Modifying Effects of Physical Processes on Starch and Dietary Fiber Content of Foodstuffs

Abstract

1. Introduction

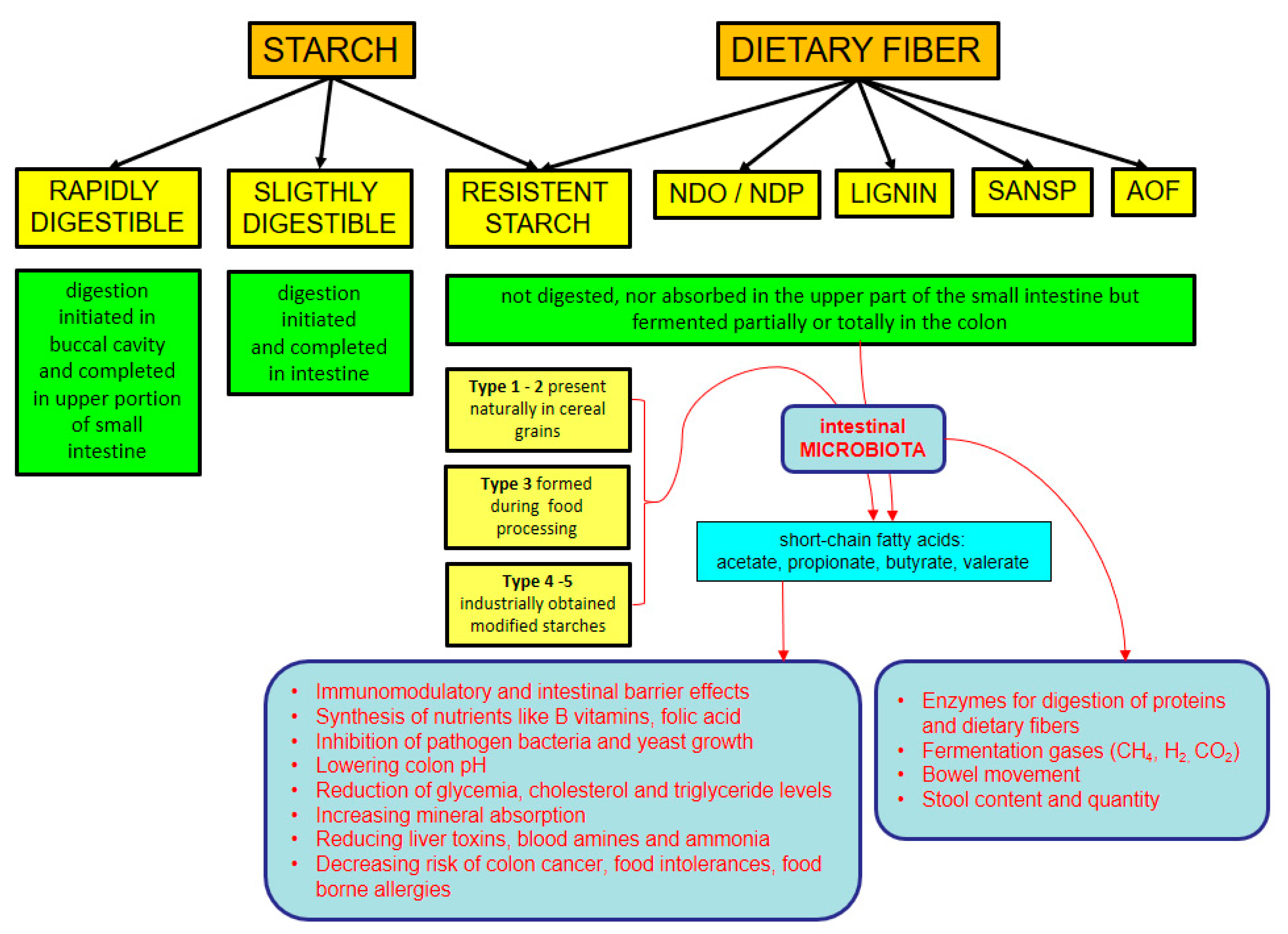

2. Role of Carbohydrates in Nutrition and Food Processing

3. The Modification of Carbohydrates and Their Properties

3.1. Size Reduction

3.2. Heat Treatment

3.3. High Pressure and Its Combination with Heat Treatment

3.4. Extrusion

3.5. Atmospheric and Cold Plasma

3.6. Radiation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aktas-Akyldiz, E.; Masatcioglu, M.T.; Köksel, H. Effect of extrusion treatment on enzymatic hydrolysis of wheat bran. J. Cereal Sci. 2020, 93, 102941. [Google Scholar] [CrossRef]

- Arslan, M.; Rakha, A.; Xiaobo, Z.; Mahmod, M.A. Complimenting gluten free bakery products with dietary fiber: Opportunities and constraints. Trends Food Sci. Technol. 2018, 83, 194–202. [Google Scholar] [CrossRef]

- Coda, R.; Katinka, K.; Rizello, C.G. Bran bioprocessing for enhanced functional properties. Curr. Opin. Food Sci. 2015, 1, 50–55. [Google Scholar] [CrossRef]

- Tian, S.; Sun, Y. Influencing factor of resistant starch formation and application in cereal products: A review. Int. J. Biol. Macromol. 2018, 149, 424–431. [Google Scholar] [CrossRef]

- Kaur, B.; Ariffin, F.; Bhat, R.; Karim, A.A. Progress in starch modification in the last decade. Food Hydrocoll. 2012, 26, 398–404. [Google Scholar] [CrossRef]

- Chen, X.; Luo, J.; Fu, L.; Cai, D.; Lu, X.; Liang, Z.; Zhua, J.; Lia, L. Structural, physicochemical, and digestibility properties of starch-soybean peptide complex subjected to heat moisture treatment. Food Chem. 2019, 297, 124957. [Google Scholar] [CrossRef]

- Al-Laham, S.H.; Peppelenbosch, M.P.; Roelofsen, H.; Vonk, R.J.; Venema, K. Biological effects of propionic acid in humans, metabolism potential applications and underlying mechanism. Biochim. Biophys. Acta 2010, 1801, 1175–1183. [Google Scholar] [CrossRef]

- Tungland, B.C.; Meyer, D. Nondigestible oligo- and polysaccharides (dietary fiber): Their physiology and role in human health and Food. Compr. Rev. Food Sci. Food Saf. 2002, 3, 90–109. [Google Scholar] [CrossRef]

- Bhise, S.; Kaur, A. Synergetic effect of polyols and fibres on baking, sensory and textural quality of bread with improved shelf life. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 1–12. [Google Scholar] [CrossRef]

- Chu, J.; Zhao, H.; Lu, Z.; Lu, F.; Bie, X.; Zhang, C. Improved physicochemical and functional properties of dietary fiber from millet bran fermented by Bacillus natto. Food Chem. 2019, 294, 79–86. [Google Scholar] [CrossRef]

- Marco, C.; Rosell, C.M. Breadmaking performance of protein enriched, gluten-free breads. Eur. Food Res. Technol. 2008, 227, 1205–1213. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y. Physicochemical and functional properties of coconut [Cocos nucifera L] cake dietary fibres: Effects of cellulase hydrolysis, acid treatment and particle size distribution. Food Chem. 2018, 257, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Peerjait, P.; Chiwchan, N.; Dehavastin, S. Effects of pretreatment methods on health-related functional properties of high dietary fibre powder from lime residues. Food Chem. 2012, 132, 1891–1898. [Google Scholar] [CrossRef]

- Botham, R.L.; Ryden, P.; Robertson, J.A.; Ring, S.G. Structural features of polysaccharides and their influence on fermentation behavior. In Functional Properties of Nondigestible Carbohydrates; Guillon, F., Ed.; INRA: Nantes, France, 1998; pp. 46–49. [Google Scholar]

- Slavin, J. Fiber and prebiotics: Mechanisms and health benefits. Nutrients 2013, 5, 1417–1435. [Google Scholar] [CrossRef] [PubMed]

- Rowland, I.R.; Rumney, C.J.; Coutts, J.T.; Lievense, L.C. Effect of Bifidobacterium longum and inulin on gut bacterial metabolism and carcinogen-induced aberrant crypt foci in rats. Carcinogenesis 1998, 19, 281–285. [Google Scholar] [CrossRef]

- Louis, P.; Hold, G.L.; Flint, H.J. The gut microbiota, bacterial metabolites and colorectal cancer. Nat. Rev. Microbiol. 2014, 12, 661–672. [Google Scholar] [CrossRef]

- Brownlee, I.A. The physiological roles of dietary fibre. Food Hydrocoll. 2011, 25, 238–250. [Google Scholar] [CrossRef]

- Makarem, N.; Scott, M.; Quatromoni, P.; Jacques, P.; Parekh, N. Trends in dietary carbohydrate consumption from 1991 to 2008 in the Framingham Heart Study Offspring Cohort. Br. J. Nutr. 2014, 111, 2010–2023. [Google Scholar] [CrossRef]

- El Khoury, D.; Balfour-Ducharme, S.; Joye, I.J. A review on the gluten-free diet: Technological and nutritional challenges. Nutrients 2018, 10, 1410. [Google Scholar] [CrossRef]

- Bonilla, J.C.; Erturk, M.Y.; Kokini, J.L. Understanding the role of gluten subunits [LMW, HMW glutenins and gliadin] in the networking behavior of a weak soft wheat dough and a strong semolina wheat flour dough and the relationship with linear and non-linear rheology. Food Hydrocoll. 2020, 108, 106002. [Google Scholar] [CrossRef]

- Kalichevsky, M.T.; Jaroszkiewicz, E.M.; Blanshard, J.M.V. Glass transition of gluten 1: Gluten and gluten–sugar mixtures. Int. J. Biol. Macromol. 1992, 14, 257–266. [Google Scholar] [CrossRef]

- Wang, P.; Zhengyu, J.; Xu, X. Physicochemical alterations of wheat gluten proteins upon dough formation and frozen storage. A review from gluten, glutenin and gliadin perspectives. Trends Food Sci. Technol. 2015, 46, 189–198. [Google Scholar] [CrossRef]

- Csapó, J.; Csapóné, K.Z. Élelmiszer-Kémia; Mezőgazda Kiadó: Budapest, Hungary, 2003; p. 468. [Google Scholar]

- Ojogbo, E.; Ogunsona, E.O.; Mekkonen, T.H. Chemical and physical modifications of starch for renewable polymeric materials. Mater. Today Sustain. 2020, 7–8, 100028. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Jackson, D.S. Chapter 5 Starch Gelatinization. Adv. Food Nutr. Res. 2008, 55, 221–268. [Google Scholar]

- Zheng, X.; Li, L.; Wang, X. Molecular characterization of arabinoxylans from hull-less barley milling fractions. Molecules 2011, 16, 2743–2753. [Google Scholar] [CrossRef]

- Farooq, Z.; Boye, J.I. Novel food and industrial applications of pulse flours and fractions. In Pulse Foods: Processing, Quality and Nutraceutical Applications; Academic Press: London, UK, 2011; pp. 283–323. [Google Scholar]

- Prückler, M.; Siebenhandl-Ehn, S.; Apprich, S.; Höltinger, S.; Haas, C.; Schmid, E.; Kneifel, W. Wheat bran-based biorefinery. 1: Composition of wheat bran and strategies of functionalization. LWT 2013, 56, 211–221. [Google Scholar] [CrossRef]

- Van Craeyveld, V.; Holopainen, U.; Selinheimo, E.; Poutanen, K.; Delcour, J.A.; Courtin, C.M. Extensive dry ball milling of wheat and rye bran leads to in situ production of arabinoxylan oligosaccharides through nanoscale fragmentation. J. Agric. Food Chem. 2009, 57, 8467–8473. [Google Scholar] [CrossRef] [PubMed]

- Noort, M.W.J.; van Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R.J. The effect of particle size of wheat bran fractions on bread quality—Evidence for fibre-protein interactions. J. Cereal Sci. 2010, 52, 59–64. [Google Scholar] [CrossRef]

- Chen, J.S.; Fei, M.J.; Shi, C.L.; Tian, C.J.; Sun, C.L.; Zhang, H.; Ma, Z.; Dong, H.X. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 2011, 53, 217–224. [Google Scholar] [CrossRef]

- Zhang, D.; Moore, W. Wheat bran particle size effects on bread baking performance and quality. J. Sci. Food Agric. 1999, 79, 805–809. [Google Scholar] [CrossRef]

- Coda, R.; Kärki, I.; Nordlund, E.; Heiniö, R.-J.; Poutanen, K.; Katina, K. Influence of particle size on bioprocess induced changes on technological functionality of wheat bran. Food Microbiol. 2014, 37, 69–77. [Google Scholar] [CrossRef]

- Bucsella, B.; Takács, Á.; Reding, W.; Schwendener, U.; Kálmán, F.; Tömösközi, S. Rheological and stability aspects of dry and hydrothermally heat treated aleurone-rich wheat milling fraction. Food Chem. 2017, 220, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Zhengbiao, G.U. Morphology of modified starches prepared by different methods. Food Res. Int. 2010, 43, 767–772. [Google Scholar] [CrossRef]

- Chi, C.; Li, X.; Lu, P.; Miao, S.; Zhang, Y.; Chen, L. Dry heating and annealing treatment synergistically modulate starch structure and digestibility. Int. J. Biol. Macromol. 2019, 137, 554–561. [Google Scholar] [CrossRef]

- Marston, K.; Khouryieh, H.; Aramouni, F. Effect of heat treatment of sorghum flour on the functional properties of gluten-free bread and cake. LWT 2016, 65, 637–644. [Google Scholar] [CrossRef]

- Padalino, L.; Caliandro, R.; Chita, G.; Conte, A.; Del Nobile, M.A. Study of drying process on starch structural properties and their effect on semolina pasta sensory quality. Carbohydr. Polym. 2016, 153, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-X.; Liu, H.-M.; Fan, L.-Y.; Qin, G.-Y.; Wang, X.-D. Effect of various drying pretreatments on the structural and functional properties of starch isolated from Chinese yam [Dioscorea opposita Thumb.]. Int. J. Biol. Macromol. 2019, 153, 1299–1309. [Google Scholar] [CrossRef] [PubMed]

- Colussi, R.; Kringel, D.; Kaur, L.; Zavareze, E.R.; Dias, A.R.G.; Singh, J. Dual modification of potato starch: Effects of heat-moisture and high pressure treatments on starch structure and functionalities. Food Chem. 2020, 318, 126475. [Google Scholar] [CrossRef] [PubMed]

- Cahyana, Y.; Wijaya, E.; Halimah, T.S.; Marta, H.; Suryadi, E.; Kurniati, D. The effect of different thermal modifications on slowly digestible starch and physicochemical properties of green banana flour [Musa acuminata colla]. Food Chem. 2019, 274, 274–280. [Google Scholar] [CrossRef]

- Huang, T.-T.; Zhou, D.-N.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Effect of debranching and heat-moisture treatments on structural characteristics and digestibility of sweet potato starch. Food Chem. 2015, 187, 218–224. [Google Scholar] [CrossRef]

- Hung, V.P.; Binh, T.V.; Nhi, Y.H.P.; Phi, L.T.N. Effect of heat-moisture treatment of unpolished red rice on its starch properties and in vitro and in vivo digestibility. Int. J. Biol. Macromol. 2020, 154, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zara, M.; Collins, S.A.R.; Elliston, A.; Wilson, D.R.; Käsper, A.; Waldron, K.W. Characterization of cell wall components of wheat bran following hydrothermal pretreatment and fractionation. Biofuels 2015, 8, 23. [Google Scholar]

- Nandeesh, K.; Jyotsana, R.; Rao, G.V. Effect of differently treated wheat bran on rheology, microstructure and quality characteristics of soft dough biscuits. J. Food Process. Preserv. 2011, 35, 179–200. [Google Scholar] [CrossRef]

- Nyström, L.; Lampi, M.-A.; Rita, H.; Aura, A.-M.; Oksman-Caldentey, K.-M.; Piironen, V. Effects of processing on availability of total plant sterols, steryl ferulates and steryl glycosides from wheat and rye bran. J. Agric. Food Chem. 2007, 55, 9059–9065. [Google Scholar] [CrossRef]

- Aktas-Akyldiz, E.; Matilla, O.; Sozer, N.; Poutanen, K.; Köksel, H.; Nordlund, E. Effect of steam explosion on enzymatic hydrolysis and baking quality of wheat bran. J. Cereal Sci. 2017, 78, 25–32. [Google Scholar] [CrossRef]

- Wang, S.; Liu, C.; Wang, S. Drying methods used in starch isolation change properties of C-type chestnut [Castanea mollissima] starches. LWT 2016, 73, 663–669. [Google Scholar] [CrossRef]

- Han, Z.; Shi, R.; Sun, D.-W. Effects of novel physical processing techniques on the multi-structures of starch. Trends Food Sci. Technol. 2020, 97, 126–135. [Google Scholar] [CrossRef]

- Dupuis, J.H.; Liu, Q.; Yada, R.Y. Methodologies for increasing the resistant starch content of food starches: A review. Compr. Rev. Food Sci. Food Saf. 2014, 13, 1219–1234. [Google Scholar] [CrossRef]

- Singh, A.; Raigond, P.; Lal, M.K.; Singh, B.; Thakur, N.; Changan, S.S.; Kumar, D.; Dutt, S. Effect of cooking methods on glycemic index and in vitro bioaccessibility of potato [Solanum tuberosum L.] carbohydrates. LWT 2020, 127, 109363. [Google Scholar] [CrossRef]

- Bembem, K.; Sadana, B. Effect of cooking methods on the nutritional composition and antoixidant activity of potato tubers. Int. J. Food Sci. Nutr. 2013, 2, 26–30. [Google Scholar]

- Steiner, J.; Franke, K.; Kießling, M.; Fischer, S.; Töpfl, S.; Heinz, V.; Becker, T. Influence of hydrothermal treatment on the structura modification of spent grain specific carbohydrates and the formation of degradation products using model compounds. Carbohydr. Polym. 2018, 184, 315–322. [Google Scholar] [CrossRef]

- Pei-Ling, L.; Xiao-Song, H.; Qun, S. Effect of high hydrostatic pressure on starches: A review. Starke 2010, 62, 615–628. [Google Scholar] [CrossRef]

- Zavareze, R.E.; Pinto, Z.V.; Klein, B.; El Halal, M.L.S.; Elias, C.M.; Prentice-Hernández, C.; Dias, G.R.A. Development of oxidised and heat–moisture treated potato starch film. Food Chem. 2012, 132, 344–350. [Google Scholar] [CrossRef]

- Liu, H.; Fan, H.; Cao, R.; Blanchard, C.; Wang, M. Physicochemical properties and in vitro digestibility of sorghum starch altered by high hydrostatic pressure. Int. J. Biol. Macromol. 2016, 92, 753–760. [Google Scholar] [CrossRef]

- Sun, B.; Rahman, M.M.; Tar’an, B.; Yu, P. Determine effect of pressure heating on carbohydrate related molecular structures in association with carbohydrate metabolic profiles of cool-climate chickpeas using globar spectroscopy. Spectrochim. Acta A 2018, 201, 8–18. [Google Scholar] [CrossRef]

- Santala, O.; Kiran, A.; Sozer, N.; Poutanen, K.; Nordlund, E. Enzymatic modification and particle size reduction of wheat bran improves the mechanical properties and structure of bran-enriched expanded extrudates. J. Cereal Sci. 2014, 60, 448–456. [Google Scholar] [CrossRef]

- Yan, X.; Wu, Z.-Z.; Li, Y.-L.; Yin, F.; Ren, K.-X.; Tao, H. The combined effects of extrusion and heat-moisture treatment on the physicochemical properties and digestibility of corn starch. Int. J. Biol. Macromol. 2019, 134, 1109–1112. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Wu, J.; Luo, S.; Chen, R.; Liu, C.; Gilbert, R.G. Modification of retrogradation property of rice starch by improved extrusion cooking technology. Carbohydr. Polym. 2019, 213, 192–198. [Google Scholar] [CrossRef]

- Yousefi, A.R.; Razavi, S.M.A. Steady shear flow behavior and thixotropy of wheat starch gel: Impact of chemical modification, concentration and saliva addition. J. Food Process Eng. 2016, 39, 31–43. [Google Scholar] [CrossRef]

- Fang, F.; Martinez, M.M.; Campanella, O.H.; Hamaker, B.R. Long-term low shear-induced highly viscous waxy potato starch gel formed through intermolecular double helices. Carbohydr. Polym. 2020, 232, 115815. [Google Scholar] [CrossRef]

- Bailoni, L.; Mantovani, R.; Pagnin, G.; Schiavon, S. Effects of physical treatments on the resistant starch content and in vitro organic matter digestibility of different cereals in horses. Livest. Sci. 2006, 100, 14–17. [Google Scholar] [CrossRef]

- Al-Loman, A.; Ju, L.-K. Enzyme-based processing of soybean carbohydrate: Recent developments and future prospects. Enzyme Microb. Technol. 2017, 106, 35–47. [Google Scholar] [CrossRef]

- Misra, N.N.; Yadav, B.; Roopesh, M.S.; Jo, C. Cold plasma for effective fungal and mycotoxin control in foods: Mechanisms, inactivation effects, and applications. Compr. Rev. Food Sci. Food Saf. 2019, 18, 106–120. [Google Scholar] [CrossRef]

- Zhou, Y.; Yan, Y.; Shi, M.; Liu, Y. Effect of an atmospheric pressure plasma jet on the structure and physicochemical properties of waxy and normal maize starch. Polymers 2019, 11, 8. [Google Scholar] [CrossRef]

- Thirumdas, R.; Deshmuk, R.R.; Annapure, U.S. Effect of low temperature plasma on the functional properties of basmati rice flour. J. Food Sci. Terchnol. 2016, 53, 2742–2751. [Google Scholar] [CrossRef]

- Thirumdas, R.; Trimukhe, A.; Deshmuk, R.R.; Annapure, U.S. Functional and rheological properties of cold plasma treated rice starch. Carbohydr. Polym. 2017, 157, 1723–1731. [Google Scholar] [CrossRef]

- Okyere, A.Y.; Bertoft, E.; Annor, G.A. Modification of cereal and tuber waxy starches with radio frequency cold plasma and its effects on waxy starch properties. Carbohydr. Polym. 2019, 223, 115075. [Google Scholar] [CrossRef]

- Banura, S.; Thirumdas, R.; Kaur, A.; Deshmuk, R.R.; Annapure, U.S. Modification of starch using low pressure radio frequency air plasma. LWT 2017, 89, 719–724. [Google Scholar] [CrossRef]

- Held, S.; Tyl, C.E.; Annor, G.A. Effect of radio frequency cold plasma treatment on intermediate wheatgrass [Thinopyrum intermedium] flour and dough properties in comparison to hard and soft wheat [Triticum aestivum L.]. J. Food Qual. 2019, 2019, 1085172. [Google Scholar] [CrossRef]

- Nguyễn, L.T.; Trinh, S.K. Structural, functional properties and in vitro digestibility of maize starch under heat-moisture and atmospheric cold plasma treatments. Vietnam J. Sci. Technol. 2018, 56, 751–760. [Google Scholar] [CrossRef]

- Scholtz, V.; Sera, B.; Khun, J.; Sery, M. Effects of nonthermal plasma on wheat grains and products. J. Food Qual. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Bahrami, N.; Bayliss, D.; Chope, G.; Penson, S.; Perehinec, T.; Fisk, I.D. Cold plasma: A new technology to modify wheat flour functionality. Food Chem. 2016, 202, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Polesi, L.F.; Sarmento, S.B.S.; de Moraes, J.; Franco, C.M.L.; Carniatti-Brazaca, G.S. Physicochemical and structural characteristics of rice starch modified by irradiation. Food Chem. 2016, 191, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.-H.; Othman, Z.; Lee, J.-S. Gamma irradiation of corn starches with different amylose-to-amylopectin ratio. J. Food Sci Technol. 2015, 52, 6218–6229. [Google Scholar] [CrossRef]

- Atrous, H.; Benbettaieb, N.; Chouaibi, M.; Attia, H.; Ghorbel, D. Changes in wheat and potato starches induced by gamma irradiation: A comparative macro and microscopic study. Int. J. Food Prop. 2015, 20, 1532–1546. [Google Scholar] [CrossRef]

- Brașoveanu, M.; Nemtanu, M.-R. Aspects on starches modified by ionizing radiation processing. In Applications of Modified Starches; Huicochea, E.F., Villalobos, R.R., Eds.; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Lewandowicz, G.; Jankowski, T.; Fornal, J. Effect of microwave radiation on physico-chemical properties and structure of cereal starches. Carbohdydr. Polym. 2000, 42, 193–199. [Google Scholar] [CrossRef]

- Shen, H.; Fan, D.; Huang, L.; Gao, Y.; Lian, H.; Zhao, J.; Zhang, H. Effects of microwaves on molecular arrangements in potato starch. RSC Adv. 2017, 7, 14348–14353. [Google Scholar] [CrossRef]

- Román, L.; Martínez, M.M.; Rosell, C.M.; Gómez, M. Effect of microwave treatment on physicochemical properties of maize flour. Food Bioprocess Technol. 2015, 8, 1330–1335. [Google Scholar] [CrossRef]

- Kurdziel, M.; Labanowska, M.; Pietrzyk, S.; Sobolewska-Zielínska, J.; Michalec, M. Changes in the physicochemical properties of barley and oat starches upon the use of environmentally friendly oxidation methods. Carbohydr. Polym. 2019, 210, 339–349. [Google Scholar] [CrossRef]

- Nawaz, H.; Waheed, R.; Nawaz, M.; Shahwar, D. Physical and chemical modifications in starch structure and reactivity. In Chemical Properties of Starch; Emeje, M., Ed.; IntechOpen Ltd.: London, UK, 2020. [Google Scholar] [CrossRef]

- Bajer, D.; Kaczmarek, H.; Bajer, K. The structure and properties of different types of starch exposed to UV radiation: A comparative study. Carbohydr. Polym. 2013, 98, 477–482. [Google Scholar] [CrossRef]

- Vatanasuchart, N.; Naivikul, O.; Charoenrein, S.; Sriroth, K. Molecular properties of cassava starch modified with different UV irradiations to enhance baking expansion. Carbohydr. Polym. 2005, 61, 80–87. [Google Scholar] [CrossRef]

- Franco, C.M.L.; Ogawa, C.; Rabachini, T.; Rocha, T.S.; Cereda, M.P.; Jane, J.-L. Effect of lactic acid and UV irradiation on the cassava and corn starches. Braz. Arch. Biol. Technol. 2010, 53, 443–454. [Google Scholar] [CrossRef]

- Peyron, S.; Abecassis, J.; Autran, J.-C.; Rouau, X. Influence of UV exposure on phenolic acid content, mechanical properties of bran, and milling behavior of durum wheat [Triticum Durum Desf.]. Cereal Chem. 2002, 79, 726–731. [Google Scholar] [CrossRef]

- Reynolds, A.N.; Akerman, A.P.; Mann, J. Dietary fibre and whole grains in diabetes management: Systematic review and meta-analyses. PLoS Med. 2020, 17, e1003053. [Google Scholar] [CrossRef]

- Ocvirk, S.; Wilson, A.S.; Appolonia, C.N.; Thomas, T.K.; O’Keefe, S.J.D. Fiber, fat, and colorectal cancer: New insight into modifiable dietary risk factors. Curr. Gastroenterol. Rep. 2019, 21, 62. [Google Scholar] [CrossRef]

| Physical Processes | Effects on Carbohydrate Properties | |

|---|---|---|

| Size reduction | Increase in fiber solubility [27] | |

| Heat treatment | Superheating Heat moisture treatment Annealing Drying | Modified starch formation [5,28,29] Starch damage [30] Modification of resistant content formation [25,31,32] Starch complex formation [30,33,34,35] Increase in fiber solubility [36,37] Changes in the starch digestibility time [29,38] |

| Cooking, baking | Increase in the starch digestibility time [39] Change in glycemic index [39] | |

| Combined high temperature and pressure treatment | High hydrostatic pressure, autoclaving, steam explosion | Changes in resistant starch content [32,40] Fiber solubility increases [37] |

| Extrusion | Increase in starch solubility [41] Increase in resistant starch content [32,42] Increase in fiber solubility [1,43] | |

| Cold plasma treatment | Increase in resistant starch content [44,45,46] | |

| Radiation | Changes in amylose–amylopectin ratios [47,48,49] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagy, R.; Máthé, E.; Csapó, J.; Sipos, P. Modifying Effects of Physical Processes on Starch and Dietary Fiber Content of Foodstuffs. Processes 2021, 9, 17. https://doi.org/10.3390/pr9010017

Nagy R, Máthé E, Csapó J, Sipos P. Modifying Effects of Physical Processes on Starch and Dietary Fiber Content of Foodstuffs. Processes. 2021; 9(1):17. https://doi.org/10.3390/pr9010017

Chicago/Turabian StyleNagy, Róbert, Endre Máthé, János Csapó, and Péter Sipos. 2021. "Modifying Effects of Physical Processes on Starch and Dietary Fiber Content of Foodstuffs" Processes 9, no. 1: 17. https://doi.org/10.3390/pr9010017

APA StyleNagy, R., Máthé, E., Csapó, J., & Sipos, P. (2021). Modifying Effects of Physical Processes on Starch and Dietary Fiber Content of Foodstuffs. Processes, 9(1), 17. https://doi.org/10.3390/pr9010017