Abstract

The dewatering of substrates is one of the key tasks in the handling of material flows in a circular economy. Besides belt filters, sedimenters, and decanters, screw presses are frequently used to reduce the water content of substrates. However, screw presses available on the market are usually designed for high throughputs (>5 m3/h). The dewatering of smaller feed rates (<1 m3/h), however, requires more compact solutions. For this reason, a compact screw press (short screw length), which is normally used in agriculture for cow manure dewatering, was investigated in this work, as there exist no publications on this type of compact screw press. A mobile test setup was developed and loaded with different material such as digested sludge from a wastewater treatment plant, commercially available potting soil, wood shavings, and biological waste. The dry matter content of the feed material, the feed material itself, the screw rotational speed, and the weight setting (pressure) at the back plate were varied, and the effects on the dewatering result were recorded. A significant influence on the dewatering result was found for the weight setting, the type of substrate (particle size), and the dry substance content of the feed material. The tests confirmed that the compact screw press separator is suitable for the dewatering of wood shavings and biological waste (with an increase in dry matter percentage of up to 7.7%). The direct dewatering of potting soil and digested sludge is not possible and can only be implemented by using structural support material. This study fills the gap between published work on large screw presses and potentially new application fields of compact screw press manure separators, which, until now, have only been used in agriculture.

1. Introduction

Total greenhouse gas emissions in the EU are equivalent to 3311 million tons of CO2 per year. Looking at the total emissions, a downward trend can be observed over the years. Nevertheless, in certain sectors, emissions are still increasing. One of these sectors is the road transport of goods. According to source [1] (table ES.1, page v), the greenhouse gas emissions in this sector increased by 131 million tons of CO2 equivalent in the period between 1990 and 2021. In the future, complete CO2 neutrality can only be guaranteed if all possible saving measures are considered. Therefore, especially in these sectors, potential energy savings still need to be identified and existing processes need to be optimized. One example of a process that can be optimized is the collection of biological waste.

Biological waste is often collected separately so that biogas can be produced. With a share of 34% of the total amount of household waste, biological waste is the largest single component [2]. In the EU alone, this corresponds to 88 million tons of biological waste per year [2]. A large part of this is pure water, which cannot be metabolized into biogas. As a result, a large amount of energy is wasted during transport. To avoid this waste of energy, the dewatering of biological waste could be applied. Through the reduced transport volume, fossil fuels and consequently greenhouse gas emissions could be saved. As dewatering would have to be carried out at a large number of sites, compact and widely available solutions would be needed. This is also the reason why the dewatering properties of a small manure separator were investigated in this study. Its main application is the solid–liquid separation of manure, using the principle of a screw press. Screw presses usually consist of a perforated screen basket with a rotating screw inside. The screw transports the material along the axis of rotation, exerting a steadily increasing pressure. Due to this compression, the water is squeezed out of the feed material, and it can subsequently flow off through the holes in the screen basket. Since the water does not contain any hazardous substances, it can be safely discharged into the sewerage system.

The dewatering of biological waste with screw presses is not new, and the dewatering process with different screw presses has been described in previous studies. Fu, Shuangcheng et al. (2023) [3] suggest that the importance of the influencing factors for the dewatering process decreases in the following order: the dry matter content of the feed, pressure, and rotational speed. The study refers to an output stream of 234.2 kg/day. The work of B. El Idrissi et al. (2019) [4] undermines these findings and describes a strong influence of feed composition (fibre network and particle size), pressure, and rotational speed. It was shown that the water content in the outlet flow increases at higher rotational speeds and at lower pressures. Furthermore, it was observed that the fibre network structure and the particle size of the feed strongly influence the dewaterability of a certain substrate. Also, K. Mudryk et al. (2016) [5] described a strong influence of the pressure on the dewatering result. The experiments of this study showed that the water content initially decreases continuously with increasing pressure. When a certain level is reached, no further (or only a slight) decrease in water content can be observed.

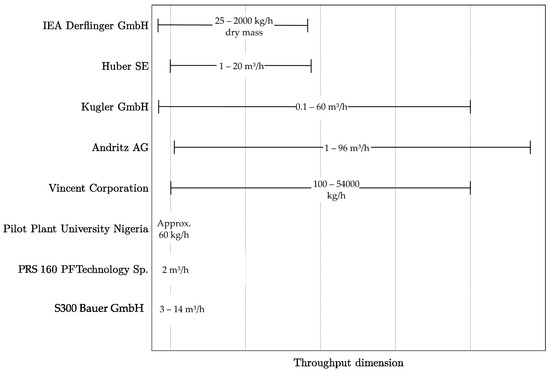

The difference in the manure separator of this study compared to the devices used in previous studies is the low capacity and the short screw length compared to other screw presses used on an industrial scale. Figure 1 underlines this assumption, by comparing available screw presses and screw presses used in experimental setups with the throughput capacity of the manure separator. There is no published work available on the dewatering behaviour of manure separators except for manufacturers’ information on manure dewatering. The present study fills this information gap and includes an extended evaluation study on non-typical (non-manure) substrates for the manure separator as there is a need for compact screw presses in a circular economy. Examples for applications are coarse fraction dewatering after mechanical wet pre-treatment of waste or the local dewatering of food waste in hotels to reduce transportation costs.

Figure 1.

Comparison of the throughput capacities of different screw presses. The upper four values show the capacity range of screw press models from the product lines of different manufacturers. The lower three values are specific for one screw press model. The pilot plant of the University of Nigeria is the one used in [6]. The PRS 160 press is used in [5]. The masses and volumes refer to the wet weight of the feed, if not mentioned otherwise [6,7,8,9,10,11,12,13].

As shown in Figure 1, the throughput capacity of the manure separator is comparable to some laboratory-scale screw presses and is significantly lower than most commercially available solutions. The screw length of the manure separator is approximately 0.5 m. Most of the other commercially available solutions show screw lengths of 1 to 7 m [4,8,9]. The short screw length reduces the dewatering path, and the effects have not yet been investigated sufficiently. Prior observations have suggested that acceptable dewatering results can be generated for biological waste even with shorter dewatering paths. This observation, and thus the viability of such a compact solution, should have been confirmed by the series of tests conducted. These tests were primarily aimed at investigating influencing variables, such as the speed, dry substance content of the feed material, and different weight settings at the exit hatch of the press. To be able to interpret the results adequately, particle characterization of the substrates was also performed. The particle size distribution, the dry substance content, and the density of the substrate are important influencing factors.

To be able to give an estimate of possible savings, a simplified potential analysis was carried out based on the example of the province of Tyrol in Austria.

2. Materials and Methods

2.1. Experimental Setup

Figure 1 shows the BAUER GmbH S300 manure separator used for the experiments. A mobile profile frame was used to mount the press, which was extended by a funnel-shaped feeding device. This allowed the flexible variation of the test location and the test procedure. A rotating screw is located inside the device, which ensures the transport of the feed material in the direction of the outlet hatch. It is rotated by a 50 Hz and 2.2 kW multi-range gear motor. The motor can generate a maximum speed of 1775 RPM. At full power, this corresponds to a screw speed of 27 rpm. The speed is controlled by a Siemens LOGO!, which allows stepless control between 0 and 100%. The screw is enclosed by a perforated cylinder, the so-called screen basket. This component is available in different designs so that the number and size of the holes can influence the particle discharge through the pressed-off liquid. In the first part of the screw, dewatering takes place due to gravity. Water that is weakly bound can flow off freely in this section. In the second part of the screw, the feed material is compressed and, thus, bound water is pressed out of the feed material. The extracted water can flow off through the holes in the screen basket in order to be disposed of.

Weights are attached to the outlet hatch via a joint. The distance between the weights and the outlet hatch can be varied, and in this way, the degree of dewatering can be influenced. According to the manufacturer, the press is best suited for manure with a dry matter content between 7 and 9% [7]. For this type of feed material, dry matter contents of up to 32% can be achieved by the pressing process [7].

2.2. Parameter Experiments

To describe the dewatering behaviour more precisely, selected parameters were varied, and their influence on the press result was investigated in more detail. Various weight settings, rotational speeds, and different dry substance contents of the feed material were analysed in this way. To ensure the highest possible homogeneity of the input material during this series of tests, pressed wood briquettes were used instead of biological waste. These wood briquettes were suspended in a vat of water and subsequently transferred by hand into the funnel of the manure separator. Each experimental run was performed by adding 50 L of water and then adding the appropriate amount of wood briquettes. For each prepared wood briquette mixture, a sample of the feed material and the pressed material was taken. All samples were dried at 60 °C till weight constancy.

The exact parameters for each partial test are shown in Table 1.

Table 1.

Experimental conditions for each set of experiments.

2.3. Substrate Experiments

In addition to the sub-tests for the determination of the parameter influences, experiments were also carried out with different substrates:

- Potting soil: The experiments were conducted at a weight setting of 0 cm and a rotational speed of 10%. For each experiment, 20 L of water was used. Both pure potting soil and mixtures with potting soil and wood briquettes were used for mixing the feed material.

- Digested sludge: The tests were carried out at a weight setting of 0 cm and a speed of 10%. Materials pressed were pure digested sludge, digested sludge mixed with water and digested sludge mixed with wood briquettes and water. Different combinations between the mixing partners were investigated to be able to generate a pressing result.

- Bedding (wood shavings): For the tests, suspensions with a dry substance content of approx. 4% were prepared. A total volume of 20 L of water was used, the speed was kept constant at 10%, and the weight settings were varied. Weight settings of 0 cm, 13.8 cm and 27.5 cm were examined in more detail. Three replicates were performed for each weight setting.

- Biological waste: the biological waste was not mixed with water, but only coarsely shredded with an agitator from STIER Industrial GmbH prior to the pressing process.

Also, in this series of tests, a sample was taken before and after each pressing operation and dried to constant weight.

2.4. Particle Characterization

Particle characterization of each substrate was carried out by the following analysis:

- Dry matter content: A representative sample was taken from each substrate and dried to constant weight at 60 °C in a drying oven for 96 to 120 h (4–5 days). Samples were weighed twice at 6 to 8 h intervals on the evaluation day to verify weight constancy. By weighing the samples before and after the drying process, the percentage of dry matter could be determined.

- Bulk density: To determine the bulk density, a measuring cylinder was filled with a sample, and the mass and volume of the bulk was noted. The bulk density was determined for three different compression levels. For this purpose, the measuring cylinder was either clamped in the sieve tower for ten seconds, tapped several times on the table, or not moved at all after filling.

- Particle density: The particle density was determined by the automatic gas pycnometer Ultrapyc 1200e V5.06 from Quantachrome Corporation. Three measurement runs were performed for each substrate, and their mean value was determined.

- Particle size distribution: The particle size distribution was determined by sieving. Sieves with mesh sizes of 13.2, 5.6, 4.0, 3.15, 2.0, 1.0 and 0.8 mm were used for the sieving process. A certain amount of substrate was weighed and sieved in the sieve tower for 10 min at an amplitude of 70%. The sieves were weighed before and after sieving, and the difference was used to determine the respective particle density and particle sum curves. For each substrate, three sieve runs were performed and the average value was calculated.

3. Results

3.1. Parameter Experiments

The correlation between the dry matter content of the pressed substrate and the respective influencing parameter was illustrated in a graph. The values were used to calculate the formula of a regression line and the coefficient of determination R2. The formulae of the regression lines are built up based on the following basic structure.

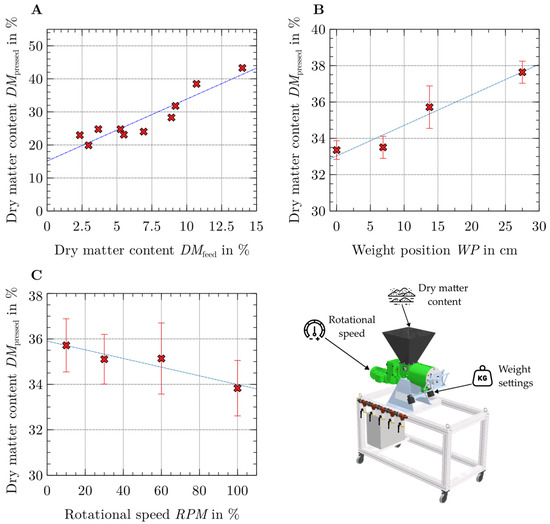

DMpressed indicates the dry matter content of the pressed material, and P is the value of the varied parameter. The coefficients a and b of each parameter are shown in Table 2. The graphs with the measured values and the calculated regression lines are shown in Figure 2.

Table 2.

Coefficients of the regression lines from Figure 2.

Figure 2.

The figures show the results of the parameter variation experiments. (x) is the mean value (of 3 experiments) and the error bars show the standard deviation. Each figure shows the influence of a certain varied parameter on the dry matter content of the pressed material. Figure (A) shows the influence of the dry matter content of the feed; figure (B) shows the influence of different weight positions; and figure (C) shows the influence of different rotational speeds.

To assess the significance of the influencing parameters, a t-test of the correlation coefficient was carried out. This confirmed that the weight setting and the dry substance content of the feed material had a significant influence on the pressing result. Although the dry substance content in the pressed material decreased with increasing rpm, the corresponding t-test was negative.

3.2. Substrate Experiments

The dewatering performance is manly influenced by the input material properties. Therefore, the study comprised a selection of substrates considering potential future application, repeatability, and availability.

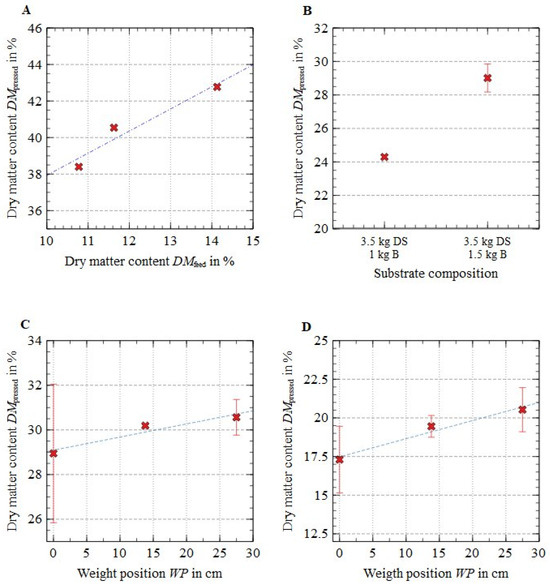

- Potting soil: In the test with pure potting soil, no dewatering result could be achieved. No press cake was formed at the outlet hatch, and the mixture passed through the press without any dewatering. By adding wood briquettes, this problem could be solved and, thus, dewatering with three different dry matter contents in the feed material could be carried out. The results of these test runs are shown in Figure 3A.

- Digested sludge: In the tests with pure digested sludge and the mixture of water and pure digested sludge, no result could be achieved. The dry matter content of the pure digested sludge was already too high and, therefore, no further dewatering took place. With the mixture of water and digested sludge, no press cake was formed and, thus, no dewatering could be achieved. Only the addition of wood briquettes enabled dewatering to take place. Two different dry matter contents were investigated for this raw material. The results are shown in Figure 3B.

- Bedding (wood shavings): Dewatering of the wood shavings was possible without the addition of wood briquettes. The feed material formed a press cake immediately and thus generated a good press result. Three different weight settings were investigated to assess the dewatering properties. Three repetitions were carried out for each weight setting and the mean value was calculated. The results with the corresponding regression line are shown in Figure 3C. A t-test of the correlation coefficient was also carried out for this test series. However, this did not confirm a significant correlation between the weight setting and the dewatering result.

- Biological waste: In the case of biological waste, it was shown that even coarse shredding was sufficient to significantly increase the dry matter content through the pressing process. As with the wood shavings, three different weight settings were tested. Three repetitions were carried out for each weight setting and the respective mean was calculated. The results are shown in Figure 3D. The t-test of the correlation coefficient was also negative in this case, so no significant influence of the weight setting could be confirmed. The pressing process resulted in a maximum dry matter increase of 7.7% for bio-waste. This result served as the basis for a potential analysis.

The results of the different substrates are shown in Figure 3. The coefficients of each regression line are displayed in Table 3.

Table 3.

Coefficients of the regression lines from Figure 3.

Figure 3.

The figures show the results of the experiments with different substrates. (x) is the mean value (of 3 experiments) and the error bars show the standard deviation. Each figure shows the results of the conducted experiments of one specific substrate. (A) Potting soil; (B) digested sludge; (C) bedding (wood shavings); (D) biological waste.

3.3. Particle Characterization

3.3.1. Dry Matter Content

The dry matter content was determined with the starting materials and not with the prepared mixtures. In Table 4, all dry matter contents and their standard deviation are listed. The range of dry matter content was between 12.7% (biological waste) and 96.4% (wood briquettes). As the goal of the study was the evaluation of non-typical substrates, this broad range was selected. The first four substrates show haptic fully dry impression. The biological waste with 12.7% dry matter is “normal” biological waste as it can be found in almost every separately collected biological waste bin.

Table 4.

Average dry matter content and standard deviation of each substrate.

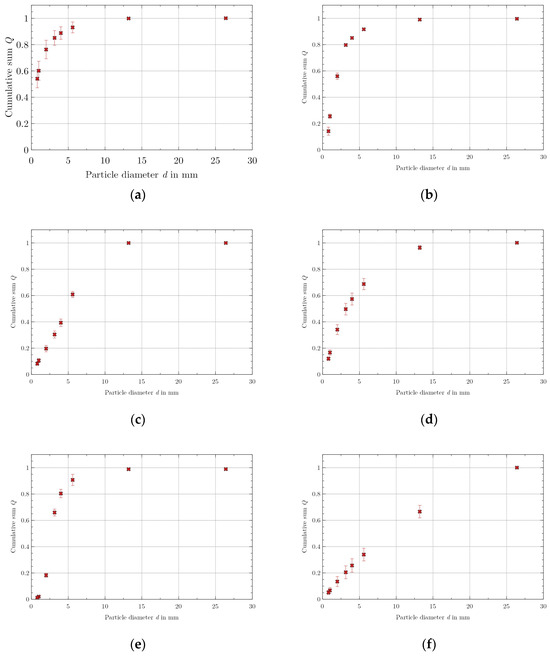

3.3.2. Particle Size Distribution

The particle size distribution of each substrate was illustrated by the cumulative sum curve. The corresponding diagrams are shown in Figure A1 in the Appendix. The wood briquettes (Appendix A Figure A1a) had a median diameter of 0.74 mm and 10% were larger than 5 mm, which is typical for wood briquettes produced from carpenter wood waste. The potting soil (Appendix A Figure A1b) had a higher percentage of larger particles (median diameter 1.80 mm) compared to the wood briquettes. The digested sludge sieving analysis (Appendix A Figure A1c) showed a median diameter of 4.79 mm. This value can be seen critically, as digested sludge tends to form stable agglomerates in the drying process. Appendix A Figure A1d shows a mixture of digested sludge and wood briquettes and so the particle size distribution is in between the ranges, respectively. The wood shavings (Appendix A Figure A1e) had a median diameter of 2.77 mm. As sieving analysis uses the minimum characteristic size of the particle and the wood shavings were mostly plate-shaped, a direct comparison of the particle sizes was not appropriate. The biological waste contained a certain number of large constituents (peppers, zucchinis, strawberries, orange peels…), which led to a coarse particle size distribution.

3.3.3. Bulk Density

The maximum and minimum bulk density of each substrate is summarized in Table 5. This parameter is essential for the estimation of the volume of the substrate, so it has major relevance to the calculation of transport and storage costs. As a result of the particle size and particle shape and the heterogeneous material composition, the range covers values from 111 (wood briquettes) to 687 (dried digested sludge). The broad value range of biological waste (160–246 kg/m3) can be explained by the influence of the sample size on the analytical results.

Table 5.

Average minimum and maximum bulk density of each substrate.

3.3.4. Particle Density

The maximum and minimum particle density of each substrate, measured with gas pycnometry, is summarized in Table 6, which has a range of 1476 kg/m3 (wood briquettes) up to 1690 kg/m3 (potting soil). According to the material properties, it can be assumed that the gas has a penetration of 100%.

Table 6.

Average particle density and standard deviation of each substrate.

4. Discussion

In this paper, the dewatering properties of a compact screw press manure separator were investigated to fill information gaps on the dewatering performance for non-typical (non-manure) substrates. Therefore, the screw press was operated with selected input material and a variation in the operational parameters (the speed of the screw, weight setting at the back plate, and dry mass of the input material). Most of the substrates are categorized as non-typical, so a comparison of the results with the literature is limited. The current literature mostly uses easy-to-handle substrates (e.g., wood fibres [4], post-ferment of an agricultural biogas plant [5], no substrate property specification [3], and cassava mash [6]). The particle size of the substrates decisively determines the dewatering properties. The dewatering of material with a high proportion of small particles is very difficult with this type of screw press (0% water removal for potting soil with a median diameter of 1.80 mm and pure digested sludge with a median diameter 4.79 mm). If this type of material already has a high dry matter content, the binding strength of the water is so high that no further dewatering can take place. The digested sludge has its limit of dewatering at 20–29% dry matter content. This dewatering behaviour is also observed in the wastewater treatment sector, where digested sludge cannot be mechanically dewatered without adding flocculation agents, and a dry matter content of 30% is commonly known to be the maximum value for screw presses. Sludge dewatering has more influencing factors than investigated in the present paper, such as pH value, temperature, organic fraction, inorganic fraction, or chemical composition [14]. With lower dry substance contents, the small particles are not able to build up a press cake and, thus, no dewatering can take place as the inlet material flows through the dewatering section without being dewatered. For potting soil and digested sludge, dewatering is only made possible by adding dry solids, supporting the structural material with a higher proportion of larger particles. The weight setting at the back plate increases the dry matter content from 17.3% (average; position 0 cm) to 20.5% (average; position 27.5 cm). This is in agreement with the results of [4]. In the tests with biological waste and wood shavings, a positive tendency, but no significant influence (t-test) of the weight settings, can be confirmed. However, the studies [3,4,5] also suggested that the increase in dry matter is reduced when a certain pressure is reached. This effect could not be proven by the experiments, because the weights used for generating the pressure were rather small. For a future application field of the compact screw press, the idea of decentralized biological waste dewatering can be roughly analysed as follows: Assuming an increase in dry matter for biological waste of 7.7%, less water is transported from the waste source to the waste disposer. Assuming that all biological waste mass of 93,210 t/a in the province of Tyrol (Austria) is dewatered and then transported 60 km to the biogas plant for disposal, an annual saving of 46,111 kWh could be achieved [7,15,16,17,18,19,20,21] by local dewatering. The cost savings resulting from lower personnel, maintenance, and fuel costs are suggested to be even presumably higher. This is only one potential new application field of the compact screw press.

5. Conclusions

The compact screw press, which was investigated in this study, has until now only been used in agriculture for cow manure dewatering. Compared to typical screw presses, this type of press is shorter, less prone to errors, easy to maintain, and suitable for low capacities (<1 m3/h input). So far, there has been no published work available on the dewatering performance of this type of separator. The weight settings, the particle size, and the dry matter content of the feed material were identified as significant influencing variables. The results show that this separator can be used for wood particle dewatering as well as for biological waste dewatering. Both substrates have the potential to become future application fields of this type of dewatering device.

Author Contributions

Conceptualization, I.S., T.S. and M.P.; methodology, I.S. and T.S.; validation, I.S., T.S., M.P., M.B. and A.S.; formal analysis, I.S. and M.B.; investigation, I.S., C.M. and T.K.; resources, T.K.; data curation, C.M., A.S. and M.K.; writing—original draft preparation, T.S., I.S. and M.B.; writing—review and editing, M.B., T.S., M.P., C.M., T.K, A.S. and M.K.; visualization, T.K., M.B. and A.S.; supervision, M.P.; project administration, C.M. and T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Figure A1.

Figures (a–f) show the cumulative sum of the particle size distribution: (a) wood briquettes; (b) potting soil; (c) digested sludge; (d) digested sludge + wood briquettes; (e) bedding (wood shavings); (f) biological waste.

References

- European Environment Agency. Annual European Union Greenhouse Gas Inventory 1990–2021 and Inventory Report 2023; European Environment Agency: Brüssel, Belgium, 2023; Available online: https://www.eea.europa.eu/publications/annual-european-union-greenhouse-gas-2 (accessed on 27 February 2023).

- European Environment Agency. Bio-Waste in Europe: Turning Challenges into Opportunities; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-9480-223-1. [Google Scholar]

- Fu, S.; Dou, B.; Zhang, X.; Li, K. An Interactive Analysis of Influencing Factors on the Separation Performance of the Screw Press. Separations 2023, 10, 245. [Google Scholar] [CrossRef]

- El idrissi, B.; Loranger, É.; Lanouette, R.; Bousquet, J.P.; Martinez, M. Dewatering parameters in a screw press and their influence on the screw press outputs. Chem. Eng. Res. Des. 2019, 152, 300–308. [Google Scholar] [CrossRef]

- Mudryk, K.; Frączek, J.; Jewiarz, M.; Wróbel, M.; Dziedzic, K. Analysis of Mechanical Dewatering of Digestate. Agric. Eng. 2016, 20, 157–166. [Google Scholar] [CrossRef][Green Version]

- Kolawole, O.P.; Agbetoye, L.A.; Ogunlowo, S.; Samuel, T.M. Effect of Speed and Back Pressure on the Performance of Screw Press in Dewatering of Cassava Mash. GJSETR 2012, 2, 17–23. [Google Scholar] [CrossRef]

- Röhren—und Pumpenwerk BAUER. Separator S300—Röhren—und Pumpenwerk BAUER. Available online: https://www.bauer-at.com/de/produkte/guelletechnik/separatoren/separator-s300/ (accessed on 27 February 2023).

- Vincent Corp. Products: Screw Press, Fiber Filter, Shredder|Vincent Corp. Available online: https://vincentcorp.com/products/ (accessed on 1 March 2023).

- Kugler GmbH. Serie S-RS Ring-Press|KUGLER GmbH. Available online: https://www.kugler-gmbh.de/schneckenpressen/schneckenpressen-serie-ring-press/ (accessed on 7 May 2023).

- IEA Derflinger Gmbh. Schneckenpresse, Filterpresse, Schlammentwässerung. Available online: https://www.iea-press.com/de/#spw-produkte (accessed on 7 May 2023).

- HUBER SE. Schlammentwässerung. Available online: https://www.huber.de/de/produkte/schlammbehandlung/schlammentwaesserung.html (accessed on 7 May 2023).

- ANDRITZ AG. C-Press Screw Press. Available online: https://www.andritz.com/products-en/group-de/separation/screens-drains-presses/c-press-screw-press (accessed on 7 May 2023).

- Pftechnology. Screw Dewatering Press—Pftechnology. Available online: https://www.pftechnology.eu/en/products/screw-dewatering-press/ (accessed on 1 December 2023).

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef] [PubMed]

- Al-Wahaibi, A.; Osman, A.I.; Al-Muhtaseb, A.H.; Alqaisi, O.; Baawain, M.; Fawzy, S.; Rooney, D.W. Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci. Rep. 2020, 10, 15719. [Google Scholar] [CrossRef] [PubMed]

- Ghaffariyan, M.; Barrier, C.; Brown, M.; Kühmaier, M.; Acuna, M. A Short Review of Timber Truck Fuel Consumption Studies; Australian Forest Operations Research Alliance (AFORA): Queensland, Australia, 2018. [Google Scholar]

- Landesregierung, A.D.T. Kompostier—und Biogasanlagenerhebung. Available online: https://www.tirol.gv.at/umwelt/abfall/diagramm-kompostieranlagenerhebung/ (accessed on 20 April 2023).

- Noor, M.M.; Wandel, A.; Yusaf, T.F. The development of mild combustion open burner experimental setup. In Proceedings of the International Conference on Mechanical Engineering Research (ICMER2013), Pahang, Malaysia, 1–3 July 2013. [Google Scholar]

- Stadt Wien. Abfallwirtschaftskonzept (AWK)—Aufbau, Inhalt und Vorlage. Available online: https://www.wien.gv.at/umweltschutz/abfall/konzept.html (accessed on 23 April 2023).

- Statistik Austria. Energieeinsatz der Haushalte. Available online: https://www.statistik.at/statistiken/energie-und-umwelt/energie/energieeinsatz-der-haushalte (accessed on 24 April 2023).

- Statistik Austria. Bevölkerung im Jahresdurchschnitt. Available online: https://www.statistik.at/statistiken/bevoelkerung-und-soziales/bevoelkerung/bevoelkerungsstand/bevoelkerung-im-jahresdurchschnitt (accessed on 24 April 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).