According to a research article published by Questar Pipeline Company, the presence of natural gas liquids in transmission pipelines has seen an increase, which has been accompanied by a decline in the price difference between natural gas and natural gas liquids. This shift has led to an increased focus on the monitoring of the HCDP by pipeline companies in order to ensure the safety and reliability of the system. The study explored both indirect and direct methods for the determination and implementation of HCDP in pipelines. A direct method, the Chilled Mirror method, was used to measure HCDP directly on the pipeline, and these measurements were compared with indirect HCDP temperature data obtained by analyzing the composition data from a chromatograph, calculated using state equations [

4]. In the article by Barbosa, the HCDP was investigated by utilizing both direct and indirect methods. Based on the results of these measurements, recommendations were proposed for selecting the appropriate method to detect HCDP [

5]. In the study conducted by Benton, the effectiveness of various methods for detecting HCDP in natural gas transmission pipelines was compared. The study compared the Chilled Mirror method and indirect measurement method with automatic dew point detection methods. The results showed that the use of automatic measuring devices was more efficient in determining HCDP with a high sensitivity. The increasing demand for natural gas highlights the importance of accurate HCDP determination in ensuring the safety and reliability of the gas transmission system [

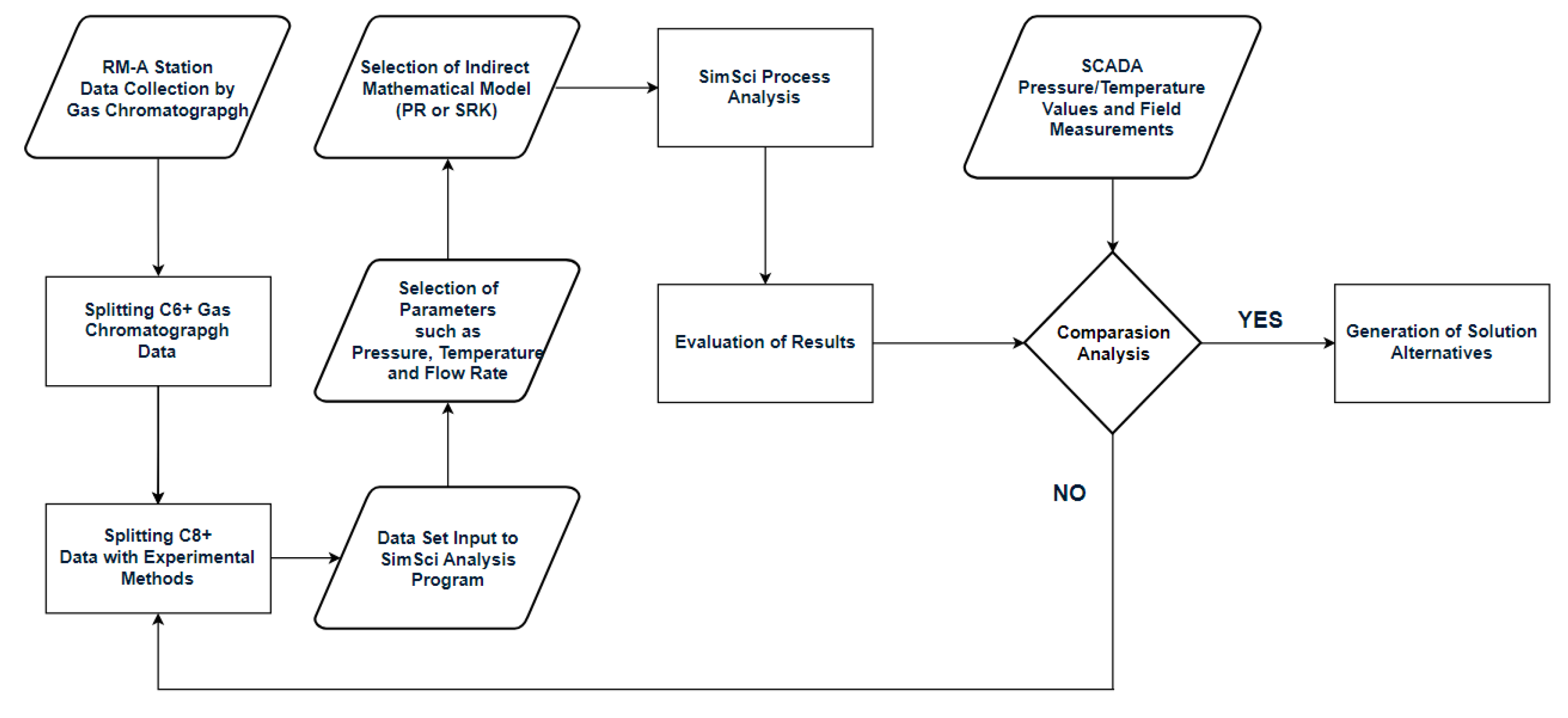

6]. In the study conducted by Aniefiok and Boniface, the hydrocarbon dew point temperature, which plays a crucial role in pipeline operation, was determined using the equation of state (EOS) and gas chromatography analysis methods. The study outlines a method for determining the composition of the C

6/C

7/C

8 components of C

6+ data, including the calculation of specific gravity through iteration [

7]. In the study by Aniefiok, the limitations of C

6+ separation methods in determining the composition of natural gas liquids for the prediction of HCDP temperature were explored. Three different methods of C

6+ decomposition were applied, utilizing PR and SRK state equations, and the results were analyzed using HYSYS. The study found that the HCDP temperature was ranked differently among the models created, with variations in the 50/25/25, 47/26/17, and 60/30/10 splitting ratios [

8]. In the article by E. Voutsas, the aim was to determine the dew points of gas condensate mixtures using thermodynamic modeling. The significance of accurate and robust phase equation models for the oil and natural gas industry was highlighted. The UMR-PRU equation of state was applied and compared with the commonly used cubic models PR and SRK, as well as the non-cubic PC-SAFT equation of state. The model was evaluated on both synthetic and real gases, and it was found that the UMR-PRU equation of state provides a precise prediction of the dew point and liquid formation point of gas condensates [

9]. In the study conducted by Pu Zhang, it was highlighted that there is a scarcity of data on hydrocarbon dew point measurements, leading to uncertainty in existing models. In order to address this, the study aimed to establish a new model using a dataset of approximately 1000 hydrocarbon dew point measurements. The dataset was modeled using eight known equations of state, including SRK, SRK-Twu, PR, and GERG-2008. The results showed that there were significant deviations in the high-pressure region above 6 MPa, compared to the low-pressure region below 6 MPa. Among the models tested, GERG-2008 performed best for synthetic gases, with a deviation of 1.44 °C. For real gases, the PSRK and SRK-Twu models showed the best performance, with an average deviation of 2.5 °C. These results were discussed in the study [

10]. In the study conducted by Mu and Cui in 2018, the hydrocarbon dew points of eight synthetic natural gas mixtures were measured using the Isothermal Pressure Search method and high-pressure transparent sapphire cells. The experimental temperature range was from 234.5 K to 295.35 K, and the pressure range was from 1.706 MPa to 11.495 MPa. The results were used to evaluate the prediction performance of the SRK and PR equations of state. The findings showed that the cricondentherm and cricondenbar decreased as the concentration of methane increased. Conversely, the cricondentherm and cricondenbar increased with increasing concentrations of other hydrocarbon components, such as ethane and C

3+. The results indicated that a 0.98% molar change in N-pentane concentration resulted in a 22 K decrease in the critical condensation temperature and a 1.9 to 2.7 MPa decrease in the cricondenbar. The PR method showed mean absolute deviations of 0.79–1.53% with the experimental data, while the SRK method showed clear deviation from the measured values [

11]. In the study by Di Fan, a method for tracking the composition of natural gas in pipe networks was developed. The method combines hydraulic simulation and heat transfer modeling, utilizing a specialized grid system to accurately predict gas composition in real-time. The method includes simulation of transient flow, tracking of gas composition, and calculation of relevant parameters. The results show accurate predictions of gas composition and reliable simulation of transient flow. However, care must be taken when considering the effects of LNG/H2 injection into the network [

12]. A new model for tracking the gas composition in a transportation network has been introduced by Bermúdez. The model involves a system of differential equations and is coupled with a flow model to maintain mass conservation of each species. The validity of the model was tested on a real network and the results were in good agreement with actual measurements [

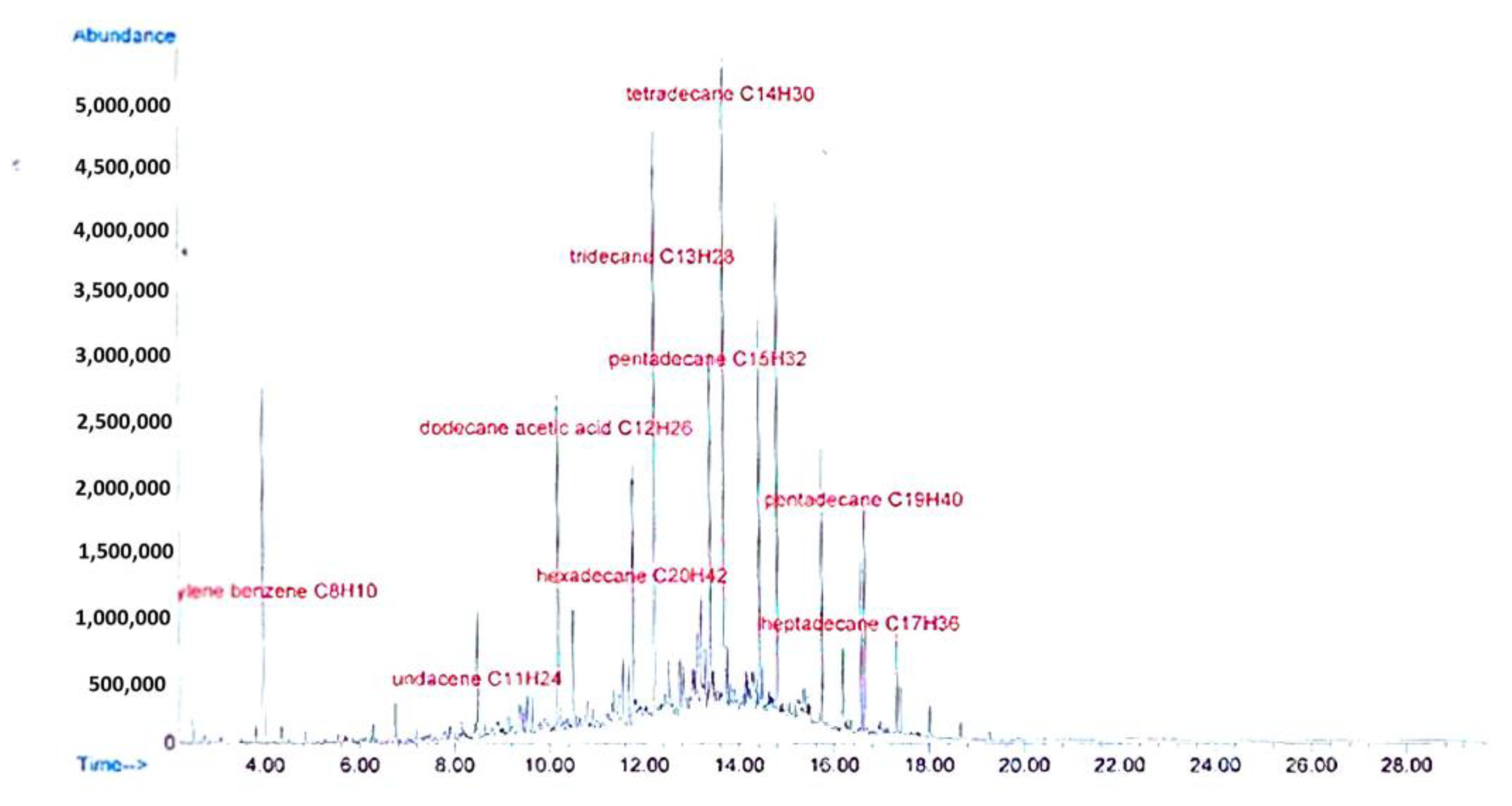

13]. In the study by the Mechanical Engineering Department of the Eindhoven University of Technology, a 32-component Russian gas is modeled to study the formation of a liquid film layer. Based on soil temperature, the formation rate is estimated to be between 4.5 to 6 mm/year. The study utilizes the Aspen HYSYS to model the formation of the liquid film layer under various conditions, and the results indicate that the C

12/C

13/C

14 layer is primarily affected [

14]. In the study by Bullin, the determination of the hydrocarbon dew point was investigated through the use of the Chilled Mirror and indirect methods. The study involved the addition of 0.45 m

3/h of liquid, and the results indicated that phase change and condensate formation were not observed at this level. The analysis conducted in the study focused on determining the dew point through these detection methods [

15]. In the study conducted by Navarro-Ochoa and Figueredo-Medina, the critical temperature parameters of Colombian natural gas were determined. According to the Colombian regulations for natural gas transmission, the cricondentherm must not exceed 7.2 °C. However, the study suggests that a different cricondentherm limit could be proposed for the Caribbean coast based on the weather conditions. An investigation was conducted in the study on the methods of determining hydrocarbon dew points in gas transmission lines globally, and a thermodynamic and hydraulic study was developed considering the weather conditions on the Caribbean coast. The PR was utilized as the thermodynamic model in the study. The unprocessed natural gas composition from three different gas wells was used as reference. Based on the results, it was concluded that a new critical condensing temperature was determined to be between 10–12.6 °C due to the hot weather conditions in Colombia [

16]. The study by M.S. Shah aimed to determine the hydrocarbon dew point of natural gas resources in different locations in Bangladesh in order to avoid hydrocarbon condensation. To achieve this, experiments were conducted to determine the effects of sample volume, chamber temperature, and sample conditioning on the measured dew points. The results showed that there was no effect from sample volume or sample conditioning, but the chamber temperature was observed to have a slight effect of approximately 0.9 °C on the measured dew points. The findings highlight the importance of carefully controlling the conditions during the measurement process to accurately determine the hydrocarbon dew point [

17]. According to the study presented by W. Zamrudy at the ATASEC conference, the offshore natural gas lines of a gas company have a depth of 70 m, which poses a risk of condensation. The aim of the study was to evaluate the impact of different operating conditions on condensate formation between two stations located 105 km apart. The Aspen HYSYS program was used to simulate the data received from the gas chromatograph device at station A, as well as the piping properties and operating conditions from station B. The results showed that liquid phase formation occurred in the offshore pipeline between stations B and C on the second day. To prevent this, the authors proposed passing the natural gas through a separator or treating it with carbon dioxide separation and cleaning the pipeline through pigging [

18]. In this study, presented at the Abu Dhabi International Fair and Congress, the authors aim to determine the hydrocarbon dew point pressure using smart algorithms. The estimation of the hydrocarbon dew point temperature is challenging due to the variability of composition and distribution in natural gas reserves. Currently, various methods such as equations of state, analytical methods, and empirical correlations are used to estimate the hydrocarbon dew point pressure at variable temperatures and compositions. However, these methods have limitations such as low precision or high computational costs. To address these limitations, the authors develop a new empirical correlation for hydrocarbon dew point pressure estimation using computational intelligence algorithms, such as artificial neural networks, functional networks, and support vector machines. The results show that hydrocarbon dew point pressure estimation is possible within a short calculation time, and among the models used, artificial neural networks have the lowest average absolute error, the highest coefficient of determination, and a mathematical model that does not require specialized knowledge [

19]. In the research conducted by Schouten, it is observed that changes in pressure and temperature within the pipeline can result in the temperature of the natural gas approaching the hydrocarbon dew point temperature, thereby increasing the likelihood of natural gas liquid formation. To address this issue, the study investigates the effect of adding hydrogen to the mixture. The results of the analysis, which included a 16.7% addition of hydrogen, suggest that the mixture had a positive impact on reducing the formation of liquid [

20].

In the study conducted by Olsen, the aim is to produce hydrocarbons at the highest level within the framework of economic and environmentally friendly practices in the oil and natural gas industry. The research focuses on evaluating various physical and chemical methods for the recovery of natural gas liquids and examining the advantages and disadvantages of these methods. [

21]. In the article by Abeer M. Shoaib, simulation of parameters such as pressure, temperature, and bypass ratio are conducted to calculate the density of condensate in the DPCU unit of the Dabaa gas production facility in Egypt. Additionally, a study is presented that explores the replacement of the JT valve with a turboexpander [

22]. In the study conducted by Zaidi, an economic model is presented for the prevention of the formation of natural gas liquid. The objective of the research is to convert valuable and unaccounted natural gas liquids into liquid fuel through filtration. The cost analyses of cyclonic and cartridge-based filtration options are performed [

23]. In the article authored by Bian and Cao, the application of supersonic separation technology in the production of natural gas is evaluated. This technology, used to separate impurities, water, and natural gas liquids from natural gas, is explored through theoretical analysis, experimentation, and numerical analysis of the condensation characteristics of the Laval nozzle and the separation mechanism of the supersonic separator. The study also provides a summary of the research on natural gas liquefaction and the separation of acidic gases. The cooling performances of the Laval nozzle, turboexpander, vortex tube, and JT valve are compared, with the Laval nozzle emerging as a promising new technology with superior cooling performance [

24].

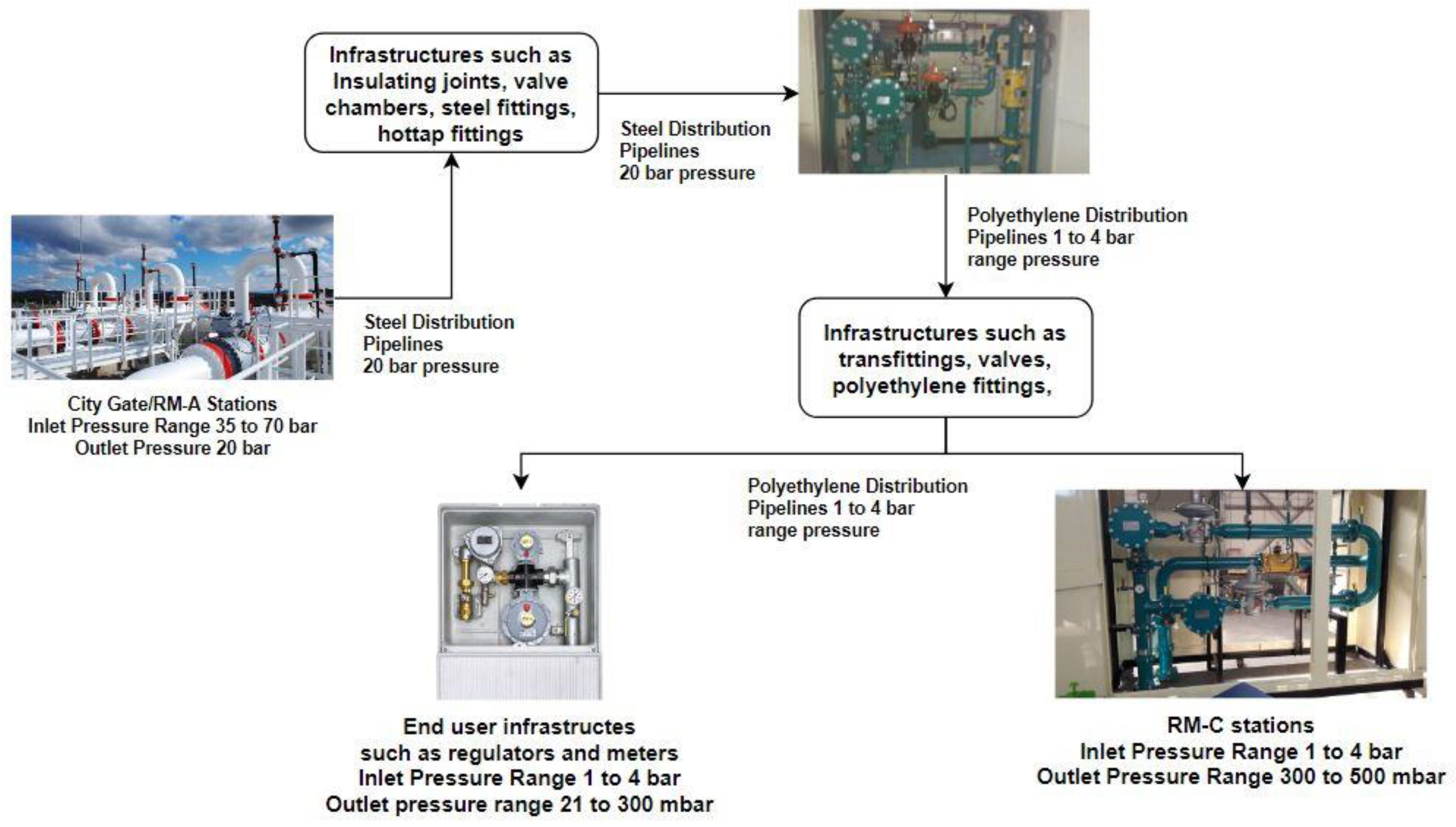

Studies of Natural Gas Liquids in natural gas facilities have been conducted to understand the causes of formation and methods to eliminate them. The focus of these studies has been on the methods of indirect and direct measurement of the hydrocarbon dew point temperature. These methods are primarily used for direct and indirect measurement on transmission lines and for the basic operation of liquid dispersion in accompanying gas production processes. Although some literature references the distribution networks below 50 bar pressure, there are limited direct studies on comprehensive analysis and measurement for low-pressure networks. Natural gas lines have different designs for transportation from production to distribution and delivery to end-users. Hence, each natural gas transmission or distribution network should be evaluated based on its design values and analyzed accordingly. The study presented in this article compares indirect analysis using decomposition methods specified in the literature, as well as a new approach created based on C6+ measurement data and compared to the accepted methods.