Investigation of a Hydraulic Channel for Plastic Particles Sorting via Experimental and Numerical Tools

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. Separation Tests

2.3. CFD Model

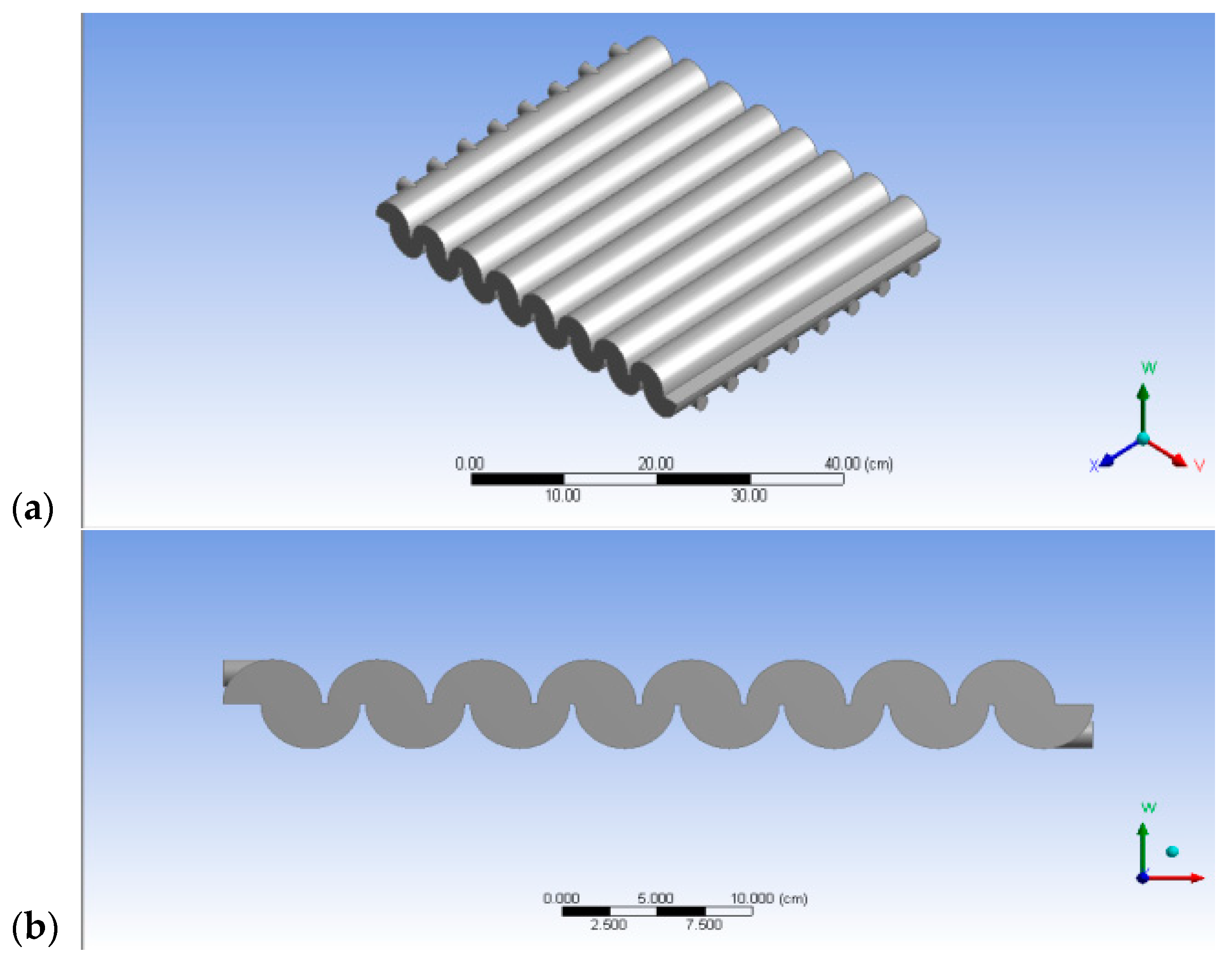

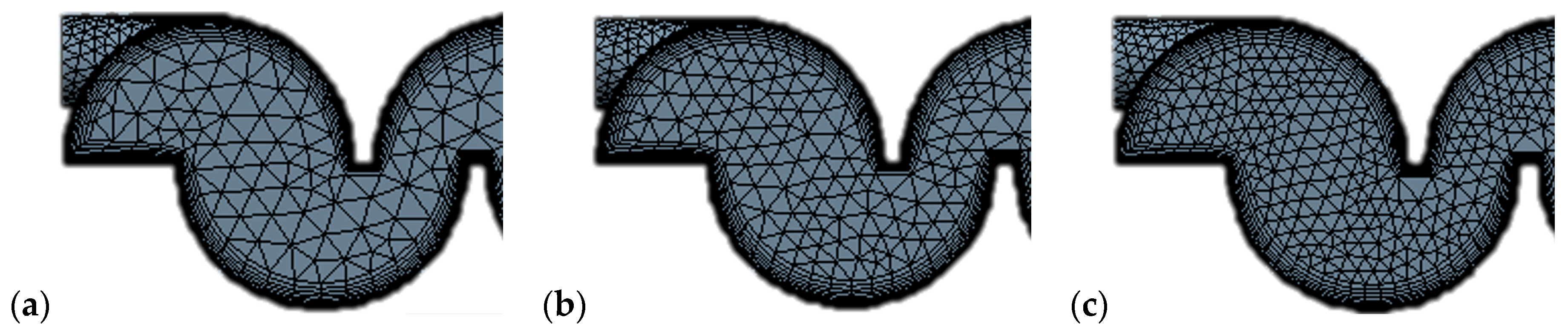

2.3.1. Geometry Creation and Grid Generation

2.3.2. Fluid Phase Modeling

2.3.3. Solid Phase Modeling

2.3.4. Boundary Conditions

3. Results

3.1. Experimental Results

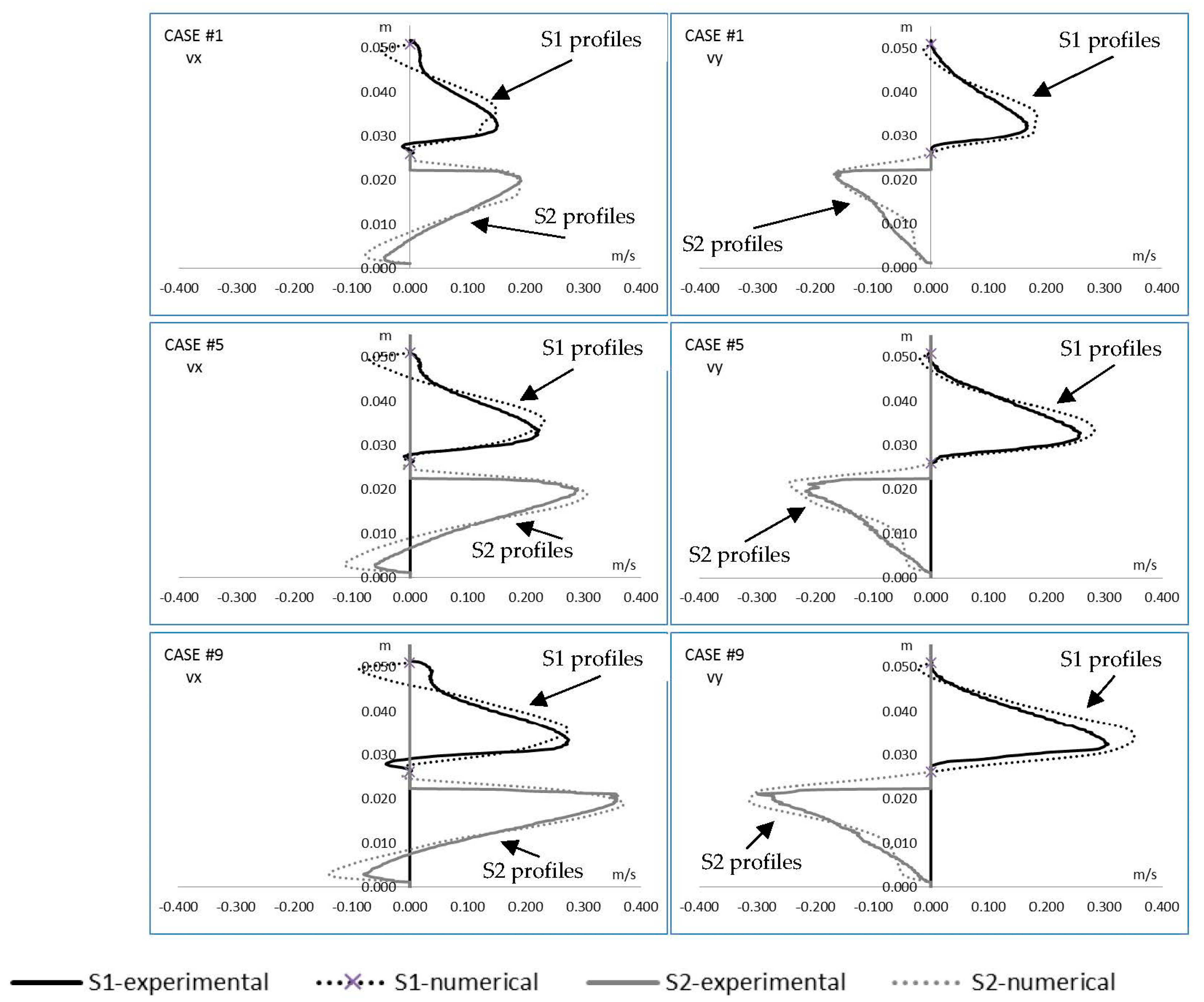

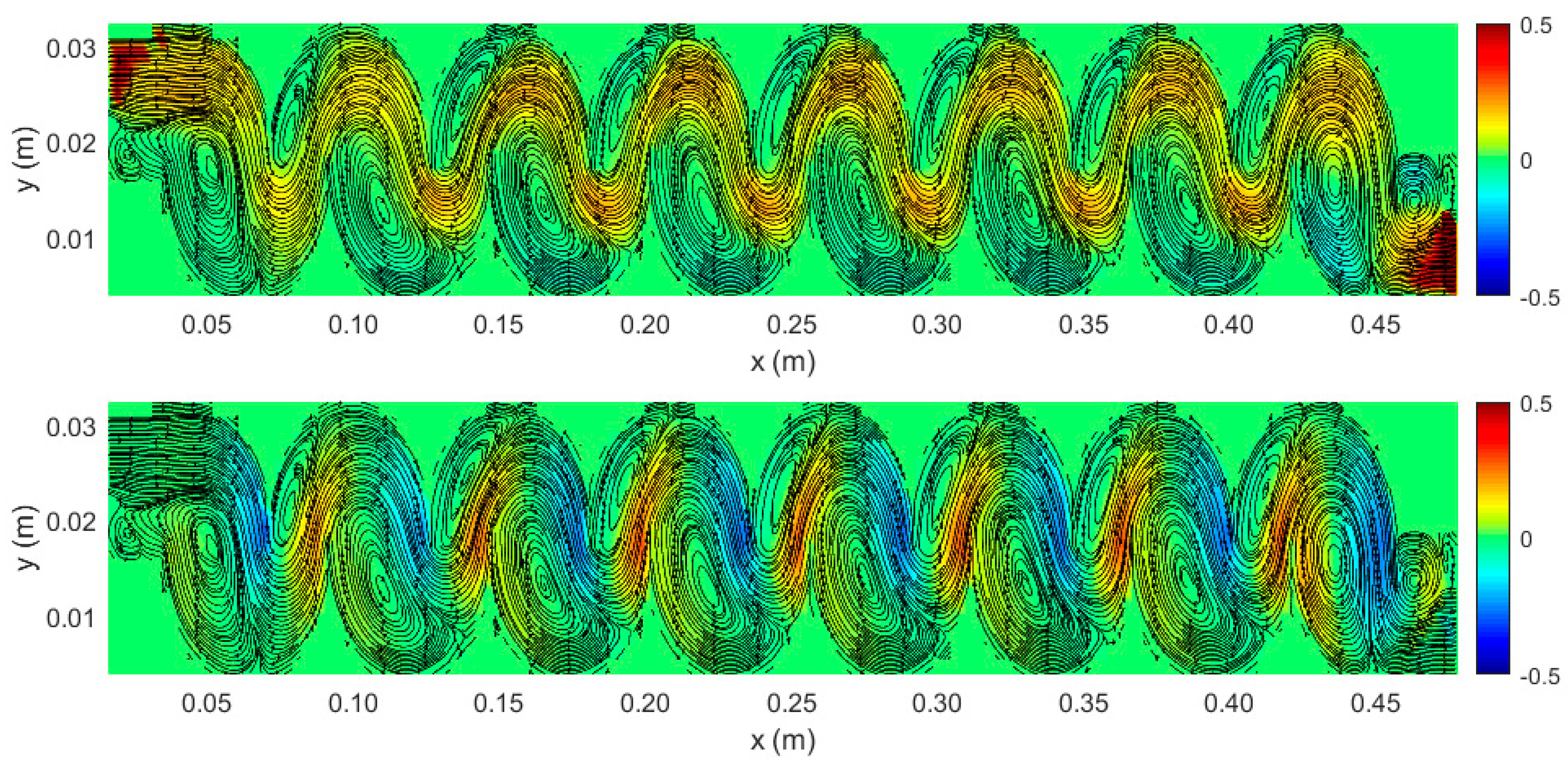

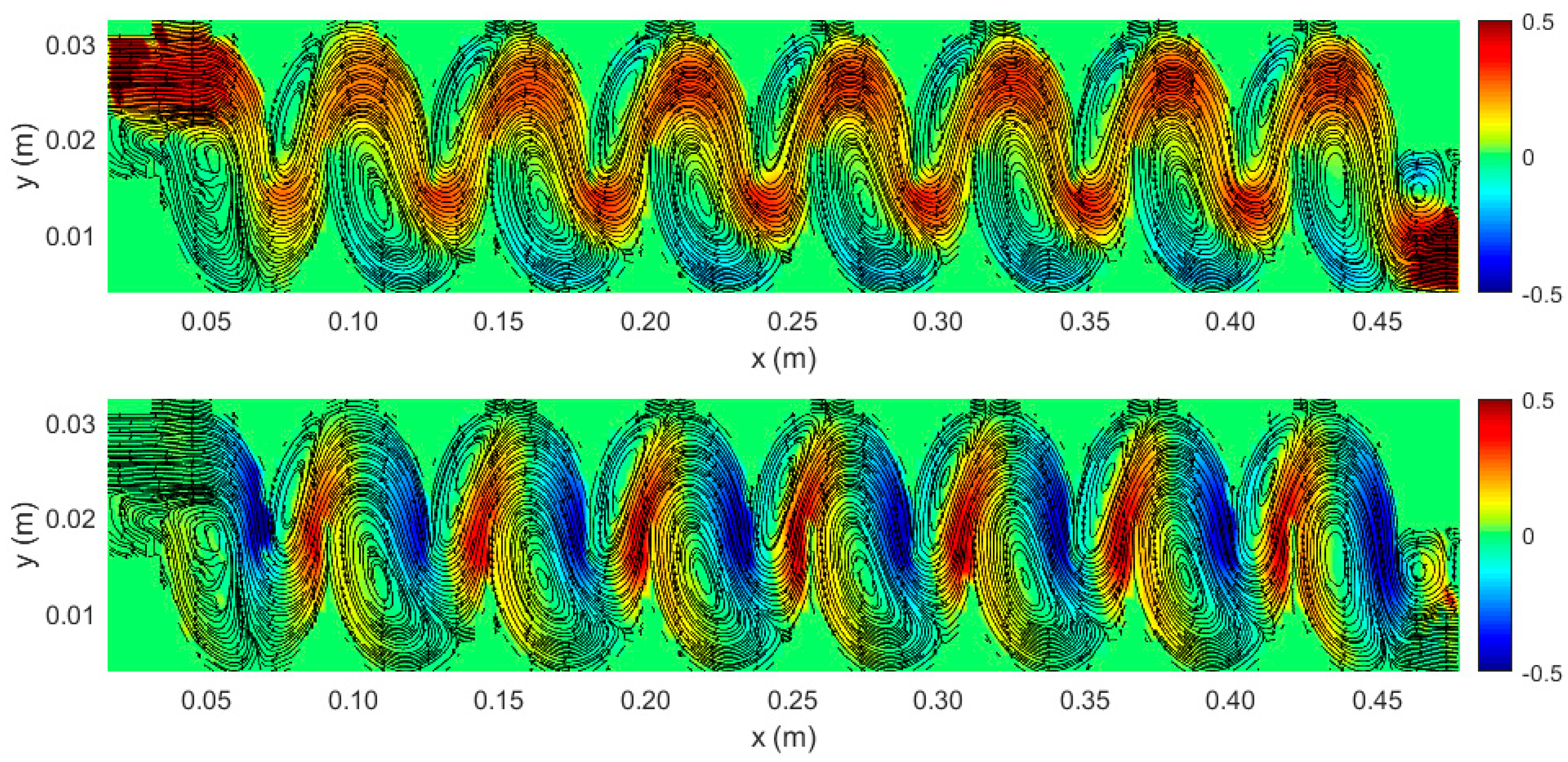

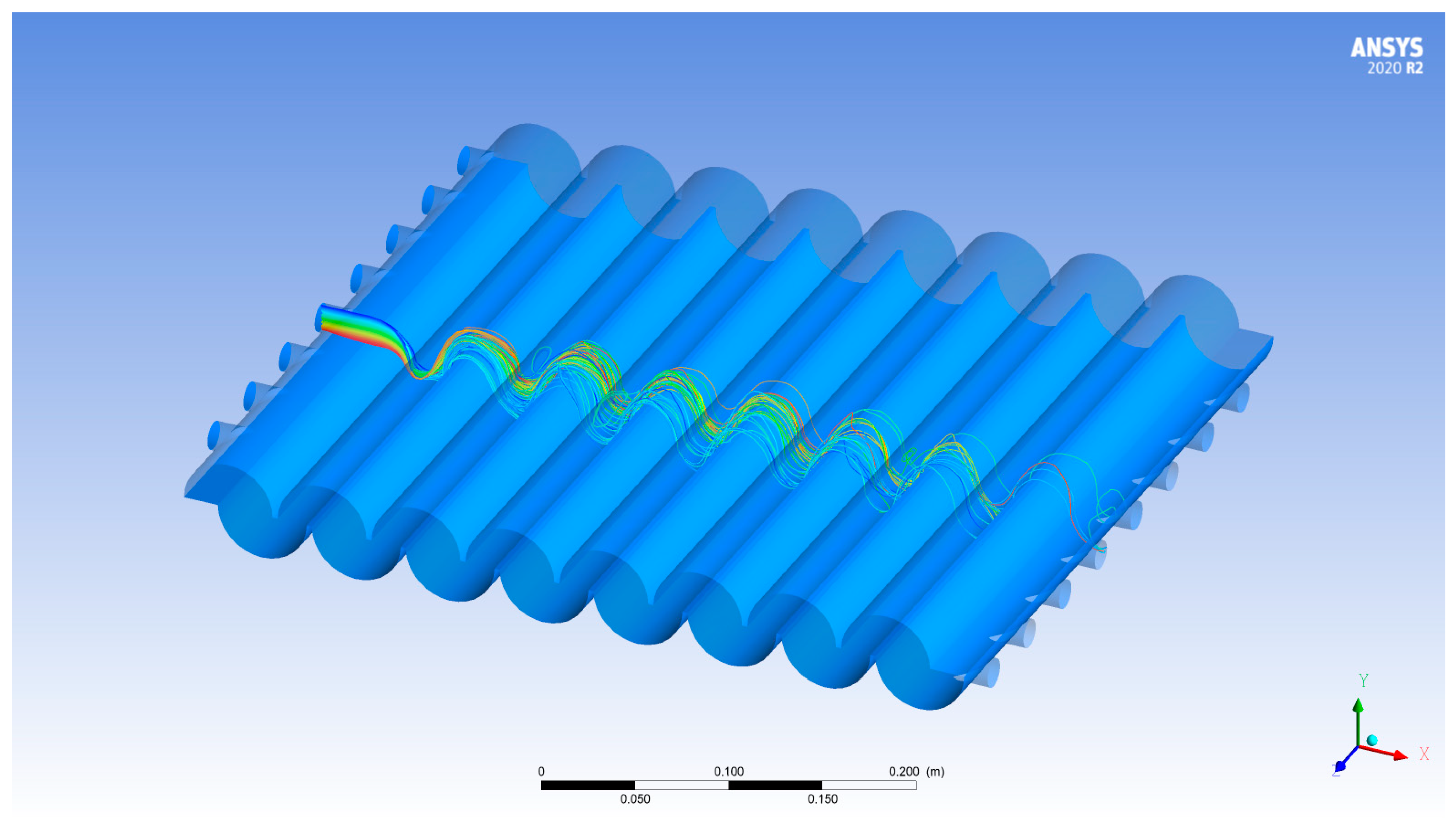

3.2. Numerical Results

4. Conclusions

- A mesh of size 3·10−3 m was suitable for reproducing the observations;

- Laminar and different turbulent models, i.e., k-ε and k-ω, were employed and validated with experimental results; the k-ω SST model turned out to be the one providing results remarkably similar to the experimental ones and was then chosen to test the behavior of the particles within the apparatus;

- The qualitative representation of the velocity field makes it possible to identify three different characteristic flow structures within the separator channel: (i) a principal transport current along the entire longitudinal section that may drag the material inside the device according to its size, density, and shape, and, in each chamber, (ii) a lower recirculation zone that may subtract particle from the main current or from the bottom of the chamber and (iii) an upper recirculation zone that may capture particles from the main current slowing down their settling with the chamber or their displacement within the apparatus;

- The user-defined boundary condition for solid particles was demonstrated to be effective in reproducing the results of mono-material separation tests. As already demonstrated with experiments, encouraging separation results can be achieved using several combinations of polymers, namely PET-PVC, PET-PC, and PVC-PC, and appropriate hydraulic conditions.

Funding

Data Availability Statement

Conflicts of Interest

References

- Tkaczyk, S.; Kuzincow, J.; Ganczewski, G. Life Cycle Assessment in Management of Socially Responsible Enterprise. Found. Manag. 2014, 6, 71–82. [Google Scholar] [CrossRef]

- Shen, L.; Haufe, J.; Patel, M.K. Product Overview and Market Projection of Emerging Bio-BASED Plastics, PRO-BIP 2009; Utrecht University: Utrecht, The Netherlands, 2009. [Google Scholar]

- EUROPEAN BIOPLASTICS. Fact Sheet. What Are Bioplastics? Material Types, Terminology and Labels—An Introduction. 2018. Available online: https://docs.european-bioplastics.org/publications/fs/EuBP_FS_What_are_bioplastics.pdf (accessed on 10 September 2023).

- Lin, D.; Yang, G.; Dou, P.; Qian, S.; Zhao, L.; Yang, Y.; Fanin, N. Microplastics negatively affect soil fauna but stimulate microbial activity: Insights from a field-based microplastic addition experiment. Proc. R. Soc. B 2020, 287, 20201268. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Lavender Law, K. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe. Plastics—The Facts 2021/2022. An Analysis of European Plastics Production, Demand and Waste Data. 2022. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 10 September 2023).

- Lange, J.P. Managing plastic waste—Sorting, recycling, disposal, and product redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Shent, H.; Pugh, R.J.; Forssberg, E. A review of plastics waste recycling and the flotation of plastics. Resour. Conserv. Recycl. 1999, 25, 85–109. [Google Scholar] [CrossRef]

- Gent, M.R.; Menendez, M.; Toraño, J.; Diego, I. Recycling of plastic waste by density separation: Prospects for optimization. Waste Manag. Res. 2009, 27, 175–187. [Google Scholar] [CrossRef] [PubMed]

- Tilmatine, A.; Medles, K.; Bendimerad, S.E.; Boukholda, F.; Dascalescu, L. Electrostatic separators of particles: Application to plastic/metal, metal/metal and plastic/plastic mixtures. Waste Manag. 2009, 29, 228–232. [Google Scholar] [CrossRef] [PubMed]

- Yanar, D.K.; Kwetkus, B.A. Electrostatic separation of polymer powders. J. Electrost. 1995, 35, 257–266. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.; Hu, B.; Serranti, S.; Bonifazi, G. The W2Plastics Project: Exploring the Limits of Polymer Separation. Open Waste Manag. J. 2010, 3, 90–98. [Google Scholar] [CrossRef]

- Yuan, H.; Fu, S.; Tan, W.; He, J.; Wu, K. Study on the hydrocyclonic separation of waste plastics with different density. Waste Manag. 2015, 45, 108–111. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, F.; Wei, X.; Yang, Y.; Xu, S.; Deng, D.; Wang, Y.Z. From trash to treasure: Chemical recycling and upcycling of commodity plastic waste to fuels, high valued chemicals and advanced materials. J. Energy Chem. 2022, 69, 369–388. [Google Scholar] [CrossRef]

- Bauer, M.; Lehner, D.; Schwabl, H.; Flachberger, L.; Kranzinger, R.; Pomberger, W. Sink–float density separation of post-consumer plastics for feedstock recycling. J. Mater. Cycles Waste Manag. 2018, 20, 1781–1791. [Google Scholar] [CrossRef]

- Lupo, E.; Moroni, M.; La Marca, F.; Fulco, S.; Pinzi, V. Investigation on an innovative technology for wet separation of plastic wastes. Waste Manag. 2016, 51, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Adamsson, A.; Stovin, V.; Bergdahl, L. Bed Shear Stress Boundary Condition for storage tank sedimentation. J. Environ. Eng. 2003, 129, 651–658. [Google Scholar] [CrossRef]

- Dufresne, M.; Vazquez, J.; Terfous, A.; Ghenaim, A.; Poulet, J.B. Experimental investigation and CFD modelling of flow, sedimentation, and solids separation in a combined sewer detention tank. Comput. Fluids 2009, 38, 1042–1049. [Google Scholar] [CrossRef]

- Schmitt, V.; Dufresne, M.; Vazquez, J.; Fischer, M.; Morin, A. Optimization of a hydrodynamic separator using a multiscale computational fluid dynamics approach. Water Sci. Technol. 2013, 68, 1574–1581. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Wan, G.; Sun, G.; Xue, X.; Shi, M. Solids Concentration Simulation of Different Size Particles in a Cyclone Separator. Powder Technol. 2008, 183, 94–104. [Google Scholar] [CrossRef]

- Tarpagkou, R.; Pantokratoras, A. CFD methodology for sedimentation tanks: The effect of secondary phase on fluid phase using DPM coupled calculations. Appl. Math. Model. 2013, 37, 3478–3494. [Google Scholar] [CrossRef]

- Moroni, M.; Lupo, E.; Della Pelle, V.; Pomponi, A.; La Marca, F. Experimental Investigation of the Productivity of a Wet Separation Process of Traditional and Bio-Plastics. Separations 2018, 5, 26. [Google Scholar] [CrossRef]

- Shindler, L.; Moroni, M.; Cenedese, A. Spatial-temporal improvements of a two-frame particle-tracking algorithm. Meas. Sci. Technol. 2010, 21, 115–401. [Google Scholar] [CrossRef]

- Shindler, L.; Monica, M.; Cenedese, A. Using optical flow equation for particle detection and velocity prediction in particle tracking. Appl. Math. Comput. 2012, 218, 8684–8694. [Google Scholar] [CrossRef]

- Moroni, M.; Mei, A.; Leonardi, A.; Lupo, E.; La Marca, F. PET and PVC separation with hyperspectral imagery. Sensors 2015, 15, 2205–2227. [Google Scholar] [CrossRef] [PubMed]

- Hanjalić, K.; Kenjereš, S. Some developments in turbulence modeling for wind and environmental engineering. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1537–1570. [Google Scholar] [CrossRef]

- ANSYS. ANSYS FLUENT Theory Guide; ANSYS Inc.: Canonsburg, PA, USA, 2011. [Google Scholar]

- Dubief, Y.; Djenidi, L.; Antonia, R.A. The measurement of ∂u∂y in a turbulent boundary layer over a riblet surface. Int. J. Heat Fluid Flow 1997, 18, 183–187. [Google Scholar] [CrossRef]

- Vierendeels, J.; Degrotoe, J. Introduction to Computational Fluid Dynamics, Annual Lecture Series von Karman Institute. 2014. Available online: https://www.vki.ac.be/index.php/component/jevents/eventdetail/326/-/introduction-to-computational-fluid-dynamics?Itemid=789 (accessed on 10 February 2023).

- Menter, F. Two Equation Eddy-Viscosity Turbulence Modeling for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- ANSYS. ANSYS FLUENT User’s Guide; ANSYS Inc.: Canonsburg, PA, USA, 2011. [Google Scholar]

- La Marca, F.; Moroni, M.; Cherubini, L.; Lupo, E.; Cenedese, A. Separation of plastic waste via the hydraulic separator Multidune under different geometric configurations. Waste Manag. 2012, 32, 1306–1315. [Google Scholar] [CrossRef]

- Moroni, M.; La Marca, F.; Cherubini, L.; Cenedese, A. Recovering plastics via the hydraulic separator Multidune: Flow analysis and efficiency tests. Int. J. Environ. Res. 2013, 7, 113–130. [Google Scholar]

| Case # | MFS 10−3 m | Number of Nodes | Number of Elements |

|---|---|---|---|

| 1 | 5 | 411,066 | 1,045,074 |

| 5 | 5 | 419,254 | 1,085,413 |

| 9 | 5 | 421,273 | 1,105,216 |

| 1 | 4 | 592,709 | 1,528,616 |

| 5 | 4 | 599,365 | 1,587,456 |

| 9 | 4 | 605,730 | 1,628,975 |

| 1 | 3 | 981,525 | 2,555,892 |

| 5 | 3 | 995,874 | 2,595,413 |

| 9 | 3 | 1,001,148 | 2,671,870 |

| Polymer Name | Sedimentation Efficacy from Experiments (%) | Sedimentation Efficacy from Numerical Simulations (%) | ||||

|---|---|---|---|---|---|---|

| Case #1 | Case #5 | Case #9 | Case #1 | Case #5 | Case #9 | |

| PC 1-V | 82.8 | 0.0 | 0.0 | 77.6 | 0.0 | 0.0 |

| PET 2-V | 99.2 | 0.0 | 0.0 | 94.0 | 0.0 | 0.0 |

| PVC 2-V | 100 | 31.5 | 0.0 | 98.7 | 35.0 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moroni, M. Investigation of a Hydraulic Channel for Plastic Particles Sorting via Experimental and Numerical Tools. Separations 2024, 11, 5. https://doi.org/10.3390/separations11010005

Moroni M. Investigation of a Hydraulic Channel for Plastic Particles Sorting via Experimental and Numerical Tools. Separations. 2024; 11(1):5. https://doi.org/10.3390/separations11010005

Chicago/Turabian StyleMoroni, Monica. 2024. "Investigation of a Hydraulic Channel for Plastic Particles Sorting via Experimental and Numerical Tools" Separations 11, no. 1: 5. https://doi.org/10.3390/separations11010005

APA StyleMoroni, M. (2024). Investigation of a Hydraulic Channel for Plastic Particles Sorting via Experimental and Numerical Tools. Separations, 11(1), 5. https://doi.org/10.3390/separations11010005