Effects of Different Winemaking Yeasts on the Composition of Aroma-Active Compounds and Flavor of the Fermented Jujube Wine

Abstract

1. Introduction

2. Methods and Materials

2.1. Raw Materials and Winemaking Yeasts

2.2. Preparation of Jujube Juice

2.3. Fermentation

2.4. Gas Chromatography-Mass Spectrometry (GC-MS) Analysis

2.5. Sensory Analysis

2.6. Statistical Analysis

3. Results and Discussion

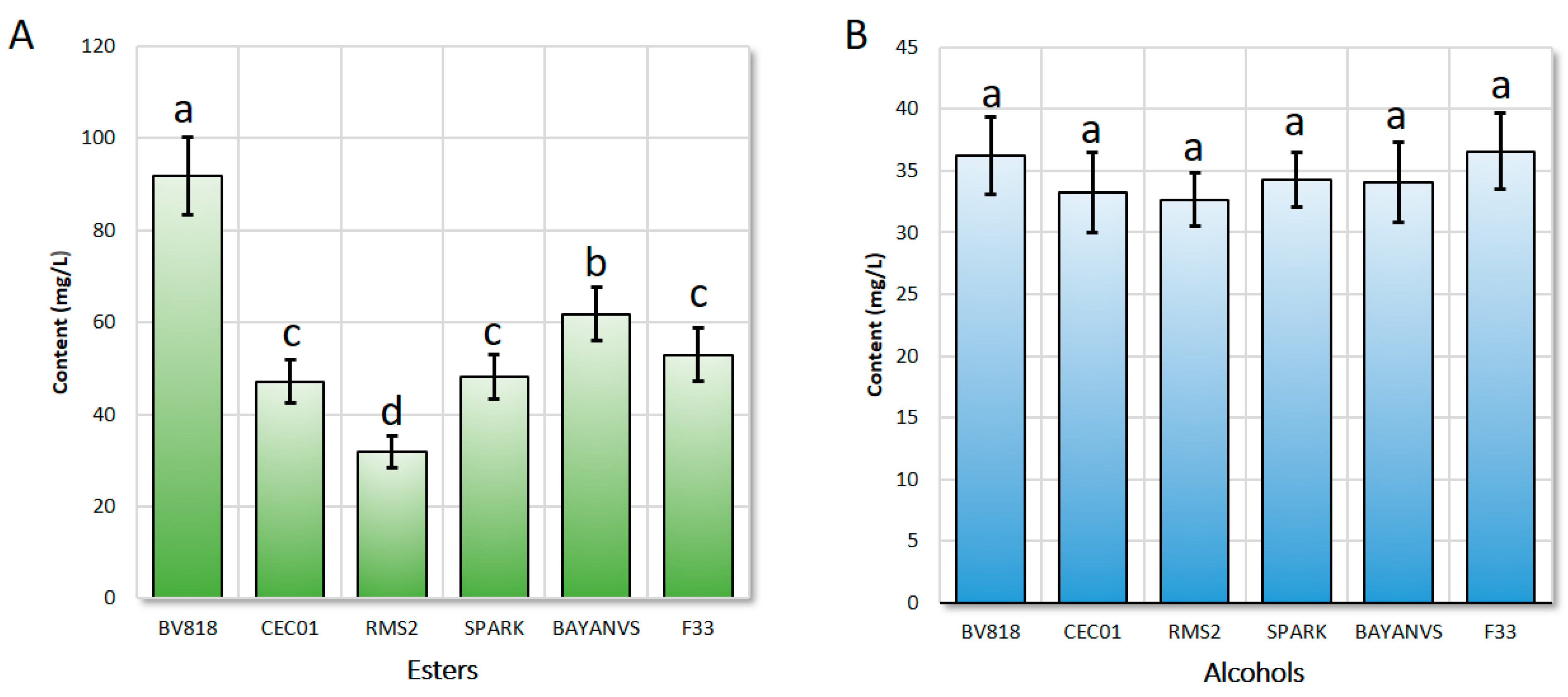

3.1. Comparison of the Composition of Aroma-Active Compounds

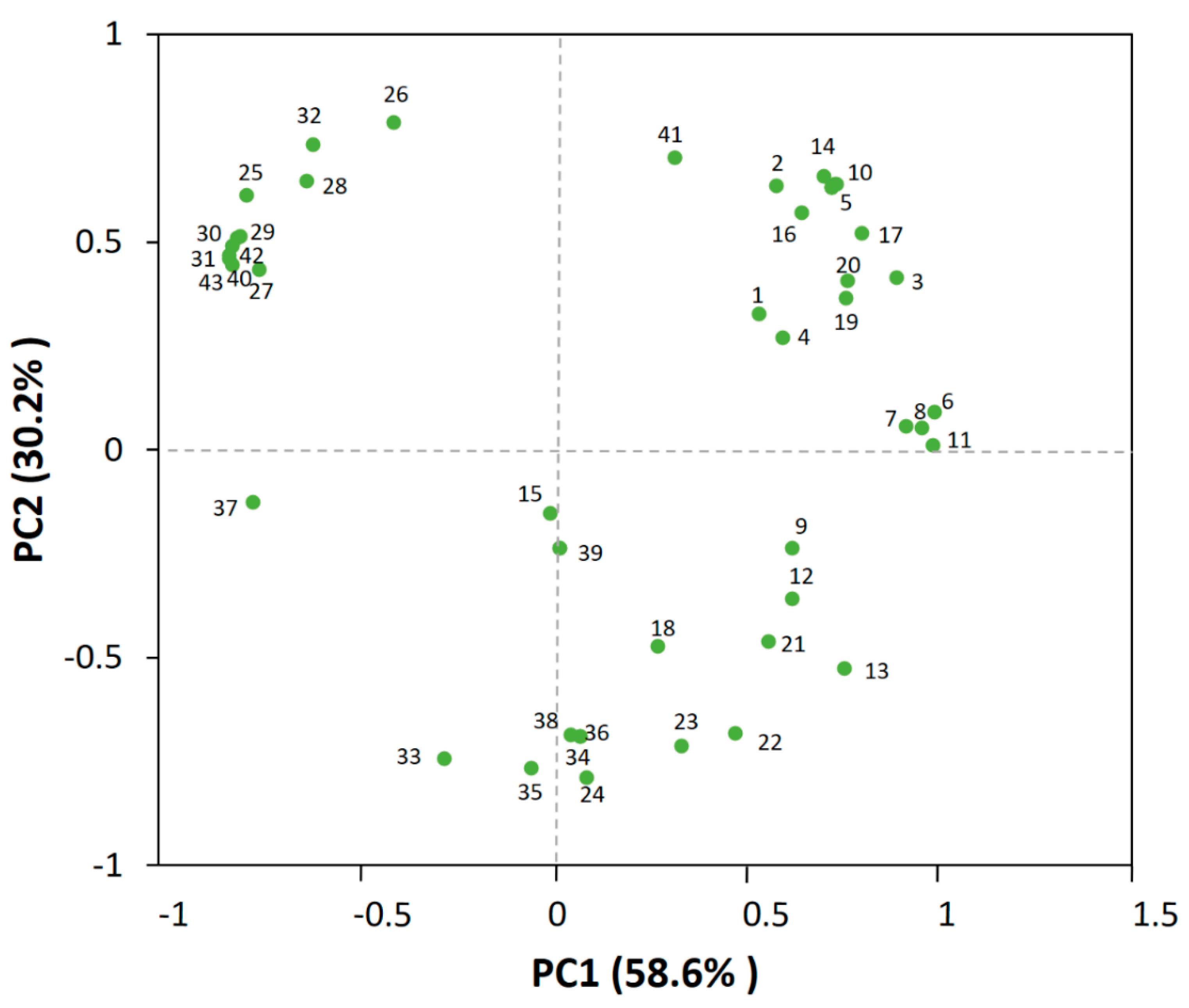

3.2. Principle Component Analysis (PCA)

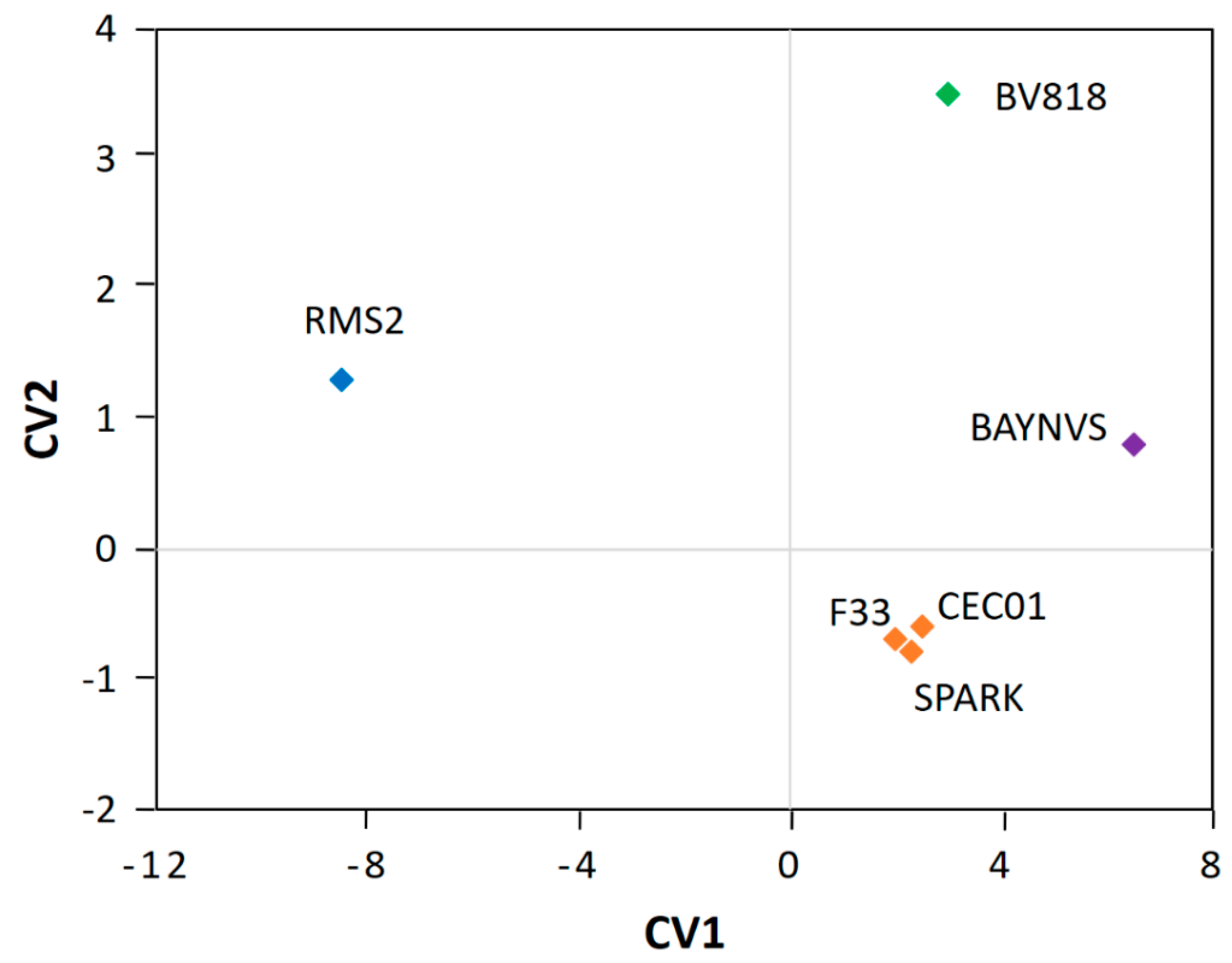

3.3. Canonical Correlation Analysis (CCA)

3.4. Evaluation of the Overall Flavor Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, W.; Tang, F.; Shan, C.; Hou, Q.; Zhang, Z.; Dong, Y.; Guo, Z. Pretreatment methods affecting the color, flavor, bioactive compounds, and antioxidant activity of jujube wine. Food Sci. Nutr. 2020, 8, 4965–4975. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Peng, Q.; Yuan, Y.; Shen, J.; Xie, X.; Wang, M. Isolation, structures and bioactivities of the polysaccharides from jujube fruit (Ziziphus jujuba Mill.): A review. Food Chem. 2017, 227, 349–357. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Shi, W.; Wang, X.; Wang, Y. Non-rainfall water contributions to dryland jujube plantation evapotranspiration in the Hilly Loess Region of China. J. Hydrol. 2020, 583, 124604. [Google Scholar] [CrossRef]

- Liao, C.; Liu, X.; Gao, A.; Zhao, A.; Hu, J.; Li, B. Maintaining postharvest qualities of three leaf vegetables to enhance their shelf lives by multiple ultraviolet-C treatment. LWT 2016, 73, 1–5. [Google Scholar] [CrossRef]

- Kuşçu, A.; Bulantekin, Ö. Determination of phenolics, organic acids, minerals and volatile compounds of jujube (Ziziphus jujuba miller) jam produced by under vacuum evaporation compared with open pan method. J. Food Meas. Charact. 2021, 15, 1127–1138. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, L.; Wang, Z.; Liu, Z.; Zhao, Z.; Zhou, G.; Liu, M.; Liu, P. Variations of the nutritional composition of jujube fruit (Ziziphus jujuba Mill.) during maturation stages. Int. J. Food Prop. 2020, 23, 1066–1081. [Google Scholar] [CrossRef]

- Hu, D.; Fan, Y.; Tan, Y.; Tian, Y.; Liu, N.; Wang, L.; Zhao, D.; Wang, C.; Wu, A. Metabolic profiling on Alternaria toxins and components of Xinjiang jujubes incubated with pathogenic Alternaria alternata and Alternaria tenuissima via orbitrap high-resolution mass spectrometry. J. Agric. Food Chem. 2017, 65, 8466–8474. [Google Scholar] [CrossRef]

- Cai, W.; Tang, F.; Shan, C.; Yang, L.; Zhan, Q.; Zhao, X.; Ning, M. Changes in volatile compounds of fermented mixed drink using commercial yeast strain. Przem. Chem. 2018, 97, 1398–1405. [Google Scholar]

- Kang, T.; Woo, K.; Lee, J.; Jeong, H. Fermentation characteristics of wine using fresh jujube. Food Eng. Prog. 2006, 10, 164–171. [Google Scholar]

- Yuan, L.; Li, G.; Yan, N.; Wu, J.; Due, J. Optimization of fermentation conditions for fermented green jujube wine and its quality analysis during winemaking. J. Food Sci. Technol. 2021, 58, 1–12. [Google Scholar]

- Zhang, R.; Song, Z.; Liu, Y.; Gao, X. Fermentation technology of red jujube wine. Food Res. Dev. 2017, 38, 138–142. [Google Scholar]

- Xu, L.F.; Tang, Z.S.; Wen, Q.H.; Zeng, X.A.; Brennan, C.; Niu, D. Effects of pulsed electric fields pretreatment on the quality of jujube wine. Int. J. Food Sci. Technol. 2019, 54, 3109–3117. [Google Scholar] [CrossRef]

- Tang, F.; Cai, W.; Shan, C.; Guo, Z.; Hou, Q.; Zhang, Z.; Dong, Y. Dynamic changes in quality of jujube wine during fermentation. J. Food Process. Preserv. 2020, 44, e14704. [Google Scholar] [CrossRef]

- Lee, J.-E.; Yun, J.H.; Lee, A.R.; Kim, S.S. Volatile components and sensory properties of jujube wine as affected by material preprocessing. Int. J. Food Prop. 2018, 21, 2052–2061. [Google Scholar] [CrossRef]

- Lê, S.; Josse, J.; Husson, F. FactoMineR: An R package for multivariate analysis. J. Stat. Softw. 2008, 25, 1–18. [Google Scholar] [CrossRef]

- González, I.; Déjean, S.; Martin, P.; Baccini, A. CCA: An R package to extend canonical correlation analysis. J. Stat. Softw. 2008, 23, 1–14. [Google Scholar] [CrossRef]

- Xia, Y.; Liu, Y.; Wang, J.; Shuang, Q. Assessment of key aroma compounds in fresh jujube brandy by GC-O-MS and odor activity value. J. Food Process. Preserv. 2020, 44, e14494. [Google Scholar] [CrossRef]

- Niu, Y.; Wang, P.; Xiao, Z.; Zhu, J.; Sun, X.; Wang, R. Evaluation of the perceptual interaction among ester aroma compounds in cherry wines by GC–MS, GC–O, odor threshold and sensory analysis: An insight at the molecular level. Food Chem. 2019, 275, 143–153. [Google Scholar] [CrossRef]

- Guo, J.; Yan, Y.; Wang, M.; Wu, Y.; Liu, S.-Q.; Chen, D.; Lu, Y. Effects of enzymatic hydrolysis on the chemical constituents in jujube alcoholic beverage fermented with Torulaspora delbrueckii. LWT Food Sci. Technol. 2018, 97, 617–623. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, X.; Yuan, F.; Deng, B.; Yu, X. Biocatalysis of Heterogenously-Expressed Chitosanase for the Preparation of Desirable Chitosan Oligosaccharides Applied against Phytopathogenic Fungi. ACS Sustain. Chem. Eng. 2020, 8, 4781–4791. [Google Scholar] [CrossRef]

- Liguori, L.; Albanese, D.; Crescitelli, A.; Di Matteo, M.; Russo, P. Impact of dealcoholization on quality properties in white wine at various alcohol content levels. J. Food Sci. Technol. 2019, 56, 3707–3720. [Google Scholar] [CrossRef]

- Liao, C.; Liu, X.; Shan, L. Optimization of liquid media and biosafety assessment for algae-lysing bacterium NP23. Can. J. Microbiol. 2014, 60, 593–597. [Google Scholar] [CrossRef]

- Liao, C.; Liu, X. High-cell-density cultivation and algicidal activity assays of a novel algicidal bacterium to control algal bloom caused by water eutrophication. Water Air Soil Pollut. 2014, 225, 1–8. [Google Scholar] [CrossRef]

- Ruiz, J.; Kiene, F.; Belda, I.; Fracassetti, D.; Marquina, D.; Navascués, E.; Calderón, F.; Benito, A.; Rauhut, D.; Santos, A. Effects on varietal aromas during wine making: A review of the impact of varietal aromas on the flavor of wine. Appl. Microbiol. Biotechnol. 2019, 103, 7425–7450. [Google Scholar] [CrossRef]

- Shi, W.-K.; Wang, J.; Chen, F.-S.; Zhang, X.-Y. Effect of Issatchenkia terricola and Pichia kudriavzevii on wine flavor and quality through simultaneous and sequential co-fermentation with Saccharomyces cerevisiae. LWT Food Sci. Technol. 2019, 116, 108477. [Google Scholar] [CrossRef]

| Code | Chemicals | BV818 | CEC01 | RMS2 | SPARK | BAYANVS | F33 | Threshold |

|---|---|---|---|---|---|---|---|---|

| 1 | Ethyl acetate | 4.05 ± 0.32 | 1.74 ± 0.06 | 1.94 ± 0.04 | 2.43 ± 0.21 | 2.52 ± 0.12 | 1.96 ± 0.13 | 12 |

| 2 | Ethyl butyrate | 0.42 ± 0.02 | 0.23 ± 0.01 | 0.23 ± 0.01 | 0.20 ± 0.01 | 0.23 ± 0.03 | 0.14 ± 0.02 | 1 |

| 3 | Isoamyl acetate | 5.20 ± 0.62 | 4.02 ± 0.42 | 4.46 ± 0.41 | 4.23 ± 0.34 | 3.51 ± 0.28 | 4.94 ± 0.31 | 2 |

| 4 | Methyl caproate | N.D. | N.D. | 0.08 ± 0.02 | 0.11 ± 0.03 | 0.19 ± 0.04 | 0.08 ± 0.01 | |

| 5 | Ethyl hexanoate | 14.09 ± 1.32 | 10.29 ± 1.51 | 11.76 ± 0.92 | 11.69 ± 0.87 | 19.95 ± 1.95 | 11.44 ± 0.93 | 0.2 |

| 6 | Hexyl acetate | 0.04 ± 0.01 | 0.06 ± 0.01 | 0.06 ± 0.01 | 0.05 ± 0.01 | 0.17 ± 0.04 | 0.07 ± 0.02 | |

| 7 | Ethyl heptanoate | 1.97 ± 0.14 | 1.85 ± 0.12 | N.D. | N.D. | 3.05 ± 0.33 | 2.08 ± 0.28 | |

| 8 | Ethyl 6-heptenoate | 0.04 ± 0.01 | 0.02 ± 0.01 | 0.19 ± 0.03 | 0.01 ± 0.01 | 0.05 ± 0.01 | 0.05 ± 0.01 | |

| 9 | Methyl caprylate | 0.31 ± 0.03 | N.D. | 0.08 ± 0.02 | 0.21 ± 0.03 | 0.32 ± 0.04 | 0.21 ± 0.02 | |

| 10 | Ethyl caprylate | 32.61 ± 2.02 | 15.75 ± 1.72 | 0.03 ± 0.01 | 16.65 ± 1.22 | 28.97 ± 2.23 | 18.84 ± 1.43 | 1.2 |

| 11 | Ethyl cis-4-octenate | 0.04 ± 0.01 | 0.51 ± 0.02 | 0.03 ± 0.01 | N.D. | N.D. | 0.56 ± 0.04 | |

| 12 | Methyl decanoate | 0.30 ± 0.03 | 0.11 ± 0.01 | 10.11 ± 1.02 | 0.12 ± 0.01 | N.D. | 0.11 ± 0.01 | |

| 13 | Hexyl hexanoate | 0.06 ± 0.01 | 0.01 ± 0.01 | N.D. | N.D. | N.D. | N.D. | |

| 14 | Ethyl decanoate | 28.03 ± 2.42 | 10.86 ± 1.33 | 0.04 ± 0.01 | 10.87 ± 1.02 | N.D. | 10.67 ± 1.23 | 0.2 |

| 15 | Amyl caprylate | 0.27 ± 0.02 | N.D. | N.D. | N.D. | N.D. | N.D. | 1.2 |

| 16 | Ethyl benzoate | 0.05 ± 0.01 | N.D. | 0.09 ± 0.02 | N.D. | N.D. | 0.02 ± 0.01 | |

| 17 | Phenethyl acetate | 0.55 ± 0.04 | 0.24 ± 0.01 | 0.03 ± 0.01 | 0.28 ± 0.01 | 0.28 ± 0.01 | 0.39 ± 0.02 | 0.25 |

| 18 | Ethyl undecanoate | 2.95 ± 0.12 | 1.15 ± 0.21 | 0.36 ± 0.42 | 1.04 ± 0.11 | 2.04 ± 0.13 | 1.27 ± 0.14 | |

| 19 | Isoamyl decanoate | 0.13 ± 0.02 | 0.06 ± 0.01 | N.D. | N.D. | 0.05 ± 0.01 | N.D. | |

| 20 | Ethyl 3-phenylpropionate | 0.57 ± 0.04 | 0.29 ± 0.01 | 1.58 ± 0.11 | 0.26 ± 0.02 | 0.28 ± 0.03 | N.D. | 0.12 |

| 21 | Ethyl arachidate | N.D. | N.D. | 0.69 ± 0.04 | 0.01 ± 0.01 | 0.03 ± 0.01 | N.D. | |

| 22 | Ethyl palmitate | N.D. | N.D. | 0.11 ± 0.03 | N.D. | N.D. | N.D. | |

| 23 | Isoamyl formate | N.D. | N.D. | N.D. | N.D. | N.D. | 0.12 ± 0.03 | |

| 24 | Octyl acetate | N.D. | N.D. | N.D. | N.D. | 0.08 ± 0.01 | 0.04 ± 0.01 | |

| Total esters | 91.82 ± 8.34 | 47.19 ± 4.63 | 31.87 ± 3.52 | 48.17 ± 4.74 | 61.76 ± 5.82 | 53.00 ± 5.72 | ||

| 25 | Isobutanol | 1.14 ± 0.08 | 1.09 ± 0.07 | 0.81 ± 0.04 | 0.89 ± 0.08 | N.D. | 0.10 ± 0.02 | 100 |

| 26 | Isoamyl alcohol | 29.28 ± 3.12 | 29.88 ± 3.23 | 26.57 ± 2.14 | 29.98 ± 2.17 | 30.94 ± 3.24 | 32.80 ± 3.12 | 50 |

| 27 | N-hexanol | 0.08 ± 0.02 | 0.07 ± 0.01 | 0.02 ± 0.01 | 0.07 ± 0.02 | 0.23 ± 0.03 | 0.06 ± 0.01 | 0.25 |

| 28 | 2-decen-1-ol | N.D. | N.D. | 4.11 ± 0.42 | 0.09 ± 0.02 | 0.12 ± 0.03 | N.D. | |

| 29 | 2-decyl alcohol | 0.04 ± 0.01 | 0.03 ± 0.01 | 0.72 ± 0.04 | 0.04 ± 0.01 | 0.09 ± 0.02 | 0.03 ± 0.01 | |

| 30 | 2,3-Butanediol | 1.26 ± 0.04 | 0.21 ± 0.02 | 0.17 ± 0.01 | 1.18 ± 0.12 | 0.10 ± 0.04 | 1.00 ± 0.02 | |

| 31 | Linalool | 0.04 ± 0.01 | 0.04 ± 0.01 | 0.20 ± 0.06 | 0.04 ± 0.01 | N.D. | 0.04 ± 0.01 | |

| 32 | Phenylethanol | 4.40 ± 0.44 | 1.90 ± 0.17 | 0.06 ± 0.01 | 1.98 ± 0.11 | 2.59 ± 0.21 | 2.55 ± 0.23 | 14 |

| Total alcohols | 36.24 ± 3.72 | 33.22 ± 3.32 | 32.66 ± 2.73 | 34.27 ± 2.54 | 34.07 ± 3.57 | 36.58 ± 3.42 | ||

| 33 | Isovaleric acid | 0.10 ± 0.02 | 0.10 ± 0.01 | 0.19 ± 0.03 | 0.10 ± 0.02 | 0.02 ± 0.01 | 0.11 ± 0.01 | 0.33 |

| 34 | Caproic acid | 0.58 ± 0.03 | 0.36 ± 0.01 | 0.25 ± 0.01 | N.D. | 0.36 ± 0.02 | 0.35 ± 0.01 | 0.42 |

| 35 | Acetic acid | 0.71 ± 0.07 | 0.69 ± 0.06 | 0.04 ± 0.01 | 0.84 ± 0.08 | 0.77 ± 0.06 | 0.64 ± 0.05 | 200 |

| 36 | Enanthate | 0.09 ± 0.02 | 0.05 ± 0.01 | 0.01 ± 0.01 | 0.05 ± 0.01 | 0.05 ± 0.01 | 0.05 ± 0.01 | |

| 37 | Bitter acid | 2.42 ± 0.22 | 0.62 ± 0.12 | 0.09 ± 0.01 | 0.69 ± 0.13 | 0.68 ± 0.15 | 0.67 ± 0.12 | 0.5 |

| 38 | Pelargonic acid | 0.12 ± 0.04 | 0.08 ± 0.02 | 0.02 ± 0.01 | 0.10 ± 0.01 | 0.08 ± 0.01 | 0.07 ± 0.01 | |

| 39 | Decanoic acid | 0.96 ± 0.12 | 0.16 ± 0.03 | 0.11 ± 0.02 | 0.12 ± 0.01 | 0.10 ± 0.01 | 0.14 ± 0.02 | |

| Acid value | 4.92 | 2.06 | 0.71 | 1.9 | 2.06 | 2.03 | ||

| 40 | Styrene | 0.59 ± 0.07 | 0.35 ± 0.02 | 0.10 ± 0.01 | 0.86 ± 0.08 | 0.51 ± 0.05 | 0.58 ± 0.04 | |

| 41 | Alpha-farnesene | 0.76 ± 0.07 | 0.04 ± 0.01 | 0.03 ± 0.01 | N.D. | N.D. | N.D. | |

| 42 | Decanal | N.D. | 0.03 ± 0.01 | 0.04 ± 0.01 | 0.02 ± 0.01 | 0.03 ± 0.01 | N.D. | |

| 43 | Damastone | 0.08 ± 0.03 | 0.04 ± 0.01 | 1.13 ± 0.12 | 0.04 ± 0.01 | 0.04 ± 0.01 | 0.04 ± 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Yu, X.; Zhu, F.; Liu, G.; Chu, L.; Yan, X.; Ma, Y.; He, F.; Li, G.; Zhang, Y.; et al. Effects of Different Winemaking Yeasts on the Composition of Aroma-Active Compounds and Flavor of the Fermented Jujube Wine. Processes 2021, 9, 970. https://doi.org/10.3390/pr9060970

Zhao Y, Yu X, Zhu F, Liu G, Chu L, Yan X, Ma Y, He F, Li G, Zhang Y, et al. Effects of Different Winemaking Yeasts on the Composition of Aroma-Active Compounds and Flavor of the Fermented Jujube Wine. Processes. 2021; 9(6):970. https://doi.org/10.3390/pr9060970

Chicago/Turabian StyleZhao, Yan, Xiaobin Yu, Fengtao Zhu, Guangpeng Liu, Le Chu, Xinhuan Yan, Yinfei Ma, Fatao He, Gen Li, Ying Zhang, and et al. 2021. "Effects of Different Winemaking Yeasts on the Composition of Aroma-Active Compounds and Flavor of the Fermented Jujube Wine" Processes 9, no. 6: 970. https://doi.org/10.3390/pr9060970

APA StyleZhao, Y., Yu, X., Zhu, F., Liu, G., Chu, L., Yan, X., Ma, Y., He, F., Li, G., Zhang, Y., Tan, M., & Lu, Y. (2021). Effects of Different Winemaking Yeasts on the Composition of Aroma-Active Compounds and Flavor of the Fermented Jujube Wine. Processes, 9(6), 970. https://doi.org/10.3390/pr9060970