Impact of Sunflower Meal Protein Isolate Supplementation on Pasta Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Sunflower Meal Protein Isolate (SMPI)

2.3. Pasta Preparation

2.4. Amino Acid Profile

2.5. Rheological Properties

2.6. Chemical Composition

2.7. Color Measurement

2.8. Cooking Quality

2.9. Textural Profile Analysis (TPA)

2.10. Sensory Evaluation of Pasta

2.11. Statistical Analyses

3. Results and Discussion

3.1. Amino Acid Content of WF and SMPI

3.2. Rheological Characteristics of Blends from Wheat Flour with SMPI

3.3. Pasting Profile (RVA)

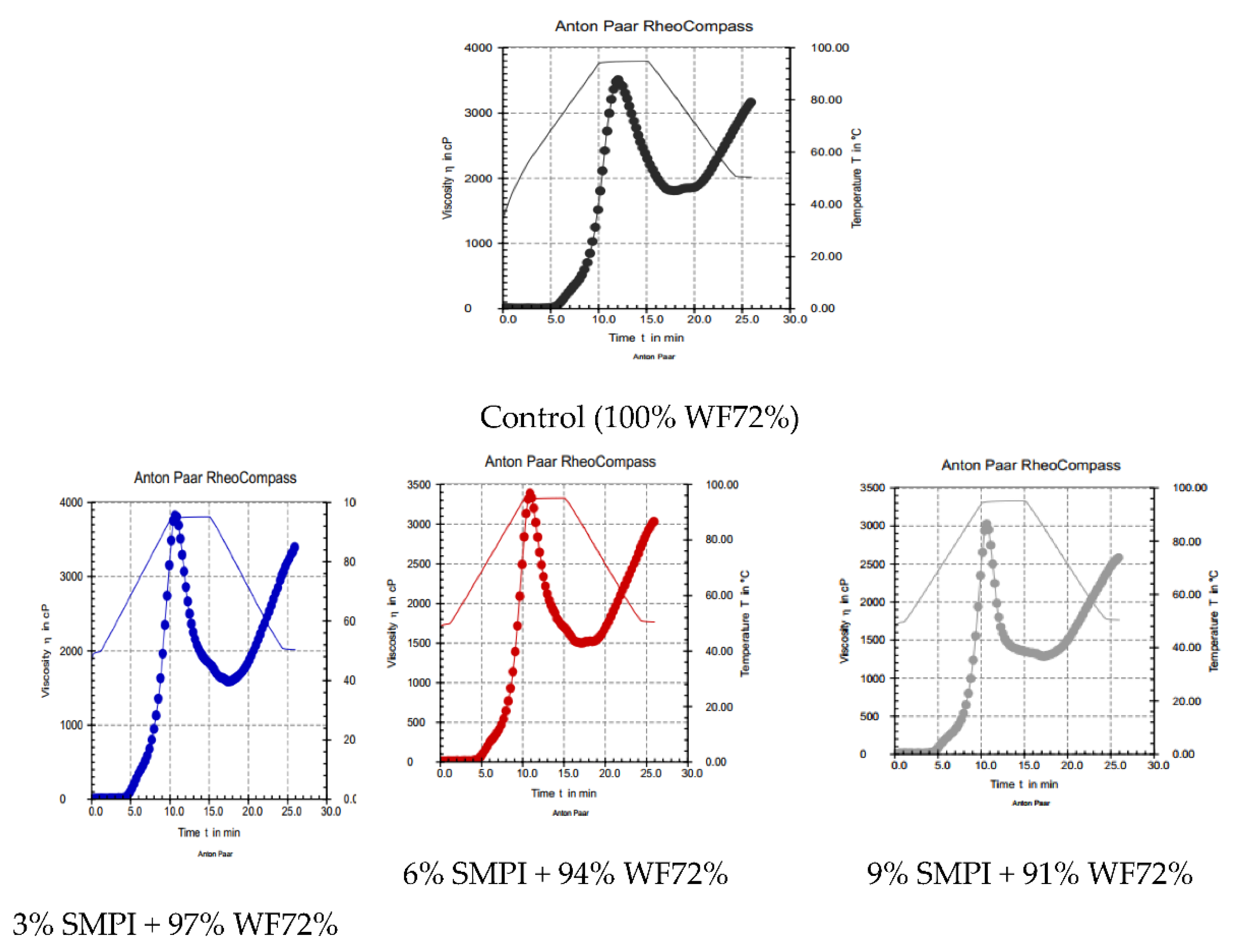

3.4. Proximate Composition of Raw Materials (WF, SMPI) and Pasta

3.5. Color Parameters

3.6. Cooking Quality of Pasta

3.7. Texture Parameters of Pasta

3.8. Sensory Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zaky, A.A.; Chen, Z.; Qin, M.; Wang, M.; Jia, Y. Assessment of antioxidant activity, amino acids, phenolic acids and functional attributes in defatted rice bran and rice bran protein concentrate. Prog. Nutr. 2020, 22, e2020069. [Google Scholar]

- Helkar, P.B.; Sahoo, A. Review: Food Industry By-Products used as a Functional Food Ingredients. Int. J. Waste Resour. 2016, 6, 1000248. [Google Scholar]

- Zaky, A.A.; Simal-Gandara, J.; Eun, J.-B.; Shim, J.-H.; Abd El-Aty, A.M. Bioactivities, Applications, Safety, and Health Benefits of Bioactive Peptides from Food and By-Products: A Review. Front. Nutr. 2022, 8, 815640. [Google Scholar] [CrossRef]

- Zaky, A.A.; Liu, Y.; Han, P.; Chen, Z.; Jia, Y. Effect of pepsin–trypsin in vitro gastro-intestinal digestion on the antioxidant capacities of ultra-filtrated rice bran protein hydrolysates (molecular weight > 10 kDa; 3–10 kDa, and< 3 kDa). Int. J. Pept. Res. Ther. 2020, 26, 1661–1667. [Google Scholar]

- Sredanović, S.A.; Lević, J.D.; Jovanović, R.D.; Đuragić, O.M. The nutritive value of poultry diets containing sunflower meal supplemented by enzymes. Acta Period. Technol. 2012, 43, 79–91. [Google Scholar] [CrossRef]

- Dabbour, M.; He, R.; Ma, H.; Musa, A. Optimization of ultrasound assisted extraction of protein from sunflower meal and its physicochemical and functional properties. J. Food Process. Eng. 2018, 41, e12799. [Google Scholar] [CrossRef]

- Dabbour, M.; Jiang, H.; Mintah, B.K.; Wahia, H.; He, R. Ultrasonic-assisted protein extraction from sunflower meal: Kinetic modeling, functional, and structural traits. Innov. Food Sci. Emerg. Technol. 2021, 74, 102824. [Google Scholar] [CrossRef]

- Ivanova, P.; Chalova, V.; Koleva, L.; Pishtiyski, I. Amino acid composition and solubility of proteins isolated from sunflower meal produced in Bulgaria. Int. Food Res. J. 2013, 20, 2995. [Google Scholar]

- De Oliveira Filho, J.G.; Egea, M.B. Sunflower seed byproduct and its fractions for food application: An attempt to improve the sustainability of the oil process. J. Food Sci. 2021, 86, 1497–1510. [Google Scholar] [CrossRef]

- Pasqualone, A.; Punzi, R.; Trani, A.; Summo, C.; Paradiso, V.M.; Caponio, F.; Gambacorta, G. Enrichment of fresh pasta with antioxidant extracts obtained from artichoke canning by-products by ultrasound-assisted technology and quality characterisation of the end product. Int. J. Food Sci. Technol. 2017, 52, 2078–2087. [Google Scholar] [CrossRef]

- Kadam, S.; Prabhasankar, P. Marine foods as functional ingredients in bakery and pasta products. Food Res. Int. 2010, 43, 1975–1980. [Google Scholar] [CrossRef]

- Marchylo, B.A.; Dexter, J.E. Pasta production. In Cereals Processing Technology; Owens, G., Ed.; CRC Press: Boca Raton, FL, USA; Boston, MA, USA; New York, NY, USA; Washington, DC, USA, 2001; pp. 109–130. [Google Scholar]

- Borneo, R.; Aguirre, A. Chemical composition, cooking quality, and consumer acceptance of pasta made with dried amaranth leaves flour. LWT-Food Sci. Technol. 2008, 41, 1748–1751. [Google Scholar] [CrossRef]

- Özyurt, G.; Uslu, L.; Yuvka, I.; Gökdoğan, S.; Atci, G.; Ak, B.; Işik, O. Evaluation of the cooking quality characteristics of pasta enriched with Spirulina platensis. J. Food Qual. 2015, 38, 268–272. [Google Scholar] [CrossRef]

- Coello, K.E.; Peñas, E.; Martinez-Villaluenga, C.; Cartea, M.E.; Velasco, P.; Frias, J. Pasta products enriched with moringa sprout powder as nutritive dense foods with bioactive potential. Food Chem. 2021, 360, 130032. [Google Scholar] [CrossRef]

- Boroski, M.; de Aguiar, A.C.; Boeing, J.S.; Rotta, E.M.; Wibby, C.L.; Bonafé, E.G.; de Souza, N.E.; Visentainer, J.V. Enhancement of pasta antioxidant activity with oregano and carrot leaf. Food Chem. 2011, 125, 696–700. [Google Scholar] [CrossRef]

- Zaky, A.A.; Chen, Z.; Liu, Y.; Li, S.; Jia, Y. Preparation and assessment of bioactive extracts having antioxidant activity from rice bran protein hydrolysates. J. Food Meas. Charact. 2019, 13, 2542–2548. [Google Scholar] [CrossRef]

- Hussein, A.M.; Kamil, M.M.; Mohamed, G.F. Physicochemical and sensorial quality of semolina defatted guava seed flour composite pasta. J. Am. Sci. 2011, 7, 623–629. [Google Scholar]

- Zaky, A.A.; Liu, Y.; Han, P.; Ma, A.; Jia, Y. Effect of flavorzyme digestion on the antioxidant capacities of ultra-filtrated rice bran protein hydrolyzates. J. Food Process. Preserv. 2020, 44, e14551. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 20th ed.; AOAC Internationa: Gaithersburg, MA, USA, 2016. [Google Scholar]

- AACC. Official Methods of the American Association of Cereal Chemists. Methods 54-21, 16-50, and 16-51, 10th ed.; The Association: St. Paul, MN, USA, 2000. [Google Scholar]

- Bourne, M.C. Food Texture and Viscosity: Concept and Measurement; Elsevier Press: New York, USA; London, UK, 2003. [Google Scholar]

- Ivanova, P.; Chalova, V.; Koleva, L.; Pishtiyski, I.; Perifanova-Nemska, M. Optimization of protein extraction from sunflower meal produced in Bulgaria. Bulg. J. Agric. Sci. 2012, 18, 153–160. [Google Scholar]

- San Juan, L.D.; Villamide, M.J. Nutritional evaluation of sunflower products for poultry as affected by the oil extraction process. Poult. Sci. 2001, 80, 431–437. [Google Scholar] [CrossRef]

- Rodge, A.B.; Sonkamble, S.M.; Salve, R.V.; Hashmi, S.I. Effect of hydrocolloid (guar gum) incorporation on the quality characteristics of bread. J. Food Process. Technol. 2012, 3, 136. [Google Scholar] [CrossRef]

- Indrani, D.; Soumya, C.; Rajiv, J.; Venkateswara Rao, G. Multigrain bread—Its dough rheology, microstructure, quality and nutritional characteristics. J. Texture Stud. 2010, 41, 302–319. [Google Scholar] [CrossRef]

- Hefni, M.; Witthöft, C.M. Increasing the folate content in Egyptian baladi bread using germinated wheat flour. LWT-Food Sci. Technol. 2011, 44, 706–712. [Google Scholar] [CrossRef]

- Mohamed, A.A.; Rayas-Duarte, P.; Shogren, R.L.; Sessa, D.J. Low carbohydrates bread: Formulation, processing and sensory quality. Food Chem. 2006, 99, 686–692. [Google Scholar] [CrossRef]

- Hussein, A.S.; Fouad, M.; El-Shenawy, M. Production of functional Pan Bread from Mixture of Tiger Nut Flour, Milk Permeate and Hard Wheat Flour. Egypt. J. Chem. 2022, 65, 509–517. [Google Scholar]

- Peymanpour, G.; Rezaei, K.; Sorkhilalehloo, B.; Pirayeshfar, B.; Najafian, G. Changes in Rheology and Sensory Properties of Wheat Bread with the Addition of Oat Flour. J. Agr. Sci. Tech. 2012, 14, 339–348. [Google Scholar]

- Hussein, A.M.S.; Ali, H.S.; Al-Khalifa, A.R. Quality Assessment of Some Spring Bread Wheat Cultivars. Asian J. Crop Sci. 2018, 10, 10–21. [Google Scholar] [CrossRef][Green Version]

- Gómez, M.; Oliete, B.; Rosell, C.M.; Pando, V.; Fernández, E. Studies on cake quality made of wheat–chickpea flour blends. LWT-Food Sci. Technol 2008, 41, 1701–1709. [Google Scholar] [CrossRef]

- Adebowale, Y.A.; Adeyemi, I.A.; Oshodi, A.A. Functional and physicochemical properties of flours of six Mucuna species. Afr. J. Biotechnol. 2005, 41, 461–1468. [Google Scholar]

- Hallén, E.; İbanoğlu, Ş.; Ainsworth, P. Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. J. Food Eng. 2004, 63, 177–184. [Google Scholar] [CrossRef]

- Muralikrishna, G.; Nirmala, M. Cereal α-amylases-an overview. Carbohydr. Polym. 2005, 60, 163–173. [Google Scholar] [CrossRef]

- Van Hung, P.; Maeda, T.; Morita, N. Dough and bread qualities of flours with whole waxy wheat flour substitution. Food Res. Int. 2007, 40, 273–279. [Google Scholar] [CrossRef]

- Renzetti, S.; Arendt, E.K. Effect of protease treatment on the baking quality of brown rice bread: From textural and rheological properties to biochemistry and microstructure. J. Cereal Sci. 2009, 50, 22–28. [Google Scholar] [CrossRef]

- Alexandrino, T.D.; Ferrari, R.A.; de Oliveira, L.M.; Rita de Cássia, S.C.; Pacheco, M.T.B. Fractioning of the sunflower flour components: Physical, chemical and nutritional evaluation of the fractions. LWT 2017, 84, 426–432. [Google Scholar] [CrossRef]

- Fouad, M.T.; Hussein, A.S.; El-Shenawy, M.A. Production of pasta using tiger nut and fermented permeate with some probiotic bacteria. Egypt. J. Chem. 2022, 65, 569–578. [Google Scholar]

- Hussein, A.S.; Saber, M.; Daoud, E.; Alshafei, M.; Ziada, Y.; Gamal, A.; Ezelarab, H.; Saber, L.; Naeem, M.A.; Kamal, E. Formulation and Evaluation of Biscuits from Functional Flour Mixture to enhance of antioxidants reflecting on nutrition in Patients. Egypt. J. Chem. 2022, 65, 455–466. [Google Scholar] [CrossRef]

- El-Faham, S.Y.; Mohsen, M.; Sharaf, A.; Zaky, A. Utilization of mango peels as a source of polyphenolic antioxidants. Curr. Sci. Int. 2016, 5, 529–542. [Google Scholar]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M.; Raymundo, A. Incorporation of Chlorella vulgaris and Spirulina maxima biomass in pasta products. Part 1: Preparation and evaluation. J. Sci. Food Agric. 2010, 90, 1656–1664. [Google Scholar] [CrossRef]

- Sozer, N.; Dalgıç, A.C.; Kaya, A. Thermal, textural and cooking properties of spaghetti enriched with resistant starch. J. Food Eng. 2007, 81, 476–484. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Haber, T.; Lewczuk, J.; Madrias, M. Quality evaluation of selected extra pasta on the Warsaw market. Przeg. Zboz-Mlyn 1997, 41, 26–29. [Google Scholar]

- Dick, J.W.; Youngs, V.L. Evaluation of durum wheat, semolina and pasta in the United States. In Durum Wheat Chemistry and Technology; Fabriani, G., Lintas, C., Eds.; American Association of Cereal Chemists Inc.: St. Paul, MN, USA, 1998; pp. 237–248. [Google Scholar]

- Chang, H.C.; Wu, L.C. Texture and quality properties of chinese fresh egg noodles formulated with green seaweed (Monostroma nitidum) powder. J. Food Sci. 2008, 79, S398–S404. [Google Scholar] [CrossRef] [PubMed]

| Amino Acids | Wheat Flour (g/100 g Sample) | SMPI (g/100 g Protein) |

|---|---|---|

| Essential amino acids | ||

| Threonine (THR) | 0.3 ± 0.72 | 3.51 ± 0.38 |

| Valine (VAL) | 0.47 ± 0.23 | 3.78 ± 0.12 |

| Methionine | 0.17 ± 0.04 | 2.36 ± 0.06 |

| Isoleucine (ILE) | 0.45 ± 0.19 | 3.25 ± 0.34 |

| Leucine (LEU) | 0.77 ± 0.17 | 6.27 ± 0.08 |

| Phenylalanine (PHE) | 0.6 ± 0.23 | 5.87 ± 0.42 |

| Histidine (HIS) | 0.24 ± 0.14 | 3.28 ± 0.18 |

| Lysine (LYS) | 0.25 ± 0.07 | 2.43 ± 0.17 |

| Total EAA | 3.25 | 30.75 |

| Nonessential amino acids | ||

| Serine (SER) | 0.5 ± 0.10 | 4.77 ± 0.11 |

| Glutamic (GLU) | 3.18 ± 0.32 | 22.57 ± 0.08 |

| Proline (PRO) | 1.13 ± 0.08 | 5.41 ± 0.06 |

| Glycine (GLY) | 0.42 ± 0.04 | 6.38 ± 0.09 |

| Alanine (ALA) | 0.44 ± 0.16 | 5.36 ± 0.12 |

| Aspartic (ASP) | 0.46 ± 0.37 | 10.12 ± 0.23 |

| Tyrosine (TYR) | 0.39 ± 0.13 | 3.78 ± 0.34 |

| Arginine (ARG) | 0.4 ± 0.04 | 9.24 ± 0.10 |

| Cystine (CYS) | 0.23 ± 0.05 | 1.62 ± 0.12 |

| Total NEAA | 7.15 | 69.25 |

| Samples | Water Absorption (%) | Arrival Time (min) | Dough Development Time (min) | Dough Stability (min) | Mixing Tolerance Index (BU) | Dough Weakening (BU) |

|---|---|---|---|---|---|---|

| Control | 62.0 d | 1.50 d | 2.00 d | 7.00 d | 40 d | 100 d |

| Pasta with 3% SMPI | 64.5 c | 2.00 c | 2.50 c | 8.50 c | 50 c | 120 c |

| Pasta with 6% SMPI | 67.0 b | 2.75 b | 3.00 b | 10.00 b | 60 b | 130 b |

| Pasta with 9% SMPI | 69.0 a | 3.25 a | 3.25 a | 11.50 a | 70 a | 140 a |

| Samples | Peak Vis. (cP) | Trough1 (cP) | Break Down (cP) | Final Vis. (cP) | Setback (cP) | Peak Time (min) | Pasting Temp. (°C) | Peak Temp. (°C) |

|---|---|---|---|---|---|---|---|---|

| Control | 3516 a | 1477 a | 1709 d | 3185 b | 330 d | 12.1 a | 61.2 bc | 94.8 a |

| Pasta with 3% SMPI | 3462 b | 1157 b | 1780 b | 3401 a | 461 a | 10.8 c | 64.5 a | 94.7 b |

| Pasta with 6% SMPI | 3389 c | 1121 c | 1890 a | 3047 c | 342 c | 10.9 b | 62 b | 94.7 b |

| Pasta with 9% SMPI | 3027 d | 840 d | 1742 c | 2582 d | 445 b | 10.7 bc | 61.6 c | 94.7 b |

| Parameters | SMPI | Wheat Flour (WF) | Pasta Supplemented with Different Concentrations of SMPI | |||

|---|---|---|---|---|---|---|

| Control | 3% SMPI | 6% SMPI | 9% SMPI | |||

| Moisture | 3.47 ± 0.13 d | 11.65 ± 0.11 a | 5.65 ± 0.09 b,c | 5.82 ± 0.03 b,c | 6.02 ± 0.04 b | 6.32 ± 0.05 b |

| Protein | 87.12 ± 1.22 a | 10.90 ± 0.19 d,e | 11.00 ± 0.07 e | 13.52 ± 0.09 d | 17.15 ± 0.11 c | 19.33 ± 0.13 b |

| Fat | 0.32 ± 0.001 e | 1.22 ± 0.05 b | 1.28 ± 0.00 a | 1.18 ± 0.002 a,b | 1.06 ± 0.005 c | 0.96 ± 0.006 d |

| Fiber | 2.10 ± 0.11 a | 0.79 ± 0.02 c | 0.52 ± 0.0 f | 0.65 ± 0.001 e | 0.73 ± 0.003 d | 0.81 ± 0.002 b |

| Ash | 1.84 ± 0.09 a | 0.81 ± 0.03 e | 0.82 ± 0.0 e | 0.96 ± 0.03 d | 1.09 ± 0.05 c | 1.15 ± 0.03 b |

| Carbohydrate * | 5.15 | 74.63 | 80.73 | 77.87 | 73.95 | 71.43 |

| Samples | L* | a* | b* | |||

|---|---|---|---|---|---|---|

| Raw | Cooked | Raw | Cooked | Raw | Cooked | |

| Control | 72.30 ± 0.28 a | 69.15 ± 0.45 a | 1.55 ± 0.03 d | 3.05 ± 0.09 d | 17.19 ± 0.19 d | 14.15 ± 0.23 d |

| Pasta with 3% SMPI | 57.15 ± 0.32 b | 64.12 ± 0.33 b | 5.24 ± 0.09 c | 4.05 ± 0.08 c | 21.35 ± 0.11 c | 25.30 ± 0.27 c |

| Pasta with 6% SMPI | 49.15 ± 0.2 c | 56.22 ± 0.25 c | 7.01 ± 0.035 b | 5.02 ± 0.13 b | 24.20 ± 0.25 b | 28.15 ± 0.39 b |

| Pasta with 9% SMPI | 44.50 ± 0.40 d | 51.11 ± 0.17 d | 7.99 ± 0.02 a | 6.11 ± 0.19 a | 26.17 ± 0.88 a | 33.10 ± 0.48 a |

| LSD at 0.05 | 6.05 | 4.95 | 1.02 | 0.85 | 1.71 | 2.75 |

| Samples | Weight Increase (%) | Volume Increase (%) | Cooking Loss (%) |

|---|---|---|---|

| Control | 207 ± 2.22 d | 170 ± 2.80 d | 3.50 ± 0.17 d |

| Pasta with 3% SMPI | 229 ± 3.25 c | 183 ± 3.10 c | 4.25 ± 0.21 c |

| Pasta with 6% SMPI | 236 ± 4.60 b | 196 ± 3.65 b | 4.85 ± 0.19 b |

| Pasta with 9% SMPI | 252 ± 4.95 a | 215 ± 2.80 a | 5.10 ± 0.15 a |

| LSD at 0.05 | 9.761 | 10.021 | 0.234 |

| Parameters | Pasta Samples from Wheat Flour (WF) and SMPI | |||||||

|---|---|---|---|---|---|---|---|---|

| Control | Pasta with 3% SMPI | Pasta with 6% SMPI | Pasta with 9% SMPI | |||||

| Raw | Cooked | Raw | Cooked | Raw | Cooked | Raw | Cooked | |

| Hardness (N) | 77.07 ± 0.12 | 12.02 ± 0.14 | 55.15 ± 0.09 | 9.10 ± 0.13 | 52.70 ± 0.09 | 6.85 ± 0.08 | 53.75 ± 0.14 | 5.52 ± 0.11 |

| Deformation at Hardness (mm) | 0.31 ± 0.17 | 8.61 ± 0.11 | 0.26 ± 0.22 | 8.83 ± 0.15 | 6.50 ± 0.10 | 10.70 ± 0.01 | 5.60 ± 0.09 | 10.55 ± 0.04 |

| Deformation at Hardness (%) | 0.95 ± 0.32 | 85.66 ± 0.28 | 0.85 ± 0.43 | 87.93 ± 0.35 | 20.15 ± 0.42 | 107.65 ± 0.27 | 19.40 ± 0.31 | 104.65 ± 0.19 |

| Hardness Work (mJ) | 0.46 ± 0.07 | 22.55 ± 0.04 | 15.20 ± 0.10 | 24.90 ± 0.09 | 38.20 ± 0.12 | 32.72 ± 0.26 | 50.94 ± 0.06 | 25.18 ± 0.04 |

| Load at Target (N) | 77.07 ± 0.31 | 12.02 ± 0.34 | 55.15 ± 0.42 | 9.10 ± 0.31 | 40.35 ± 0.14 | 6.85 ± 0.11 | 53.75 ± 0.15 | 5.52 ± 0.25 |

| Peak Stress (N/m2) | 36711 ± 0.07 | 3581 ± 0.09 | 27065 ± 0.12 | 3596 ± 0.14 | 21132 ± 0.04 | 3535 ± 0.03 | 27355 ± 0.08 | 2793 ± 0.06 |

| Strain at Peak Load | 0.01 ± 0.43 | 0.86 ± 0.52 | 0.01 ± 0.34 | 0.90 ± 0.27 | 0.23 ± 0.33 | 1.11 ± 0.28 | 0.22 ± 0.19 | 1.10 ± 0.17 |

| Fracturability (N) | 73.07 ± 0.19 | 0.41 ± 0.11 | 55.15 ± 0.08 | 0.35 ± 0.04 | 28.89 ± 0.16 | 0.23 ± 0.12 | 32.77 ± 0.17 | 0.45 ± 0.20 |

| Fracture Load Drop Off (N) | 65.01 ± 0.37 | 0.17 ± 0.39 | 44.82 ± 0.42 | 0.07 ± 0.31 | 27.55 ± 0.47 | 0.19 ± 0.38 | 28.85 ± 0.19 | 0.13 ± 0.13 |

| 1st Fracture Work Done (mJ) | 13.90 ± 0.17 | 0.03 ± 0.26 | 7.35 ± 0.31 | 0.03 ± 0.15 | 3.28 ± 0.29 | 0.03 ± 0.33 | 5.19 ± 0.14 | 0.11 ± 0.18 |

| 1st Fracture Deformation (mm) | 0.30 ± 0.05 | 0.25 ± 0.09 | 0.26 ± 0.28 | 0.35 ± 0.26 | 0.19 ± 0.23 | 0.18 ± 0.11 | 0.22 ± 0.10 | 1.01 ± 0.08 |

| 1st Fracture Deformation (%) | 0.92 ± 0.09 | 7.16 ± 0.07 | 0.82 ± 0.05 | 7.15 ± 0.03 | 0.58 ± 0.12 | 12.82 ± 0.14 | 0.85 ± 0.05 | 12.10 ± 0.09 |

| Samples | Color (10) | Flavor (10) | Mouthfeel (10) | Elasticity (10) | OA (10) | Total (50) |

|---|---|---|---|---|---|---|

| Control | 9.65 ± 0.55 a | 9.71 ± 0.30 a | 9.90 ± 0.38 a | 9.82 ± 0.48 a | 9.50 ± 0.31 a | 48.58 ± 1.05 a |

| Pasta with 3% SMPI | 8.75 ± 0.49 b | 9.20 ± 0.52 a | 9.52 ± 0.45 a | 9.65 ± 0.39 a | 9.17 ± 0.28 a | 46.29 ± 1.01 a |

| Pasta with 6% SMPI | 7.80 ± 0.61 c | 8.65 ± 0.28 b | 8.90 ± 0.51 a | 9.30 ± 0.32 a | 8.65 ± 0.39 a | 43.30 ± 1.29 b |

| Pasta with 9% SMPI | 7.20 ± 0.72 c | 8.05 ± 0.62 b | 7.75 ± 0.55 b | 9.22 ± 0.25 a | 8.01 ± 0.35 b | 40.23 ± 1.45 b |

| LSD at 0.05 | 0.811 | 0.805 | 0.901 | NS | 0.795 | 2.061 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaky, A.A.; Hussein, A.S.; Mostafa, S.; Abd El-Aty, A.M. Impact of Sunflower Meal Protein Isolate Supplementation on Pasta Quality. Separations 2022, 9, 429. https://doi.org/10.3390/separations9120429

Zaky AA, Hussein AS, Mostafa S, Abd El-Aty AM. Impact of Sunflower Meal Protein Isolate Supplementation on Pasta Quality. Separations. 2022; 9(12):429. https://doi.org/10.3390/separations9120429

Chicago/Turabian StyleZaky, Ahmed A., Ahmed S. Hussein, Sayed Mostafa, and A. M. Abd El-Aty. 2022. "Impact of Sunflower Meal Protein Isolate Supplementation on Pasta Quality" Separations 9, no. 12: 429. https://doi.org/10.3390/separations9120429

APA StyleZaky, A. A., Hussein, A. S., Mostafa, S., & Abd El-Aty, A. M. (2022). Impact of Sunflower Meal Protein Isolate Supplementation on Pasta Quality. Separations, 9(12), 429. https://doi.org/10.3390/separations9120429