3 W Continuous-Wave Room Temperature Quantum Cascade Laser Grown by Metal-Organic Chemical Vapor Deposition

Abstract

1. Introduction

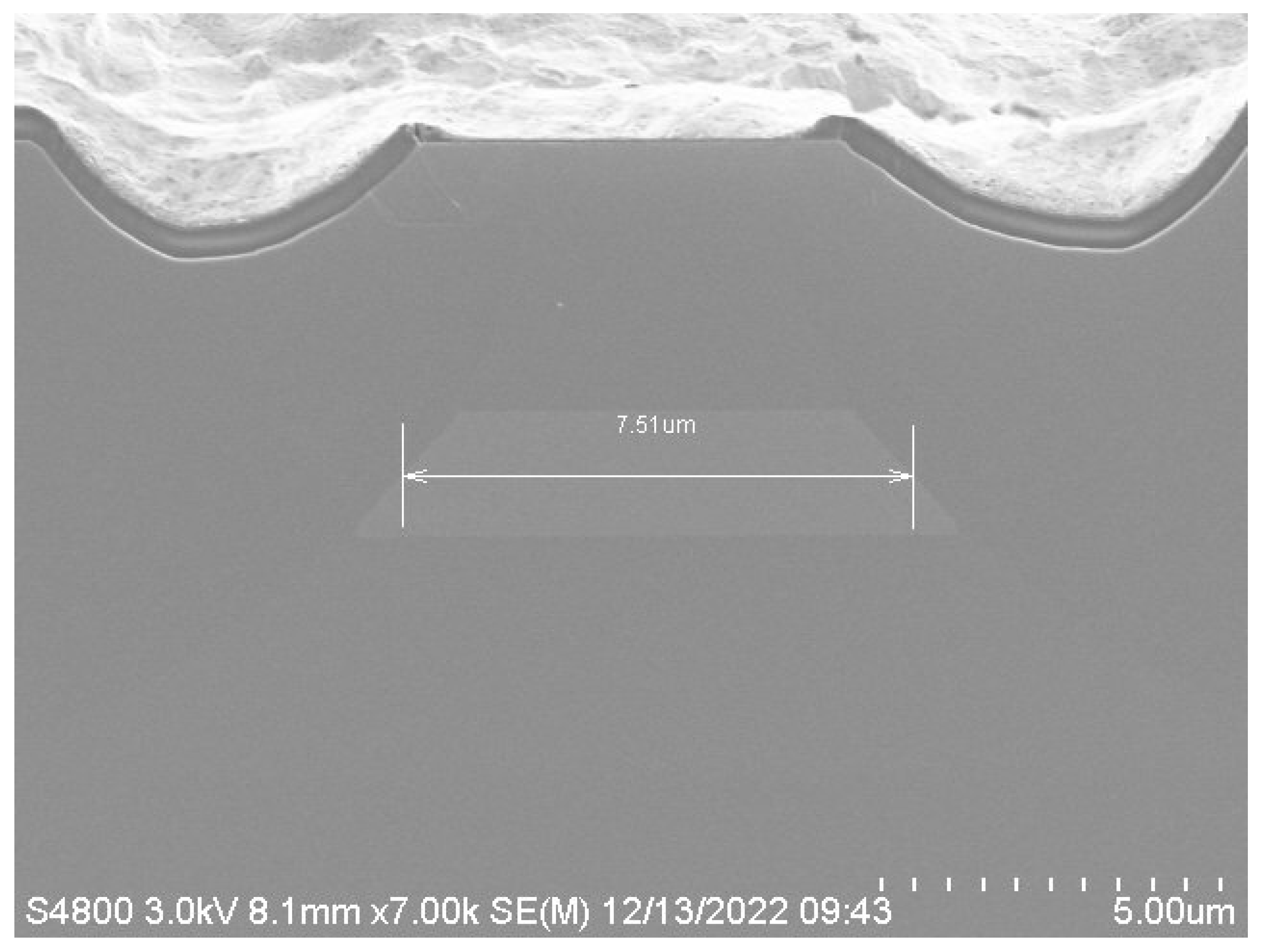

2. Materials and Methods

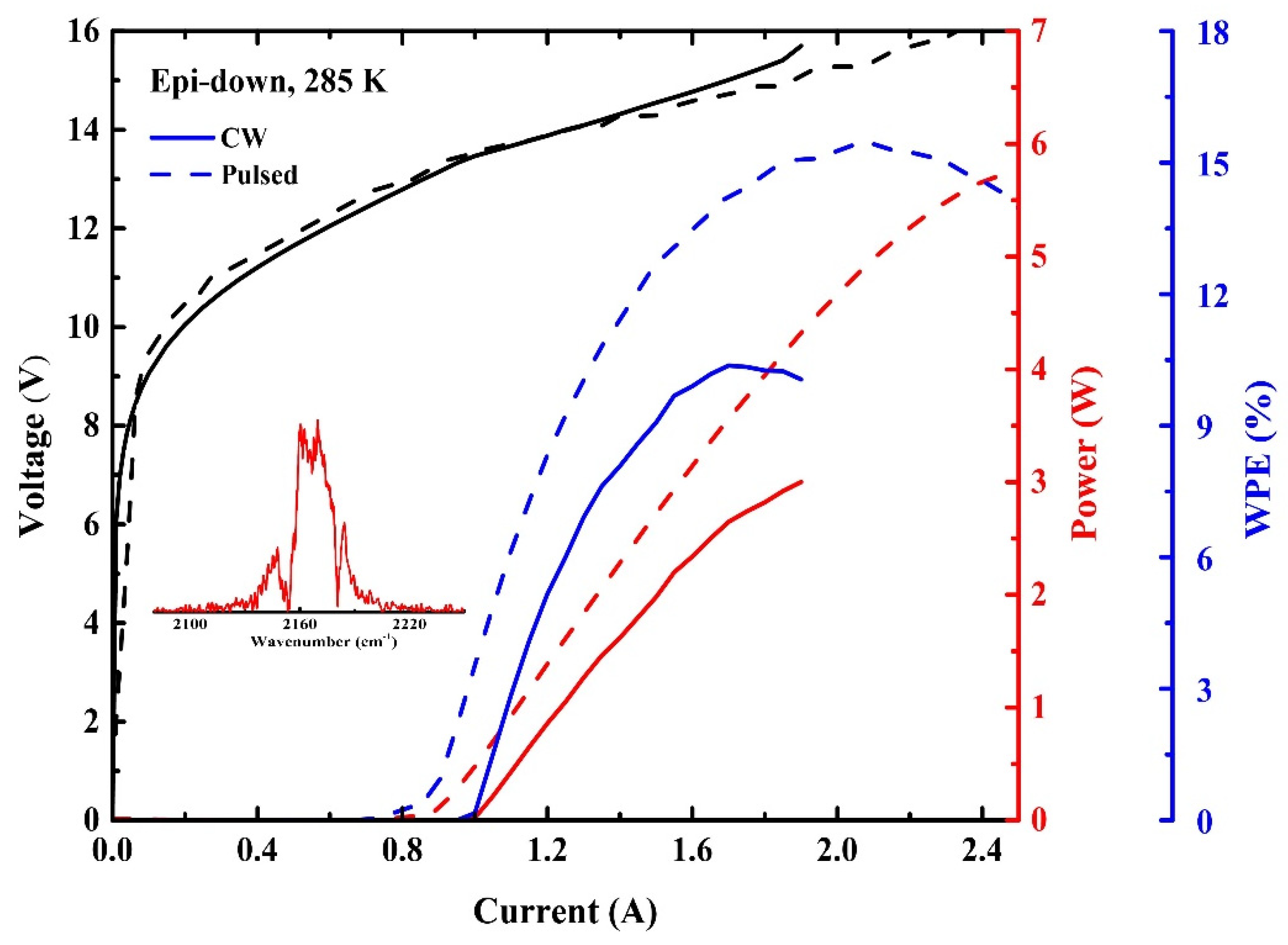

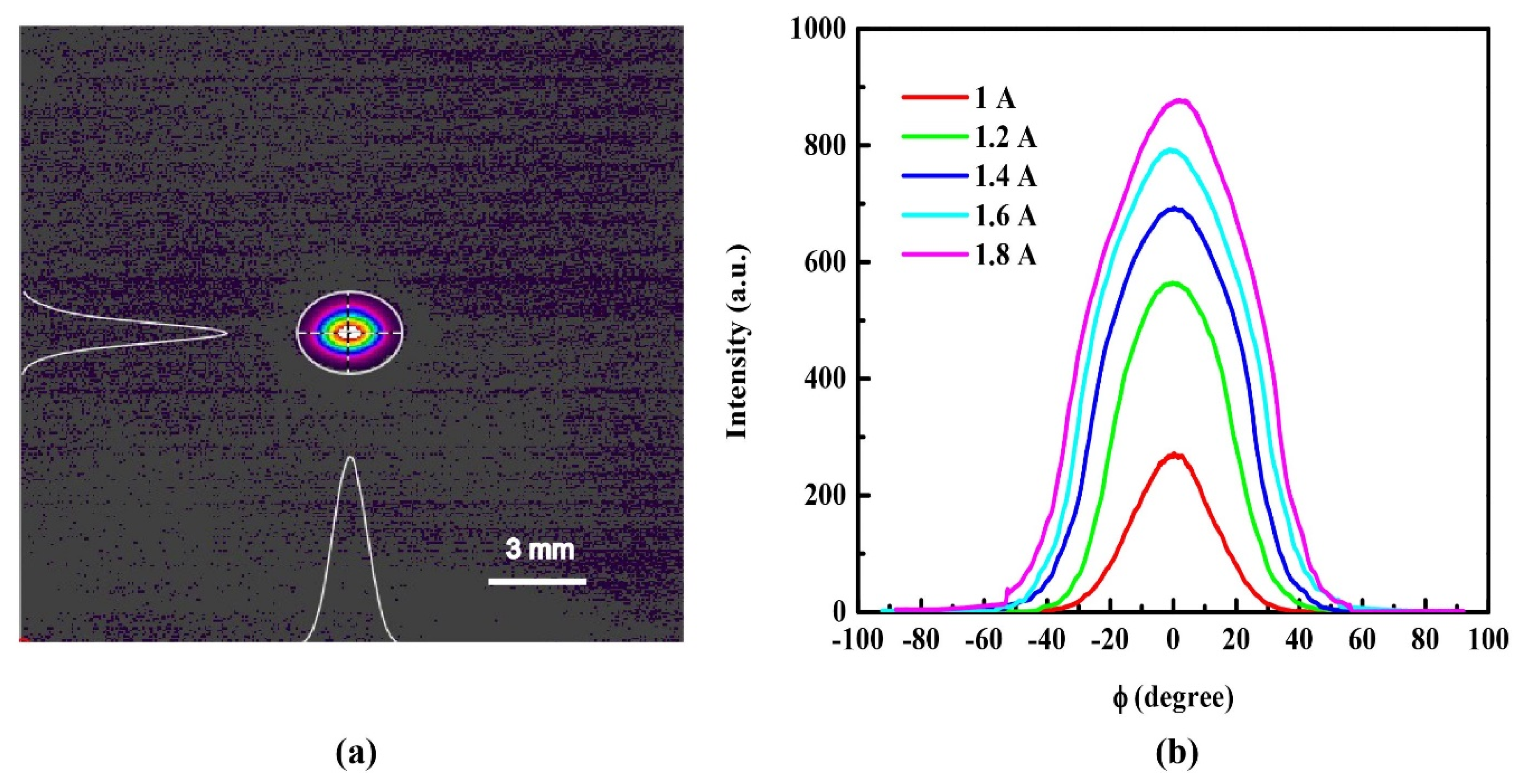

3. Results and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Z/mm | Dx/mm | Dy/mm |

|---|---|---|

| 300 | 3.04 | 2.57 |

| 500 | 3.24 | 3.02 |

| 700 | 3.57 | 3.55 |

| 1100 | 4.60 | 4.92 |

| 1300 | 5.25 | 5.84 |

| 1500 | 6.02 | 6.66 |

References

- Faist, J.; Capasso, F.; Sivco, D.L.; Sirtori, C.; Hutchinson, A.L.; Cho, A.Y. Quantum cascade laser. Science 1994, 264, 553–556. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, J.; Guan, Y.; Yang, P.; Zhuo, N.; Zhai, S.; Liu, J.; Wang, L.; Liu, S.; Liu, F.; et al. Ultralow power consumption of a quantum cascade laser operating in continuous-wave mode at room temperature. Opt. Express 2020, 28, 36497–36504. [Google Scholar] [CrossRef]

- Wang, Z.; Kapsalidis, F.; Wang, R.; Beck, M.; Faist, J. Ultra-low threshold lasing through phase front engineering via a metallic circular aperture. Nat. Commun. 2022, 13, 230. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, J.; Sun, Y.; Zhuo, N.; Zhai, S.; Liu, J.; Wang, L.; Liu, S.; Liu, F. High performance distributed feedback quantum cascade laser emitting at lambda approximately 6.12 um. Opt. Express 2022, 30, 5848–5854. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, J.; Cheng, F.; Zhuo, N.; Zhai, S.; Liu, J.; Wang, L.; Liu, S.; Liu, F.; Wang, Z. Watt-level, high wall plug efficiency, continuous-wave room temperature quantum cascade laser emitting at 7.7 microm. Opt. Express 2020, 28, 40155–40163. [Google Scholar] [CrossRef] [PubMed]

- Fei, T.; Zhai, S.; Zhang, J.; Zhuo, N.; Liu, J.; Wang, L.; Liu, S.; Jia, Z.; Li, K.; Sun, Y.; et al. High power λ~8.5 μm quantum cascade laser grown by MOCVD operating continuous-wave up to 408 K. J. Semicond. 2021, 42, 112301. [Google Scholar] [CrossRef]

- Botez, D.; Kirch, J.D.; Boyle, C.; Oresick, K.M.; Sigler, C.; Kim, H.; Knipfer, B.B.; Ryu, J.H.; Lindberg, D.; Earles, T.; et al. High-efficiency, high-power mid-infrared quantum cascade lasers [Invited]. Opt. Mater. Express 2018, 8, 1378. [Google Scholar] [CrossRef]

- Bai, Y.; Bandyopadhyay, N.; Tsao, S.; Slivken, S.; Razeghi, M. Room temperature quantum cascade lasers with 27% wall plug efficiency. Appl. Phys. Lett. 2011, 98, 181102. [Google Scholar] [CrossRef]

- Lyakh, A.; Suttinger, M.; Go, R.; Figueiredo, P.; Todi, A. 5.6 μm quantum cascade lasers based on a two-material active region composition with a room temperature wall-plug efficiency exceeding 28%. Appl. Phys. Lett. 2016, 109, 121109. [Google Scholar] [CrossRef]

- Lu, Q.; Slivken, S.; Wu, D.; Razeghi, M. High power continuous wave operation of single mode quantum cascade lasers up to 5 W spanning lambda approximately 3.8–8.3 microm. Opt. Express 2020, 28, 15181–15188. [Google Scholar] [CrossRef]

- Zhou, W.; Lu, Q.Y.; Wu, D.H.; Slivken, S.; Razeghi, M. High-power, continuous-wave, phase-locked quantum cascade laser arrays emitting at 8 microm. Opt. Express 2019, 27, 15776–15785. [Google Scholar] [CrossRef] [PubMed]

- Spitz, O.; Didier, P.; Durupt, L.; Diaz-Thomas, D.A.; Baranov, A.N.; Cerutti, L.; Grillot, F. Free-space communication with directly modulated mid-infrared quantum cascade devices. IEEE J. Sel. Top. Quantum Electron. 2022, 28, 1–9. [Google Scholar] [CrossRef]

- Dely, H.; Bonazzi, T.; Spitz, O.; Rodriguez, E.; Gacemi, D.; Todorov, Y.; Pantzas, K.; Beaudoin, G.; Sagnes, I.; Li, L.; et al. 10 Gbit s−1 free space data transmission at 9 µm wavelength with unipolar quantum optoelectronics. Laser Photonics Rev. 2021, 16, 2100414. [Google Scholar] [CrossRef]

- Bismuto, A.; Terazzi, R.; Beck, M.; Faist, J. Influence of the growth temperature on the performances of strain-balanced quantum cascade lasers. Appl. Phys. Lett. 2011, 98, 091105. [Google Scholar] [CrossRef]

- Razeghi, M.; Lu, Q.Y.; Bandyopadhyay, N.; Zhou, W.; Heydari, D.; Bai, Y.; Slivken, S. Quantum cascade lasers: From tool to product. Opt. Express 2015, 23, 8462–8475. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Slivken, S.; Darvish, S.R.; Razeghi, M. Room temperature continuous wave operation of quantum cascade lasers with 12.5% wall plug efficiency. Appl. Phys. Lett. 2008, 93, 021103. [Google Scholar] [CrossRef]

- Lyakh, A.; Maulini, R.; Tsekoun, A.; Go, R.; Pflügl, C.; Diehl, L.; Wang, Q.J.; Capasso, F.; Patel, C.K.N. 3 W continuous-wave room temperature single-facet emission from quantum cascade lasers based on nonresonant extraction design approach. Appl. Phys. Lett. 2009, 95, 141113. [Google Scholar] [CrossRef]

- Lyakh, A.; Maulini, R.; Tsekoun, A.; Go, R.; Patel, C.K.N. Tapered 4.7 μm quantum cascade lasers with highly strained active region composition delivering over 4.5 watts of continuous wave optical power. Opt. Express 2012, 20, 4382–4388. [Google Scholar] [CrossRef]

- Patel, C.K.N.; Troccoli, M.; Barron-Jimenez, R.; Titterton, D.H.; Grasso, R.J.; Richardson, M.A. Quantum cascade lasers: 25 years after the first demonstration. In Proceedings of the Technologies for Optical Countermeasures XVI, Strasbourg, France, 7 October 2019; SPIE: Washington, DC, USA, 2019; p. 1116102. [Google Scholar]

- Zhijun, L.; Wasserman, D.; Howard, S.S.; Hoffman, A.J.; Gmachl, C.F.; Xiaojun, W.; Tanbun-Ek, T.; Liwei, C.; Fow-Sen, C. Room-temperature continuous-wave quantum cascade lasers grown by MOCVD without lateral regrowth. IEEE Photonics Technol. Lett. 2006, 18, 1347–1349. [Google Scholar] [CrossRef]

- Lyakh, A.; Pflügl, C.; Diehl, L.; Wang, Q.J.; Capasso, F.; Wang, X.J.; Fan, J.Y.; Tanbun-Ek, T.; Maulini, R.; Tsekoun, A.; et al. 1.6W high wall plug efficiency, continuous-wave room temperature quantum cascade laser emitting at 4.6 μm. Appl. Phys. Lett. 2008, 92, 111110. [Google Scholar] [CrossRef]

- Troccoli, M.; Diehl, L.; Bour, D.P.; Corzine, S.W.; Yu, N.; Wang, C.Y.; Belkin, M.A.; Hofler, G.; Lewicki, R.; Wysocki, G.; et al. High-Performance Quantum Cascade Lasers Grown by Metal-Organic Vapor Phase Epitaxy and Their Applications to Trace Gas Sensing. J. Light. Technol. 2008, 26, 3534–3555. [Google Scholar] [CrossRef]

- Xie, F.; Caneau, C.; LeBlanc, H.P.; Visovsky, N.J.; Chaparala, S.C.; Deichmann, O.D.; Hughes, L.C.; Zah, C.-E.; Caffey, D.P.; Day, T. Room Temperature CW Operation of Short Wavelength Quantum Cascade Lasers Made of Strain Balanced GaxIn1-xAs/AlyIn1-yAs Material on InP Substrates. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1445–1452. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, X.; Fan, J.-Y.; Gmachl, C.F. High performance “continuum-to-continuum” quantum cascade lasers with a broad gain bandwidth of over 400 cm−1. Appl. Phys. Lett. 2010, 97, 081115. [Google Scholar] [CrossRef]

- Troccoli, M. High-Power Emission and Single-Mode Operation of Quantum Cascade Lasers for Industrial Applications. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 61–67. [Google Scholar] [CrossRef]

- Yang, Q.; Lösch, R.; Bronner, W.; Hugger, S.; Fuchs, F.; Aidam, R.; Wagner, J. High-peak-power strain-compensated GaInAs/AlInAs quantum cascade lasers (λ∼4.6 μm) based on a slightly diagonal active region design. Appl. Phys. Lett. 2008, 93, 251110. [Google Scholar] [CrossRef]

- Sun, Y.; Yin, R.; Zhang, J.; Liu, J.; Fei, T.; Li, K.; Guo, K.; Jia, Z.; Liu, S.; Lu, Q.; et al. High-performance quantum cascade lasers at λ∼9 µm grown by MOCVD. Opt. Express 2022, 30, 37272. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Bandyopadhyay, N.; Tsao, S.; Selcuk, E.; Slivken, S.; Razeghi, M. Highly temperature insensitive quantum cascade lasers. Appl. Phys. Lett. 2010, 97, 251104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fei, T.; Zhai, S.; Zhang, J.; Lu, Q.; Zhuo, N.; Liu, J.; Wang, L.; Liu, S.; Jia, Z.; Li, K.; et al. 3 W Continuous-Wave Room Temperature Quantum Cascade Laser Grown by Metal-Organic Chemical Vapor Deposition. Photonics 2023, 10, 47. https://doi.org/10.3390/photonics10010047

Fei T, Zhai S, Zhang J, Lu Q, Zhuo N, Liu J, Wang L, Liu S, Jia Z, Li K, et al. 3 W Continuous-Wave Room Temperature Quantum Cascade Laser Grown by Metal-Organic Chemical Vapor Deposition. Photonics. 2023; 10(1):47. https://doi.org/10.3390/photonics10010047

Chicago/Turabian StyleFei, Teng, Shenqiang Zhai, Jinchuan Zhang, Quanyong Lu, Ning Zhuo, Junqi Liu, Lijun Wang, Shuman Liu, Zhiwei Jia, Kun Li, and et al. 2023. "3 W Continuous-Wave Room Temperature Quantum Cascade Laser Grown by Metal-Organic Chemical Vapor Deposition" Photonics 10, no. 1: 47. https://doi.org/10.3390/photonics10010047

APA StyleFei, T., Zhai, S., Zhang, J., Lu, Q., Zhuo, N., Liu, J., Wang, L., Liu, S., Jia, Z., Li, K., Sun, Y., Guo, K., & Liu, F. (2023). 3 W Continuous-Wave Room Temperature Quantum Cascade Laser Grown by Metal-Organic Chemical Vapor Deposition. Photonics, 10(1), 47. https://doi.org/10.3390/photonics10010047