A Hybrid Data-Based and Model-Based Approach to Process Monitoring and Control in Sheet Metal Forming

Abstract

1. Introduction

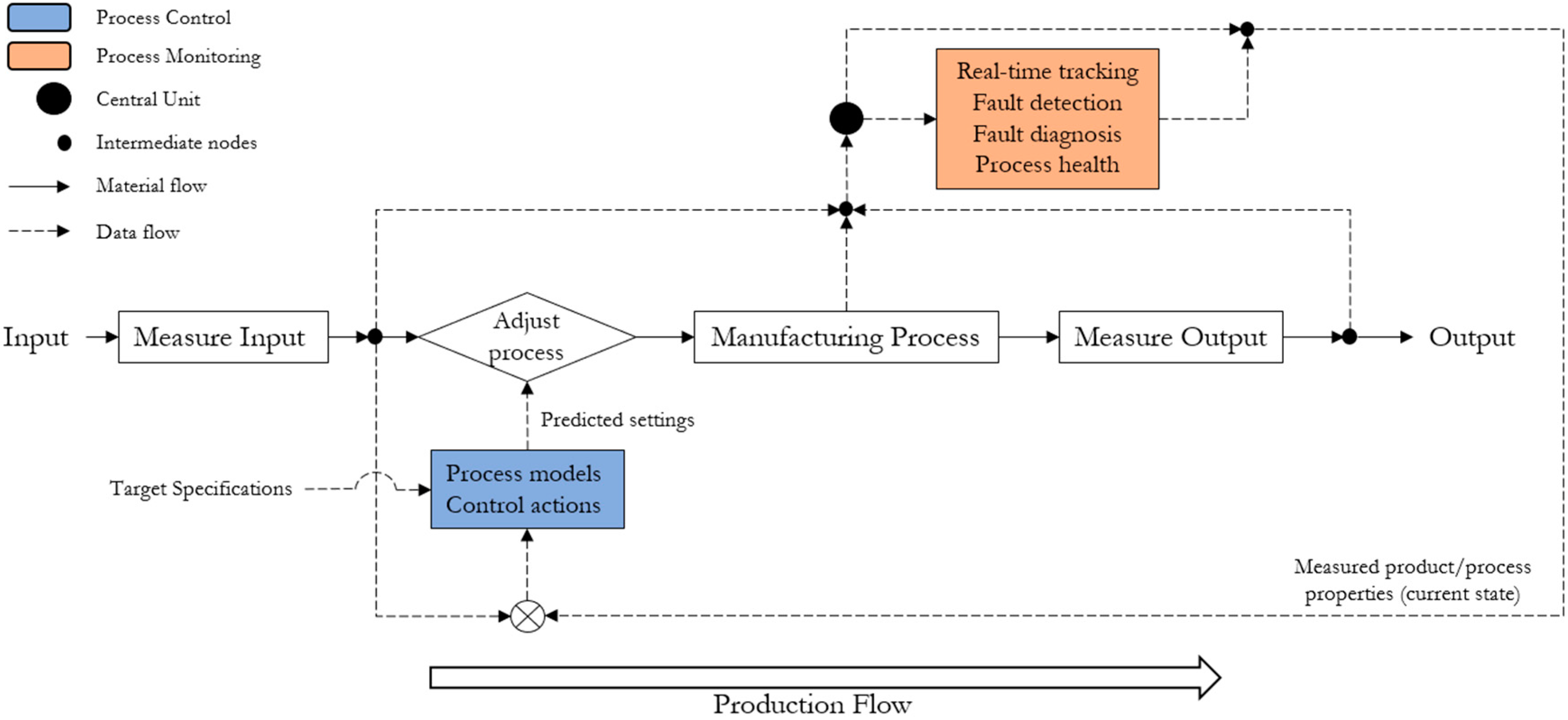

2. A Theoretical Basis for Process Monitoring and Control

2.1. Process Monitoring

2.2. Process Control

3. Process Control within Metal Forming: Challenges and Opportunities

4. Research Approach

5. Results

5.1. Motivation for the Framework

5.2. Instantiating the Framework

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Purr, S.; Wendt, A.; Meinhardt, J.; Moelzl, K.; Werner, A.; Hagenah, H.; Merklein, M. Data-driven inline optimization of the manufacturing process of car body parts. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 159. [Google Scholar]

- Harsch, D.; Heingärtner, J.; Hortig, D.; Hora, P. Observability of quality features of sheet metal parts based on metamodels. In Computational Plasticity XIV. Fundamentals and Applications, Proceedings of the XIV International Conference on Computational Plasticity, Fundamentals and Applications (COMPLAS 2017), Barcelona, Spain, 5–7 September 2017; CIMNE: Barcelona, Spain, 2017; pp. 692–703. [Google Scholar]

- Harsch, D.; Fischer, P.; Berisha, B.; Heingärtner, J.; Renkci, Y.; Hora, P. Considering fluctuations of material properties, stainless steel 1.4301, on manufacturability of kitchen sinks. In IOP Conference Series: Materials Science and Engineering; IOP: Waterloo, ON, Canada, 2018; Volume 418. [Google Scholar]

- Fischer, P.; Harsch, D.; Heingärtner, J.; Renkci, Y.; Hora, P. Approaches for control in deep drawing. In Proceedings of the Forming Technology Forum, Enschede, The Netherlands, 12–13 October 2017; pp. 43–48. [Google Scholar]

- Tatipala, S.; Pilthammar, J.; Sigvant, M.; Wall, J.; Johansson, C.M. Introductory study of sheet metal forming simulations to evaluate process robustness. In IOP Conference Series: Materials Science and Engineering; IOP: Waterloo, ON, Canada, 2018; Volume 418. [Google Scholar]

- Polyblank, J.A.; Allwood, J.M.; Duncan, S.R. Closed-loop control of product properties in metal forming: A review and prospectus. J. Mater. Process. Technol. 2014, 214, 2333–2348. [Google Scholar] [CrossRef]

- Reis, M.; Gins, G. Industrial process monitoring in the big data/industry 4.0 era: From detection, to diagnosis, to prognosis. Processes 2017, 5, 35. [Google Scholar] [CrossRef]

- Van Stein, B.; Van Leeuwen, M.; Wang, H.; Purr, S.; Kreissl, S.; Meinhardt, J.; Bäck, T. Towards data driven process control in manufacturing car body parts. In Proceedings of the International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 15–17 December 2016; pp. 459–462. [Google Scholar]

- Xu, S.; Lu, B.; Bell, N.; Nixon, M. Outlier detection in dynamic systems with multiple operating points and application to improve industrial flare monitoring. Processes 2017, 5, 28. [Google Scholar] [CrossRef]

- Xie, X.; Schenkendorf, R. Robust process design in pharmaceutical manufacturing under batch-to-batch variation. Processes 2017, 7, 509. [Google Scholar] [CrossRef]

- Denkena, B.; Dittrich, M.A.; Uhlich, F. Augmenting milling process data for shape error prediction. In Proceedings of the 49th CIRP Conference on Manufacturing Systems (CIRP-CMS), Stuttgart, Germany, 25–27 May 2016; Volume 57, pp. 487–491. [Google Scholar]

- Son, J.; Du, Y. Model-based stochastic fault detection and diagnosis of lithium-ion batteries. Processes 2019, 7, 38. [Google Scholar] [CrossRef]

- Auerbach, T.; Beckers, M.; Buchholz, G.; Eppelt, U.; Gloy, Y.S.; Fritz, P.; Reßmann, A.; Khawli, T.A.; Kratz, S.; Lose, J.; et al. Meta-modeling for manufacturing processes. In International Conference on Intelligent Robotics and Applications; Springer: Berlin/Heidelberg, Germany, 2011; pp. 199–209. [Google Scholar]

- Schulz, W.; Al Khawli, T. Meta-modelling techniques towards virtual production intelligence. In Advances in Production Technology; Springer: Cham, Switzerland, 2015; pp. 69–84. [Google Scholar]

- Reis, M.S.; Saraiva, P.M.; Bakshi, B.R. Multiscale statistical process control using wavelet packets. AIChe J. 2008, 54, 2366–2378. [Google Scholar] [CrossRef]

- Reis, M.S.; Gins, G.; Rato, T.J. Incorporation of process-specific structure in statistical process monitoring: A review. J. Qual. Technol. 2019, 51, 407–421. [Google Scholar] [CrossRef]

- Djurdjanovic, D.; Mears, L.; Niaki, F.A.; Haq, A.U.; Li, L. Process and operations control in modern manufacturing. In Proceedings of the 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017. [Google Scholar]

- Djurdjanovic, D.; Mears, L.; Niaki, F.A.; Haq, A.U.; Li, L. State of the art review on process, system, and operations control in modern manufacturing. J. Manuf. Sci. Eng. 2018, 140, 061010. [Google Scholar] [CrossRef]

- Duncan, S. Model based control of product properties: Challenges and Opportunities. In Proceedings of the Forming Technology Forum, Enschede, The Netherlands, 12–13 October 2017; pp. 2–4. [Google Scholar]

- Havinga, J.; Mandal, P.K.; Van Den Boogaard, T. Exploiting data in smart factories: real-time state estimation and model improvement in metal forming mass production. Int. J. Mater. Form. 2019, 1–11. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: state of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Shewhart, W.A. Economic Control of Quality of Manufactured Product; D. Van Nostrand Company Inc.: New York, NY, USA, 1931. [Google Scholar]

- Roberts, S.W. Control chart tests based on geometric moving averages. Technometrics 1959, 1, 239–250. [Google Scholar] [CrossRef]

- Qin, S.J. Survey on data-driven industrial process monitoring and diagnosis. Annu. Rev. Control 2012, 36, 220–234. [Google Scholar] [CrossRef]

- Van Den Kerkhof, P.; Vanlaer, J.; Gins, G.; Van Impe, J.F.M. Analysis of smearing-out in contribution plot based fault isolation for Statistical Process Control. Chem. Eng. Sci. 2013, 104, 285–293. [Google Scholar] [CrossRef]

- Westerhuis, J.A.; Gurden, S.P.; Smilde, A.K. Generalized contribution plots in multivariate statistical process monitoring. Chemom. Intell. Lab. Syst. 2000, 51, 95–114. [Google Scholar] [CrossRef]

- Yin, S.; Ding, S.X.; Xie, X.; Luo, H. A review on basic data-driven approaches for industrial process monitoring. IEEE Trans. Ind. Electron. 2014, 61, 6418–6428. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Chantzis, D.; Doukas, C.; Papacharalampopoulos, A.; Chryssolouris, G. Monitoring and control of manufacturing processes: A review. Procedia CIRP 2013, 8, 421–425. [Google Scholar] [CrossRef]

- Lim, Y.; Venugopal, R.; Ulsoy, A.G. Advances in the control of sheet metal forming. IFAC Proc. Vol. 2008, 41, 1875–1883. [Google Scholar] [CrossRef]

- Al-Salti, M.; Statham, A. A review of the literature on the use of SPC in batch production. Qual. Reliab. Eng. Int. 1994, 10, 49–61. [Google Scholar] [CrossRef]

- Campbell, W.J.; Firth, S.K.; Edgar, T.F. A comparison of run-to-run control algorithms. In American Control Conference; IEEE: New York, NY, USA, 2002; Volume 3, pp. 2150–2155. [Google Scholar]

- Hardt, D.E. Modeling and control of manufacturing processes: Getting more involved. J. Dyn. Syst. Meas. Control 1993, 115, 291–300. [Google Scholar] [CrossRef]

- Demeri, M.Y.; Hsu, C.W.; Ulsoy, A.G. Application of real-time process control in sheet metal forming. In Proceedings of the 2000 Japan–USA Symposium, Ann Arbor, MI, USA, 23–26 July 2000. [Google Scholar]

- Blessing, L.T.M.; Chakrabarti, A. DRM: A Design Research Methodology; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Tatipala, S.; Wall, J.; Johansson, C.M.; Sigvant, M. Data-driven modelling in the era of Industry 4.0: A case study of friction modelling in sheet metal forming simulations. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2018; Volume 1063. [Google Scholar]

- Sigvant, M.; Pilthammar, J.; Tatipala, S.; Andreasson, E. Smart stamping: Improved quality in stamping by model driven control. In Proceedings of the Forming Technology Forum, Zurich, Switzerland, 2–3 July 2018; pp. 59–62. [Google Scholar]

- Wohlin, C. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering—EASE ’14, London, UK, 13–14 May 2014; pp. 1–10. [Google Scholar]

- Heingärtner, J.; Fischer, P.; Harsch, D.; Renkci, Y.; Hora, P. Q-Guard—An intelligent process control system. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2017; Volume 896. [Google Scholar]

- Reis, M.S.; Braatz, R.D.; Chiang, L.H. Big data—Challenges and future research directions. Chem. Eng. Prog. 2016, 112, 46–50. [Google Scholar]

- Negri, E.; Fumagalli, L.; Macchi, M. A review of the roles of digital twin in CPS-based production systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

| Data-Driven Approaches | Model-Driven Approaches | |

|---|---|---|

| Issues/Challenges |

|

|

| Merits |

|

|

| Demerits |

|

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tatipala, S.; Wall, J.; Johansson, C.; Larsson, T. A Hybrid Data-Based and Model-Based Approach to Process Monitoring and Control in Sheet Metal Forming. Processes 2020, 8, 89. https://doi.org/10.3390/pr8010089

Tatipala S, Wall J, Johansson C, Larsson T. A Hybrid Data-Based and Model-Based Approach to Process Monitoring and Control in Sheet Metal Forming. Processes. 2020; 8(1):89. https://doi.org/10.3390/pr8010089

Chicago/Turabian StyleTatipala, Sravan, Johan Wall, Christian Johansson, and Tobias Larsson. 2020. "A Hybrid Data-Based and Model-Based Approach to Process Monitoring and Control in Sheet Metal Forming" Processes 8, no. 1: 89. https://doi.org/10.3390/pr8010089

APA StyleTatipala, S., Wall, J., Johansson, C., & Larsson, T. (2020). A Hybrid Data-Based and Model-Based Approach to Process Monitoring and Control in Sheet Metal Forming. Processes, 8(1), 89. https://doi.org/10.3390/pr8010089