Abstract

In this study, a roasting-hydrolysis-acid leaching process is used to extract scandium from the scandium rough concentrate. The scandium rough concentrate containing Sc2O3 of 76.98 g/t was obtained by magnetic separation, gravity separation, and electric separation from Sc-bearing Vi-Ti magnetite tailings in the Panxi area of China. The majority of scandium in scandium rough concentrate mainly occurs in diopside, titanopyroxene, montmorillonite, chlorite, talc, aluminosilicate minerals, and isomorphism. Sodium salt and scandium coarse concentrate are added into the roasting furnace for roasting, which makes the fusion reaction of silicon, aluminum and sodium salt to produce soluble salts such as sodium silicate and sodium metaaluminate. Scandium is further recovered from the hydrolysis residue by acid leaching. Test results show scandium leaching recovery of 95.12% and the acid leaching residue with Sc2O3 content of 8.12 g/t are obtained, while the extraction of scandium is obvious. There is no obvious peak value of Scandium spectrum in hydrochloric acid leach residue. Most of scandium in hydrolytic residue is dissolved into Sc3+ and enters into the liquid phase. The main minerals in leach residue are perovskite, ferric silicate, and olivine.

1. Introduction

In the crust, the specific minerals of scandium are very rare. Moreover, there are only small economic reserves of Sc-bearing minerals including only thortveitite (Sc,Y)2Si2O7, scandium phosphite ScPO4·2H2O, bazzite Be3(Sc,Al)2Si6O18, titanium silicate mineral Sc(Nb,Ti,Si)2O5, and befanamite (Sc,Zr)2Si2O7, etc. In nature, scandium mostly occurs in ilmenite, zircon, bauxite, rare earth ore, ilmenite, V-Ti magnetite, tungsten ore, tin ore, uranium ore, coal, and other minerals [1]. The global scandium reserves are about 2 million tons, with China accounting for 27.5%, ranking first in the world. There are more than 800 kinds of scandium bearing minerals, which are complex in mineral composition and low in scandium content. They are distributed in other minerals in isomorphic or adsorption states, making the enrichment, separation, and extraction of high-purity scandium quite complex [2]. Scandium and its compounds have many excellent properties and are widely used in national defense, electric light source, aerospace, chemical industry, metallurgy, and other fields [3]. With of scandium consumption increasing year by year, it is of great practical significance to find more scandium containing materials and effectively extract and recover scandium from them [4,5,6,7].

The recovery of scandium mainly refers to the scandium enriched in some intermediate products or by-products when comprehensively treating scandium bearing mineral resources. When processing scandium bearing mineral resources, scandium has different trends, resulting in the different characteristics of scandium rich materials. Beneficiation, hydrometallurgy, precipitation method, extraction method, and ion exchange method are the main process of recovering scandium from primary ores, slag, and waste liquid [8,9,10,11].

At present, the main objects of scandium recovery in primary ores are phosphorite, some rare earth ores, mica ores, brown yttrium niobium ores and some tailings of titanium and iron separation. The main methods to produce scandium concentrate are gravity separation, flotation, magnetic separation and electric separation. It is very important to recover scandium from primary ore, analyze the physicochemical properties of main scandium bearing minerals, select reasonable beneficiation methods to find out the trend of scandium and produce scandium concentrate [12,13,14,15,16].

The recovery of scandium from slag mainly refers to the leaching and extraction of scandium from some smelting slag of ferrotungsten and tin, the slag of ferrotungsten and ferromanganese, the chlorinated fume or the chlorinated waste melt of titanium tetrachloride production by high temperature boiling chlorination of ilmenite and the coal ash. The leaching efficiency of scandium directly affects the recovery of scandium extraction. Generally, the best leaching agent, the particle size of leaching material, solid-liquid ratio, leaching time and temperature should be determined according to the characteristics of slag system. Scandium oxide, a common compound of scandium in nature, is insoluble in dilute acid and can only be dissolved at high temperature and in concentrated acid. Hydrochloric acid, hydrofluoric acid, sulfuric acid, nitric acid is the main leaching agent of scandium extraction. In general, chlorination roasting leaching, hydrolysis leaching and adding auxiliaries leaching can also be used to improve the leaching efficiency of scandium [17,18].

Therefore, rare and precious metals can be recovered by thermochemical treatment before recovery, and Scandium is easy to react with hydrochloric acid at high temperature to form scandium chloride and dissolve in the solution. This can change the structure of minerals and speed up the chemical reaction after adding auxiliaries. Common chlorinators include sodium chloride, potassium chloride, barium chloride, calcium chloride, magnesium chloride, etc. Alkali fusion agents include caustic soda, sodium carbonate, sodium bicarbonate, etc. Auxiliaries is usually some catalyst.

In recent years, the combination of mineral processing and hydrometallurgical separation technology has been widely used in the field of comprehensive recovery and extraction of scandium, which greatly improves the concentration ratio and recovery rate of scandium. In future research and production, the recovery process of main metals and other valuable metals should be considered, with the recovery and extraction process of scandium simplified, and the production cost reduced as much as possible. To obtain scandium products with a high purity and recovery rate, it is necessary to combine multiple methods to improve the extraction process, to find more materials that can recover scandium, as well as improve the recovery and extraction methods of scandium, which will be of great significance to the effective use of the source [19,20,21,22].

The value of scandium accounts for about 47% of Panzhihua V-Ti magnetite. The economic value of scandium is more than four hundred million USD, ranking first in the economic value of all elements of Panzhihua V-Ti magnetite. Because the grade of Panzhihua V-Ti magnetite is not high, it produces a large amount of tailings, which not only occupy a lot of arable land, but also pollute the environment. There are rare scandium-containing minerals, making it difficult to separate and extract scandium. Consequently, scandium and its compounds become rather expensive. Scandium in V-Ti magnetite is mainly enriched in the tailings of titanium separation by beneficiation process, so it is necessary to extract scandium from the tailings of titanium separation. The tailings of V-Ti magnetite are pretreated by magnetic separation gravity separation electro separation process to enrich scandium to obtain scandium concentrate [23,24,25,26,27].

The main minerals in scandium concentrate are diopside, titanaugite, albite, hornblende, montmorillonite, mica, olivine, etc. Due to the high content of aluminum, silicon, calcium, and magnesium in the scandium concentrate, and the complex mineral composition, if the scandium is leached directly by hydrochloric acid, the amount of leaching agent will be increased significantly, and the impurities in the leaching solution will also be increased, which will further harm the separation and purification of scandium in the leaching solution. Therefore, in this study, roasting-hydrolysis is used for pretreatment to remove most of the water soluble salts such as the sodium salts of silicon and alumina, which creates favorable conditions for the further separation of scandium from hydrolysis residue by acid leaching, and plays an important role in improving the leaching recovery of scandium, increasing the concentration of Sc3+ ions and reducing the content of unwanted components in the leaching solution [28,29,30,31].

2. Materials and Methods

2.1. Sampling

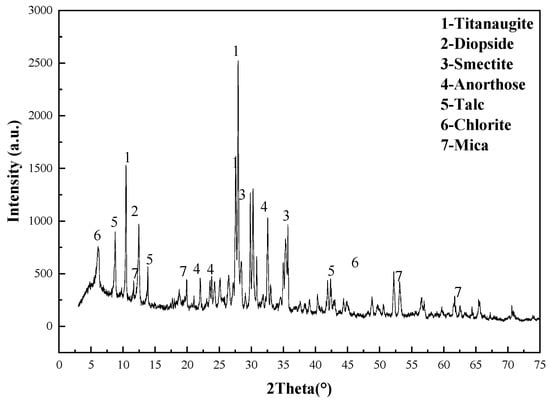

The tailings samples of V-Ti magnetite from Panzhihua area of China were collected, which contained 38.61 g/t of Sc2O3. The mineral composition of the tailings is complex, and the content of scandium is very low. The scandium rough concentrate containing 76.98 g/t of Sc2O3 was further enriched by magnetic separation, gravity separation, and electric separation from the tailings samples of V-Ti magnetite, and granularity of scandium rough concentrate less than 0.074 mm. There is no independent scandium mineral in scandium concentrate, and the minerals closely related to scandium are mainly titanium pyroxene, plagioclase, diopside, chlorite, mica, etc. The main chemical composition analysis of scandium concentrate is shown in Table 1, the main Sc-bearing minerals analysis in the scandium rough concentrate is shown in Table 2, and the X-ray diffraction (XRD) analysis of the sample is shown in Figure 1.

Table 1.

Main chemical composition analysis results of scandium rough concentrate (wt %).

Table 2.

Main Sc-bearing minerals in the scandium rough concentrate (wt %).

Figure 1.

X-ray diffraction (XRD) diffractogram of scandium rough concentrate.

2.2. Main Chemical Reagent and Equipment

The main chemical reagents used in this test are sodium hydroxide (purity, 99.5%), sodium carbonate (purity, 99.5%), sodium peroxide (purity, 99.5%), sodium bicarbonate (purity, 99.5%), sodium oxide (purity, 99.5%), hydrochloric acid (purity, 36.5%), hydrofluoric acid (purity, 50%), sulfuric acid (purity, 99.8%), nitric acid (purity, 99.5%), and sodium silicate (purity, 99%), all of which come from Guangzhou Chemical Reagent, Co., Ltd., Guangzhou, China.

The main equipment of the experiment are: muffle furnace (≤1100 °C, Shanghai Shiyan Electric Furnace Co., Ltd. Shanghai, China), Magnetic stirrer (1.5L, Jilin Exploration Machinery Factory, Changchun, China), Mechanical stirrer (1.5L, Jilin Exploration Machinery Factory, Changchun, China), Cone ball mill (Φ 240 × 90 mm, Jilin Exploration Machinery Factory, Changchun, China), Disc grinder (Φ 300 × 150 mm, Jilin Exploration Machinery Factory, Changchun, China), Drying box (Shanghai Shiyan Electric Furnace Co., Ltd., Shanghai, China), Vacuum filter (Φ 300, Southwest Chengdu Experimental Equipment Co., Ltd., Chengdu, China), Ceramic mortar(Φ 100, Beijing Grinder Instrument Co., Ltd., Beijing, China), Separating funnel (100 ml, 500 ml, 1000 ml, Taizhou Gaogang Kejia Experimental Equipment Co. Ltd., Taizhou, China).

2.3. Procedure

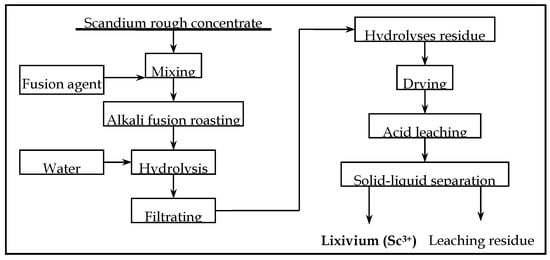

The main Sc-bearing carrier minerals in scandium rough concentrate are closely related to silica-aluminate minerals, such as chlorite, montmorillonite, talc and amphibole, it will lead to the consumption of a large amounts of extractants by direct acid leaching and increase the content of impurities in the leaching solution, which is not conducive to further separation and purification of scandium in the subsequent process. Therefore, the process of roasting hydrolysis leaching (shown in Figure 2) is adopted to treat the scandium rough concentrate.

Figure 2.

Scheme of the sandium separation process from scandium rough concentrate.

Raw materials (a mass of 100 g for each test) are mixed the with chemical agents (Na2CO3, NaOH, NaHCO3, Na2O2, Na2O, Na2SO4, etc.) in a 5%–25% proportion and put them into the roasting furnace for roasting, and the sodium salt reacts with SiO2 and Al2O3 in the scandium rough concentrate to generate soluble Na2SiO3 and NaAlO2. After hydrolysis, Na2SiO3 and NaAlO2 are removed, so as to reduce the content of silicon and aluminum in the leaching liquid and create favorable conditions for the subsequent leaching and separation of scandium from the hydrolysis residue. After hydrolysis residue (a mass of 100 g for each test) is added with a certain amount of leaching agents (hydrochloric acid, nitric acid, sulfuric acid and hydrofluoric acid), scandium is further separated.

By analyzing the content of Si, Al and Sc in the hydrolytic residue obtained from different roasting hydrolysis process conditions, the effect of removing Si, Al and the effect of enriching Sc were evaluated. By analyzing the content of scandium in the leaching residue produced by acid leaching of hydrolysis residue, leaching efficiency (LE) of Scandium to evaluate the separation effect of Scandium, and dissolution efficiency (DE) to evaluate the dissolution degree of the leaching residue can be calculated. The calculation formulas are shown in Equations (1) and (2):

where Q1 is of weight before acid leaching/g, Q2 is of weight after acid leaching/g, β1 is of scandium oxide content before acid leaching/%, and β2 is of scandium oxide content before acid leaching/%.

LE = (Q1 × β1 − Q2 × β2 )/(Q1 × β1) × 100%

DE = (Q1 − Q2)/Q1 × 100%

2.4. Analysis and Characterization

The chemical composition of solid materials was analyzed by Z–2000 atomic absorption spectrophotometer (Hitachi Co., Ltd. Tokyo, Japan), the diffraction grating was Zenier-tana Type, 1800 lines/mm, the flash wavelength was 200 nm, the wavelength range was 190–900 nm, the automatic peak seeking setting, and the spectral bandwidth was divided into 4 grades (0.2, 0.4, 1.3, and 2.6 nm) for the analysis of mineral chemical composition. Inductively coupled plasma mass spectrometry (8800 ICP-MS/MS, Agilent Technologies Inc. California, USA) were used to determine the Sc2O3 content of solid materials (scandium rough concentrate, hydrolysis residue, leaching residue).

The mineral phase composition of solid substances (scandium rough concentrate, hydrolysis residue, leaching residue) was analyzed by X-ray diffraction (XRD, X Pert pro, Panaco, The Netherlands). The microstructure of the solid products was observed by SEM (S440, Hirschmann Laborgerate GmbH & Co. KG, Eberstadt, Germany) equipped with an energy dispersive X-ray spectroScopy (EDS) detector (UItra55, CarlzeissNTS GmbH, Hirschmann Laborgerate GmbH & Co. KG, Eberstadt, Germany).

3. Results and Discussion

3.1. Removal of Silica and Alumina by Roasting—Hydrolysis

3.1.1. Effect of Different Roasting Agent

Effect of different alkali fusion roasting agent tests were carried out under the conditions of roasting temperature of 800 °C, roasting time of 30 min, alkali fusion agent dosage of 20%, hydrolysis temperature of 40 °C, hydrolysis time of 60 min, hydrolysis solid-liquid ratio of R1 = 1:1.5, and the results are shown in Table 3.

Table 3.

Effect results of different fusion agent on removal of silica and alumina.

It is known from Table 3 that when sodium hydroxide was used as the fusion agent of alkali fusion roasting, the content of SiO2 and Sc2O3 in the hydrolysis residue slag was 12.86% and 95.91 g/t respectively; when sodium oxide was used as the fusion agent of alkali fusion roasting, the content of Al2O3 and Sc2O3 in the hydrolysis residue slag was 13.25% and 94.98 g/t respectively. The mixture of sodium hydroxide and sodium oxides was considered as the fusion agent of alkali fusion roasting to reduce silicon and aluminum at the same time.

3.1.2. Effect of Roasting Agent Dosage

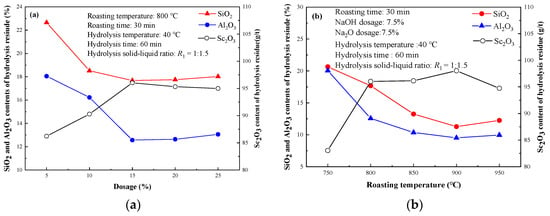

The results of alkali fusion roasting dosage tests are shown in Figure 3a. In the process of alkali fusion roasting, chemical reaction occurs with silicon, aluminum, etc. in the material, and the amount of alkali fusion agent increases, which is conducive to the formation of sodium silicate and sodium metaaluminate. The equations are shown in Equations (3) and (4).

2NaOH + Al2O3 = 2NaAlO2 + H2O

Na2O + SiO2 = Na2SiO3

Figure 3.

Effect results of fusion agent dosage (a) and alkali fusion roasting temperature (b).

Excess alkali fusing agent will react with other elements and consume unnecessary alkali fusing agent; insufficient alkali fusing agent cannot effectively fuse with the target component in the material, which is not conducive to the removal of silicon and aluminum, will increase the content of impurities in the scandium containing leach solution produced by the subsequent hydrolysis residue leaching and separation of scandium, and affect the separation and purification of scandium containing leach solution. Therefore, fusion agent dosages of 15% (sodium hydroxide dosage of 7.5%, sodium oxide dosage of 7.5%) were suitable, and the contents of SiO2, Al2O3, and Sc2O3 in the hydrolysis residue were 17.68%, 12.57%, and 96.03 g/t respectively.

3.1.3. Effect of Roasting Temperature

The results of alkali fusion roasting temperature are shown in Figure 3b. Increasing the alkali fusion roasting temperature is conducive to reducing the content of silicon and aluminum and increasing the concentration of scandium, but when the roasting temperature exceeds 900 °C, the reduction of silicon and aluminum is relatively small. When the roasting temperature was increased to 950 °C, the content of SiO2, Al2O3 and Sc2O3 in the hydrolytic residue was 11.24, 9.42%, and 98.09 g/t respectively. Compared with the roasting temperature of 900 °C, SiO2 and Al2O3 were increased by 0.97% and 0.44% respectively, and Sc2O3 was decreased by 3.3 g/t, which shows that when the alkali fusion roasting temperature is increased to a certain value, the fusion chemical reaction is basically in equilibrium. Therefore, the roasting temperature of 900 °C was more appropriate and reasonable, and the contents of SiO2, Al2O3, and Sc2O3 in the hydrolysis residue were 11.28, 9.52%, and 98.04 g/t, respectively.

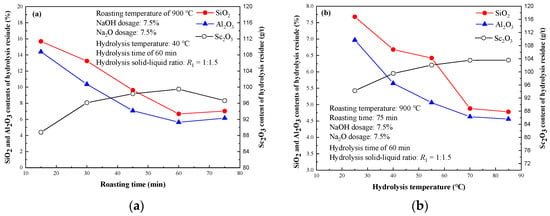

3.1.4. Effect of Roasting Time

The results of alkali fusion roasting time are shown in Figure 4a. The roasting process of alkali fusion involves complex physical and chemical changes, and the roasting time is also one of the main factors affecting the degree of the chemical reaction. The reaction degree of alkali fusion agent with silicon and aluminum is not enough, which affects the formation of soluble salts such as sodium silicate and sodium metaaluminate, and is not conducive to the reduction of harmful elements silicon and aluminum. The process of alkali fusion roasting is easy to cause chemical reaction between alkali fusion agent and other components. The Sc2O3 content increased when the roasting time increased to 60 min based on Figure 4a. Compared with the roasting time of 75 min, SiO2 and Al2O3 were 0.35%, 0.50% lower and Sc2O3 was 2.85 g/t higher. The optimum roasting time of alkali fusion was 60 min. The contents of SiO2, Al2O3 and Sc2O3 in the hydrolytic residue were 6.68, 5.65%, and 99.51 g/t respectively.

Figure 4.

Effect results of alkali fusion roasting time (a) and hydrolysis temperature (b).

3.1.5. Effect of Hydrolysis Condition

(1) Hydrolysis Temperature

The results of hydrolysis temperature are shown in Figure 4b. In the process of hydrolysis, increasing the temperature is conducive to the dissolution of soluble sodium salt into the liquid phase, and improving the dissolution rate of the soluble sodium salt of silicon and aluminum. With the increase of temperature, the silicon and aluminum in the hydrolysis residue decreased, while the scandium increased. When the hydrolysis temperature was lower than 50 °C, the content of silicon and aluminum in the hydrolysis residue was higher than 5%. When the leaching temperature was raised to 85 °C, the contents of SiO2 and Al2O3 in the hydrolysis residue were 4.78% and 4.56% respectively. Compared with the leaching temperature of 70 °C, SiO2 and Al2O3 were reduced by 0.1 and 0.07 percentage respectively. The high hydrolysis temperature leads to the increase of water evaporation, which affects the solid-liquid ratio of leaching and is not conducive to the dissolution of soluble salt. Therefore, the hydrolysis temperature of 70 °C was suitable. The contents of SiO2, Al2O3 and Sc2O3 in the hydrolysis residue were 4.88, 4.63 and 103.52 g/t respectively.

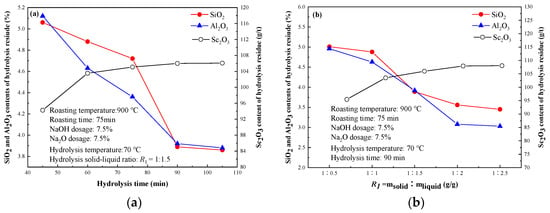

(2) Hydrolysis Time

The results of hydrolysis time are shown in Figure 5a. Prolonging hydrolysis time is conducive to reducing the content of silicon and aluminum in hydrolysis residue and enriching scandium. When the hydrolysis time increased from 60 to 105 min, the content of Sc2O3 in the hydrolysis residue increased from 103.52 to 106.06 g/t, increased by 2.54 g/t, and SiO2 and Al2O3 decreased to less than 4%. Compared with the hydrolysis time of 90 and 105 min, the content difference of SiO2 and Al2O3 is very small, which are 0.03 and 0.04 percentage respectively, which shows that the hydrolysis process needs a certain dissolution time. When the time reaches a certain degree, the soluble sodium salts such as silicon and aluminum have dissolved. The optimum hydrolysis time was 90 min, and the contents of SiO2, Al2O3 and Sc2O3 in the hydrolysis residue were 3.89, 3.92%, and 105.99 g/t, respectively.

Figure 5.

Effect results of hydrolysis leaching temperature (a) and hydrolysis solid to liquid ratio (b).

(3) Hydrolysis Solid to Liquid Ratio

The results of hydrolysis solid to liquid ratio are shown in Figure 5b. The soluble salts in the alkali fusion roasting slag need a reasonable solid-liquid ratio when they are released into the liquid phase during the hydrolysis process. The increase of solid content in the hydrolysis process is easy to produce mechanical entrainment coating, which is not conducive to the dissolution of soluble sodium salt and has adverse effects on the reduction of silicon and aluminum. With the decrease of solid-liquid ratio, the content of silicon and aluminum in the hydrolysis residue decreased. When R1 = 1:2, the content of SiO2, Al2O3 and Sc2O3 in the hydrolysis residue were 3.56, 3.08%, and 107.94 g/t, respectively. When R1 = 1:2.5, the contents of SiO2, Al2O3 and Sc2O3 in the hydrolysis residue were 3.45, 3.03%, and 108.06 g/t respectively. As there is little difference, the hydrolysis residue to solid–liquid of R2 = 1:2 was suitable.

3.1.6. Scale-Up Test of Roasting-Hydrolysis

The ideal indexes impurities removal of silica and alumina were obtained by roasting and hydrolysis test. In order to further investigate the repeatability of the test conditions, six roasting tests were carried out, and the ore mass of each roasting scandium concentrate increased to 1000 g. The six roasting ores were mixed and used as hydrolysis leaching samples. And the hydrolysis residue was used as the raw material for further separating scandium by acid leaching. The test results are shown in Table 4.

Table 4.

Main chemical composition analysis results of hydrolysis residue (wt %).

It is known from Table 4 that Sc2O3 was enriched from 76.98 g/t to 108.24 g/t after roasting hydrolysis treatment of Scandium coarse concentrate, with concentration ratio = 108.24/76.98 = 1.41; SiO2 was reduced from 27.08% to 11.24%, Al2O3 was reduced from 21.67% to 10.78%, demonstrating the significant effect of removing silicon, aluminum, and enriching scandium. Other components, such as CaO, MgO, and TiO2 are also enriched to some extent.

3.2. Scandium Extraction of Hydrolysis Residue by Acid Leaching

3.2.1. Effect of Different Acid Leaching Agent

Different acid leaching agent tests were conducted to investigate the influence rules on scandium extraction, and the conditions employed are leaching agent dosage of 10%, solid-liquid ratio of R2 = 1:1, leaching time of 60 min, leaching temperature of 40 °C, and the results are shown in Table 5.

Table 5.

Effect results of different leaching agent on scandium extraction.

In the process of roasting of scandium concentrate, part of scandium forms scandium oxide and the other part of scandium still exists in the form of other compounds, which makes the mineral phase of scandium change. Reasonable selection of leaching medium can improve the leaching efficiency of scandium. Sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid were selected as leaching agents to carry out the comparative effect test of scandium extraction. Therefore, hydrochloric acid as the leaching medium is more reasonable. Scandium leaching efficiency of 76.17%, dissolution efficiency of 23.86%, and leaching residue with Sc2O3 content of 36.78 g/t were obtained.

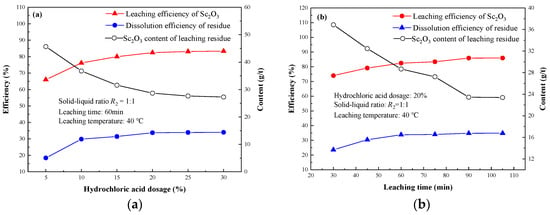

3.2.2. Effect of Hydrochloric Acid Dosage

The results of different hydrochloric acid dosage are shown in Figure 6a. When the amount of hydrochloric acid is increased to 20%, the leaching efficiency of scandium was 82.45%, the Sc2O3 in leaching residue was 28.67 g/t, and the dissolution efficiency was 33.75%. When the amount of hydrochloric acid was more than 20%–30%, the leaching efficiency of scandium increased less, the content of scandium in leaching residue decreased less, and the dissolution efficiency tended to be stable. This shows that excess hydrochloric acid can improve the leaching efficiency of scandium to a limited extent, and the dosage of hydrochloric acid is one of the factors affecting scandium extraction. Other factors can be adjusted to further improve the scandium extraction index. When hydrochloric acid dosage was 20%, scandium leaching efficiency of 82.45%, dissolution efficiency of 33.72%, and leaching residue with Sc2O3 content of 28.67 g/t were obtained.

Figure 6.

Effect results of hydrochloric acid dosage (a) and leaching time (b).

3.2.3. Effect of Leaching Time

The results of acid leaching time are shown in Figure 6b. The content of other elements except Sc3+ in the leaching solution is also increased, which is not conducive to further separation and purification of scandium. The main chemical product of scandium in the leaching process is ScCl3. In order to increase the production of ScCl3 as much as possible, it is necessary to have sufficient chemical reaction time. When the leaching time is less than 90 min, the leaching efficiency of scandium decreases obviously. When the leaching time is increased to 105 min, the leaching efficiency of scandium increases slightly, and the dissolution efficiency of materials increases to 34.82%. Therefore, the leaching time of 90 min was suitable. Scandium leaching efficiency of 85.87%, dissolution efficiency of 23.44%, and leaching residue with Sc2O3 content of 23.44 g/t were obtained.

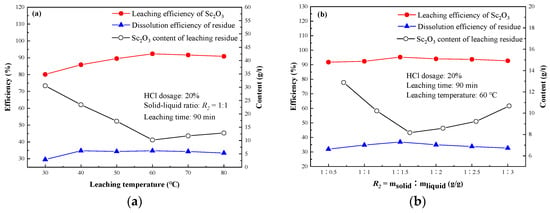

3.2.4. Effect of Leaching Temperature

The results of acid leaching temperature are shown in Figure 7a. When the leaching temperature was lower than 60 °C, the leaching efficiency of scandium decreases obviously; when the leaching temperature was higher than 60 °C, the leaching efficiency of scandium decreased. The leaching temperature increased to 80 °C, and the leaching efficiency of scandium decreased to 90.87%, which indicates that the leaching temperature increased in a certain range, and the leaching efficiency of scandium increased regularly. However, the high temperature was unfavorable to the leaching of scandium. On the premise of ensuring the ideal leaching efficiency of scandium, the lower the leaching temperature is, the more favorable it will be for the subsequent practical application. Therefore, the leaching temperature of 60 °C was suitable. Scandium leaching efficiency of 92.37%, dissolution efficiency of 34.78%, and leaching residue with Sc2O3 content of 10.22 g/t were obtained.

Figure 7.

Effect results of leaching temperature (a) and leaching solid to liquid ratio (b).

3.2.5. Effect of Leaching Solid to Liquid Ratio

The results of leaching solid to liquid ratio are shown in Figure 7b. With the decrease of solid-liquid ratio, the leaching efficiency of scandium increases first and then decreases. When the solid-liquid ratio R2 = 1:1.5, the highest leaching efficiency of scandium was 95.24%. The solid-liquid ratio is the ratio of solid mass to liquid mass in the leaching system, which is an indicator of pulp concentration. When the ratio of solid to liquid R2 was higher or lower than 1:1.5, the leaching efficiency of scandium decreases. This is related to the ionization degree of H+, Cl− and Sc3+ in the chemical reaction of leaching process. The increase of solid-liquid ratio, the decrease of concentration of leaching system and the increase of ionization degree of ions increase the chance of ScCl3 formed by the combination of Sc3+ and Cl−, which is conducive to the chemical reaction and promote the leaching of Scandium. But the concentration of leaching system is too low, and the concentration of leaching agent in unit pulp is significantly reduced. In order to improve the progress of chemical reaction and the leaching efficiency of scandium, it is necessary to guarantee the leaching agent in a reasonable concentration range. Therefore, the solid-liquid ratio R2 = 1:1.5 was suitable. Scandium leaching efficiency of 95.24%, dissolution efficiency of 36.82%, and leaching residue with Sc2O3 content of 8.17 g/t were obtained.

3.2.6. Scale-Up Acid Leaching Test of Scandium Extraction

In order to further verify the test repeatability, the scale-up test was carried out under comprehensive conditions, and employed a hydrochloric acid dosage of 20%, leaching time of 90 min, leaching temperature of 60 °C, and solid–liquid ratio of R2 = 1:1.5. The mass of ore samples was increased to 1000 g for each test and the scale-up test was repeated three times. The main chemical components of the leaching residue are shown in Table 6. It can be seen from Table 6 that the scandium content in the leaching residue of the scale-up test was 8.12 g/t, and the dissolution efficiency was 34.99%, and the leaching efficiency of scandium was 95.12%. Compared with the single leaching condition, the scandium extraction index is relatively ideal.

Table 6.

Main chemical composition analysis results of scale-up acid leaching test (wt %).

3.3. Analysis and Characterization of Scandium Rough Concentrate, Roasting Ores, Hydrolysis Residue, and Leaching Residue

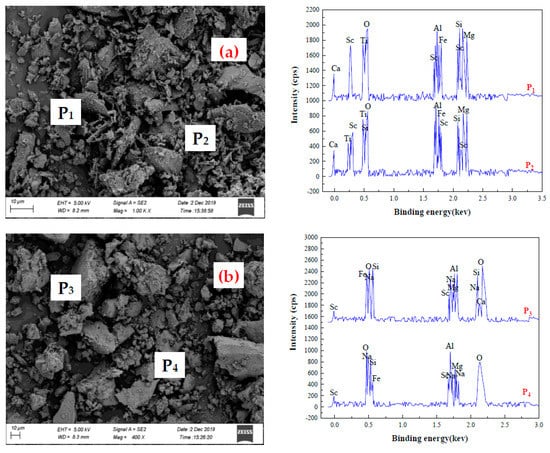

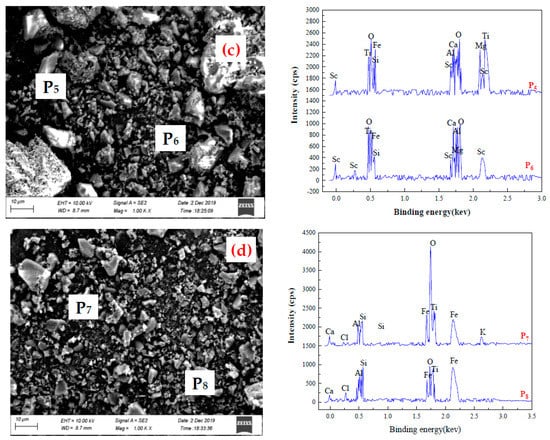

The novel process of alkali fusion roasting-hydrolysis-acid leaching was used to treat the scandium rough concentrate, which realized the efficient extraction of scandium. Scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS) were used to analyze the scandium rough concentrate, alkali fusion roasted ore, hydrolysis residue and leaching residue respectively. X-ray diffraction (XRD) was used to analyze the main minerals in the leaching residue. The SEM-EDS images analysis results of scandium rough concentrate, roasting ores, hydrolysis residue, and leaching residue are shown in Figure 8. The XRD analysis results of hydrochloric acid leaching residue are shown in Figure 9.

Figure 8.

SEM-EDS images analysis results (a) scandium rough concentrate, (b) roasting ores, (c) hydrolysis residue, (d) leaching residue.

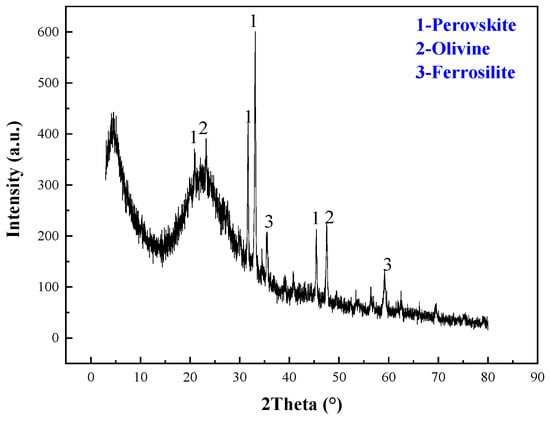

Figure 9.

X-ray diffraction (XRD) diffractogram of hydrochloric acid leaching residue.

Analysis and characterization results from Figure 8 and Figure 9 show that, after alkali fusion roasting, the morphology of the scandium rough concentrate has changed, which destroys the crystal structure of Sc-bearing minerals. After the hydrolysis residue dissolves most of the silicon and aluminum, the scandium content is further enriched, which creates favorable conditions for the acid leaching separation of scandium, thereby greatly reducing the silicon and aluminum content in the scandium containing leaching solution. There is no obvious peak value of Sc spectrum in EDS analysis spectrum of hydrochloric acid leach residue. The data in Table 6 show that the content of scandium in leach residue was 8.12 g/t, and the leaching efficiency of scandium is 95.12%. This shows that most of scandium in alkali fusion baking water leach residue is dissolved into Sc3+ and then enters into liquid phase, and the leaching efficiency of scandium was 95.12%, demonstrating the significant separation effect of scandium. The main minerals of the leaching residue are perovskite, ferric silicate, and olivine.

4. Conclusions

Based on the results obtained in this work, we draw the following conclusions:

(1) Rough scandium concentrate contained Sc2O3 of 76.98 g/t was prepared from Sc-bearing V-Ti magnetite tailings in the Panxi area by magnetic separation, gravity separation, and electric separation. The minerals closely related to scandium are mainly titanaugite, plagioclase, diopside, chlorite, and mica.

(2) A roasting-hydrolysis-acid leaching is used to treat the scandium rough concentrate. SiO2 and Al2O3 are removed in advance by roasting-hydrolysis to decrease impurities in Scandium lixivium. Test results show that Sc2O3 in the hydrolytic residue was enriched from 76.98 g/t to 108.24 g/t, with the enrichment ratio of 108.24/76.98 = 1.41; SiO2 was reduced from 27.08% to 11.24%, Al2O3 was reduced from 21.67% to 10.78% under the following conditions: roasting temperature of 900 °C, roasting time of 75 min, sodium hydroxide dosage of 7.5%, sodium oxide dosage of 7.5%, hydrolysis temperature of 70 °C, hydrolysis time of 90 min, hydrolysis solid-liquid ratio of R1 = 1:2.

(3) Scandium is further recovered from roasting-hydrolysis residue by acid leaching, test results show that the leaching efficiency of scandium was 95.12% and the leaching residue with Sc2O3 content of 8.12 g/t under the conditions of hydrochloric acid dosage of 20%, leaching time of 90 min, leaching temperature of 60 °C, solid-liquid ratio of R2 = 1:1.5 were obtained.

(4) SEM, EDS, XRD analysis, and characterization results show that there is no obvious peak value of Sc spectrum in hydrochloric acid leaching residue, most of scandium in hydrolytic residue is dissolved into the liquid phase, and the main minerals of the leaching residue are perovskite, ferric silicate, and olivine.

Author Contributions

This is a joint work of the six authors; each author was in charge of their expertise and capability: J.X. for writing, formal analysis, and original draft preparation; Y.P. and W.D. for conceptualization; T.C. for validation; Z.W. For methodology; K.Z. for investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Sichuan Science and Technology Program (Grant Nos. 2018FZ0092); Key Laboratory of Sichuan Province for Comprehensive Utilization of Vanadium and Titanium Resources Foundation(2018FTSZ35); China Geological Big Survey (Grant No. DD20190694).

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design, analyses, and interpretation of any data of the study.

References

- Moëlo, Y.; Lulzac, Y.; Rouer, O.; Palvadeau, P.; Gloaguen, É.; Léone, P. Scandium mineralogy: Pretulite with scandian zircon and xenotime-(Y) within an apatite-rich oolitic ironstone from Saint-Aubin-Des-Châteaux, Armorican Massif, France. Can. Mineral. 2002, 40, 1657–1673. [Google Scholar] [CrossRef]

- Chi, R.A.; Wang, D.Z. Rare Earth Dressing and Extraction Technology; Science Press: Beijing, China, 1996; p. 293. [Google Scholar]

- Xiao, J.H.; Wang, J.M.; Wang, Z. Study on Occurrence State of Scandium of Scandium-Containing Rare Earth Ore in Western of Sichuan Province. Chin. Rare Earths 2018, 39, 40–47. (In Chinese) [Google Scholar]

- Anawati, J.; Azimi, G. Recovery of scandium from Canadian bauxite residue utilizing acid baking followed by water leaching. Waste Manag. 2019, 95, 549–559. [Google Scholar] [CrossRef] [PubMed]

- Borra, C.R.; Mermans, J.; Blanpain, B.; Pontikes, Y.; Binnemans, K.; Van Gerven, T. Selective recovery of rare earths from bauxite residue by combination of sulfation, roasting and leaching. Miner. Eng. 2016, 92, 151–159. [Google Scholar] [CrossRef]

- Le, W.H.; Kuang, S.T.; Zhang, Z.F.; Wu, G.L.; Li, Y.L.; Liao, C.F.; Liao, W.P. Selective extraction and recovery of Scandium from sulfate medium by Cextrant 230. Hydrometallurgy 2018, 178, 54–59. [Google Scholar] [CrossRef]

- Onghena, B.; Borra, C.R.; Van Gerven, T.; Binnemans, K. Recovery of Scandium from sulfation-roasted leachates of bauxite residue by solvent extraction with the ionic liquid betainium bis (trifluoromethylsulfonyl) imide. Sep. Purif. Technol. 2017, 176, 208–219. [Google Scholar] [CrossRef]

- Li, G.H.; Ye, Q.; Deng, B.N.; Luo, J.; Rao, M.J.; Peng, Z.W.; Jiang, T. Extraction of scandium from scandium-rich material derived from bauxite ore residues. Hydrometallurgy 2018, 176, 62–68. [Google Scholar] [CrossRef]

- Li, S.C.; Kim, S.C.; Kang, C.G. Recovery of Scandium from KOH sub-molten salt leaching cake of fergusonite. Miner. Eng. 2019, 137, 200–206. [Google Scholar] [CrossRef]

- Biswal, J.; Goswami, S.; Pant, H.J.; Bamankar, Y.R.; Rao, T.V.R.V.; Upadhay, R.K.; Dash, A. Synthesis, Characterization, Neutron Activation, and Application of Scandium Oxide Microsphere in Radioactive Particle Tracking Experiments. Ind. Eng. Chem. Res. 2016, 55, 3–12. [Google Scholar] [CrossRef]

- Gao, L.K.; Rao, B.; Dai, H.X.; Hong, Z.; Xie, H.Y. Separation and Extraction of Scandium and Titanium from a Refractory Anatase Lixivium by Solvent Extraction with D2EHPA and Primary Amine N1923. J. Chem. Eng. Jpn. 2019, 52, 822–828. [Google Scholar] [CrossRef]

- Hu, J.S.; Zou, D.; Chen, J.; Li, D.Q. A novel synergistic extraction system for the recovery of Scandium (III) by Cyanex 272 and Cyanex 923 in sulfuric acid medium. Sep. Purif. Technol. 2019, 23, 115977. [Google Scholar]

- Xiao, J.H.; Zhang, Y.S. Recovering Cobalt and Sulfur in Low Grade Cobalt-Bearing V–Ti Magnetite Tailings Using Flotation Process. Processes 2019, 7, 536. [Google Scholar] [CrossRef]

- Jankovsky, O.; Sedmidubsky, D.; Simek, P.; Klimova, K.; Bousa, D.; Boothroyd, C.; Mackova, A.; Sofer, Z. Separation of thorium ions from wolframite and Scandium concentrates using graphene oxide. Phys. Chem. Chem. Phys. 2015, 17, 25272–25277. [Google Scholar] [CrossRef] [PubMed]

- Kostikova, G.V.; Mal’tseva, I.E.; Zhilov, V.I. Extraction Recovery of Scandium and Concomitant Elements with Isoamyldialkylphosphine Oxide from Different Media. Russ. J. Inorg. Chem. 2019, 64, 277–282. [Google Scholar] [CrossRef]

- Purcell, W.; Potgieter, H.; Nete, M.; Mnculwane, H. Possible methodology for niobium, tantalum and Scandium extraction in ferrocolumbite. Miner. Eng. 2018, 119, 57–66. [Google Scholar] [CrossRef]

- Rychkov, V.N.; Semenishchev, V.S.; Mashkovtsev, M.A.; Kirillov, E.V.; Kirillov, S.V.; Bunkov, G.M.; Botalov, M.S. Deactivation of the Scandium concentrate recovered from uranium leach liquors. J. Radioanal. Nucl. Chem. 2016, 310, 1247–1253. [Google Scholar] [CrossRef]

- Ding, W.; Xiao, J.H.; Peng, Y.; Shen, S.Y.; Chen, T. Iron Extraction from Red Mud using Roasting with Sodium Salt. Miner. Process. Extr. Metall. Rev. 2019. [Google Scholar] [CrossRef]

- Kudryavskii, Y. Technology of deep removal of impurities from Scandium oxide with the acquisition of high-purity Scandium oxide. Russ. J. Non-Ferr. Met. 2011, 52, 420–422. [Google Scholar] [CrossRef]

- Xiao, J.H.; Zhang, Y.S. Extraction of Cobalt and Iron from Refractory Co-Bearing Sulfur Concentrate. Processes 2020, 8, 200. [Google Scholar] [CrossRef]

- Kuzmin, V.I.; Kuzmina, V.N.; Gudkova, N.V.; Kuzmin, D.V. Extraction of metal bromides from chloride brines with mixtures of molecular iodine and tributyl phosphate. Hydrometallurgy 2018, 180, 221–228. [Google Scholar] [CrossRef]

- Sharaf, M.; Yoshida, W.; Kubota, F.; Goto, M. Selective Extraction of Scandium by a Long Alkyl Chain Carboxylic Acid/Organophosphonic Ester Binary Extractant. Solvent Extr. Ion Exch. 2018, 36, 647–657. [Google Scholar] [CrossRef]

- Xiao, J.H.; Zhou, L.L. Increasing Iron and Reducing Phosphorus Grades of Magnetic-Roasted High-Phosphorus Oolitic Iron Ore by Low-Intensity Magnetic Separation–Reverse Flotation. Processes 2019, 7, 388. [Google Scholar] [CrossRef]

- Smirnov, P.R.; Grechin, O.V. Structure of concentrated aqueous solutions of Scandium chloride. Russ. J. Phys. Chem. A 2017, 91, 517–520. [Google Scholar] [CrossRef]

- Simonova, T.N.; Fedotov, A.N.; Alemasova, N.V. Extraction of Scandium Nitrate and Thiocyanate Complexes Using Two-Phase Aqueous Systems and the Determination of Scandium. J. Anal. Chem. 2018, 73, 18–22. [Google Scholar] [CrossRef]

- Peng, Y.; Xiao, J.H.; Deng, B.; Wang, Z.; Liu Ny Yang, D.G.; Ding, W.; Chen, T.; Wu, Q. Study on separation of fine-particle ilmenite and mechanism using flocculation flotation with sodium oleate and polyacrylamide. Physicochem. Probl. Miner. Process. 2020, 56, 161–172. [Google Scholar]

- Zhang, W.; Yu, S.Q.; Zhang, S.C.; Zhou, J.; Ning, S.Y.; Wang, X.P.; Wei, Y.Z. Separation of Scandium from the other rare earth elements with a novel macro-porous silica-polymer based adsorbent HDEHP/SiO2-P. Hydrometallurgy 2019, 185, 117–124. [Google Scholar] [CrossRef]

- Souza, A.G.O.; Aliprandini, P.; Espinosa, D.C.R.; Tenorio, J.A.S. Scandium Extraction from Nickel Processing Waste Using Cyanex 923 in Sulfuric Medium. JOM 2019, 71, 2003–2009. [Google Scholar] [CrossRef]

- Xiao, J.H.; Ding, W.; Peng, Y.; Wu, Q.; Chen, Z.Q.; Wang, Z.; Wang, J.M.; Peng, T.F. Upgrading iron and removing phosphorus of high phosphorus Oolitic iron ore by segregation roasting with Calcium chloride and Calcium hypochlorite. J. Min. Metall. Sect. B Metall. 2019, 55, 305–314. [Google Scholar] [CrossRef]

- Xiao, J.H.; Liang, G.J.; Huang, W.X.; Ding, W.; Peng, Y.; Wu, Q. Research on Separating Iron and Scandium of Scandium-contained Red Mud Using Sodium Chloride Segregation Roasting-Low Intensity Magnetic Separation-Hydrochloric Acid Leaching. Adv. Eng. Sci. 2019, 51, 199–209. (In Chinese) [Google Scholar]

- Zhou, G.T.; Li, Q.G.; Sun, P.; Guan, W.J.; Zhang, G.Q.; Cao, Z.Y.; Zeng, L. Removal of impurities from Scandium chloride solution using 732-type resin. J. Rare Earths 2018, 36, 311–316. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).