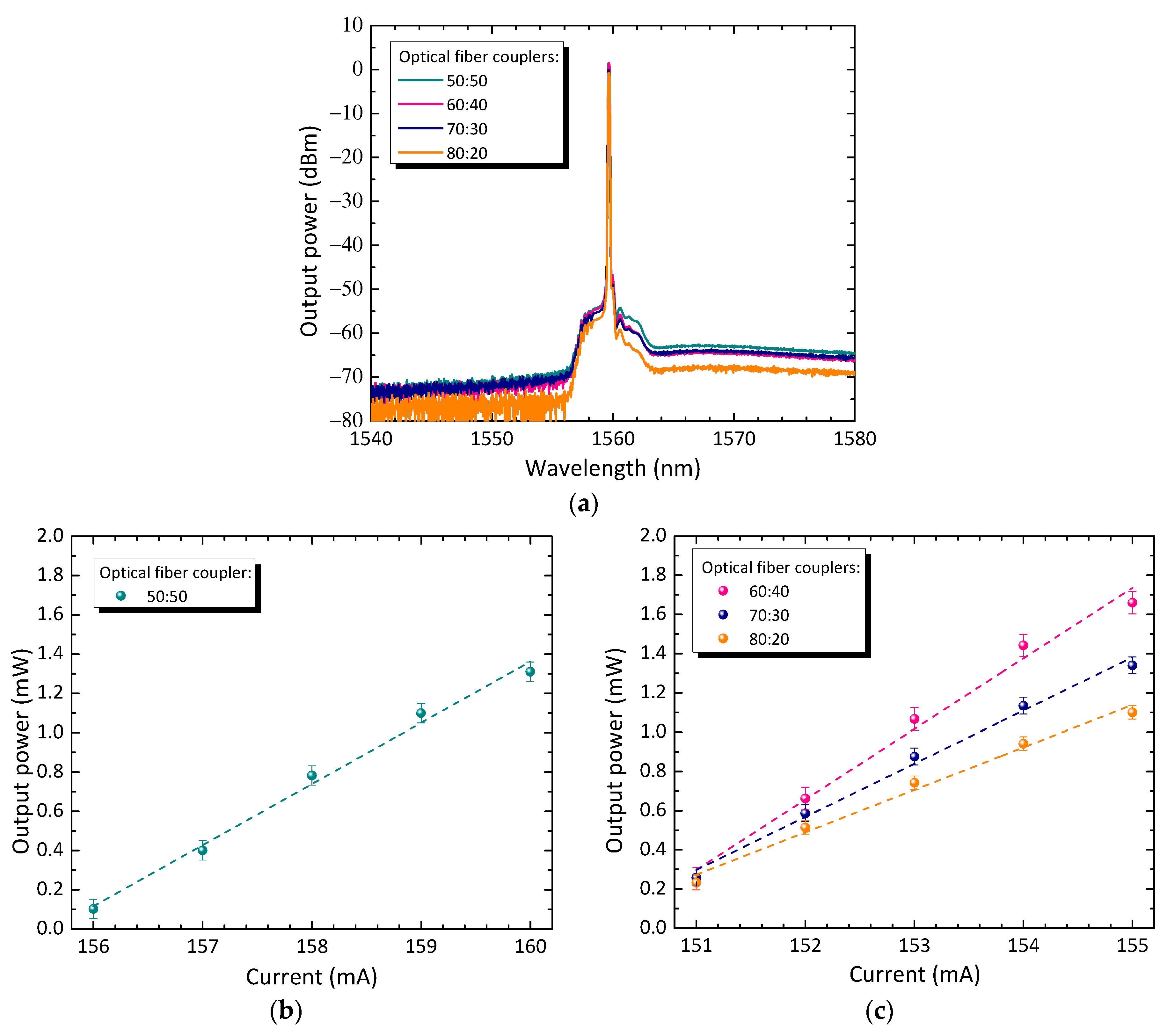

3.1. Fiber Laser System Characterization

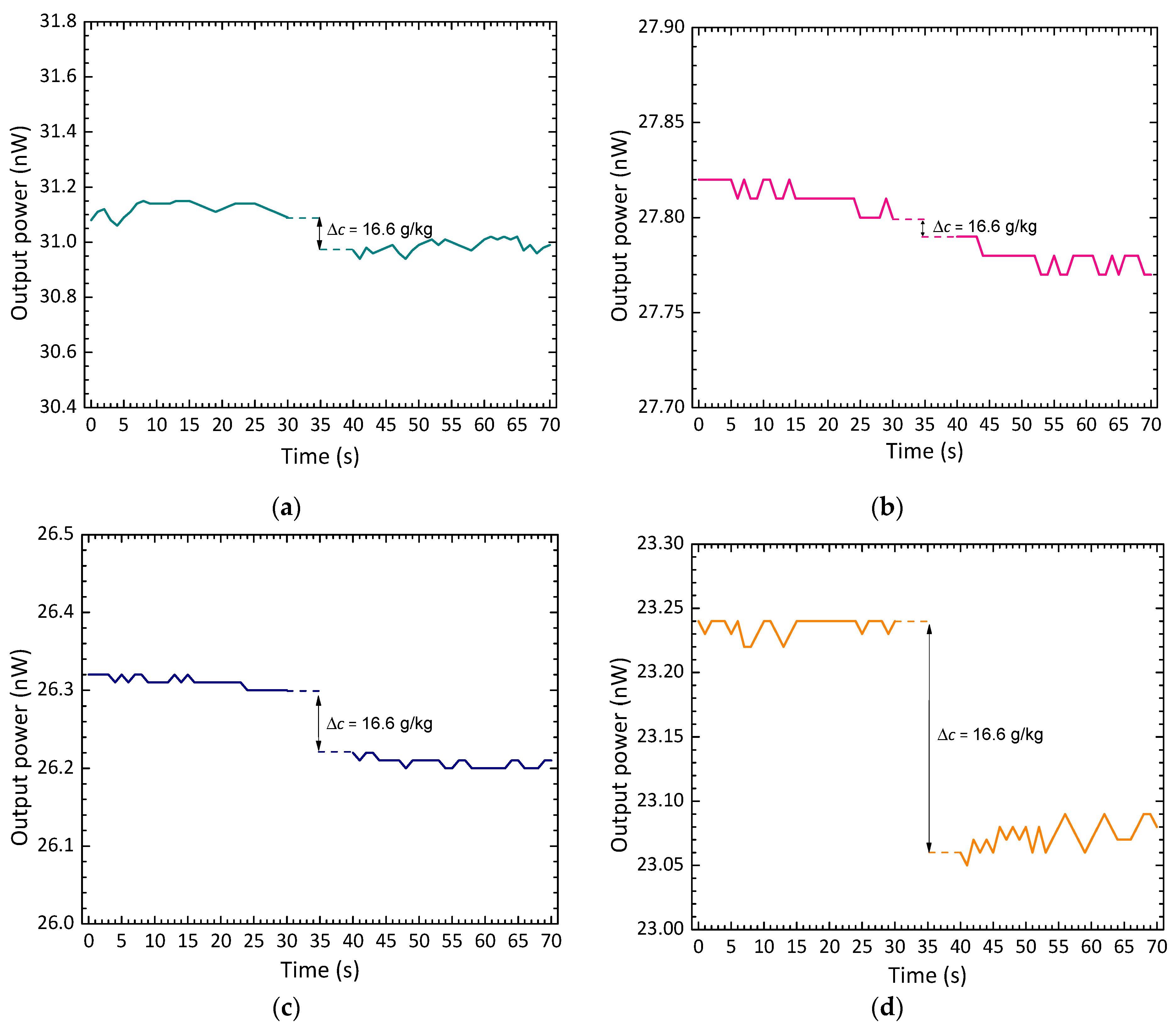

3.2. Fiber Laser Systems for Concentration Sensing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maiman, T. Stimulated Optical Radiation in Ruby. Nature 1960, 187, 493–494. [Google Scholar] [CrossRef]

- Kissinger, C.D. Fiber Optic Proximity Probe. U.S. Patent 3327584A, 27 June 1967. [Google Scholar]

- Ahmad, H.; Zulkhairi, A.S.; Azzuhri, S.R. Temperature sensor and fiber laser based on optical microfiber knot resonator. Optik 2018, 154, 294–302. [Google Scholar] [CrossRef]

- Guo, K.; He, J.; Xu, G.; Wang, Y. Dual-polarization distributed feedback fiber laser sensor based on femtosecond laser-inscribed in-fiber stressors for simultaneous strain and temperature measurements. IEEE Access 2020, 8, 97823–97829. [Google Scholar] [CrossRef]

- Jauregui-Vazquez, D.; Alvarez-Chavez, J.A.; Lozano-Hernandez, T.; Estudillo-Ayala, J.M.; Sierra-Hernandez, J.M.; Offerhaus, H.L. Fiber Laser Sensor Configurations for Refractive Index, Temperature and Strain: A Review. Photonics 2023, 10, 495. [Google Scholar] [CrossRef]

- Desurvire, E.; Simpson, J.R.; Becker, P.C. High-gain erbium-doped traveling-wave fiber amplifier. Opt. Lett. 1987, 12, 888–890. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Ngo, N.Q.; Shum, P.; Guan, B.-O.; Tam, H.-Y.; Dong, X. Concentration-induced nonuniform power in tunable erbium-doped fiber lasers. Opt. Lett. 2004, 29, 358. [Google Scholar] [CrossRef] [PubMed]

- Correia, R.; Sinha, R.; Norris, A.; Korposh, S.; Talbot, S.; Hernandez, F.U.; Morgan, S.P. Optical fiber sensing at the interface between tissue and medical device. In Proceedings of the International Conference on Biophotonics, Perth, Australia, 30 April–1 May 2017. [Google Scholar]

- Dong, X.; Ngo, N.Q.; Shum, P.; Tam, H.-Y.; Dong, X. Linear cavity erbium-doped fiber laser with over 100 nm tuning range. Opt. Express 2003, 11, 1689–1694. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, W.; Xu, T.; He, J.; Zhang, F.; Li, F. Fiber laser sensing system and its applications. Photonic Sens. 2011, 1, 43–53. [Google Scholar] [CrossRef]

- Hadeler, O.; Ibsen, M.; Zervas, M.N. Distributed-feedback fiber laser sensor for simultaneous strain and temperature measurements operating in the radio-frequency domain. Appl. Opt. 2001, 40, 3169. [Google Scholar] [CrossRef]

- Hecht, E. Optics, 5th ed.; Pearson: London, UK, 2015. [Google Scholar]

- Ryglowski, L.; Cyprych, K.; Mysliwiec, J. The differentiation procedure between amplified spontaneous emission and lasing phenomena. Opt. Commun. 2022, 510, 127939. [Google Scholar] [CrossRef]

- Soares, L.; Novais, S.; Ferreira, A.; Frazão, O.; Silva, O.S. Detection of the Crystallization Process of Paracetamol with a Multi-Mode Optical Fiber in a Reflective Configuration. Sensors 2019, 20, 87. [Google Scholar] [CrossRef] [PubMed]

| Variable | Unit | 50:50 | 60:40 | 70:30 | 80:20 |

|---|---|---|---|---|---|

| nW | 0.04 | 0.01 | 0.01 | 0.01 | |

| g/kg | 16.6 | 16.6 | 16.6 | 16.6 | |

| nW | 0.21 | 0.05 | 0.12 | 0.19 | |

| Resolution | g/kg | 6.32 | 6.64 | 2.77 | 1.75 |

| Optical Coupler | 50:50 | 60:40 | 70:30 | 80:20 |

|---|---|---|---|---|

| Lasing | ✓ | ✓ | ✓ | ✓ |

| Sensitivity [pW/(g/kg)] | ||||

| Resolution (g/kg) | 6.32 | 6.64 | 2.77 | 1.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares, L.; Perez-Herrera, R.A.; Novais, S.; Ferreira, A.; Silva, S.; Frazão, O. Linear Fiber Laser Configurations for Optical Concentration Sensing in Liquid Solutions. Photonics 2024, 11, 393. https://doi.org/10.3390/photonics11050393

Soares L, Perez-Herrera RA, Novais S, Ferreira A, Silva S, Frazão O. Linear Fiber Laser Configurations for Optical Concentration Sensing in Liquid Solutions. Photonics. 2024; 11(5):393. https://doi.org/10.3390/photonics11050393

Chicago/Turabian StyleSoares, Liliana, Rosa Ana Perez-Herrera, Susana Novais, António Ferreira, Susana Silva, and Orlando Frazão. 2024. "Linear Fiber Laser Configurations for Optical Concentration Sensing in Liquid Solutions" Photonics 11, no. 5: 393. https://doi.org/10.3390/photonics11050393

APA StyleSoares, L., Perez-Herrera, R. A., Novais, S., Ferreira, A., Silva, S., & Frazão, O. (2024). Linear Fiber Laser Configurations for Optical Concentration Sensing in Liquid Solutions. Photonics, 11(5), 393. https://doi.org/10.3390/photonics11050393