Storage Duration Prediction for Long-Expired Frozen Meat Exceeding State Reserve Time via Swept-Source Optical Coherence Tomography (SS-OCT) under Low-Frequency Electric Field

Abstract

1. Introduction

2. Materials and Methods

2.1. Meat Sample

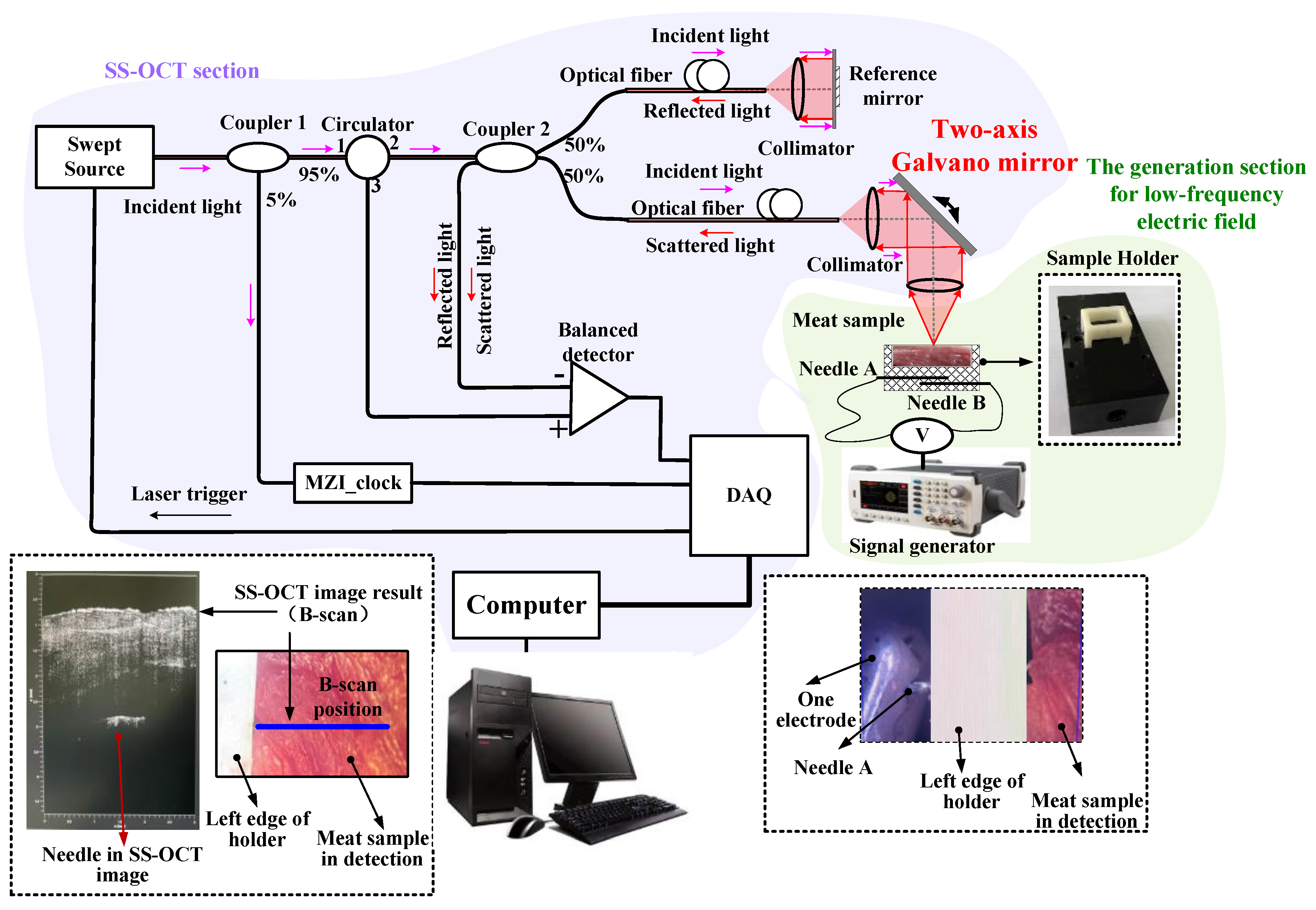

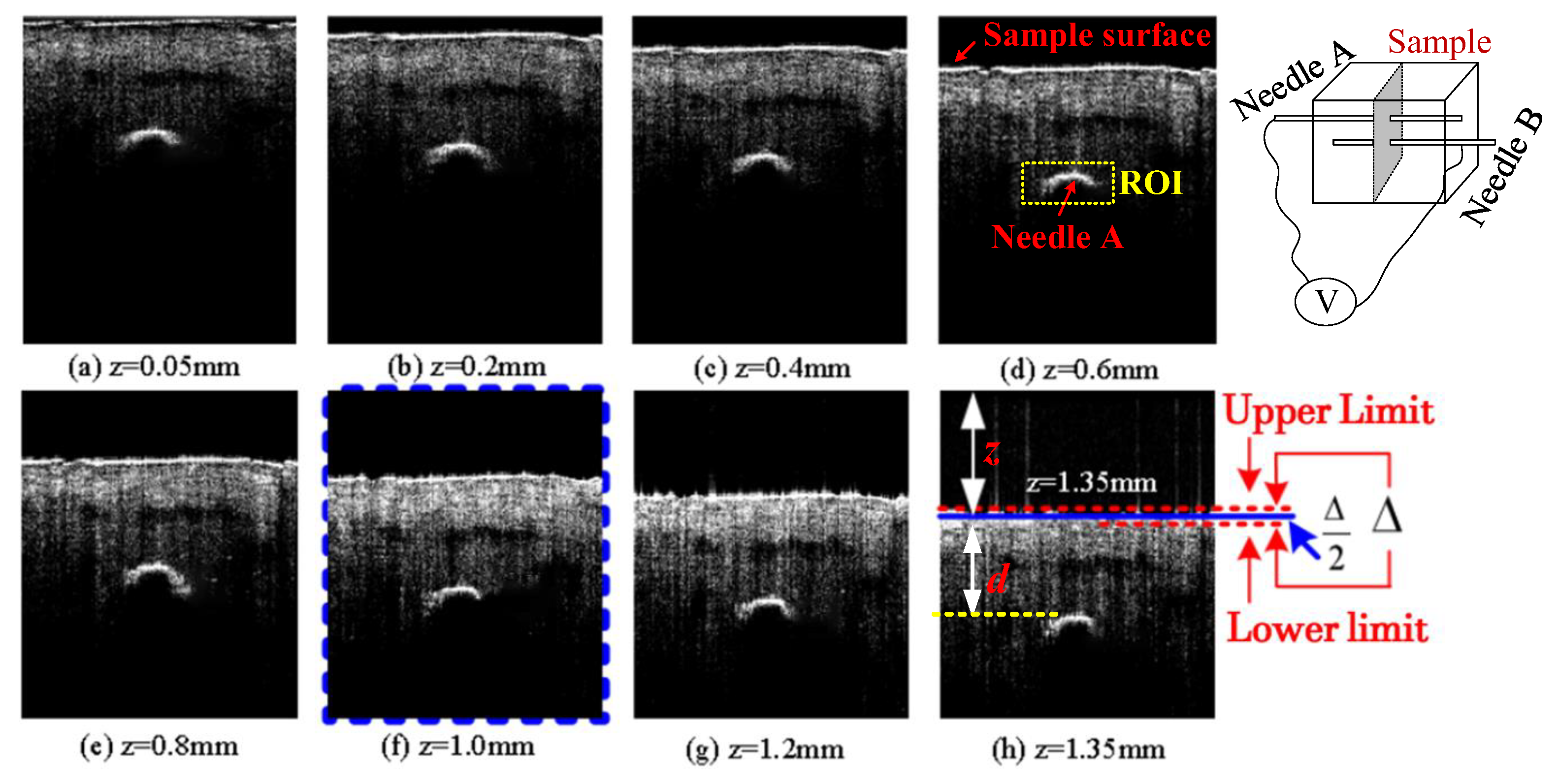

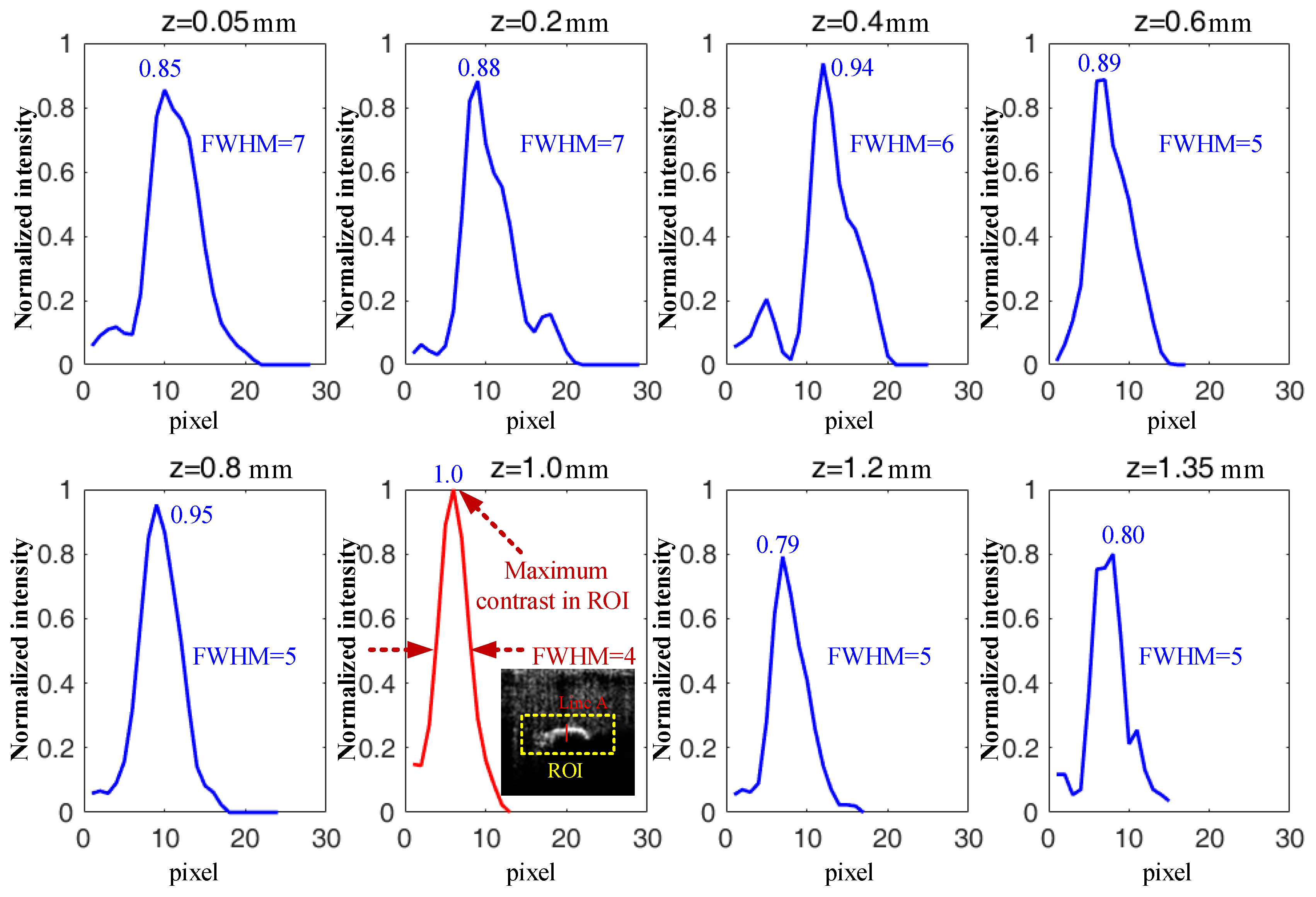

2.2. Experimental System Setup

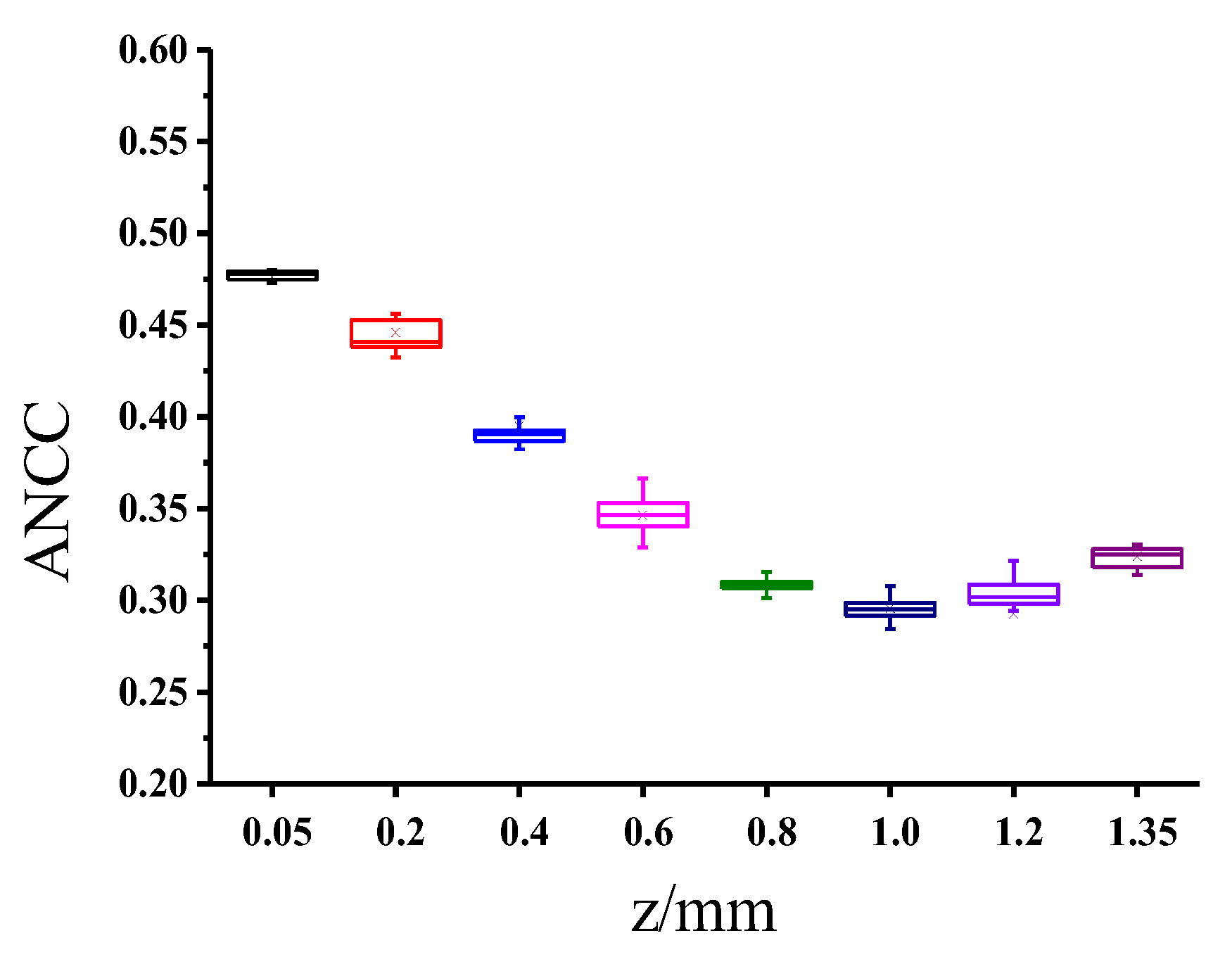

2.3. Average Normalized Cross Correlation (ANCC)

3. Results

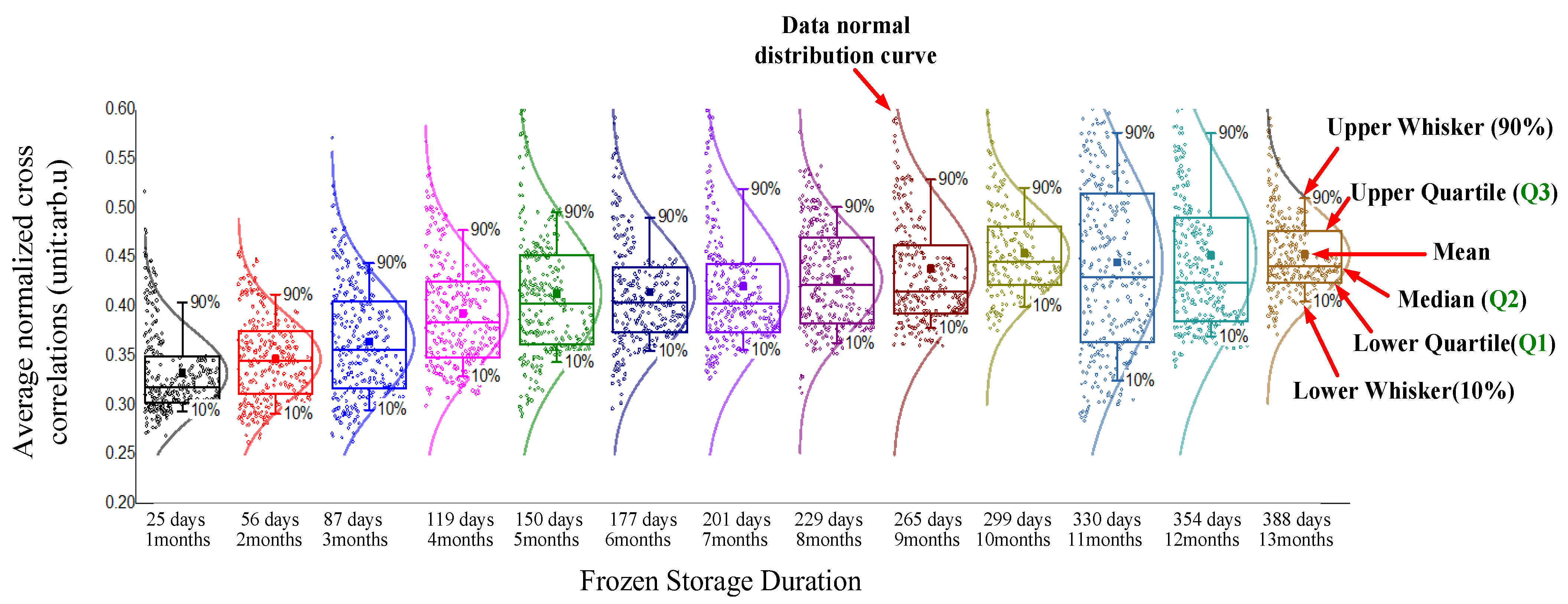

3.1. ANCC for Different Frozen Storage Durations

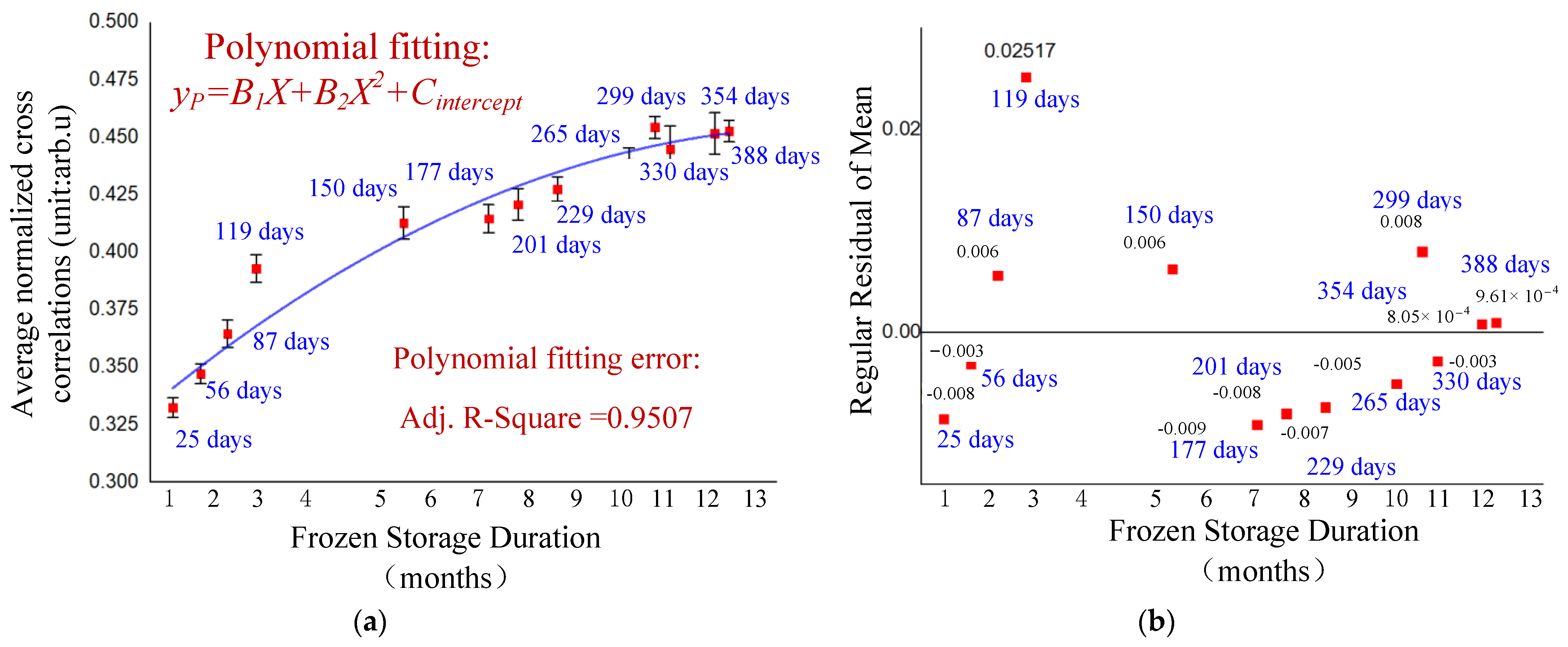

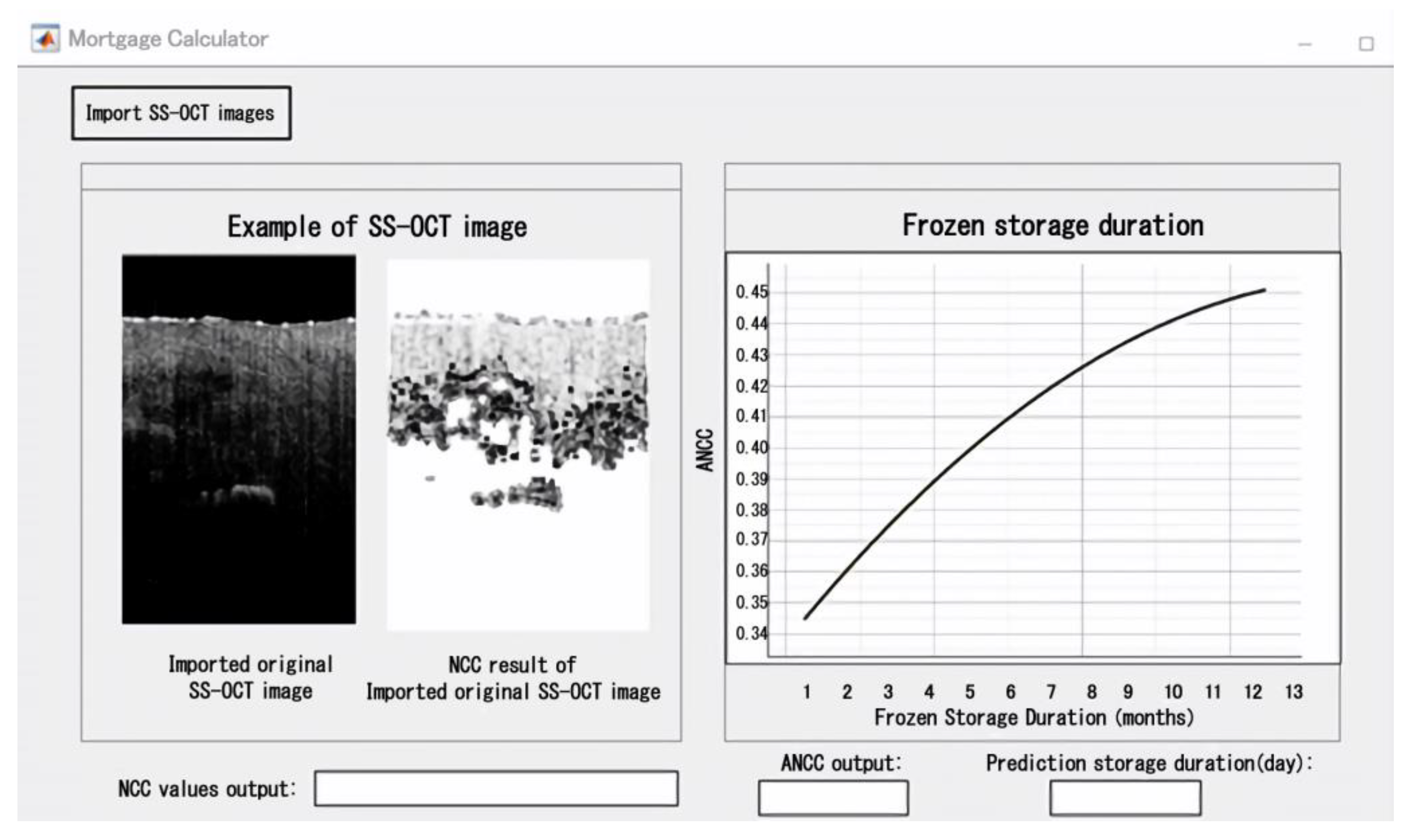

3.2. ANCC Inversion Law for Frozen Storage Duration

4. Discussion

4.1. ANCC and Biological Characteristics

4.2. ANCC Influencing Factor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, L.; Zhang, M.; Mujumdar, A.S. Technological innovations or advancement in detecting frozen and thawed meat quality: A review. Crit. Rev. Food Sci. 2021, 63, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Sabikun, N.; Bakhsh, A.; Ismail, I.; Hwang, Y.H.; Rahman, M.S.; Joo, S.T. Changes in physicochemical characteristics and oxidative stability of pre- and post-rigor frozen chicken muscles during cold storage. JFST 2019, 56, 4809–4816. [Google Scholar] [CrossRef] [PubMed]

- Muela, E.; Monge, P.; Sanudo, C.; Campo, M.M.; Beltrán, J.A. Meat quality of lamb frozen stored up to 21 months: Instrumental analyses on thawed meat during display. Meat Sci. 2015, 102, 35–40. [Google Scholar] [CrossRef] [PubMed]

- Byun, J.S.; Min, J.S.; Kim, I.S.; Kim, J.W.; Chung, M.S.; Lee, M. Comparison of indicators of microbial quality of meat during aerobic cold storage. J. Food Prot. 2003, 66, 1733–1737. [Google Scholar] [CrossRef] [PubMed]

- Xie, A.; Sun, D.W.; Zhu, Z.; Pu, H. Nondestructive Measurements of Freezing Parameters of Frozen Porcine Meat by NIR Hyperspectral Imaging. Food Bioprocess Technol. 2016, 9, 1444–1454. [Google Scholar] [CrossRef]

- Xie, A.; Sun, D.W.; Xu, Z.; Zhu, Z. Rapid detection of frozen pork quality without thawing by Vis–NIR hyperspectral imaging technique. Talanta 2015, 139, 208–215. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Sun, D.W.; Pu, H.; Wei, Q.; Wang, X. Protein content evaluation of processed pork meats based on a novel single shot (snapshot) hyperspectral imaging sensor. J. Food Eng. 2019, 240, 207–213. [Google Scholar] [CrossRef]

- Leitgeb, R.; Hitzenberger, C.K.; Fercher, A.F. Performance of Fourier domain vs. time domain optical coherence tomography. Opt. Express 2003, 11, 889–894. [Google Scholar] [CrossRef] [PubMed]

- Thampi, A.; Hitchman, S.; Coen, S.; Vanholsbeeck, F. Towards real time assessment of intramuscular fat content in meat using optical fiber-based optical coherence tomography. Meat Sci. 2021, 181, 108411. [Google Scholar] [CrossRef] [PubMed]

- Pena, A.; Sadovoy, A.; Doronin, A.; Bykov, A.; Meglinski, I. Evaluation of freshness of soft tissue samples with optical coherence tomography assisted by low frequency electric field. Sovrem. Tehnol. 2015, 7, 69–74. [Google Scholar] [CrossRef][Green Version]

- Thampi, A.; Hitchman, S.; Coen, S.; Vanholsbeeck, F. Optical coherence tomography to predict the quality of meat. In Optical Coherence Imaging Techniques and Imaging in Scattering Media III; SPIE: Bellingham, WA, USA, 2019; p. 11078. [Google Scholar]

- Trabelsi, S. Measuring changes in radio-frequency dielectric properties of chicken meat during storage. J. Food Meas Charact 2018, 12, 683–690. [Google Scholar] [CrossRef]

- Youn, J.I.; Akkin, T.; Milner, T.E. Electrokinetic measurement of cartilage using differential phase optical coherence tomography. Physiol. Meas. 2004, 25, 85–95. [Google Scholar] [CrossRef] [PubMed]

- Jia, P.; Zhao, H.; Qin, Y. Laser Lens Size Measurement Using Swept-Source Optical Coherence Tomography. Appl. Sci. 2020, 10, 4936. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E.; Masters, B.R. Digital Image Processing, Third Edition. J. Biomed Opt. 2009, 14, 029901. [Google Scholar] [CrossRef]

- Lim, J.S. Two-Dimensional Signal. and Image Processing; Prentice Hall: Englewood Cliffs, NJ, USA, 1990; p. 548. [Google Scholar]

- Benjamini, Y. Opening the box of a boxplot. TAS 1988, 42, 257–262. [Google Scholar]

- Teuteberg, V.; Kluth, I.K.; Ploetz, M.; Krischek, C. Effects of duration and temperature of frozen storage on the quality and food safety characteristics of pork after thawing and after storage under modified atmosphere. Meat Sci. 2020, 174, 108419. [Google Scholar] [CrossRef] [PubMed]

- Wei, R.; Wang, P.; Han, M.; Chen, T.; Xu, X.; Zhou, G. Effect of freezing on electrical properties and quality of thawed chicken breast meat. AJAS 2016, 30, 569–575. [Google Scholar] [CrossRef] [PubMed]

| Frozen Storage Duration | Samples after Thawing | PH Value | Temperature When Measured | Measured Sample Piece Number | |

|---|---|---|---|---|---|

| Months | Days | ||||

| 1 | 25 |  | 5.33 | 20.1 °C | 297 |

| 2 | 56 |  | 5.41 | 20.3 °C | 275 |

| 3 | 87 |  | 5.42 | 20.0 °C | 297 |

| 4 | 119 |  | 5.49 | 20.3 °C | 297 |

| 5 | 150 |  | 6.04 | 20.1 °C | 297 |

| 6 | 177 |  | 5.83 | 20.0 °C | 297 |

| 7 | 201 |  | 5.06 | 20.3 °C | 297 |

| 8 | 229 |  | 5.63 | 20.2 °C | 297 |

| 9 | 265 |  | 5.69 | 20.3 °C | 297 |

| 10 | 299 |  | 5.83 | 20.1 °C | 298 |

| 11 | 330 |  | 5.51 | 20.1 °C | 297 |

| 12 | 354 |  | 5.99 | 20.3 °C | 297 |

| 13 | 388 |  | 5.94 | 20.0 °C | 297 |

| Frozen Storage Duration | Lower Quartile (Q1) | Median (Q2) | Upper Quartile (Q3) | Mean | |

|---|---|---|---|---|---|

| Months | Days | ||||

| 1 | 25 | 0.27 | 0.32 | 0.52 | 0.33 |

| 2 | 56 | 0.26 | 0.35 | 0.46 | 0.35 |

| 3 | 87 | 0.26 | 0.36 | 0.61 | 0.36 |

| 4 | 119 | 0.30 | 0.38 | 0.66 | 0.39 |

| 5 | 150 | 0.29 | 0.40 | 0.69 | 0.41 |

| 6 | 177 | 0.30 | 0.40 | 0.70 | 0.41 |

| 7 | 201 | 0.33 | 0.40 | 0.73 | 0.42 |

| 8 | 229 | 0.31 | 0.42 | 0.62 | 0.44 |

| 9 | 265 | 0.36 | 0.42 | 0.70 | 0.44 |

| 10 | 299 | 0.38 | 0.45 | 0.61 | 0.45 |

| 11 | 330 | 0.28 | 0.43 | 0.74 | 0.44 |

| 12 | 354 | 0.34 | 0.42 | 0.83 | 0.45 |

| 13 | 388 | 0.37 | 0.44 | 0.73 | 0.45 |

| Sample | #1 | #2 | #3 | #4 | #5 | #6 | #7 | #8 | #9 |

| Within 4 Months | Within 5–8 Months | Within 9–13 Months | |||||||

| Ground truth (days) | 28 | 54 | 120 | 155 | 199 | 225 | 279 | 311 | 368 |

| Prediction results (days) | 26.4 | 55.3 | 125.2 | 151.0 | 203.4 | 231.3 | 285.5 | 320.4 | 364.4 |

| Absolute Error (days) | 1.6 | −1.3 | −5.2 | 4.0 | −4.4 | −6.3 | −6.5 | −9.4 | 3.6 |

| Relative Error | 5.71% | 2.40% | 4.33% | 2.58% | 2.21% | 2.80% | 2.33% | 3.02% | 0.98% |

| Mean Error | 4.15% | 2.53% | 2.11% | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Li, R.; Shen, X.; He, L.; Huang, J.; Song, C.; Fan, Z.; Zhao, H.; Li, K.; Xie, M.; et al. Storage Duration Prediction for Long-Expired Frozen Meat Exceeding State Reserve Time via Swept-Source Optical Coherence Tomography (SS-OCT) under Low-Frequency Electric Field. Photonics 2023, 10, 956. https://doi.org/10.3390/photonics10090956

Zhang L, Li R, Shen X, He L, Huang J, Song C, Fan Z, Zhao H, Li K, Xie M, et al. Storage Duration Prediction for Long-Expired Frozen Meat Exceeding State Reserve Time via Swept-Source Optical Coherence Tomography (SS-OCT) under Low-Frequency Electric Field. Photonics. 2023; 10(9):956. https://doi.org/10.3390/photonics10090956

Chicago/Turabian StyleZhang, Lu, Ruoxuan Li, Xiaorong Shen, Linkai He, Jie Huang, Chi Song, Zeyu Fan, Hong Zhao, Kejia Li, Meizhen Xie, and et al. 2023. "Storage Duration Prediction for Long-Expired Frozen Meat Exceeding State Reserve Time via Swept-Source Optical Coherence Tomography (SS-OCT) under Low-Frequency Electric Field" Photonics 10, no. 9: 956. https://doi.org/10.3390/photonics10090956

APA StyleZhang, L., Li, R., Shen, X., He, L., Huang, J., Song, C., Fan, Z., Zhao, H., Li, K., Xie, M., Peng, J., Jia, P., Deng, X., & Yang, M. (2023). Storage Duration Prediction for Long-Expired Frozen Meat Exceeding State Reserve Time via Swept-Source Optical Coherence Tomography (SS-OCT) under Low-Frequency Electric Field. Photonics, 10(9), 956. https://doi.org/10.3390/photonics10090956