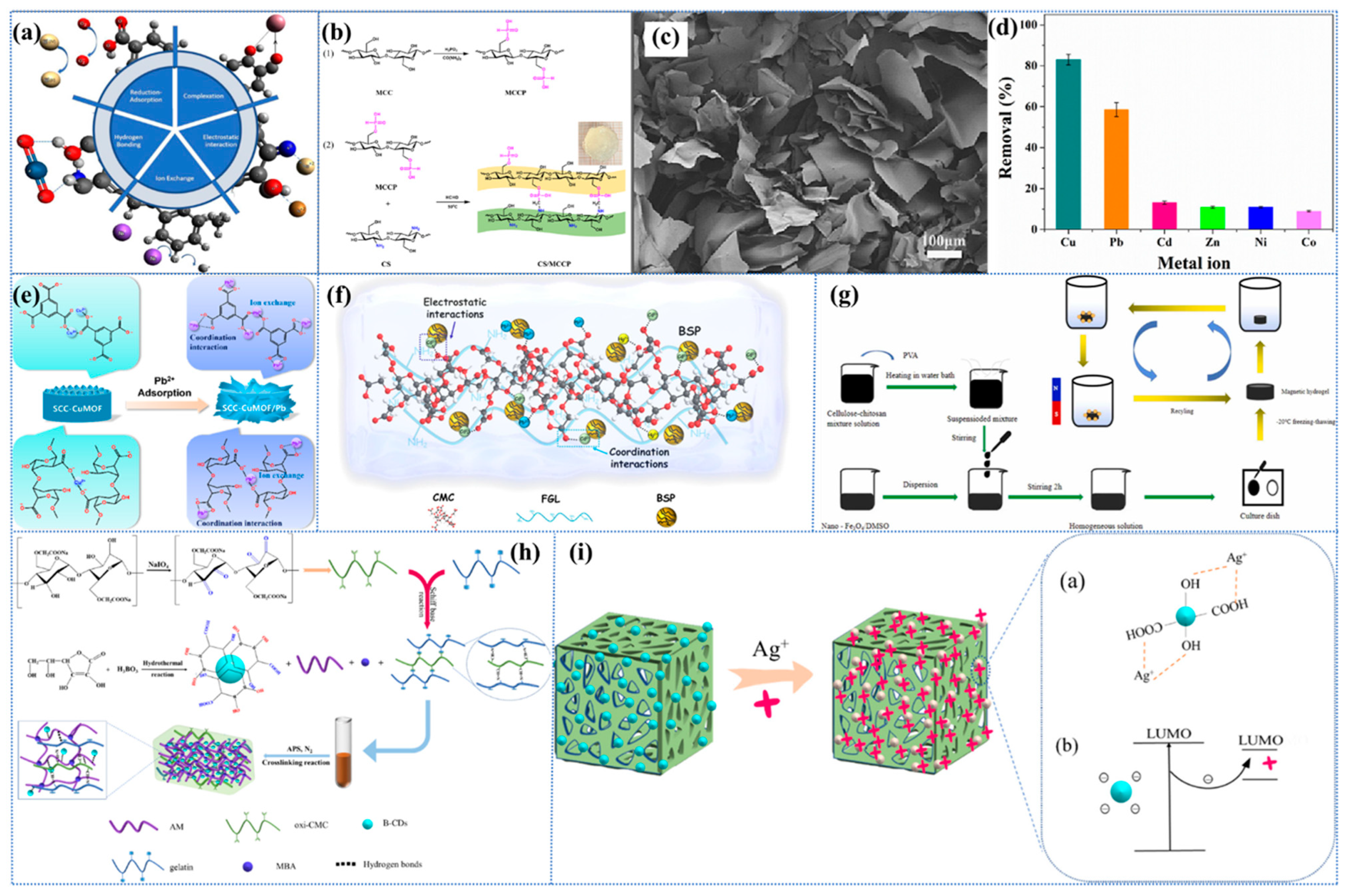

Abstract

The rapid pace of global industrialization and population growth has intensified freshwater scarcity and water pollution, necessitating urgent solutions. Adsorption technology, favored for its cost-effectiveness, simplicity, and scalability, has emerged as a promising approach. Hydrogels, particularly cellulose-based hydrogels (CBHs), have gained significant attention as green adsorbents due to their biodegradability, non-toxicity, low cost, and exceptional adsorption capacity. This paper reviews recent advancements in CBHs for sustainable wastewater treatment, focusing on synthesis techniques, performance, and mechanisms for removing heavy metals, dyes, and micropollutants. Updated applications and their outcomes are also discussed. Despite their advantages, CBHs face challenges such as limited mechanical strength, practical production difficulties, insufficient reuse studies, and separation inefficiencies. This review addresses these issues and explores future prospects for their practical implementation. The findings provide valuable insights into advancing CBHs in sustainable and efficient water treatment solutions.

1. Introduction

Extreme climate change, such as global warming and drought, as well as emerging pollutants, have been threatening water security [1,2,3,4,5]. Compounding this issue is the ongoing rise in the global population and levels of industrialization, resulting in an unabating demand for potable water supplies [6,7,8,9,10]. Moreover, the issue of water scarcity is becoming increasingly pronounced due to the contamination of water bodies by wastewater emanating from various industrial sectors, including textiles, smelting, chemicals, pharmaceuticals, and food production [11,12,13,14,15]. It is imperative to treat wastewater prior to its discharge. In order to meet the requirements for the discharge of treated wastewater, a variety of efficient water and wastewater treatment technologies have been developed to remove pollutants from water [16,17,18,19,20]. These include the development of new membranes [21,22,23,24,25,26,27], disinfection technologies [28,29,30,31,32,33], advanced oxidation processes [34,35,36,37,38], and the use of high-performance adsorbents in the context of adsorption treatment [39,40,41,42,43,44]. Among the technologies mentioned above, adsorption is one of the most widely used for the sustainable and effective removal of pollutants from water.

Compared to other water treatment technologies, adsorption is economical, efficient, selective, and easy to operate with low energy requirements [45,46,47,48]. In the industrial context, conventional adsorbents encompass derivatives of activated carbon, graphene, carbon nanotubes, and analogous materials. Furthermore, adsorbent materials encompass polymer-based systems (for instance, polyacrylonitrile derivatives [49,50,51,52,53,54]) and porous materials (e.g., metal–organic frameworks [55,56,57,58,59,60,61] and zeolites [62,63,64,65]). Among these, porous materials are frequently utilized as functional components in the construction of composite adsorbents—a consequence of their elevated specific surface area and tunable pore structure. However, these industrial adsorbents typically exhibit certain substantial drawbacks, including the requirement of energy-intensive production processes (e.g., pyrolysis), the complexity of regeneration, and the overall high costs of production [66,67,68,69,70]. Consequently, there is a growing interest in the development of alternative adsorbents utilizing a range of innovative materials that have demonstrated enhanced adsorptive removal of pollutants. In this regard, hydrogels are relatively new in the development of alternative adsorbents with the built-in ability to capture a wide range of pollutants from water [71,72,73,74,75,76].

Hydrogels are three-dimensional networks of polymer chains that can absorb and retain large amounts of water without being water soluble [77,78,79]. They are widely used in biomedical and environmental applications due to their bioactivity, biocompatibility, and high-water content. In addition, they are highly porous, hydrophilic, non-toxic, and highly functional, making them an ideal alternative to green adsorbents [80,81]. Hydrogels can be classified according to their composition, cross-linking mechanism, and swelling behavior [82,83,84,85]. In the field of hydrogel preparation, petroleum-based materials such as N-isopropylacrylamide, hydroxyethyl methacrylate, and acrylic acid are frequently utilized due to their efficacy in contaminant removal from water. However, the utilization of synthetic polymer hydrogels is accompanied by significant environmental concerns, as well as the challenges posed by their cost and limited accessibility. Consequently, there is an increasing inclination towards utilizing natural materials in the fabrication of hydrogels [1,75,86,87]. Among the natural polymers utilized in the development of hydrogels, cellulose stands as the most prevalent polysaccharide (a significant constituent of plant cell walls) and is widely regarded as the optimal choice for hydrogel-based polymers due to its unique properties such as low cost, easy availability, biodegradability, high biocompatibility, non-toxicity, renewability, and reusability [45,88]. Nevertheless, inherent limitations of natural polymers result in certain disadvantages of hydrogels based on natural materials, including inadequate mechanical strength [89,90]. Fortunately, the employment of diverse strategies has led to the enhancement of natural polymer hydrogels in terms of mechanical strength. For instance, dual and interpenetrating network hydrogels have been shown to be an effective strategy for enhancing the mechanical strength of natural polymer-based hydrogels [1,91,92].

In the domain of water and wastewater treatment, cellulose-based hydrogels (CBHs) have been shown to possess significant potential as highly adsorbent materials for the removal of micropollutants, heavy metals, and dyes from contaminated water [93,94,95,96,97]. In recent years, driven by the goal of a circular economy, researchers have expanded the application dimensions of CBHs. This has enabled not only enhanced adsorption capacity and selectivity of target pollutants, but also efficient recovery and enrichment of strategic metal resources (e.g., uranium and lithium) in wastewater through the design of specific functional groups (e.g., phosphoric acid moiety and amidoxime moiety) [98]. For instance, in one report, phosphorylated CNF (PHO-CNF) was utilized with an exceptionally high adsorption capacity (1550 mg/g) and selectivity for U(VI) [99]. This can be attributed to the high surface area, anionic charge, and the high affinity of the phosphate group for U(VI) of PHO-CNF. In addition, it has been demonstrated that the charge–radius ratio of the phosphate group to U(VI) and the hydrolysis of U(VI) also contribute to the high selectivity. Huang et al. generated nanostructured poly-amidoxime (PAO) structural domains in situ in the CNF matrix, which resulted in high adsorption and selectivity for U [100]. This functionality-oriented molecule was designed to provide the high surface area of PHO-CNF and the high affinity of PHO-CNF for U(VI). This functionally oriented molecular design provides an innovative solution for integrated water treatment–resource recovery technologies.

In light of the aforementioned points, the present review offers a comprehensive overview of recent advancements in the development of sustainable and efficient CBHs for wastewater treatment. The paper’s central theme is advanced preparation techniques and performance optimization methods for CBHs, as well as their recent applications in the removal of pollutants from wastewater. The discussion highlights their advantages, limitations, and future prospects. A critical analysis of various examples was undertaken, and it can be concluded that CBHs are one of the effective adsorbents for the removal of heavy metals, dyes, and micropollutants. It is hoped that this paper will provide insights into new strategies for developing high-performance CBHs for water treatment.

Although previous reviews have established a methodological framework for CBHs from synthesis to performance evaluation (e.g., Le et al.) [77], focusing on the application of CBHs in the field of heavy metal removal (e.g., Kushwaha et al. and Persano et al.) [45,88], their analyses have still concentrated on only one aspect of CBHs, particularly neglecting dye adsorption and micropollutant remediation. This paper offers a distinctive integration of existing research, highlighting advances in the removal mechanism of CBHs and their potential for micropollutant removal. Through critical analysis of various examples, it is concluded that CBHs will emerge as a multifunctional remediation platform, transcending the conventional role of adsorbents.

2. Cellulose-Based Hydrogels for Sustainable and Efficient Water Treatment

2.1. Basic Properties and Chemical Structure of Cellulose

Cellulose, the most abundant natural polymer on Earth, is a long-chain polysaccharide consisting of β-D-glucose units linked together by β-1,4-glycosidic bonds [101,102]. This unique molecular architecture renders cellulose exceptional physicochemical stability and utility through water insolubility [103]. The long chains of cellulose form two distinct regions: highly ordered crystalline and less-structured amorphous through a dual structural arrangement. The former further enhances stability and mechanical strength, while the latter brings reactivity as well as biological properties [101,104]. Predominantly sourced from plant cell walls, cellulose can also be biosynthesized by microbial species. There are ongoing efforts to utilize agricultural waste as the primary cellulose resource [105].

Cellulose can also be converted into cellulose derivatives (CD), such as cellulose nanocrystals (CNC), cellulose nanofibrils (CNF), bacterial nanocellulose (BNC), and other cellulose derivatives, through chemical or mechanical pre-treatments, in response to the needs of different wastewater treatments [106,107,108]. Specifically, the chemical modification of cellulose by esterification [109], grafting, etherification, oxidation [110], and cross-linking is a common procedure, yielding the desired CDs. In addition to these methods, treatments involving acids, alkalis, and a combination of organic and inorganic reagents can also be employed to achieve the desired result [106,111,112]. It has been demonstrated that through the process of modification, it is possible to introduce additional functional groups into cellulose, thereby increasing the number of hydrogel adsorption sites. In addition, this process enables the regulation of the pore structure of cellulose, resulting in an enhancement of the specific surface area of the hydrogel. Furthermore, it has been shown that modified cellulose can be further optimized to enhance its performance advantages, and it can be endowed with responsiveness to specific stimuli. It is evident that modified hydrogels have the capacity to be utilized in the immobilization of enzymes or catalysts, enhancing operational stability, recyclability, and catalytic efficacy in continuous processes.

2.2. Cellulose-Based Hydrogels for Water and Wastewater Treatment

CBHs have been demonstrated to be both sustainable and effective in the removal of a variety of water pollutants, including metals, dyes, and micropollutants, while enabling desalination and atmospheric water harvesting [74]. The hydrophilic nature of CBHs facilitates water uptake and transport. This, in conjunction with their high porosity, enables efficient water uptake and the effective adsorption of pollutants [113]. In addition, hydrogels prepared with cellulose have been shown to exhibit excellent stability and mechanical strength, and can be reused for water treatment [77]. Another fascinating feature of CBH is their biodegradability, which allows them to be degraded by microorganisms in water, air, or soil [88]. This has the effect of reducing the environmental impact of residual materials after water treatment and increasing the sustainability of the whole process.

The preparation of CBHs can be categorized into three distinct methodologies: physical cross-linking, chemical cross-linking, and self-assembly synthesis. In physical cross-linking methods, cellulose chains are cross-linked using physical means such as temperature, pressure, or radiation, and the hydrogels obtained consist of non-covalent cross-links and are, therefore, reversible networks [114]. These non-covalent forces can be van der Waals forces, hydrogen bonding, hydrophobic, or electronic interactions [45]. Chemical cross-linking, which involves the use of chemical cross-linking agents to covalently link cellulose chains, has been shown to outperform physical cross-linking [115]. The reason for this is that chemical cross-linking produces irreversible networks with higher stability, adsorption, and mechanical properties. Self-assembled 3D networks, on the other hand, rely on cellulose’s inherent capacity to form ordered structures, a process that involves intermolecular forces such as van der Waals forces, hydrogen bonding, and electrostatic interactions [116,117,118,119].

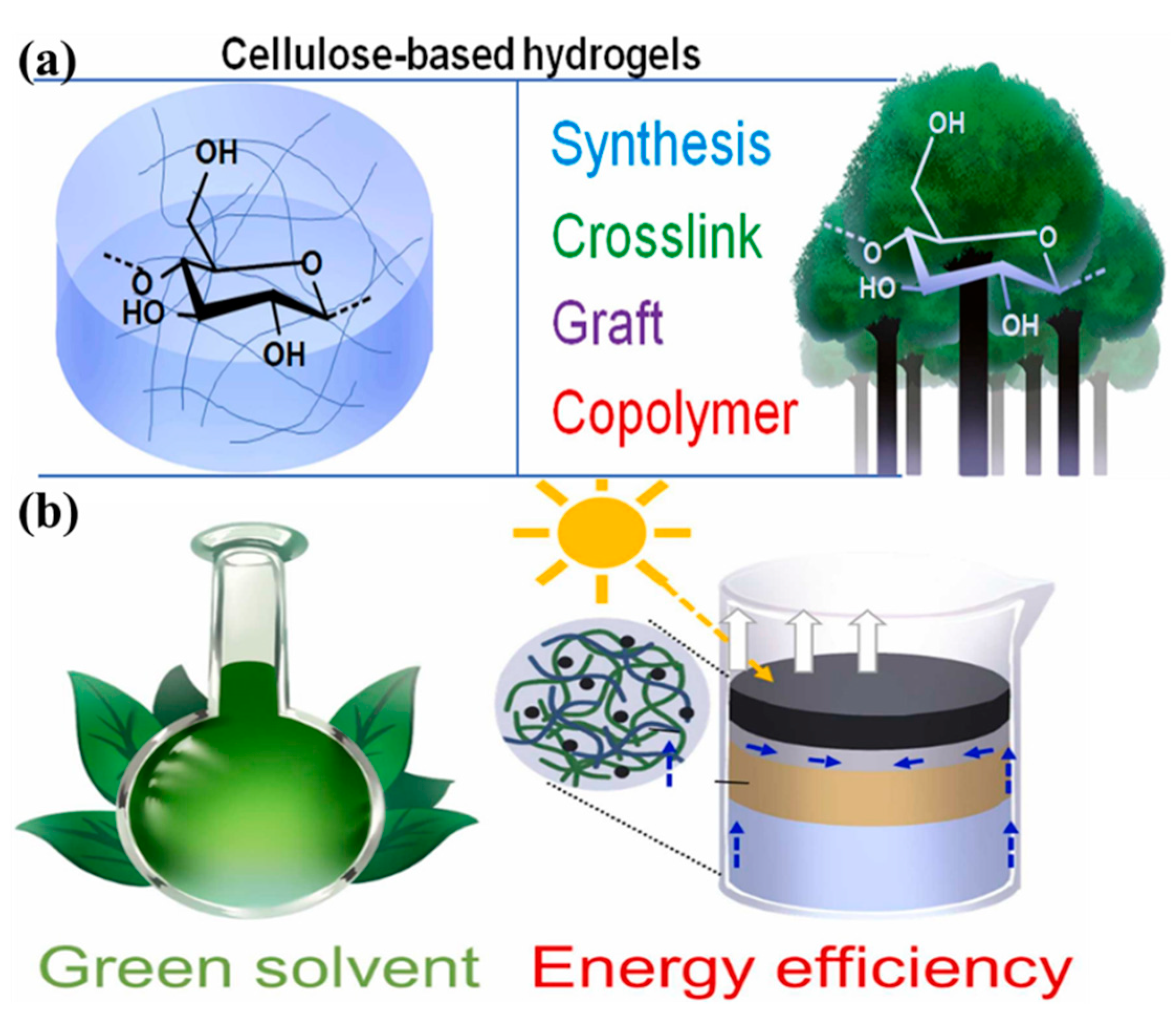

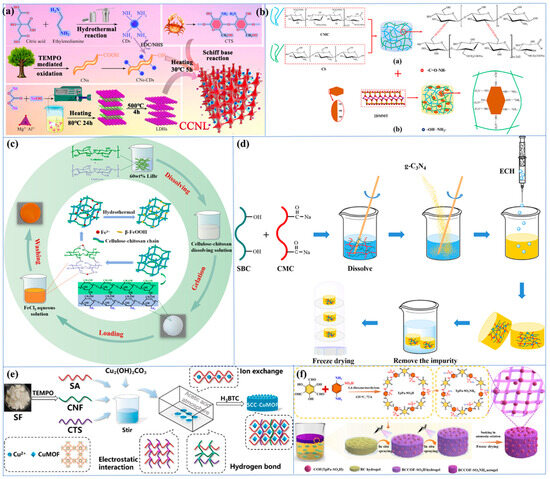

CBHs performance is tunable via cross-linking, co-mingling, or functionalization, enhancing contaminant selectivity, structural stability, reusability, and operational efficiency in aqueous remediation [120]. Precise control over factors governing cellulose hydrogel characteristics (e.g., cross-linking density and crystallinity ratio) enables tailored engineering of functionality and stability to meet application-specific performance benchmarks in biomedical, environmental, and materials engineering systems [101,121]. The initial factor to be considered is the selection of a solvent to enhance the solubility of cellulose, which consequently impacts the structure and properties of the resulting hydrogel [122,123]. Presently, green solvents, such as deep eutectic solvents, are more prevalent in research, as they are capable of effectively dissolving cellulose while maintaining its excellent biocompatibility and biodegradability [101,124,125]. The properties of CBHs are influenced by many factors, including pH, temperature, and swelling kinetics. For instance, the pH of the medium affects the ionization state of cellulose, thereby influencing its structural integrity and interactions within the hydrogel matrix. Conversely, elevated temperatures have been observed to promote cellulose solubilization, as well as cross-linking reactions, resulting in the rapid formation of stable hydrogel networks [126]. Furthermore, the cross-linking method employed is pivotal in determining the structural and functional properties of CBHs. Given the considerable effect that the cross-linking method has on the material’s properties and its suitability for a specific application, the chosen method must be consistent with the intended use of the hydrogel [127]. As illustrated in Figure 1, the synthesis of CBHs is depicted, along with a schematic representation of a green and energy-efficient production process.

Figure 1.

Synthesis of cellulose-based hydrogels: (a) chemical or physical cross-linking and copolymerization; (b) schematic representation of the production of cellulose-based hydrogels using green solvents and energy-saving techniques. Reproduced from [77], Copyright (2023), with permission from Elsevier.

3. Sustainable Synthesis and Processing of Cellulose-Based Hydrogels

In the context of sustainable water treatment, the synthesis methods employed have a significant impact on the stability, regeneration, and reusability of the internal structure of hydrogels. In the context of efficient water treatment, the synthesis methods employed result in variations in the composition and nature of reactive functional groups present on the surface of the hydrogel, as well as in the specific surface area of the porous structure. These variations, in turn, have a significant impact on the adsorption capacity, hydrophilicity, and the rate of water treatment of the hydrogel. In light of these considerations, the factors influencing the sustainability and efficiency of hydrogels during the synthesis and processing of CBHs are becoming increasingly significant in materials research [96]. A significant challenge in synthesizing CBHs pertains to their solubility in common solvents. While certain cellulose derivatives exhibit water solubility, natural cellulose demonstrates virtually no solubility in most prevalent organic and inorganic solvents. Consequently, the selection of an appropriate solvent system for the dissolution of cellulose is a prerequisite for the synthesis of hydrogels. Commonly employed solvents include alkali/urea (or thiourea), LiCl/dimethylacetamide, N-methyl-morpholine-N-oxide, and ionic liquids [113].

The presence of hydrophilic functional groups (e.g., hydroxyl groups (-OH)) on the cellulose chains allows them to form stable 3D network structures through physical cross-linking (e.g., electrostatic interactions) and chemical cross-linking (covalent interactions using cross-linking agents) [113]. These processes are essential for retaining a large amount of water in the interstitial spaces and, thus, forming hydrogels. The primary methodologies employed for the preparation of CBHs encompass physical cross-linking and chemical cross-linking. Each method possesses distinct advantages and application areas. Through judicious selection and combination of these methods, the structure and performance of hydrogels can be tailored to meet the specific requirements of wastewater treatment. Table 1 provides a concise overview of several manufacturing methodologies and their respective characteristics.

Table 1.

Fabrication methods and their characteristics.

Table 1.

Fabrication methods and their characteristics.

| Methods | Characteristic | References |

|---|---|---|

| Physical cross-linking by hydrogen bonding, ionic interactions, hydrophobic interactions, π–π interactions, and van der Waals forces | Low toxicity, high porosity, higher adsorption opportunities, low sensitivity to pH, and easy regeneration (it is a reversible process), but weak mechanical strength and stability | [113] |

| Chemical cross-linking using cross-linking agents | High mechanical strength and stability, easy to handle, and common; however, toxicity exists and has a large impact on biocompatibility | [128] |

| IPN or semi-IPN | High strength, toughness, and self-healing; complex preparation and existing compatibility issues between different polymer networks | [129] |

| Use of radiation to initiate free radical reactions that promote cross-linking | Fast response, excellent transparency, homogeneity, and mechanical properties, particularly suitable for 3D printing technology; high requirements for control of radiation source, dose, and exposure time | [127] |

3.1. Physical Cross-Linking

The physical cross-linking process renders CBHs reversible since cellulose chains are assembled in a three-dimensional structure formed by intertwining intra- and intermolecular hydrogen bonding, ionic bonding, hydrophobic interactions, and non-permanent forces (e.g., electrostatic forces). In contradistinction to chemical cross-linking, physical cross-linking does not utilize toxic cross-linking agents. Consequently, the resulting hydrogels are more biocompatible and possess low toxicity, which constitutes their primary advantage [130,131,132,133,134]. Furthermore, the presence of a weak interaction force between polymer chains facilitates the formation of physically crosslinked hydrogels with greater ease and expediency. Furthermore, this cross-linking renders the hydrogels more biodegradable, as the weak interactions within the polymer network are more susceptible to degradation than covalent bonds [135]. The aforementioned properties extend the application areas of physically crosslinked CBHs. Conversely, the absence of strong chemical bonds (covalent bonds) within the hydrogel network typically results in physically crosslinked hydrogels that are prone to rapid dissolution and reduced stability [136]. The advent of the dual network hydrogel process represents a significant advancement in addressing the limitations of physically crosslinked hydrogels [137].

In conclusion, despite the poor stability and mechanical properties of CBHs developed through physical cross-linking processes, they are still widely used for adsorption water treatment because of their many attractive advantages, including high porosity, higher chance of adsorption of contaminants, low sensitivity to pH, easy reversible regeneration, and no reduction of the final adsorption capacity due to the potential reaction with cross-linking agents [113,138].

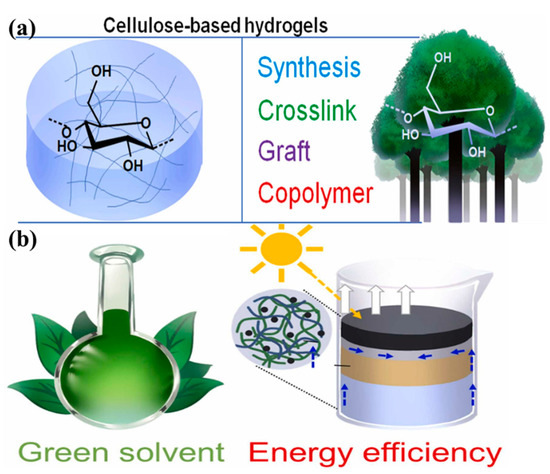

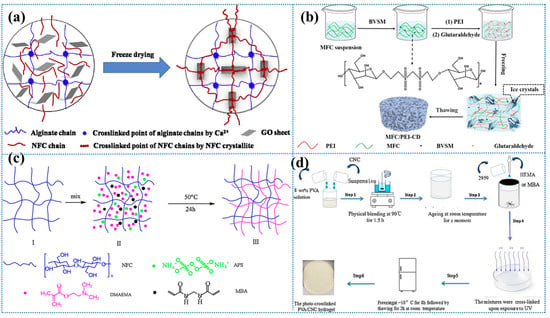

3.1.1. Repeated Freeze–Thaw Cycles

One of the most widely utilized physical cross-linking methodologies employed in the fabrication of sustainable and efficient cellulose-based hydrogel adsorbents is the cryogenic method, which is also designated as the repeated freeze–thaw cycle process [139,140]. The freeze–thaw process has been shown to promote the interaction of hydrogen bonds between cellulose molecules through repeated freeze–thaw cycles. This results in a reduction in mechanical strength, yet it ensures excellent biocompatibility and tunability [141,142]. During these cycles, when the polymer solution is subjected to low temperatures for the purpose of crystallization, the large amount of solvent or low molecular solutes present within it serves to increase the concentration of the polymer by minimizing the chain space in the polymer and forcing the chains to align and combine into a connected network structure of insoluble polymers, which ultimately leads to phase separation and the formation of a hydrogel (as shown in Figure 2a) [113,136]. Furthermore, the process of freeze–thaw cycling has been demonstrated to result in the formation of a porous structure within the hydrogel, thereby increasing the specific surface area. This phenomenon is primarily attributable to the space left by the ice crystals that melt during the thawing phase [113]. The degree of gelation and the mechanical properties of freeze–thaw hydrogels are contingent on pH, polymer concentration, freezing temperature, freeze–thaw time, and number of freeze–thaw cycles.

In a study conducted by Wang et al. [143], a polyvinyl alcohol (PVA)/carboxymethyl cellulose (CMC) composite hydrogel with a high degree of cross-linking was developed for the adsorption of heavy metal ions through repeated freeze–thaw cycles (Figure 2b). Specifically, an insoluble hydrogel was produced by freezing a mixed aqueous solution of PVA and CMC in varying proportions at −20 °C and thawing it at room temperature, repeating the process five times. The findings demonstrated that the proportion of PVA to CMC exerted a substantial influence on the physical characteristics and swelling of the hydrogels. An increase in the CMC content resulted in a decrease in the gel fraction but an increase in the degree of swelling. The swelling degree of pure PVA hydrogel was 416%, while the hydrogel with a 1:2 ratio of PVA/CMC reached 1437%. This phenomenon can be attributed to the enhanced hydrophilicity of CMC, which is accompanied by a reduced amount of PVA. The reduced amount of PVA leads to a lower physical cross-linking density of the hydrogel, thereby facilitating the penetration of water molecules and consequently resulting in an increased swelling capacity. In addition, the hydrogel exhibited excellent adsorption and reduction capabilities, particularly towards Ag+. Unfortunately, their study did not evaluate the recycling performance of this hydrogel further to verify its adsorption sustainability, but the report still opens up the idea of designing CBH with tunable performance. In a separate report, Graphene Oxide (GO) and Attapulgite (ATP) were innovatively introduced into the three-dimensional network structure of bacterial cellulose (BC) PVA by freeze–thaw cycling, and BC/PVA/GO/ATP composite hydrogels were constructed by using the strong interacting hydrogen bonding, which resulted in the increase in the specific surface area of the hydrogel and the improvement in the thermal stability [144]. In contrast, this paper also investigated the reusability and sustainability of the material, which remained above 83.67% after four cycles. The introduction of GO and ATP has been demonstrated to enhance mechanical properties, optimize the pore structure, and form a more compact porous structure. Furthermore, the study has opened up the possibility of conferring multifunctionality to hydrogels. However, the dispersive nature of GO and ATP has also been shown to present significant challenges during preparation; moreover, the study overlooked the impact of these substances on biocompatibility.

In recent years, freeze cross-linking, a novel physical cross-linking method for the synthesis of products with high water content, high compressive strength, and high compression recovery, was developed [145]. Hydrogels were prepared by adding aqueous citric acid (CA) into frozen carboxymethylcellulose nanofiber (CMCF) sols, followed by the thawing of the sols (as illustrated in Figure 2c). This cross-linking method is simple and does not require synthetic reagents, which makes it highly practical and sustainable. The resulting hydrogels are characterized by their high level of biodegradability and are considered non-toxic and environmentally friendly. Furthermore, the freeze cross-linking method facilitates the production of more versatile CMCF hydrogels through the mixing of the CMCF solution with other powder materials (e.g., bentonite) before freezing, and allows for moulding [145]. The powder adsorbent material can be immobilized in this way and, subsequently, easily and efficiently removed from the medium without the use of adhesives, which causes a reduction in the specific surface area of the adsorbent. It is imperative to exercise meticulous control over the freezing rate in this novel cross-linking technique, where slower rates may result in abnormally large pores and faster rates may result in weaker mechanical structures.

3.1.2. Ionotropic Gelation

Ionotropic Gelation (IG) is a notable physical cross-linking hydrogel technology that forms a network structure by allowing electrostatic interactions to produce ionic cross-linking between two ionic substances [146,147,148], at least one of which should be a polymer (e.g., cellulose), under specific conditions [113,149]. In a study, SA/HPC hydrogel beads were synthesized by IG of sodium alginate (SA) and hydroxypropyl cellulose (HPC) solutions at different ratios (0:50, 75:25, and 100:0) [150]. The adsorption properties of the prepared ionically cross-linked hydrogels were found to be largely influenced by the concentration of the two ionic substances from which they were composed, as indicated by adsorption tests. The 75:25 ratio exhibited a higher adsorption capacity of 47.72 mg/g and a 95.45% adsorption percentage of Pb2+. The ionic conductivity, biocompatibility, low toxicity, and reversible crosslinking are all important features of ionic crosslinked CBHs. However, in the context of ionic crosslinked hydrogels, the size of the cations [151], their valence [152], hydration, and the nature of the interaction are pivotal in determining their gel behavior [153].

It is evident that, despite the capacity of CBHs produced by the IG method to furnish a mobile space for free ions, this concomitantly signifies a diminution in thermal and chemical stability, which is deleterious to the long-term utilization of hydrogels. The conductivity and mechanical properties of hydrogels have been demonstrated to be negatively correlated in extant studies, a factor that may also limit their application areas. Additionally, there remains a challenge in accurately characterizing the ion–polymer interactions present within ionic crosslinked networks, which in turn hinders the development of tailored properties.

3.1.3. Self-Assembling

In many cases, adsorption wastewater treatment prefers hydrogels without chemical cross-linking agents to avoid the toxicity of the cross-linking agent. In this sense, self-assembled CBHs hydrogels without the use of foreign cross-linkers have attracted much attention. Self-assembled CBHs are formed when cellulose and its derivatives are used as building blocks to self-assemble to form nanofibers or microfibers through noncovalent interactions (van der Waals forces, electrostatic interactions, hydrogen bonding, and π–π stacking interactions); then, these fibers are entwined to form a strong three-dimensional network structure [154,155,156]. For instance, TEMPO (2,2,6,6-tetramethylpiperidin-1-yloxy)-oxidized cellulose nanofibers (TOCN) and cationic guar gum (CGG) form a hydrogel instantaneously upon contact with each other, and this cross-linking is wholly spontaneous without the assistance of any cross-linking agent [154]. The TOCN/CGG hydrogel is notable for its porous structure and abundance of active sites, which confer upon it a remarkable potential for the removal of heavy metal ions and organic dyes from wastewater. This hydrogel system is entirely biomass-based and does not include any toxic chemicals [157]. Furthermore, the coating of wrapped filter papers in a layer-by-layer deposition process results in hydrogel-coated oil/water separation materials [113,158]. The mechanical properties of self-assembled CBH can be optimized by varying the concentration of the constituent monomers. Li et al. [159] conducted further research on TOCN/CGG self-assembled hydrogels following Cu2+ adsorption, which demonstrated sensitive responsiveness to load weight due to their flexibility and conductivity, which can be utilized as electrodes with optimal performance for supercapacitors, providing a good example for sustainable all-polysaccharide hydrogel management and the utilization of aquatic heavy metal ions. Moreover, the coordination of complex self-assembled structures and various functions is imperative to expand the application areas of CBHs.

To further investigate the gelation behavior of the self-assembly technique, ref. [160] used different concentrations and combinations of negatively charged TOCN on the surface and partially deacetylated chitin nanofibers (PDChNF) with positively charged surfaces to produce CBH by a simple electrostatic force-induced self-assembly gelation process (Figure 2d). The freeze–dried aerogels demonstrated remarkably high levels of adsorption efficiency, with the capacity to adsorb As3+ (217 mg·g−1) and methylene blue (MB) (531 mg·g⁻1) [160]. Subsequent studies demonstrated that the process of self-assembled CBH formation is concentration-independent; however, higher concentrations are conducive to the retention of greater quantities of water. The yield of self-assembly is found to be contingent on the mass ratio of PDChNF/TOCN, which increases with increasing mass ratio in the early stage. The findings indicate that the optimal mass ratio is 5/5, at which point the yield can reach 99% [160]. However, it is observed that the net charge of PDChNF is not equal to zero at this point, which can be attributed to the larger size and aspect ratio of TOCN; thus, a higher charge of PDChNF is required to maintain gelation. Due to the strong electrostatic attraction between the components, the self-assembly preparation is shown to be significantly faster than other physical and chemical cross-linking techniques (with a completion time of under one minute). In addition to being environmentally friendly and time-efficient, the self-assembly technique requires a very low concentration of nanofibers (0.01 wt%), the constituent of the hydrogel, compared to other conventional methods. In summary, the generation of CBHs by electrostatic force-induced self-assembly is a novel and simple method, and the adsorption process is sustainable yet efficient.

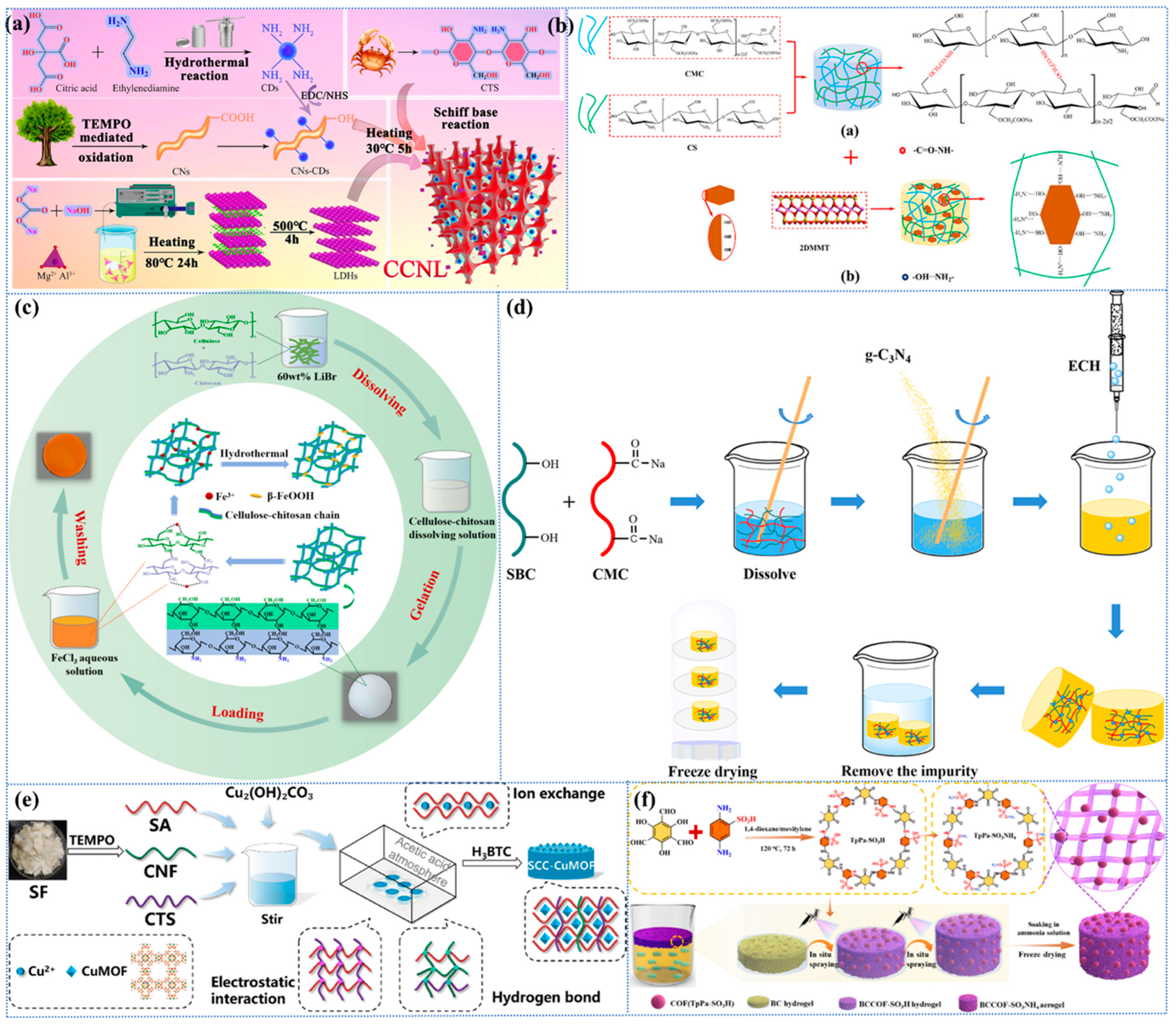

Figure 2.

(a) Schematic representation of a physically cross-linked hydrogel prepared by freeze–thawing. Reproduced from [113]. (b) The schematic of the PVA/CMC hydrogel, prepared by the freeze–thawing process, is presented, along with its cross-sectional image following the adsorption of heavy metals. Reproduced from [143], Copyright (2016), with permission from American Chemical Society. (c) Schematic representation of the CMCF-F hydrogel, prepared by the freeze cross-linking method. Reproduced from [145], Copyright (2020), with permission from American Chemical Society. (d) (a,b) TEMPO and mechanical exfoliation to produce TOCNF; (c,d) NaOH and mechanical exfoliation to produce PDChNF; (e) electrostatic-force-induced self-assembly gelation; (f) digital images illustrate that the ultralight BHA was captured by a marker pen due to static electricity; (g) SEM image of BHA exhibits a highly porous structure. Reproduced from [160], Copyright (2019), with permission from American Chemical Society.

Figure 2.

(a) Schematic representation of a physically cross-linked hydrogel prepared by freeze–thawing. Reproduced from [113]. (b) The schematic of the PVA/CMC hydrogel, prepared by the freeze–thawing process, is presented, along with its cross-sectional image following the adsorption of heavy metals. Reproduced from [143], Copyright (2016), with permission from American Chemical Society. (c) Schematic representation of the CMCF-F hydrogel, prepared by the freeze cross-linking method. Reproduced from [145], Copyright (2020), with permission from American Chemical Society. (d) (a,b) TEMPO and mechanical exfoliation to produce TOCNF; (c,d) NaOH and mechanical exfoliation to produce PDChNF; (e) electrostatic-force-induced self-assembly gelation; (f) digital images illustrate that the ultralight BHA was captured by a marker pen due to static electricity; (g) SEM image of BHA exhibits a highly porous structure. Reproduced from [160], Copyright (2019), with permission from American Chemical Society.

3.2. Chemical Cross-Linking

Chemical cross-linking involves the introduction of a cross-linking agent that reacts with the hydroxyl groups on the cellulose molecular chain to form strong covalent bonds, which results in tighter bonding and the formation of an irreversible hydrogel network with higher stability, adsorption, and mechanical properties than physical cross-linking [161,162,163]. Chemically cross-linked hydrogels are characterized by their resistance to melting or decomposition, even under heat treatment, and their insolubility in water until the covalent bonds are broken, thus justifying the term ’permanent system’ [128,164]. The process of chemical cross-linking can be initiated through various mechanisms, including esterification, free radical polymerization, click chemistry, and Michael addition, among others. Cross-linking agents are available from both synthetic and natural sources, and the most commonly used cross-linking agents are citric acid [165], succinic acid, epichlorohydrin [166], polyethylene glycol diacrylate, divinyl sulfone, and glutaraldehyde [167,168].

However, the utilization of cross-linking agents may also engender certain issues, as the pore size of the polymer chains is diminished, and the increased crystallinity can exert a not insignificant negative influence on the adsorption capacity and swelling rate. Furthermore, cross-linkers and higher cross-linking densities have been observed to bind to some of the binding sites of the adsorbent, thereby reducing the adsorption capacity. Therefore, it is essential to strike a balance between the desired mechanical strength and the maximization of adsorption capacity [138].

Despite the numerous enhancements in performance characteristics exhibited by chemically crosslinked CBHs, the selection of crosslinking agents and the concentrations employed must be approached with the utmost seriousness. An excessive or inappropriate utilization of crosslinking agents has the potential to induce toxicity, thereby constituting a potential hazard to biological organisms [101]. For instance, certain isocyanates are recognized for their cytotoxic effects. Consequently, there is an urgent need to develop cross-linking techniques that can enhance mechanical properties while ensuring biocompatibility.

The development of chemically crosslinked hydrogels is currently focused on the identification or synthesis of new, low-toxicity, environmentally friendly crosslinking agents, as well as the optimization of crosslinking conditions and routes to obtain the desired properties without compromising their safety.

3.2.1. Free Radical Polymerization Crosslinking

A significant number of CBHs are synthesized by a free radical polymerization process, which is a well-characterized three-step process including initiation, propagation of the polymer chain, and termination [138]. The initiation step involves the use of a special chemical (e.g., potassium persulfate (KPS), tetramethylene diamine (TEMED), or ammonium persulfate (APS)) as an initiator, which decomposes to produce free radicals in the presence of light, pressure, temperature, redox reactions, or radiation. The polymer chains begin to form and propagate by initiating a reaction. During the process of propagation, the polymer chains undergo an extension phase, at which point the incorporated crosslinker reacts with the growing polymer chains to form a three-dimensional polymer network structure. The termination of polymerization is brought about by a combination or disproportionation reaction [113]. In comparison to alternative types of polymerization processes, free radicals are utilized extensively due to their numerous advantages, including a faster synthesis process, less demanding reaction conditions, ease of implementation, wider temperature range, and lower cost [136].

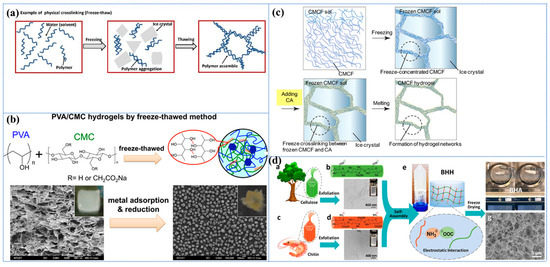

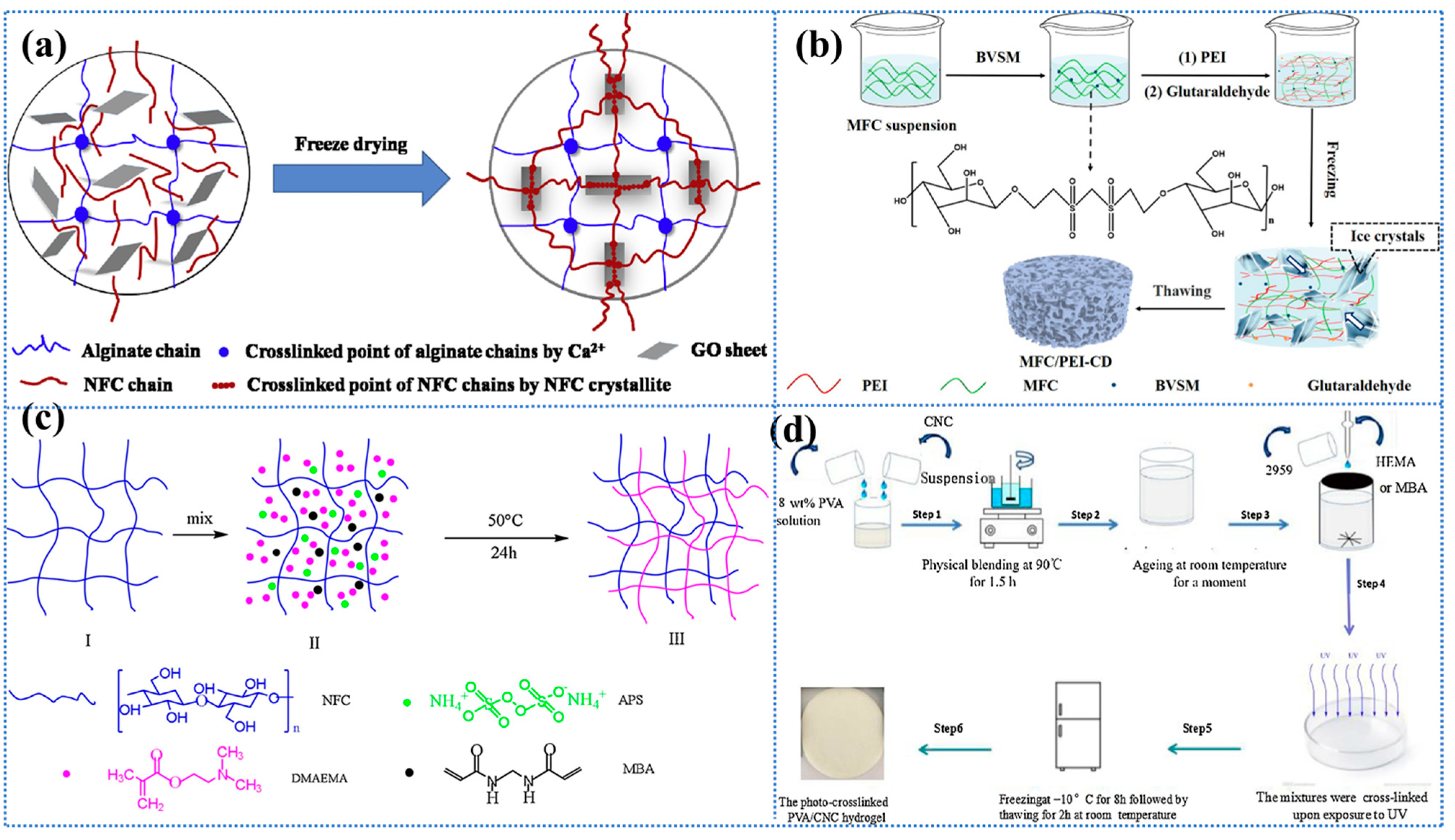

Acrylic acid (AA)-grafted cellulose-based nanohydrogels (Poly-X-CNF-g-AA) were prepared by free radical polymerization induced at 90 °C in the presence of 50 mg of APS as an initiator and 20 mg of N, N′-methylene-bis-(acrylamide) (MBA) as a cross-linking agent in 24 mL of cellulose-based sol with grafted AA chains on the surface (Figure 3a) [169]. The material was immersed in an Al3+ solution to facilitate further cross-linking, thereby forming a dual network hydrogel. In their study, Ning et al. [170] synthesized HEC-co-p(AA-AM)/TA hydrogels by grafting AA and acrylamide (AM) onto hydroxyethyl cellulose (HEC) and then modifying them with tannic acid (TA). The resulting hydrogels exhibited excellent MB adsorption properties (3438.27 mg/g) and high reusability. This phenomenon can be ascribed to the incorporation of TA-like modifiers within the CBHs, a process that facilitated the attainment of a uniform pore structure, thereby enhancing the adsorption performance [170]. Zhao et al. [171] prepared a modified cellulose-based hydrogel by an innovative method of simultaneous crosslinking and grafting of AM and AA (Figure 3b). During the process, APS was added to an aqueous solution of microcrystalline cellulose (MCC) to generate hydroxyl radicals. Subsequently, a mixed solution of AA, AM, and MBA was added gradually, and stirring continued at 50 °C for 2 h until complete polymerization. The hypothesis that acrylate and acrylamide monomers can be concurrently and efficiently crosslinked and grafted onto the initial cellulose material was substantiated. This pathway facilitates the synthesis of more complex, compact, and stable network structures, thereby enhancing strength and toughness. In addition, their ability to simultaneously increase the number of different kinds and amounts of active groups rapidly, simply, and effectively makes this hydrogel simultaneously exhibit remarkable adsorption capacity and high reusability for Cu2+, Pb2+, and Cd2+, which is a great advantage of this innovative approach. However, this polymerization pathway is contingent on elevated temperatures and extended reaction times, in addition to homogeneous mixing.

One of the most promising methods for preparing hydrogels is photoinduced polymerization, whose most common cross-linking mechanism is also free radical cross-linking. In comparison with alternative conventional techniques, this method possesses numerous advantageous characteristics, including low cost, simplicity, non-pollution, fast curing, low energy consumption, and low reaction temperature. During the reaction process, when the photosensitizer is exposed to light, it generates free radicals and triggers a polymerization reaction to form a crosslinked polymer network. This crosslinking technique is characterized by its gentleness, efficiency, and environmental friendliness [161]. Lamkhao et al. [172] successfully synthesized a highly porous photocatalyst/hydrogel composite by novel photoinitiated AM polymerization using MBA as a cross-linker and zinc oxide (ZnO) as a photosensitizer. This provides a direction for the development of composite hydrogels with the synergistic effect of both the adsorption of hydrogels and the photocatalytic ability of photocatalysts to improve the pollutant removal efficiency.

The enzyme type and its catalytic pathway can be selected to determine the mechanism of enzyme-induced cross-linking, which can also be free radicals. The most significant advantages of this method include mild cross-linking conditions, ease of handling, rapid gelation, excellent biodegradability, clean cross-linking systems, and the ability to cross-link in situ [173]. This approach avoids the toxicity of chemical cross-linking agents and improves mechanical strength. However, the most significant disadvantages of enzyme cross-linking methods are the high cost; susceptibility to allergic reactions; and, in some cases, low efficiency.

It is evident that the application of numerous methods on CBHs, including photoinitiation and enzymatic crosslinking, has not been fully developed due to certain limitations. However, as scientific and technological progress continues, the development of non-toxic, environmentally friendly cross-linking agents and gentle, energy-saving cross-linking methods is poised to become a central focus in research endeavors concerning CBHs.

3.2.2. Schiff Base Reaction

The Schiff base reaction involves the cross-linking of aldehyde and amine groups to the polymer chain via a condensation reaction to form dynamic covalent imine bonds [168,174]. This process enables chemical cross-linking without the use of additional cross-linking agents and can be used as a natural cross-linking mechanism while giving hydrogels their unique dynamic reversibility. This reaction is characterized by its reversibility, rapid synthesis, high chemical selectivity, and non-toxicity of the products. Hydrogels obtained using this method are self-healing, biocompatible, and sensitive to pH changes, allowing the preparation of multifunctional hydrogels with smart responses [175]. Remarkably, this inherent self-repairing capability does not necessitate an external stimulus; rather, it functions optimally within mild conditions [176]. Furthermore, the gelation time, mechanical strength, and self-repairing properties of the hydrogels can be tuned by modifying the reaction conditions [177]. The propensity of cellulose to undergo the Schiff base reaction is attributable to the prevalence of hydroxyl groups within its molecular structure.

Sethi et al. [178] covalently crosslinked dialdehyde carboxymethyl cellulose (DCMC) with gelatin using Schiff base reaction to form a novel hydrogel (DCMC-cl-G) without using any foreign cross-linking agent. This novel hydrogel was then used for the adsorptive removal of rhodamine B (RhB) and methyl violet (MV). It was demonstrated that the absence of any foreign cross-linking agent during the Schiff base reaction can result in the formation of biopolymer-based hydrogels that exhibit enhanced stability, and superior adsorption capacity (with maximum percentages of RhB and MV of 96.5% and 90%, respectively), biodegradability (82.67% degradation in 12 weeks), and ease of reuse [178]. The study demonstrated that the Schiff alkali reaction is not inferior to chemical cross-linking methods using cross-linking agents for the preparation of hydrogels, especially biopolymer-based hydrogels with excellent properties. In a separate report, the aldehyde groups of bifunctional hairy nanofibrillar cellulose (BHNC) and the amine groups of aminated dendritic fibrous nanostructured (colloidal) silica particles (DFNS-NH2) were employed for the formation of hybrid hydrogel nanocomposites by chemical cross-linking via the Schiff base reaction (Figure 3c) [179]. The absence of the need for an additional cross-linker in this synthesis is attributable to the functionality of the amine groups on the surface of DFNS as active sites for the Schiff base reaction with the aldehyde groups of BHNC. Furthermore, this novel material possesses the capacity for enhanced and adaptable adsorption capacity through the modulation of functional groups on DFNS-BHNC or the alteration of the mass ratio of DFNS-BHNC, constituting a significant advantage [179]. These adsorbent materials are exclusively prepared from biodegradable and non-toxic organic and inorganic materials in green solvents through a green cross-linking process and also possess a wide range of functional groups that can be used as potential adsorbents for a wide range of pollutants.

In comparison with conventional chemical cross-linking techniques, which rely heavily on cross-linkers, hydrogels derived from the Schiff base reaction are not limited by their toxicity and low biocompatibility. The covalent bonds obtained from the Schiff base reaction are closely related to the structure of the hydrogel network, which in turn affects the properties of the hydrogel such as porosity and solubility [180]. The inherent properties of CBHs, including self-healing, mechanical, and swelling properties, can be readily tuned by modulating the number of reactants and the strength of the Schiff base reaction. In addition, within specific environments, the Schiff base structure may lack sufficient stability and may be susceptible to hydrolysis [181]. At present, the focus of the Schiff base reaction is on the traditional condensation reaction, with relatively little research being carried out on novel synthetic methods (e.g., microwave-assisted synthesis and ionic liquid catalysis). Moreover, the potential of the Schiff base reaction for application in many fields has not yet been fully explored, and its stability and degradation still need to be optimized.

3.2.3. Click Chemistry

Click chemistry is a method of synthesizing macromolecules based on carbon-heteroatom bonding. It is a simple and rapid process that can provide a mild and efficient pathway to modify cellulose, endowing it with specific structures, properties, and functions [161,182,183,184]. Representative reactions of click chemistry include copper-catalyzed azide-alkyne cycloaddition (CuAAC) and thiol-ene/one-click reactions. However, the former is comparatively less reported than the latter, suggesting potential for further development.

The thiol-ene/yne reaction is typically conducted under mild aqueous conditions, exhibiting high conversion and selectivity without the necessity of toxic metal catalysts. Wang et al. [182] utilized a novel and straightforward cellulose-based hydrogel fabrication method to selectively separate anionic and cationic dyes. The synthesis of cellulose methacrylate (CM) was initiated and, subsequently, CM organic gels were prepared by the self-crosslinking of vinyl groups. These organic gels were then converted into CM-MA hydrogels and CM-CH hydrogels through the chemical grafting of 3-mercaptopropionic acid (MA) and Cysteamine hydrochloride (CH) via thiol-ene click chemistry, a process that occurred under UV irradiation, thereby generating additional active binding sites.

Liu et al. [185] discovered that the amino–anhydride reaction adheres to the principles of the click reaction, and that it can be expeditiously executed, resulting in the formation of hydrogels in water, which is auspicious for a broad spectrum of applications. In their experiments, they initially copolymerized maleic anhydride (MA) and AA to form PAM, then added a certain amount of glycidyl-trimethyl-ammonium chloride 90% (GTMAC) to cellulose solution to obtain QC, and finally prepared a new quaternary ammonium-based semi-IPN-gel adsorbent by a simple amino–anhydride click reaction by mixing PAM, QC, and poly-(allylamine hydrochloride) (PAH) (Figure 3d). In addition, the optimal conditions for the preparation of hydrogels were investigated through a series of one-way experiments (involving a 50:1 molar ratio of AA to MA, a 10:1 molar ratio of PAM to PAH at 6% mass concentration, and a 15% mass concentration of QC). However, it should be noted that one-factor experiments may overlook the potential interactions between multiple factors. Furthermore, the employment of single-factor experiments has the potential to elucidate the distinct effects of various factors on the performance of hydrogels. This approach can facilitate the identification of the most economical and efficient preparation conditions, thereby ensuring the stability and reproducibility of the material’s performance in subsequent studies. This, in turn, will provide a theoretical foundation for future in-depth research. The present study provides a comprehensive analysis of hydrogels made by this particular reaction from a number of perspectives and, thus, complements reports on the preparation of hydrogels based on the reaction of amino–anhydride in water. However, the authors do not report much on the reusability of this method, which is a significant shortcoming.

The Diels–Alder (DA) reaction of thermally reversible cycloaddition between conjugated diene and pro-diene (e.g., substituted olefin) compounds can also be categorized as a click reaction that can be carried out in aqueous environments under mild conditions without the need for catalysts or initiators [177]. This demonstrates the advantages of high efficiency, selectivity, and the absence of by-product formation [186]. The utilization of water as a solvent in DA reactions has become a fundamental aspect of research, primarily due to the hydrophobic effect, which results in a substantial increase in the reaction rate [187]. Moreover, the sustainable advantages associated with its green properties have contributed to its emergence as a predominant approach in contemporary research. Kramer et al. [187] used cellulose nanofibers as substrates to synthesize cellulose-based nanohydrogels via the DA click reaction of furan/maleimide in water. However, the extant literature suggests that the CBHs obtained through the DA reaction require specific chemical modification, which increases the complexity and cost of the synthesis, especially for the application of the hydrogels obtained from this reaction to water treatment. Consequently, there are too few reports in this area.

3.2.4. Radiation Crosslinking

Synthesis of CBHs by radiation treatment using different types of radiation (e.g., gamma rays, electron beams, microwave, and UV radiation) is also an alternative method of inducing cross-linking in polymer chains without the use of chemical cross-linkers, initiators, or catalysts [127]. This approach has the advantage of avoiding potential toxicity problems and can be carried out at ambient or below-ambient temperatures [188,189]. The density of chemical bonds is contingent on the irradiation dose and duration that are utilized to initiate the reaction kinetics. In comparison with chemically induced cross-linking, this method is a wholly environmentally benign synthetic process involving zero waste generation and offers significant advantages in the formation and sterilization of single-step CBHs [138]. Radiation cross-linking is a process that has been demonstrated to result in the production of hydrogels that exhibit excellent transparency, homogeneity, and mechanical properties, making them particularly suitable for use in 3D printing technology [101].

It has been demonstrated that gamma rays can induce cross-linking, thereby forming highly cross-linked and stable hydrogels. This process has been shown to enhance mechanical strength and swelling capacity, thus improving the adsorption efficiency of pollutants [190]. In addition, it has been reported that the rational incorporation of AA further enhances the adsorption properties by providing additional functional groups while improving the adsorption efficiency and selectivity of the hydrogel [191]. Sutradhar et al. also identified research gaps regarding γ-radiation-induced hydrogels, including the optimal radiation dose and competitive adsorption relationships in the presence of multiple contaminants. In light of the aforementioned studies and to address the extant research gap, they initially synthesized γ-irradiated carboxymethyl cellulose (CMC)/AA hydrogels with the capacity to enhance the adsorption efficiency and capacity of MB dyes (Figure 3e) [192]. Subsequent exploration of the synthesis protocol, radiation dose, adsorption efficiency, environmental friendliness, competitive adsorption behavior, and the effectiveness of MB dye removal was undertaken in-depth, providing unique insights for wastewater treatment applications. In the synthesis process, CMC/AA hydrogels were obtained by incorporating AA at different concentrations (7.5% to 15.0%) into the CMC slurry; followed by neutralization with KOH; and then by γ-irradiation of the mixtures using a Co-60 source at doses of 1, 2, 3, 5, 8, and 10 kGy [192]. It has been demonstrated that when properly grafted AA (at 5–7.5%) is utilized, it exerts a disruptive effect on the crystal structure of CMC, thereby enhancing the thermal stability of the hydrogel and increasing the adsorption capacity. However, further cross-linking resulted in reduced pore size and a more rigid structure, thus reducing dye penetration. However, further evaluation of the overall effectiveness of hydrogels synthesized by γ-radiation polymerization for environmental applications is still required. In a separate study, Masry et al. [193] pioneered a special study on the synthesis of hydroxyethyl cellulose (HEC)/AA/CX (Cyanex 471X) hydrogels using gamma radiation and systematically investigated the effect of gamma radiation on the HEC properties, gel fractions, swelling properties, and metal adsorption capacity. It is noteworthy that Nattawan et al. [194] successfully inserted cellulose purified from bagasse into hydrogel composites by the gamma irradiation technique, which also demonstrated notable adsorption capacity and adsorption efficiency.

Microwave (MW) irradiation-assisted synthesis has been utilized for hydrogel preparation, a method that is more environmentally friendly than traditional heating modes, such as heat conduction and convection mechanisms [195,196,197]. This method has garnered significant attention due to its ability to substantially reduce the time and energy consumption of the cross-linking process without compromising the physical and chemical properties of the final product. Additionally, it is characterized by its faster, more selective, and more homogeneous heating characteristics. Furthermore, the resulting hydrogels exhibit a high degree of water retention and biocompatibility [198]. However, the effect of the MW-assisted cross-linking reaction on the physicochemical properties of the resulting hydrogels has not been explored in more detail. To address this issue, Santoso et al. [195] evaluated the physicochemical properties of epichlorohydrin (ECH)-crosslinked cellulose hydrogels prepared by the MW method, including the pore morphology, chemical composition, crystallinity, thermal stability, and water absorption capacity (Figure 3f). In summary, the cross-linking agent ECH was incorporated into the cellulose solution and the MW-assisted cross-linking process was conducted using a domestic microwave oven. Concurrently, a thermostatic water bath was regulated to facilitate the cross-linking of the cellulose polymer chains. The study demonstrated that MW irradiation has great potential for the rapid, cost-effective, and energy-efficient preparation of CBHs. However, further studies are required to ascertain the effect of MW irradiation power and duty cycle on the degree of cross-linking, which in turn affects the mechanical properties and the porous structure of the resulting hydrogel materials. Such studies will provide an important basis for the development of high-performance porous hydrogels. In a separate study, a novel CAB hydrogel bead was developed for the adsorption of chlorpyrifos (CP) in water [199]. This was achieved by preparing the bead dropwise from an aqueous solution of cellulose acetate (CA) via microwave irradiation of a crosslinking polyethylene glycol (PEG) crosslinker. The cross-linking process induced by microwave irradiation ensured the integrity of the network, facilitated by the H-bonding of the CA and PEG units of the hydrogel unit.

In conclusion, the radiation-crosslinked cellulose-based hydrogel technology is a green preparation method with significant potential. However, it should be noted that cellulose and its derivatives are susceptible to degradation during the radiation process, which may result in a reduction in their mechanical strength.

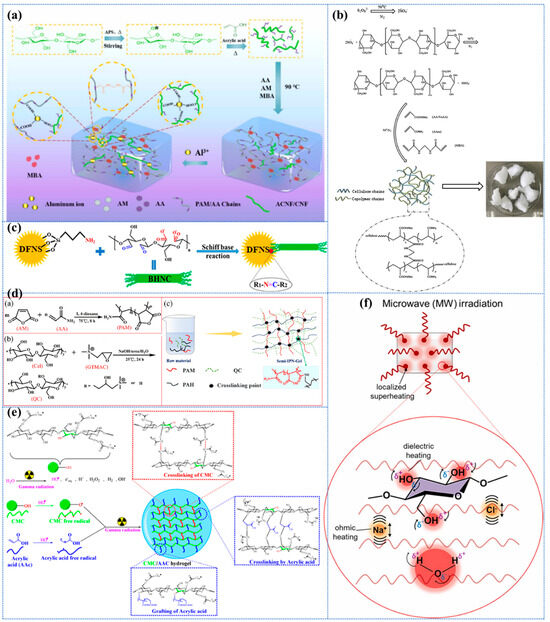

Figure 3.

(a) Schematic diagram of Poly-X-CNF-g-AA composite double cross-linked hydrogel. Reproduced from [169], Copyright (2023), with permission from Elsevier. (b) Program for the synthesis of biosorbent (MCC-g-(AA-co-AM)). Reproduced from [171], Copyright (2019), with permission from Elsevier. (c) Cross-linking between BHNC and DFNS-NH2 by Schiff base reaction. Reproduced from [179], Copyright (2020), with permission from American Chemical Society. (d) Synthesis process: (a) PAM; (b) QC; and (c) semi-IPN-gel. Reproduced from [185], Copyright (2022), with permission from Elsevier. (e) Possible grafting and cross-linking reaction mechanisms in CMC/AA hydrogels. Reproduced from [192]. (f) Schematic of MW irradiation on a cellulose gel solution. Reproduced from [195], Copyright (2022), with permission from Elsevier.

Figure 3.

(a) Schematic diagram of Poly-X-CNF-g-AA composite double cross-linked hydrogel. Reproduced from [169], Copyright (2023), with permission from Elsevier. (b) Program for the synthesis of biosorbent (MCC-g-(AA-co-AM)). Reproduced from [171], Copyright (2019), with permission from Elsevier. (c) Cross-linking between BHNC and DFNS-NH2 by Schiff base reaction. Reproduced from [179], Copyright (2020), with permission from American Chemical Society. (d) Synthesis process: (a) PAM; (b) QC; and (c) semi-IPN-gel. Reproduced from [185], Copyright (2022), with permission from Elsevier. (e) Possible grafting and cross-linking reaction mechanisms in CMC/AA hydrogels. Reproduced from [192]. (f) Schematic of MW irradiation on a cellulose gel solution. Reproduced from [195], Copyright (2022), with permission from Elsevier.

3.3. Composite Hydrogels

The numerous branches and intricate chemistry inherent in the cellulose structure give rise to relative interactions between molecules in hydrogels prepared from pure cellulose that are insufficient to ensure satisfactory mechanical strength. However, the combination of cellulose and other types of polymers or nanoparticles has been shown to produce cellulose-based composite hydrogels with a range of functionalities.

3.3.1. Nano-Reinforced Cellulose-Based Hydrogels

Nanocellulose Composite Hydrogels

In recent years, nanocellulose is often investigated for the preparation of environmentally friendly hydrogel composites, which can effectively enhance the adsorption capacity of hydrogels due to the presence of carboxyl groups in its structure [200,201,202,203,204,205]. Nanocellulose-based hydrogels exhibit a multitude of characteristic properties, including but not limited to good porosity, swelling capacity, adsorption and mechanical properties, self-healing, and smart responsiveness. However, it is also limited by the poor dispersion of nanocellulose in nonpolar solvents, leading to agglomeration as well as insufficient interfacial adhesion with their hydrophobic substrates. Consequently, recent studies on nanocellulose-based hydrogels have concentrated on their physical incorporation as fillers into synthetic and natural polymer networks for reinforcing composite hydrogels [206,207,208,209,210,211]. These nanocellulose composite hydrogels can be prepared by a number of methods, including homogenization, freeze–thawing, free radical polymerization, or UV/ion-mediated cross-linking [212]. It has been demonstrated that the controlled incorporation of modest quantities of nanocellulose into hydrogels can enhance their physical properties and prevent agglomeration. For instance, Roa et al. [200] reported that a nanocomposite hydrogel formed by free radical polymerization of 1%wt CNF with [2-(acryloyl-oxy)-ethyl]-trimethylammonium chloride (ClAETA) exhibited a maximum adsorption capacity of 1379.0 mg/g for methyl orange (MO) and concluded that the incorporation of CNF improved the MO adsorption with time. A one-way experiment revealed that the solubility of the hydrogel increased with the increase in CNF concentration and the thermal stability was improved, which might be due to the increase in the number of carboxyl groups in the hydrogel. In order to conduct further investigation into the potential of low-cost biodegradable hydrogels for the efficient removal of heavy metals from water, Alves et al. [213] prepared composite hydrogels containing different nanocellulose contents using trisodium citrate as a cross-linker. The findings demonstrated that increasing the nanocellulose content resulted in enhanced swelling capacity, increased thermal stability, elevated adsorption capacity for Cu2+, and enhanced biodegradability.

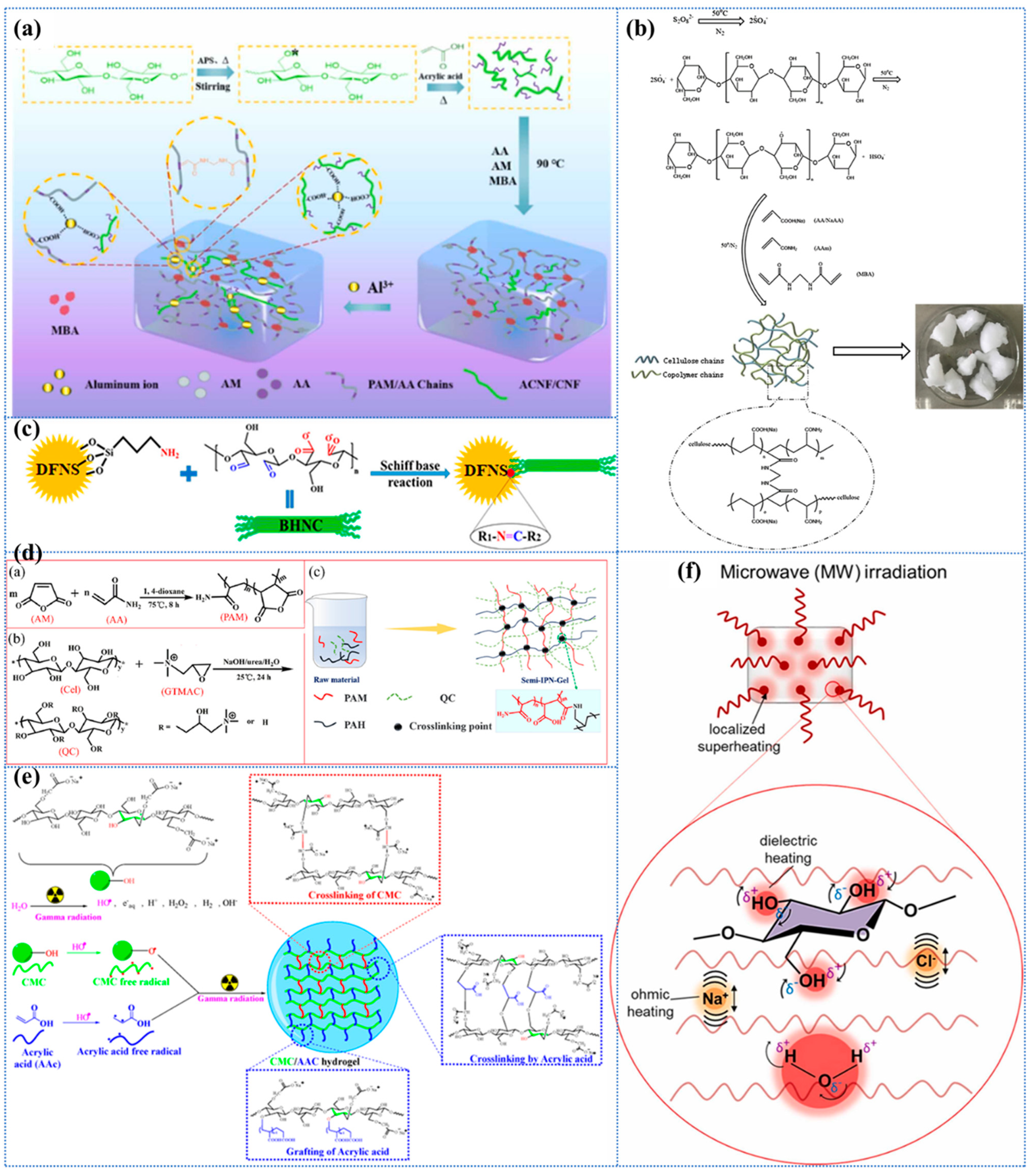

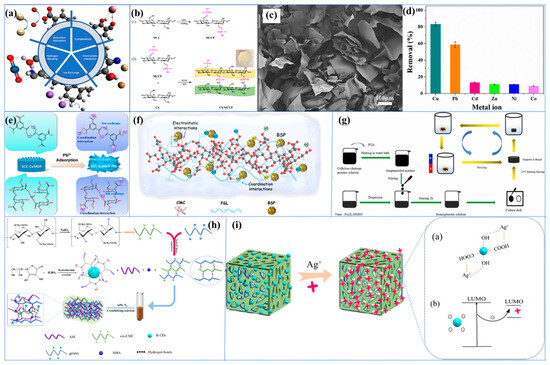

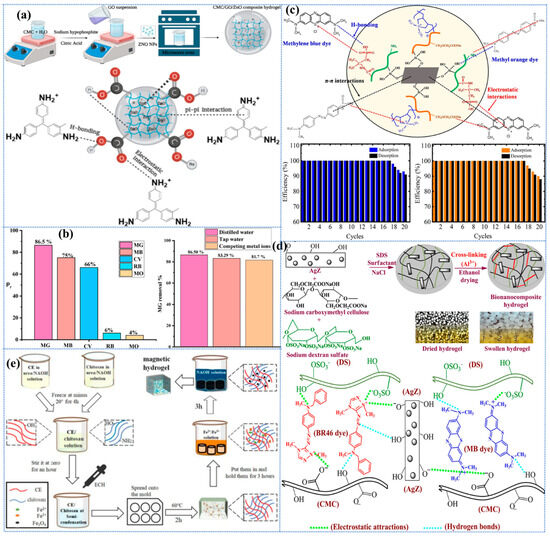

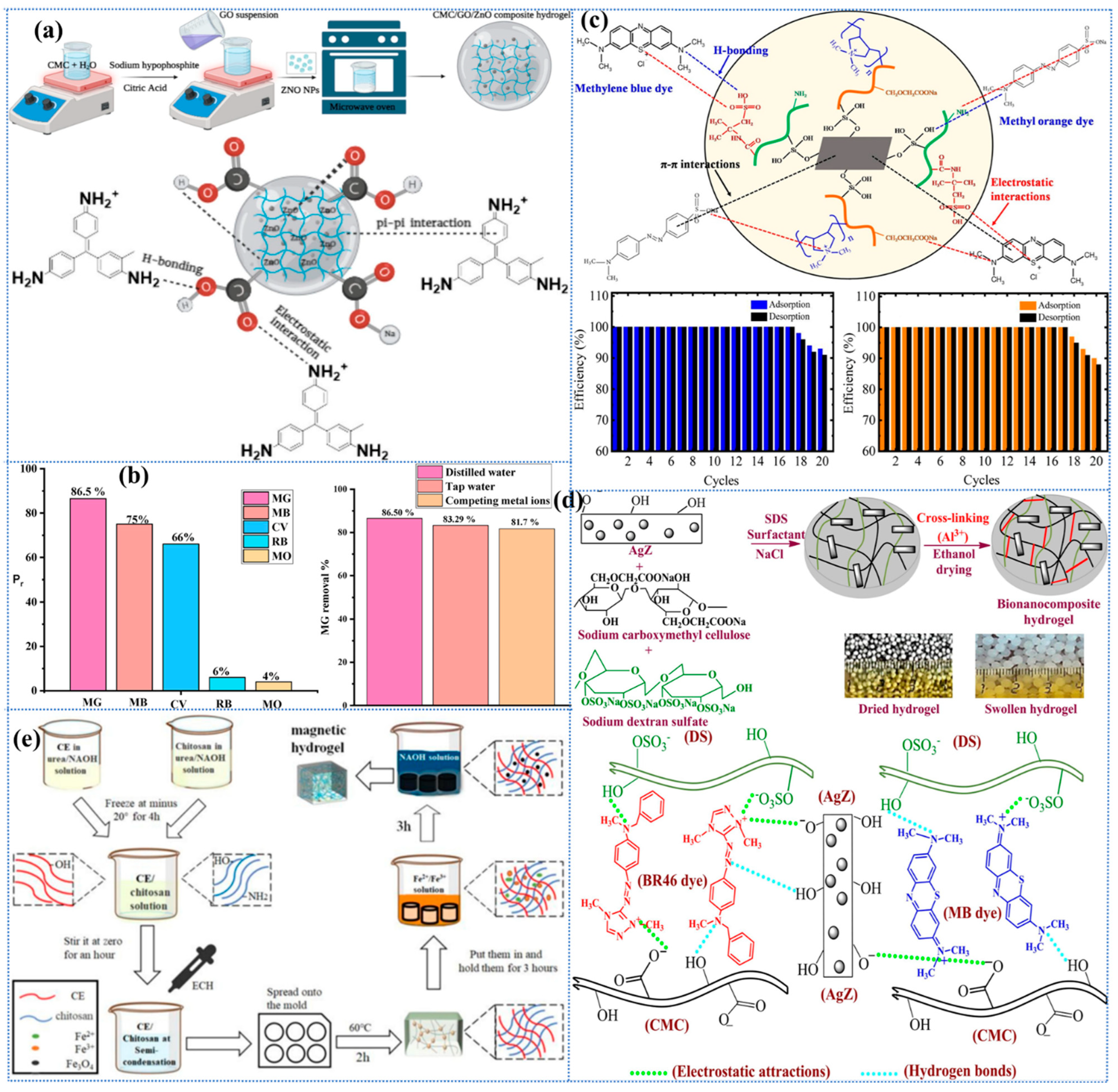

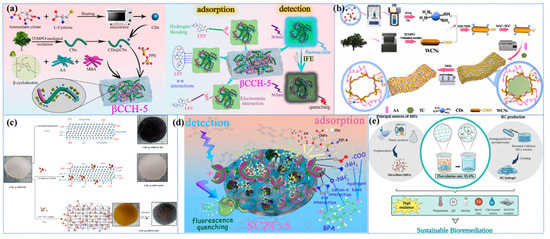

The utilization of nanocellulose-based hydrogels as carriers for immobilizing nanocomposites, such as ZnO/AgBr, has been demonstrated to enhance the removal efficiency of heavy metals through a combination of synergistic adsorption and photocatalytic effects. In a recent study, Zhang et al. [214] reported a novel nanocellulose/CDs hydrogel (NCH) consisting of cellulose nanocellulose nanofibrils (CN), carbon dots (CDs), and ZnO/AgBr nanocomposites. In this study, the carbon dots enhanced the amino-induced Cr6+ adsorption and accelerated the photocatalytic effect, resulting in an adsorption capacity of up to 315 mg/g. Zhang et al. [215] developed a pioneering CCNL composite hydrogel by first grafting CDs onto cellulose nanofibrils (CNs) and then adding glutaraldehyde cross-linking agent to a homogeneous mixture of chitosan (CS), CNs-CDs, and laminar double hydroxide (LDH) in a constitutive solution (Figure 4a).

The surface modification of nanocellulose is of paramount importance for the creation of covalent cross-linking sites using grafts (e.g., polyacrylamide, polyvinyl alcohol, carboxyl, or aldehyde groups) to enhance its interaction with the matrix [212]. For instance, Rodrigues et al. [216] synthesized chitosan-g-poly-(acrylic acid) gels containing cellulose nanoscale whiskers for the adsorption of Pb2+ and Cu2+ in wastewater.

Cellulose-Based Hydrogels Reinforced with Inorganic Nanomaterials

It has been established that the adsorptive properties of pure CBHs are frequently inadequate [217]. Consequently, the amalgamation of natural polymers with inorganic materials has been postulated to engineer composites with superior properties [218]. Moreover, the incorporation of inorganic materials has been shown to confer specific functionalities, including conductive, catalytic, adsorptive, and potentially antimicrobial properties, while concomitantly enhancing mechanical and thermal stability properties due to the synergistic effect of the cellulose matrix and the inorganic materials. Inorganic nanoparticles offer significant advantages over conventional micron-sized inorganic fillers due to their large surface area and stronger interaction with the matrix. It has been demonstrated that cellulose complexes with nanoparticles are effective in preventing agglomeration, ensuring colloidal safety and contributing to the simple separation of magnetic components post-treatment [106]. MoS2 is an inorganic nanomaterial that exhibits distinctive optical and electronic properties, making it a subject of considerable interest. When MoS2 is composited with other materials, it has been observed to confer several advantageous properties to adsorbents, including accelerated adsorption kinetics, enhanced adsorption efficiency, and improved metal selectivity [219]. In a recent report, an amphiphilic and surface-active MoS2/cellulose acetate fiber sponge has been successfully used to purify oily water by easily and selectively removing targeted oil droplets [220].

Metals and metal nanoparticles (including ZnO, TiO2, Ag, and Fe3O4) exhibit a variety of beneficial properties, such as high specific surface area, a wide range of catalytic capabilities, unique electromagnetic and optical behaviors due to their small size, and enhanced reactivity [221,222,223]. Hydrogels loaded with metals and metal nanoparticles have been shown to possess enhanced adsorption capacity for a range of contaminants, including dyes, heavy metals, and pharmaceuticals. In addition, these hydrogels have been observed to exhibit superior crystallinity and thermal stability. Moreover, the integration of metal nanoparticles facilitates the development of responsive materials, wherein variations in metal properties can be employed to stimulate responsive applications. In certain instances, metal ions have been observed to induce gelation—functioning as cross-linking agents for cellulose—which can result in the formation of metal-based methyl groups through complexation, which may lead to a sustained bactericidal effect [221]. It is important to note that the dispersion of metals and metal nanoparticles in the hydrogel matrix is a significant factor in determining the catalytic efficiency, as aggregation of nanoparticles will substantially reduce the specific surface area and the corresponding available catalytic sites. TiO2 is regarded as a highly effective inorganic nanomaterial in the synthesis of composite hydrogels. It possesses the distinctive capacity to degrade organic dye molecules through a process known as photocatalysis, concurrently enhancing the porosity, specific surface area, and pore volume of the composites [1,224]. In a report, TiO2 cross-linked montmorillonite nanosheets (MMTNS) were introduced into CMC-CS hydrogels to obtain a high surface area, available anion adsorption sites, and macropores that would be favorable for MB dye penetration (Figure 4b) [225]. The experimental results demonstrated that 97% of the dye was removed within 360 min, which was attributed to the strong ion exchange and electrostatic interactions between the MB molecules and the hydrogel. In recent years, different polycrystalline species of iron oxyhydroxides include α, β, γ, and δ [226]. Among them, β-FeOOH nanoparticles exhibit photoactivity and are also considered effective photocatalysts for dye degradation due to their synergistic effect with the photo-Fenton reaction. In addition, uniform distribution of β-FeOOH using hydrogels not only solves the problem of adsorption saturation and non-regeneration, but also enhances its adsorption and separation properties, significantly reduces the aggregation of the photocatalysts, and exposes more active sites, which facilitate the adsorption and surface photocatalytic reactions [40,227]. Yang et al. [228] prepared cellulose–chitosan composite hydrogels by co-dissolution and regeneration process using 60 wt% LiBr aqueous solution as solvent (as shown in Figure 4c). The resultant hydrogel was then subjected to immersion in a FeCl3 solution, resulting in the synthesis of β-FeOOH nanoparticles through in situ synthesis. It was demonstrated that an enhancement in the loading of β-FeOOH resulted in an augmentation in the rate of adsorption and photocatalytic degradation of MO. This phenomenon was ascribed to the sustained formation of hydroxyl radicals and holes.

It is widely accepted that nanoscale hydroxyapatite (HA) is a low-cost, environmentally friendly, biodegradable, and easily synthesized biomaterial. It has a high adsorption capacity for divalent heavy metal ions and is stable under very high oxidizing and reducing conditions [218]. The formation of cellulose/HA composite hydrogels involved the incorporation of HA into a cellulose solution, followed by sonication, addition to epichlorohydrin (ECH), homogeneous mixing, and subsequent oven baking.

Inorganic nanomaterials pose significant challenges in terms of their ability to form composites, primarily due to the persistent issues of dispersion and interfacial compatibility.

Organic Nanomaterials Reinforcing Cellulose-Based Hydrogels

Graphene and its derivatives (GO, reduced GO, and graphitic carbon nitride (G-C3N4)) have emerged as a new generation of organic nano-enhanced water treatment materials [229,230]. Graphene, a material with a wide range of fascinating properties, including remarkably high mechanical strength, thermal stability, transmittance, and electrical conductivity, has attracted significant attention in various fields of research [231,232]. Notably, the functionalization of graphene can result in a remarkably diverse array of multifunctional active adsorption sites [1]. For instance, the further amine functionalization of (TEMPO) cellulose oxide nanofibrils (TCNF)/GO hydrogels with polyethyleneimine (PEI) by Nan et al. resulted in a significant increase in surface energy, mechanical strength, and adsorption capacity [233]. This increase was attributed to an increase in the number of available amine-active adsorption sites, leading to strong hydrogen bonding. Moreover, the CMC/polyacrylic acid (PAA) hydrogels were found to be significantly enhanced with GO, which resulted in an improvement in the adsorption of cationic MB dye molecules [234]. This is attributable to a substantial reduction in the pore size and an increase in the surface area of the hydrogels by the addition of GO, as well as an improvement in the anionic charge of the hydrogels. Moreover, in addition to electrostatic interactions, it was found that hydrogen bonding and π–π stacking interactions contributed to the trapping of MB molecules onto the hydrogels. GO nanosheets, with their two-dimensional structure, possess a higher specific surface area and enhanced dispersibility. The strong covalent interactions that exist between GO nanosheets and polymer chains are particularly advantageous for the formation of composite hydrogels [235]. For instance, vinyl-triethoxy-silane (VTES) was utilized as a chemical cross-linking agent for CS- and CMC-based cross-linked nanocomposite hydrogels (NCH) following the vinyl functionalization of GO nanosheets [235].

g-C3N4, an additional two-dimensional graphene derivative, also exhibits excellent physicochemical properties due to the advantageous properties of -NH2 [236,237]. In practice, however, the adsorption capacity of g-C3N4 for organic dyes is reduced due to self-aggregation and difficulties in recovery. It was found that by adding them as reinforcement to cellulose, the aggregation of g-C3N4 was effectively suppressed, which improved reusability and simplified the separation process [238]. Moreover, for pure CMC hydrogels, it is not possible to maintain a stable structure in an aqueous environment since CMC is a water-soluble cellulose ether [239]. In their study, Chen et al. [238] combined the advantages and disadvantages of the two aforementioned materials to develop a novel CMC hydrogel enhancement, to enhance the mechanical, thermal, and adsorption properties of the hydrogel through the synergistic effect obtained by chemically cross-linking nanoscale g-C3N4. The result was a promotion in its practical application. Specifically, bagasse cellulose (SBC) and carboxymethyl cellulose (CMC) were dissolved and stirred to obtain a mixed cellulose solution (SBC/CMC); then, g-C3N4 powder was added to the solution and stirred; finally, ECH was added and crosslinked for 10 h in 60 °C water bath to obtain a g-C3N4 @SBC/CMC hydrogel (Figure 4d) [238]. The study indicates that g-C3N4 has excellent compatibility with cellulose substrates and can be uniformly dispersed in a reticulated structure without aggregation. Adsorption experiments demonstrate that the hydrogel exhibits a remarkably high selective adsorption of cationic dyes, which features intelligent separation of specific dyes and facilitates the recovery of valuable chemicals. The primary interactions between the cationic dyes and the composites are found to be synergistic interactions arising from π–π coupling, and electrostatic and hydrogen bonding. Significant electrostatic interactions with cationic MB are highly probable, with a maximum adsorption capacity of up to 362.3 mg/L, because the Tri-S-Triazine structure of the nitrogen lone pair of electrons in g-C3N4 is negatively charged. Reproducibility studies further demonstrated remarkable advantages, exhibiting only a marginal decline in adsorption capacity after seven cycles, thereby attesting to the dyes’ exceptional durability. However, at elevated ionic strengths, a decline in adsorption capacity is observed, attributable to the competition between sodium ions and cationic MB for adsorption sites.

Metal–organic frameworks (MOFs), also referred to as porous coordination polymers, are formed through the binding of organic ligands to metal-containing nodes. These frameworks possess a variety of advantageous characteristics, including tunable multifunctional, small-sized, and microporous structures, as well as high activity, which makes them particularly well-suited for use as reinforcing additives in hydrogels [240,241]. A substantial body of research has demonstrated that the in situ growth of MOFs on the hydrogel surface enhances the adsorption properties of hydrogels [242]. Typically, MOFs are in powder form with high specific surface area and adsorption capacity, but they face difficulties in recovery in practical water treatment due to their fine particles and light texture [243,244]. The selection of appropriate substrates, such as bio-organic macromolecular cellulose derivatives, has been demonstrated to regulate the growth of MOFs, thereby facilitating the recovery of functional MOFs. In recent years, cellulose has been regarded as an optimal support body for the immobilization of guest materials, with numerous examples of MOF/cellulose composites having been documented [245]. Nonetheless, the direct loading of MOFs onto cellulose substrates typically results in an inhomogeneous distribution and aggregation of MOFs particles. In order to address this issue, Cui et al. [245] developed a UiO-66/PDA/BC aerogel, in which UiO-66 nanoparticles were uniform in size, simple to use, and separated by coating a polydopamine (PDA) layer on a BC substrate to facilitate the subsequent uniform coating of UiO-66 nanoparticles. The in situ growth of MOFs must be carried out under restrictive synthesis conditions to ensure the stability of the hydrogel during processing. In order to overcome this limitation, Zhao et al. [246] prepared sodium alginate (SA)/CS/CNF/Cu2+ hydrogels (SCC-Cu) by using the semi-solvated acidified sol–gel transition method with an internal gelation method and prepared copper-based MOF composites (SCC-CuMOF) by using an in situ growth method (Figure 4e). CNF fulfils a dual role in this process, functioning both as a cross-linking agent between SA and CS, and as a filler between the dual networks, which contributes to an effective enhancement of the hydrogel’s strength. In addition, the presence of Cu2+ provides additional active sites, thereby facilitating enhanced loading of the MOF.

Covalent organic frameworks (COFs) have been identified as having significant potential for the removal of heavy metals due to their low crystalline density, high adsorption capacity, large surface area, tunable porosity, porous structure, good stability, and recyclability [247,248]. In a manner analogous to the issue of MOFs, the most common approach for COF-based composites is to mix the COF with the substrate, with hydrogels being a particularly suitable choice. It is important to note that achieving homogeneous dispersion of COF particles in hydrophilic matrices (e.g., CMC) by direct mixing is challenging [249]. However, the rather heterogeneous incorporation of COF can potentially lead to degradation of the mechanical properties of the hydrogel. Therefore, if COFs are coated on the surface of the hydrogel, they can be dispersed relatively homogeneously, while at the same time reinforcing the hydrogel [249]. In recent years, there has been a paucity of reports on the enhancement of CBHs by COFs, and the studies are relatively novel. For instance, Li et al. [250] utilized an in situ spray gel-assisted biosynthesis strategy for the first time, which led to the generation of continuous BCCOF-SO3H multilayered composite hydrogels by spraying COFs at different concentrations during the growth of BC hydrogels (Figure 4f). The composites exhibited a substantial number of hydroxyl and sulfonic acid groups, and through ion-exchange and ligand interactions, they provided a substantial number of active adsorption sites. These sites were found to have extremely high adsorption capacity, thus providing a novel method for the preparation of COF composites. In a separate study, Zhao et al. [249] prepared a novel COF@CNF@CMC composite hydrogel bead (C-CCHB) for the removal of Ni2+ from an aqueous solution. Specifically, COF was first synthesized using 2,2′-bipyridine-5,5′-formaldehyde (BP) and 1,3,5-tris(4-aminophenyl)-benzene (TAPB) as monomers and dimethyl-sulfoxide (DMSO) as a solvent. Subsequently, COF was grafted onto CNF by the Schiff base reaction, forming COF@CNF with an imine bond. Finally, COF@CNF and CMC were mixed and extruded into FeCl3 to obtain C-CCHB.

3.3.2. Multi-Network Composite Cellulose-Based Hydrogels

Dual-Network Cellulose-Based Hydrogels