1. Introduction

In recent years, BESSs have been widely used in renewable energy (RE)-based power generation (REBPG) applications and microgrids to smooth the intermittent power generation, buffer the power generation–demand differences, and improve the frequency stability of power systems. BESSs are also very useful in optimal electrical energy management and grid voltage stabilization [

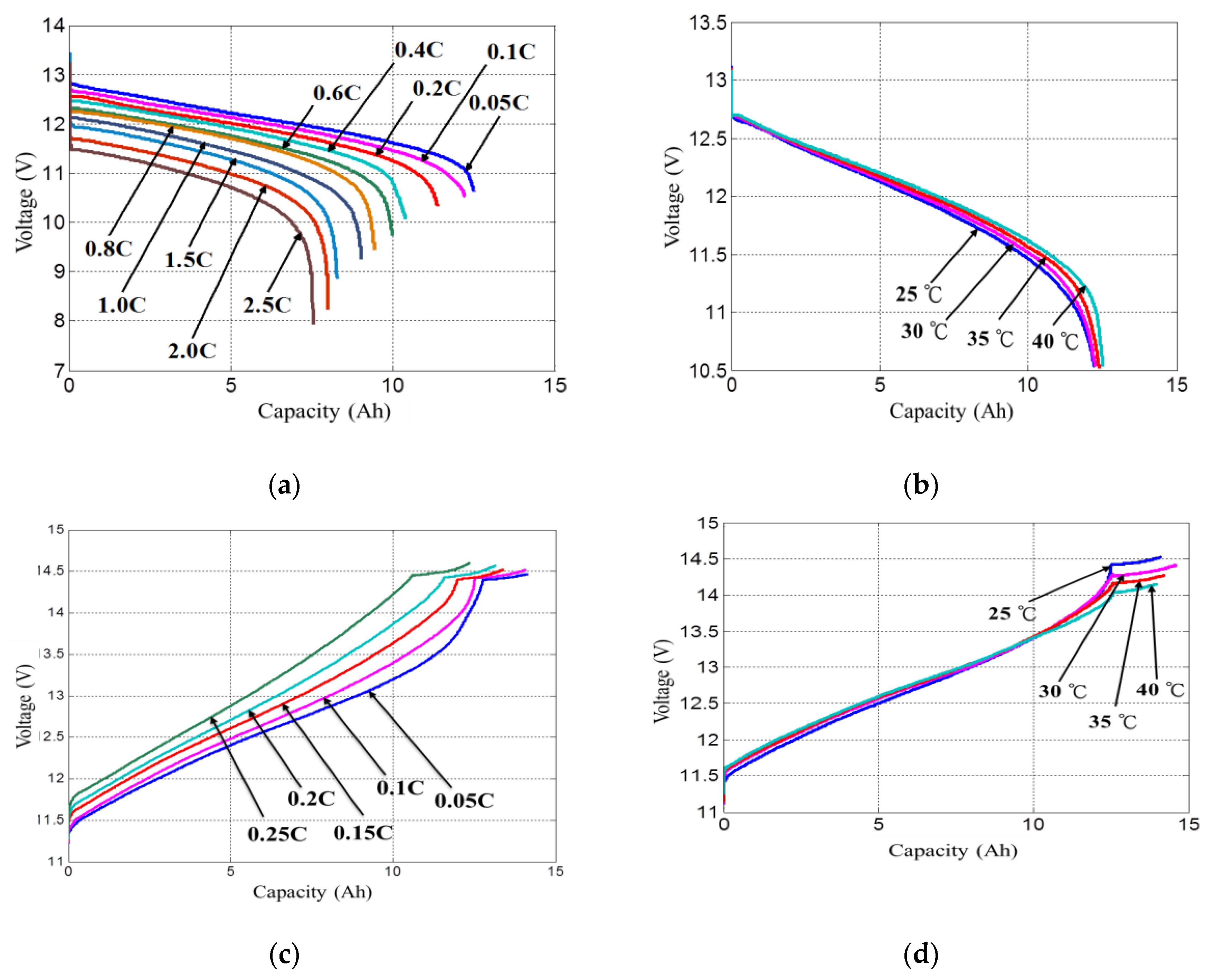

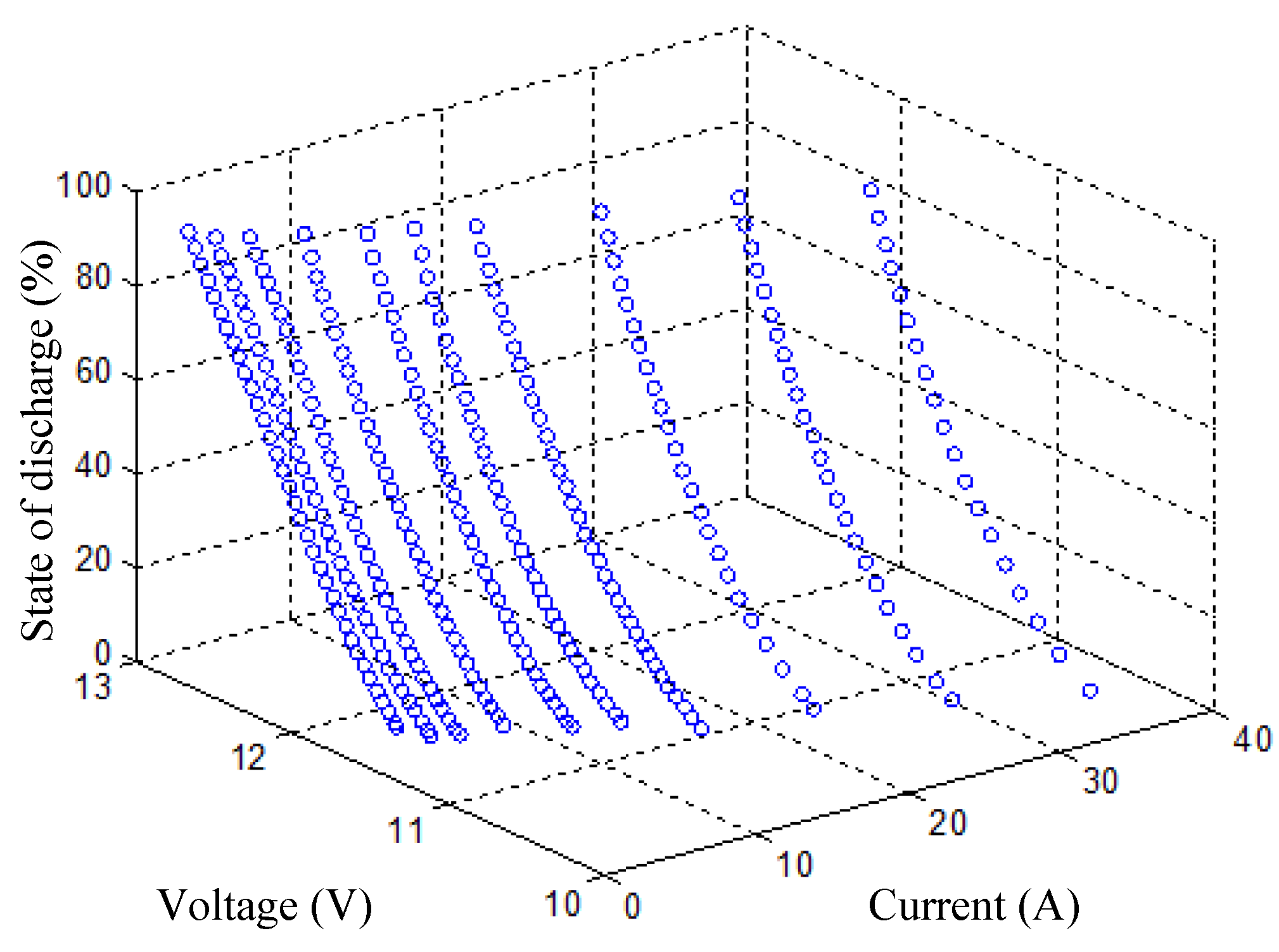

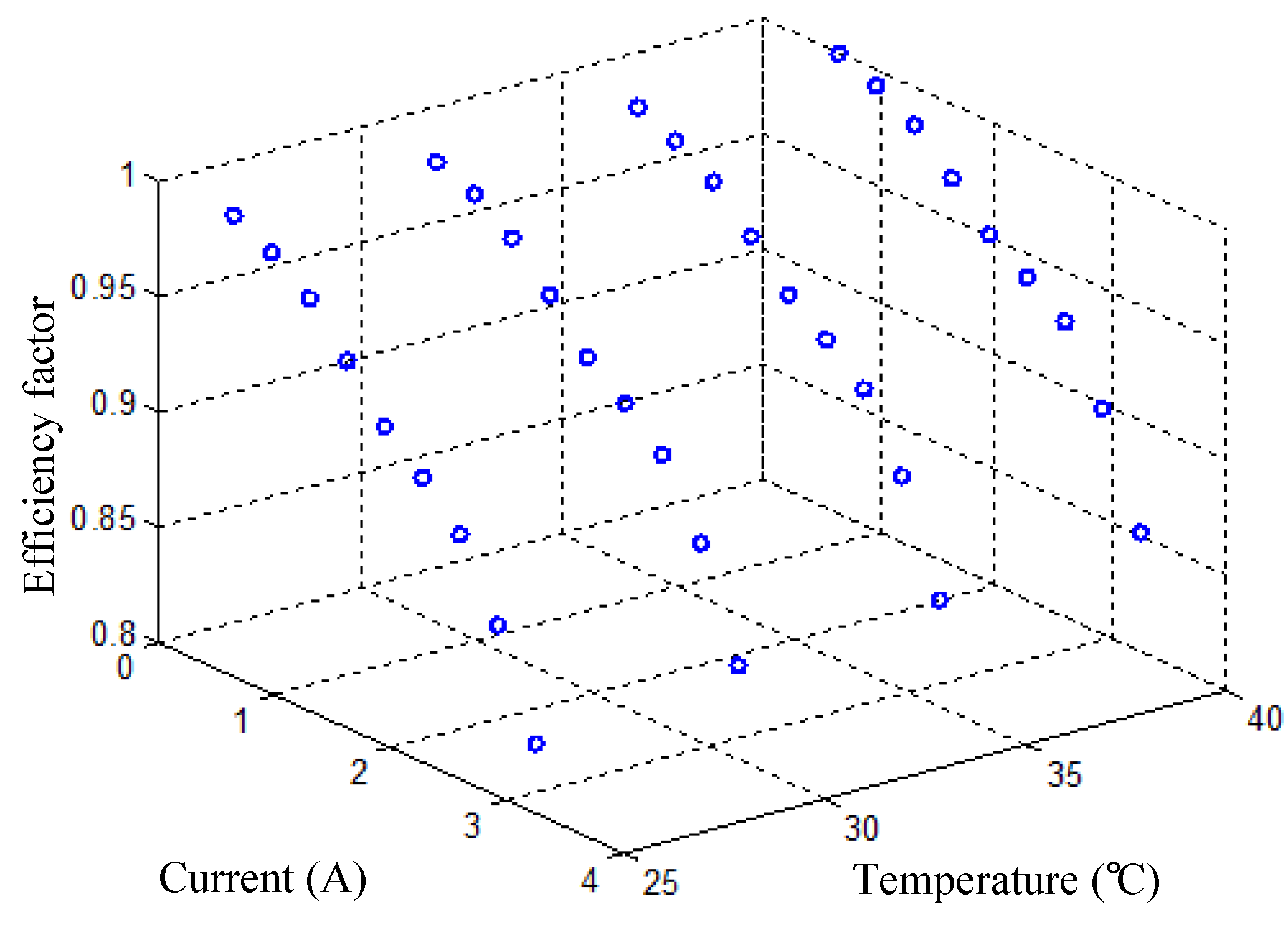

1]. In order to achieve proper compensation functions, real-time SOC information of BESS is required to determine its operational limits and prevent overcharging/overdischarging to ensure a desirable battery life. In practice, there are many factors that affect battery’s SOC, including battery current, ambient temperature, electrolyte concentration, internal impedance, and aging level, etc. It is indeed difficult to estimate accurately the battery’s SOC using existing SOC estimation techniques. Moreover, most of the existing SOC estimation techniques are only suitable for experimental analysis performed in a laboratory and may not be applicable in online estimation of battery SOC. To have a general understanding of the existing methods and the related algorithms, some of the reported SOC estimation methods are reviewed in the following part of this section.

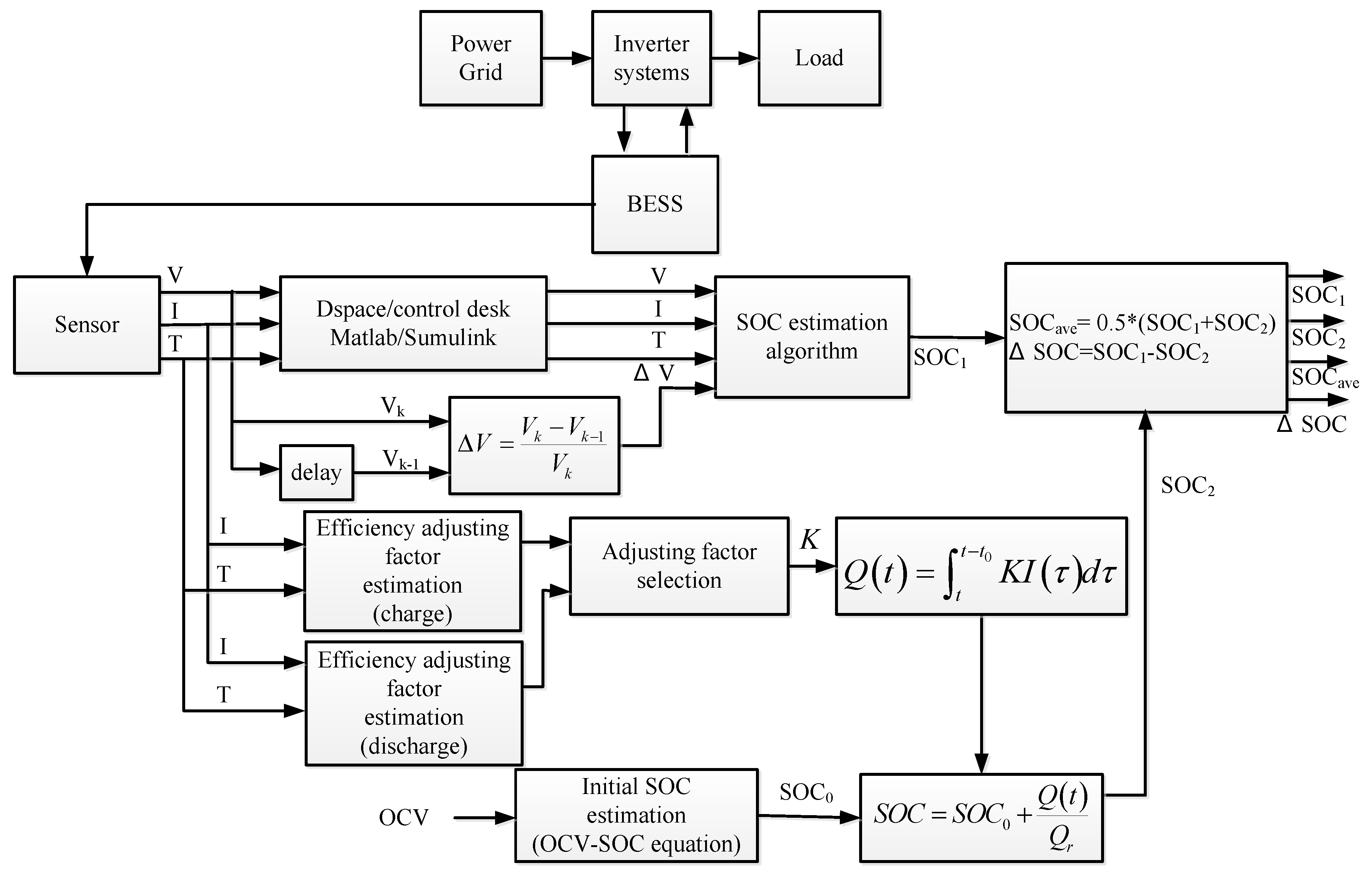

Coulomb counting method [

2,

3,

4] is based on the law of energy conservation. Through real-time sensing of battery current and the current integration over time, SOC variations can be determined. As a result, real-time SOC can be determined based on a given initial SOC value. This process can be expressed as (1):

where SOC(

t) represents real-time SOC, SOC

0 represents the initial SOC,

Qr represents battery capacity,

K is the charging or discharging efficiency adjusting factor, and

i(

t) represents battery current. This method is simple and easy to apply when initial SOC is known. However, factors such as ambient temperature and battery aging level can cause significant error over time. Consequently, certain adjusting factors are usually needed, or other estimation methods can be combined, to improve estimation accuracy.

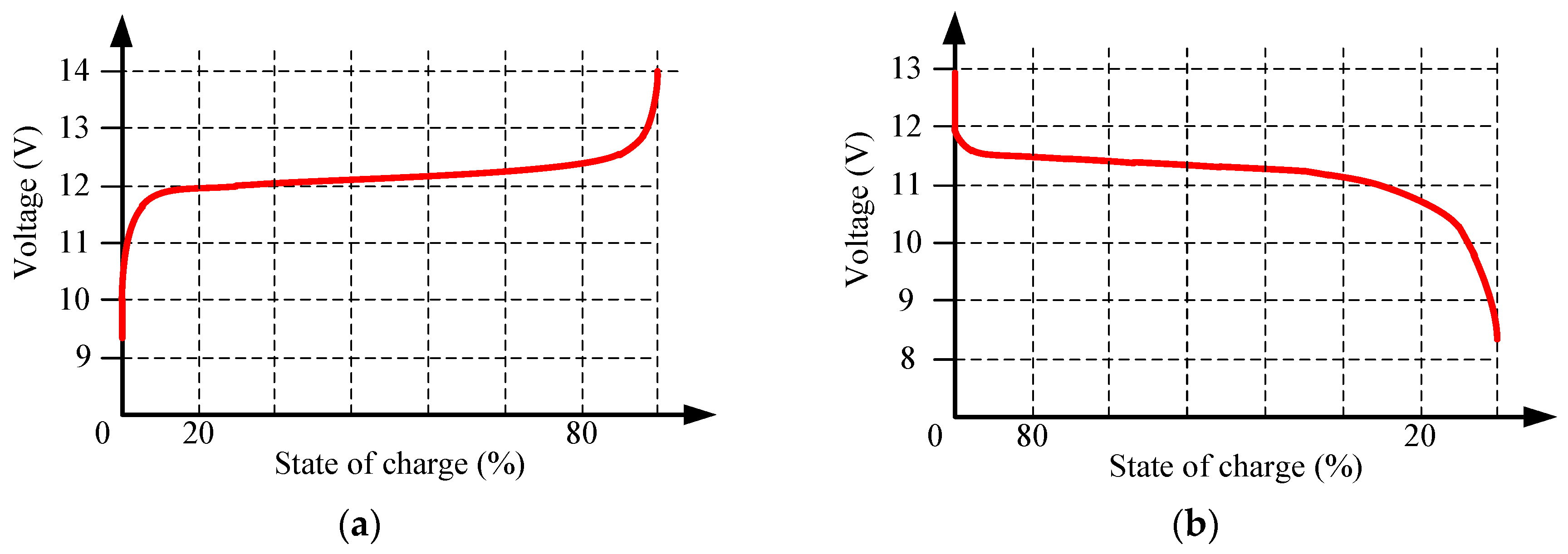

Open-circuit voltage (OCV) methods [

5,

6,

7] can be used to estimate battery SOC using the approximately proportional relationship between battery OCV and SOC. The key to this method is that when measuring the OCV, the battery must be disconnected from any load, and the distribution of internal electrolyte concentration must be uniform. During charging, the electrolyte concentration near the electrode plates is high; when discharging, the electrolyte concentration near the electrode plates is low. Therefore, after several times of charging/discharging operations, the distribution of electrolyte concentration is not uniform, and thus the OCV is not stable. In order to accurately measure the OCV, the battery must stop working for a while. At different charging/discharging rates, the chemical reaction speed of the electrolyte is different, so the required diffusion time is also variable. When electrolyte concentration returns to uniform distribution, the measured OCV can then accurately correspond to the real battery SOC. Due to the fact that this method requires a no-load condition, it is not suitable for practical applications. Furthermore, factors similar to those in the Coulomb counting method can cause errors in this method as well.

The internal resistance method [

8,

9,

10] estimates battery SOC by measuring the changes in the internal resistance of the battery. Different battery internal structures generate different resistances when current passes through, which is the reason why ideal battery capacities do not match actual operating capacities. By measuring the battery current and voltage drop, the internal resistance can be calculated. The positive correlation between internal resistance and battery SOC can then be found through experiments and used for SOC estimation. The variation in the internal resistance of a battery is normally very small (mΩ level), and thus a measuring device with relatively high accuracy is required. In addition, the internal resistance of a battery is also affected by ambient temperature, aging level, etc., so this method is more suitable for battery state of health (SOH) assessment performed in laboratory.

The load voltage method [

10,

11] estimates battery SOC by measuring battery terminal voltage when the battery is connected to a load. When using this method, in addition to battery characteristics and SOH, terminal voltage sags and swells due to internal resistance should also be considered. Therefore, the influence of battery current variation on SOC estimation must also be taken into consideration. In addition, when battery SOC is around 20–10%, the terminal voltage tends to drop exponentially. As a result, this method is not suitable for a BESS whose load is constantly changing. This method is generally used in BESS equipment with low accuracy requirements.

The electrolyte concentration of batteries increases/decreases when charged/discharged. Theoretically, there is a linear relationship between the concentration of the electrolyte and battery SOC. Therefore, the SOC can be estimated by measuring battery electrolyte concentration. Similar to internal resistance method, before measuring it is necessary to let the battery rest and the electrolyte to distribute evenly after charging/discharging. Moreover, some fully sealed batteries cannot be installed with a hydrometer. As a result, this method is more suitable for experimental testing of batteries when they are not in operation [

10].

The electrochemical impedance spectroscopy (EIS) method [

12] uses small AC voltage or current to perturb the electrodes for estimating the SOC. AC impedance data are obtained from experiments, and the corresponding electrode reaction parameters can be calculated according to equivalent circuit of the batteries. To have a whole picture of the above mentioned conventional SOC-detecting methods,

Table 1 summarizes their advantages and disadvantages.

To overcome the disadvantages of the above methods summarized in

Table 1, researchers have proposed nonlinear methods, e.g., extended Kalman filter (EKF) [

13,

14], unscented Kalman filter (UKF) [

15,

16], particle filter [

17,

18], Bayesian framework [

19,

20], sliding mode [

21,

22], nonlinear observer [

23,

24], wavelet analysis [

25,

26], and H-infinity [

27,

28,

29]. These methods are applicable to any battery and can simultaneously identify the parameters of prebuilt models and thereby estimate battery SOC through their nonlinear mapping capabilities without the need of initial SOC values. However, the required models may need to be adjusted or rebuilt when battery characteristics change, and the complexity of the models will significantly affect their SOC-estimating performance. On the other hand, some researchers have proposed intelligent algorithms for SOC estimation, such as artificial neural network (ANN) [

30,

31,

32], fuzzy logic [

33,

34,

35], support vector [

36,

37], and adaptive network-based fuzzy inference system (ANFIS) [

38,

39,

40]. These methods do not require complicated equivalent circuits or models for obtaining the nonlinear characteristics of batteries, instead it is done through their learning and inference capabilities. In [

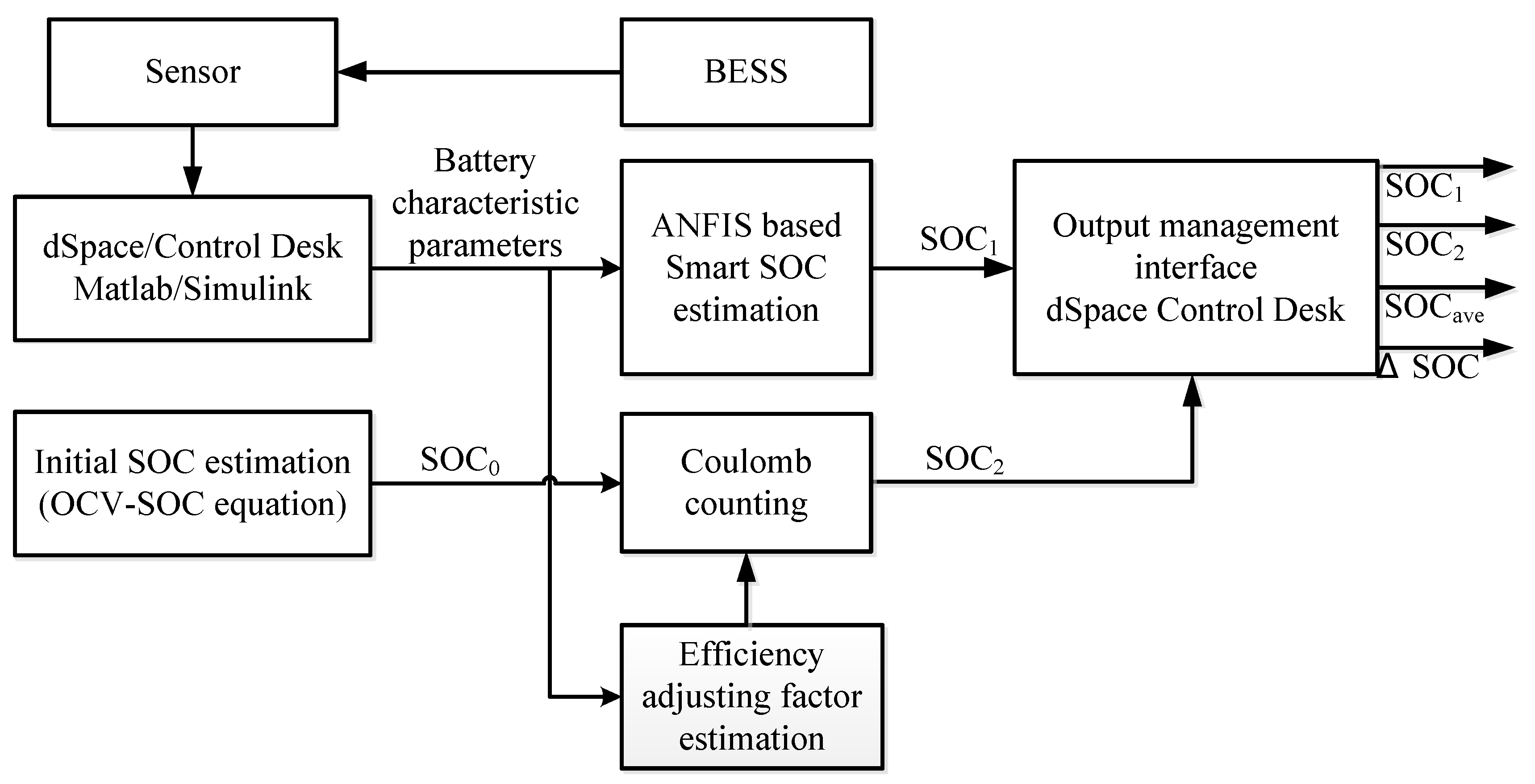

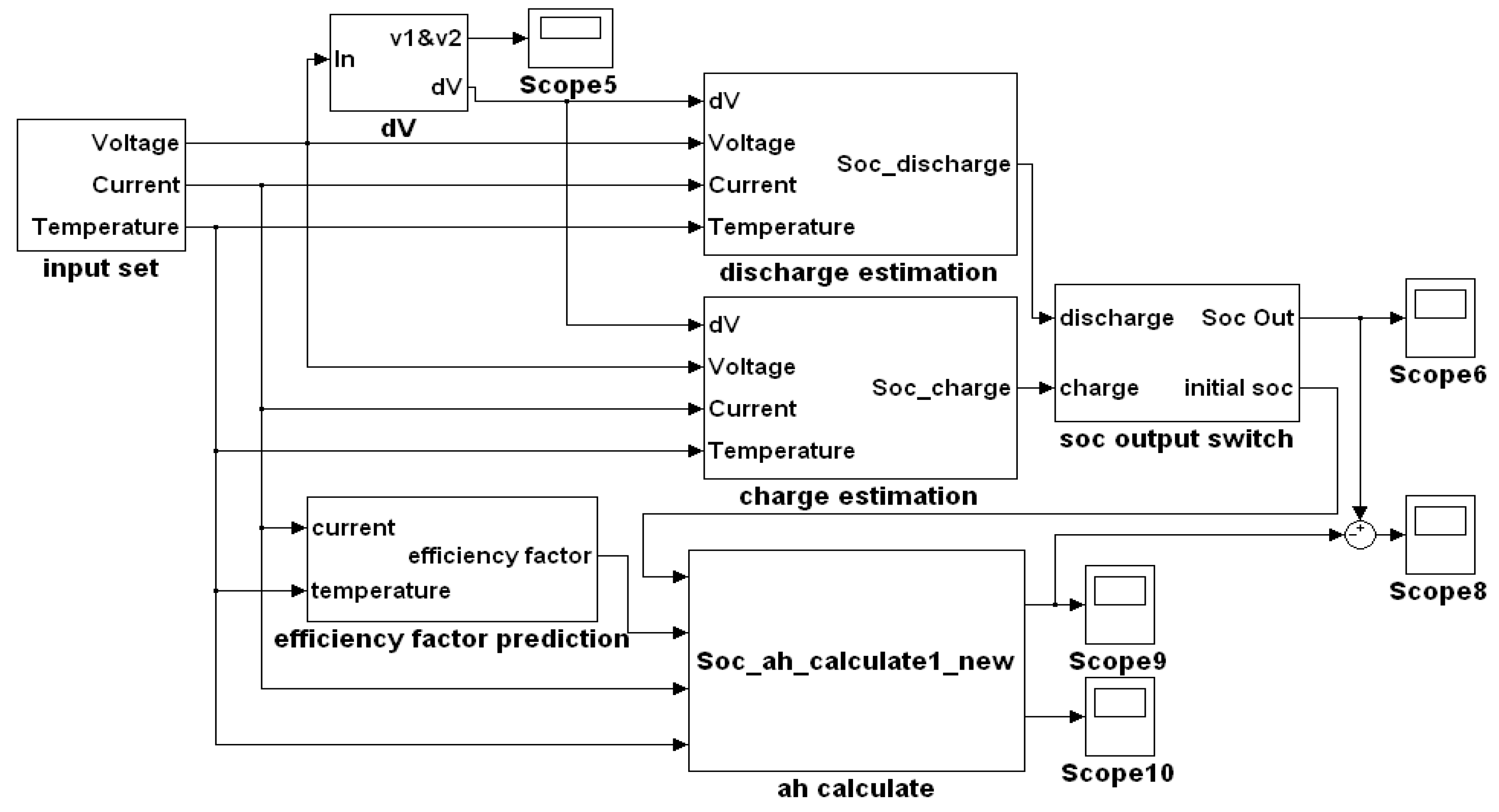

41], an ANFIS architecture was proposed to process a large number of battery characterization data through repeated charge/discharge experiments. These data were then used for battery’s SOC estimation. The above mentioned ANN and ANFIS-based SOC estimating methods are relatively easy in implementation but they have a common drawback, i.e., the reliability of estimation cannot be fully guaranteed. To improve the estimation reliability, this paper proposes a hybrid real-time battery SOC estimation scheme for practical applications, where two detecting methods, adaptive Coulomb counting method and ANFIS-based online estimating algorithm, are integrated to constitute a hybrid SOC estimation scheme. In the proposed scheme, ANFIS is used to effectively learn the nonlinear mapping relationships among the SOC and characteristic parameters of a battery during charging and discharging processes. An adaptive Coulomb counting algorithm is simultaneously used to produce a real-time estimated SOC values for double checking the correctness of the SOC estimation of ANFIS. It can be expected that the proposed hybrid SOC-detecting scheme with parallel estimating mechanisms and multiple SOC results can effectively increase the reliability of SOC monitoring.

Following this section, the next section explains the proposed hybrid SOC estimation scheme and briefly introduces the ANFIS principle. The third section introduces the arrangement of battery experiments and the method used to obtain characteristic parameters, describes the battery measurement experiment platform, and analyzes the obtained parameters. In addition, this section also explains how to establish an ANFIS in a MATLAB environment, and the correctness of the SOC estimation scheme is verified through simulations. An inverter integrated BESS hardware setup is explained in the fourth section for further verifying the proposed hybrid real-time SOC estimation scheme via experimental tests. A real-time digital control system was developed with the dSPACE DS1104 platform, and three test cases were carried out. Finally, a conclusion is drawn in the fifth section.

4. Inverter Integrated Hardware Implementation of Hybrid SOC Estimation Scheme

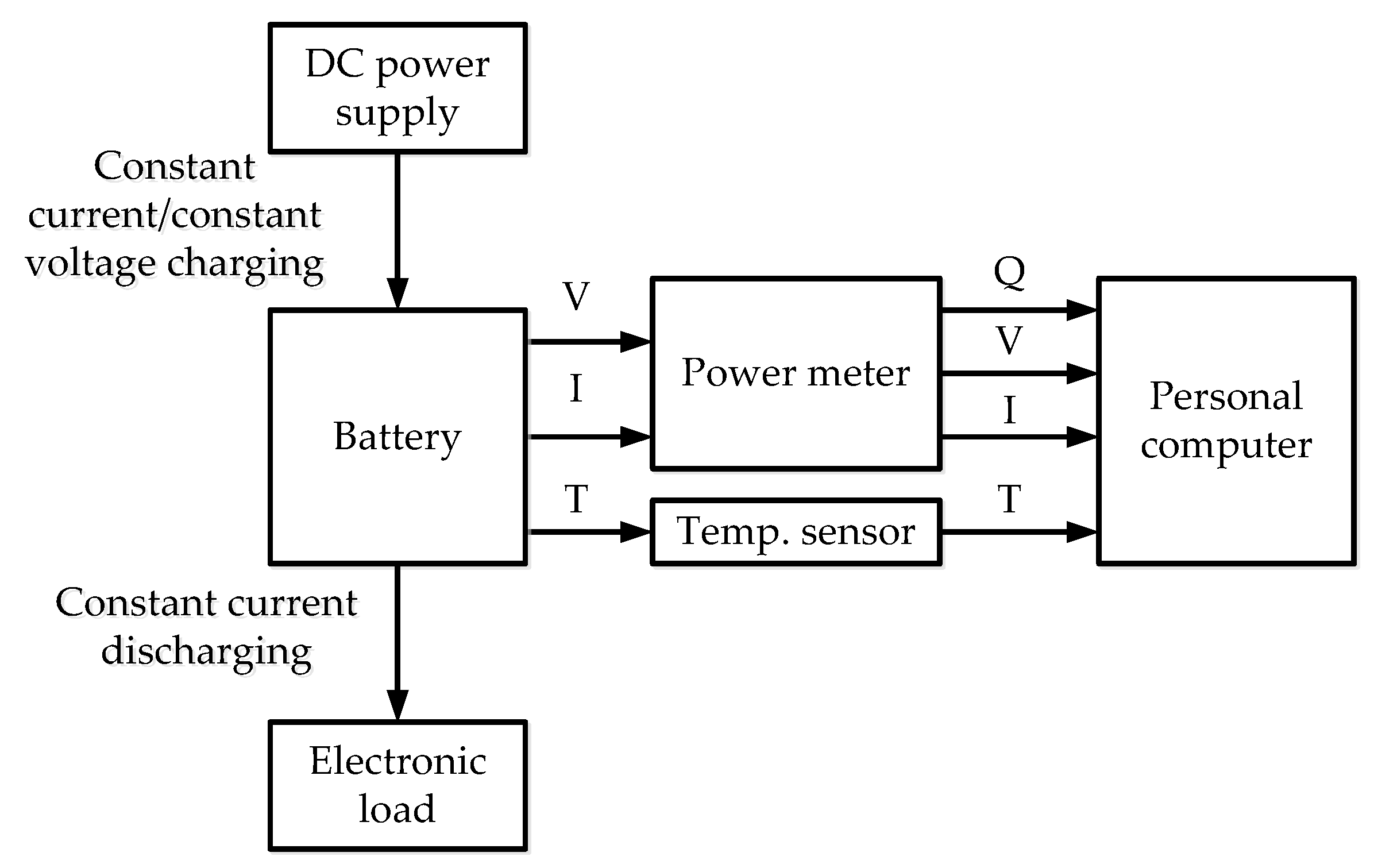

To further test the feasibility of the proposed algorithm, an inverter integrated BESS hardware setup was implemented with dSPACE real-time digital control interface. The DS1104 and dSPACE Real-Time Interface (RTI) interface are used to efficiently perform the arranged charging/discharging cases. RTI is a MATLAB/Simulink graphical interface tool provided by dSPACE, and it makes practical verification of control strategies using dSPACE1104 quite efficient. In addition, its ControlDesk can be used for data measurement, monitoring, and recording.

Figure 20 shows a typical ControlDesk interface designed for the hardware implementation of the proposed hybrid real-time SOC estimator.

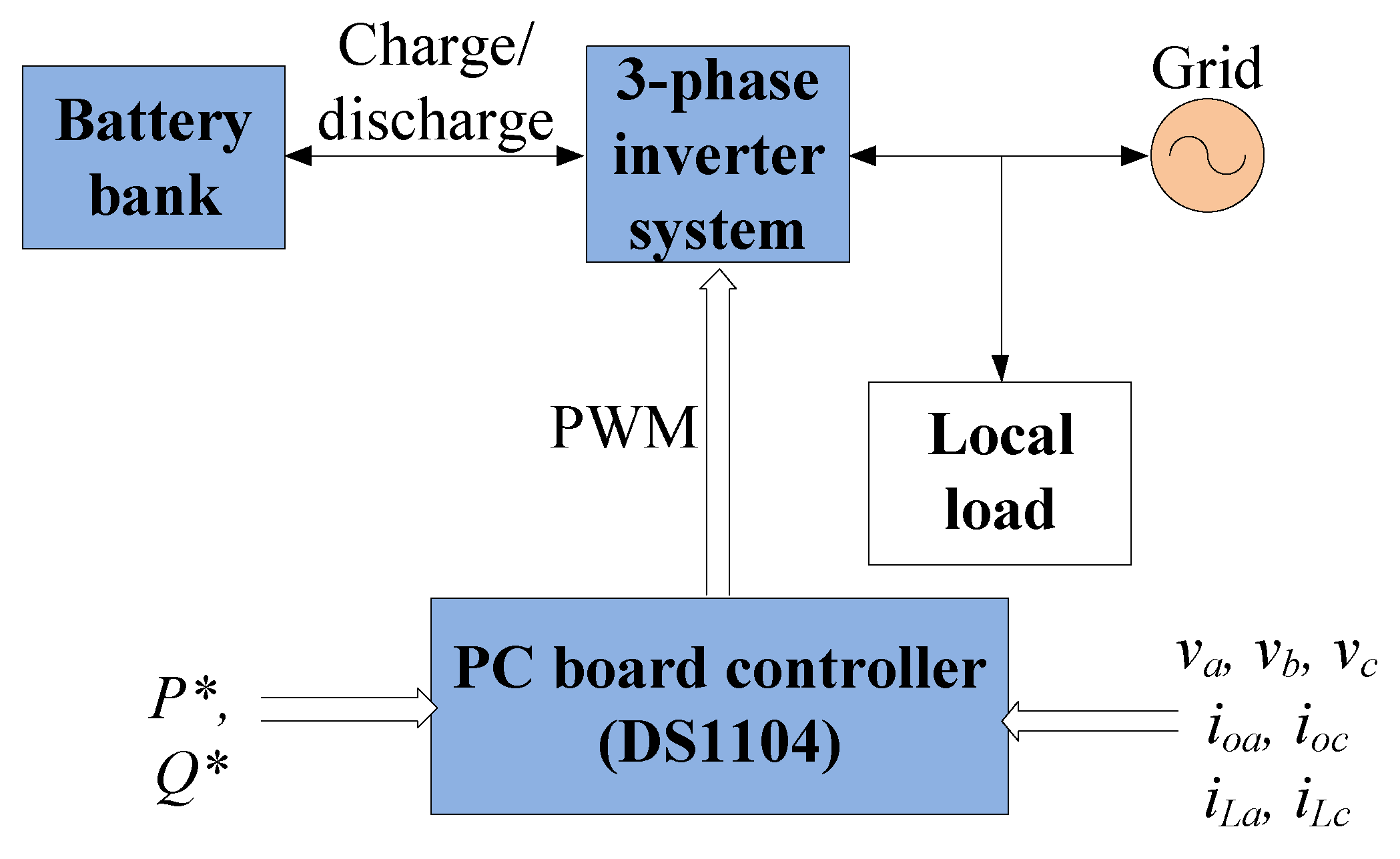

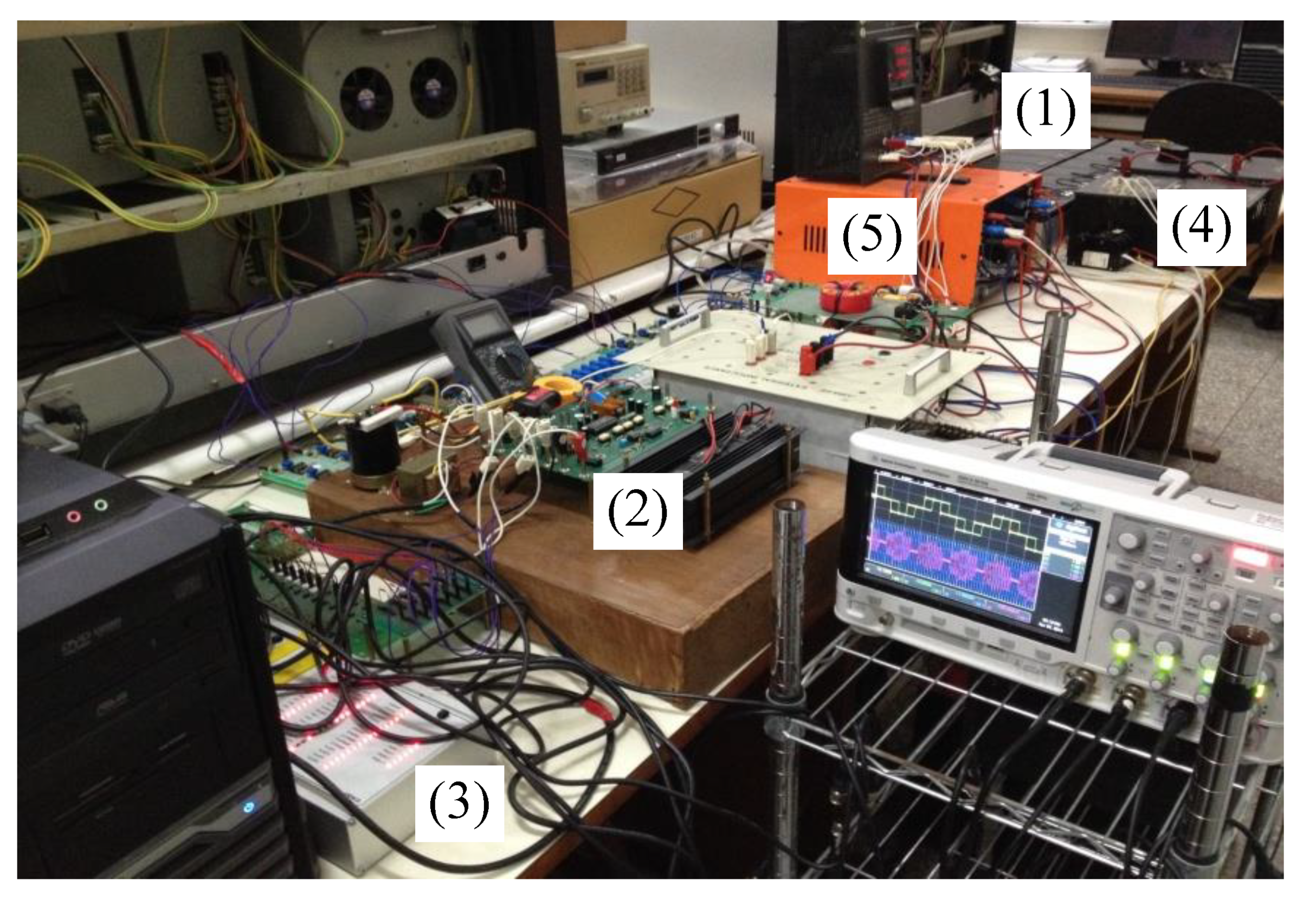

The block diagram of a grid-connected three-phase inverter system with a battery bank is shown in

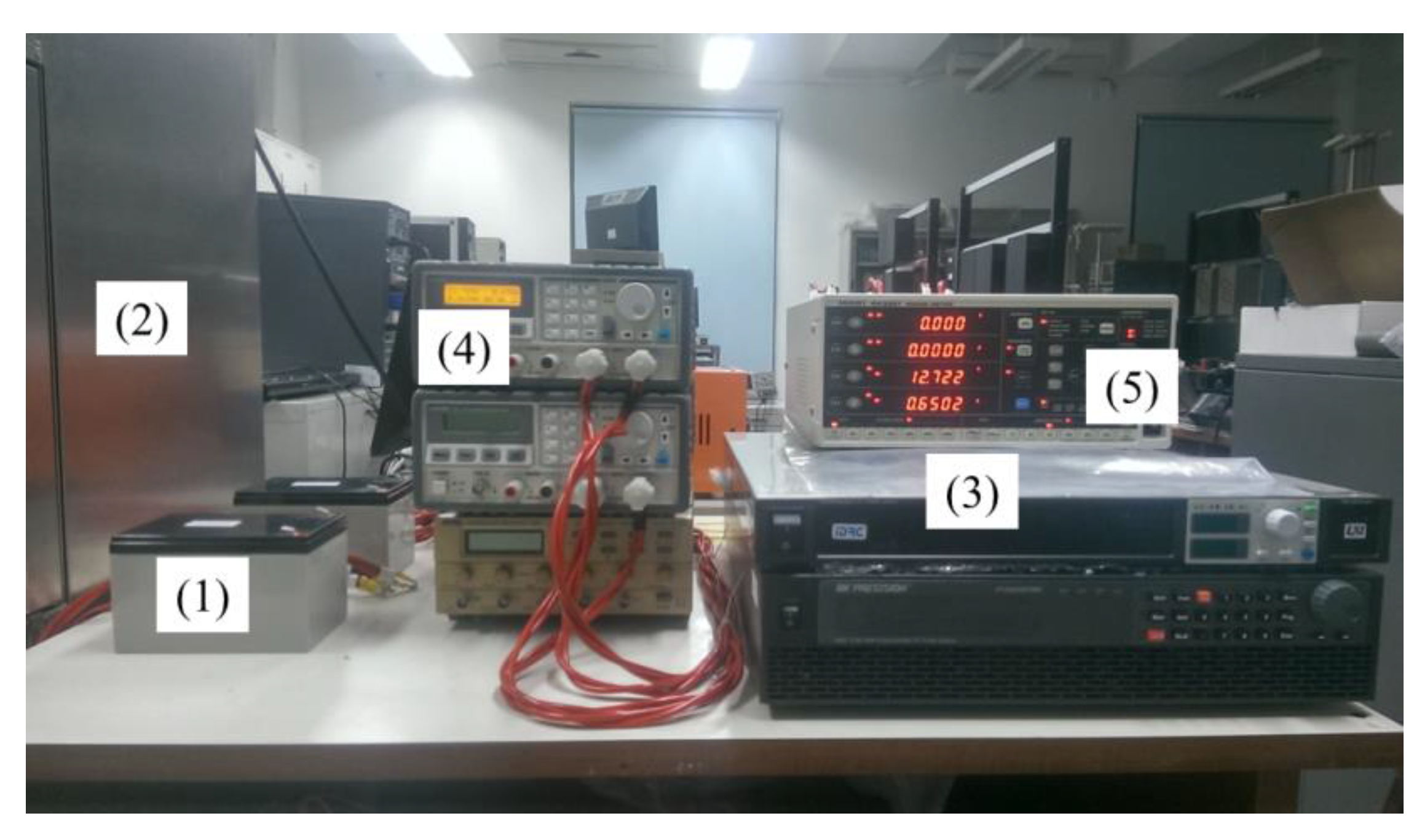

Figure 21, and a photo of the hardware implementation is shown in

Figure 22, including (1) battery bank, (2) three-phase inverter, (3) controller (DS1104), (4) local load, and (5) power grid. The control command of the three-phase inverter is equivalent to the charging/discharging power, and the feedback signals include system voltage, inverter output current, and load current. In this experiment, nine identical lead-acid batteries with rated capacities of 14 Ah and voltages of 12 V were connected in series at the DC side of the inverter as the battery bank. The bidirectional three-phase inverter charges/discharges the batteries by adjusting active power command. When discharging, because part of the power is consumed by the local load, a larger AC power command is required to achieve active power feeding to the grid. When charging, because only the power absorbed by the battery bank is considered, the AC power required for charging is close to DC power. With the analog-to-digital (ADC) processing, DS1104 feeds actual line voltage and line current signals back to the computer for the related power calculations.

In this section, three test cases were carried out for verifying the performance of the proposed real-time SOC estimation mechanism: case 1 was for charging operation, case 2 was for discharging operation, and case 3 was for charging/discharging operation. All test cases were performed at room temperature of 25 °C. In case 1 and case 2, SOC was measured at a fixed battery voltage. In case 3, the performance of the proposed ANFIS-based estimation scheme and Coulomb counting were compared through a charge–discharge cycle.

In case 1, charging voltage range was measured between 11.7 V and 14.2 V per single cell, and charging current was 3 A. Measurement was performed at 12.3 V and 13.7 V, respectively.

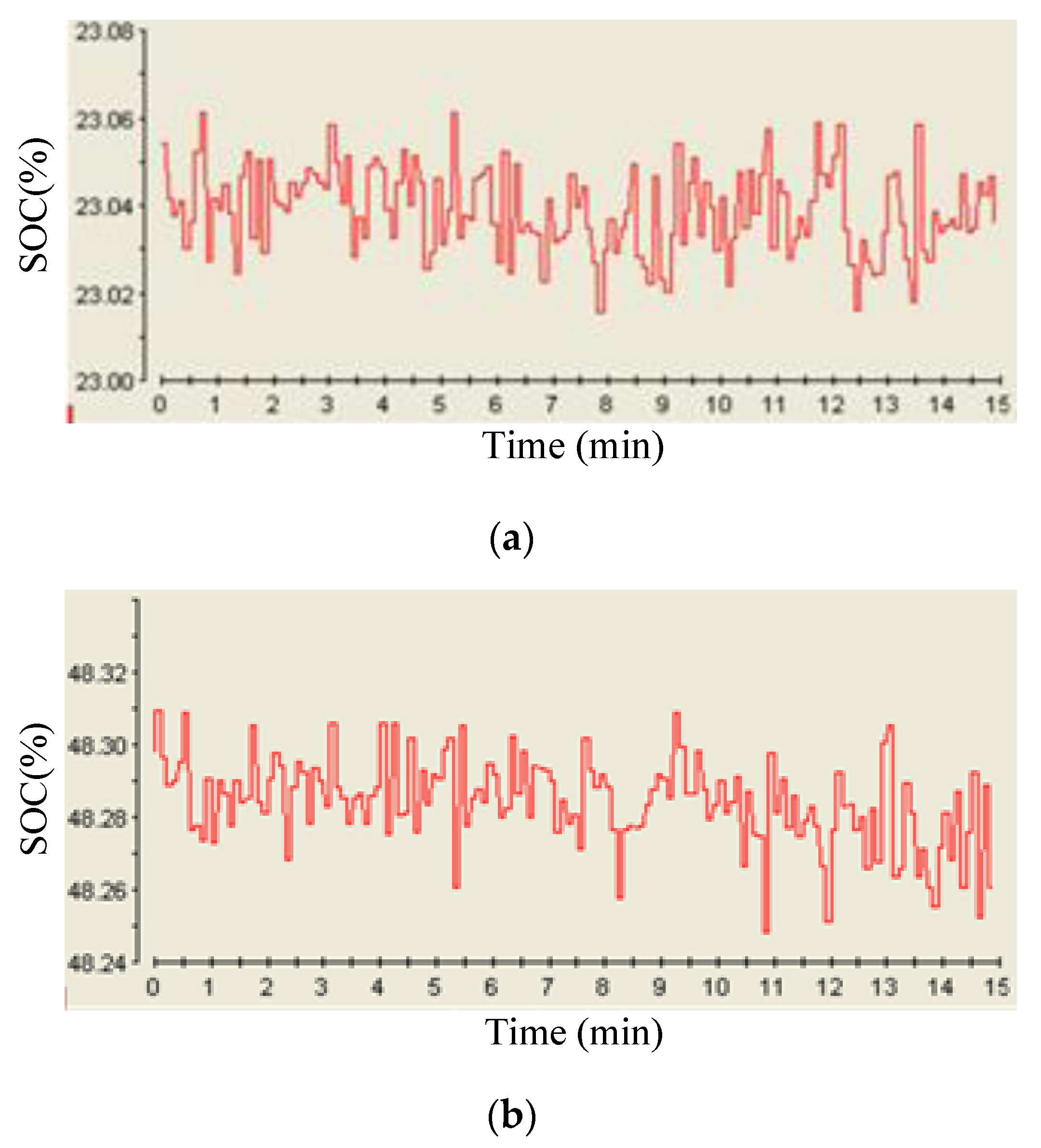

Figure 23 shows SOC estimated by ANFIS algorithm. Less than 2% error was observed, validating the precision of the proposed algorithm.

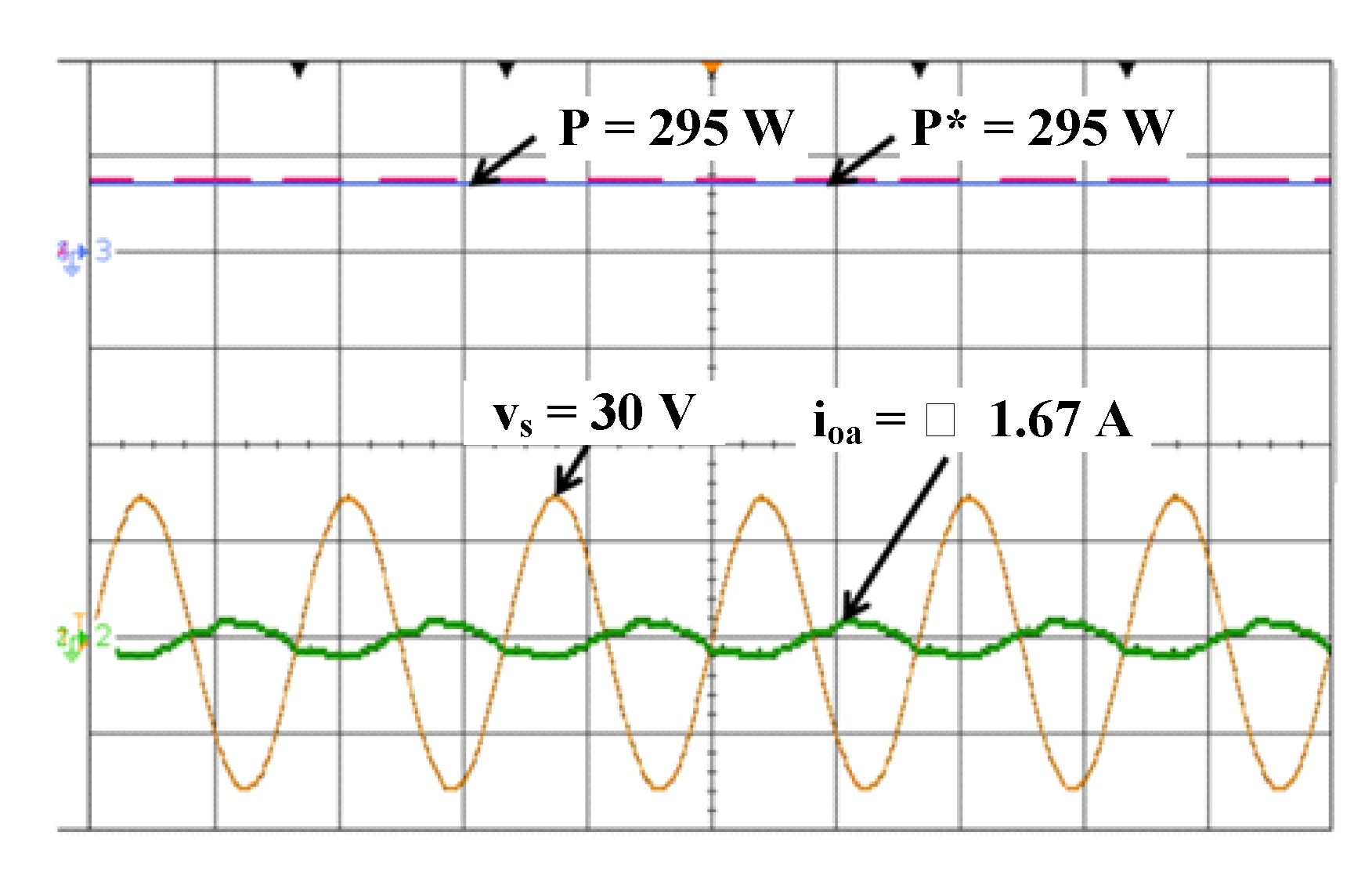

Figure 24 shows the AC active power response during charging operation, including charging power command P* and actual charging power output P, where v

s represents system voltage and i

o represents inverter output line current.

In case 2, the discharging voltage was measured between 10.1 V and 12.7 V per single cell, and discharging current amplitude was the same as that of the charging current in case 1. The measurement was performed at 11.5 V and 11.9 V, respectively.

Figure 25 shows the estimated SOC by ANFIS algorithm.

Figure 26 shows the AC active power responding to the discharging operation.

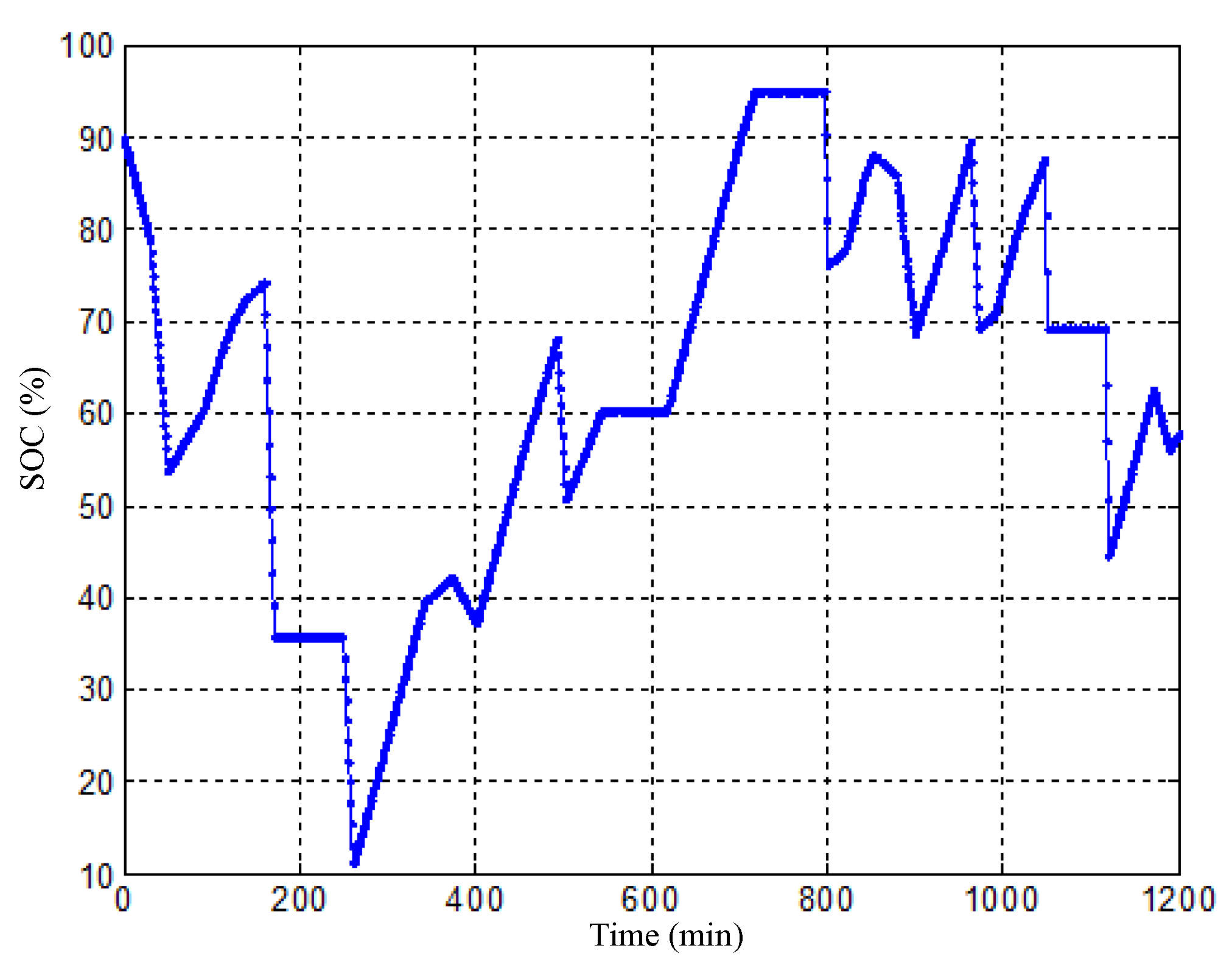

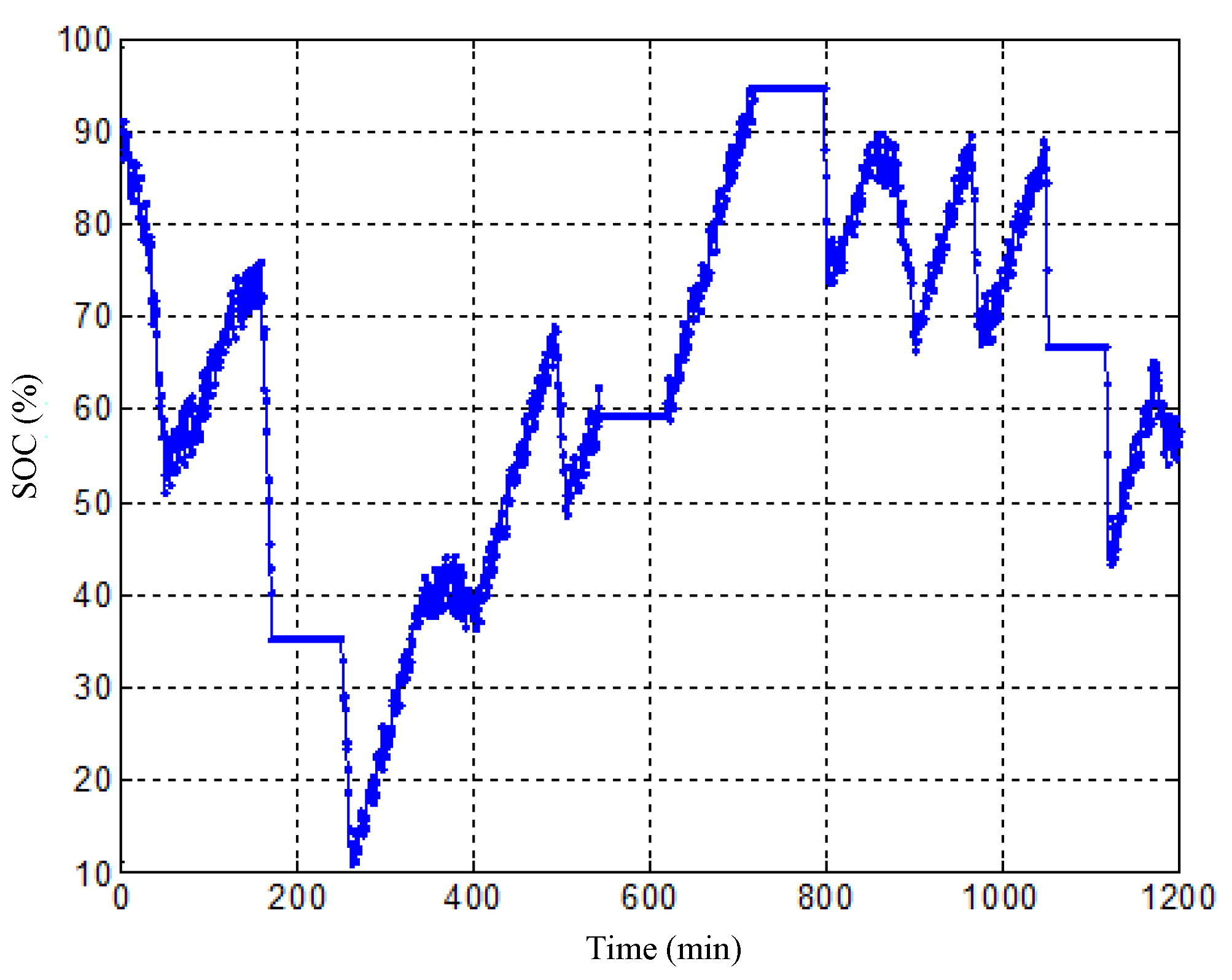

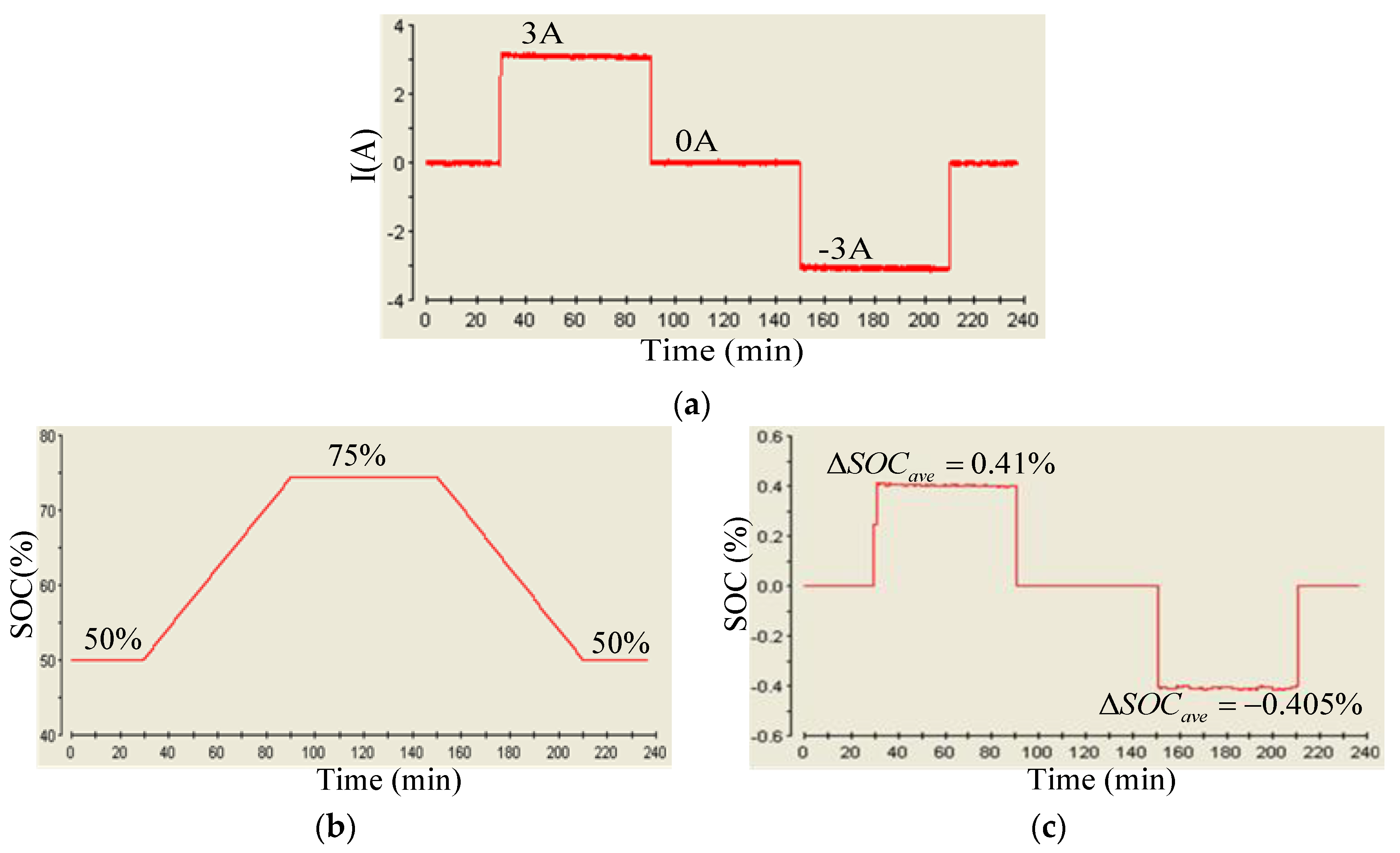

To observe the SOC estimation outputs of the ANFIS real-time SOC estimation scheme and the Coulomb counting method used in the proposed hybrid SOC estimating scheme, in case 3 both the charging and discharging currents were set to be 3 A. The initial SOC was set to 50%. The charging time and discharging time were 1 h each. The battery was firstly set to be charged with a −390 W real power, then rest for 1 h, and then be discharged with a 295 W real power.

Figure 27 shows a set of results concerning the battery current and the variation in battery SOC and ΔSOC. As can be seen in

Figure 27, a very small (<0.41%) difference between the two methods was observed.

5. Conclusions

In recent years, the BESS has been playing a significant role in various advanced electrical energy management and control applications. An accurate real-time battery’s SOC is technically desirable for achieving the designed BESS control functions; however, there are a number of factors that could affect the SOC of a battery, e.g., the charge and discharge currents, ambient temperature, electrolyte concentration, internal impedance, and the aging level, which is affected by charging and discharging cycles used. In fact, all of these have strongly squeezed the feasibility and performance of existing methods. To ensure the feasibility of SOC-detecting algorithms in practical applications, this paper has proposed a hybrid real-time SOC estimation scheme, and the lead-acid batteries were chosen for the required tests. In this paper, the existing SOC estimation methods reported in open literature have been reviewed and their advantages and drawbacks have been discussed. The design concept, theoretical basis, and implementation procedure of the proposed hybrid estimating scheme have been clearly addressed. In the proposed scheme, ANFIS is used to effectively learn the nonlinear mapping relationships among the SOC and characteristic parameters of a working battery. An adaptive Coulomb counting algorithm is simultaneously used to produce real-time estimated SOC values for double checking the correctness of the SOC estimation of ANFIS. It can be expected that the proposed hybrid SOC-detecting scheme with parallel estimating mechanisms and multiple SOC results can effectively increase the reliability of SOC monitoring. A set of comprehensive simulation and experimental studies have been carried out. Both simulation and typical measured results from an experimental BESS hardware setup demonstrating a maximum of estimated SOC deviation (ΔSOC = 0.41%) have been presented to verify the feasibility and effectiveness of the proposed SOC detection algorithm.