Utilization of Pyrolytic Carbon Black Waste for the Development of Sustainable Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Basic Material Characteristics

2.1.2. Carbon Black

2.2. Mix Design and Preparation of Test Specimens

2.3. Testing Methods

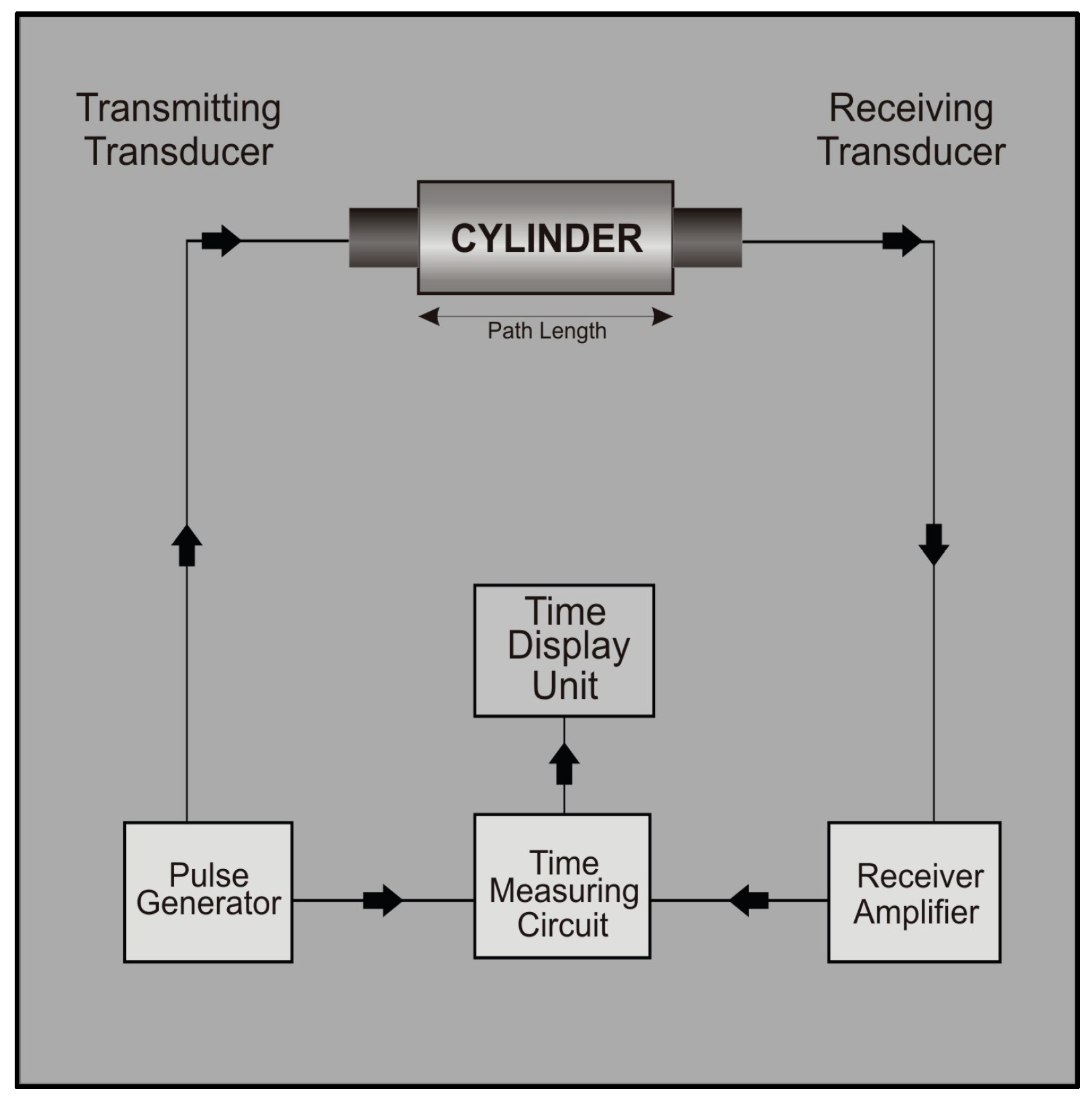

2.3.1. Non-Destructive Testing

- µ = Poisson ratio;

- V = pulse velocity (m/s);

- ρ =density of concrete (kg/m3);

- Ed = dynamic modulus of elasticity (GPa).

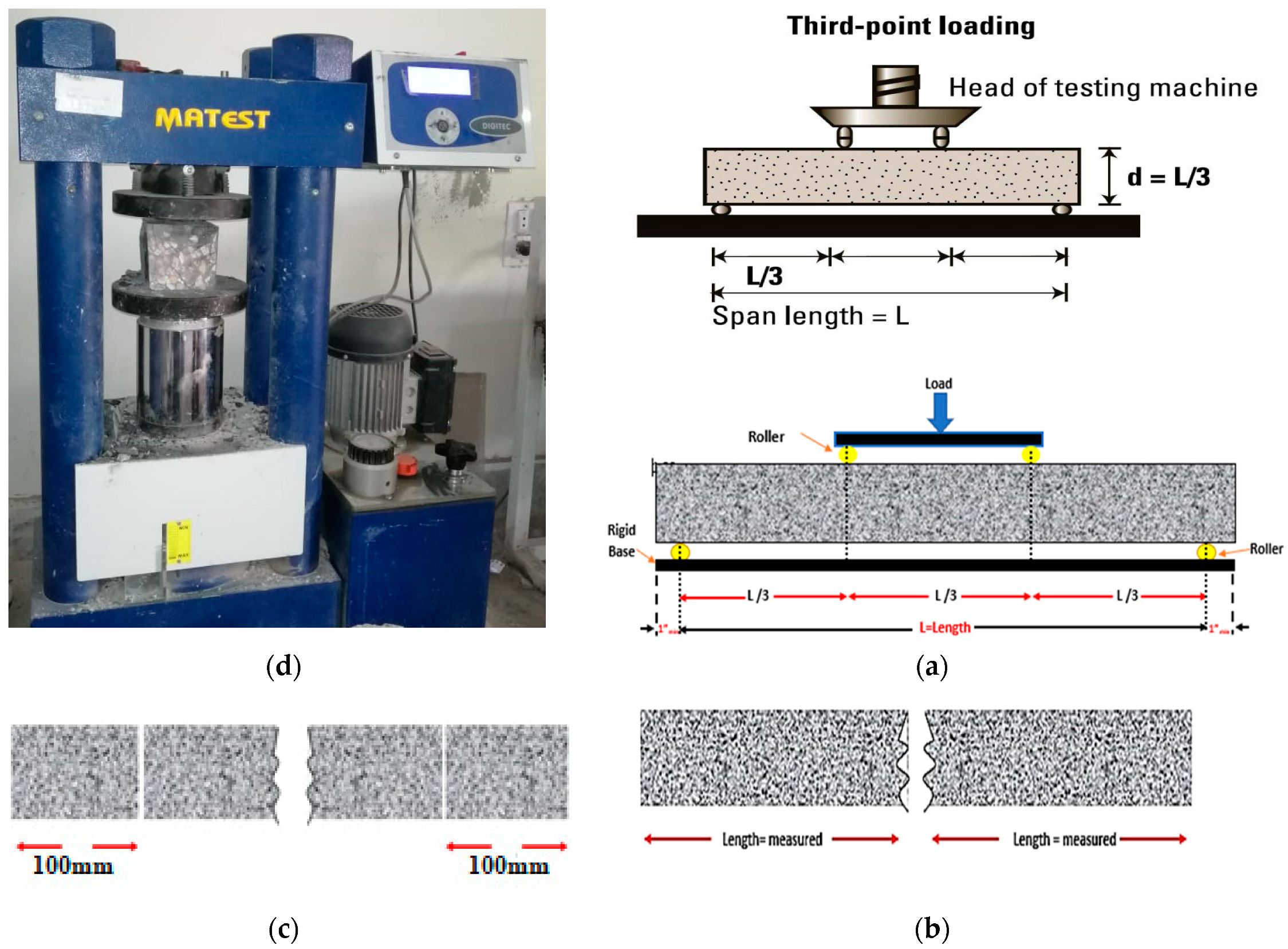

2.3.2. Destructive Testing

- fc’ = compressive strength (MPa);

- fr = flexural strength (MPa).

3. Results and Discussion

3.1. Fresh Concrete Test

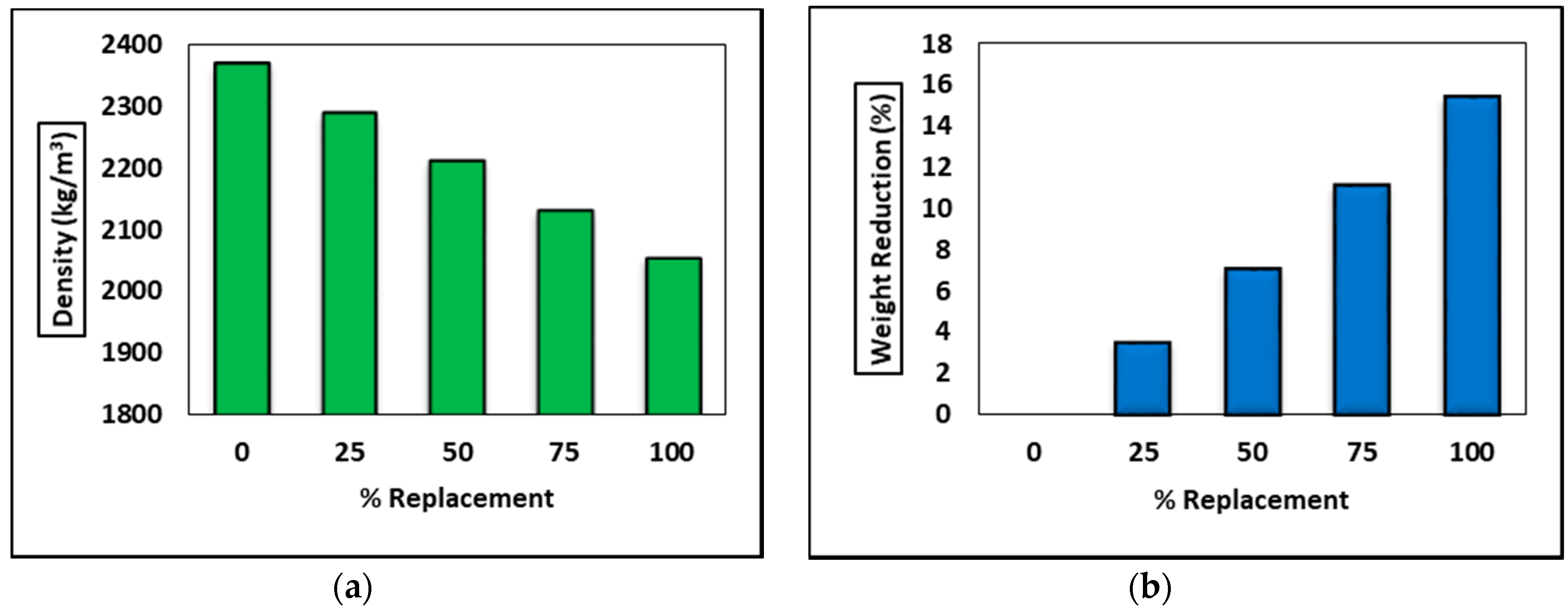

3.2. Density

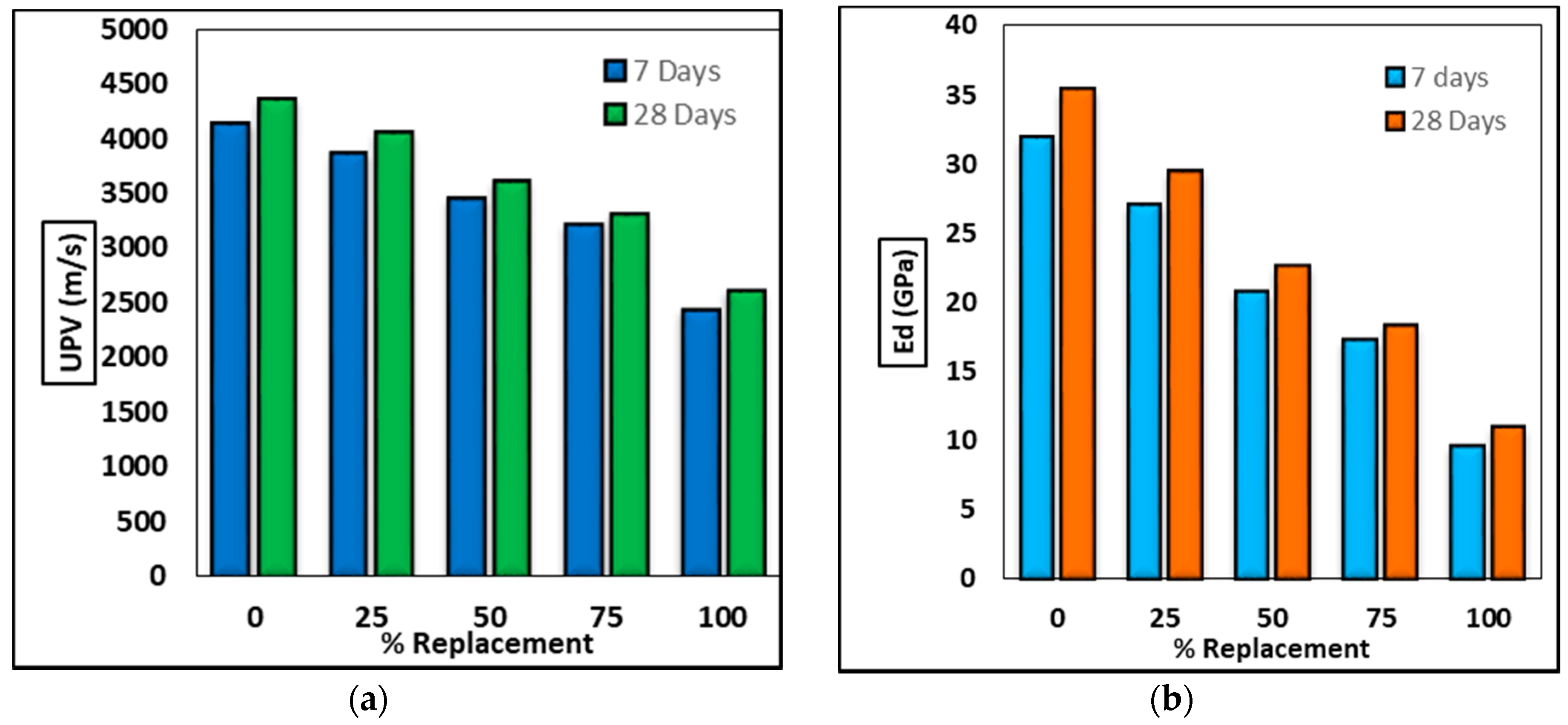

3.3. Non-Destructive Testing

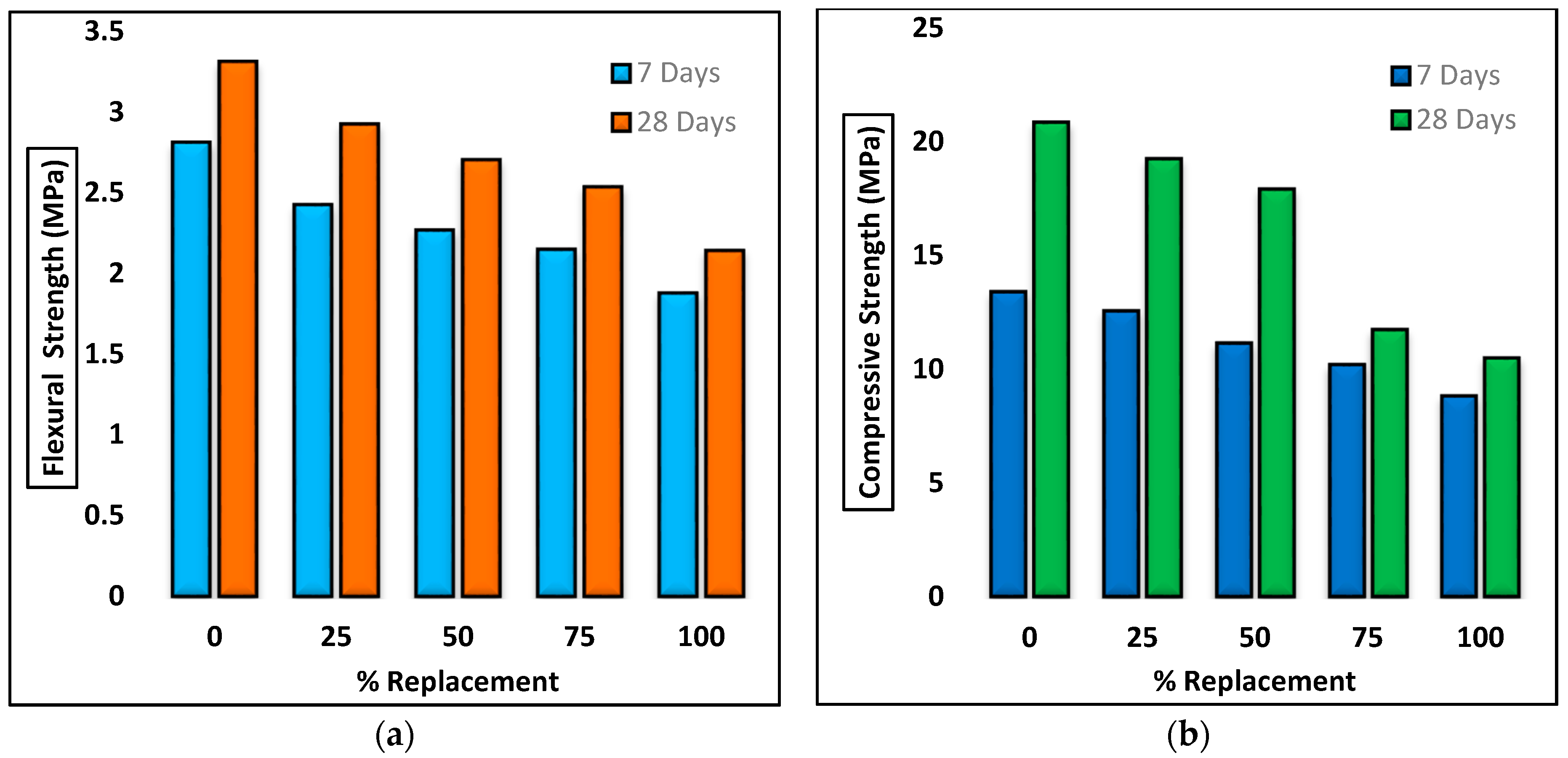

3.4. Destructive Testing

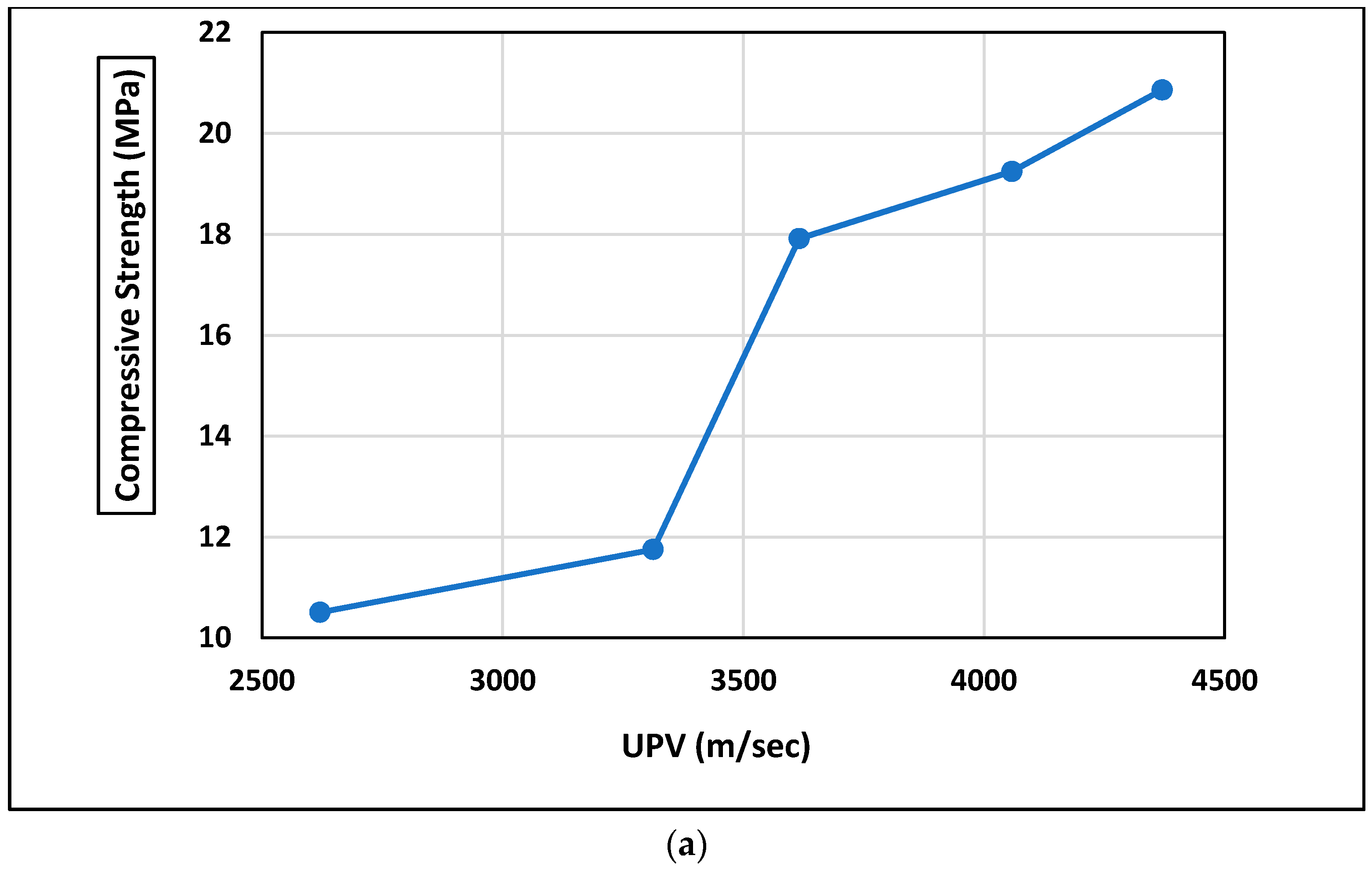

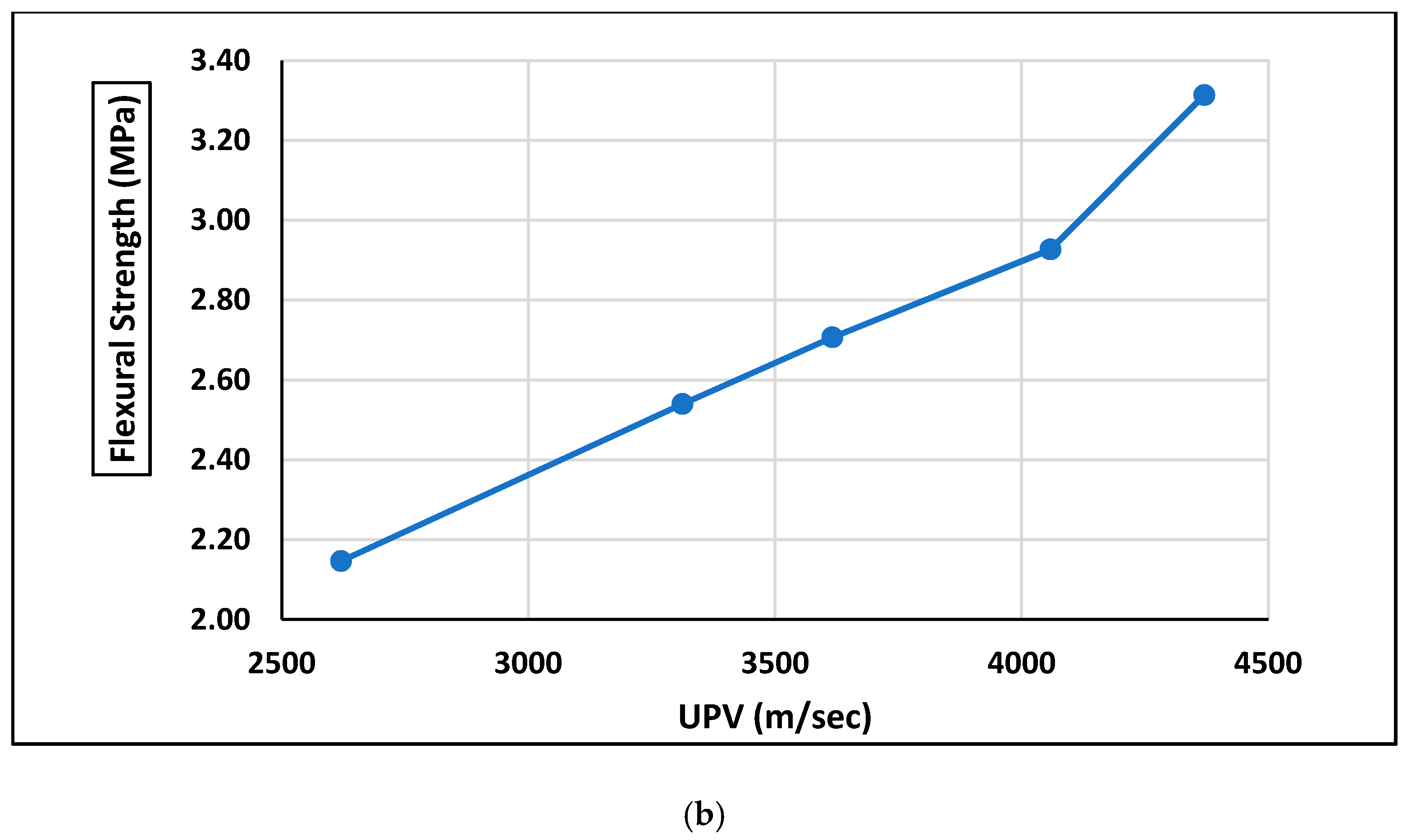

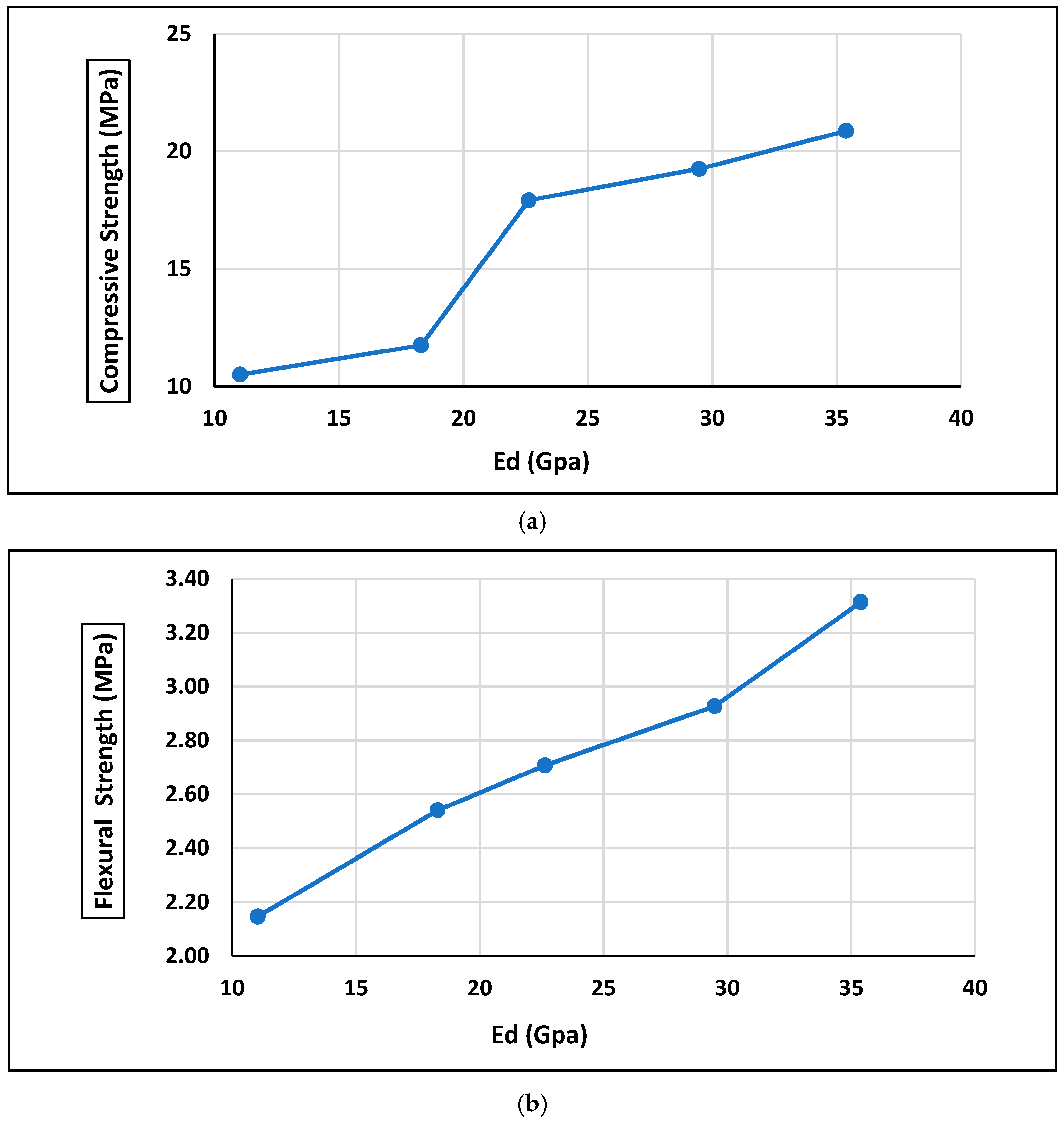

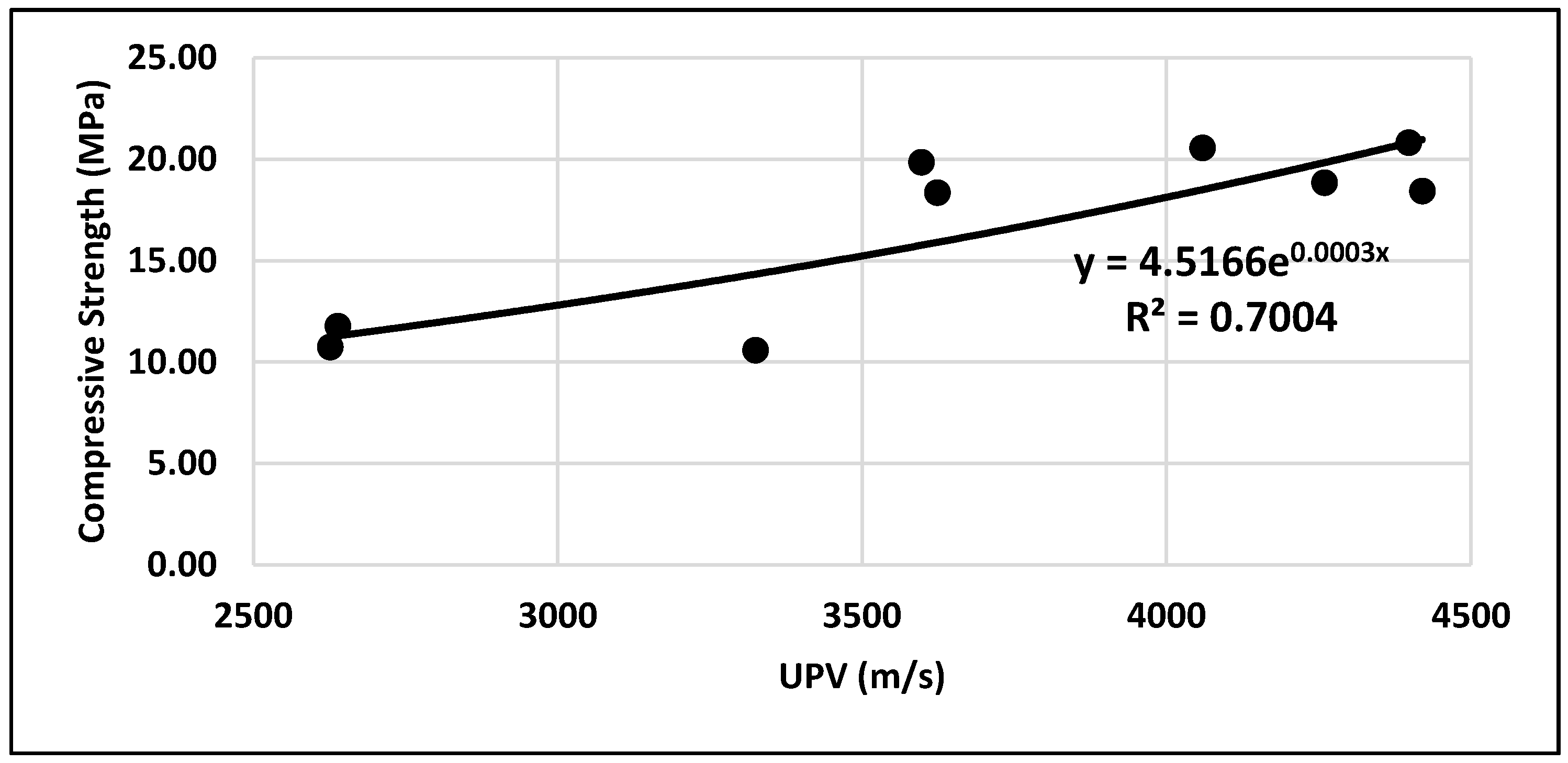

3.5. Destructive and Non-Destructive Results

3.6. Statistical Analysis

3.7. Cost Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ismail, I.; Saim, A.A.; Latif Saleh, A. Properties of hardened concrete bricks containing expanded polystyrene beads. In Proceedings of the 5th Asia-Pacific Structural Engineering and Construction Conference, Johor Bahru, Malaysia, 26–28 August 2003. [Google Scholar]

- Scrivener, K.L.; Kirkpatrick, R.J. Innovation in use and research on cementitious material. Cem. Concr. Res. 2008, 38, 128–136. [Google Scholar] [CrossRef]

- Padma, B.; Pandeeswari, K. Experimental investigation on the properties of concrete with carbon black and PET. Int. J. Adv. Res. 2016, 4, 1082–1088. [Google Scholar]

- Manoharan, P.; Ravichandran, P.T.; Annadurai, R.; Rajkumar, P.K. Studies on Properties of Concrete Using Crumb Rubber as Fine Aggregate. In International Conference on Intelligent Computing and Applications; Springer: Singapore, 2019; pp. 197–203. [Google Scholar]

- Xu, Y.; Jiang, L.; Xu, J.; Li, Y. Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr. Build. Mater. 2012, 27, 32–38. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Alshihri, M.M.; Azmy, A.M.; El-Bisy, M.S. Neural networks for predicting compressive strength of structural light weight concrete. Constr. Build. Mater. 2009, 23, 2214–2219. [Google Scholar] [CrossRef]

- Yasar, E.; Atis, C.D.; Kilic, A.; Gulsen, H. Strength properties of lightweight concrete made with basaltic pumice and fly ash. Mater. Lett. 2003, 57, 2267–2270. [Google Scholar] [CrossRef]

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and thermal properties of lightweight concretes with vermiculite and EPS using air-entraining agent. Constr. Build. Mater. 2014, 57, 190–197. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Contribution of hybrid fibers on the properties of the high-strength lightweight concrete having good workability. Cem. Concr. Res. 2005, 35, 913–917. [Google Scholar] [CrossRef]

- Ferrándiz-Mas, V.; García-Alcocel, E. Durability of expanded polystyrene mortars. Constr. Build. Mater. 2013, 46, 175–182. [Google Scholar] [CrossRef]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Chia, K.S.; Zhang, M.H. Water permeability and chloride penetrability of high-strength lightweight aggregate concrete. Cem. Concr. Res. 2002, 32, 639–645. [Google Scholar] [CrossRef]

- Kitouni, S.; Houari, H. Lightweight concrete with Algerian limestone dust. Part II: Study on 50% and 100% replacement to normal aggregate at timely age. Cerâmica 2015, 61, 462–468. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, D.; Yang, J. Mechanical Properties and Conversion Relations of Strength Indexes for Stone/Sand-Lightweight Aggregate Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 5402953. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, M.G.; Gomes, A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 2013, 53, 962–972. [Google Scholar] [CrossRef]

- Qurashi, M.A.; Shah, S.A.R.; Farhan, M.; Taufiq, M.; Khalid, W.; Arshad, H.; Waseem, M. Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete. Processes 2019, 7, 791. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A.; Najimi, M. Properties of multi-strength grade EPS concrete containing silica fume and rice husk ash. Constr. Build. Mater. 2012, 35, 211–219. [Google Scholar] [CrossRef]

- Colangelo, F.; Messina, F.; Di Palma, L.; Cioffi, R. Recycling of non-metallic automotive shredder residues and coal fly-ash in cold-bonded aggregates for sustainable concrete. Compos. Part B 2017, 116, 46–52. [Google Scholar] [CrossRef]

- Sabaa, B.; Ravindrarajah, R.S. Engineering properties of lightweight concrete containing crushed expanded polystyrene waste. In Proceedings of the Symposium MM: Advances in Materials for Cementitious Composites, Boston, MA, USA, 1–3 December 1997. [Google Scholar]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Václavík, V.; Dvorský, T.; Dirner, V.; Daxner, J.; Šťastný, M. Polyurethane foam as aggregate for thermal insulating mortars and lightweight concrete. Tech. Gazette 2012, 19, 665–672. [Google Scholar]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Williams, P.T.; Besler, S.; Taylor, D.T. The pyrolysis of scrap automotive tyres: The influence of temperature and heating rate on product composition. Fuel 1990, 69, 1474–1482. [Google Scholar] [CrossRef]

- Garrick, G.M. Analysis and Testing of Waste Tire Fiber Modified Concrete. LSU Master’s Thesis, Louisiana State University and Agricultural and Mechanical College, Baton Rouge, LA, USA, 2005. [Google Scholar]

- Hernández-Olivares, F.; Barluenga, G.; Parga-Landa, B.; Bollati, M.; Witoszek, B. Fatigue behaviour of recycled tyre rubber-filled concrete and its implications in the design of rigid pavements. Constr. Build. Mater. 2007, 21, 1918–1927. [Google Scholar] [CrossRef]

- Khatib, Z.K.; Bayomy, F.M. Rubberized Portland cement concrete. J. Mater. Civ. Eng. 1999, 11, 206–213. [Google Scholar] [CrossRef]

- Atahan, A.O.; Yücel, A.Ö. Crumb rubber in concrete: Static and dynamic evaluation. Constr. Build. Mater. 2012, 36, 617–622. [Google Scholar] [CrossRef]

- Najim, K.B.; Hall, M.R. Mechanical and dynamic properties of self-compacting crumb rubber modified concrete. Constr. Build. Mater. 2012, 27, 521–530. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Bakar, B.A.; Ismail, H.; Akil, H.M. Effect of partial replacement of sand by recycled fine crumb rubber on the performance of hybrid rubberized-normal concrete under impact load: Experiment and simulation. J. Clean. Prod. 2013, 59, 284–289. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J. Concrete made with used tyre aggregate: Durability-related performance. J. Clean. Prod. 2012, 25, 42–50. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Turatsinze, A.; Bonnet, S.; Granju, J.L. Potential of rubber aggregates to modify properties of cement based-mortars: Improvement in cracking shrinkage resistance. Constr. Build. Mater. 2007, 21, 176–181. [Google Scholar] [CrossRef]

- Ho, A.; Turatsinze, A.; Vu, D. On the potential of rubber aggregates obtained by grinding end-of-life tyres to improve the strain capacity of concrete. In Concrete Repair, Rehabilitation and Retrofitting II; CRC Press/Balkema: AK Leiden, The Netherlands, 2008. [Google Scholar]

- Martínez, J.D.; Cardona-Uribe, N.; Murillo, R.; García, T.; López, J.M. Carbon black recovery from waste tire pyrolysis by demineralization: Production and application in rubber compounding. Int. J. Environ. Waste Manag. 2019, 85, 574–584. [Google Scholar] [CrossRef] [PubMed]

- Zabaniotou, A.; Antoniou, N.; Bruton, G. Analysis of good practices, barriers and drivers for ELTs pyrolysis industrial application. Waste Manag. 2014, 34, 2335–2346. [Google Scholar] [CrossRef] [PubMed]

- Raza, M.A.; Vakil, A.; Anjum, N.; Gani, T.; Ansari, A. A Review on Influence of Manufacturing Waste (Carbon Black) on Properties of Concrete. Int. J. Sci. Res. Sci. Technol. (IJSRST). 2018, 4, 129–131. [Google Scholar]

- Sagar, M.; Nibedita, K.; Manohar, N.; Kumar, K.R.; Suchismita, S.; Pradnyesh, A.; Jayaramudu, J.A. potential utilization of end-of-life tyres as recycled carbon black in EPDM rubber. Waste Manag. 2018, 74, 110–122. [Google Scholar] [CrossRef]

- Gómez-Hernández, R.; Panecatl-Bernal, Y.; Méndez-Rojas, M.Á. High yield and simple one-step production of carbon black nanoparticles from waste tires. Heliyon 2019, 5, e02139. [Google Scholar] [CrossRef]

- Ding, Y.; Chen, Z.; Han, Z.; Zhang, Y.; Pacheco-Torgal, F. Nano-carbon black and carbon fiber as conductive materials for the diagnosing of the damage of concrete beam. Constr. Build. Mater. 2013, 43, 233–241. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Partial replacement of carbon fiber by carbon black in multifunctional cement–matrix composites. Carbon 2007, 45, 505–513. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, G.; Hussain, A.; Pacheco-Torgal, F.; Zhang, Y. Effect of steel fiber and carbon black on the self-sensing ability of concrete cracks under bending. Constr. Build. Mater. 2019, 207, 630–639. [Google Scholar] [CrossRef]

- Jeyashree, T.; Chitra, G. Experimental Studies on Concrete Elements Using waste Carbon Black as Filler Material. Asian J. Civ. Eng. (BHRC) 2017, 18, 21–30. [Google Scholar]

- Dehghanpour, H.; Yilmaz, H.K.; Ipek, M. Evaluation of recycled nano carbon black and waste erosion wires in electrically conductive concretes. Constr. Build. Mater. 2019, 221, 109–121. [Google Scholar] [CrossRef]

- Xiao, W.; Sun, Q.; Liu, J.; Xiao, B.; Glans, P.A.; Li, J.; Li, R.; Guo, J.; Yang, W.; Sham, T.K.; et al. Utilizing the full capacity of carbon black as anode for Na-ion batteries via solvent co-intercalation. J. Nano Res. 2017, 10, 4378–4387. [Google Scholar] [CrossRef]

- Masadeh, S. The effect of added carbon black to concrete mix on corrosion of steel in concrete. Miner. Mater. Charact. Eng. 2015, 3, 271. [Google Scholar] [CrossRef]

- Santhiago, M.; Corrêa, C.C.; Bernardes, J.S.; Pereira, M.P.; Oliveira, L.J.; Strauss, M.; Bufon, C.C. Flexible and foldable fully printed carbon black conductive nanostructures on paper for high-performance electronic, electrochemical, and wearable devices. ACS Appl. Mater. Interfaces 2017, 9, 24365–24372. [Google Scholar] [CrossRef] [PubMed]

- Goldman, A.; Bentur, A. The influence of microfillers on enhancement of concrete strength. Cem. Concr. Res. 1993, 23, 962–972. [Google Scholar] [CrossRef]

- Lim, S.X.; Wong, K.L.; Zhang, Z.; Neto, A.H.C.; Sow, C.H. Polychromic carbon black: Laser galvanized multicolour fluorescence display. J. Nano Res. 2019, 12, 733–740. [Google Scholar] [CrossRef]

- Paczosa-Bator, B.; Cabaj, L.; Piech, R.; Skupień, K. Potentiometric sensors with carbon black supporting platinum nanoparticles. Anal. Chem. 2013, 85, 10255–10261. [Google Scholar] [CrossRef]

- Kharita, M.; Yousef, S.; AlNassar, M. The effect of carbon powder addition on the properties of hematite radiation shielding concrete. Prog. Nucl. Energy 2009, 51, 388–392. [Google Scholar] [CrossRef]

- Chitra, G.; Selvi, P.V.; Vijayalakshmi, D. Carbon black as an additive in conventional concrete. Int. J. Emerg. Tech. Adv. Eng. 2014, 4, 194–201. [Google Scholar]

- Srivastava, S.K.; Mishra, Y.K. Nanocarbon reinforced rubber nanocomposites: Detailed insights about mechanical, dynamical mechanical properties, payne, and mullin effects. Nanomaterials 2018, 8, 945. [Google Scholar] [CrossRef]

- Carbas, R.J.; da Silva, L.F.; Andrés, L.F. The Mechanical Response of a Structural Epoxy Adhesive Reinforced with Carbon Black Nanoparticles. Microsc. Microanal. 2019, 25, 187–191. [Google Scholar] [CrossRef] [PubMed]

- ASTM C150-07. Standard Specification for Portland Cement; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM C114-06. Standard Test Methods for Chemical Analysis of Hydraulic Cement; American Society for Testing of Materials: Philadelphia, PA, USA, 2004. [Google Scholar]

- ASTM C187-98. Standard Test Method for Normal Consistency of Hydraulic Cement; Annual Book of ASTM Standards, American Society for Testing and Material: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM C191-13. Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C188-17. Standard Test Method for Density of Hydraulic Cement; American Society for Testing and Material: West Conshohocken, PA, USA, 2009. [Google Scholar]

- BSI, BS EN 196-3. Methods of Testing Cement–Part 3: Determination of Setting Times and Soundness; British Standards Institution: London, UK, 2005. [Google Scholar]

- ASTM C136-01. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; Annual Book of Standards, American Society for Testing and Material: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM C33/C33M-11a. Standard Specification for Concrete Aggregates; American Society for Testing and Material: West Conshohocken, PA, USA, 2004; pp. 1–11. [Google Scholar]

- ASTM C29/C29M-07. Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- BSI B812-112:1990. Testing Aggregates. Method for Determination of Aggregate Impact Value (AIV); British Standards Institution: London, UK, 1990. [Google Scholar]

- BSI B812-110:1990. Testing Aggregates—Methods for Determination of Aggregate Crushing Value (ACV); British Standards Institution: London, UK, 1990. [Google Scholar]

- ASTM C131/C131M. Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM C128-15. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C143/C143M-05a. Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM: Philadelphia, PA, USA, 2005. [Google Scholar]

- ASTM C192/C192M-18. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Shetty, M.S. Concrete Technology, 2nd ed.; S. Chand & Company Ltd.: New Delhi, India, 2005. [Google Scholar]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM C597-16. Standard Test Method for Pulse Velocity through Concrete; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Al-Amawee, A.H.; Salman, M.M. The Ratio between Static and Dynamic Modulus of Elasticity in Normal and High Strength Concrete. J. Eng. Sustain. Dev. 2006, 10, 163–174. [Google Scholar]

- ASTM C78/C78M-18. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); American Society for Testing and Materials: Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM C39/C39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; Annual book of ASTM standards: Conshohocken, PA, USA, 2018. [Google Scholar]

- McCormac, J.C.; Brown, R.H. Design of Reinforced Concrete; John Wiley & Sons: Manhattan, NY, USA, 2015. [Google Scholar]

- Akers, D.J.; Gruber, R.D.; Ramme, B.W.; Boyle, M.J.; Grygar, J.G.; Rowe, S.K.; Bremner, T.W.; Kluckowski, E.S.; Sheetz, S.R.; Burg, R.G.; et al. Guide for Structural Lightweight-Aggregate Concrete; ACI 213R-03; American Concrete Institute (ACI): Michigan, MI, USA, 2003. [Google Scholar]

| LOI | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| 3.48 | 20.80 | 4.97 | 3.15 | 63.17 | 1.86 | 2.64 | 0.66 | 0.42 |

| Property | Unit | Result | Standard |

|---|---|---|---|

| Ordinary Portland Cement | |||

| Bulk Density | kg/m3 | 1440.00 | ASTM C-188 |

| Normal Consistency | % | 28.00 | ASTM C-187 |

| Fineness | % | 96.34 | ASTM C-184 |

| Initial Setting Time | mints | 135.00 | ASTM C-191 |

| Final Setting Time | mints | 190.00 | ASTM C-191 |

| Soundness | mm | 1.00 | BS 196-3 |

| Fine Aggregates | |||

| Fineness Modulus | __ | 2.17 | ASTM C-136 |

| Bulk Density | kg/m3 | 1529.00 | ASTM C-29 |

| Coarse Aggregates | |||

| Bulk Density | kg/m3 | 1500.00 | ASTM C-29 |

| Aggregate Impact Value | % | 20.45 | BS 812-3 |

| Aggregate Crushing Value | % | 26.50 | BS 812-3 |

| Los Angeles abrasion | % | 31.00 | ASTM C-131 |

| Water Absorption | % | 3.50 | ASTM C-127 |

| Property | Unit | Result | Standard |

|---|---|---|---|

| Fineness Modulus | __ | 0.835 | ASTM C-136 |

| Bulk Density | kg/m3 | 801 | ASTM C-29 |

| Mix ID | Unit | WCB-0 | WCB-25 | WCB-50 | WCB-75 | WCB-100 |

|---|---|---|---|---|---|---|

| W/C Ratio | __ | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 |

| Water | Liter | 269.18 | 269.18 | 269.18 | 269.18 | 269.18 |

| Replacement of WCB | % | 0 | 25 | 50 | 75 | 100 |

| Cement | kg/m3 | 414.12 | 414.12 | 414.12 | 414.12 | 414.12 |

| Fine Aggregate | kg/m3 | 660.31 | 494.27 | 330.15 | 164.12 | 0 |

| Coarse Aggregate | kg/m3 | 1293.90 | 1293.90 | 1293.90 | 1293.90 | 1293.90 |

| Waste Carbon Black (WCB) | kg/m3 | 0 | 85.88 | 173.66 | 259.54 | 345.42 |

| Mix ID | Slump (cm) |

|---|---|

| WCB-0 | 5.08 |

| WCB-25 | 13.97 |

| WCB-50 | 15.24 |

| WCB-75 | 16.51 |

| WCB-100 | 7.62 |

| Mix ID | Experimental fr (MPa) | ACI fr (MPa) | % Difference |

|---|---|---|---|

| WCB-0 | 3.31 | 3.20 | –3.43 |

| WCB-25 | 2.93 | 3.07 | +4.78 |

| WCB-50 | 2.71 | 2.96 | +9.23 |

| WCB-75 | 2.54 | 2.40 | –5.51 |

| WCB-100 | 2.15 | 2.27 | +5.58 |

| Mix ID | UPV (m/s) | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| WCB-0 | 4370.44 ± 11.41 | 3.31 ± 0.07 | 20.86 ± 1.43 |

| WCB-25 | 4058.46 ± 9.96 | 2.93 ± 0.07 | 19.25 ± 1.15 |

| WCB-50 | 3616.25 ± 16.78 | 2.71 ± 0.06 | 17.92 ± 2.56 |

| WCB-75 | 3312.80 ± 20.21 | 2.54 ± 0.06 | 11.75 ± 1.34 |

| WCB-100 | 2620.66 ± 21.08 | 2.15 ± 0.07 | 10.51 ± 1.41 |

| Mix ID | Cement | Aggregate | Sand | WCB | Total | Cost Saving |

|---|---|---|---|---|---|---|

| USD($) | USD($) | USD($) | USD($) | USD($) | (%) | |

| WCB-0 | 29.39 | 9.81 | 3.93 | 0 | 48.34 | -- |

| WCB-25 | 29.39 | 9.81 | 2.94 | 0.48 | 47.83 | 1.06 |

| WCB-50 | 29.39 | 9.81 | 1.96 | 0.98 | 47.35 | 2.05 |

| WCB-75 | 29.39 | 9.81 | 0.98 | 1.46 | 46.85 | 3.08 |

| WCB-100 | 29.39 | 9.81 | 0 | 1.95 | 46.36 | 4.10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, F.; Khan, M.A.; Qurashi, M.A.; Shah, S.A.R.; Khan, N.M.; Khursheed, Z.; Rahim, H.S.; Arshad, H.; Farhan, M.; Waseem, M. Utilization of Pyrolytic Carbon Black Waste for the Development of Sustainable Materials. Processes 2020, 8, 174. https://doi.org/10.3390/pr8020174

Ali F, Khan MA, Qurashi MA, Shah SAR, Khan NM, Khursheed Z, Rahim HS, Arshad H, Farhan M, Waseem M. Utilization of Pyrolytic Carbon Black Waste for the Development of Sustainable Materials. Processes. 2020; 8(2):174. https://doi.org/10.3390/pr8020174

Chicago/Turabian StyleAli, Faizan, Mishmal Ahmed Khan, Muhammad Ahmed Qurashi, Syyed Adnan Raheel Shah, Nasir Mahmood Khan, Zia Khursheed, Hafiz Shahzaib Rahim, Hunain Arshad, Muhammad Farhan, and Muhammad Waseem. 2020. "Utilization of Pyrolytic Carbon Black Waste for the Development of Sustainable Materials" Processes 8, no. 2: 174. https://doi.org/10.3390/pr8020174

APA StyleAli, F., Khan, M. A., Qurashi, M. A., Shah, S. A. R., Khan, N. M., Khursheed, Z., Rahim, H. S., Arshad, H., Farhan, M., & Waseem, M. (2020). Utilization of Pyrolytic Carbon Black Waste for the Development of Sustainable Materials. Processes, 8(2), 174. https://doi.org/10.3390/pr8020174