Synergistic Enhancement of Sludge Deep Dewatering via Tea Waste and Sludge-Derived Biochars Coupled with Polyaluminum Chloride

Abstract

1. Introduction

2. Materials and Methods

2.1. Sludge Samples and Chemical Reagents

2.2. Biochar Preparation

2.3. Sludge Conditioning and Dewatering Tests

2.4. Water State Characterization and Multiscale Analysis

2.5. Physicochemical and Biochemical Characterization of Sludge

3. Results and Discussion

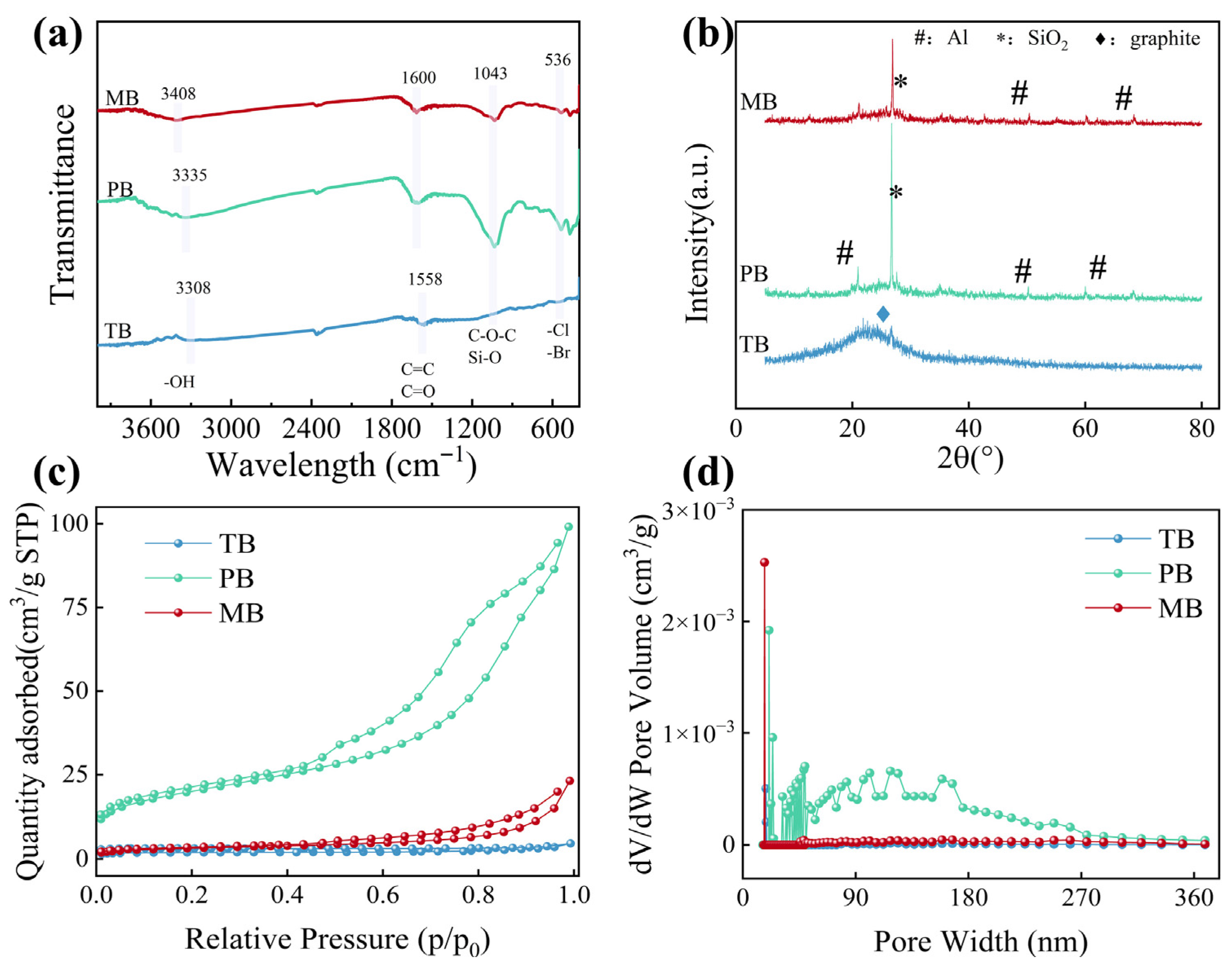

3.1. Physicochemical Characteristics of Biochars

3.2. Sludge Dewaterability and Water Distribution Characteristics

3.3. Changes in Physicochemical Properties of Sludge

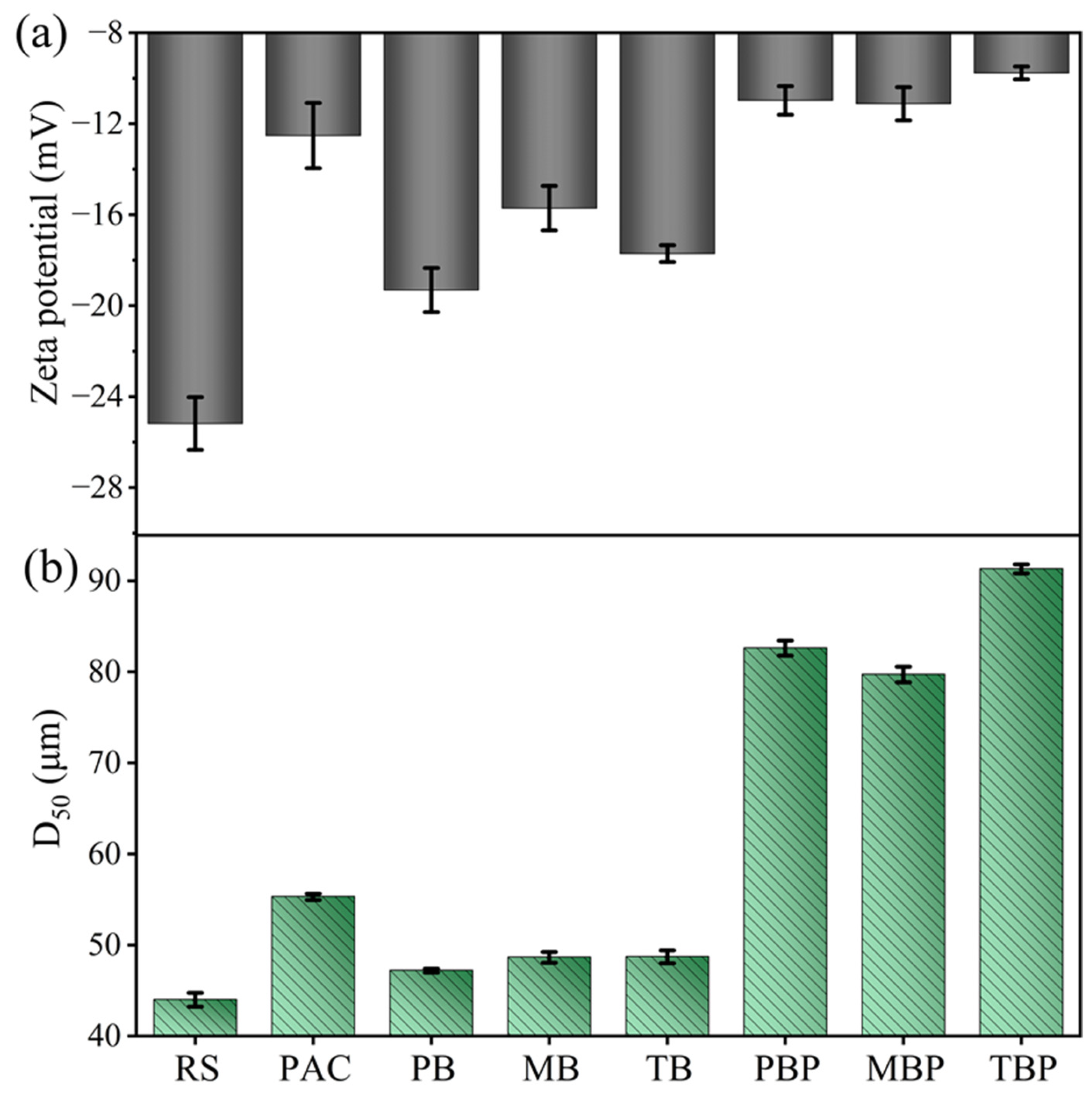

3.3.1. Zeta Potential and Particle Size

3.3.2. Rheological Properties

3.3.3. EPS

3.3.4. Floc Morphology and Microstructural Characteristics

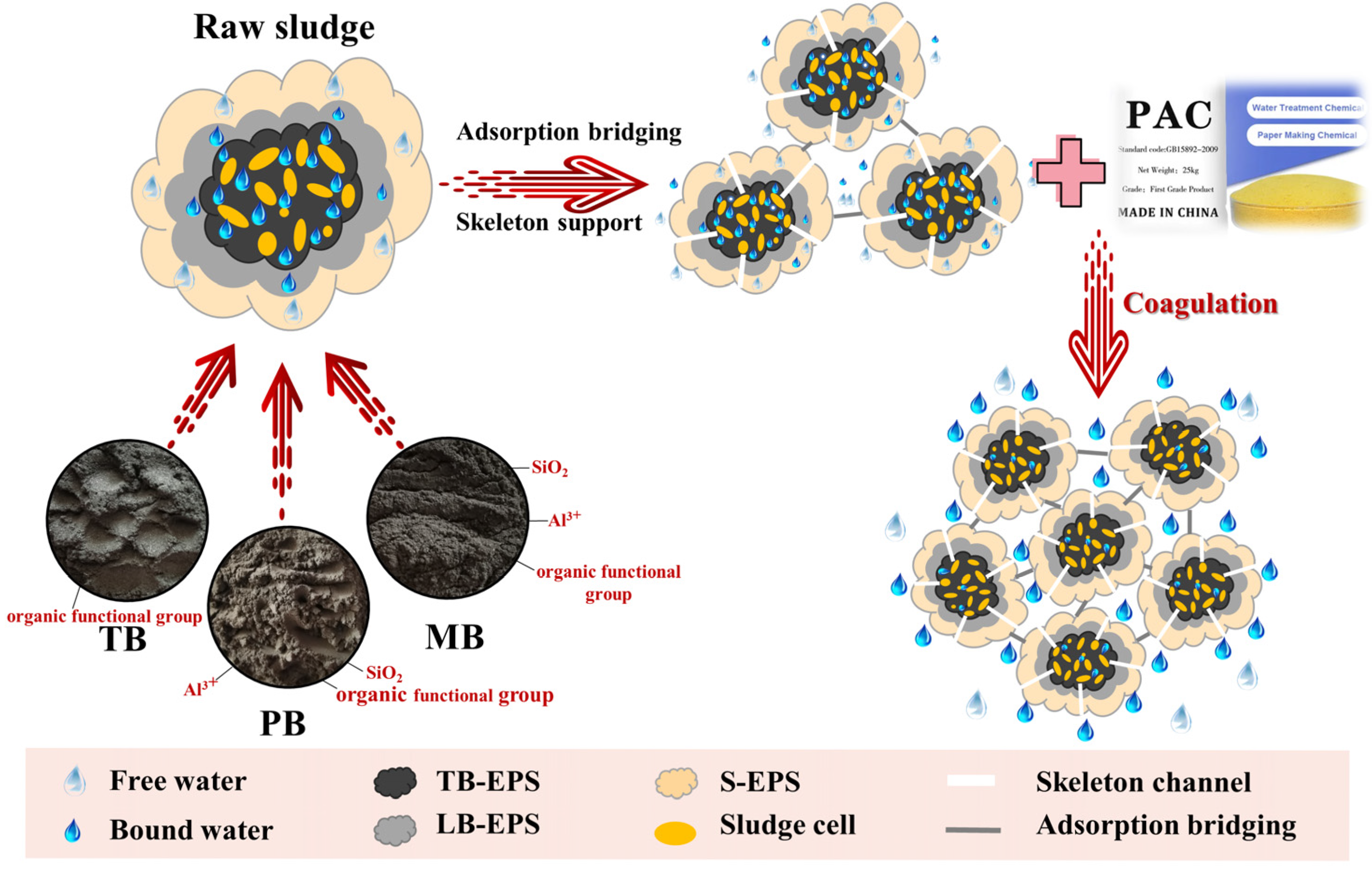

3.4. Proposed Dewatering Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Hua, Y.; Zhao, S.; Yang, D.; Chen, S.; Song, Q.; Gao, J.; Dai, X. Worldwide Research Progress and Trend in Sludge Treatment and Disposal: A Bibliometric Analysis. ACS EST Eng. 2023, 3, 1083–1097. [Google Scholar] [CrossRef]

- Zheng, W.; Shao, Y.; Qin, S.; Wang, Z. Future directions of sustainable resource utilization of residual sewage sludge: A review. Sustainability 2024, 16, 6710. [Google Scholar] [CrossRef]

- Bao, P.; Du, C.; Li, Y.; Jiang, H.; Zhou, L.; Yu, G.; Sun, S.; Zhou, L.; Li, X.; Teng, J.; et al. Application of skeleton builders to sludge dewatering and disposal: A critical review. Sci. Total Environ. 2024, 906, 167106. [Google Scholar] [CrossRef]

- Zhang, X.; Ye, P.; Wu, Y. Enhanced technology for sewage sludge advanced dewatering from an engineering practice perspective: A review. J. Environ. Manag. 2022, 321, 115938. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Zhou, Y. Iron-based advanced oxidation processes for enhancing sludge dewaterability: State of the art, challenges, and sludge reuse. Water Res. 2022, 218, 118499. [Google Scholar] [CrossRef] [PubMed]

- Yao, P.; You, A. Optimization of thermal–alkaline pretreatment for dewatering of excess sludge followed by thermal/persulfate oxidation for the elimination of extracellular ARGs in TAP-treated filtrate. Water Sci. Technol. 2023, 87, 2210–2222. [Google Scholar] [CrossRef]

- Pang, H.; Xu, Y.; Ren, R.; He, J.; Pan, X.; Wang, L. Enhanced anaerobic digestion of waste activated sludge by alkaline protease-catalyzing hydrolysis: Role and significance of initial pH adjustment. Chem. Eng. J. 2023, 467, 143323. [Google Scholar] [CrossRef]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef]

- Cao, B.; Zhang, T.; Zhang, W.; Wang, D. Enhanced technology based for sewage sludge deep dewatering: A critical review. Water Res. 2021, 189, 116650. [Google Scholar] [CrossRef]

- Harmaji, A.; Jafari, R.; Simard, G. Valorization of residue from aluminum industries: A review. Materials 2024, 17, 5152. [Google Scholar] [CrossRef]

- Jiang, Y.; Gao, F.; Zhang, N.; Li, J.; Xu, M.; Jiang, Y. Dehydration Performance of Municipal Sludge and Its Dewatering Conditioning Methods: A Review. Ind. Eng. Chem. Res. 2023, 62, 11337–11357. [Google Scholar] [CrossRef]

- Qi, Y.; Thapa, K.B.; Hoadley, A.F. Hoadley, Application of filtration aids for improving sludge dewatering properties–A review. Chem. Eng. J. 2011, 171, 373–384. [Google Scholar] [CrossRef]

- Wang, J.; Liu, H.; Deng, H.; Jin, M.; Xiao, H.; Yao, H. Deep dewatering of sewage sludge and simultaneous preparation of derived fuel via carbonaceous skeleton-aided thermal hydrolysis. Chem. Eng. J. 2020, 402, 126255. [Google Scholar] [CrossRef]

- Xiao, K.; Lv, Y.; Yu, W.; Yang, J. Visualization of water transfer channel in sludge dewatering conditioned with skeleton builders by X-ray micro-computed tomography. Chemosphere 2024, 355, 141818. [Google Scholar] [CrossRef]

- Li, W.; Wang, W.; Wu, D.; Yang, S.; Fang, H.; Sun, S. Mechanochemical treatment with red mud added for heavy metals solidification in municipal solid waste incineration fly ash. J. Clean. Prod. 2023, 398, 136642. [Google Scholar] [CrossRef]

- Chen, K.; Sun, Y.; Fan, J.; Gu, Y. The dewatering performance and cracking-flocculation-skeleton mechanism of bioleaching-coal fly ash combined process for sewage sludge. Chemosphere 2022, 307, 135994. [Google Scholar] [CrossRef]

- Kuryntseva, P.; Karamova, K.; Galitskaya, P.; Selivanovskaya, S.; Evtugyn, G. Biochar functions in soil depending on feedstock and pyrolyzation properties with particular emphasis on biological properties. Agriculture 2023, 13, 2003. [Google Scholar] [CrossRef]

- Ramos, R.; Abdelkader-Fernández, V.K.; Matos, R.; Peixoto, A.F.; Fernandes, D.M. Metal-supported biochar catalysts for sustainable biorefinery, electrocatalysis, and energy storage applications: A review. Catalysts 2022, 12, 207. [Google Scholar] [CrossRef]

- Senadheera, S.S.; Withana, P.A.; Lim, J.Y.; You, S.; Chang, S.X.; Wang, F.; Rhee, J.H.; Ok, Y.S. Carbon negative biochar systems contribute to sustainable urban green infrastructure: A critical review. Green Chem. 2024, 26, 10634–10660. [Google Scholar] [CrossRef]

- Lei, H.; Wang, Z.; Li, S.; Zhu, M. Recent advancements in chemical recycling and biodegradation of post-consumer polystyrene waste. Green Chem. 2025, 27, 9357–9413. [Google Scholar] [CrossRef]

- Li, S.; Lü, F.; Zhang, H.; Shao, L.; He, P. Electron exchange capacities of colloidal biochar: Affected by spatial structure distribution instead of particle size. Chem. Eng. J. 2023, 455, 140567. [Google Scholar] [CrossRef]

- Zhang, J.; Li, P.; Yu, Y.; Xu, Y.; Jia, W.; Zhao, S. A review of natural polysaccharides-based flocculants derived from waste: Application efficiency, function mechanism, and development prospects. Ind. Eng. Chem. Res. 2023, 62, 15774–15789. [Google Scholar] [CrossRef]

- Liu, B.; Guo, K.; Yue, Q.; Gao, Y.; Gao, B. Effect of Microplastics on the Coagulation Mechanism of Polyaluminum—Titanium Chloride Composite Coagulant for Organic Matter Removal Revealed by Optical Spectroscopy. ACS EST Eng. 2024, 4, 1914–1926. [Google Scholar] [CrossRef]

- Miao, S.; Wei, Y.; Chen, J.; Wei, X. Extraction methods, physiological activities and high value applications of tea residue and its active components: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 12150–12168. [Google Scholar] [CrossRef] [PubMed]

- You, Z.; Zhao, L.; Zhao, K.; Liao, H.; Wen, S.; Xiao, Y.; Cheng, B.; Lei, S. Highly tunable three-dimensional porous carbon produced from tea seed meal crop by-products for high performance supercapacitors. Appl. Surf. Sci. 2023, 607, 155080. [Google Scholar] [CrossRef]

- Wang, H.F.; Qi, H.Y.; Lian, Z.H.; Zhang, Y.L.; Li, J.; Zeng, R.J. A unified operating procedure is crucial to evaluate sludge dewaterability, taking the setup of refrigerated storage time as an example. J. Environ. Manag. 2022, 307, 114528. [Google Scholar] [CrossRef]

- Rao, B.; Su, J.; Xu, S.; Pang, H.; Xu, P.; Zhang, Y.; Zhu, J.; Tu, H. Thermal and non-thermal mechanism of microwave irradiation on moisture content reduction of municipal sludge. Water Res. 2022, 226, 119231. [Google Scholar] [CrossRef]

- Wu, B.; Li, H.; Zhou, K.; Yu, N.; Xu, Q.; Chai, X.; Dai, X. Crystallization-driven evolution of water occurrence states with implications on dewaterability improvement of waste-activated sludge. Water Res. 2023, 244, 120496. [Google Scholar] [CrossRef]

- Li, X.Y.; Yang, S.F. Influence of loosely bound extracellular polymeric substances (EPS) on the flocculation, sedimentation and dewaterability of activated sludge. Water Res. 2007, 41, 1022–1030. [Google Scholar] [CrossRef]

- Yu, W.; Yang, J.; Shi, Y.; Song, J.; Shi, Y.; Xiao, J.; Li, C.; Xu, X.; He, S.; Liang, S. Roles of iron species and pH optimization on sewage sludge conditioning with Fenton’s reagent and lime. Water Res. 2016, 95, 124–133. [Google Scholar] [CrossRef]

- Liu, W.H.; Zhang, H.; Zhang, Y.L.; Sun, P.; Zeng, Y.P.; Gao, Y.Y.; Wang, H.F.; Zeng, R.J. Beyond filterability: Understanding the complexities of sludge dewatering through typical coagulation and advanced oxidation. J. Clean. Prod. 2023, 429, 139520. [Google Scholar] [CrossRef]

- Wu, B.; Wang, H.; He, Y.; Dai, X.; Chai, X. Influential mechanism of water occurrence states of waste-activated sludge: Over-focused significance of cell lysis to bound water reduction. Water Res. 2022, 221, 118737. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, D.; Yang, G.; Yuan, X.; Xu, Q.; Yang, Q.; Liu, Y.; Wang, Q.; Ni, B.J.; Tang, W.; et al. Enhanced dewaterability of anaerobically digested sludge by in-situ free nitrous acid treatment. Water Res. 2020, 169, 115264. [Google Scholar] [CrossRef] [PubMed]

- Cao, B.; Zhang, W.; Wang, Q.; Huang, Y.; Meng, C.; Wang, D. Wastewater sludge dewaterability enhancement using hydroxyl aluminum conditioning: Role of aluminum speciation. Water Res. 2016, 105, 615–624. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Wen, Q.; Yang, J.; Xiao, K.; Zhu, Y.; Tao, S.; Lv, Y.; Liang, S.; Fan, W.; Zhu, S.; et al. Unraveling oxidation behaviors for intracellular and extracellular from different oxidants (HOCl vs. H2O2) catalyzed by ferrous iron in waste activated sludge dewatering. Water Res. 2019, 148, 60–69. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Moisture content (%) | 97.77 ± 0.06 |

| pH | 6.98 ± 0.27 |

| Zeta potential (mV) | −25.20 ± 1.55 |

| Dry solids (g/L) | 22.30 ± 0.24 |

| Volatile solids (g/L) | 11.80 ± 0.10 |

| CST (s) | 97.45 ± 1.90 |

| Sample | Conditioning Reagents | Dosage | Conditioning Process | |

|---|---|---|---|---|

| PAC (% DS) | Biochars (% DS) | |||

| RS | - | - | - | - |

| PAC | PAC | 4 | - | After adding PAC solution, the mixture was stirred at 300 rpm for 3 min. |

| TB-5 | TB | - | 5 | |

| TB-10 | - | 10 | After adding different doses of tea stem biochar, the mixture was stirred at 300 rpm for 3 min. | |

| TB-15 | - | 15 | ||

| TB-20 | - | 20 | ||

| PB-5 | PB | - | 5 | After adding different doses of aluminum-based mud biochar, the mixture was stirred at 300 rpm for 3 min. |

| PB-10 | - | 10 | ||

| PB-15 | - | 15 | ||

| PB-20 | - | 20 | ||

| MB-5 | MB | - | 5 | After adding different doses of mixed biochar, the mixture was stirred at 300 rpm for 3 min. |

| MB-10 | - | 10 | ||

| MB-15 | - | 15 | ||

| MB-20 | - | 20 | ||

| TBP | PAC + TB | 4 | 10 | PAC solution was added first and stirred at 300 rpm for 3 min, and then biochar was added and stirred at 300 rpm for 3 min. |

| PBP | PAC + PB | |||

| MBP | PAC + MB | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.-Y.; Xu, G.; Qi, H.-Y.; Chen, X.-X.; Wang, H.-F.; Cui, X.-M. Synergistic Enhancement of Sludge Deep Dewatering via Tea Waste and Sludge-Derived Biochars Coupled with Polyaluminum Chloride. Separations 2025, 12, 229. https://doi.org/10.3390/separations12090229

Zhang Q-Y, Xu G, Qi H-Y, Chen X-X, Wang H-F, Cui X-M. Synergistic Enhancement of Sludge Deep Dewatering via Tea Waste and Sludge-Derived Biochars Coupled with Polyaluminum Chloride. Separations. 2025; 12(9):229. https://doi.org/10.3390/separations12090229

Chicago/Turabian StyleZhang, Qiang-Ying, Geng Xu, Hui-Yun Qi, Xuan-Xin Chen, Hou-Feng Wang, and Xiao-Mei Cui. 2025. "Synergistic Enhancement of Sludge Deep Dewatering via Tea Waste and Sludge-Derived Biochars Coupled with Polyaluminum Chloride" Separations 12, no. 9: 229. https://doi.org/10.3390/separations12090229

APA StyleZhang, Q.-Y., Xu, G., Qi, H.-Y., Chen, X.-X., Wang, H.-F., & Cui, X.-M. (2025). Synergistic Enhancement of Sludge Deep Dewatering via Tea Waste and Sludge-Derived Biochars Coupled with Polyaluminum Chloride. Separations, 12(9), 229. https://doi.org/10.3390/separations12090229