Microscopic Characteristics and Properties of Fe-Based Amorphous Alloy Compound Reinforced WC-Co-Based Coating via Plasma Spray Welding

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

2.3. Detection and Analysis

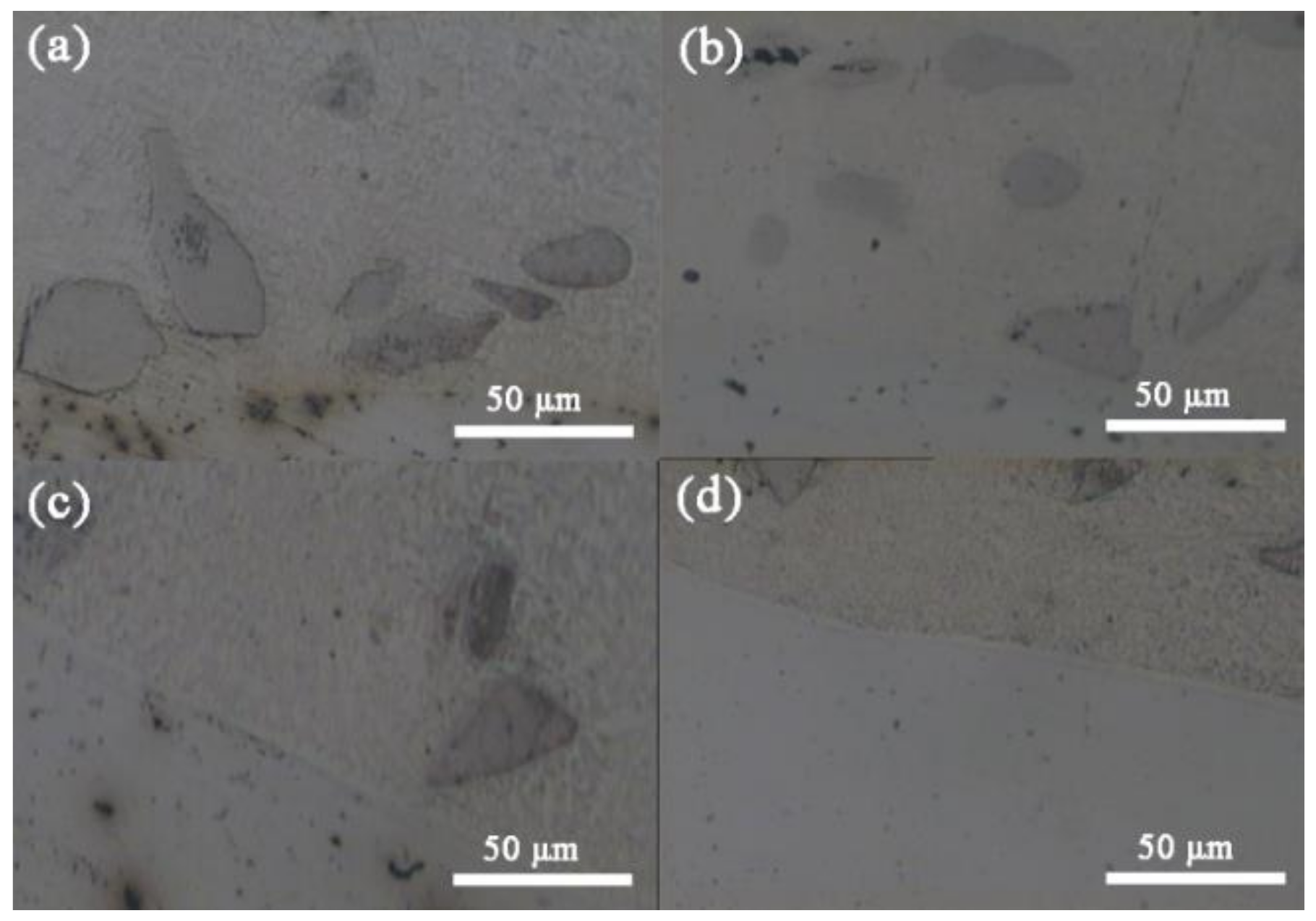

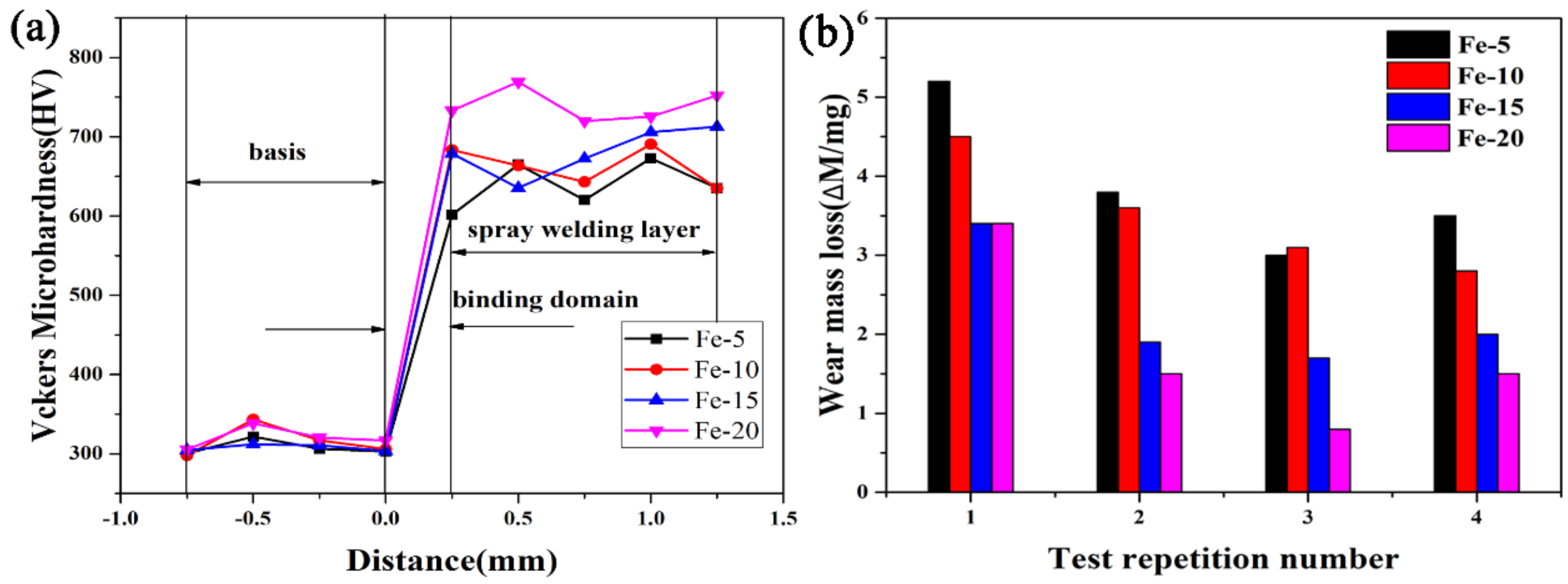

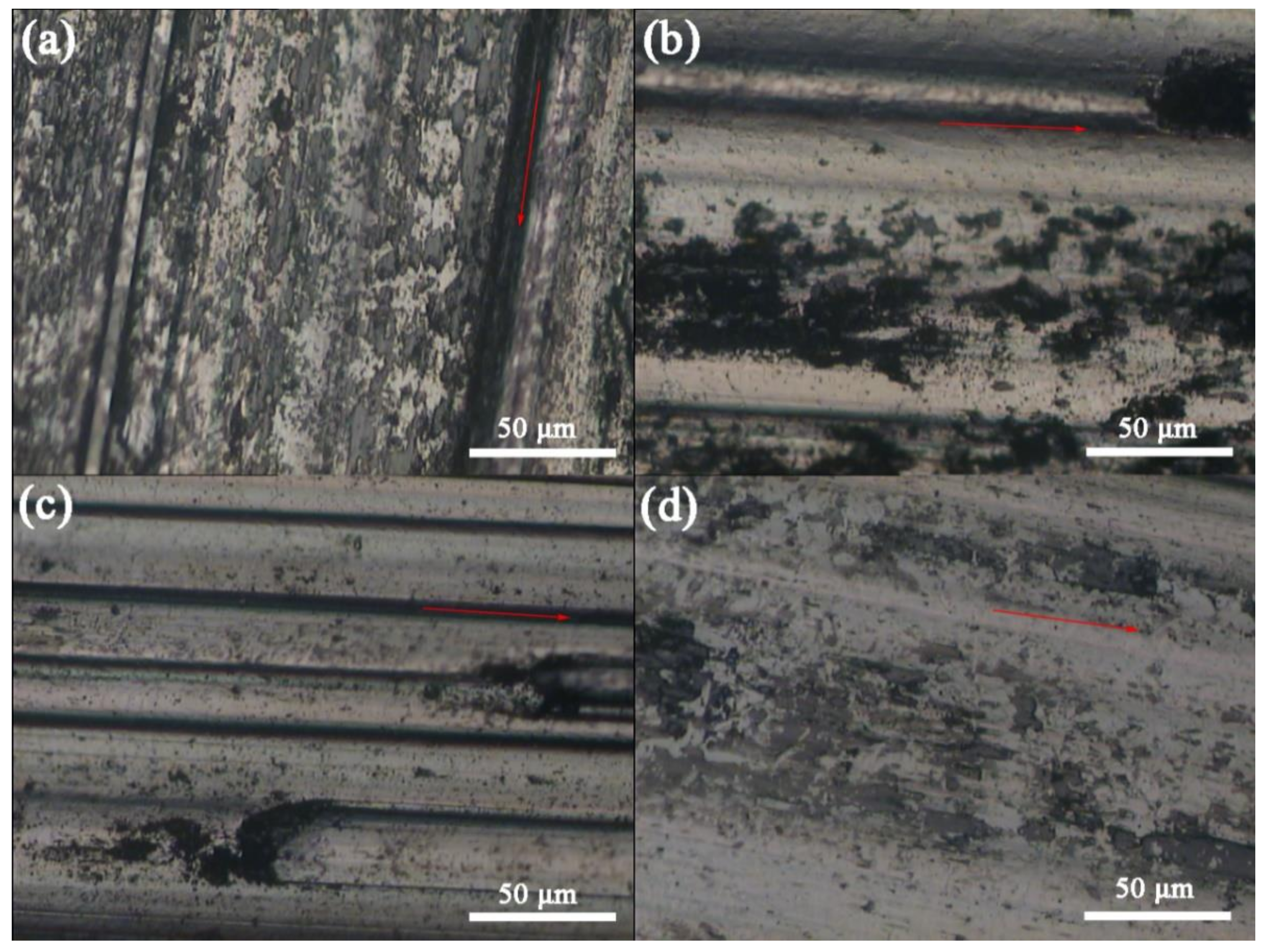

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, G.; Kumar, S.; Kumar, R. Comparative study of hot corrosion behavior of thermal sprayed alumina and titanium oxide reinforced alumina coatings on boiler steel. Mater. Res. Express 2020, 7, 26527. [Google Scholar] [CrossRef]

- Dong, T.S.; Zheng, X.D.; Li, Y.L.; Li, G.L.; Zhou, X.K.; Wang, H.D. Microstructure and Wear Resistance of FeCrBSi Plasma-Sprayed Coating Remelted by Gas Tungsten Arc Welding Process. J. Mater. Eng. Perform. 2018, 27, 4069–4076. [Google Scholar]

- Jiang, Q.; Tian, Y.; Shu, F.; Zhao, H.; Sun, Y.; He, W.; Xu, B. Strengthening mechanism and properties of Co–WC composite coatings deposited by plasma-transferred arc welding. Micro Nano Lett. 2019, 14, 717–720. [Google Scholar] [CrossRef]

- Zhang, Y.; Chi, Q.; Chang, L.; Dong, Y.; Cai, P.; Pan, Y.; Gong, M.; Huang, J.; Li, J.; He, A.; et al. Novel Fe-based amorphous compound powder cores with enhanced DC bias performance by adding FeCo alloy powder. J. Magn. Magn. Mater. 2020, 507, 166840. [Google Scholar] [CrossRef]

- Leal, E.; Gomes, U.; Alves, S.; Costa, F. The influence of powder preparation condition on densification and microstructural properties of WC-Co- Al2O3 cermets. Int. J. Refract. Met. Hard Mater. 2020, 92, 105275. [Google Scholar] [CrossRef]

- Hu, L.; Huang, J.; Liu, C.; Liu, X.; Hou, D.; Xu, C.; Zhao, Y. Effects of coupling between the laser plasma and two arcs on metal transfer in CO2 laser double-wire MIG hybrid welding. Opt. Laser Technol. 2018, 105, 152–161. [Google Scholar] [CrossRef]

- Kawase, M.; Ido, A.; Morinaga, M. Development of SiO2/TiO2/Al2O3-based/TiO2 coating for preventing sulfide corrosion in thermal power plant boilers. Appl. Therm. Eng. 2019, 153, 242–249. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, J.; Zhu, M.; Zhang, L.; Nie, P.; Li, Z. Effects of shielding gases on process stability of 10CrNi3MoV steel in hybrid laser-arc welding. J. Mater. Process. Technol. 2019, 270, 37–46. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, Y.; Zhou, J.; Zhang, G. Microstructure and properties of PTA sprayed 310/WC composite coating. Mater. Res. Express 2019, 6, 66561. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z.; Wang, B. Multi-pattern failure modes and wear mechanisms of WC-Co tools in dry turning Ti–6Al–4V. Ceram. Int. 2020, 46, 24512–24525. [Google Scholar] [CrossRef]

- Mironchuk, B.; Abrosimova, G.E.; Bozhko, S.; Drozdenko, A.; Postnova, E.; Aronin, A. Phase transformation and surface morphology of amorphous alloys after high pressure torsion. Mater. Lett. 2020, 273, 127941. [Google Scholar] [CrossRef]

- Ma, D.-D.; Xue, Y.-P.; Gao, J.; Ma, Y.; Yu, S.-W.; Wang, Y.-S.; Xue, C.; Hei, H.-J.; Tang, B. Effect of Ta diffusion layer on the adhesion properties of diamond coating on WC-Co substrate. Appl. Surf. Sci. 2020, 527, 146727. [Google Scholar] [CrossRef]

- Methong, T.; Shigeta, M.; Tanaka, M.; Ikeda, R.; Matsushita, M.; Poopat, B. Visualization of gas metal arc welding on globular to spray transition current. Sci. Technol. Weld. Join. 2017, 23, 87–94. [Google Scholar] [CrossRef]

- Staia, M.; Mejias, A.; La Barbera, J.G.; Puchi-Cabrera, E.; Villalobos-Gutierrez, C.; Santana, Y.Y.; Montagne, A.; Iost, A.; Rodriguez, M.A. Mechanical properties of WC/Co-CNT HVOF sprayed coatings. Surf. Eng. 2018, 36, 1156–1164. [Google Scholar] [CrossRef]

- Yan, W.; Qin, H.; Qiang, X.; Zhong, X. Microstructures and Wear Behavior of Ni-based Spray-welding Coating on Pure Titanium TA1 Substrate. Rare Metal. Mat. Eng. 2018, 47, 910–914. [Google Scholar]

- Maslarevic, A.; Bakic, G.M.; Djukic, M.B.; Rajicic, B.; Maksimovic, V.; Pavkov, V. Microstructure and Wear Behavior of MMC Coatings Deposited by Plasma Transferred Arc Welding and Thermal Flame Spraying Processes. Trans. Indian Inst. Met. 2020, 73, 259–271. [Google Scholar] [CrossRef]

- Kendzia, B.; Koppisch, D.; Van Gelder, R.; Gabriel, S.; Zschiesche, W.; Behrens, T.; Brüning, T.; Pesch, B. Modelling of exposure to respirable and inhalable welding fumes at German workplaces. J. Occup. Environ. Hyg. 2019, 16, 400–409. [Google Scholar] [CrossRef]

- Yu, J.; Wang, B.; Zhang, H.; Wang, Q.; Wei, L.; Chen, P.; He, P.; Feng, J. Characteristics of Magnetic Field Assisting Plasma GMAW-P The effect of the magnetic field intensity on droplet transition in plasma-GMAW-P hybrid welding was studied. Weld J. 2020, 99, S25–S38. [Google Scholar] [CrossRef]

- Bayar, I.; Ulutan, M. Surface modification of atmospheric plasma sprayed cermet coatings by plasma transferred arc method. Trans. IMF 2019, 97, 298–304. [Google Scholar] [CrossRef]

- Baiamonte, L.; Tului, M.; Bartuli, C.; Marini, D.; Marino, A.L.; Menchetti, F.; Pileggi, R.; Pulci, G.; Marra, F. Tribological and high-temperature mechanical characterization of cold sprayed and PTA-deposited Stellite coatings. Surf. Coatings Technol. 2019, 371, 322–332. [Google Scholar] [CrossRef]

- Huang, E.-W.; Hung, G.-Y.; Lee, S.Y.; Jain, J.; Chang, K.-P.; Chou, J.J.; Yang, W.-C.; Liaw, P.K. Mechanical and Magnetic Properties of the High-Entropy Alloys for Combinatorial Approaches. Crystals 2020, 10, 200. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, Q.; Wang, H.; Shu, F.; Zhao, H.; He, W.; Yu, Z. Microstructure and mechanical properties of Co-based alloy coatings fabricated by laser cladding and plasma arc spray welding. J. Alloys Compd. 2019, 785, 846–854. [Google Scholar] [CrossRef]

- Dong, S.; Jiang, F.; Xu, B.; Chen, S. Influence of Polarity Arrangement of Inter-Wire Arc on Droplet Transfer in Cross-Coupling Arc Welding. Materials 2019, 12, 3985. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Chung, H. Numerical simulation of the transition of metal transfer from globular to spray mode in gas metal arc welding using phase field method. J. Mater. Process. Technol. 2018, 251, 251–261. [Google Scholar] [CrossRef]

- Zhu, R.; Gao, W. Wear-resistance Performance of Spray-welding Coating by Plasma Weld-surfacing. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 414–418. [Google Scholar] [CrossRef]

- Shi, B.; Huang, S.; Zhu, P.; Xu, C.; Guo, P.; Fu, Y. In-situ TiN reinforced composite coatings prepared by plasma spray welding on Ti6Al4V. Mater. Lett. 2020, 276, 128093. [Google Scholar] [CrossRef]

- Chu, Z.; Deng, W.; Zheng, X.; Zhou, Y.; Zhang, C.; Xu, J.; Gao, L. Corrosion Mechanism of Plasma-Sprayed Fe-Based Amorphous Coatings with High Corrosion Resistance. J. Therm. Spray Technol. 2020, 29, 1111–1118. [Google Scholar] [CrossRef]

- Xu, L.P.; Song, J.B.; Deng, C.G.; Liu, M.; Zhou, K.S. Microstructure and Properties of WC-based Coating Reinforced by Fe-based Amorphous Alloys. Rare Metal Mat. Eng. 2020, 49, 1546–1552. [Google Scholar]

- Kim, W.R.; Heo, S.; Kim, J.-H.; Park, I.-W.; Chung, W. Multi-Functional Cr-Al-Ti-Si-N Nanocomposite Films Deposited on WC-Co Substrate for Cutting Tools. J. Nanosci. Nanotechnol. 2020, 20, 4390–4393. [Google Scholar] [CrossRef]

- Zhang, L.; Yue, F.; Li, S.F.; Yang, Y.F. Utilizing the autocatalysis of Co to prepare low-cost WC-Co powder for high-performance atmospheric plasma spraying. J. Am. Ceram. Soc. 2020, 103, 6690–6699. [Google Scholar] [CrossRef]

- Hu, M.; Tang, J.; Chen, X.-G.; Ye, N.; Zhao, X.-Y.; Xu, M.-M. Microstructure and properties of WC-12Co composite coatings prepared by laser cladding. Trans. Nonferrous Met. Soc. China 2020, 30, 1017–1030. [Google Scholar] [CrossRef]

- Mostajeran, A.; Shoja-Razavi, R.; Hadi, M.; Erfanmanesh, M.; Barekat, M.; Firouzabadi, M.S. Evaluation of the mechanical properties of WC-FeAl composite coating fabricated by laser cladding method. Int. J. Refract. Met. Hard Mater. 2020, 88, 105199. [Google Scholar] [CrossRef]

- Huang, F.; Xu, H.; Liu, W.; Zheng, S. Microscopic characteristics and properties of titaniferous compound reinforced nickel-based wear-resisting layer via in situ precipitation of plasma spray welding. Ceram. Int. 2018, 44, 7088–7097. [Google Scholar] [CrossRef]

- Boukantar, A.-R.; Djerdjare, B.; Guiberteau, F.; Ortiz, A.L. Spark plasma sinterability and dry sliding-wear resistance of WC densified with Co, Co+Ni, and Co+Ni+Cr. Int. J. Refract. Met. Hard Mater. 2020, 92, 105280. [Google Scholar] [CrossRef]

- Hua, N.; Zhang, X.; Liao, Z.; Hong, X.; Guo, Q.; Huang, Y.; Ye, X.; Chen, W.; Zhang, T.; Jin, X.; et al. Dry wear behavior and mechanism of a Fe-based bulk metallic glass: Description by Hertzian contact calculation and finite-element method simulation. J. Non-Cryst. Solids 2020, 543, 120065. [Google Scholar] [CrossRef]

- Itagaki, H.; Yachi, T.; Ogiso, H.; Sato, H.; Yamashita, Y.; Yasuoka, J.; Funada, Y. DC Arc Plasma Treatment for Defect Reduction in WC-Co Granulated Powder. Metals 2020, 10, 975. [Google Scholar] [CrossRef]

- Fu, W.; Chen, Q.-Y.; Yang, C.; Yi, D.-L.; Yao, H.-L.; Wang, H.-T.; Ji, G.-C.; Wang, F. Microstructure and properties of high velocity oxygen fuel sprayed (WC-Co)-Ni coatings. Ceram. Int. 2020, 46, 14940–14948. [Google Scholar] [CrossRef]

- Li, C.; Wang, H.; Ding, J.; Wang, S.; Li, J.; Kou, S. Effects of heat treatment on HVOF-sprayed Fe-based amorphous coatings. Surf. Eng. 2020. [Google Scholar] [CrossRef]

- Derakhshandeh, M.; Eshraghi, M.; Jam, A.; Rajaei, H.; Fazili, A. Comparative studies on corrosion and tribological performance of multilayer hard coatings grown on WC-Co hardmetals. Int. J. Refract. Met. Hard Mater. 2020, 92, 105339. [Google Scholar] [CrossRef]

- Ning, W.; Zhai, H.; Xiao, R.; He, D.; Liang, G.; Wu, Y.; Li, W.; Li, X. The Corrosion Resistance Mechanism of Fe-Based Amorphous Coatings Synthesised by Detonation Gun Spraying. J. Mater. Eng. Perform. 2020, 29, 3921–3929. [Google Scholar] [CrossRef]

- Ogino, Y.; Hirata, Y.; Asai, S. Discussion of the Effect of Shielding Gas and Conductivity of Vapor Core on Metal Transfer Phenomena in Gas Metal Arc Welding by Numerical Simulation. Plasma Chem. Plasma Process. 2020, 40, 1109–1126. [Google Scholar] [CrossRef]

- Shi, B.; Huang, S.; Zhu, P.; Xu, C.; Zhang, T. Microstructure and Wear Behavior of In-Situ NbC Reinforced Composite Coatings. Materials 2020, 13, 3459. [Google Scholar] [CrossRef] [PubMed]

- Stummer, M.; Stütz, M.; Aumayr, A.; Enzinger, N. Electron beam welding of copper using plasma spraying for filler metal deposition. Weld. World 2018, 62, 1341–1350. [Google Scholar] [CrossRef]

| Powder | C | Si | Mn | Cr | Mo | Ni | P | S | W | B | Fe | Co |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 42CrMo | 0.45 | 0.37 | 0.8 | 1.2 | 0.25 | 0.03 | 0.03 | 0.03 | -- | -- | rest | -- |

| Co-Based Alloy | 3.2 | 1.0 | 1.0 | 26.0 | -- | 22.5 | -- | -- | 5.0 | -- | 3.0 | rest |

| Fe-Based Amorphous Alloy | 1.7 | 1.8 | -- | 4.0 | -- | 7.5 | -- | -- | -- | 3.0 | rest | -- |

| Delivering Powder Gas Flow Rate (mL/min) | Plasma Gas Flow Rate (mL/min) | Feeding Voltage (V) | Standoff Distance (mm) | Powder Delivery Amount (g/min) | Current (A) | Bead Diameter (mm) |

|---|---|---|---|---|---|---|

| 400 | 300 | 20 | 10 | 20 | 125 | 2 |

| C | Si | Cr | Fe | Co | W | Ni | |

|---|---|---|---|---|---|---|---|

| 1 | 16.96 | 1.76 | 15.69 | 7.73 | 21.22 | 25.56 | 11.08 |

| 2 | 15.07 | -- | 22.42 | 8.98 | 36.09 | 2.21 | 15.23 |

| 3 | 19.21 | 2.93 | 14.94 | 9.59 | 20.79 | 22.96 | 9.58 |

| 4 | 17.74 | -- | 19.7 | 10.61 | 35.15 | 2.05 | 14.75 |

| C | Si | Cr | Fe | Co | W | Ni | |

|---|---|---|---|---|---|---|---|

| 1 | 45.62 | -- | -- | -- | -- | 54.38 | -- |

| 2 | 17.31 | 2.03 | 14.24 | 8.29 | 19.4 | 28.52 | 10.21 |

| 3 | 15.25 | 1.26 | 12.02 | 26.59 | 18.71 | 17.69 | 8.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Wang, Y.; Xu, Y.; Li, M.; Hu, Z. Microscopic Characteristics and Properties of Fe-Based Amorphous Alloy Compound Reinforced WC-Co-Based Coating via Plasma Spray Welding. Processes 2021, 9, 6. https://doi.org/10.3390/pr9010006

Xu Y, Wang Y, Xu Y, Li M, Hu Z. Microscopic Characteristics and Properties of Fe-Based Amorphous Alloy Compound Reinforced WC-Co-Based Coating via Plasma Spray Welding. Processes. 2021; 9(1):6. https://doi.org/10.3390/pr9010006

Chicago/Turabian StyleXu, Yan, Yinfeng Wang, Yi Xu, Mingyong Li, and Zheng Hu. 2021. "Microscopic Characteristics and Properties of Fe-Based Amorphous Alloy Compound Reinforced WC-Co-Based Coating via Plasma Spray Welding" Processes 9, no. 1: 6. https://doi.org/10.3390/pr9010006

APA StyleXu, Y., Wang, Y., Xu, Y., Li, M., & Hu, Z. (2021). Microscopic Characteristics and Properties of Fe-Based Amorphous Alloy Compound Reinforced WC-Co-Based Coating via Plasma Spray Welding. Processes, 9(1), 6. https://doi.org/10.3390/pr9010006