Thermal and Fluid Dynamic Performance Comparison of Three Nanofluids in Microchannels Using Analytical and Computational Models

Abstract

1. Introduction

2. Materials and Methods

2.1. Properties of Materials

2.1.1. Base Fluid Properties

2.1.2. Nanofluid Properties

| Particle | Diameter (nm) | Density (kg/m3) | Specific Heat (J/kg∙K) | Thermal Conductivity (W/m∙K) |

|---|---|---|---|---|

| Al2O3 | 45 [5] | 3600 [5] | 765 [19] | 36.0 [5] |

| CuO [20] | 29 | 6500 | 533 | 17.65 |

| SiO2 [19] | 20 | 2220 | 745 | 1.38 |

Density

Specific Heat

Thermal Conductivity

Viscosity

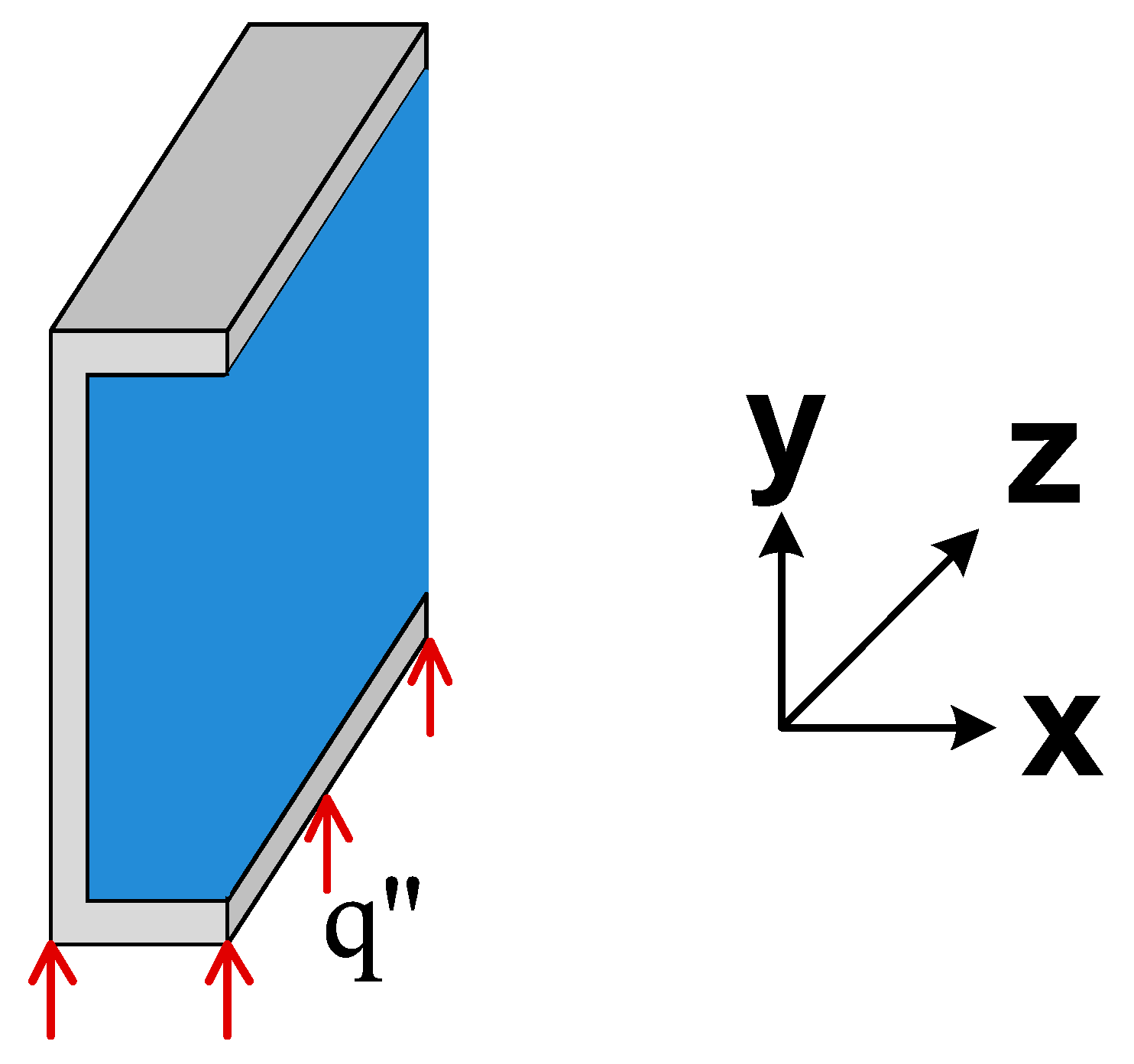

3. Microchannel Heat Exchanger

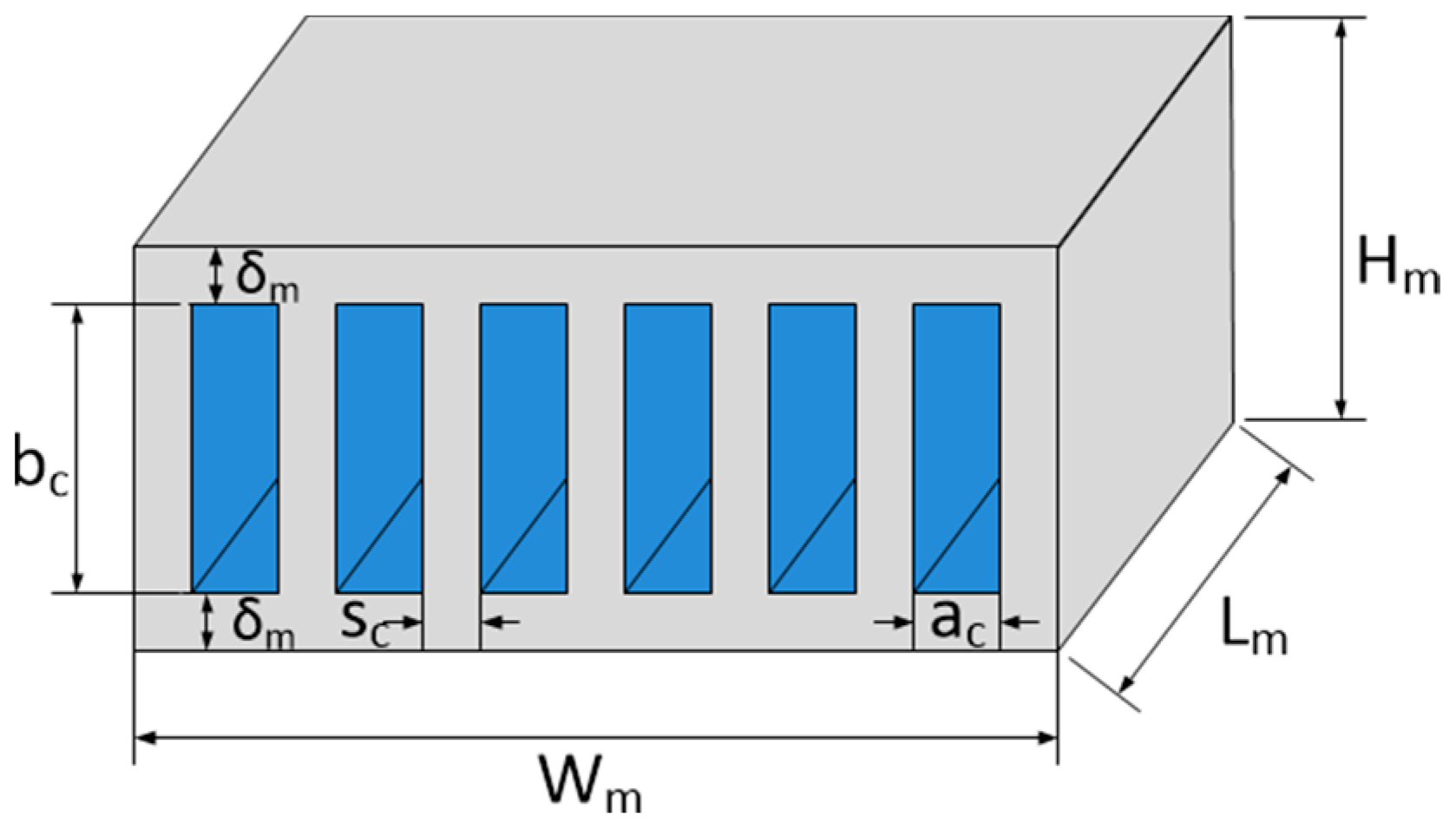

Geometries of the Heat Exchanger

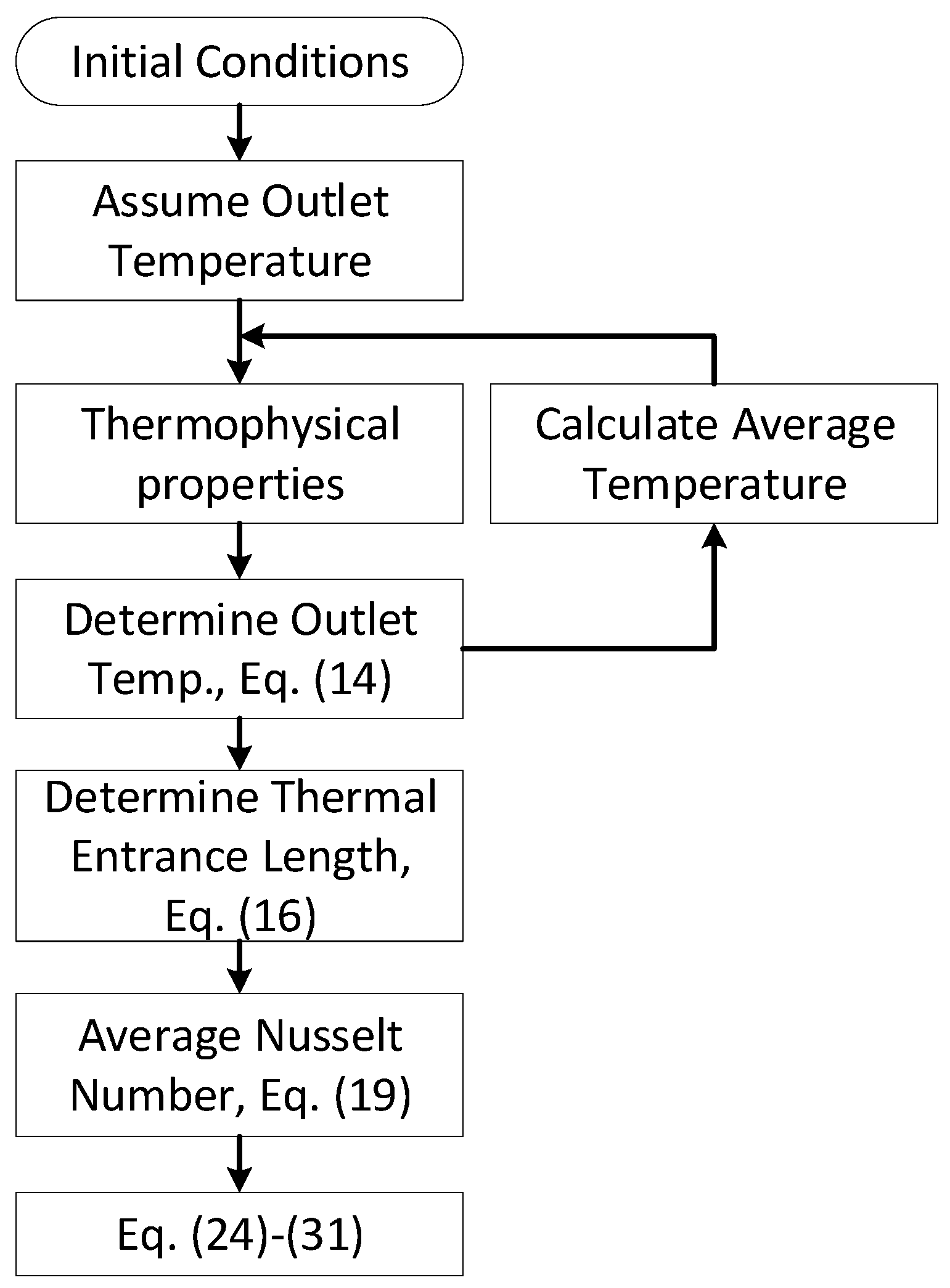

4. Analytical Procedure

4.1. Thermal and Fluid Dynamic Calculations

4.2. Comparison of Performances

- Constant Reynolds Number: This analysis compares the thermal and fluid dynamic performance of the base fluid and nanofluids with a constant Reynolds number determines.

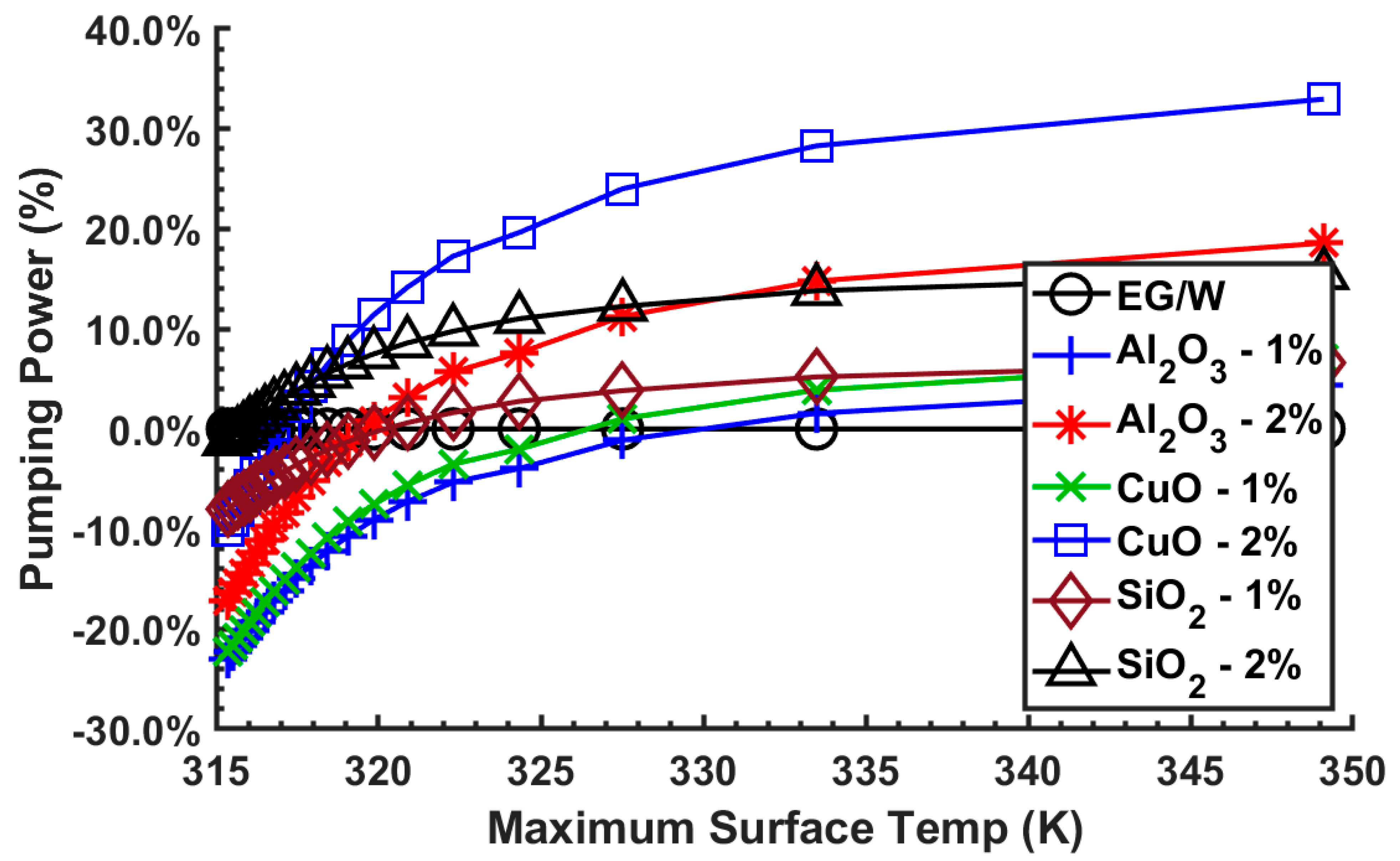

- Constant Maximum Surface Temperature: While maintaining a constant maximum surface temperature based on the base fluid calculations, determine the nanofluid fluid dynamic performance.

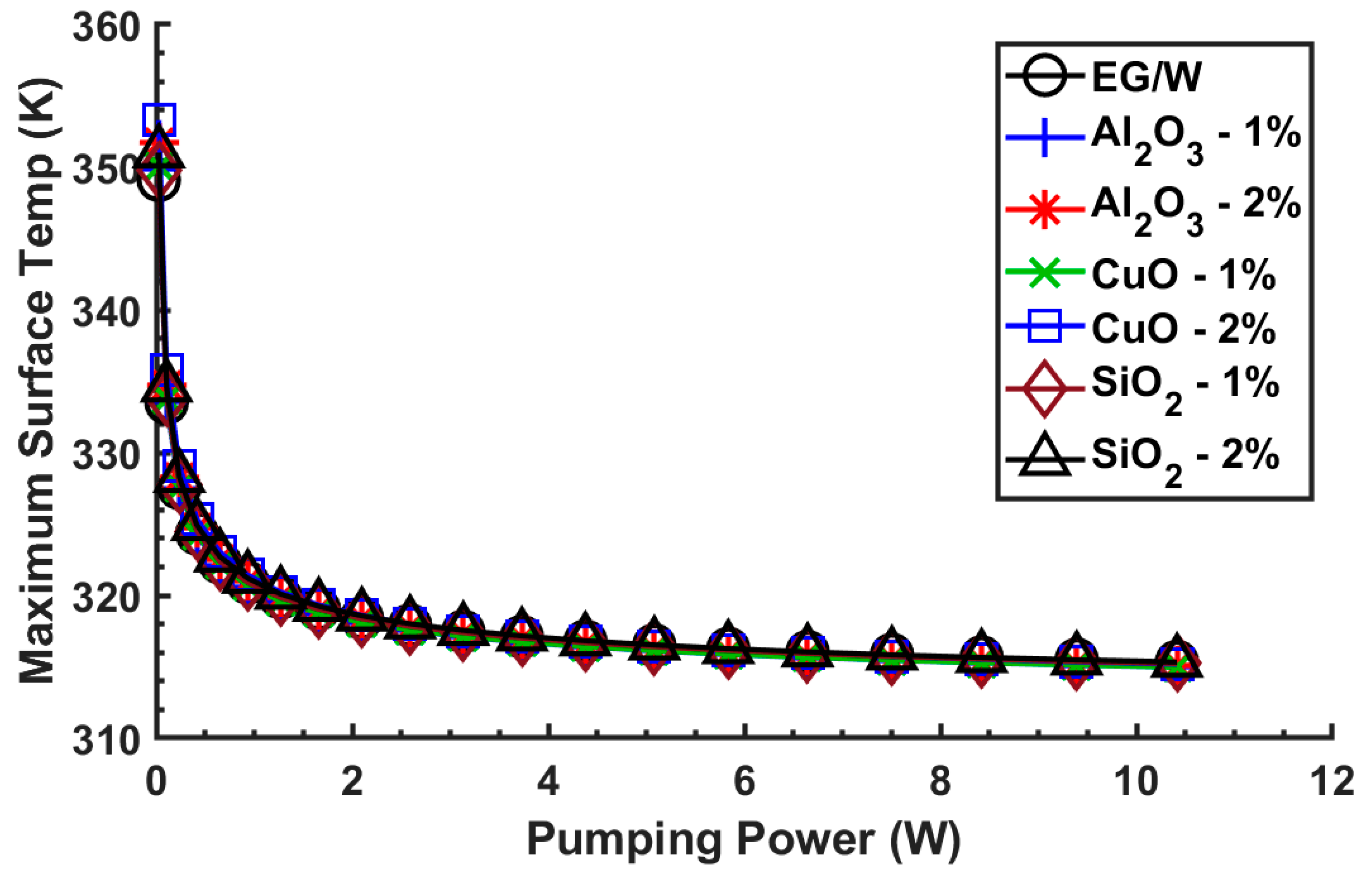

- Constant Pumping Power: While maintaining a constant pumping power based on the base fluid, compare the surface temperature as the cooling performance of nanofluids.

4.3. Operational Parameters

5. Computational Fluid Dynamic Analysis

5.1. Governing Equations

5.2. Numerical Methods

5.3. Boundary Conditions

5.4. Mesh Independence Study

6. Results

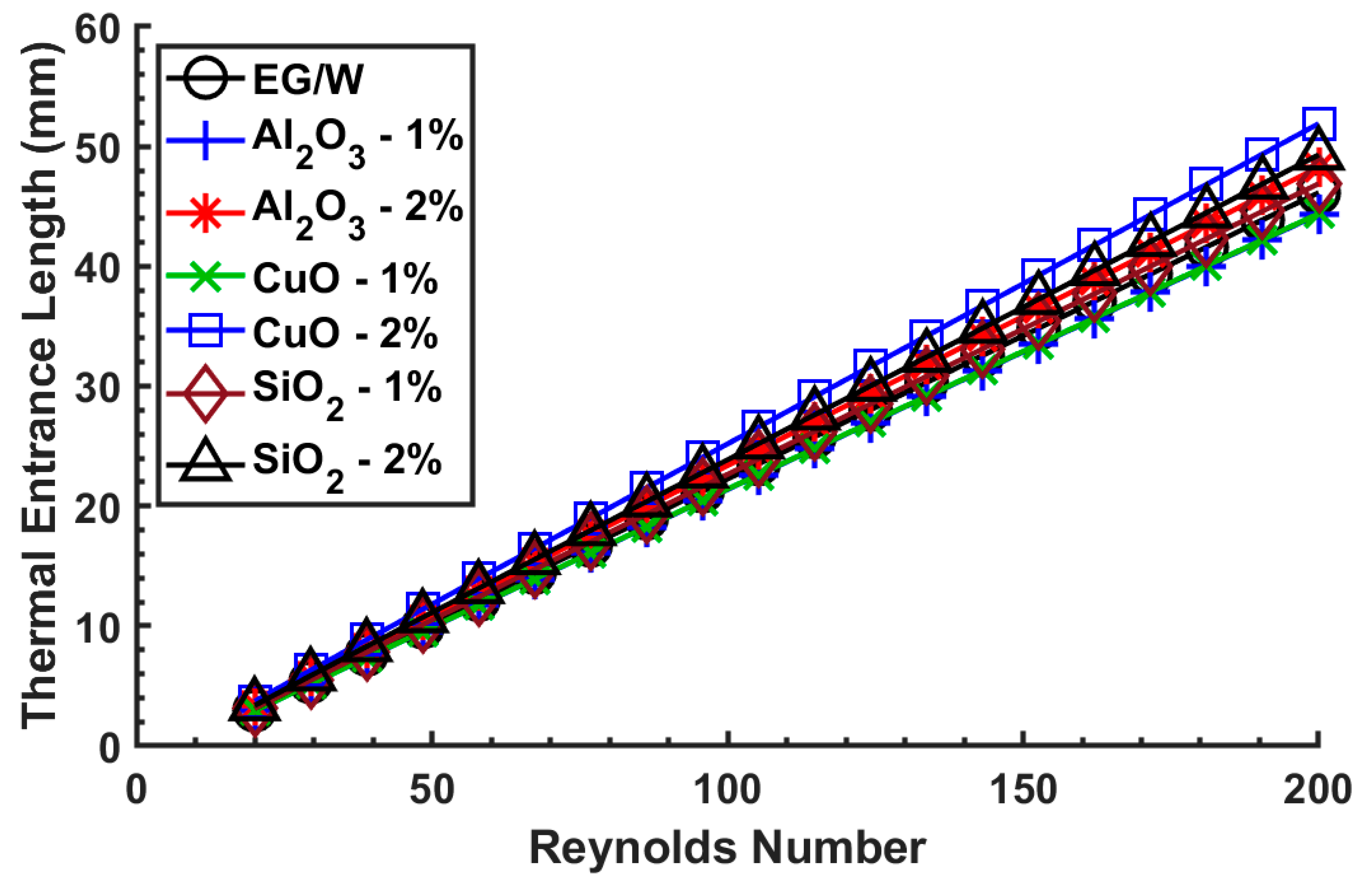

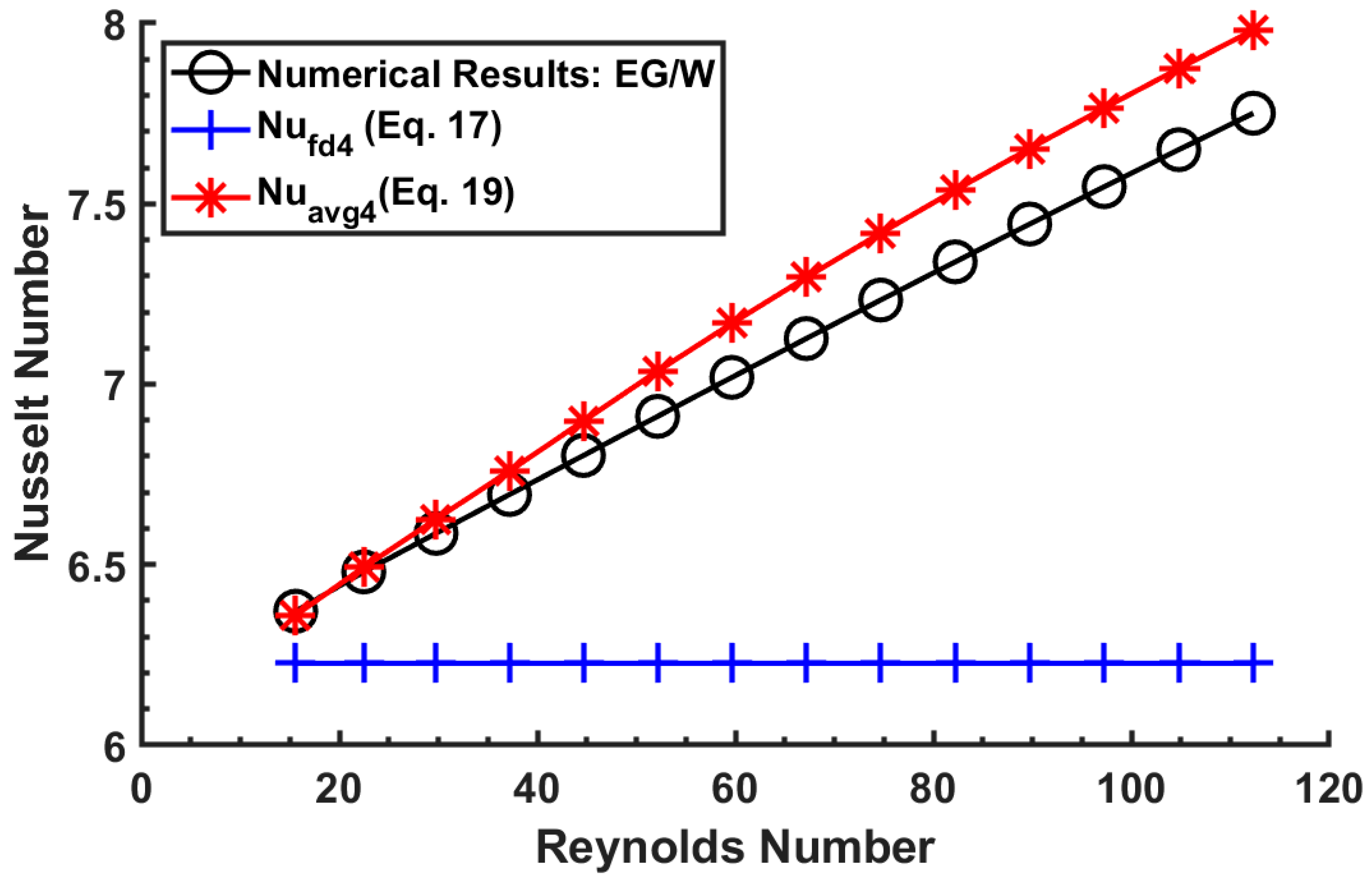

6.1. Analytical Results and Computational Model Validation

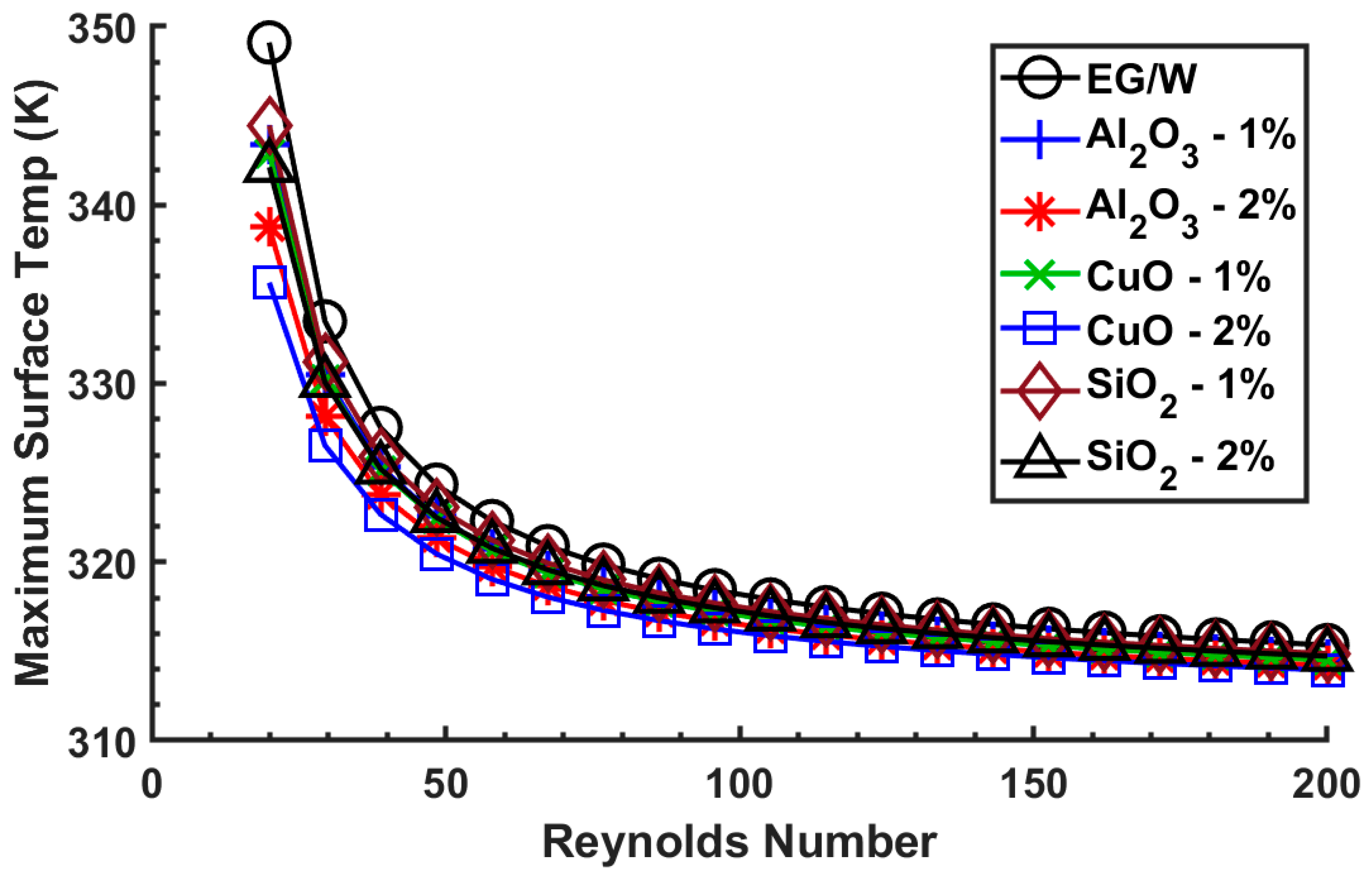

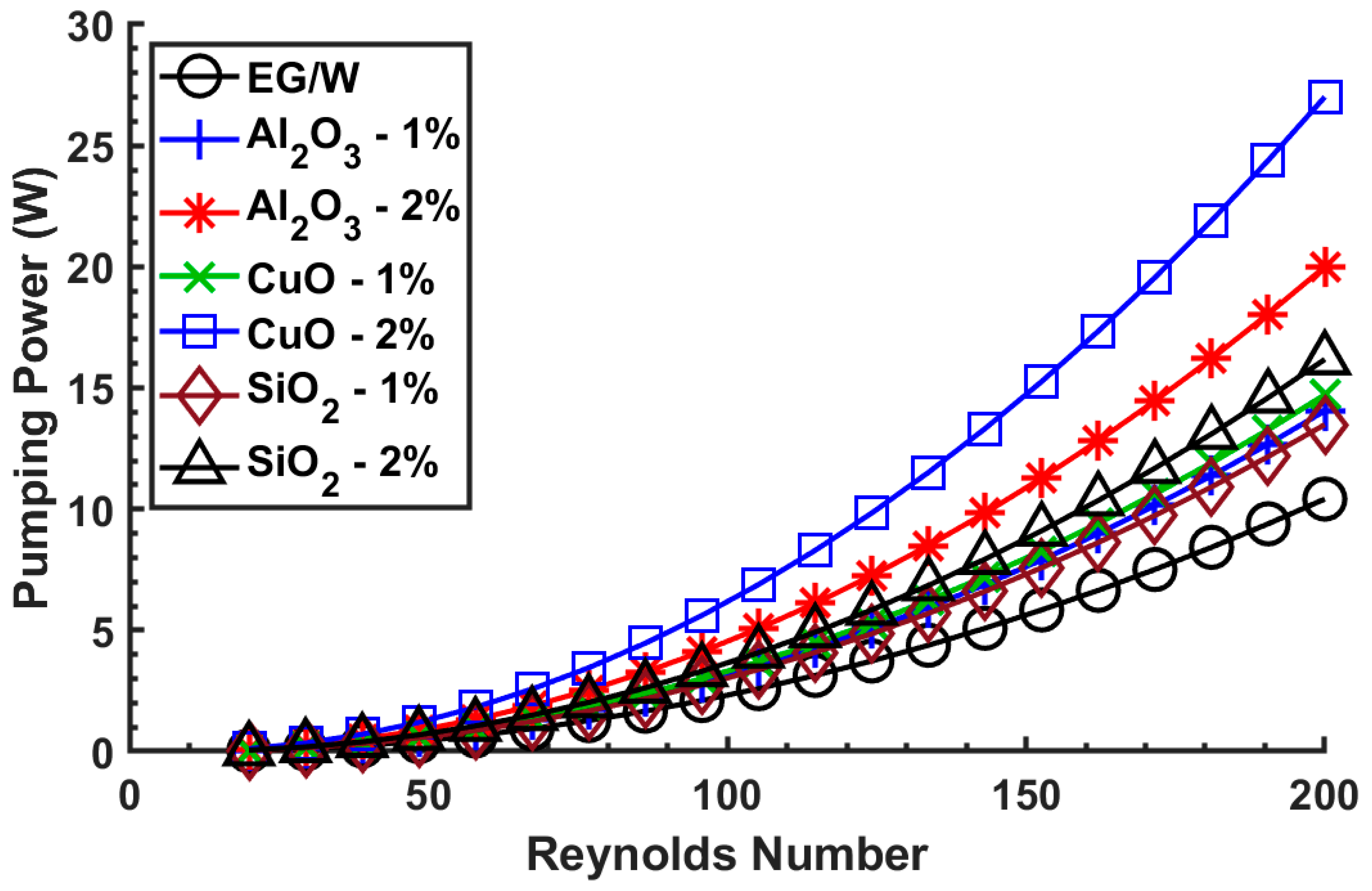

6.2. Constant Reynolds Number

6.3. Constant Maximum Surface Temperature

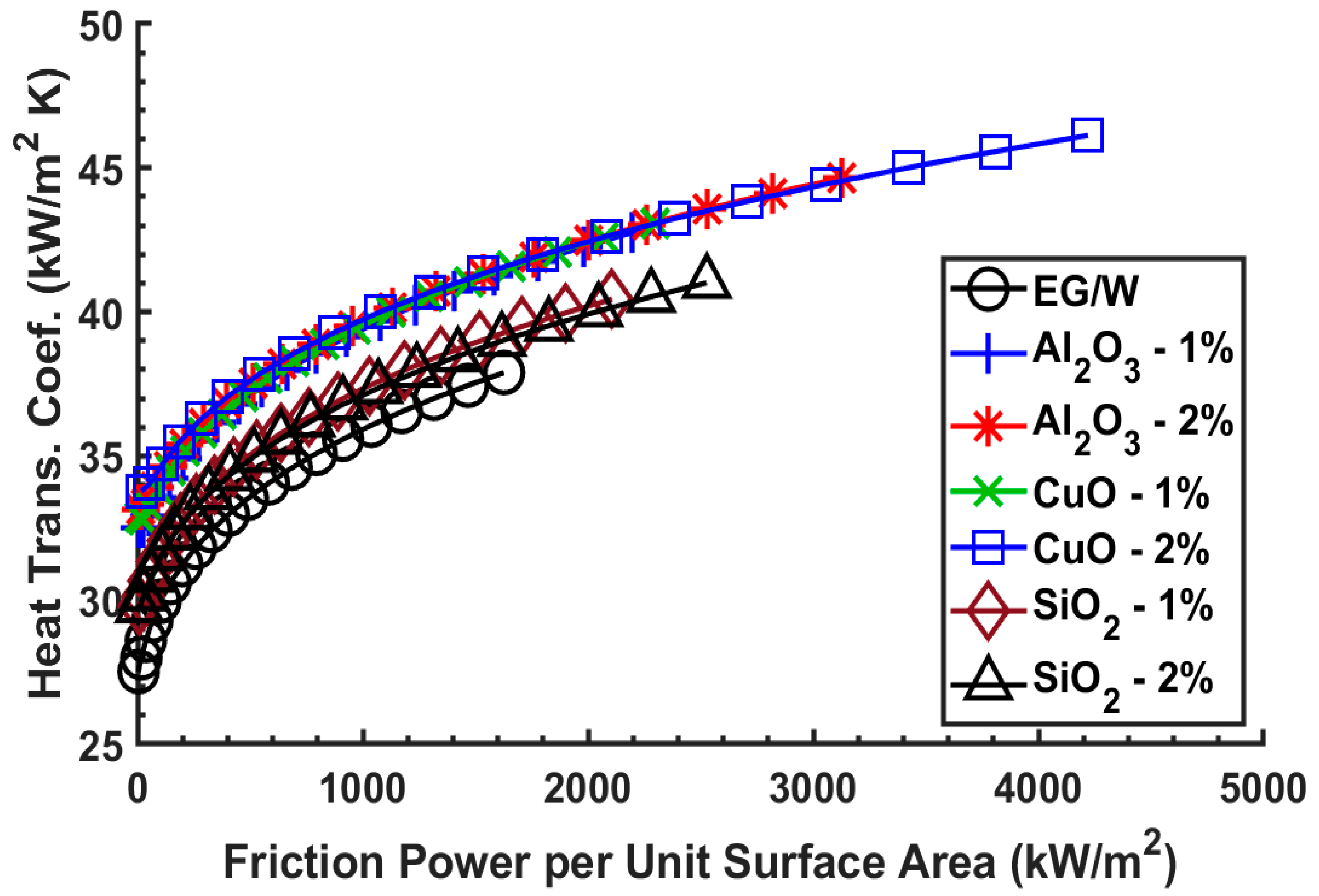

6.4. Constant Pumping Power

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VLSI. IEEE Electron. Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Koo, J.; Kleinstreuer, C. A new thermal conductivity model for nanofluids. J. Nanoparticle Res. 2005, 7, 324. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transfer. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K. Experimental determination of thermal conductivity of three nanofluids and development of new correlations. Int. J. Heat Mass Transf. 2009, 52, 4675–4682. [Google Scholar] [CrossRef]

- Minkowycz, W.J.; Sparrow, E.M.; Abraham, J.P. Nanoparticle Heat Transfer and Fluid Flow; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ray, D.R.; Das, D.K. Superior Performance of Nanofluids in an Automotive Radiator. J. Therm. Sci. Eng. Appl. 2014, 6, 041002. [Google Scholar] [CrossRef]

- Kleinstreuer, C.; Li, J.; Feng, Y. Computational Analysis of Enhanced Cooling Performance and Pressure Drop for Nanofluid Flow in Microchannel. In Nanoparticle Heat Transfer and Fluid Flow; Minkowycz, W.J., Ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2013; pp. 249–276. [Google Scholar]

- Masoumi, N.; Sohrabi, N.; Behzadmehr, A. A new model for calculating the effective viscosity of nanofluids. J. Phys. D 2009, 42, 055501. [Google Scholar] [CrossRef]

- Bianco, V.; Manca, O.; Nardini, S.; Vafai, K. Heat Transfer Enhancement with Nanofluids; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2015. [Google Scholar]

- Kandlikar, S.G.; Garimella, S.; Li, D.; Colin, S.; King, M. Heat Transfer and Fluid Flow in Minichannels and Microchannels; Elsevier Science & Technology: Kidlington, Oxford, UK, 2006. [Google Scholar]

- Fluent Academic Research, Release 18.1; ANSYS, Inc.: Canonsburg, PA, USA, 2017.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ASHRAE Handbook: Fundamentals; American Society of Heating, Refrigeration and Air-Conditioning Engineers: Atlanta, GA, USA, 2005. [Google Scholar]

- Yaws, C.L. Physical Properties: A Guide to the Physical, Thermodynamic, and Transport Property Data of Industrially Important Chemical Compounds; McGraw-Hill: New York, NY, USA, 1977. [Google Scholar]

- White, F.M. Fluid Mechanics; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Alfa Aesar, Nanoparticle and Dispersions. Available online: https://www.alfa.com/media/docs/Nanoparticles.pdf (accessed on 20 May 2020).

- Vajjha, R.S.; Das, D.K. Specific heat measurement of three nanofluids and development of new correlations. J. Heat Transfer. 2009, 131, 1–10. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K. A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power. Int. J. Heat Mass Transf. 2012, 55, 4063–4078. [Google Scholar] [CrossRef]

- Çengel, Y.A. Heat and Mass Transfer: A Practical Approach; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Vajjha, R.S.; Das, D.K.; Kulkarni, D.P. Development of new correlations for convective heat transfer and friction factor in turbulent regime for nanofluids. Int. J. Heat Mass Transf. 2010, 53, 4607–4618. [Google Scholar] [CrossRef]

- Vajjha, R.S.; Das, D.K.; Mahagaonkar, B.M. Density measurement of different nanofluids and their comparison with theory. Pet. Sci. Technol. 2009, 27, 612–624. [Google Scholar] [CrossRef]

- Xuan, Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Hamilton, R.L.; Crosser, O.K. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Sahoo, B.C.; Das, D.K.; Vajjha, R.S.; Satti, J.R. Measurement of the Thermal Conductivity of Silicon Dioxide Nanofluid and Development of Correlations. J. Nanosci. Nanotechnol. 2013, 3, 041006. [Google Scholar] [CrossRef]

- Namburu, P.K.; Kulkarni, D.P.; Dandekar, A.; Das, D.K. Experimental investigation of viscosity and specific heat of silicon dioxide nanofluids. Micro Nano Lett. 2007, 2, 67–71. [Google Scholar] [CrossRef]

- Namburu, P.K.; Kulkarni, D.P.; Misra, D.; Das, D.K. Viscosity of copper oxide nanoparticles dispersed in ethylene glycol and water mixture. Exp. Therm. Fluid Sci. 2007, 32, 397–402. [Google Scholar] [CrossRef]

- Sahoo, B.C.; Vajjha, R.S.; Ganguli, R.; Chukwu, G.A.; Das, D.K. Determination of rheological behavior of aluminum oxide nanofluid and development of new viscosity correlations. Pet. Sci. Technol. 2009, 27, 1757–1770. [Google Scholar] [CrossRef]

- Matlab 2018a; The MathWorks, Inc.: Natick, MA, USA, 2018.

- Han, L.S. Hydrodynamic Entrance Lengths for Incompressible Laminar Flow in Rectangular Ducts. J. Appl. Mech. 1960, 27, 403–409. [Google Scholar] [CrossRef]

- Phillips, R.J. Forced Convection, Liquid Cooled, Microchannel Heat Sinks. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, January 1987. [Google Scholar]

- Garimella, S.V.; Singhal, V. Single-Phase Flow and Heat Transport and Pumping Considerations in Microchannel Heat Sinks. Heat Transf. Eng. 2004, 25, 15–25. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical Data; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Steinke, M.E.; Kandlikar, S.G. Single-phase liquid friction factors in microchannels. Int. J. Therm. Sci. 2006, 45, 1073–1083. [Google Scholar] [CrossRef]

- Kakaç, S.; Shah, R.K.; Aung, W. Handbook of Single-Phase Convective Heat Transfer; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Kays, W.M.; London, A.L. Compact Heat Exchangers; Krieger Publishing Company: Malabar, FL, USA, 1984. [Google Scholar]

- Bejan, A. Entropy Generation through Heat and Fluid Flow; Wiley: New York, NY, USA, 1982. [Google Scholar]

| Property | Correlation | R2 | Error |

|---|---|---|---|

| Density | 238 K ≤ T ≤ 398 K | ||

| 1.00 | 0.01% | ||

| Viscosity | 273 K ≤ T ≤ 398 K | ||

| 1.00 | 0.91% | ||

| Specific Heat | 238 K ≤ T ≤ 398 K | ||

| 1.00 | 0.01% | ||

| Thermal Conductivity | 238 K ≤ T ≤ 398 K | ||

| 0.99 | 0.11% |

| Nanofluid | A | B | C | Max. Deviation (%) | Avg. Absolute Deviation (%) |

|---|---|---|---|---|---|

| Al2O3 | 0.2432703 | 0.5179 | 0.4250 | 5 | 2.28 |

| Type of Particle | β | Concentration |

|---|---|---|

| Al2O3 | ||

| CuO | ||

| SiO2 |

| Nanoparticle | A | B | Concentration |

|---|---|---|---|

| Al2O3 | 0.983 | 12.959 | |

| CuO | 0.9197 | 22.8539 | |

| SiO2 | 1.0249 | 6.5972 |

| Parameter | Symbol | Value |

|---|---|---|

| Channel height (µm) | 350 | |

| Thickness of bottom/top (µm) | 180 | |

| Channel Spacing (µm) | 40 | |

| Channel width (µm) | 50 | |

| Width (mm) | 10 | |

| Length (mm) | 10 | |

| Height (µm) | 530 | |

| Heat Exchanger Material | Silicon | |

| Density (kg/m3) | 1333 | |

| Specific Heat (J/kg∙K) | 700 | |

| Thermal Conductivity (W/m∙K) | 180 | |

| Parameters | Symbol | Values |

|---|---|---|

| Fluid | -- | EG/W, Al2O3, CuO, SiO2 |

| Practical range of Reynolds number | Re | 20 – 200 |

| Nanoparticle Concentration | ϕ | 1 & 2% |

| Heat flux (W/m2) | q” | 106 |

| Initial temperature (K) | T0 | 308.15 |

| Name | # of Elements | Computation Time | Velocity | Outlet Temp. | Pressure Drop | Average Wall Temp. |

|---|---|---|---|---|---|---|

| Mesh-I | 600,000 | - | - | - | - | - |

| Mesh-II | 756,000 | 141% | 0.00% | 0.00% | 0.44% | 0.00% |

| Mesh-III | 944,000 | 141% | 0.00% | 0.00% | 0.33% | 0.00% |

| Mesh-IV | 1,152,000 | 137% | 0.00% | 0.00% | 0.21% | 0.00% |

| Mesh-V | 1,480,000 | 151% | 0.00% | 0.00% | 0.23% | 0.00% |

| Mesh-VI | 2,016,000 | 169% | 0.00% | 0.00% | 0.21% | 0.00% |

| Parameter | Al2O3 - 1% | Al2O3 - 2% | CuO - 1% | CuO - 2% | SiO2 - 1% | SiO2 - 2% |

|---|---|---|---|---|---|---|

| Pressure Drop (%) | 3.9 | 3.8 | 3.8 | 3.7 | 4.1 | 4.1 |

| Nusselt Number (%) | 2.7 | 2.7 | 2.6 | 2.7 | 2.8 | 2.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ray, D.R.; Strandberg, R.; Das, D.K. Thermal and Fluid Dynamic Performance Comparison of Three Nanofluids in Microchannels Using Analytical and Computational Models. Processes 2020, 8, 754. https://doi.org/10.3390/pr8070754

Ray DR, Strandberg R, Das DK. Thermal and Fluid Dynamic Performance Comparison of Three Nanofluids in Microchannels Using Analytical and Computational Models. Processes. 2020; 8(7):754. https://doi.org/10.3390/pr8070754

Chicago/Turabian StyleRay, Dustin R., Roy Strandberg, and Debendra K. Das. 2020. "Thermal and Fluid Dynamic Performance Comparison of Three Nanofluids in Microchannels Using Analytical and Computational Models" Processes 8, no. 7: 754. https://doi.org/10.3390/pr8070754

APA StyleRay, D. R., Strandberg, R., & Das, D. K. (2020). Thermal and Fluid Dynamic Performance Comparison of Three Nanofluids in Microchannels Using Analytical and Computational Models. Processes, 8(7), 754. https://doi.org/10.3390/pr8070754