2.1. Experimental Setup and Devices

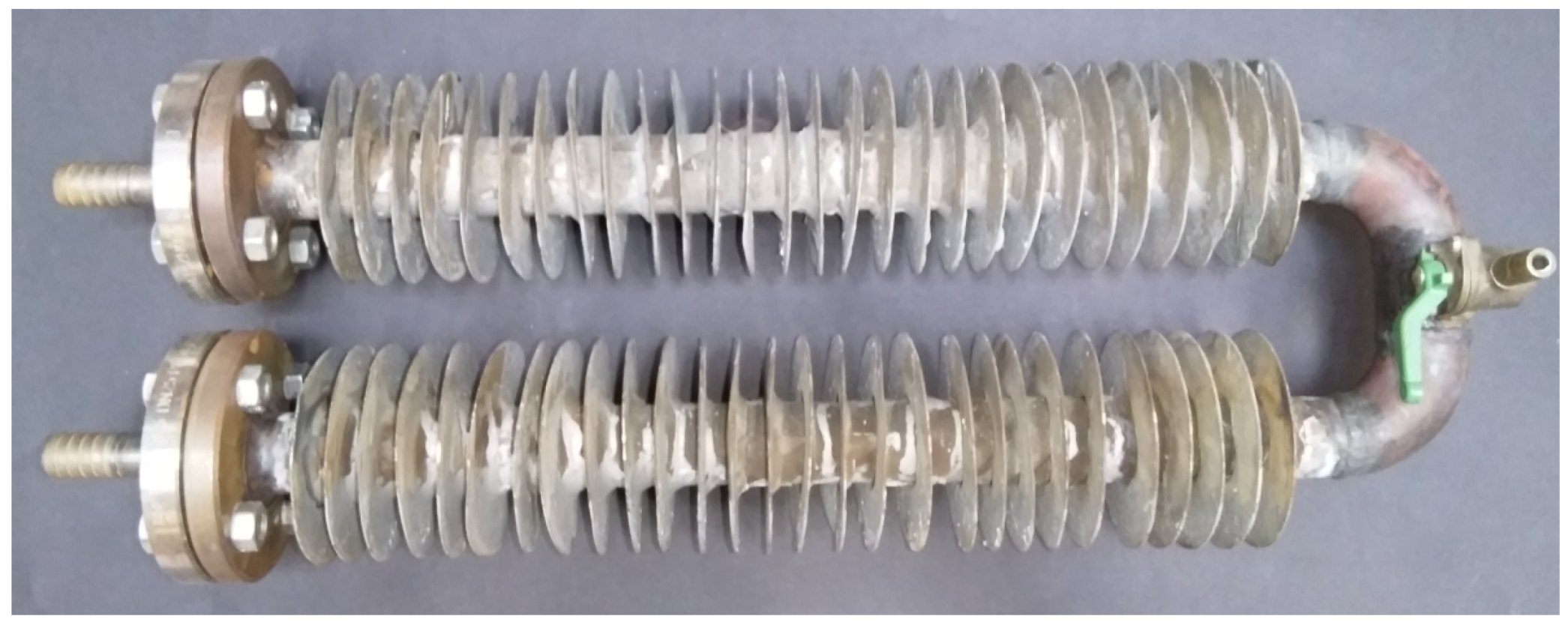

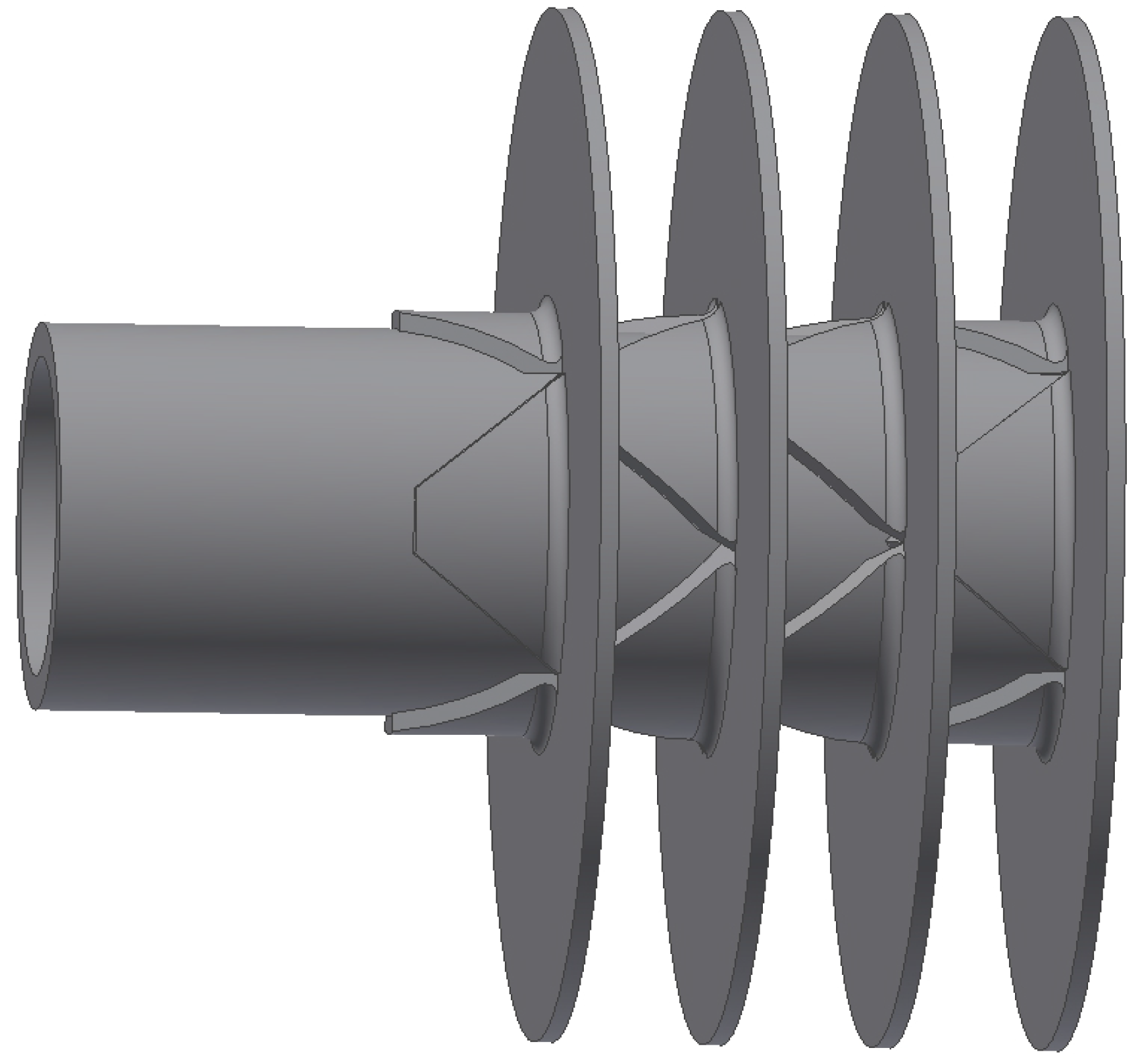

The investigated finned tube heat exchanger shown in

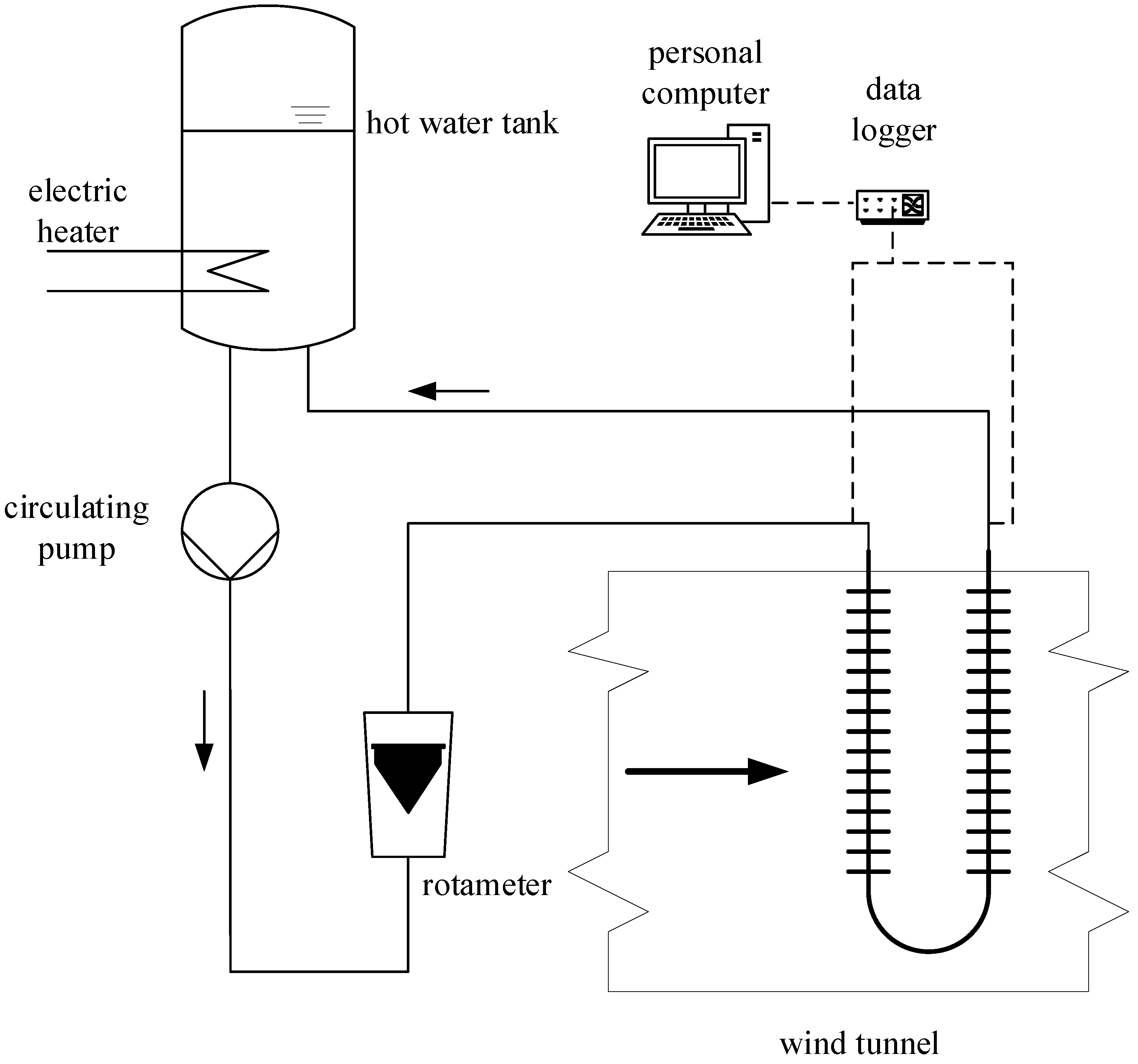

Figure 1. The 80-l hot water tank heated by electricity produces and stores the hot fluid. The hot fluid was water, and its temperature was 60

C. This hot fluid is circulated by a pump in a 3/4

hoses and flows through a rota-meter, which detects the volume flow rate. After the rotameter fluid goes through the heat exchanger. Exiting the heat exchanger, the cooled liquid returns to the water tank. The experimental setup is shown in

Figure 2.

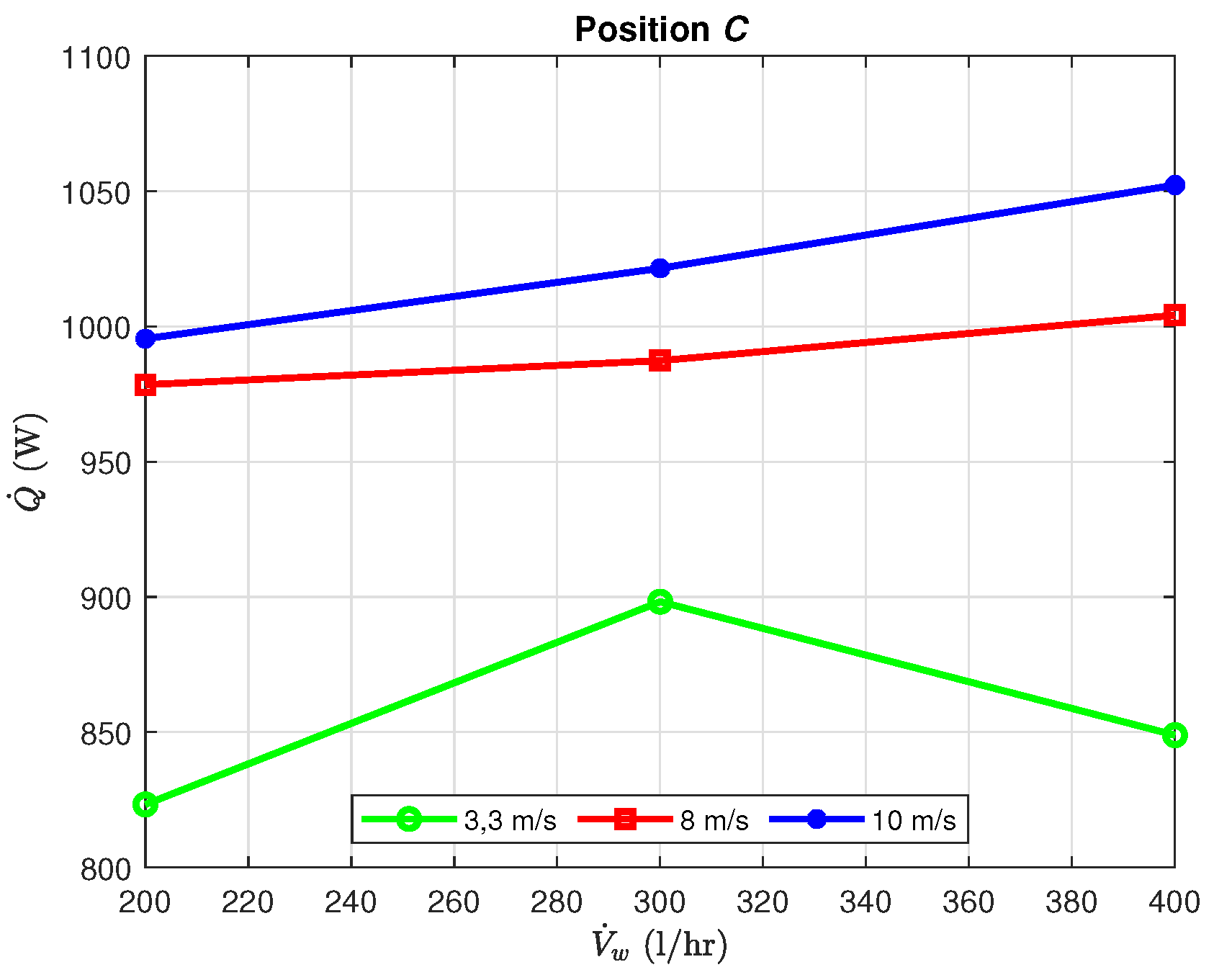

The tube register was placed in a wind tunnel. A Quantum X type MX1609 thermocouple amplifier with type K thermocouples was used for data collection. Two temperatures were measured: the inlet and outlet temperatures of the heat exchanger with 5 Hz sampling rate. Data processing was done with catman® Easy software (2006 by Hottinger Baldwin Messtechnik GmbH, Darmstad, Germany).

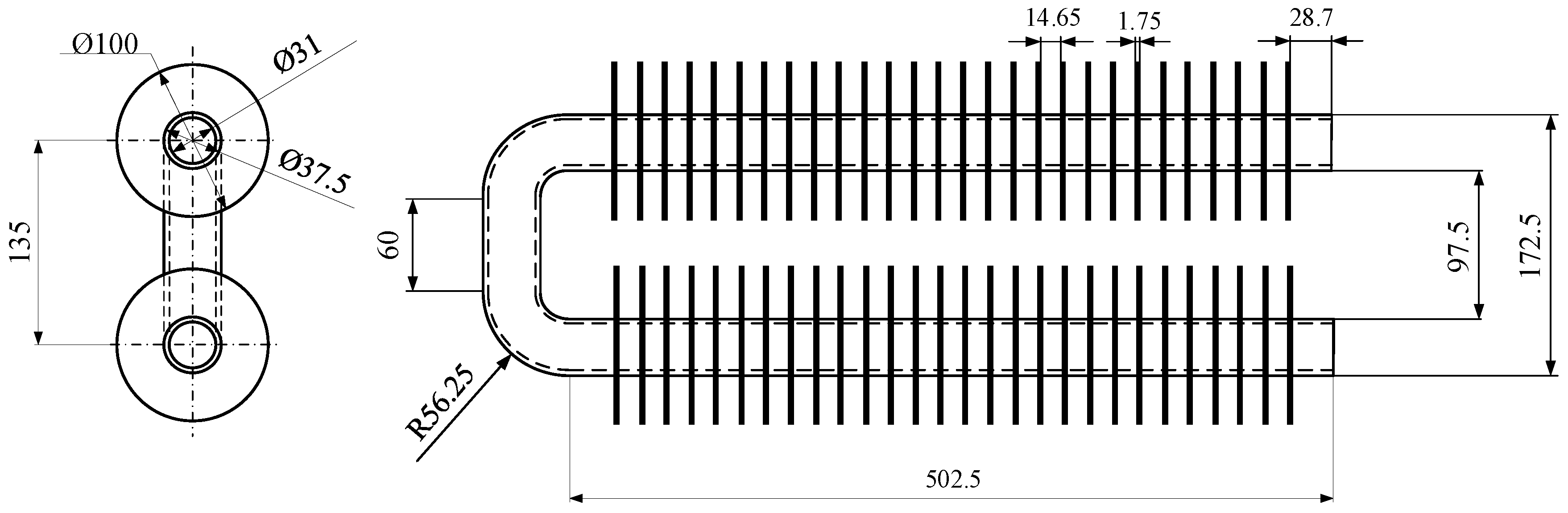

The design and dimensions of the heat exchanger are shown in

Figure 3. The tube and the fins were made of carbon steel. Later in the calculations, referring to literature and standard data, the heat conductivity was assumed to be 54 W/mK (according to EN 1993-1-2:2005, for carbon steel). The inner and outer diameters of the tube were

= 31 mm and

= 37.5 mm respectively; the length of the tube was

L = 502.5 mm. The thickness of the fins was

= 1.75 mm, the diameter of the fins was

D = 100 mm and the space between the fins was

= 14.65 mm.

In case of finned tube heat exchangers, several heat transfer surfaces must be defined. Different dimensionless numbers depend on the ratios of these surfaces that are summarized in

Table 1.

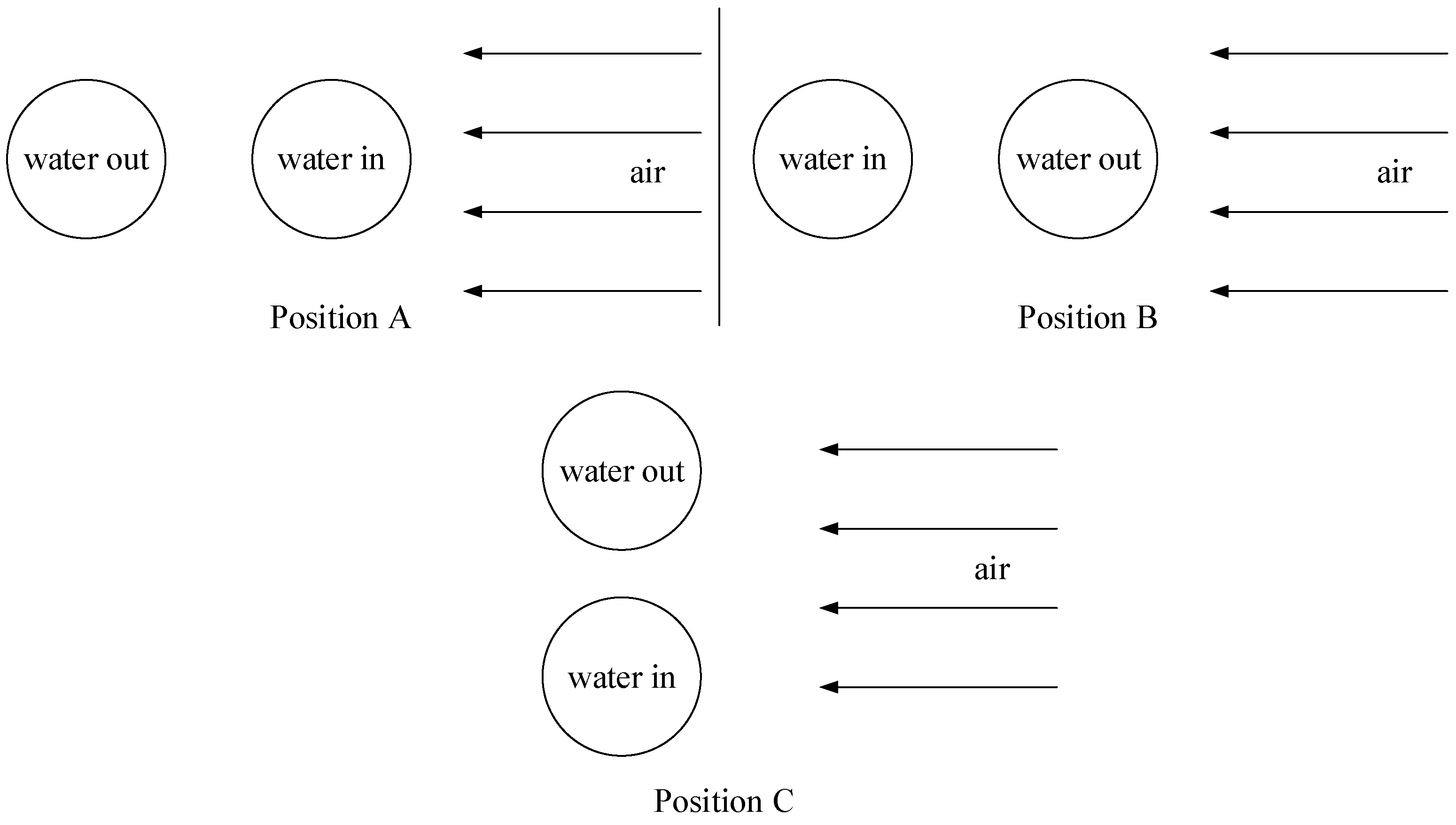

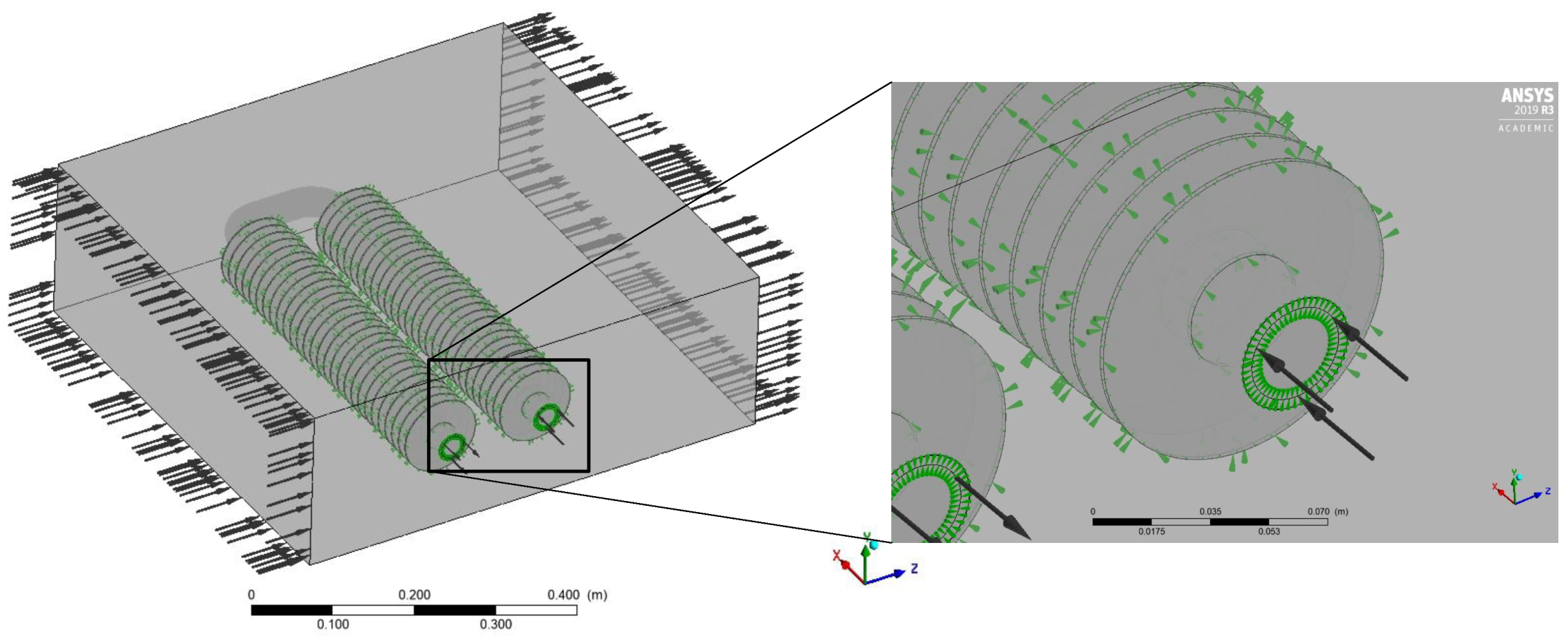

The heat exchanger was placed in three different orientations relative to the air flow, which are shown in

Figure 4. Because the air flows perpendicularly to the water in all positions, the cases have been distinguished on the basis of the resulting temperature difference. This difference will be the highest in case of position A and the lowest in case of position B.

2.2. Measurements

As presented in the abstract, the heat exchanger was investigated in three different positions. The volume flow rate of the hot fluid was changed between 100 and 450 L/h (which means fluid velocities of 0.037 m/s and 0.166 m/s respectively), while the velocity of air was changed between 3.3 and 10 m/s. The volume of the tank was large enough not to affect the measurements. In all cases, steady state was expected before the measurements begun. As a result, the smallest possible change in temperature was observed during the study period. The uncertainty in the calculations was based on the standard deviation, and its formula is

where

are the measured values,

is the mean value of those measurements and

N is the number of investigated datums. The calculation procedure was as follows: from the measured data (temperatures, volume flow rate), the surface of the heat exchanger and the specific heat at the medium temperature, the amount of heat performance can be determined by the following equation.

where

and

are the measured inlet and outlet temperatures of the hot water,

is the mass flow rate and

is the average specific heat of the water, which is the arithmetic mean of the inlet and outlet temperatures. The

can be calculated from the volume flow rate and the density. These material properties, supplemented by viscosity and thermal conductivity, vary with temperature and pressure. During the measurements, the pressure did not change; its value was 1 bar

overpressure, so the material properties only depend on the temperature, as is shown in Equation (

3).

where values of

a are constants for water are in

Table 2.

Similarly to the water, the material properties of the air also change in the function of temperature and pressure. However in the wind tunnel, the pressure is ambient (0 bar

), so the relationships are the following:

where the

b constants for air are

The material properties calculated by Equations (

3) and (

4) with coefficients in

Table 2 and

Table 3 have the following dimensions,

density is kg/m;

dynamic viscosity is Pa·s;

thermal conductivity is W/(mK);

specific heat (for constant pressure) is J/(kgK).

Equations (

3) and (

4) were prepared by the authors based on UniSim Design (Honeywell International Inc., Charlotte, NC, USA, 2020) process flow simulator data, where the unit of the temperature is

C.

In a fully developed steady state condition, it can be assumed that the heat performance given off by the water is absorbed by the air.

where the outlet temperature of air (

) can be calculated. The outlet temperature can be neglected since a relatively large amount of air flows in the wind tunnel.

The relationship between the heat performance of heat exchangers is known:

where

A is the total heat transfer area (from

Table 1); the

is the logarithmic mean temperature difference (LMTD) of the inlet and outlet temperatures. The only unknown value is the overall heat transfer coefficient, which was derived from Equations (

2) and (

6):

The aim of this present study is to compare the heat transfer coefficients from experimental, numerical and empirical relationships, and to develop a generally applicable relationship for this type of finned tube heat exchanger.

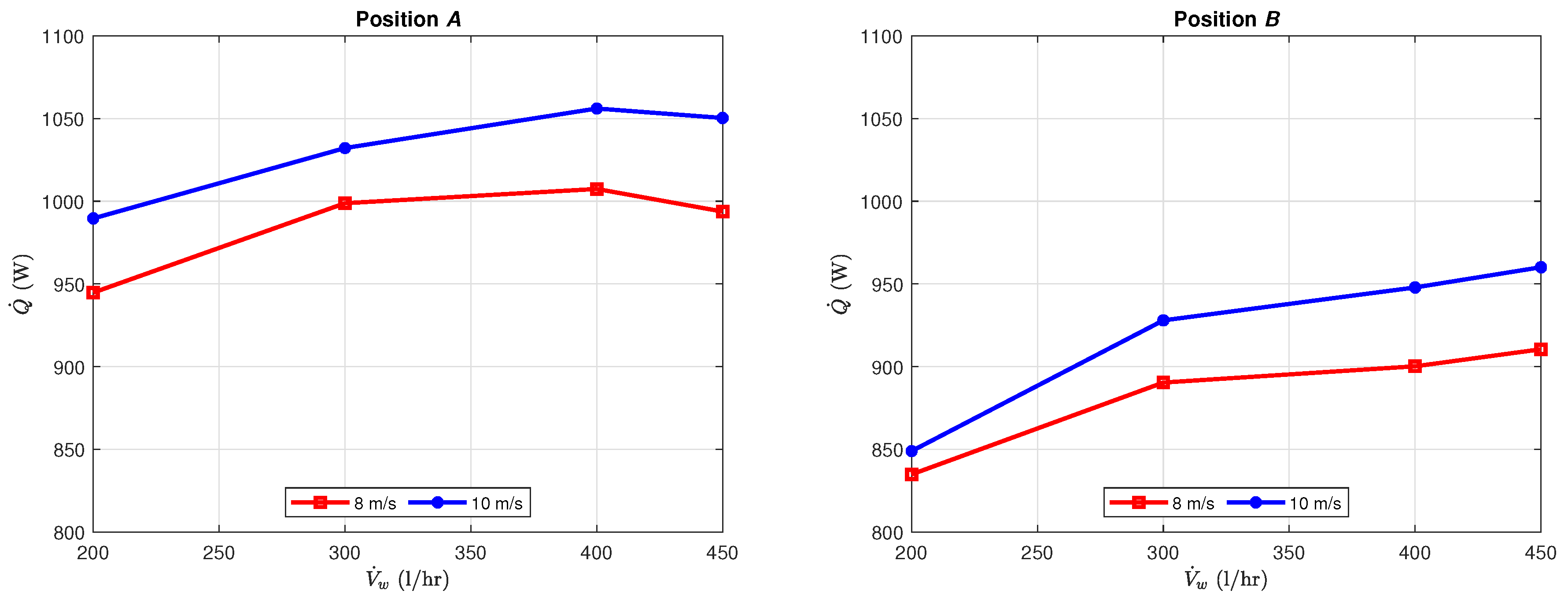

Figure 5 shows the results of the measurements. In every case, the measurement took two minutes after the steady state with a 5 Hz sample rate in positions A, B and C, as shown in

Figure 4. The graphs show that in positions A, when the higher temperature water comes into contact with the air first, the heat performance will be a higher than in position B. This is explained by the fact that at this position the temperature difference (LMTD), in other words the driving force, will be larger. The heat performances experienced in the cross-current case (position C) are roughly the same as in the quasi-counter current case (position A).

Table 4,

Table 5 and

Table 6 show the measured values and the standard deviation:

for the inlet temperature,

for the outlet temperature and

for the temperature difference:

The measured values (

,

) in

Table 4,

Table 5 and

Table 6 are the average temperatures during the measurements in stationary state, and the standard deviations calculated with Equation (

1).

According to the measured values it can be seen that the biggest temperature difference was reached in the case of position A, and the heat performance of position C is relatively close to it.