1. Introduction

Syngas, which is mainly composed of hydrogen and CO, is considered a form of potential fuel and has wide application prospects in gas turbine power generation. However, like all other fossil fuels, syngas emits pollutants such as NO

x as it burns. Diluting the combustion mixture is a general method to control NO

x emissions [

1,

2,

3], especially with high temperature diluents to create a distributed reaction zone and mild combustion [

2]. Gas diluents, which normally denote incombustible gas, including N

2, CO

2, H

2O, and exhaust gas re- circulation (EGR) [

4], can significantly reduce the chemical reaction rate and temperature of the reaction zone, and thus decrease the formation of NO

x. The utilization of low calorific value (LCV) gas fuels, including a massive amount of incombustible gas, such as syngas, is a typical dilution combustion. It is of great significance to study the effect of dilution on the combustion characteristics of syngas in future applications.

Mixing hydrogen with hydrocarbon fuels can significantly reduce carbon emissions. Premixed, lean-burn is an effective combustion method to reduce the emission of nitrogen oxide [

5]. The premixed dilution combustion of hydrogen-blended fuel is also an important method to improve efficiency and reduce emissions of gas turbine [

6].

Laser diagnostic technologies, including planar laser-induced fluorescence (PLIF) and Rayleigh scattering (RS), are widely used in the research of combustion. PLIF technology is used widely, especially for turbulent combustion, and much essential information of flames can be obtained, such as the structure of the turbulent flame [

7,

8], OH radical laser measurement [

9,

10], and other intermediate free radical products [

11]. Zhang et al. [

12] investigated the turbulent premixed flame structure characteristics of hydrogen-enriched methane/air flames diluted with CO

2 using OH-PLIF and revealed the role of hydrogen addition and CO

2 dilution on the features of the turbulent flame. Zhang et al. [

4] pointed out that both CO

2 and H

2O diluents have a certain effect on inhibiting the NO generation of CH

4/air premixed flame by OH-PLIF and Fluent in combination with the simplified mechanism. Zhang et al. [

13] studied the influence of hydrogen addition on the detailed flame structure of turbulent premixed flame of CH

4/H

2/air mixture using CH

2O/OH PLIF and revealed that hydrogen broadens the reaction zone slightly but largely decreases the preheat zone thickness.

The effect of N

2 dilution and hydrogen content on the combustion characteristics of the syngas/air premixed turbulent flame with different dilution ratios and different exit Reynolds numbers was examined in the present work. The distribution of free radical OH in the jet flame was measured by PLIF, which was mainly used to obtain the structure of the flame front and to extract the turbulent flame velocity [

2]. Different fuels were studied, which mainly consisted of a mixture of hydrogen and carbon monoxide in different proportions. The ratio of hydrogen to carbon monoxide varied from 5/95 to 75/25, which represented different types of syngas. In order to determine the effect of a high degree of dilution on the premixed turbulent flame, the proportion of dilution gas used in the experiment was up to 50%, which was higher than that used in other literature [

2,

3,

14,

15].

3. Results and Discussions

In the present work, the premixed jet flame of a syngas/air mixture with different nitrogen dilutions was investigated. The volumetric ratio of hydrogen to carbon monoxide varied from 5/95, 25/75, and 50/50 to 75/25, which represented different types of syngas. The volumetric proportion of dilution gas varied from 0, 10%, and 30% to 50% to determine the effect of high dilution on the premixed turbulent flame. The turbulent flame velocities under different operating conditions were calculated and analyzed at different Reynolds numbers.

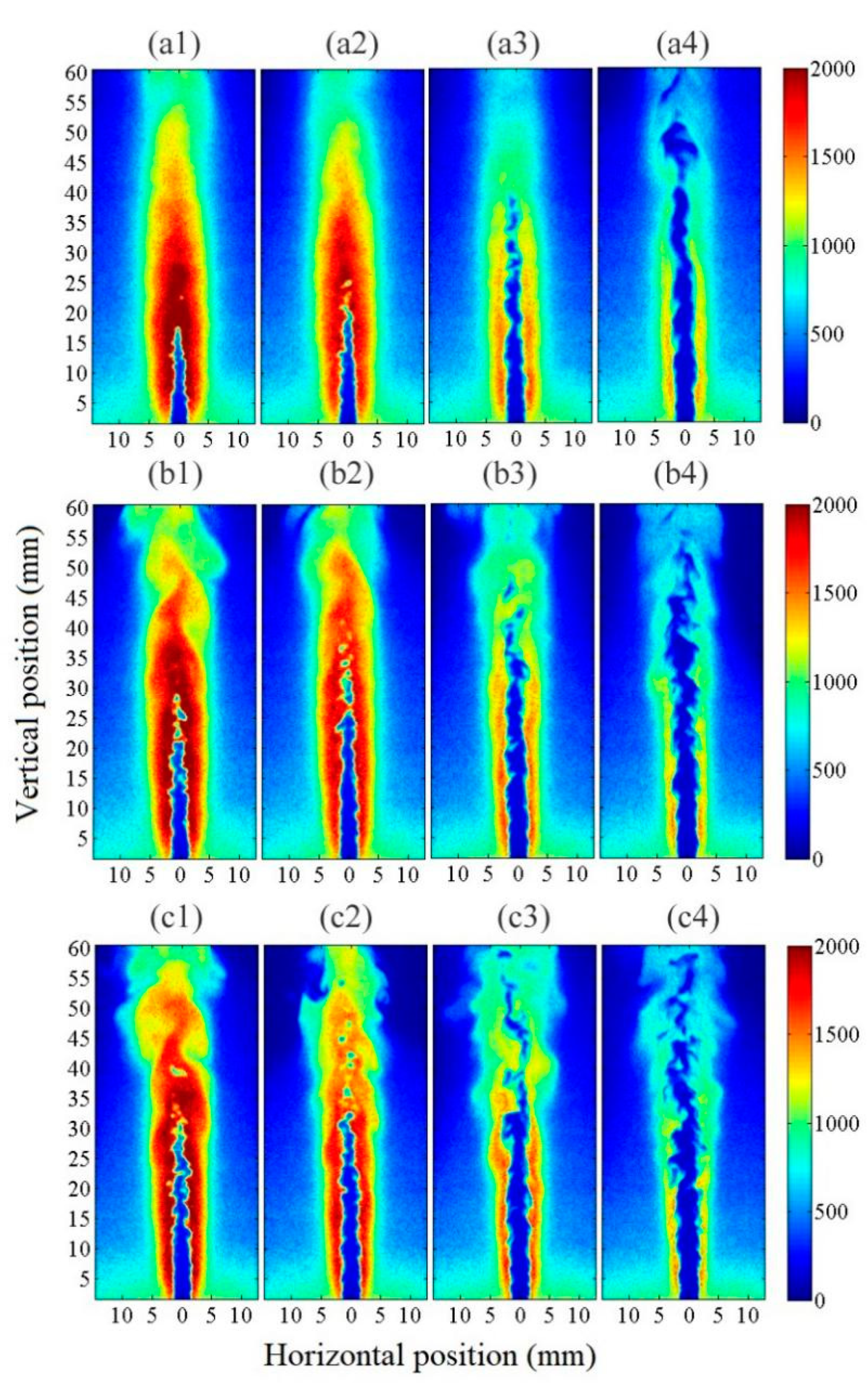

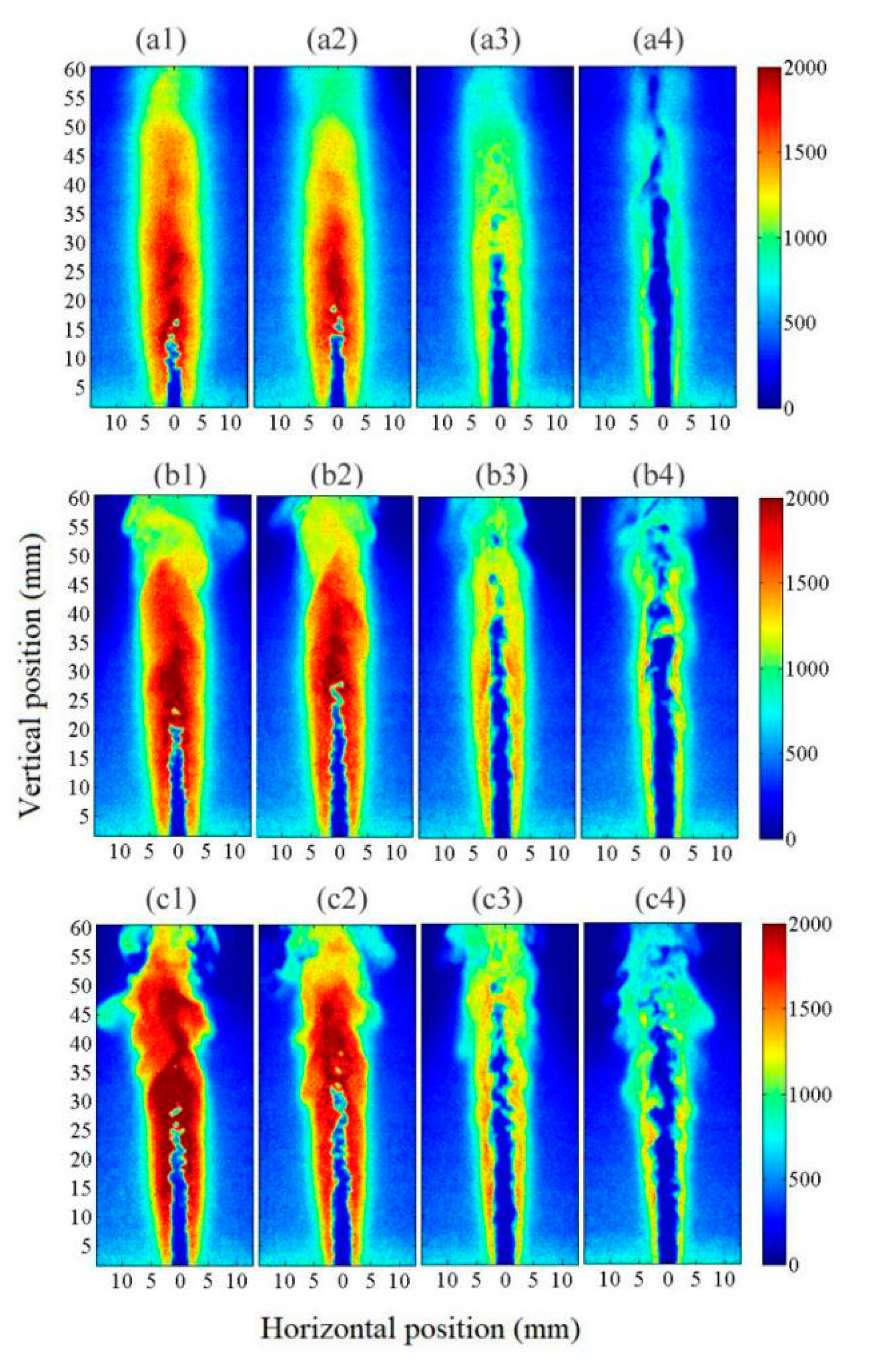

Figure 5,

Figure 6,

Figure 7 and

Figure 8 show the instantaneous OH distributions of different volumetric ratios of 5%H

2–95%CO, 25%H

2–75%CO, 50%H

2–50%CO, and 75%H

2–25%CO with different dilutions and Reynolds number at different outlets. As can be seen from these figures, the common point was that increasing the nitrogen dilution proportion greatly reduced the concentration of the OH radical, increased the flame height, and increased the vortex size of the flame. In our previous work, we studied the effects of nitrogen and carbon dioxide dilution on the combustion of gaseous fuels, such as methane [

16] and syngas [

17]. The effect of nitrogen and carbon dioxide dilution on methane combustion was investigated by formaldehyde-PLIF and OH-PLIF. The dilution resulted in the delay of combustion, the expansion of the unburned zone, and the significant decrease in the concentration of formaldehyde and OH. Compared with the super lean combustion, the dilution combustion more obviously weakened the combustion. Moreover, compared with nitrogen dilution, the OH concentration in the combustion zone was reduced more obviously by carbon dioxide dilution, but the formation of formaldehyde in the unburned zone was not affected.

The increase in the hydrogen content in the syngas increased the concentration of OH to a certain extent, and greatly reduced the size of the flame surface. These changes were greatly affected by the variation of laminar flame velocity characteristics of the premixed syngas, which was consistent with the results discussed in the previous work [

18]. In addition, changing the Reynolds number of the jet exit had very similar effects for different fuels. Increasing the exit Reynolds number enhanced the concentration distribution of OH signal, increasing the flame height and the vortex structure of the flame front.

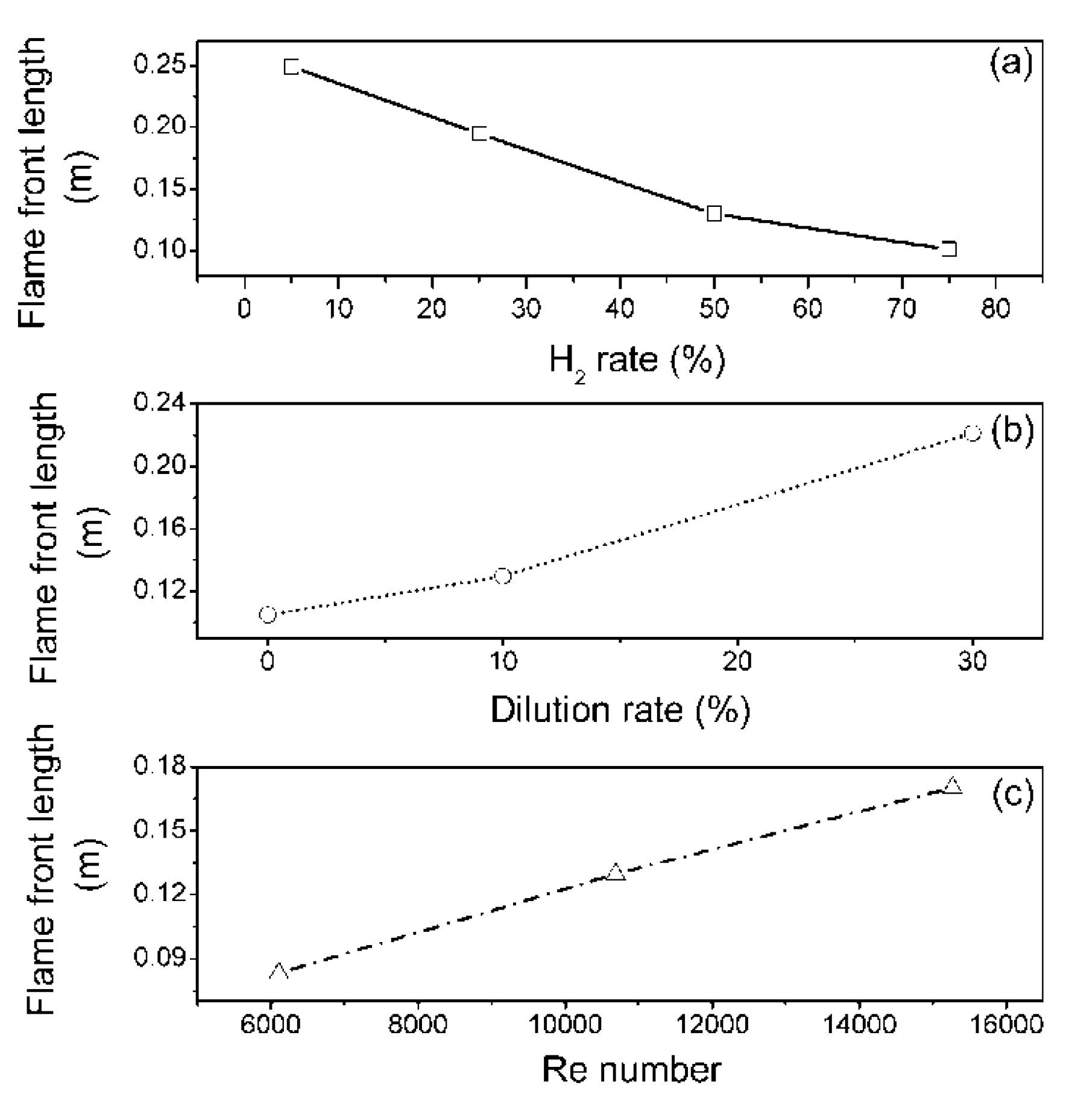

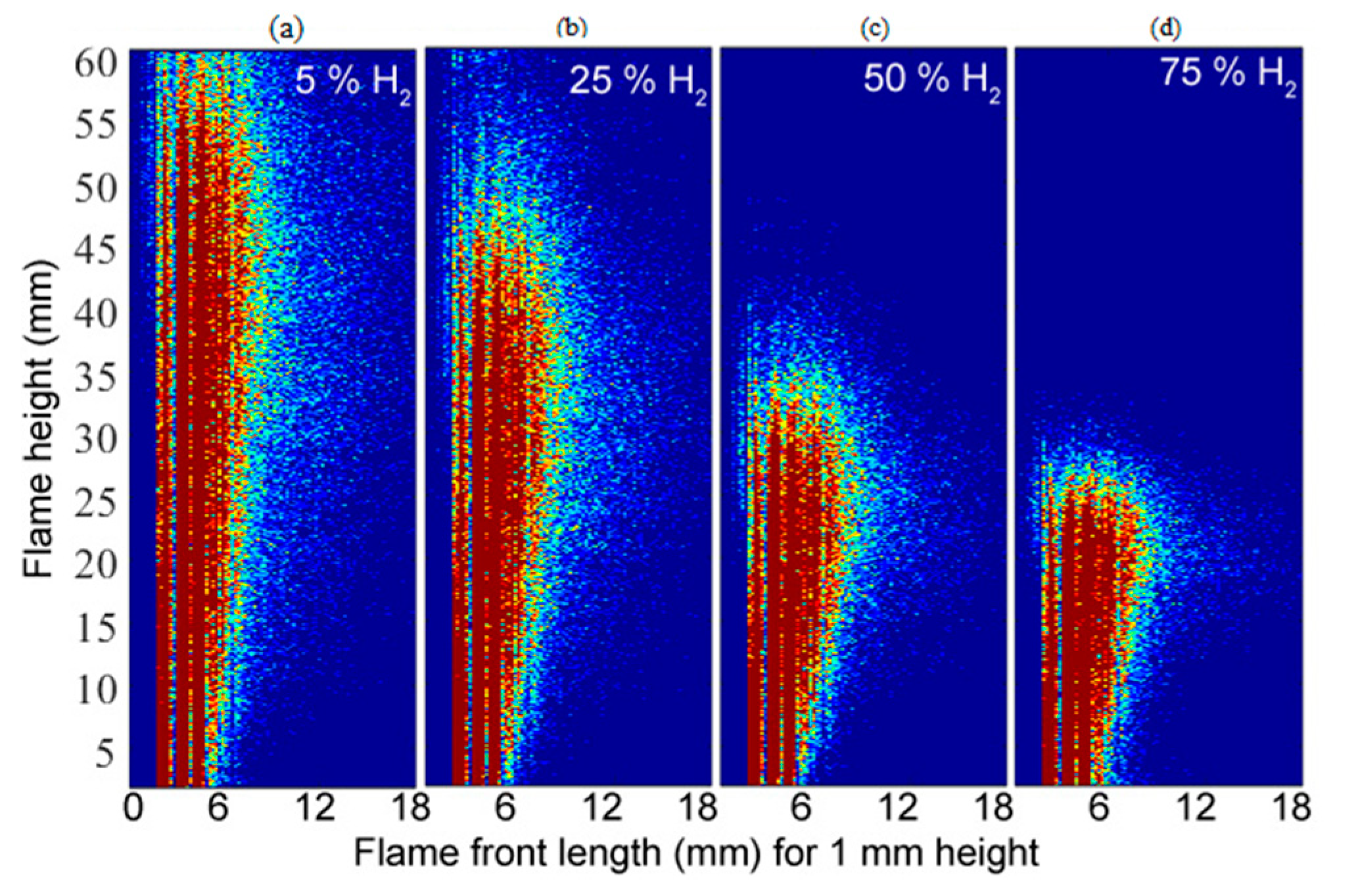

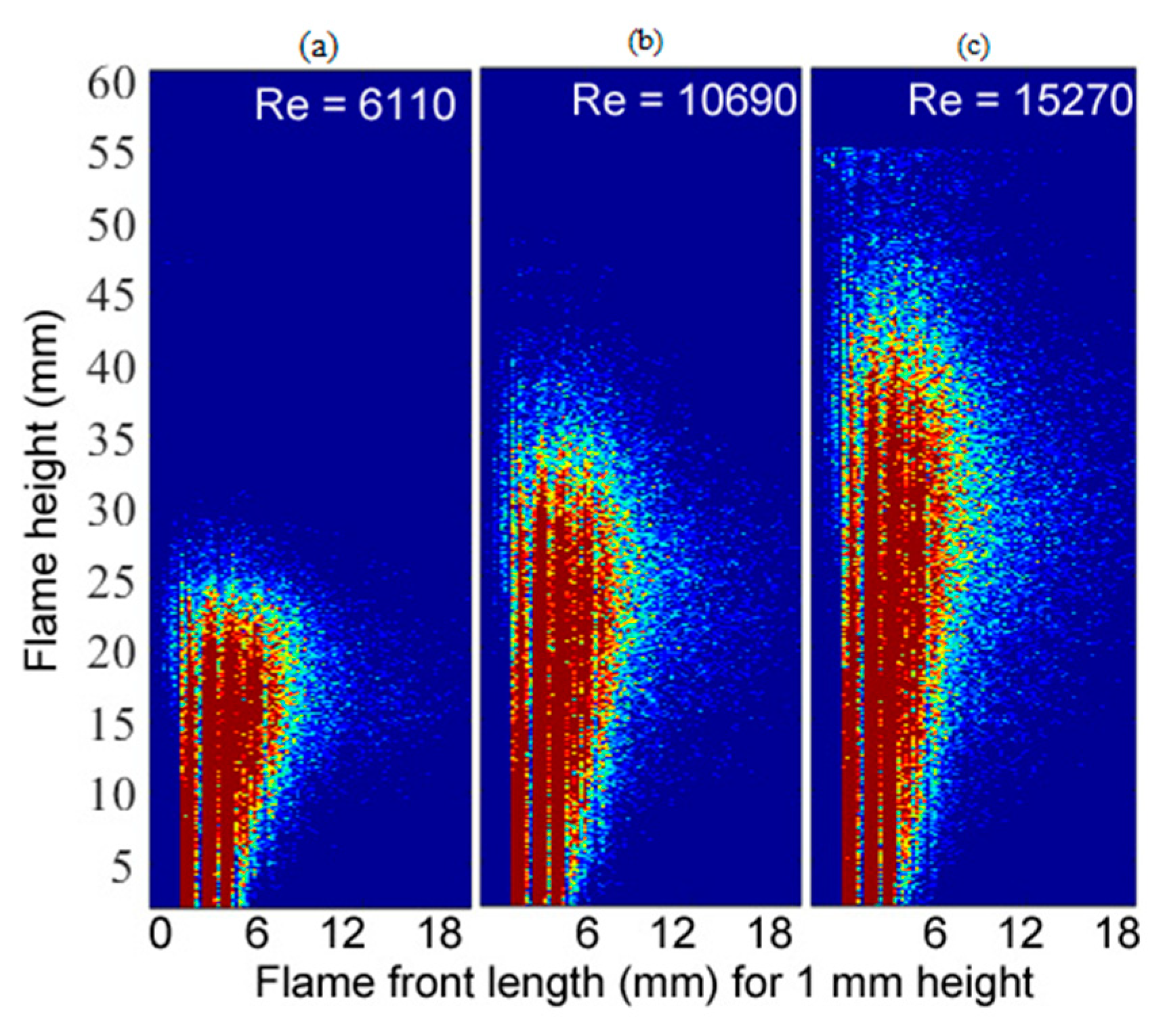

Figure 9 shows the length of the wrinkled flame front under different flame conditions. The results show that the total length of the flame front increased as the hydrogen proportion in the fuel decreased and the nitrogen dilution increased. This was mainly affected by the laminar flame velocity of the fuel. A smaller laminar flame velocity resulted in a larger flame front to sustain constant combustion under the condition of the same exit velocity. In addition, the total length of the flame front increased with the increase in turbulence intensity.

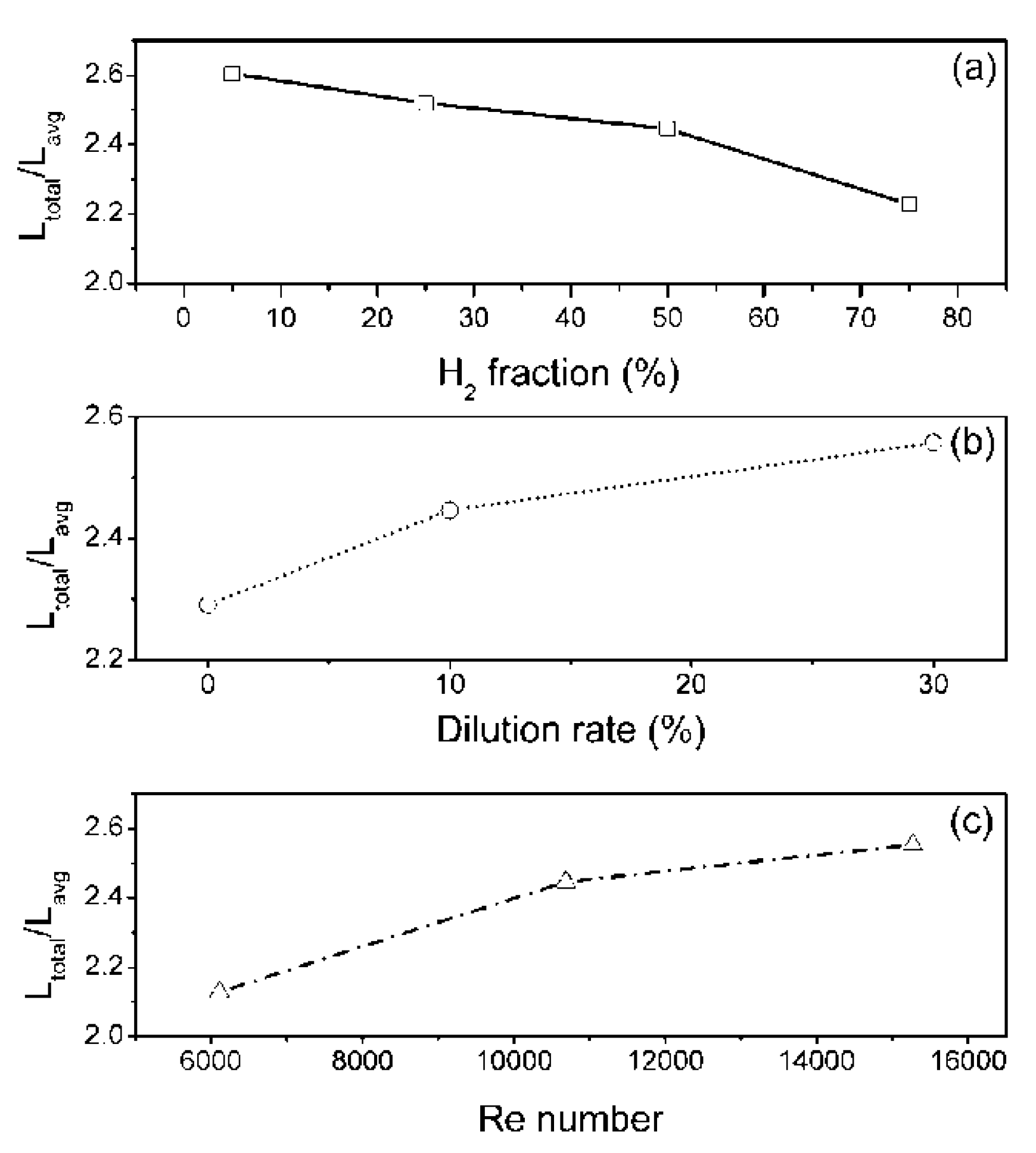

In order to obtain the effect of turbulence on combustion, the average flame front length and the total length of the wrinkled flame front are normalized in

Figure 10 to obtain the wrinkled rate of the flame front surface. It can be seen that the trend of the wrinkled rate was consistent with that of the total length of the wrinkled flame front in

Figure 9. Firstly, the wrinkled rate of flame front increased as the exit Reynolds number increased. Secondly, more abundant flame wrinkles were present in the turbulent combustion for the fuel with a lower laminar flame velocity. The increase in the wrinkle rate was mainly due to the increase in the higher wrinkle rate area caused by the expansion of the flame volume.

In order to understand the variation in the flame wrinkled rate at different flame positions under different flame conditions,

Figure 11 and

Figure 12 show the wrinkled rates at different flame heights with different hydrogen contents and Reynolds numbers at different outlets. Under different working conditions, the maximum wrinkled rate does not change much. The increase in the wrinkled rate in

Figure 10 is mainly due to the increase in the area with the high wrinkled rate caused by the change in the flame volume.

In the present work, the maximum exit velocity of turbulent jet flow was 100 m/s. It should be noted that the exit velocity of the turbulent jet flow was different from the turbulent flame velocity/speed. The exit velocity of the turbulent jet flow indicates the flow velocity of unburned premixed fuel gases and is closely related to the Reynolds number (jet flow exit velocity of 100 m/s corresponds to Reynolds number of 15,270, as shown in

Table 1), whereas the turbulent flame velocity denotes the turbulent flame propagation speed. Based on the previous studies [

19], the turbulence intensity was estimated to be about 1% of the exit velocity of the jet flow. Therefore, the turbulence intensity at the front of the present experimental flame was about 100 cm/s. The laminar flame velocity of the syngas used in the present experiment was about 100 cm/s. Thus, it was estimated that the turbulent premixed jet flame in the present experiment basically lies in the wrinkled and corrugated flamelets. In these wrinkled and corrugated regions, the area of the flame front surface, the average area of the flame surface, the wrinkled rate of the flame surface, and the rate of unburned premixed gas consumption per average flame front area—the so-called turbulent flame velocity—were analyzed.

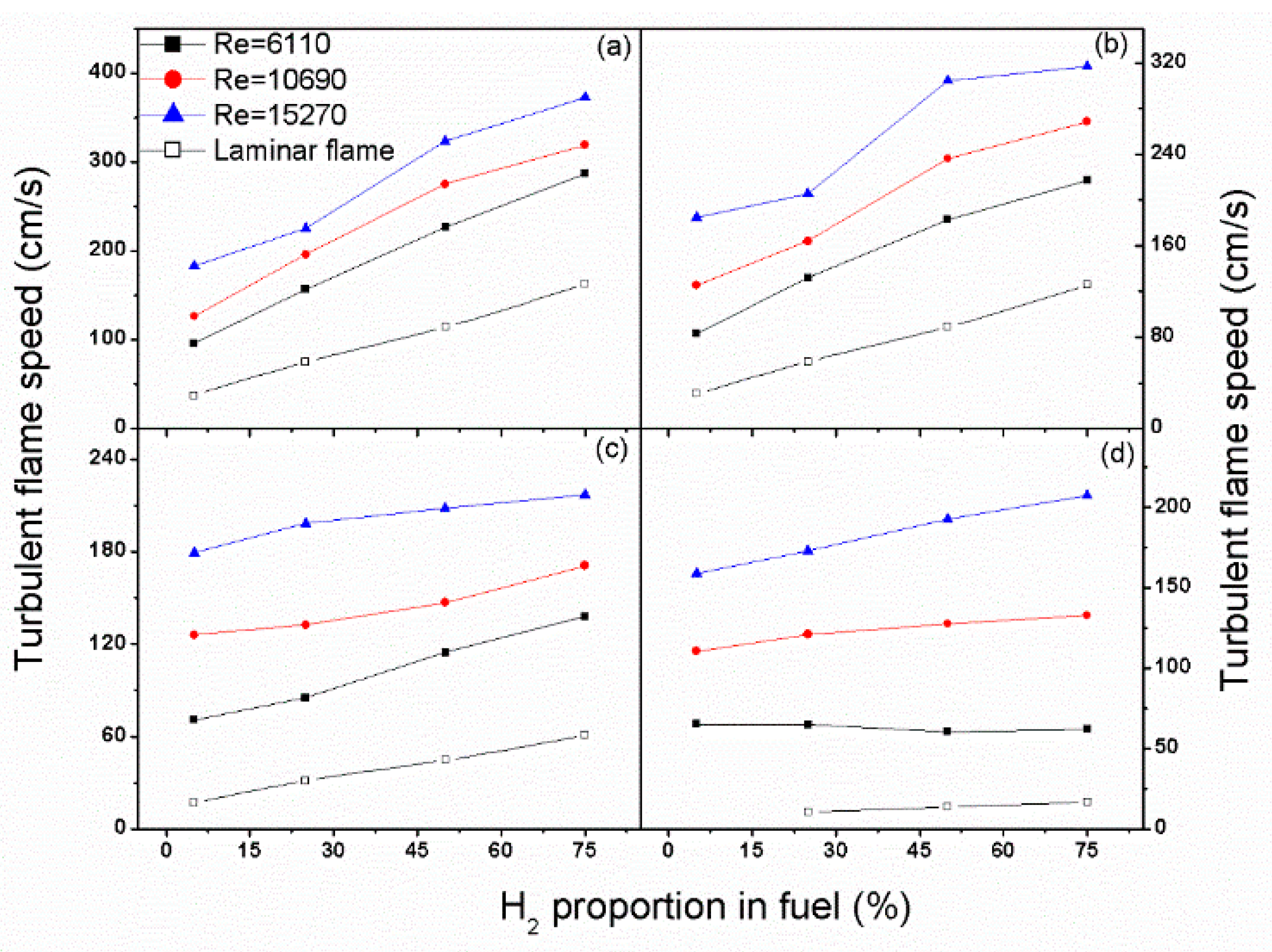

Figure 13 shows the tendency of the turbulent flame velocity to vary with the proportion of hydrogen in syngas. Compared with the laminar flame velocity obtained by CHEMKIN simulation, the turbulent and laminar flame velocities had a very similar changing trend. It can be seen that the turbulent flame velocity was basically controlled by the laminar flame velocity under invariable turbulent intensity.

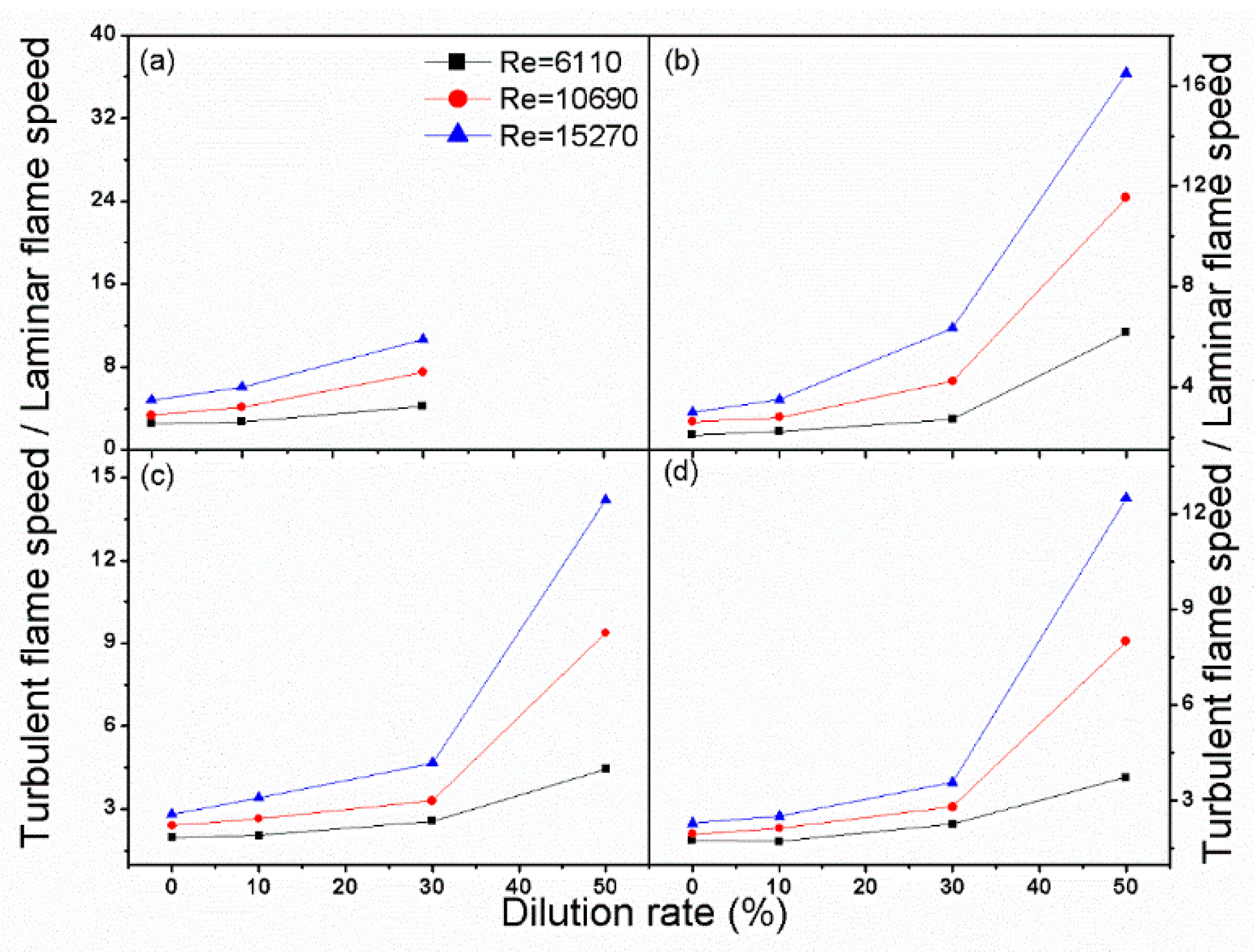

In order to study the effect of the exit velocity on turbulent flame velocity, the ratio of the turbulent flame velocity to the laminar flame velocity of syngas with the same composition was obtained, as shown in

Figure 14.

As can be seen from

Figure 14, the ratio of turbulent flame velocity to laminar flame velocity decreased significantly with the increase in hydrogen content in syngas under invariable turbulent intensity. For different operation conditions of syngas, the increase in turbulent flame velocity was consistent with the increase in exit Reynolds number, as shown in

Figure 13. Therefore, the increase in laminar flame velocity directly resulted in the decrease in the ratio of turbulent flame velocity to laminar flame velocity.

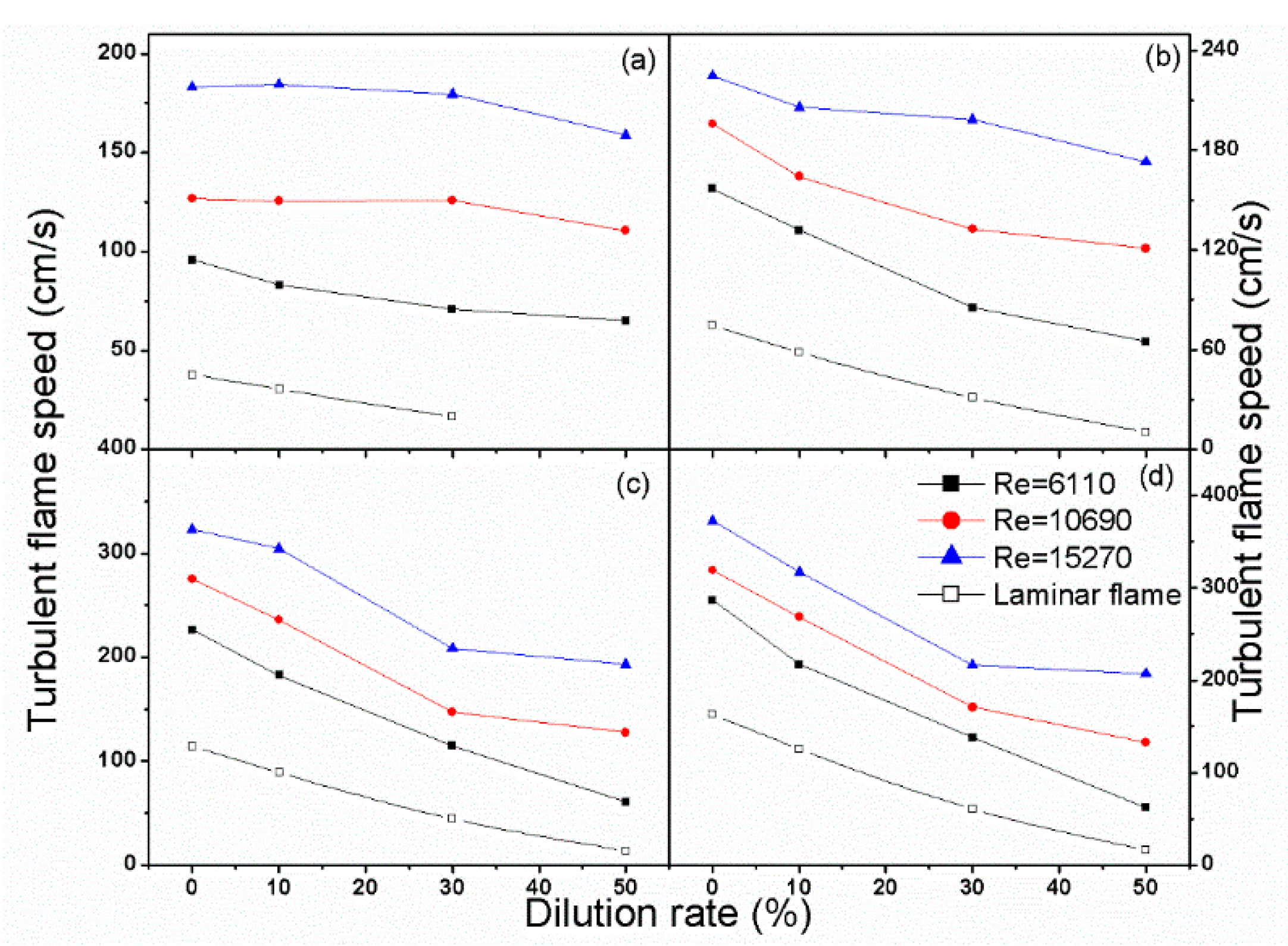

The effect of nitrogen dilution on the turbulent flame velocity of syngas is shown in

Figure 15. Similar to the effect of different hydrogen proportions on the turbulent flame velocity, the variation in the turbulent flame velocity was consistent with that of the laminar flame velocity under different nitrogen dilution ratios. Moreover, at higher dilution, the ratio of the turbulent flame velocity to the laminar flame velocity increased obviously due to the lower laminar flame velocity, as shown in

Figure 16. According to scholars, the ratio of the turbulent flame velocity to the laminar flame velocity, and the ratio of the turbulent intensity to the laminar flame velocity under lower turbulent intensity, are linear and expressed by the following formula:

where

ST stands for turbulent flame velocity,

SL stands for laminar flame velocity, and u′ represents turbulence intensity. The relationship between the ratio of the turbulent flame velocity to the laminar flame velocity, and the ratio of the outlet flow velocity to the laminar flame velocity, were studied in present work, as shown in

Figure 14. It can be seen that there was a strong linear relationship between these two ratios. This was found by fitting the linear relationship, which can be expressed as:

According to Formula (3), it was obvious that the fitting formula obtained from the present experiment was in good agreement with Formula (2). Furthermore, it was clearly seen that the turbulent flame velocities of different syngases with different hydrogen proportions and nitrogen dilution ratios was consistent. In addition, as shown in Formula (3), there was a strong linear relationship between the exit velocity and the corresponding turbulent flame velocity, as follows:

Therefore, the exit velocity used in the present work was 40, 70, and 100 m/s according to the experimental conditions. The exit velocity difference remained at a fixed value of about 30 m/s, corresponding to the turbulent flame velocity difference of about 50 cm/s, which is consistent with those shown in

Figure 9 and

Figure 15. According to Formula (2), the turbulent intensity of the flame front surface in the present experimental system was about 0.016 of the exit velocity, which was very close to the reference value of 0.01 in the literature [

19].

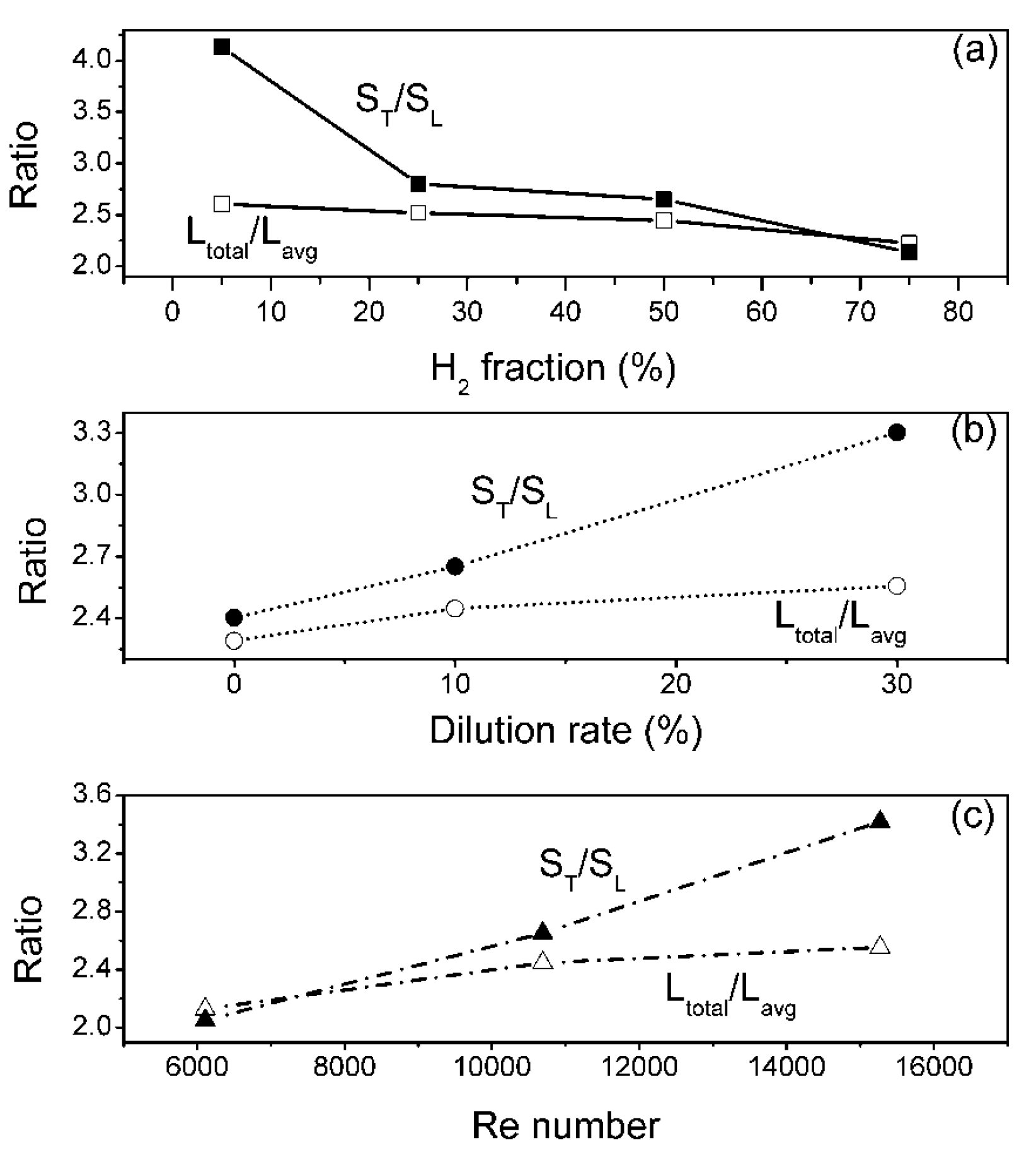

According to the definitions of laminar flame velocity and turbulent flame velocity, there was a strong correlation between the wrinkled rate obtained by the flame front length and the ratio of the turbulent flame velocity to the laminar flame velocity, which means

Ltotal/

Lavg ≈

Atotal/

Aavg ≈

ST/

SL.

Figure 17 shows both ratios for comparison, and the results show that the ratio of the turbulent flame velocity to the laminar flame velocity was generally greater than the wrinkled rate obtained previously, especially for the conditions of lower hydrogen proportion, higher nitrogen dilution rate, and larger Reynolds number. In addition, it was obvious that there was a large error in the structure of the flame front surface obtained from the two-dimensional instantaneous image and the corresponding wrinkled rate, which was smaller than that of the actual flame situation. Furthermore, the ratio of the turbulent flame velocity to the laminar flame velocity was calculated based on the laminar flame velocity under room temperature. However, higher local laminar flame velocity would occur in the turbulent flame under actual operating conditions due to the turbulent effect, which increased the preheating effect. This was consistent with our previous work on syngas [

17], which indicated that nitrogen dilution restrained the flame speed of syngas, whereas higher preheat temperature accelerated the flame speed. Through changes in the thickness of the OH layers and signal intensities, the reaction layer can be compressed by intensifying turbulence and, thereby, the combustion processes of syngas. For these reasons, the ratios in

Figure 18 were somewhat higher than those in actual conditions.