A LoRa-Based Multisensor IoT Platform for Agriculture Monitoring and Submersible Pump Control in a Water Bamboo Field

Abstract

1. Introduction

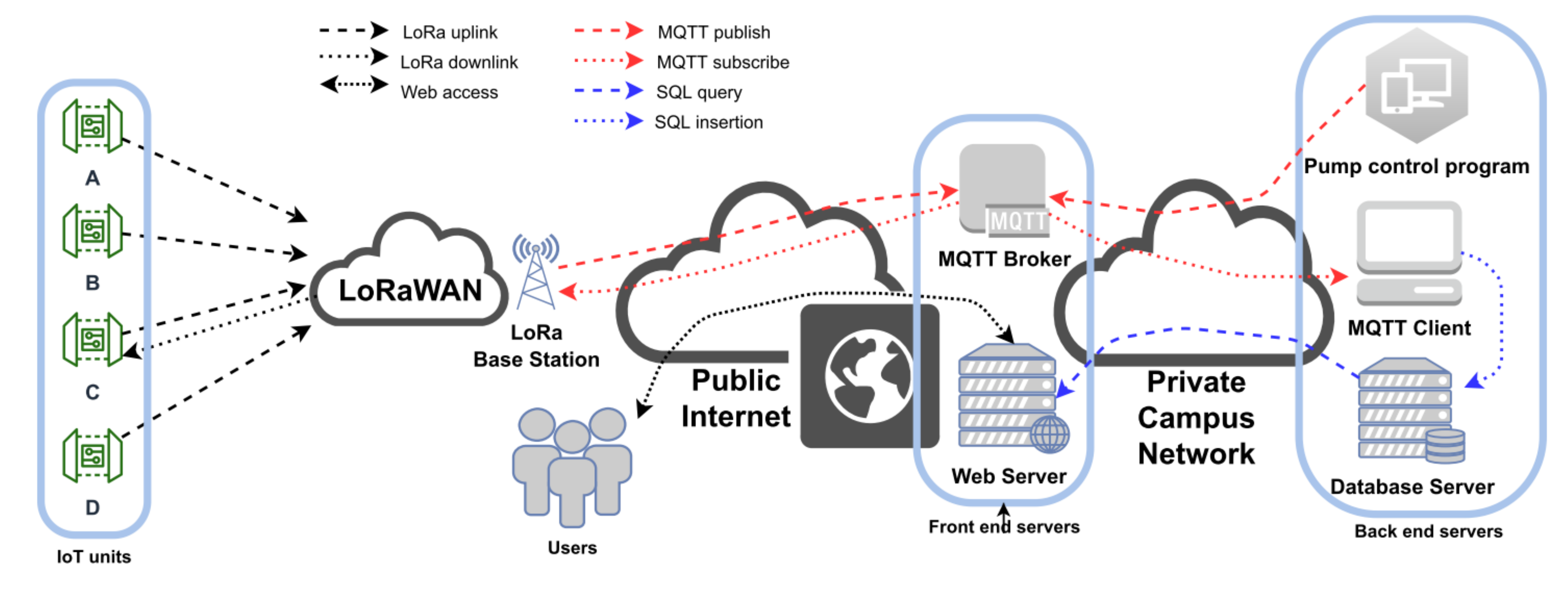

2. System Architecture

3. Design Details and Practical Considerations

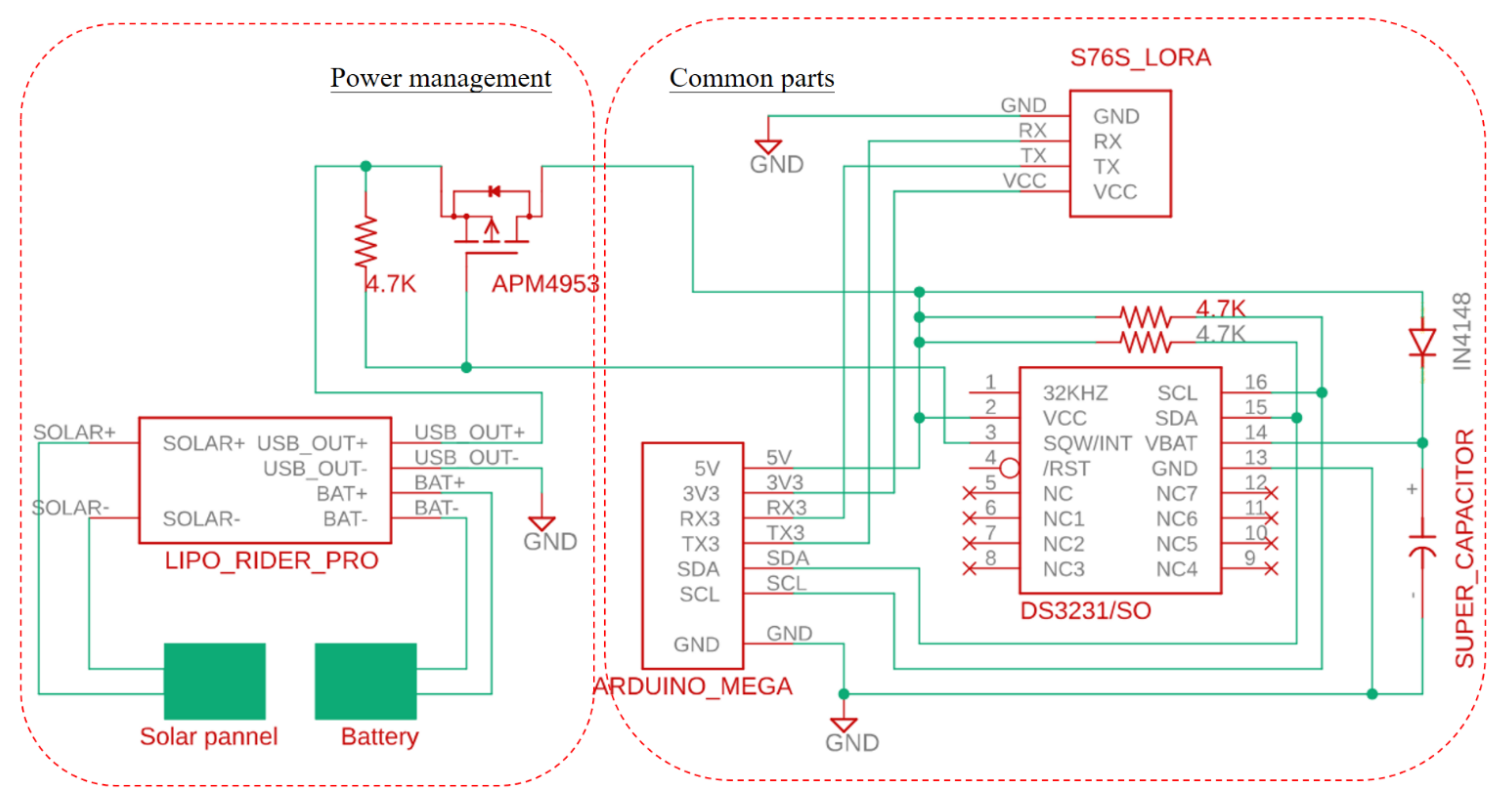

3.1. Common Parts

3.2. Special Treatments for the Power Supply

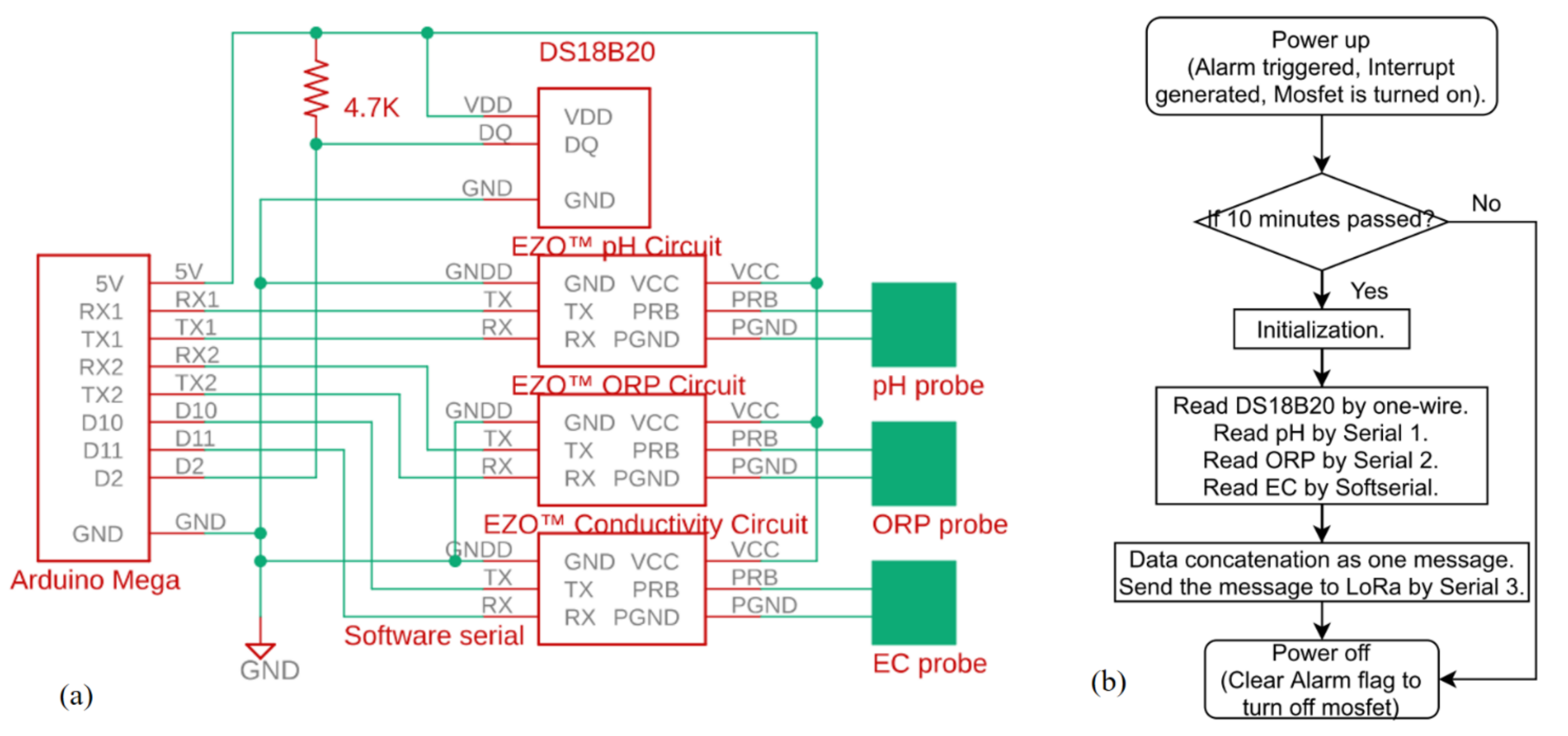

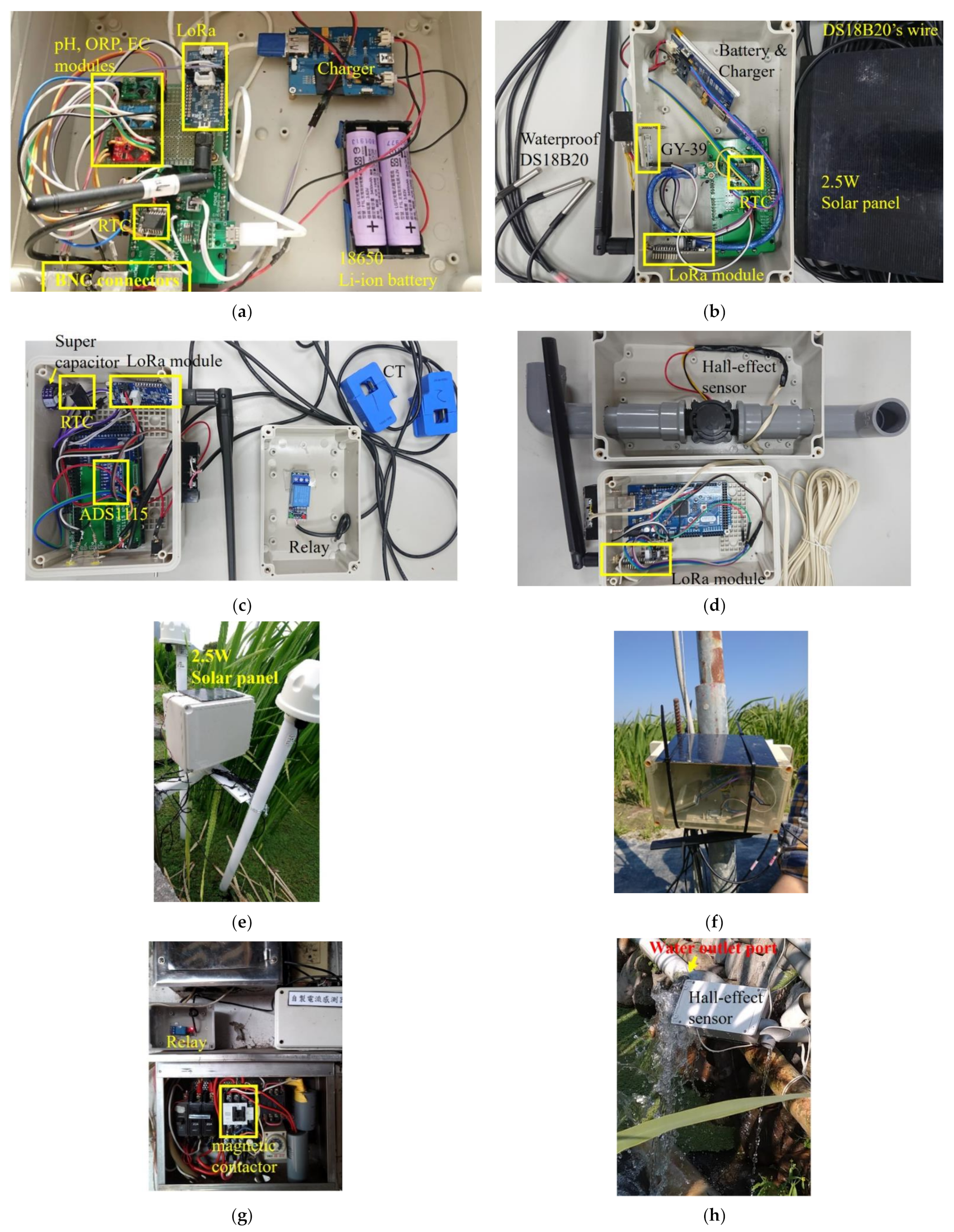

3.3. Type A Unit

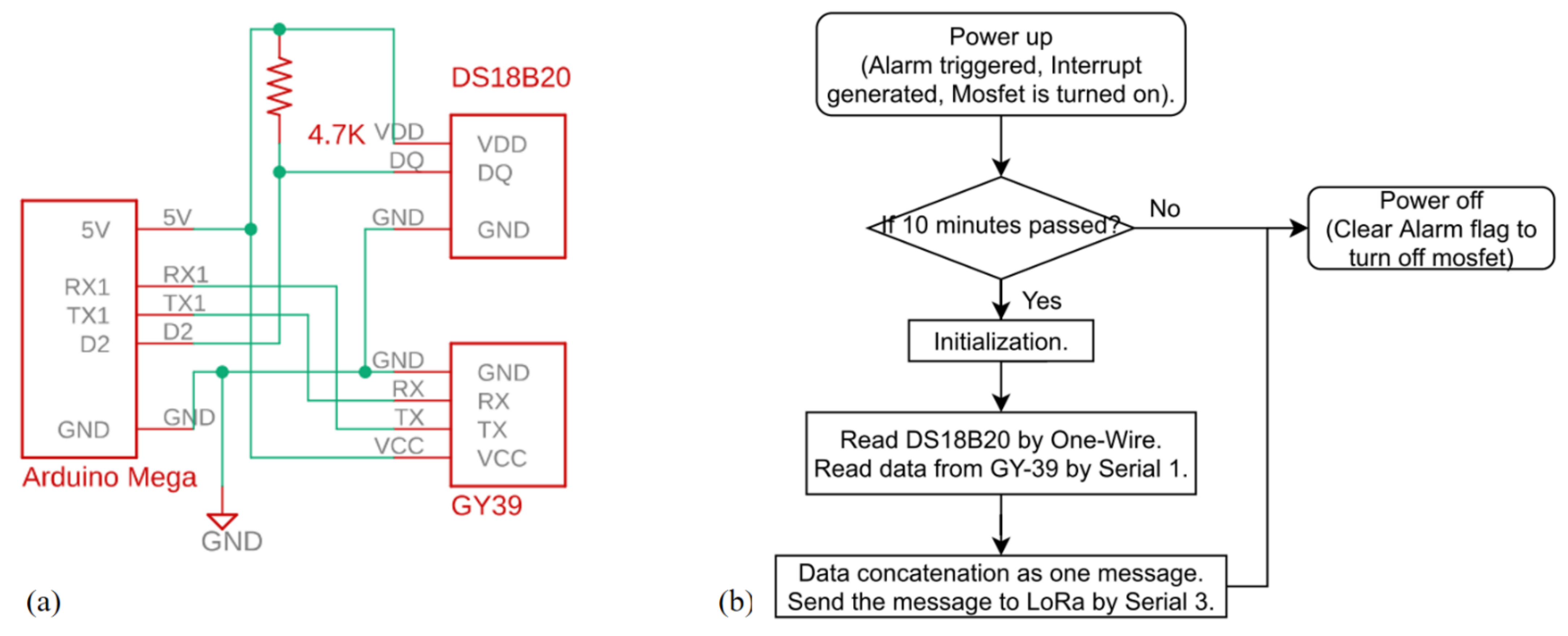

3.4. Type B Unit

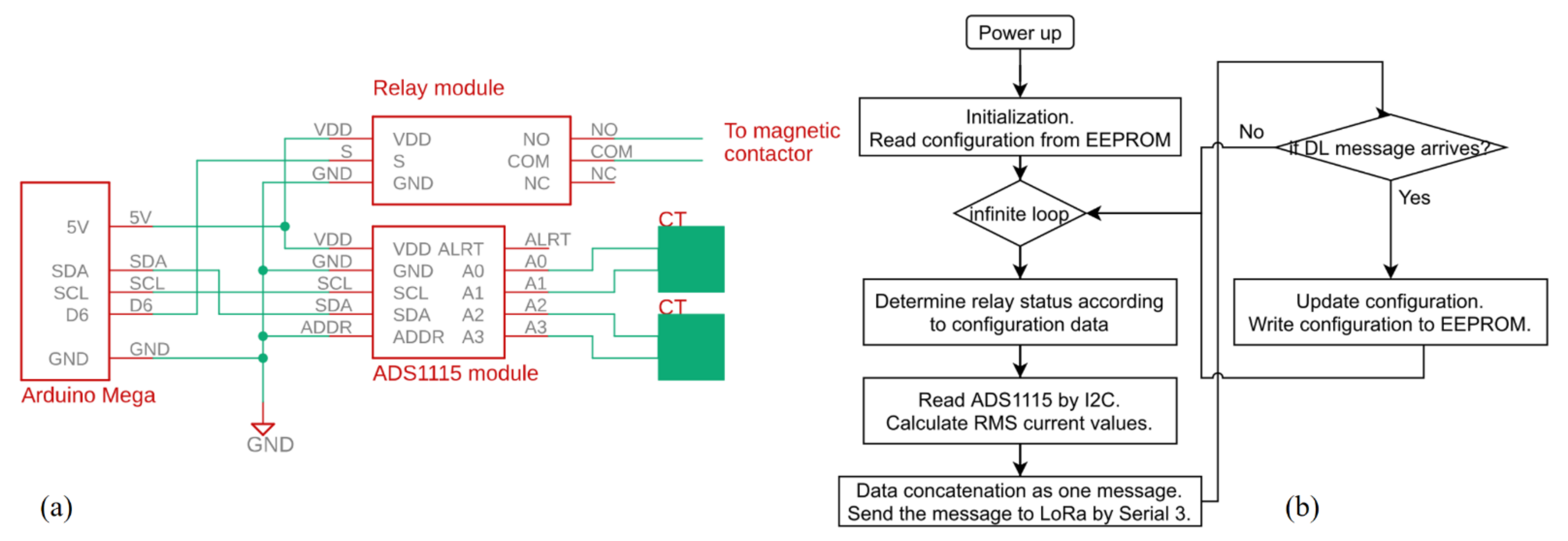

3.5. Type C Unit

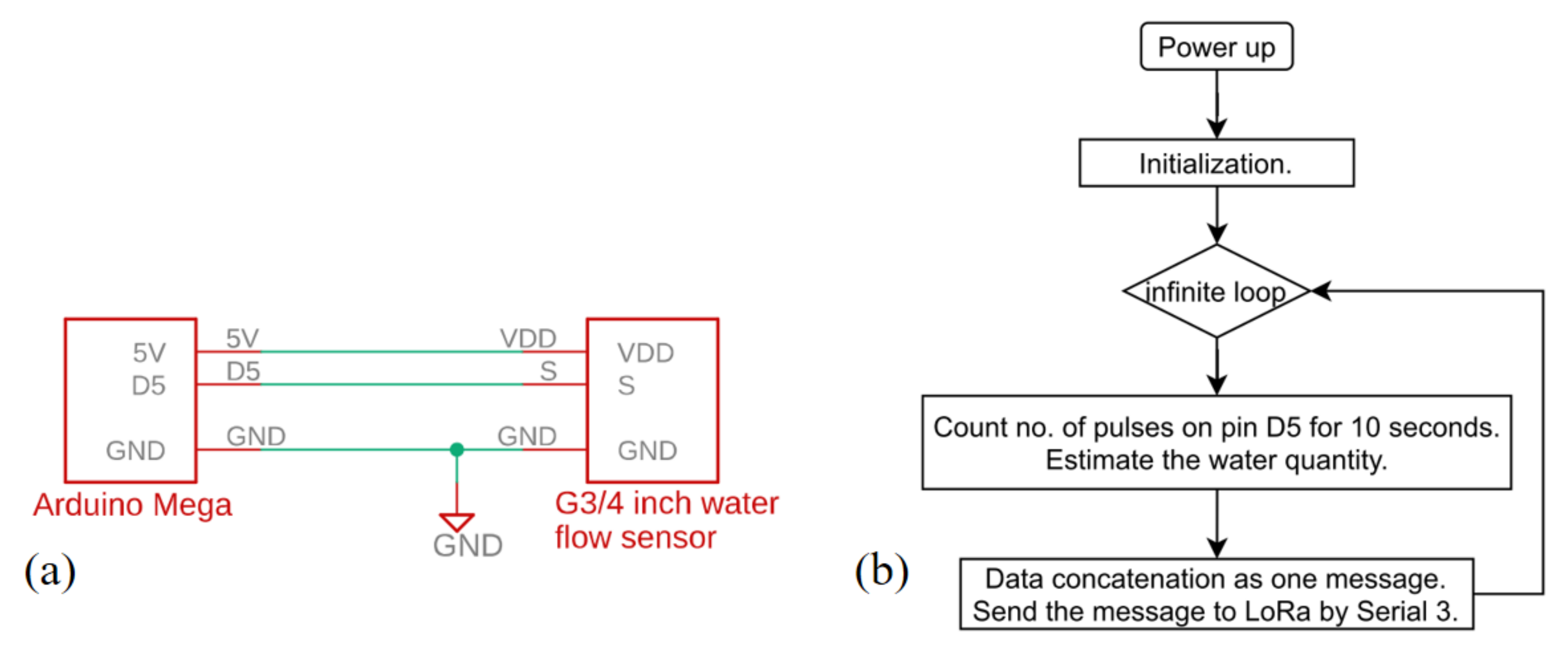

3.6. Type D Unit

3.7. Servers and Back-End Programs

4. Results and Discussion

4.1. Installation

4.2. Function Validation

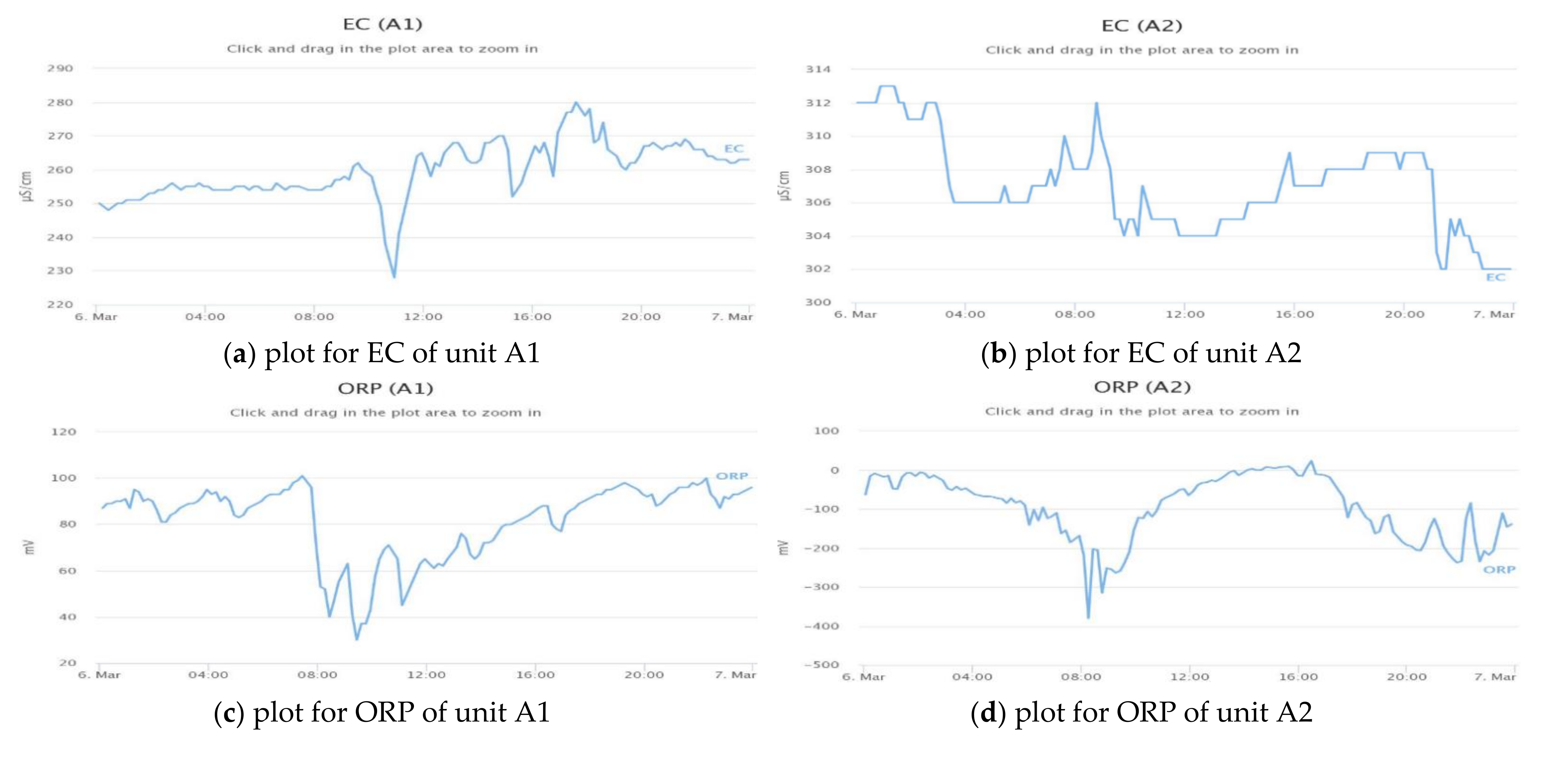

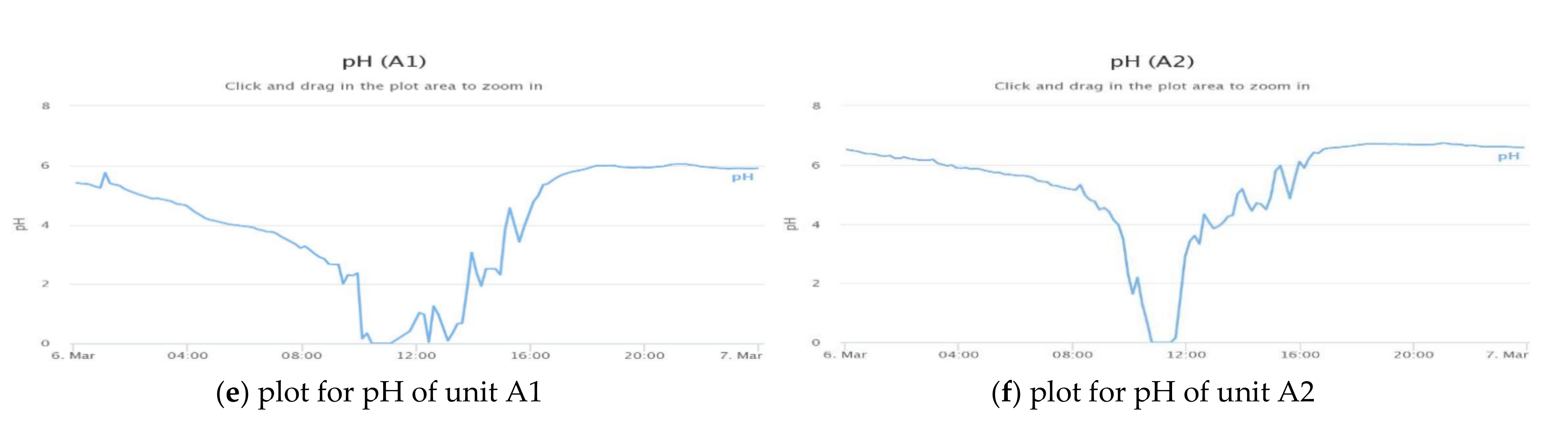

4.2.1. Water Quality Monitoring

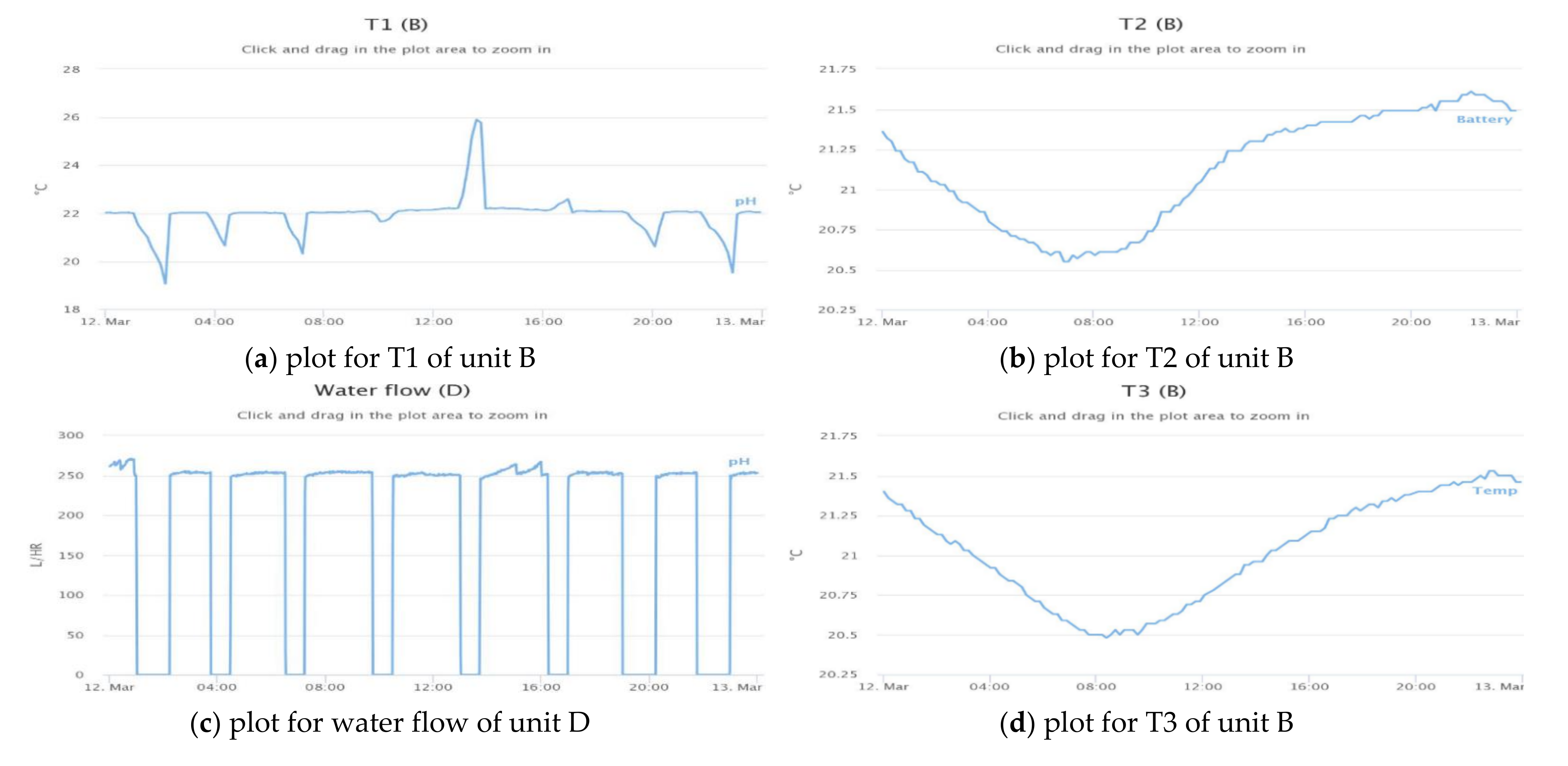

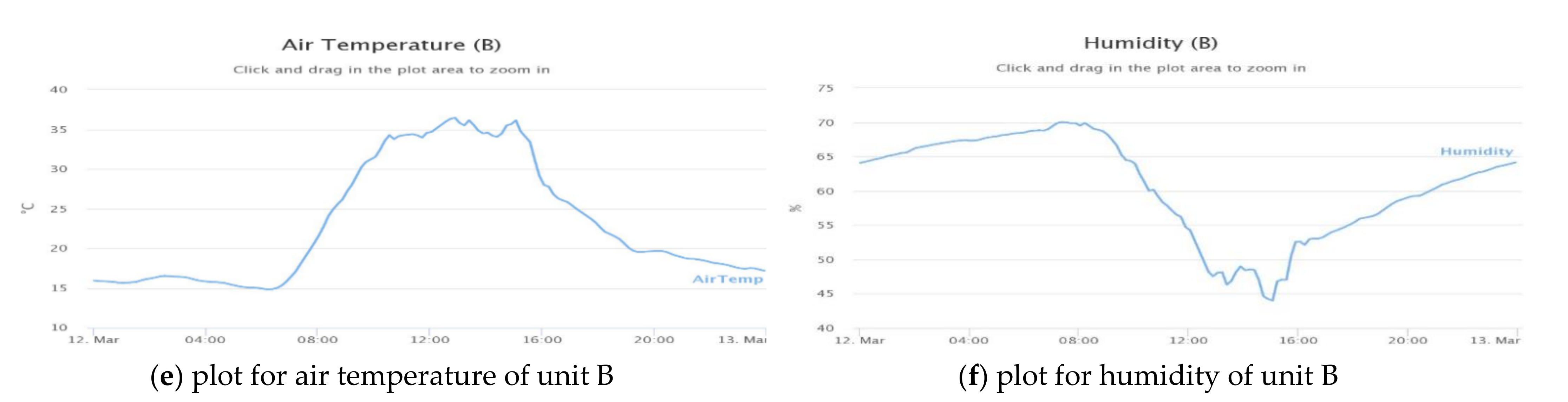

4.2.2. Environmental Data

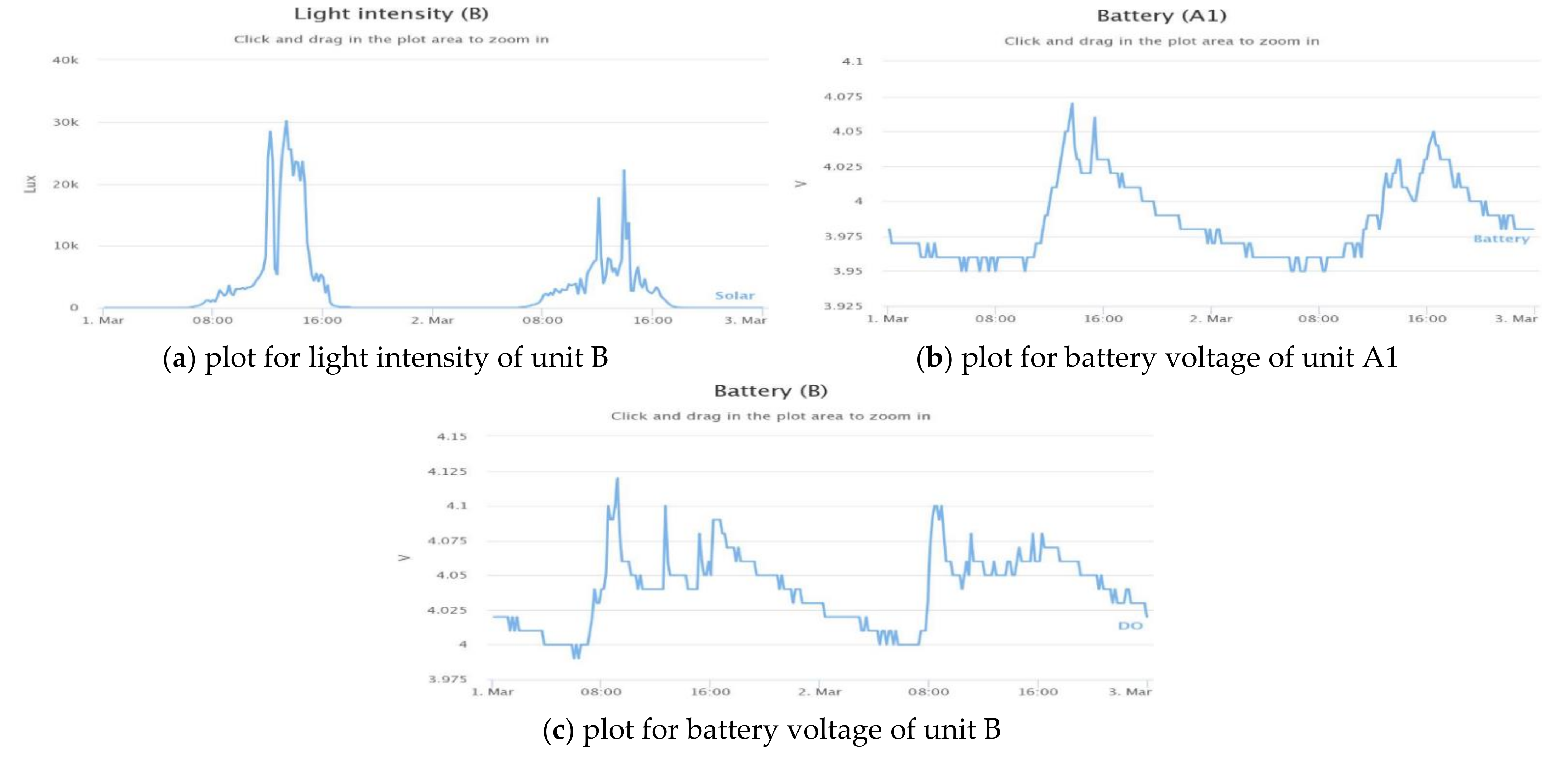

4.2.3. Power Management for Solar-Powered Units

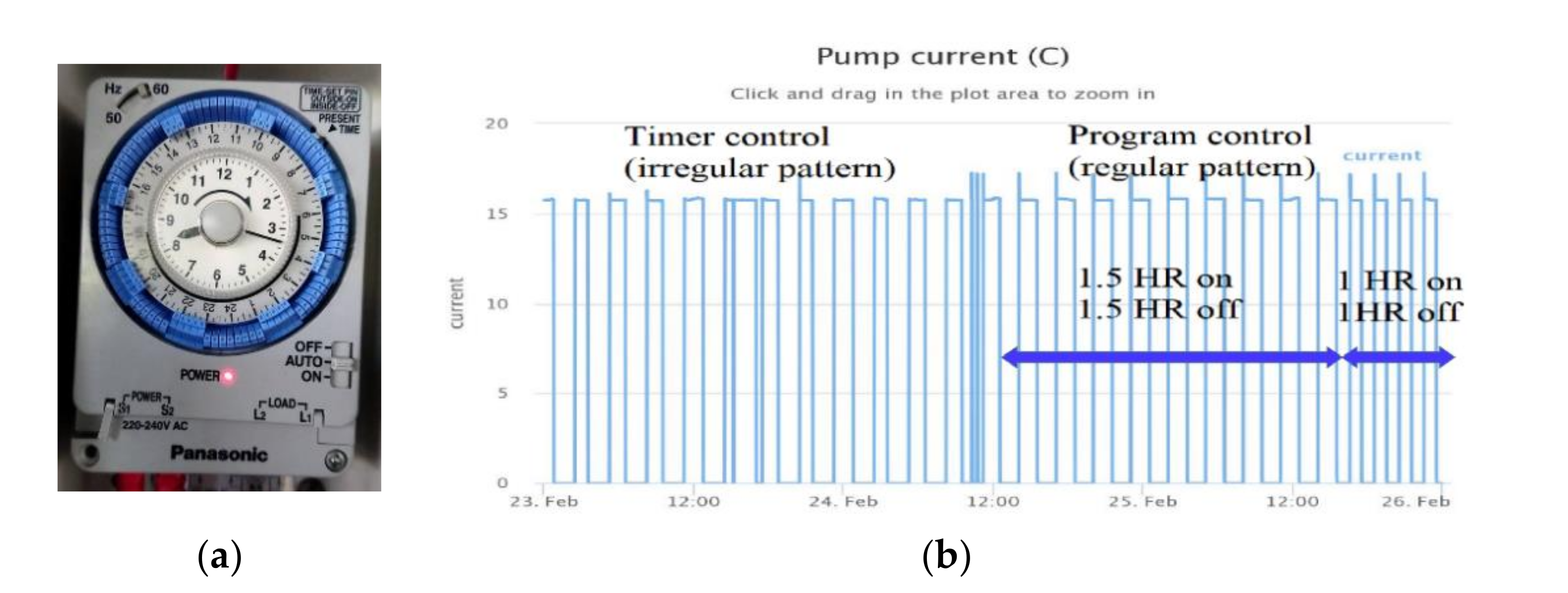

4.2.4. Remote Pump Control

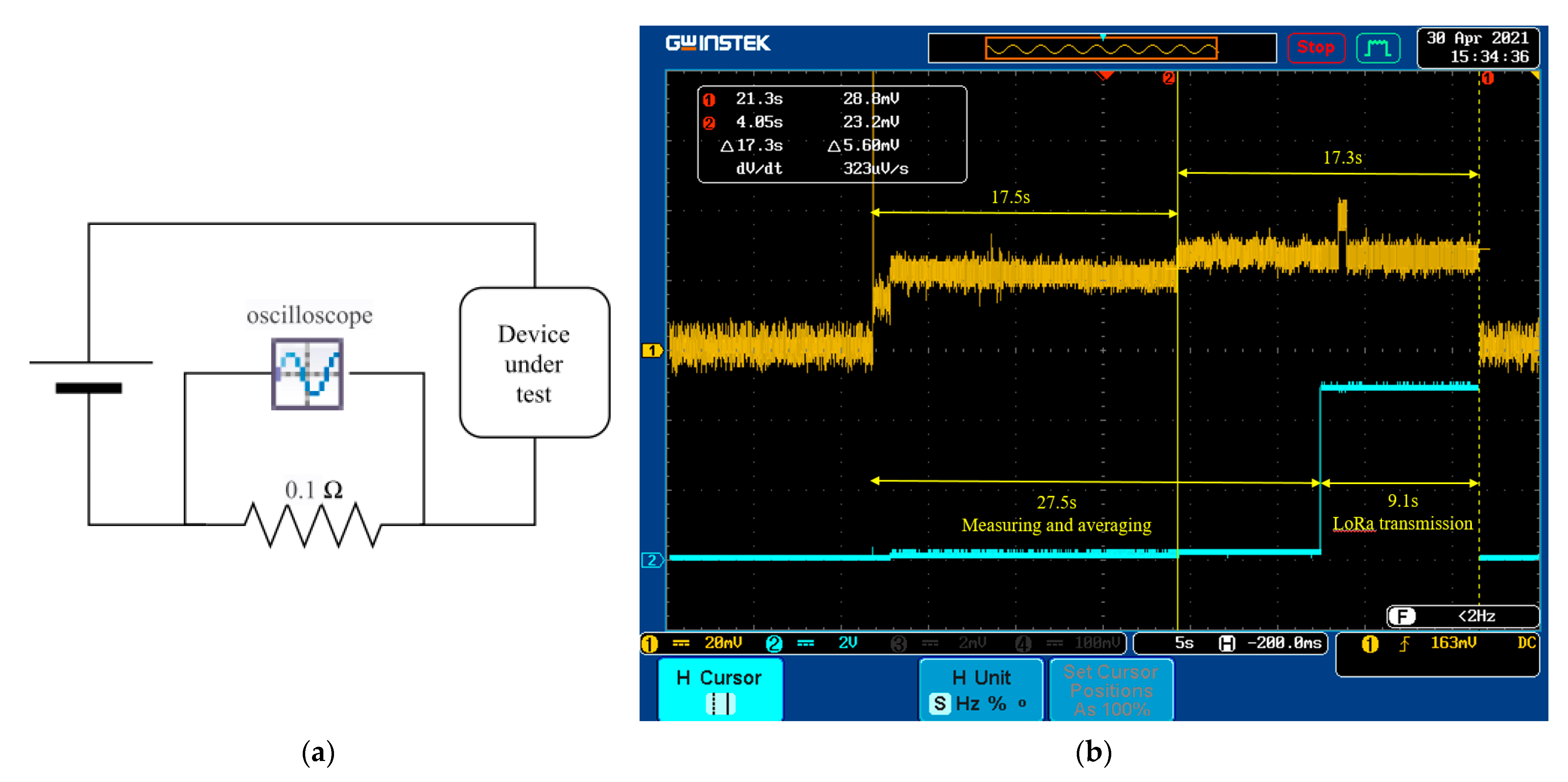

4.2.5. Power Consumption Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Makario, J.; Ngetich, K.; MAINA, C.W. Long Range Low Power Sensor Networks for Agricultural Monitoring-A Case Study in Kenya. In Proceedings of the 2019 IST-Africa Week Conference (IST-Africa), Nairobi, Kenya, 8–10 May 2019; pp. 1–8. [Google Scholar]

- Simitha, K.M.; Raj, S. IoT and WSN based water quality monitoring system. In Proceedings of the 3rd International Conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 2–14 June 2019; pp. 205–210. [Google Scholar]

- Islam, A.; Akter, K.; Nipu, N.J.; Das, A.; Rahman, M.M.; Rahman, M. Iot based power efficient agro field monitoring and irrigation control system: An empirical implementation in precision agriculture. In Proceedings of the International Conference on Innovations in Science, Engineering and Technology (ICISET), Chittagong, Bangladesh, 27–28 October 2018; pp. 372–377. [Google Scholar]

- Wu, N.; Khan, M. LoRa-based Internet-of-Things: A Water Quality Monitoring System. In Proceedings of the IEEE SoutheastCon, Huntsville, AL, USA, 11–14 April 2019; pp. 1–4. [Google Scholar]

- Ngom, B.; Diallo, M.; Gueye, B.; Marilleau, N. LoRa-based Measurement Station for Water Quality Monitoring: Case of Botanical Garden Pool. In Proceedings of the IEEE Sensors Applications Symposium (SAS), Sophia Antipolis, France, 11–13 March 2019; pp. 1–4. [Google Scholar]

- Kökten, E.; Çalışkan, B.C.; Karamzadeh, S.; Soyak, E.G. Low-Powered Agriculture IoT Systems with LoRa. In Proceedings of the IEEE Microwave Theory and Techniques in Wireless Communications (MTTW), Riga, Latvia, 1–2 October 2020; pp. 178–183. [Google Scholar]

- Boonyopakom, P.; Thongna, T. Environment Monitoring System through LoRaWAN for Smart Agriculture. In Proceedings of the IEEE 5th International Conference on Information Technology (InCIT), Chonburi, Thailand, 21–22 October 2020; pp. 12–16. [Google Scholar]

- Mya, K.T.; Sein, M.M.; Nyunt, T.T.S.; Lewlompaisarl, U.; Owada, Y. A Design for IoT Based Smart Watering System Using LoRa. In Proceedings of the IEEE 9th Global Conference on Consumer Electronics (GCCE), Kobe, Japan, 13–16 October 2020; pp. 278–279. [Google Scholar]

- Siregar, B.; Tanjung, K.; Nurmayadi, F. Remotely Controlled Water Flow Monitoring System with Mechanical Control on the Faucet using LoRa Communication. In Proceedings of the IEEE International Conference on ICT for Smart Society (ICISS), Bandung, Indonesia, 19–20 November 2020; pp. 1–5. [Google Scholar]

- Burchi, G.; Chessa, S.; Gambineri, F.; Kocian, A.; Massa, D.; Milano, P.; Milazzo, P.; Rimediotti, L.; Ruggeri, A. Information technology controlled greenhouse: A system architecture. In Proceedings of the IoT Vertical and Topical Summit for Agriculture, Tuscany, Italy, 8–9 May 2018. [Google Scholar]

- Ayaz, M.; Ammad-Uddin, M.; Sharif, Z.; Mansour, A.; Aggoune, E.-H.M. Internet-of-things (IoT)-based smart agriculture: Toward making the fields talk. IEEE Access 2019, 7, 129551–129583. [Google Scholar] [CrossRef]

- Borrero, J.D.; Zabalo, A. An autonomous wireless device for real-time monitoring of water needs. Sensors 2020, 20, 2078. [Google Scholar] [CrossRef] [PubMed]

- Kuo, Y.W.; Li, C.L.; Jhang, J.H.; Lin, S. Design of a Wireless Sensor Network-Based IoT Platform for Wide Area and Heterogeneous Applications. IEEE Sens. J. 2018, 18, 5187–5197. [Google Scholar] [CrossRef]

- Sundaram, J.P.S.; Du, W.; Zhao, Z. A survey on lora networking: Research problems, current solutions, and open issues. IEEE Commun. Surv. Tutor. 2019, 22, 371–388. [Google Scholar] [CrossRef]

- Zhao, L.; Wu, W.; Li, S. Design and implementation of an iot-based indoor air quality detector with multiple communication interfaces. IEEE Internet Things J. 2019, 6, 9621–9632. [Google Scholar] [CrossRef]

- Zhou, Q.; Zheng, K.; Hou, L.; Xing, J.; Xu, R. Design and implementation of open LoRa for IoT. IEEE Access 2019, 7, 100649–100657. [Google Scholar] [CrossRef]

- Kulkarni, P.; Hakim, Q.O.A.; Lakas, A. Experimental evaluation of a campus-deployed iot network using lora. IEEE Sens. J. 2020, 20, 2803–2811. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Zhou, L.; Zhao, J.; Dong, W.; Zhang, M.; Lv, X. Transmission tower tilt monitoring system using low-power wide-area network technology. IEEE Sens. J. 2020, 21, 1100–1107. [Google Scholar] [CrossRef]

- Aldahdouh, K.A.; Darabkh, K.A.; Al-Sit, W. A survey of 5G emerging wireless technologies featuring LoRaWAN, Sigfox, NB-IoT and LTE-M. In Proceedings of the IEEE International Conference on Wireless Communications Signal Processing and Networking (WiSPNET), Chennai, India, 21–23 March 2019; pp. 561–566. [Google Scholar]

- Olatinwo, S.O.; Joubert, T.-H. Enabling communication networks for water quality monitoring applications: A. survey. IEEE Access 2019, 7, 100332–100362. [Google Scholar] [CrossRef]

- Popli, S.; Jha, R.K.; Jain, S. A survey on energy efficient narrowband internet of things (NBIoT): Architecture, application and challenges. IEEE Access 2018, 7, 16739–16776. [Google Scholar] [CrossRef]

- Martinez, B.; Adelantado, F.; Bartoli, A.; Vilajosana, X. Exploring the performance boundaries of NB-IoT. IEEE Internet Things J. 2019, 6, 5702–5712. [Google Scholar] [CrossRef]

- Joris, L.; Dupont, F.; Laurent, P.; Bellier, P.; Stoukatch, S.; Redouté, J.-M. An autonomous sigfox wireless sensor node for environmental monitoring. IEEE Sens. Lett. 2019, 3, 1–4. [Google Scholar] [CrossRef]

- OASIS Standard. MQTT Version 5.0. Available online: https://docs.oasis-open.org/mqtt/mqtt/v5.0/mqtt-v5.0.html (accessed on 1 May 2020).

- Internet Engineering Task Force (IETF) Standard. The JavaScript Object Notation (JSON) Data Interchange Format. Available online: https://tools.ietf.org/html/rfc8259 (accessed on 1 May 2020).

| Type A (Solar) | Type B (Solar) | Type C (AC) | Type D (AC) | Type D | |

|---|---|---|---|---|---|

| Functions | pH ORP EC Water temperature | Water temperature Air temperature Humidity Atmospheric pressure Light intensity | Current Remote control | Water flow | Water meter |

| Modules (interface) | EZO pH circuit (UART) EZO ORP circuit (UART) EZO conductivity circuit (UART) DB18B20 (one wire) | DB18B20 (one wire) GY-39 (UART) | CT + ADS1115 (I2C) Relay (Pin D6) | Hall-effect sensor (Pin D5) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, Y.-W.; Wen, W.-L.; Hu, X.-F.; Shen, Y.-T.; Miao, S.-Y. A LoRa-Based Multisensor IoT Platform for Agriculture Monitoring and Submersible Pump Control in a Water Bamboo Field. Processes 2021, 9, 813. https://doi.org/10.3390/pr9050813

Kuo Y-W, Wen W-L, Hu X-F, Shen Y-T, Miao S-Y. A LoRa-Based Multisensor IoT Platform for Agriculture Monitoring and Submersible Pump Control in a Water Bamboo Field. Processes. 2021; 9(5):813. https://doi.org/10.3390/pr9050813

Chicago/Turabian StyleKuo, Yaw-Wen, Wei-Ling Wen, Xue-Fen Hu, Ying-Ting Shen, and Shen-Yun Miao. 2021. "A LoRa-Based Multisensor IoT Platform for Agriculture Monitoring and Submersible Pump Control in a Water Bamboo Field" Processes 9, no. 5: 813. https://doi.org/10.3390/pr9050813

APA StyleKuo, Y.-W., Wen, W.-L., Hu, X.-F., Shen, Y.-T., & Miao, S.-Y. (2021). A LoRa-Based Multisensor IoT Platform for Agriculture Monitoring and Submersible Pump Control in a Water Bamboo Field. Processes, 9(5), 813. https://doi.org/10.3390/pr9050813