Uniform Lighting of High-Power LEDs at a Short Distance to Plants for Energy-Saving and High-Density Indoor Farming

Abstract

1. Introduction

2. Methods and Designs

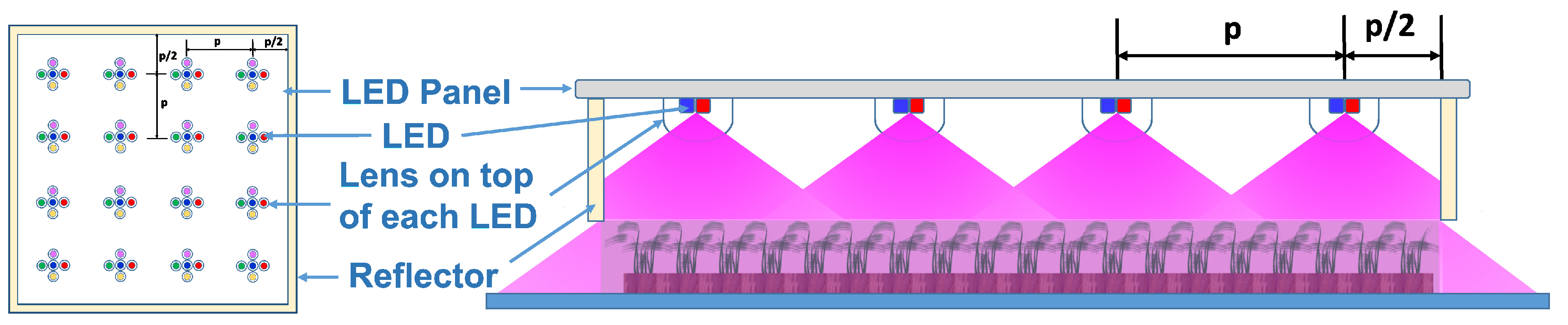

2.1. Our Solution for Uniform LED Lighting

- LEDs are arranged on an LED panel as an array of units, with each unit consisting of at least one LED or multiple LEDs at different wavelengths.

- Reflectors with 100% reflectance (i.e., mirrors) are placed vertically at half of the LED array pitch to the nearest LEDs. The reflectors eliminate the loss of photons escaping from the sides of the panel and avoid non-uniformity lighting.

- A dome lens is attached to each LED. The dome lens is formed by an outer hemisphere transparent material and an internal semi-ellipsoidal cavity. The dome lens widens the beam angle of each LED.

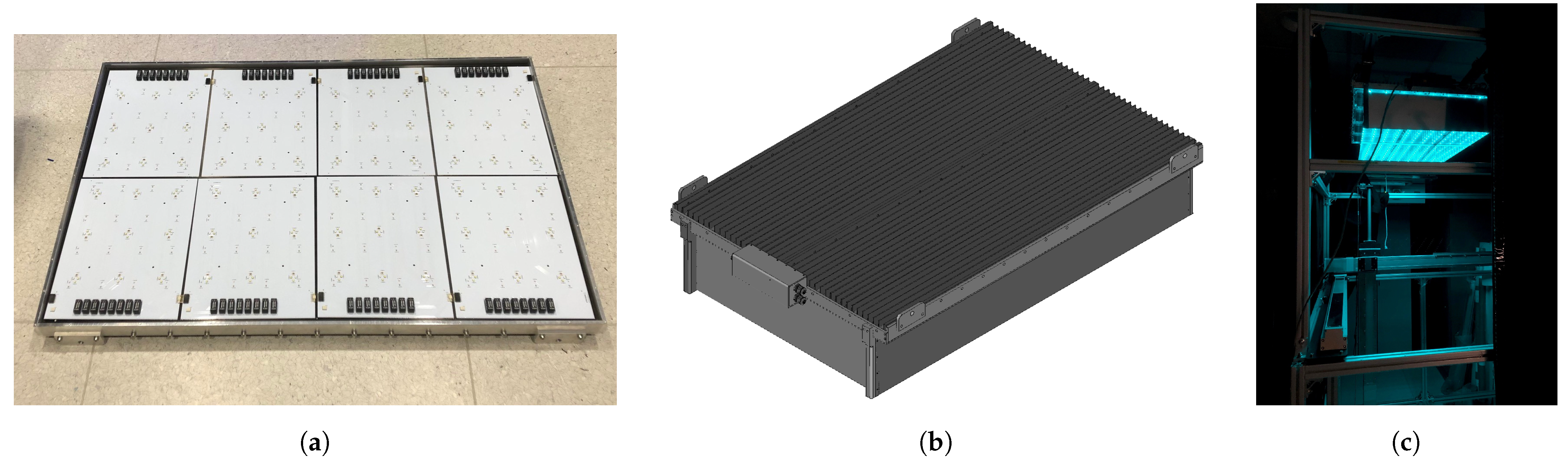

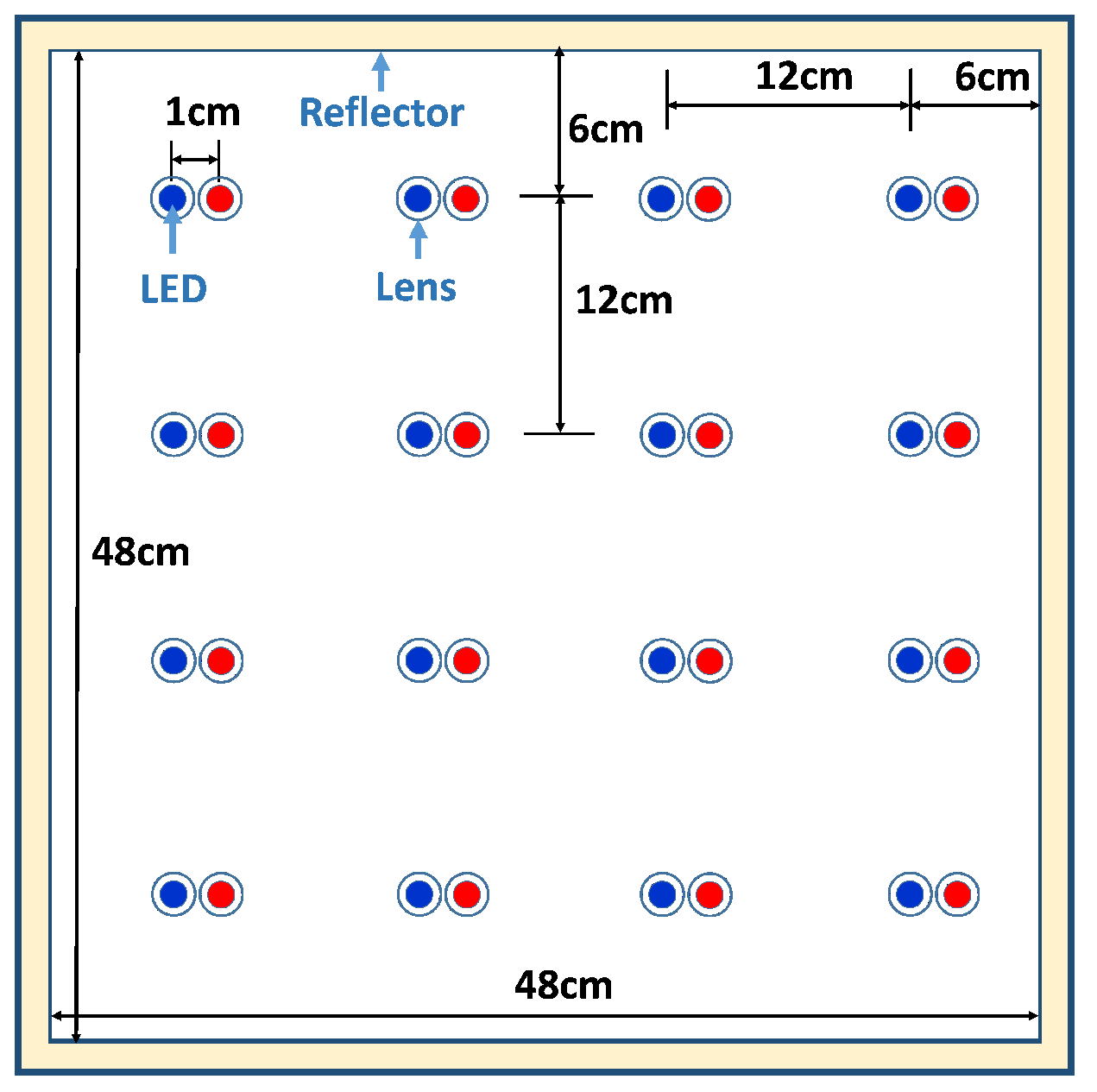

2.2. Design, Fabrication, and Characterization of the LED Panel for Uniformity Test

3. Results and Discussion

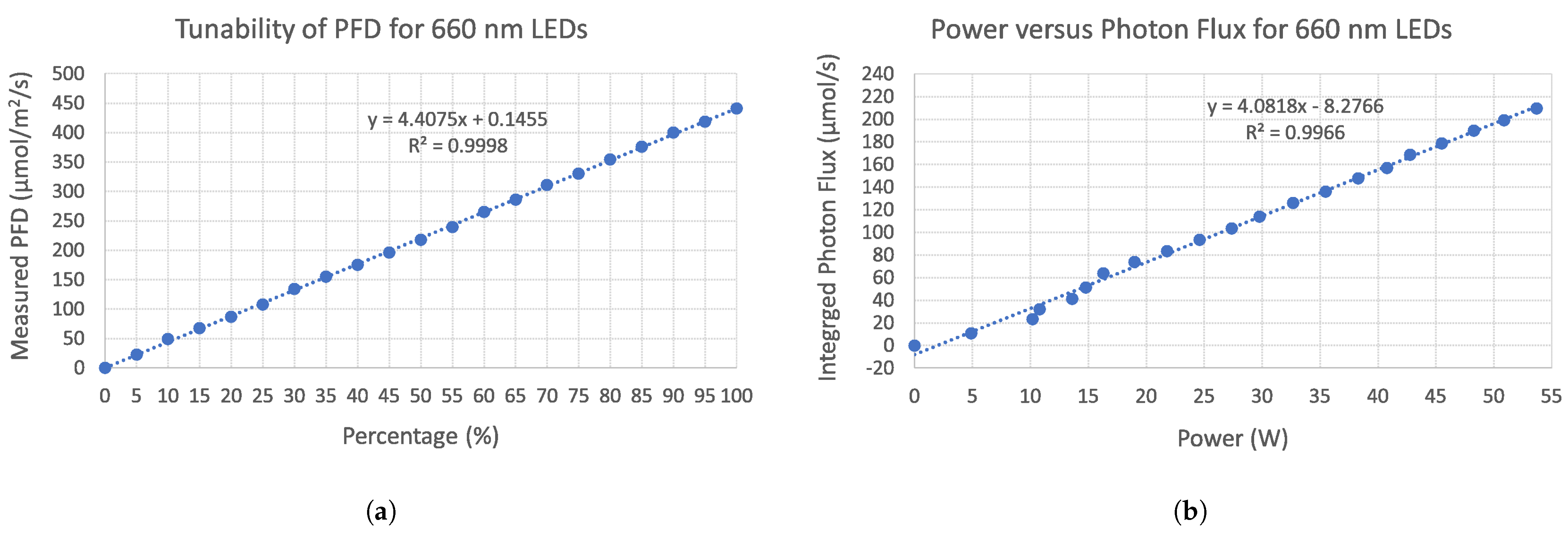

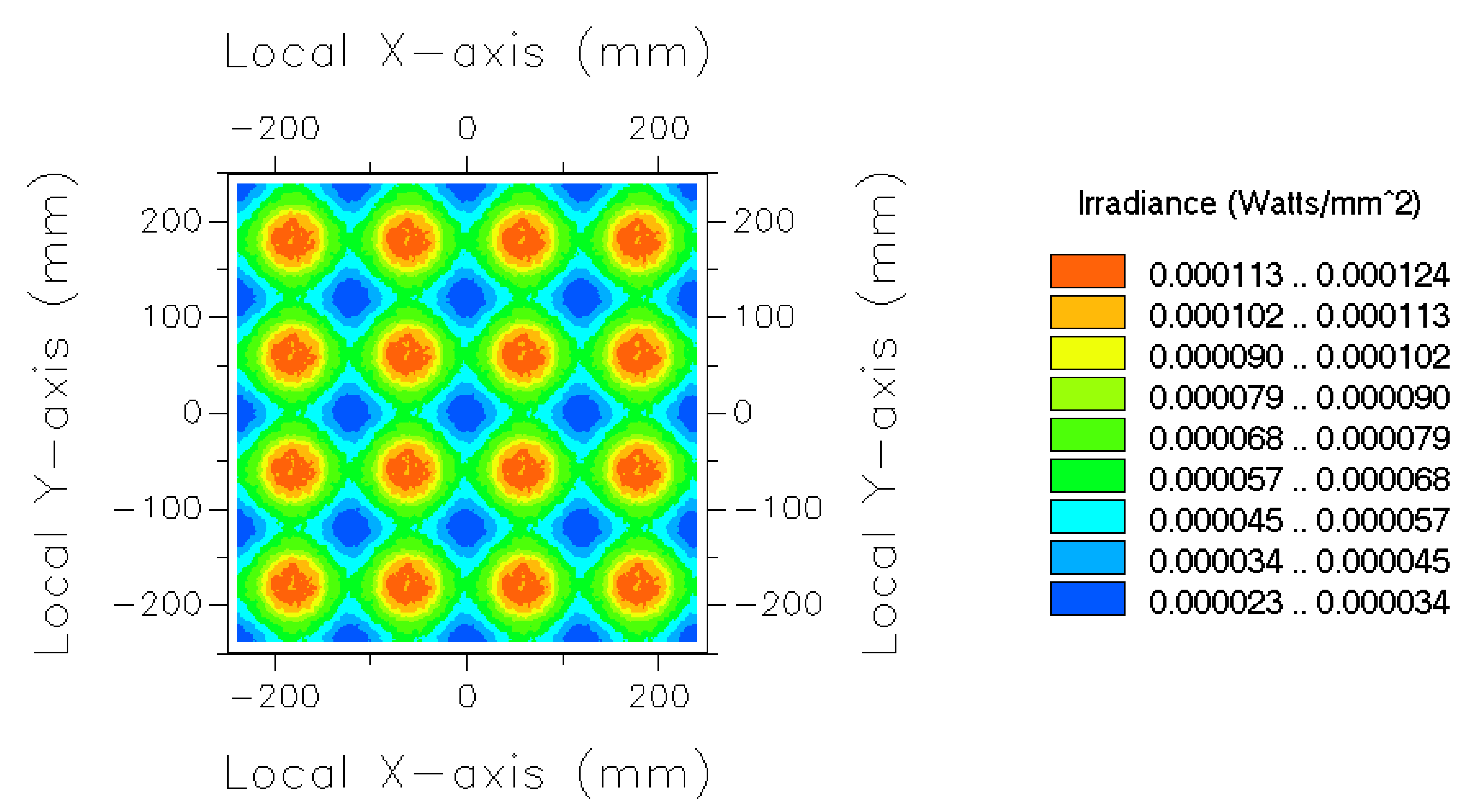

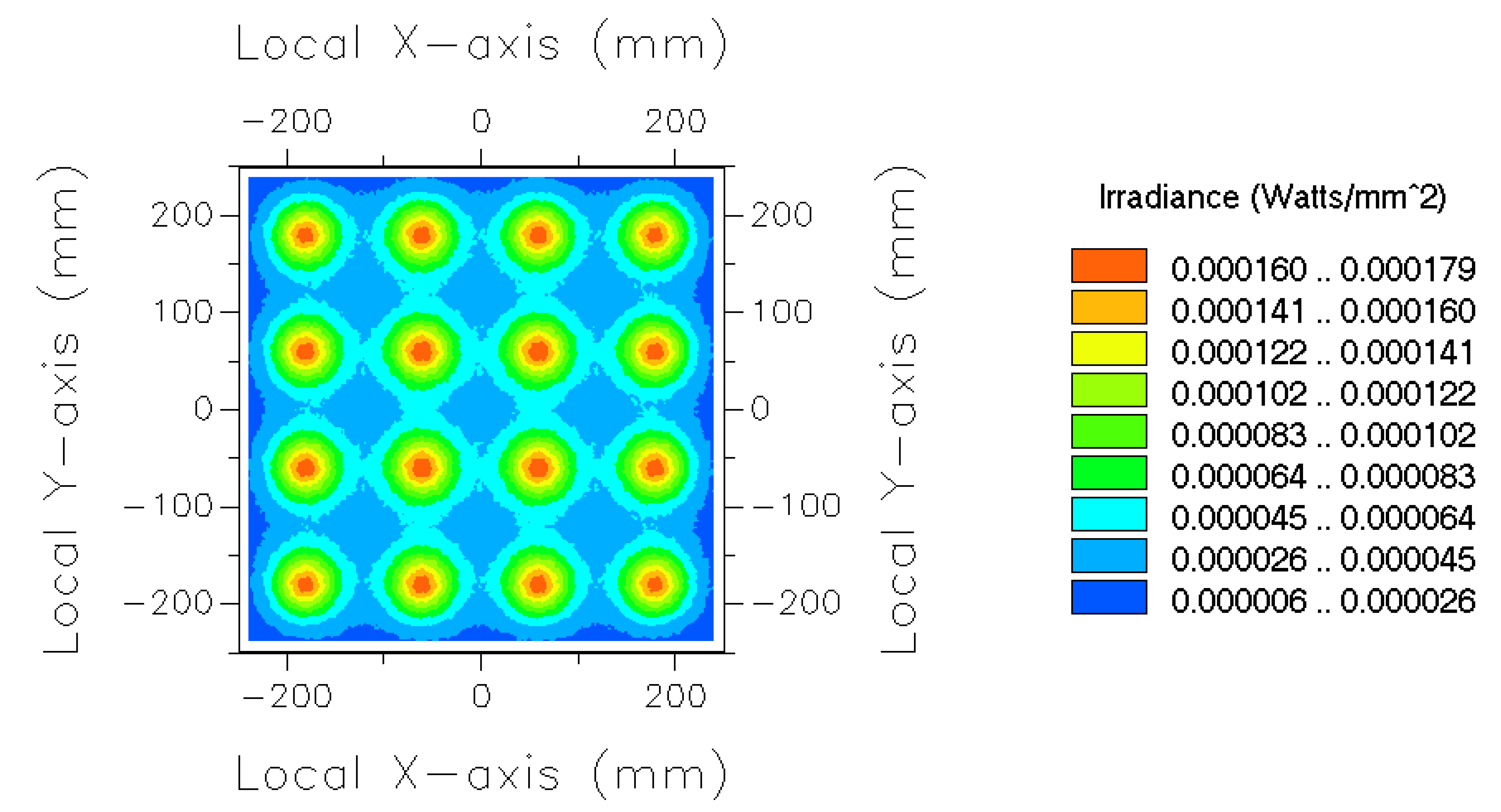

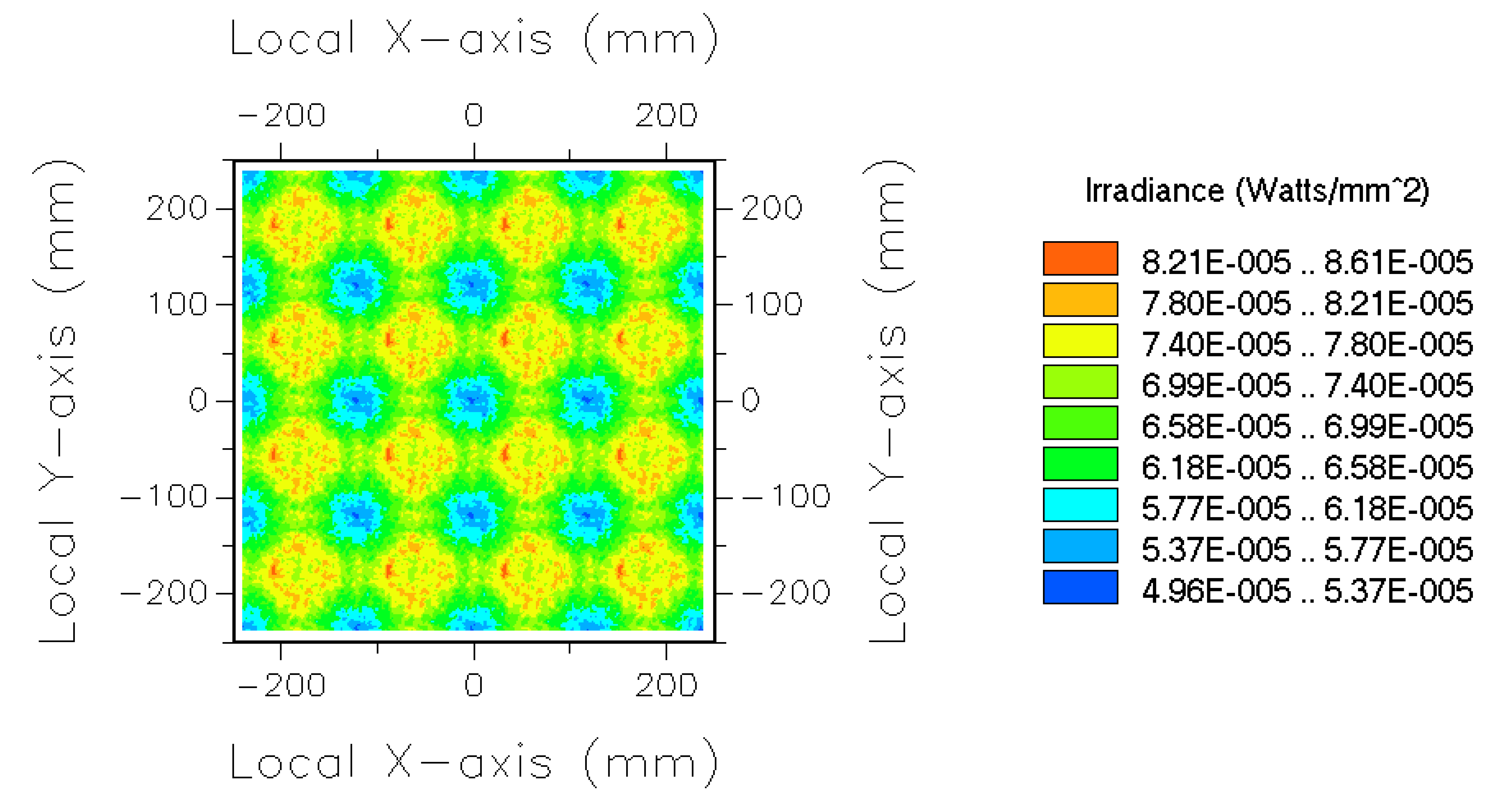

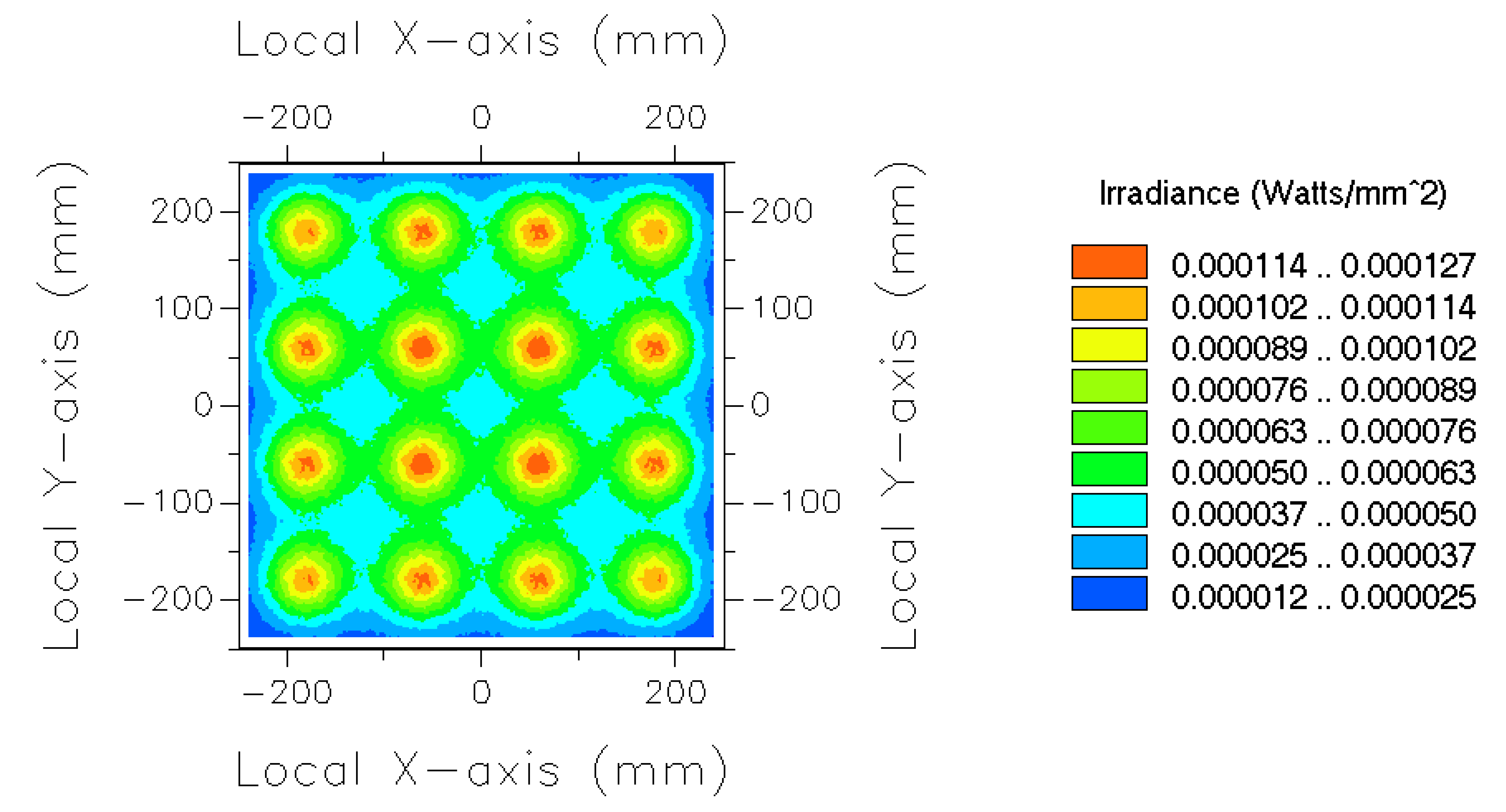

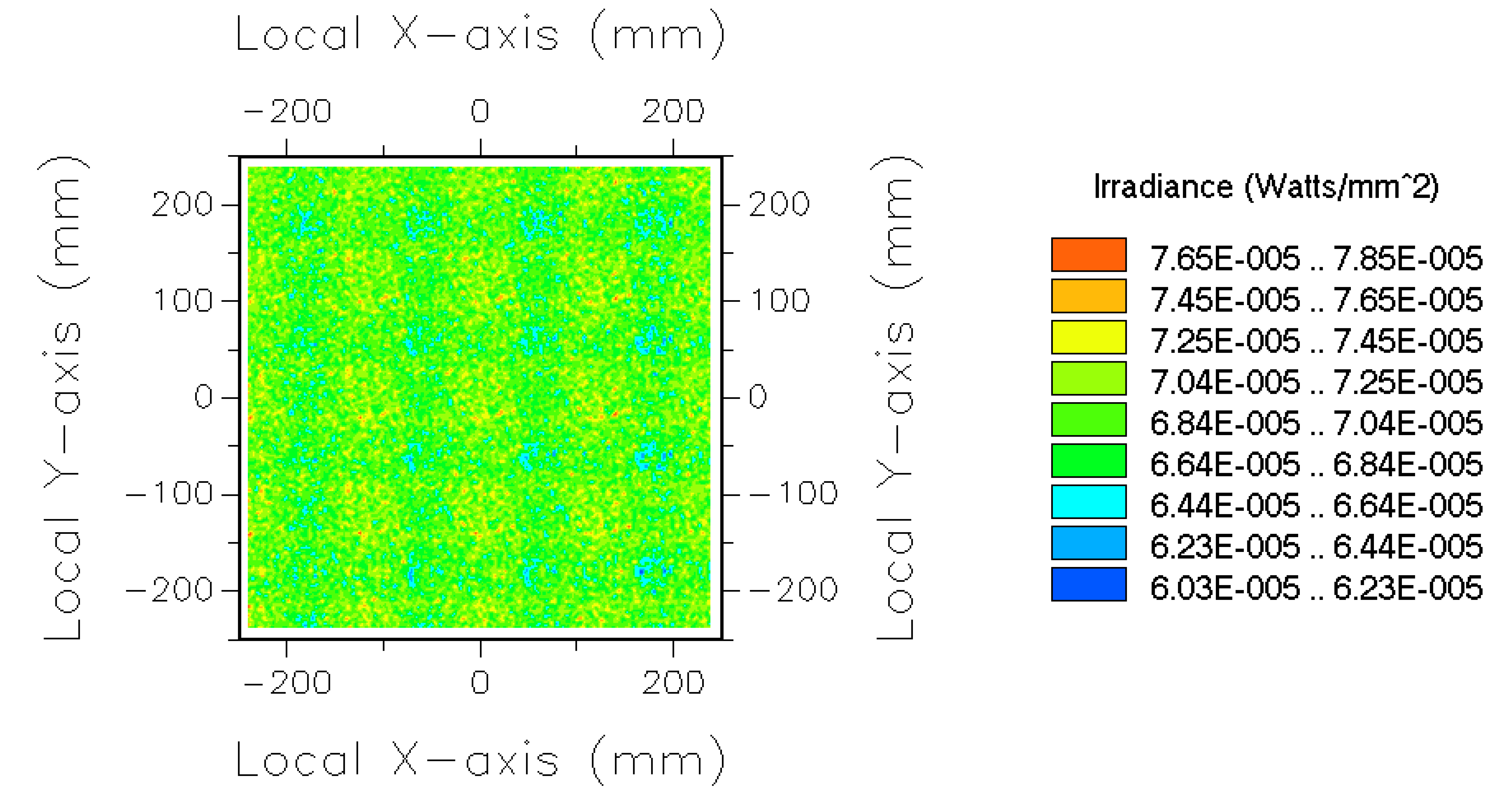

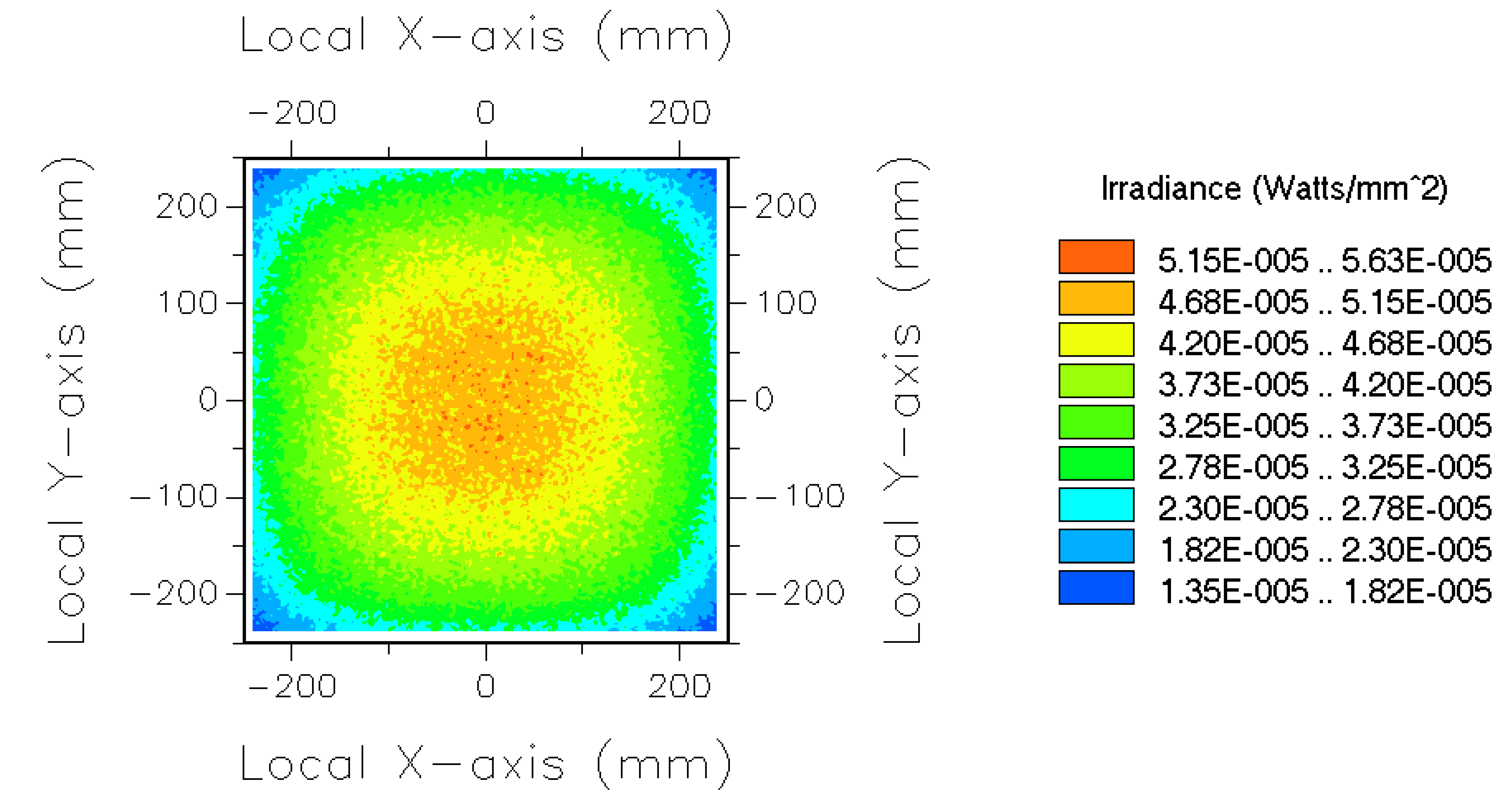

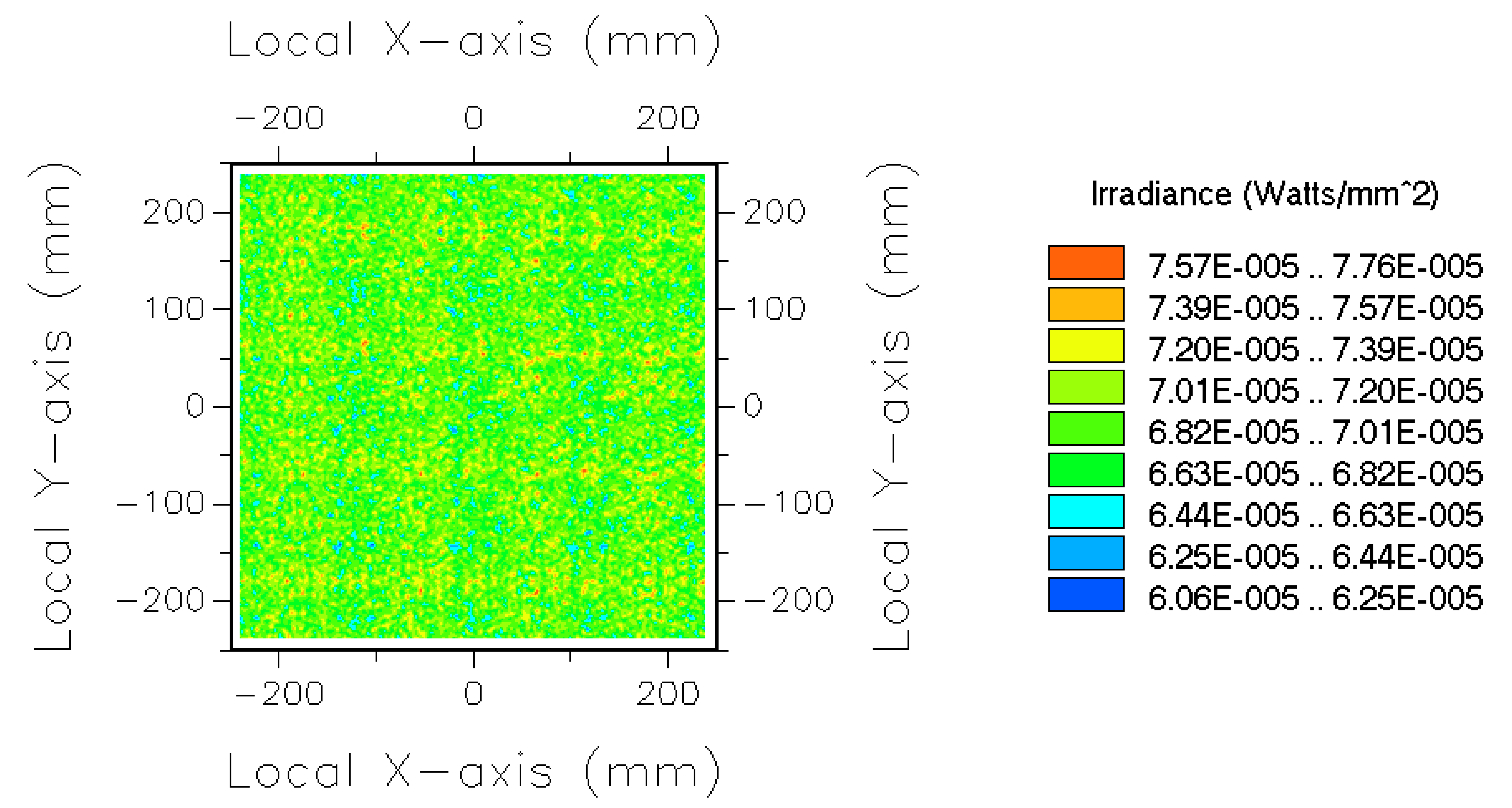

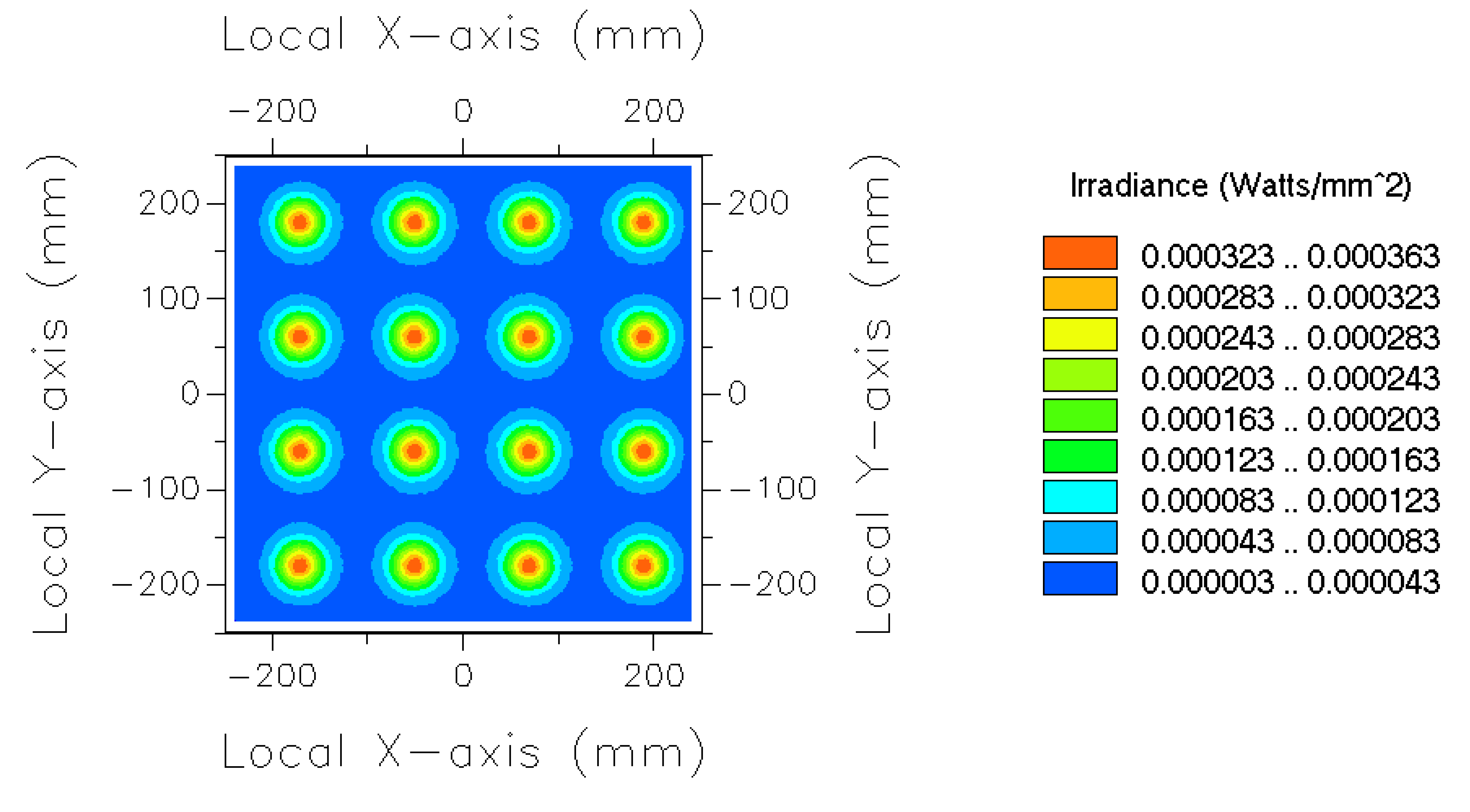

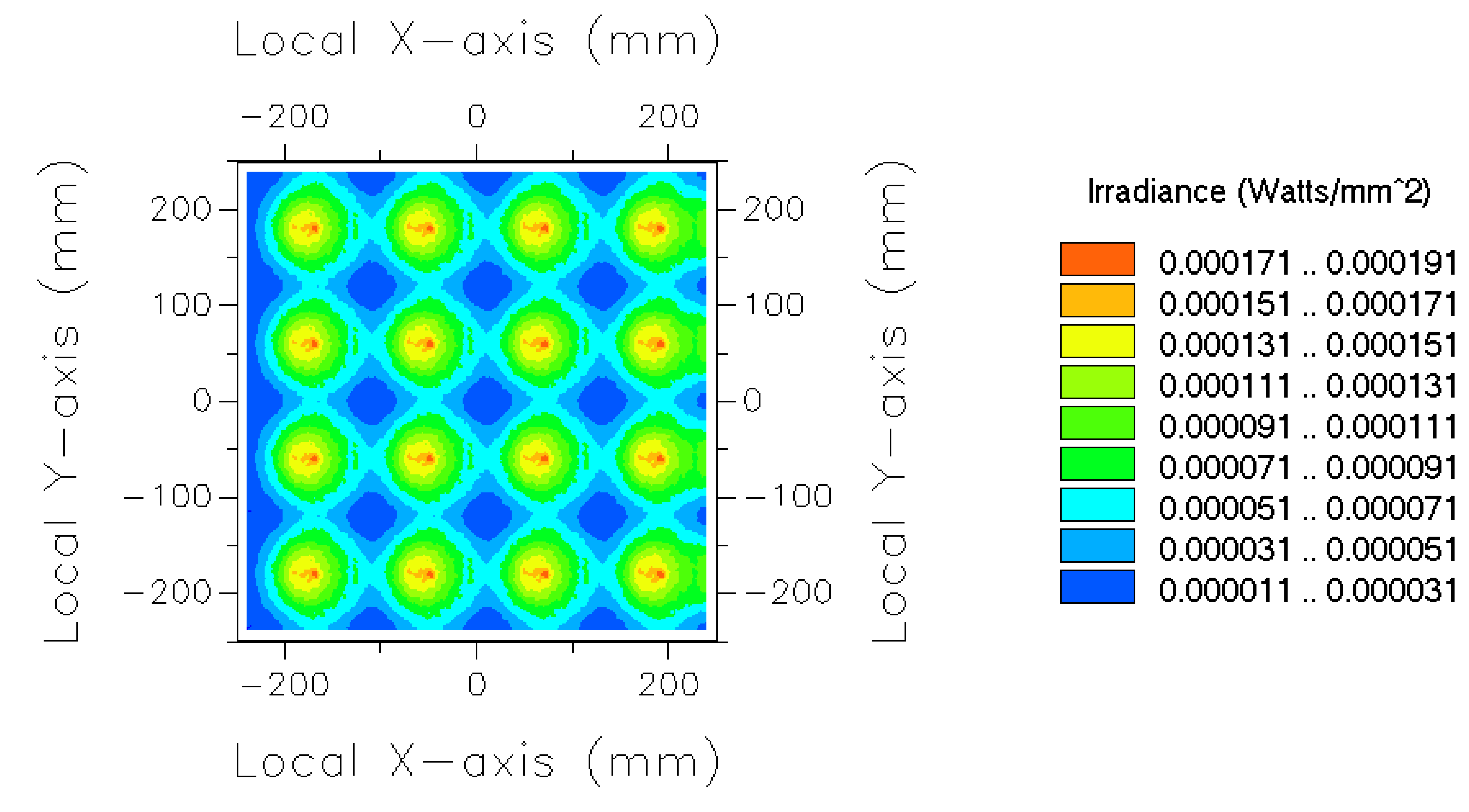

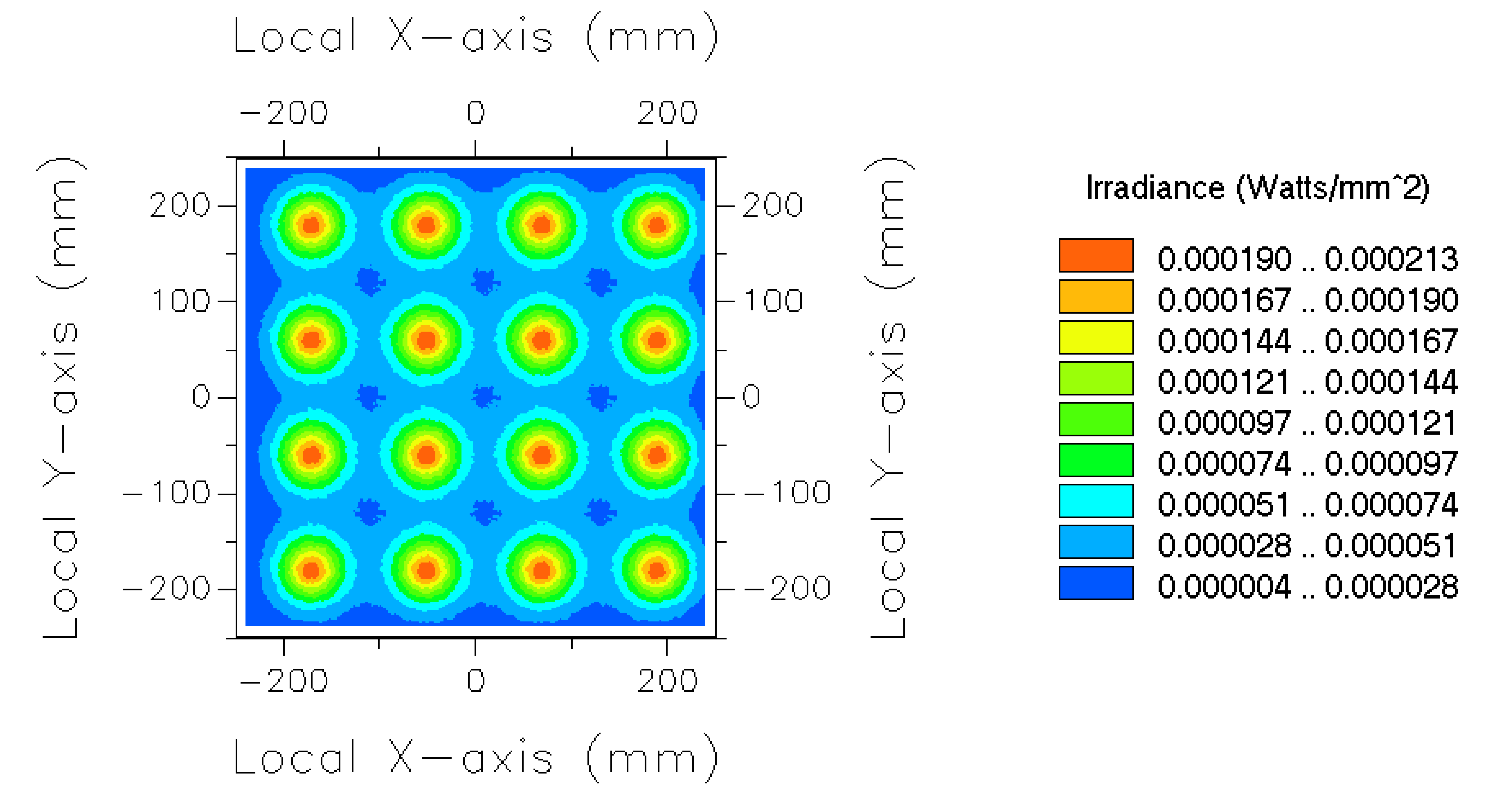

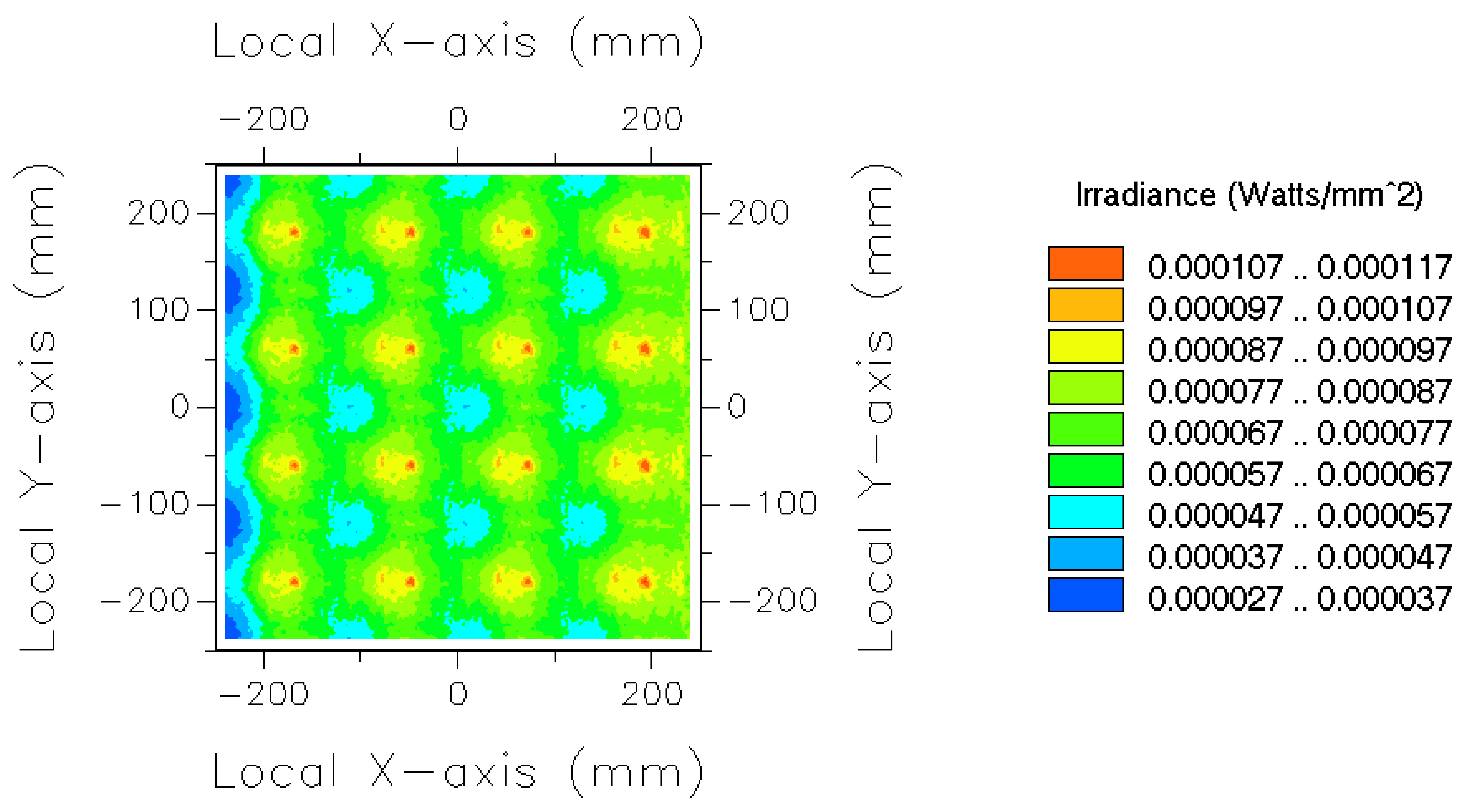

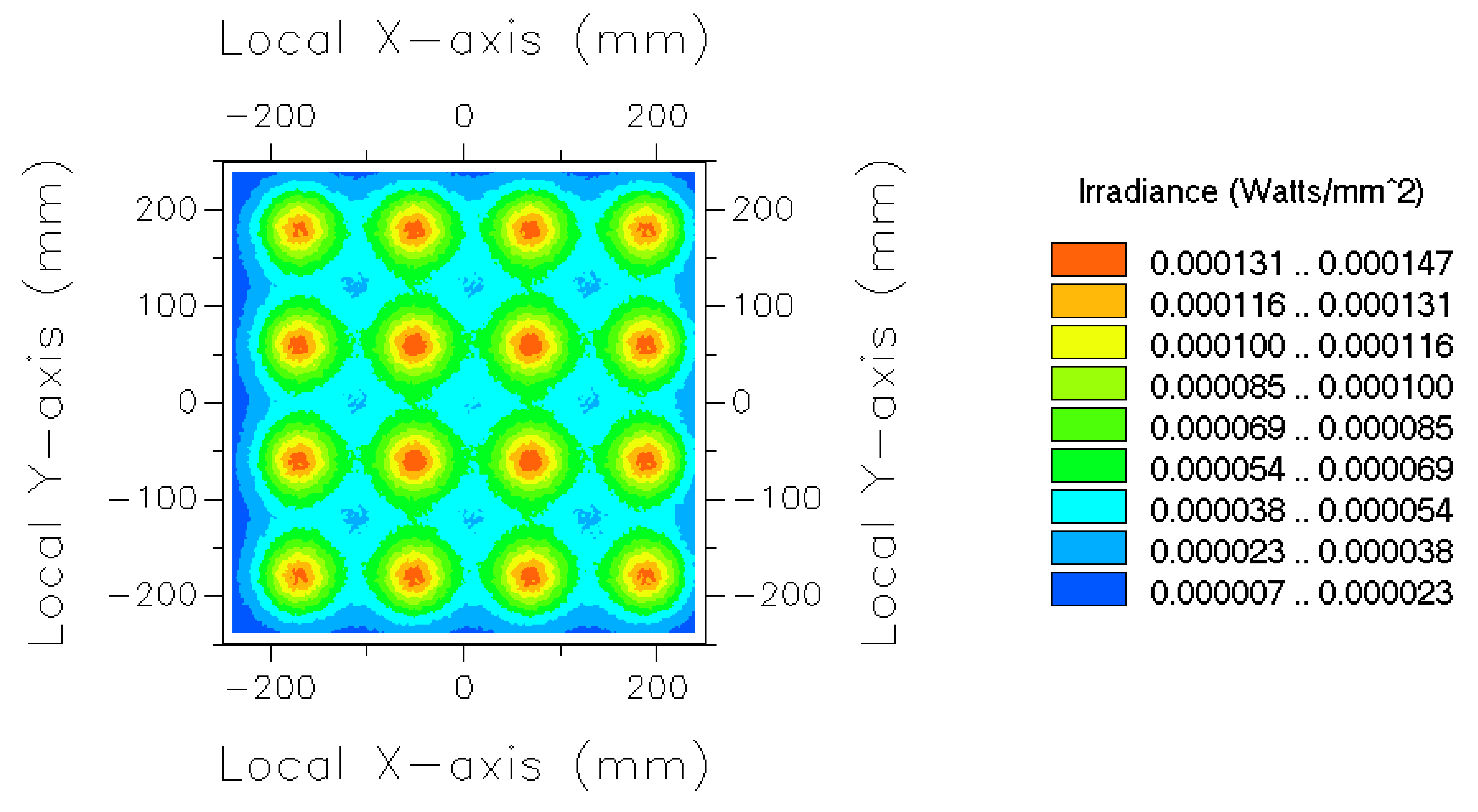

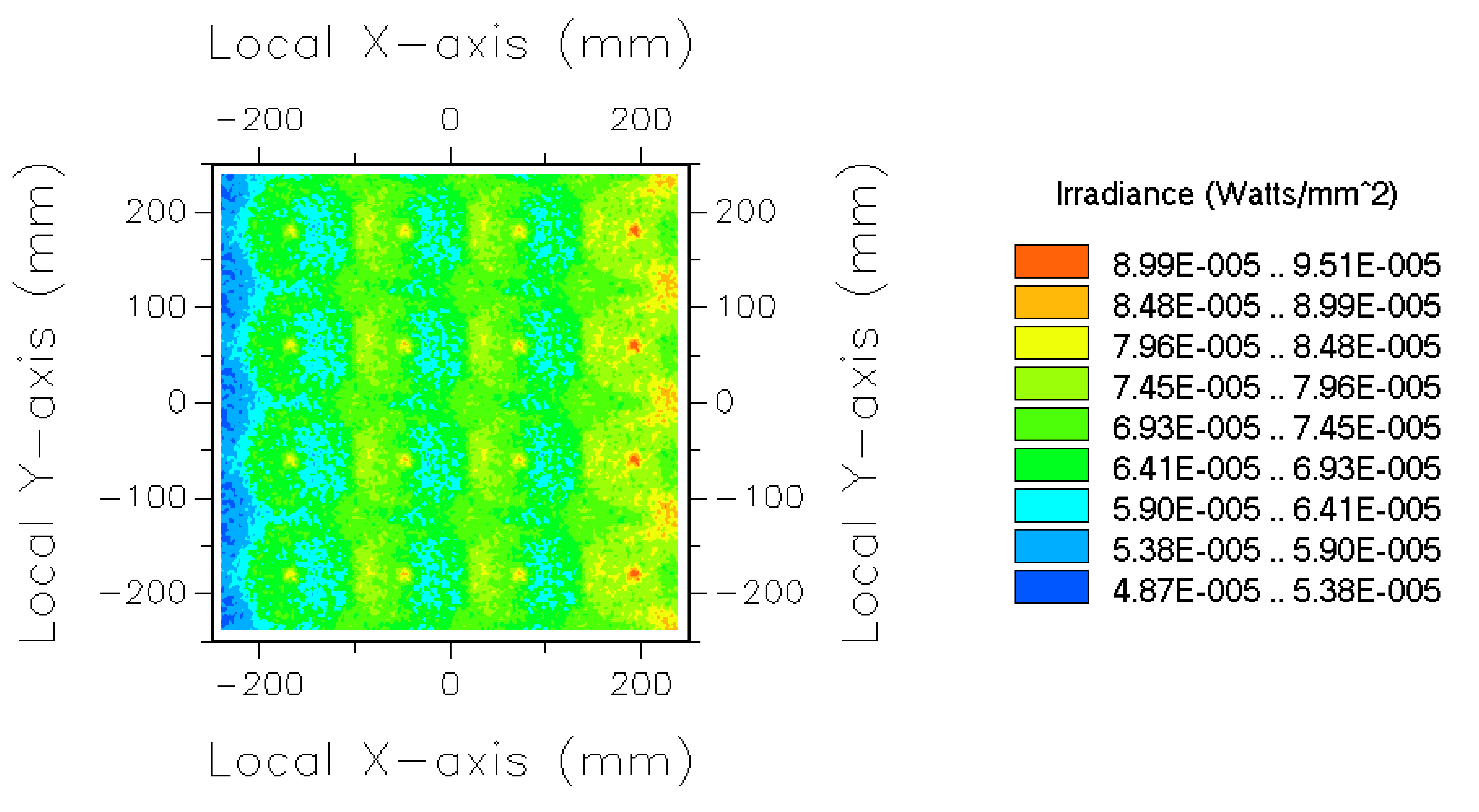

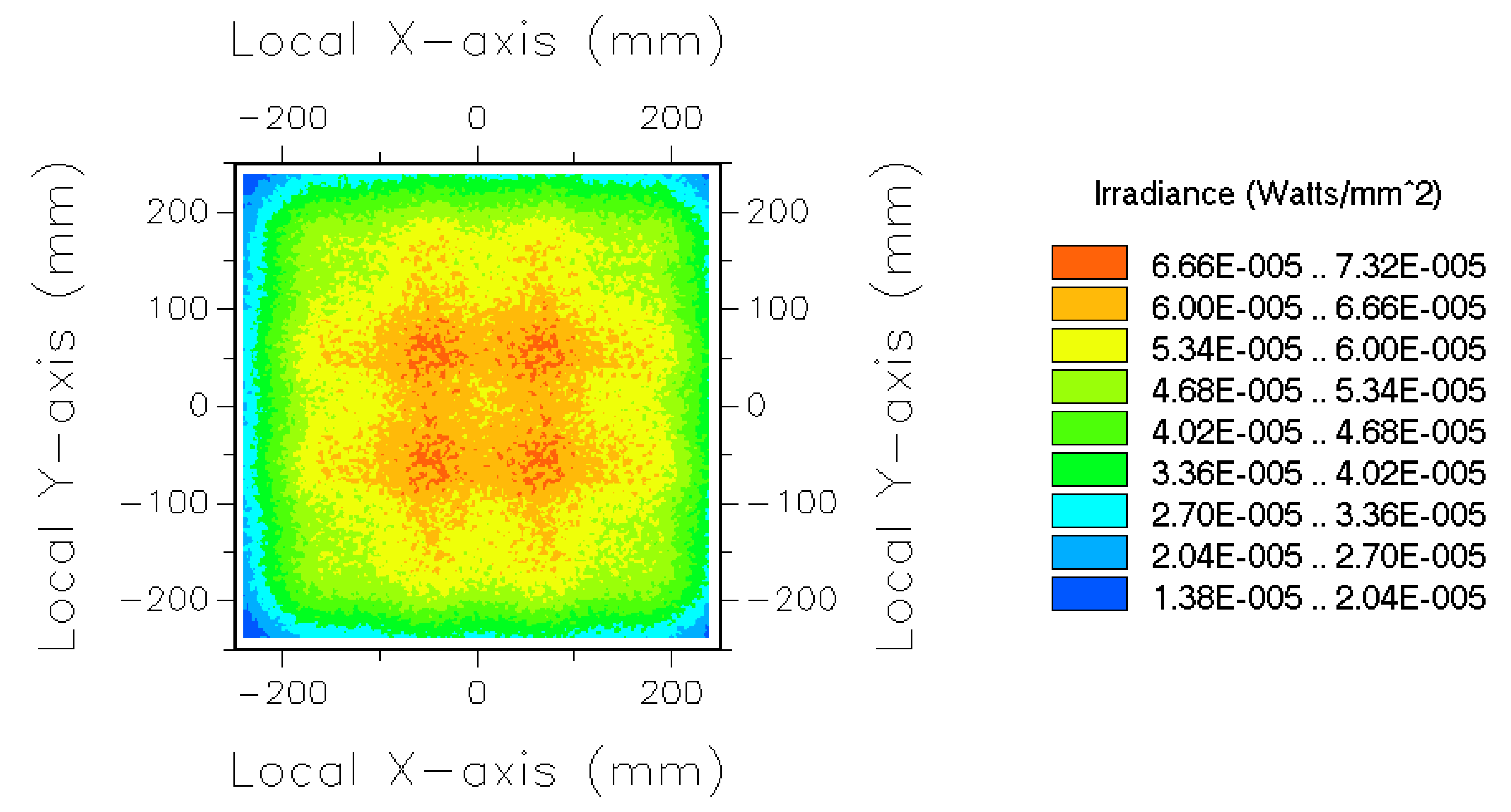

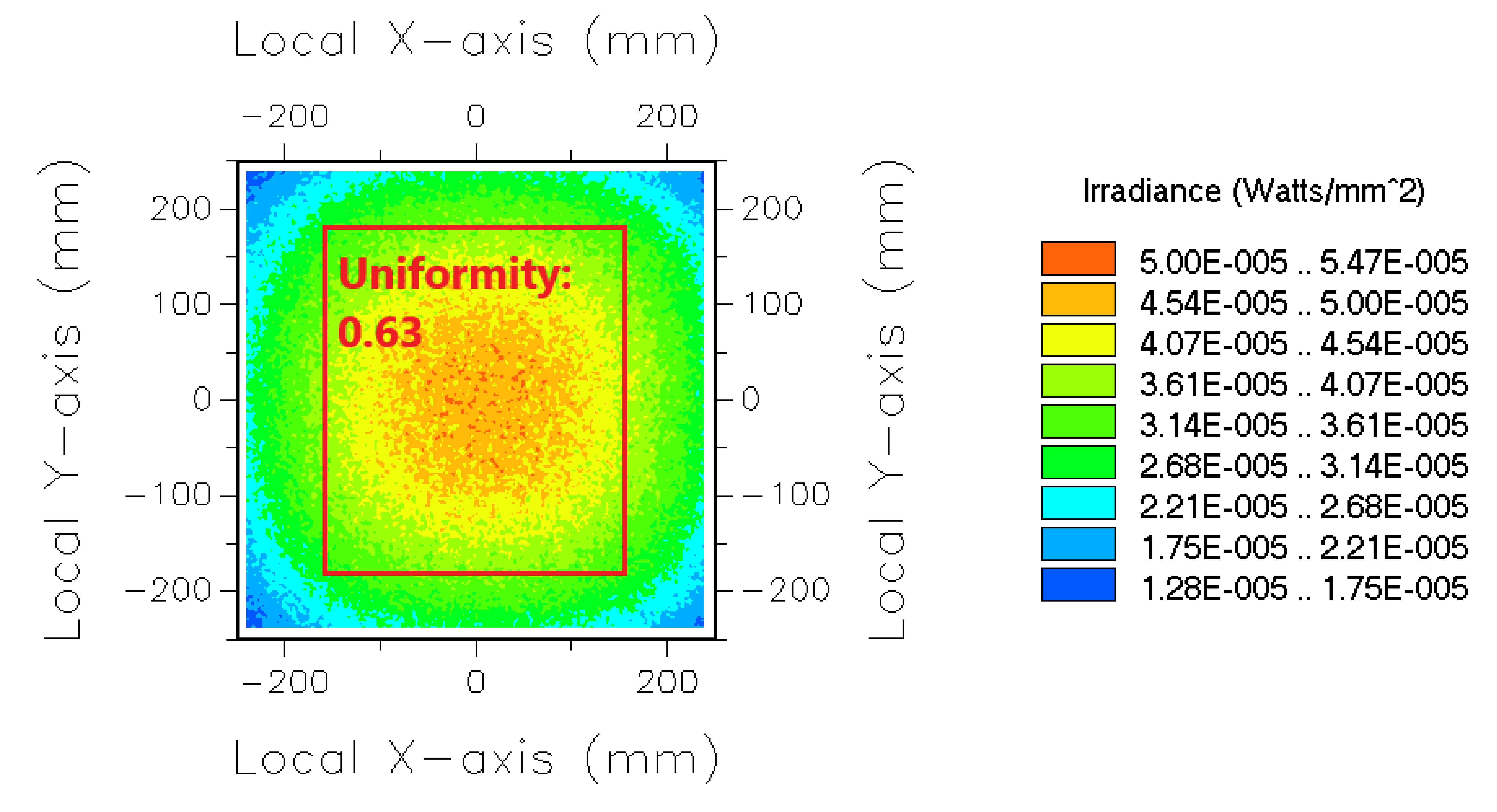

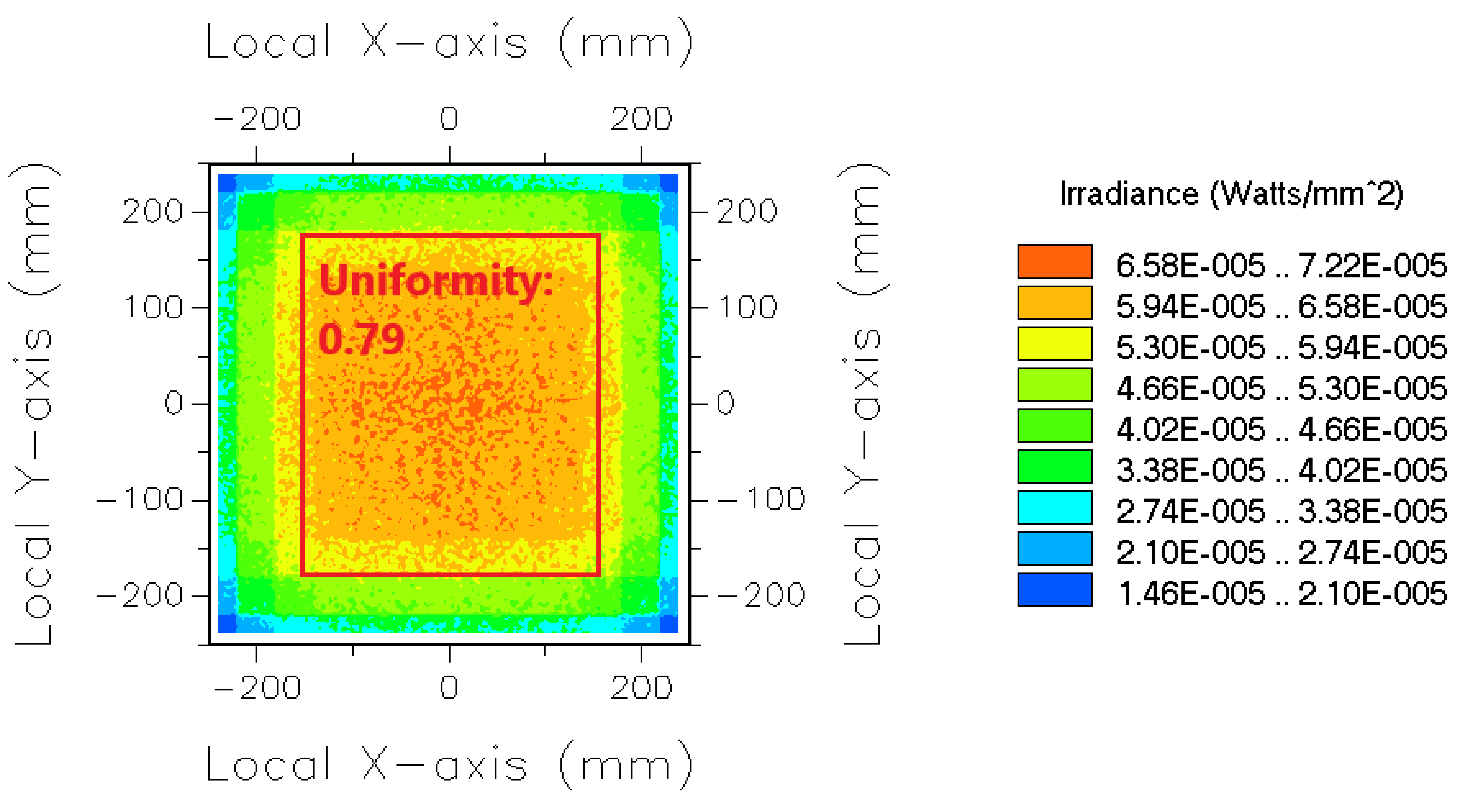

3.1. Light Uniformity and PFD Simulated for a 4 × 4 LED Array

3.2. LEDs with Different Pitch on the Same Sized Panel

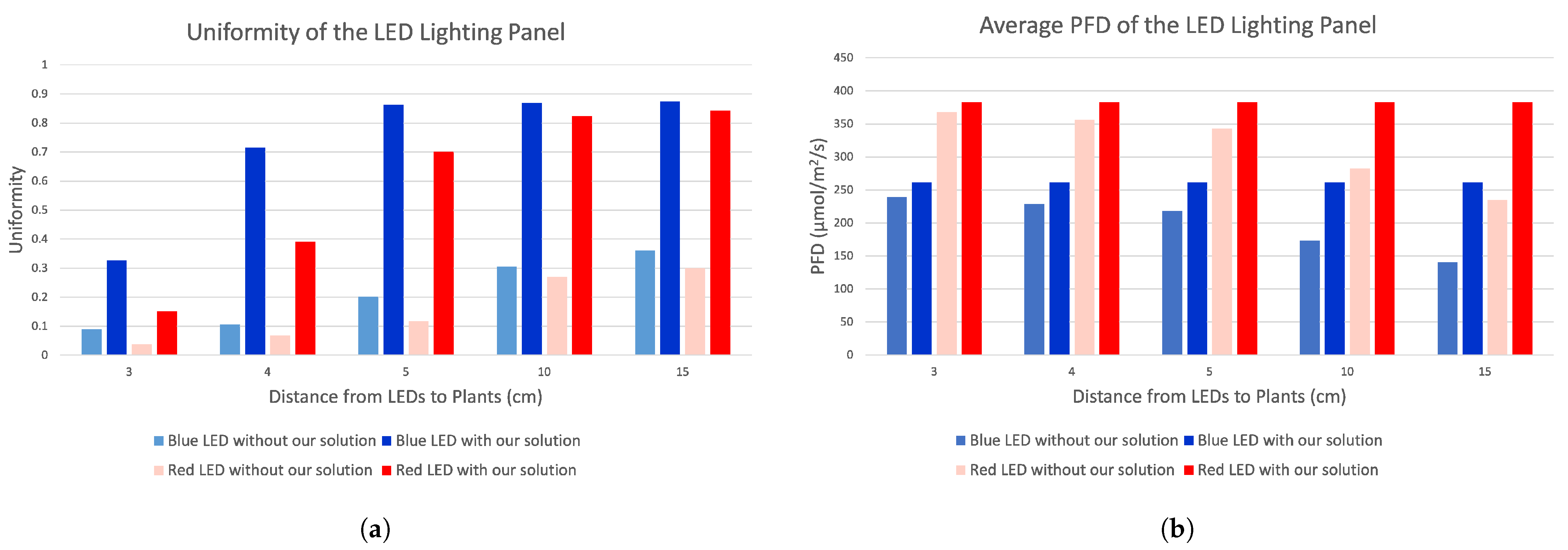

3.3. Light Uniformity Measured by the Fabricated LED Panel

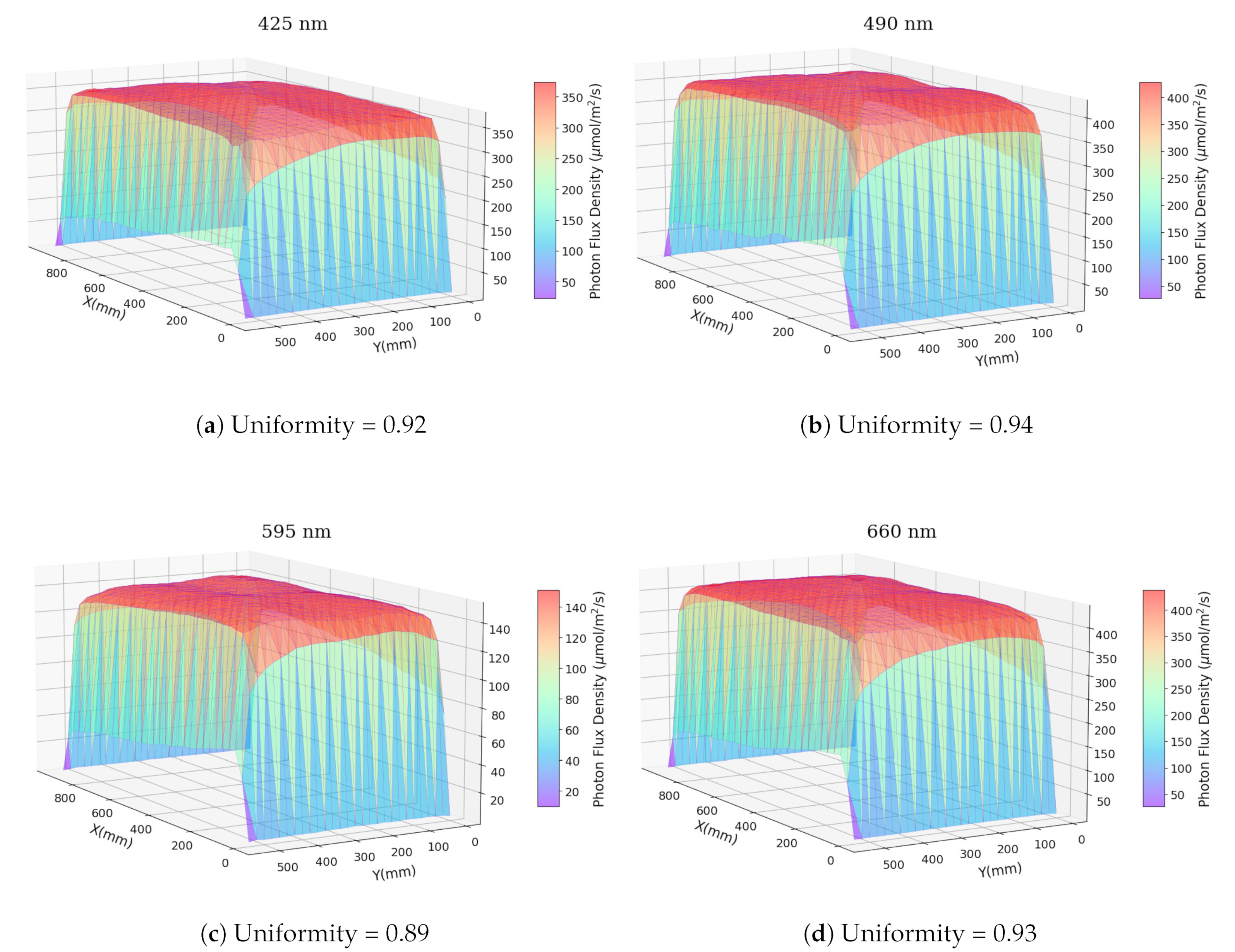

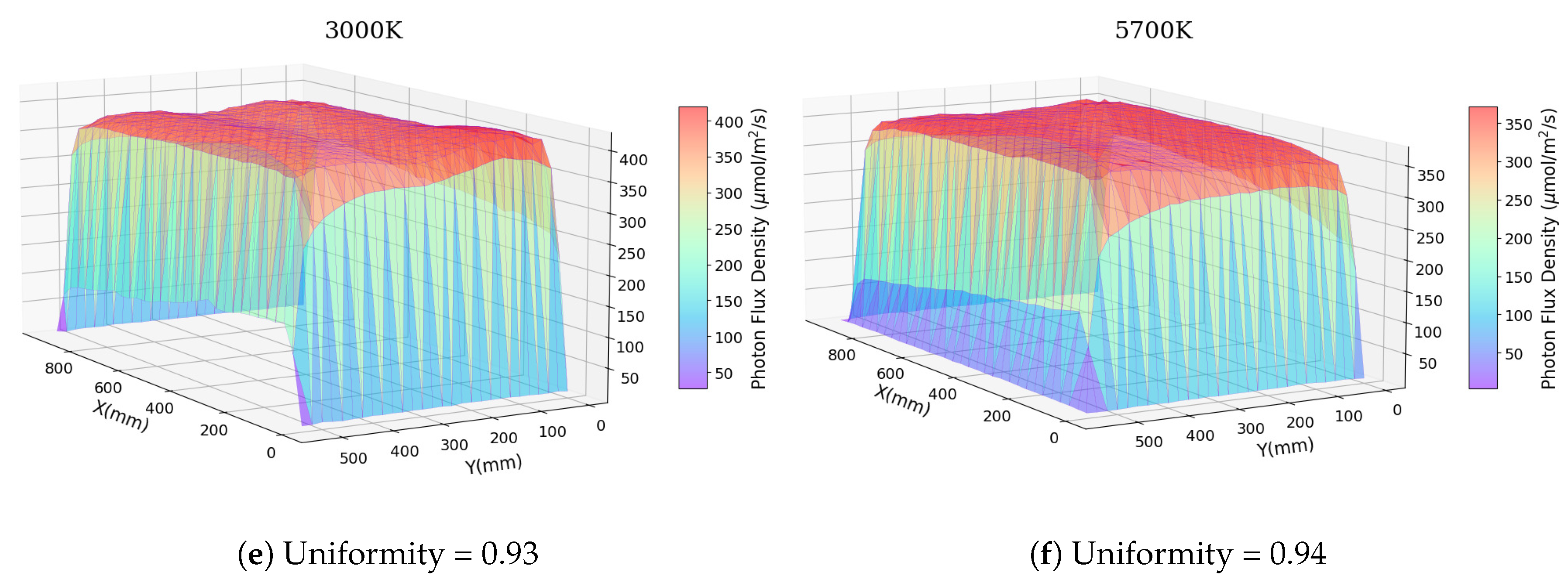

4. LED Lighting Panel’s Tunability and Energy-Saving

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Radetsky, L.C. LED and HID Horticultural Luminaire Testing Report; Technical Report; Lighting Research Center, Rensselaer Polytechnic Institute: Troy, NY, USA, 2018. [Google Scholar]

- Kozai, T.; Fujiwara, K.; Runkle, E.S. LED Lighting for Urban Agriculture; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Bugbee, B. Economics of LED lighting. In Light Emitting Diodes for Agriculture: Smart Lighting; Dutta Gupta, S., Ed.; Springer: Singapore, 2017; pp. 81–99. [Google Scholar] [CrossRef]

- Mayhoub, M.S.; Carter, D.J. Towards hybrid lighting systems: A review. Light. Res. Technol. 2010, 42, 51–71. [Google Scholar] [CrossRef]

- Bugbee, B. Toward an optimal spectral quality for plant growth and development: The importance of radiation capture. Acta Hortic. 2016, 1134, 1–12. [Google Scholar] [CrossRef]

- Snowden, M.C.; Cope, K.R.; Bugbee, B. Sensitivity of Seven Diverse Species to Blue and Green Light: Interactions with Photon Flux. PLoS ONE 2016, 11, e0163121. [Google Scholar] [CrossRef] [PubMed]

- Pattison, P.M.; Tsao, J.Y.; Brainard, G.C.; Bugbee, B. LEDs for photons, physiology and food. Nature 2018, 563, 493–500. [Google Scholar] [CrossRef] [PubMed]

- Bantis, F.; Koukounaras, A. Impact of Light on Horticultural Crops. Agriculture 2023, 13, 828. [Google Scholar] [CrossRef]

- Al Murad, M.; Razi, K.; Jeong, B.R.; Samy, P.M.A.; Muneer, S. Light Emitting Diodes (LEDs) as Agricultural Lighting: Impact and Its Potential on Improving Physiology, Flowering, and Secondary Metabolites of Crops. Sustainability 2021, 13, 1985. [Google Scholar] [CrossRef]

- Hasan, M.M.; Bashir, T.; Ghosh, R.; Lee, S.K.; Bae, H. An Overview of LEDs’ Effects on the Production of Bioactive Compounds and Crop Quality. Molecules 2017, 22, 1420. [Google Scholar] [CrossRef]

- D’Souza, C.; Yuk, H.G.; Khoo, G.H.; Zhou, W. Application of Light-Emitting Diodes in Food Production, Postharvest Preservation, and Microbiological Food Safety. Compr. Rev. Food Sci. Food Saf. 2015, 14, 719–740. [Google Scholar] [CrossRef]

- Motogaito, A.; Hashimoto, N.; Hiramatsu, K.; Murakami, K. Study of Plant Cultivation Using a Light-Emitting Diode Illumination System to Control the Spectral Irradiance Distribution. Opt. Photonics J. 2017, 7, 101–108. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Wakao, S.; Fischer, B.B.; Niyogi, K.K. Sensing and Responding to Excess Light. Annu. Rev. Plant Biol. 2009, 60, 239–260. [Google Scholar] [CrossRef]

- Massa, G.D.; Kim, H.H.; Wheeler, R.M.; Mitchell, C.A. Plant Productivity in Response to LED Lighting. Hortscience Horts 2008, 43, 1951–1956. [Google Scholar] [CrossRef]

- Sarropoulou, V.; Sperdouli, I.; Adamakis, I.D.; Grigoriadou, K. The use of different LEDs wavelength and light intensities for in vitro proliferation of cherry rootstock: Influence on photosynthesis and photomorphogenesis. Plant Cell Tissue Organ Cult. 2023, 152, 317–330. [Google Scholar] [CrossRef]

- Livadariu, O.; Maximilian, C.; Rahmanifar, B.; Cornea, C.P. LED Technology Applied to Plant Development for Promoting the Accumulation of Bioactive Compounds: A Review. Plants 2023, 12, 1075. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Field, D.L.; Ahmed, S.M.; Hasan, M.T.; Basher, M.K.; Alameh, K. LED Illumination for High-Quality High-Yield Crop Growth in Protected Cropping Environments. Plants 2021, 10, 2470. [Google Scholar] [CrossRef] [PubMed]

- Wong, C.E.; Teo, Z.W.N.; Shen, L.; Yu, H. Seeing the lights for leafy greens in indoor vertical farming. Trends Food Sci. Technol. 2020, 106, 48–63. [Google Scholar] [CrossRef]

- Wu, B.S.; MacPherson, S.; Lefsrud, M. Filtering Light-Emitting Diodes to Investigate Amber and Red Spectral Effects on Lettuce Growth. Plants 2021, 10, 1075. [Google Scholar] [CrossRef]

- Al-Kodmany, K. The Vertical Farm: A Review of Developments and Implications for the Vertical City. Buildings 2018, 8, 24. [Google Scholar] [CrossRef]

- Navigant Consulting, Inc.; Yamada, M.; Penning, J.; Schober, S.; Lee, K.; Elliott, C. Energy Savings Forecast of Solid-State Lighting in General Illumination Applications. Technical Report; U.S. Department of Energy: Washington, DC, USA, 2019. [Google Scholar]

- Schubert, E.F.; Kim, J.K. Solid-State Light Sources Getting Smart. Science 2005, 308, 1274–1278. [Google Scholar] [CrossRef]

- Tsao, J.Y.; Crawford, M.H.; Coltrin, M.E.; Fischer, A.J.; Koleske, D.D.; Subramania, G.S.; Wang, G.T.; Wierer, J.J.; Karlicek, R.F., Jr. Toward Smart and Ultra-efficient Solid-State Lighting. Adv. Opt. Mater. 2014, 2, 809–836. [Google Scholar] [CrossRef]

- Rajib, M.; Ray, K.; Mazumdar, S. A Low-Cost, Wide-Range, CCT-Tunable, Variable-Illuminance LED Lighting System. LEUKOS 2020, 16, 157–176. [Google Scholar] [CrossRef]

- Hrbac, R.; Kolar, V.; Novak, T.; Prokop, L.; Vanus, J. Low-cost solution of LED driving, designed for tunable white lighting systems. In Proceedings of the 15th IFAC Conference on Programmable Devices and Embedded Systems PDeS, IFAC-PapersOnLine. Ostrava, Czech Republic, 23–25 May 2018; Volume 51, pp. 396–401. [Google Scholar] [CrossRef]

- Murdoch, M.J. Dynamic color control in multiprimary tunable LED lighting systems. J. Soc. Inf. Disp. 2019, 27, 570–580. [Google Scholar] [CrossRef]

- Chew, I.; Kalavally, V.; Tan, C.P.; Parkkinen, J. A Spectrally Tunable Smart LED Lighting System With Closed-Loop Control. IEEE Sensors J. 2016, 16, 4452–4459. [Google Scholar] [CrossRef]

- Kozai, T.; Niu, G.; Takagaki, M. Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Sheibani, F.; Bourget, M.; Morrow, R.C.; Mitchell, C.A. Close-canopy lighting, an effective energy-saving strategy for overhead sole-source LED lighting in indoor farming. Front. Plant Sci. 2023, 14, 1215919. [Google Scholar] [CrossRef]

- Meng, Q.; Runkle, E.S. Blue Photons from Broad-Spectrum LEDs Control Growth, Morphology, and Coloration of Indoor Hydroponic Red-Leaf Lettuce. Plants 2023, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Hooks, T.; Sun, L.; Kong, Y.; Masabni, J.; Niu, G. Adding UVA and Far-Red Light to White LED Affects Growth, Morphology, and Phytochemicals of Indoor-Grown Microgreens. Sustainability 2022, 14, 8552. [Google Scholar] [CrossRef]

- Cowden, R.J.; Markussen, B.; Ghaley, B.B.; Henriksen, C.B. The Effects of Light Spectrum and Intensity, Seeding Density, and Fertilization on Biomass, Morphology, and Resource Use Efficiency in Three Species of Brassicaceae Microgreens. Plants 2024, 13, 124. [Google Scholar] [CrossRef] [PubMed]

- Sgarbi, E.; Santunione, G.; Barbieri, F.; Montorsi, M.; Lancellotti, I.; Barbieri, L. Effects of LED Lights and New Long-Term-Release Fertilizers on Lettuce Growth: A Contribution for Sustainable Horticulture. Horticulturae 2023, 9, 404. [Google Scholar] [CrossRef]

- Villard, R.G. Uniform Intensity LED Lighting System. U.S. Patent 7976187B2, 12 July 2011. [Google Scholar]

- Moreno, I.; Muñoz, J.; Ivanov, R. Uniform illumination of distant targets using a spherical light-emitting diode array. Opt. Eng. 2007, 46, 033001. [Google Scholar] [CrossRef]

- Moreno, I.; Tzonchev, R.I. Effects on illumination uniformity due to dilution on arrays of LEDs. In Proceedings of the Nonimaging Optics and Efficient Illumination Systems, Denver, CO, USA, 2–4 August 2004; Winston, R., Koshel, R.J., Eds.; International Society for Optics and Photonics, SPIE: National Harbor, MD, USA, 2004; Volume 5529, pp. 268–275. [Google Scholar] [CrossRef]

- Yang, H.; Bergmans, J.W.M.; Schenk, T.C.W.; Linnartz, J.P.M.G.; Rietman, R. Uniform illumination rendering using an array of LEDs: A signal processing perspective. IEEE Trans. Signal Process. 2009, 57, 1044–1057. [Google Scholar] [CrossRef]

- Hao, H.G.; Zhang, D.D.; Tang, S. Analysis of the LED Lamp Arrangement for Uniformity of Illumination in Indoor VLC System. J. Opt. Soc. Korea 2014, 18, 663–671. [Google Scholar] [CrossRef]

- Klase, N.P.; Duong, D.T.; Radkov, E.; Winberg, P.N. Plant Growth Lighting Device and Method. WO2012154275A1, 21 June 2012. [Google Scholar]

- Stragnola, S.V. Horticulture Lighting System for Providing Uniform Illumination from an Elevated Height. U.S. Patent 6042250A, 28 March 2000. [Google Scholar]

- Pickard, P.K. Lighting Device with Low Glare and High Light Level Uniformity. WO/2011/037877, 17 February 2011. [Google Scholar]

- Qin, Z.; Wang, K.; Chen, F.; Luo, X.; Liu, S. Analysis of condition for uniform lighting generated by array of light emitting diodes with large view angle. Opt. Express 2010, 18, 17460–17476. [Google Scholar] [CrossRef] [PubMed]

- Adams, S.P.; Tidd, M.M.; Heiner, J.J.; Carpenter, D.M. Method and Apparatus for Horticultural Lighting and Associated Optic Systems. WO/2018/058054,, 1 March 2018. [Google Scholar]

- AuYeung, D.S. LED Light Assembly with Three-Part Lens. U.S. Patent 9212803B2, 15 December 2015. [Google Scholar]

- Yorio, N.; Thosteson, E.; Soler, R.; Sullivan, S.; Balestracci, E.; Sun, W.; LeClair, R. Grow Lighting and Agricultural Systems and Methods. U.S. Patent 20160360712A1, 15 December 2016. [Google Scholar]

- Jiang, J.; To, S.; Lee, W.; Cheung, B. Optical design of a freeform TIR lens for LED streetlight. Optik 2010, 121, 1761–1765. [Google Scholar] [CrossRef]

- Kuo, C.H.; Wu, W.H.; Hsiao, W.T.; Huang, K.C. The Multi-shadow Analysis of LED Secondary Optics. Phys. Procedia 2011, 19, 233–238. [Google Scholar] [CrossRef]

- Balázs, L.; Dombi, Z.; Csambalik, L.; Sipos, L. Characterizing the Spatial Uniformity of Light Intensity and Spectrum for Indoor Crop Production. Horticulturae 2022, 8, 644. [Google Scholar] [CrossRef]

- Dougher, T.A.O.; Bugbee, B. Evidence for yellow light suppression of lettuce growth. Photochem. Photobiol. 2001, 72, 208–212. [Google Scholar] [CrossRef]

| LED Type | LED Manufacturer | Part Number | LED Driving Current (mA) | Voltage under the Driving Current at 25 °C Junction Temperature (V) | Photon Flux of Each LED (mol/s) | LEDs Arranged on Each 22 cm × 27 cm PCB | Designed Maximum PFD on an Illuminated Area at 25 °C Junction Temperature (mol/m/s) |

|---|---|---|---|---|---|---|---|

| 425 nm | Lumileds | L1CU-VLT1000000000 | 350 | 2.915 | 1.74 | 3 × 4 | 352.12 |

| 490 nm | Osram | GV QSSPA1.13-JZKZ-27-1 | 350 | 2.93 | 1.84 | 4 × 4 | 494.99 |

| 595 nm | Cree | XBDAMB-00-0000-000000703 | 350 | 2.17 | 0.70 | 4 × 4 | 189.43 |

| 660 nm | Osram | GH CSSRM4.24-V7V9-1-1-700-R33 | 350 | 1.87 | 2.93 | 3 × 3 | 444.17 |

| 3000 K | Luminus | SST-20-W30H-A120-J3302 | 350 | 2.812 | 2.12 | 3 × 4 | 429.19 |

| 5700 K | Luminus | SST-20-WDS-A120-L3572 | 350 | 2.83 | 2.48 | 3 × 3 | 376.40 |

| (a) | ||

|---|---|---|

| Condition | 16 Blue LEDs without Our Solution | 16 Blue LEDs with Our Solution |

| Lighting at 3 cm from LED panel |  Uniformity = 0.09 Uniformity = 0.09 |  Uniformity = 0.33 Uniformity = 0.33 |

| Lighting at 4 cm from LED panel |  Uniformity = 0.11 Uniformity = 0.11 |  Uniformity = 0.71 Uniformity = 0.71 |

| Lighting at 5 cm from LED panel |  Uniformity = 0.20 Uniformity = 0.20 |  Uniformity = 0.86 Uniformity = 0.86 |

| Lighting at 10 cm from LED panel |  Uniformity = 0.30 Uniformity = 0.30 |  Uniformity = 0.87 Uniformity = 0.87 |

| Lighting at 15 cm from LED panel |  Uniformity = 0.36 Uniformity = 0.36 |  Uniformity = 0.87 Uniformity = 0.87 |

| (b) | ||

| Condition | 16 Red LEDs without Our Solution | 16 Red LEDs with Our Solution |

| Lighting at 3 cm from LED panel |  Uniformity = 0.04 Uniformity = 0.04 |  Uniformity = 0.15 Uniformity = 0.15 |

| Lighting at 4 cm from LED panel |  Uniformity = 0.07 Uniformity = 0.07 |  Uniformity = 0.39 Uniformity = 0.39 |

| Lighting at 5 cm from LED panel |  Uniformity = 0.12 Uniformity = 0.12 |  Uniformity = 0.70 Uniformity = 0.70 |

| Lighting at 10 cm from LED panel |  Uniformity = 0.27 Uniformity = 0.27 |  Uniformity = 0.82 Uniformity = 0.82 |

| Lighting at 15 cm from LED panel |  Uniformity = 0.30 Uniformity = 0.30 |  Uniformity = 0.84 Uniformity = 0.84 |

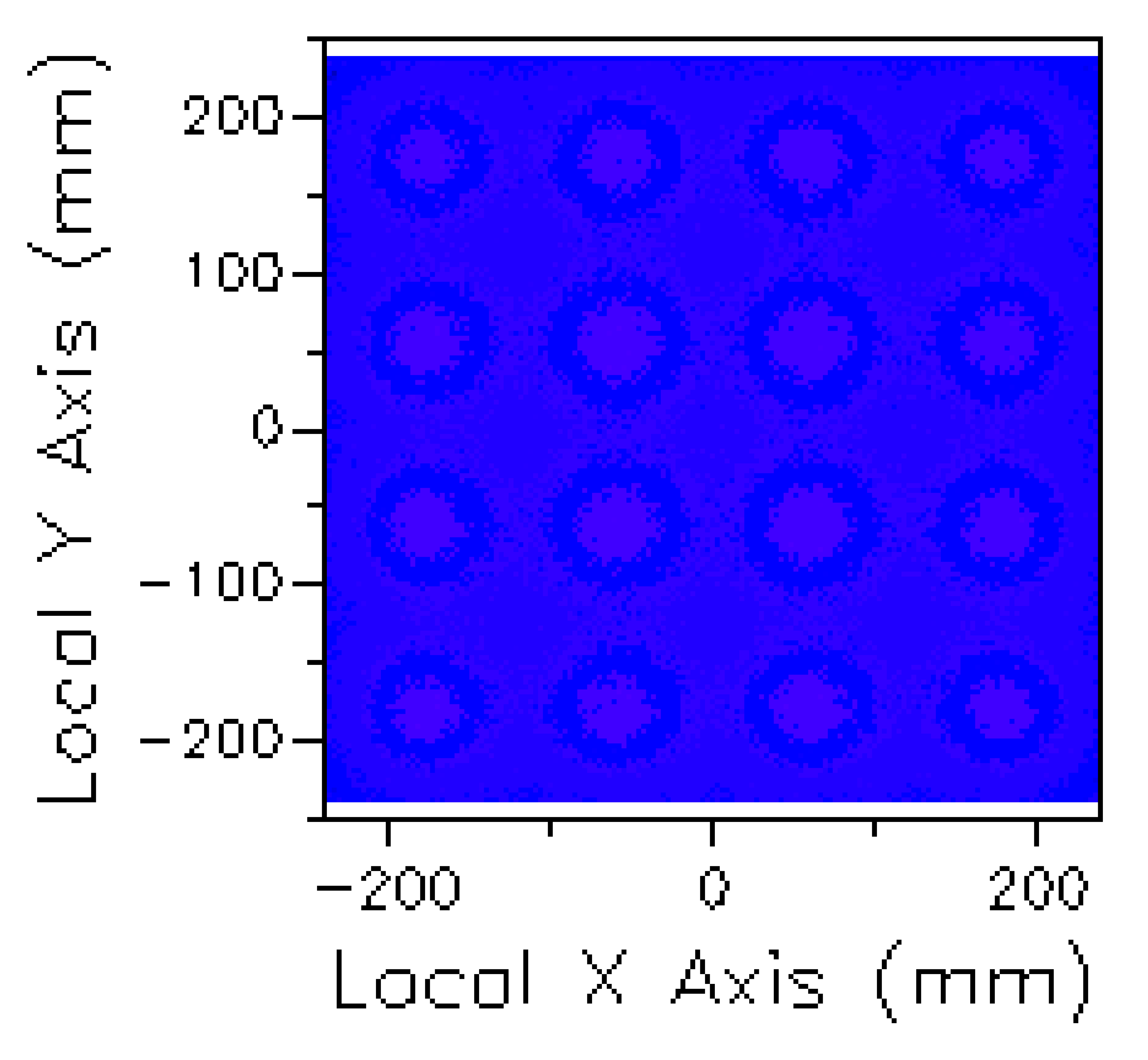

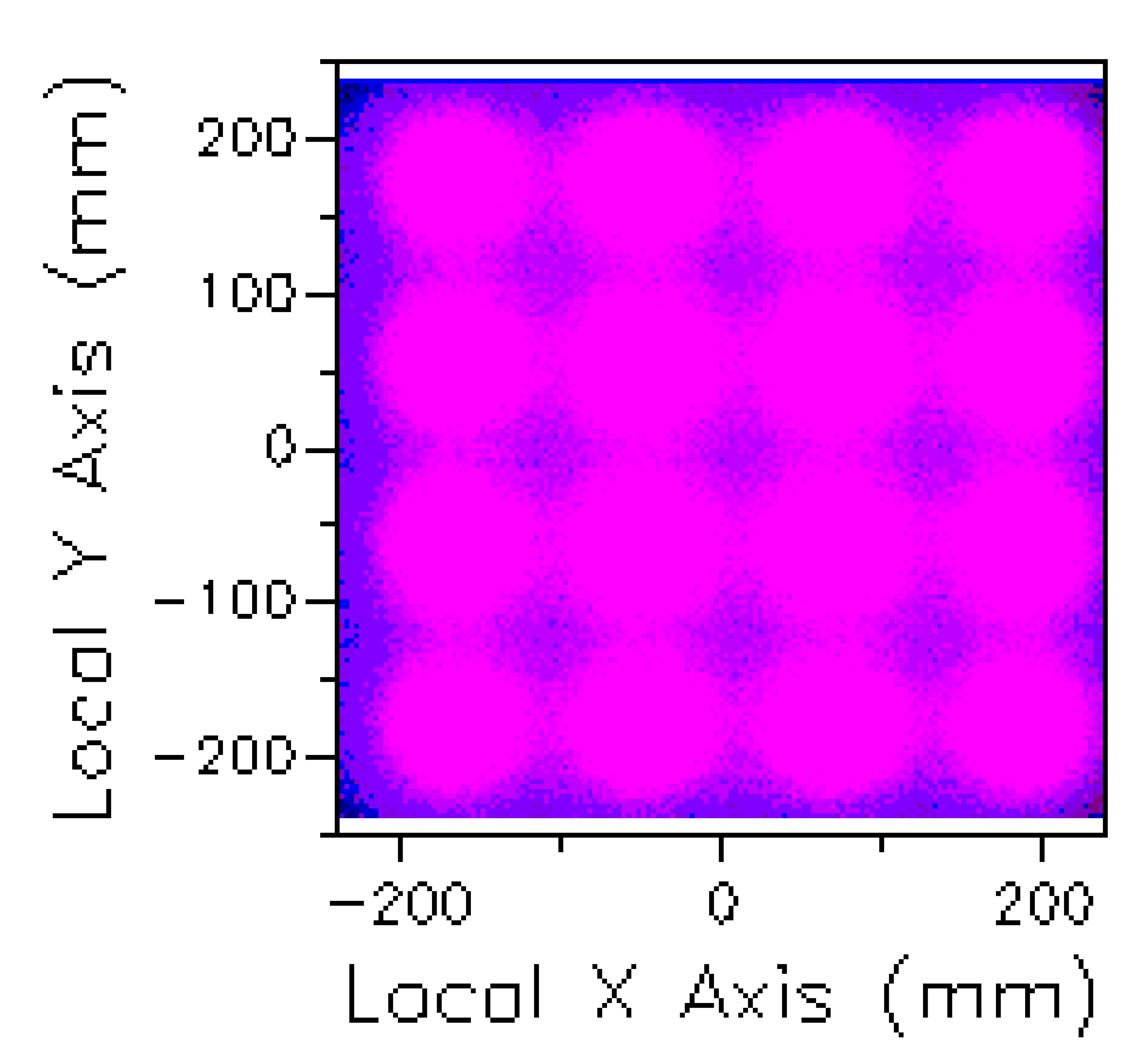

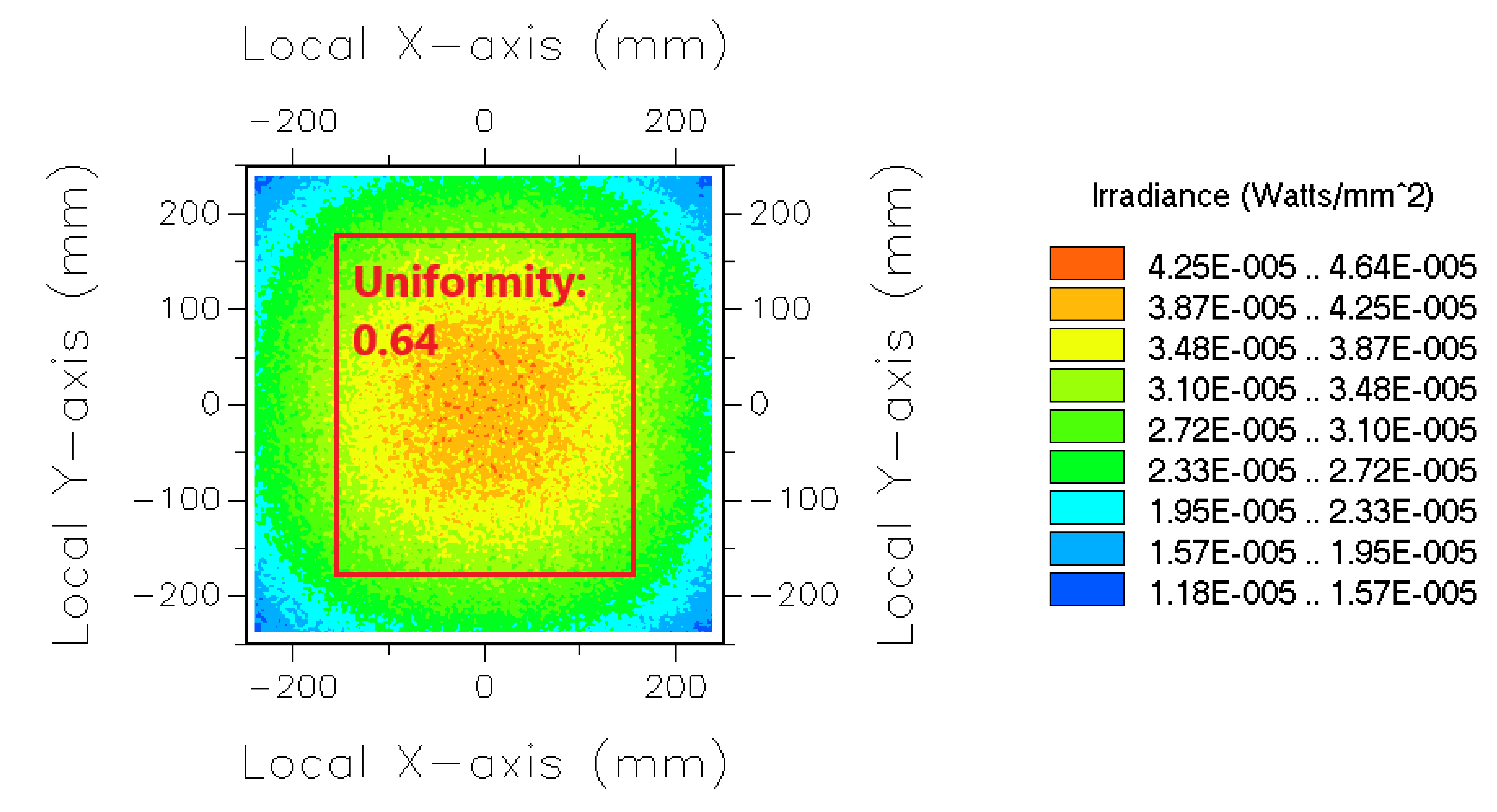

| Condition | Blue LED Only | Red LED Only | Both Blue and Red LED Are on |

|---|---|---|---|

| Without our solution at 5 cm distance from LED panel to plants |  |  |  |

| With our solution at 5 cm distance from LED panel to plants |  |  |  |

| Blue Light at 20 cm Distance From | Red Light at 20 cm Distance From | |

|---|---|---|

| LED Panel to Plants | LED Panel to Plants | |

| Without our solution |  Uniformity = 0.39 Uniformity = 0.39 |  Uniformity = 0.36 Uniformity = 0.36 |

| Our solution with 15 cm reflectors |  Uniformity = 0.28 Uniformity = 0.28 |  Uniformity = 0.28 Uniformity = 0.28 |

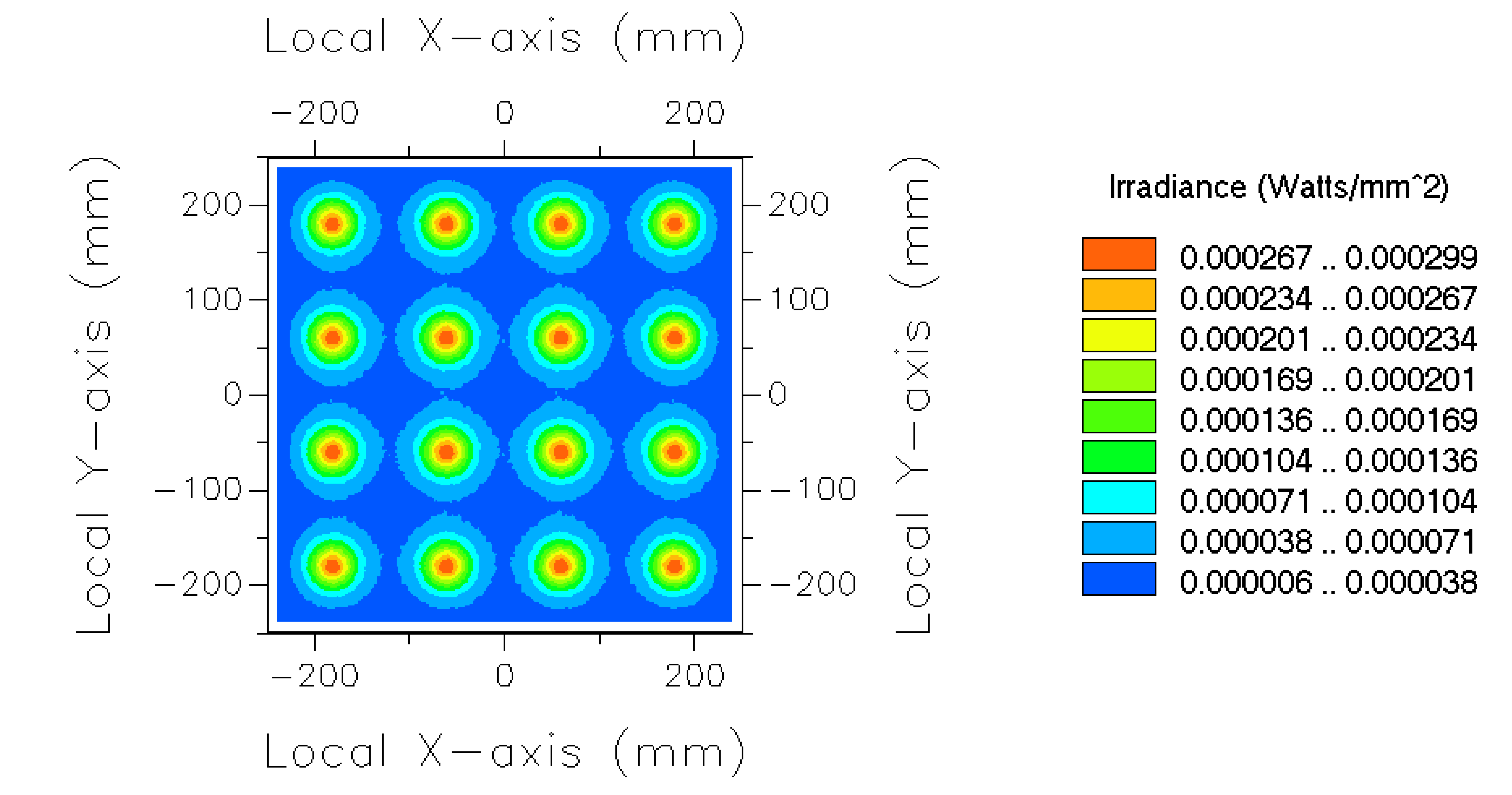

| LED Type | Uniformity Simulated (Based on Beam Profile of 3000 K LED) | Uniformity Characterized | Deviation between Simulated and Characterized Uniformity (%) | Designed Maximum PFD on the Illuminated Area at 25 °C Junction Temperature (mol/m/s) | Characterized Maximum PFD on the Illuminated Area (mol/m/s) | Deviation between Designed and Characterized PFD (%) |

|---|---|---|---|---|---|---|

| 425 nm | 0.925 | 0.92 | −0.54 | 352.12 | 363.21 | 3.15 |

| 490 nm | 0.935 | 0.94 | 0.53 | 494.99 | 416.84 | −15.79 |

| 595 nm | 0.928 | 0.89 | −4.09 | 189.43 | 151.61 | −19.97 |

| 660 nm | 0.928 | 0.93 | 0.22 | 444.17 | 426.74 | −3.92 |

| 3000 K | 0.924 | 0.93 | 0.65 | 429.19 | 395.63 | −7.82 |

| 5700 K | 0.925 | 0.94 | 1.62 | 376.40 | 361.27 | −4.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wong, T.I.; Zhou, X. Uniform Lighting of High-Power LEDs at a Short Distance to Plants for Energy-Saving and High-Density Indoor Farming. Photonics 2024, 11, 394. https://doi.org/10.3390/photonics11050394

Wong TI, Zhou X. Uniform Lighting of High-Power LEDs at a Short Distance to Plants for Energy-Saving and High-Density Indoor Farming. Photonics. 2024; 11(5):394. https://doi.org/10.3390/photonics11050394

Chicago/Turabian StyleWong, Ten It, and Xiaodong Zhou. 2024. "Uniform Lighting of High-Power LEDs at a Short Distance to Plants for Energy-Saving and High-Density Indoor Farming" Photonics 11, no. 5: 394. https://doi.org/10.3390/photonics11050394

APA StyleWong, T. I., & Zhou, X. (2024). Uniform Lighting of High-Power LEDs at a Short Distance to Plants for Energy-Saving and High-Density Indoor Farming. Photonics, 11(5), 394. https://doi.org/10.3390/photonics11050394