1. Introduction

The heat transfer mechanism plays an important role in industries, biosciences, and engineering. Many conventional fluids such as water, ethylene glycol, and engine oil are used for heat transfer in a thermal system. With the increase of consumption of energy, these conventional fluids are not enough for the fulfillment of modern demands. Numerous researchers imagine distinctive strategies to improve the heat exchange of the fluid. The heat transfer mechanism can be improved by changing the flow geometry, physical condition or by augmenting the thermal efficiency of the liquids. Numerous methods have been invented to improve the heat transfer performance of the liquids. The suspension of nanoparticles in the base fluids gives incredible change in their thermal, mechanical, optical and electronic properties because the thermal conductivity of nanoparticles is substantially more than that of fluids. The heat exchange component can be expanded by including metallic or nonmetallic particles in a base liquid, for example, water or ethylene glycol. The heterogeneous suspension of nanosize particles in the base fluid used for heat transfer is termed as nanofluids. Most of the work done on the nanofluids was related to the large-sized nanoparticles, but unfortunately, such nanoparticles have stability issues. The nano liquids were invented by Choi [

1]. He clarifies nano liquids as a liquid containing smaller scale little size particles known as nanoparticles about (1–1000 nm) in a measure. These nanoparticles help in enhancing the thermal conductivity of the traditional liquids.

Carbon nanotubes play a significant role to improve the thermal conductivity of the liquids. Carbon nanotubes CNTs were first discovered by [

2]. The TEM picture of CNTs was reported by Oberlin et al. [

3]. The needle shape nanosize structure, about 4 to 30 nm in diameter, was innovated by [

2] using an arc discharge evaporation method for its synthesis. The development of single-walled carbon nanotubes was carried out in 1993 by two research groups [

4,

5]. Carbon nanotubes may be divided into two classifications: Single-walled (SWCNTs) and Multi-Walled (MWCNTs). SWCNTs are enclosed by wrapping a layer of carbon with one particle thick layer called graphene into a cylinder. They require a catalyst for their synthesis. Most research in early 1990 reported that CNTs-nanofluids had a lot of importance in both academic and industrial communities and several applications in numerous fields like aerospace, electronics, optical and energy conservation [

6,

7]. The impact of carbon nanotube (CNT) scattering on the mechanical properties and microstructures of ultra-light frothed cement was studied by Jing and Xiangdong [

8]. A sort of uniform and stable CNT scattering arrangement was acquired by including nano-Ce(SO

4)

2. The results demonstrated that CNT scattering increments the compressive and breaking qualities of frothed cement. The impact of CNT scattering on the compressive and breaking qualities of frothed cement is anticipated through reproduction.

The ultra-high thermal conductivity of carbon nanotubes (2000–6000 W/mK) is of a higher magnitude compared with aluminum (237 W/mK) and aluminum oxides (40 W/mK). Consequently, CNTs are the object of great interest in the research area. Due to the higher thermal conductivity and potential properties of carbon nanotubes (CNT), their nanofluids exhibit much higher thermal conductivity and can remove higher heat flux as compared to pure fluid [

9,

10]. Carbon nanotubes have great dispersion properties with most base fluids; this is responsible for their long-term stability. Various techniques have been discovered by different researchers to enhance the thermal conductivities of fluid using CNTs. Kamali and Binesh [

11] investigated enhancement of heat transmission using CNTs suspension. Most of the work was performed on multi-walled carbon nanotubes (MWCNT). Pal and Sharma [

12] examined the consequence of sintering on the electro and thermophysical properties of CNTs. They examined the synthesis of silver nanocomposite using SWCNTs and MWCNTs by modified molecular level mixing method. They concluded that the comparatively enhanced mechanical and electrical properties of SWCNTs fortified nanocomposites performance better than MWCNTS strengthened nanocomposite, which are related to the high aspect ratio and higher powerful contact surface area of SWCNTs.

After the development of nanofluids, researchers depicted their work in different areas under different boundary conditions. Domairry [

13] and Rashidi et al. [

14] studied the flow of nanofluids and their significance towards industry and engineering. Heat transforms of motor oil within the sight of both sorts of CNTs between two concentric chambers is displayed in [

15]. It was demonstrated that the consideration of nanoparticles maximized the heat conductivity of liquid essentially for both turbulent and laminar flow. The results of the above problem were reviews of SWCNT-motor oil and MWCNT-motor oil. The boundary layer stream of CNTs over a curved extending surface is examined in [

16]. The homogeneous response happening in the liquid are executed by first order kinetics. The four types of nanofluids including MWCNTs-H

2O, CuO-H

2O, SiO

2-H

2O, and CuO-C

2H

6O

2, are considered in [

17]. The results of physical parameters like skin friction and Nusselt number were incorporated into this work. A comparative examination was performed by different researches using a variety of different models [

18].

Following Fourier [

19], Cattaneo [

20] presented an amendment in the Fourier model by including relaxation time for heat transfer. The effective thermal conductivity of the Maxwell model depends on thermal conductivity considered by Walvekar and Faris [

21].

The various varieties of the models describe the thermal conductivities of CNTs in different geometries. The researchers tried to improve the thermal conductivity of the CNTs by developing the advanced models [

22,

23,

24,

25,

26]. Xue [

27] suggested a model for the very large axial ratio and repaying the CNTs space dispersal. In the recent study, the Xue [

27] model was imposed to calculate the thermal conductivities of the CNTs.

The study of the thin film flow over an extended surface has several applications regarding mechanical engineering and our daily life usages. Thin film flow has been an essential subject of research. Thin film liquid is utilized for making distinctive warmth exchangers and devices in chemical systems, and these applications require a complete understanding of the flow method. The applications include wire and fiber covering, polymer getting ready, etc. This movement is joined to assemble different sorts of sheets, either metallic or plastic. The heat and mass transmission of the thin film flow over stretching sheet have been investigated by Khan et al. [

28]. Aziz et al. [

29] and Qasim et al. [

30] described the unsteady heat transfer flow of the thin film over a stretching sheet. Wang [

31] described the flow of a thin film over the stretching cylinder. The thin film spray of the nanofluid over a stretching cylinder has been studied by Khan et al. [

32]. The analysis of thin film of ΥAl

2O

3–H

2O and ΥAl

2O

3–C

2H

6O

2 nanofluids spray along a stretching cylinder is investigated by khan et al [

33]. Alshomrani and Gul [

34] considered the spray of a nanofluid film over the slippery surface of a stretching cylinder. The unsteady and natural convection of the nanofluid over a vertical geometry was studied by Loganathan and Vimala [

35].

A variety of mathematical techniques have been used by the researcher for the solution of the proposed models. The Homotopy Analysis Method (HAM) is one of the analytical techniques for the solution of nonlinear differential equations. Liao [

36] introduced this method for the first time in his Ph.D. dissertation. Later, Liao [

37] further modified this technique by introducing more auxiliary constraints. In recent decades, this method was frequently used by the researchers [

38,

39,

40,

41,

42,

43] for the solution of nonlinear differential equations. This method was modified by [

44] for faster convergence and was named as Optimal Homotopy Analysis Method (OHAM). The convergence control parameters were executed to overcome the convergence of the series solution. The convergence control parameter gives a straightforward method to look at the convergence of the series solution. This technique is genuine and does not rely upon stretching parameters. It gives a suitable way to ensure the convergence of the approximation series. A nonlinear equation is changed into a boundless linear equation with accommodation to choose the related condition and the base functions of the solution. Gul and Firdous [

45] examined the experimental and theoretical studies of graphene oxide nanofluid using the OHAM technique.

Based on the above literature review, the aim of this research is set to study the spray coating of a vertical cylinder through CNTs for the heat transfer enhancement applications. The coating materials for the rapid cooling and heat transmission is the second aim of this research. For this purpose, the BVPh 2.0 package, as mentioned in [

44,

45], is utilized to obtain the 10th order approximations for which the residual error is minimized. Recently, Gul et al. [

46] have used the BVP 2.0 package for the suitable range of the parameters up to the 10th order approximation.

2. Mathematical Formulation

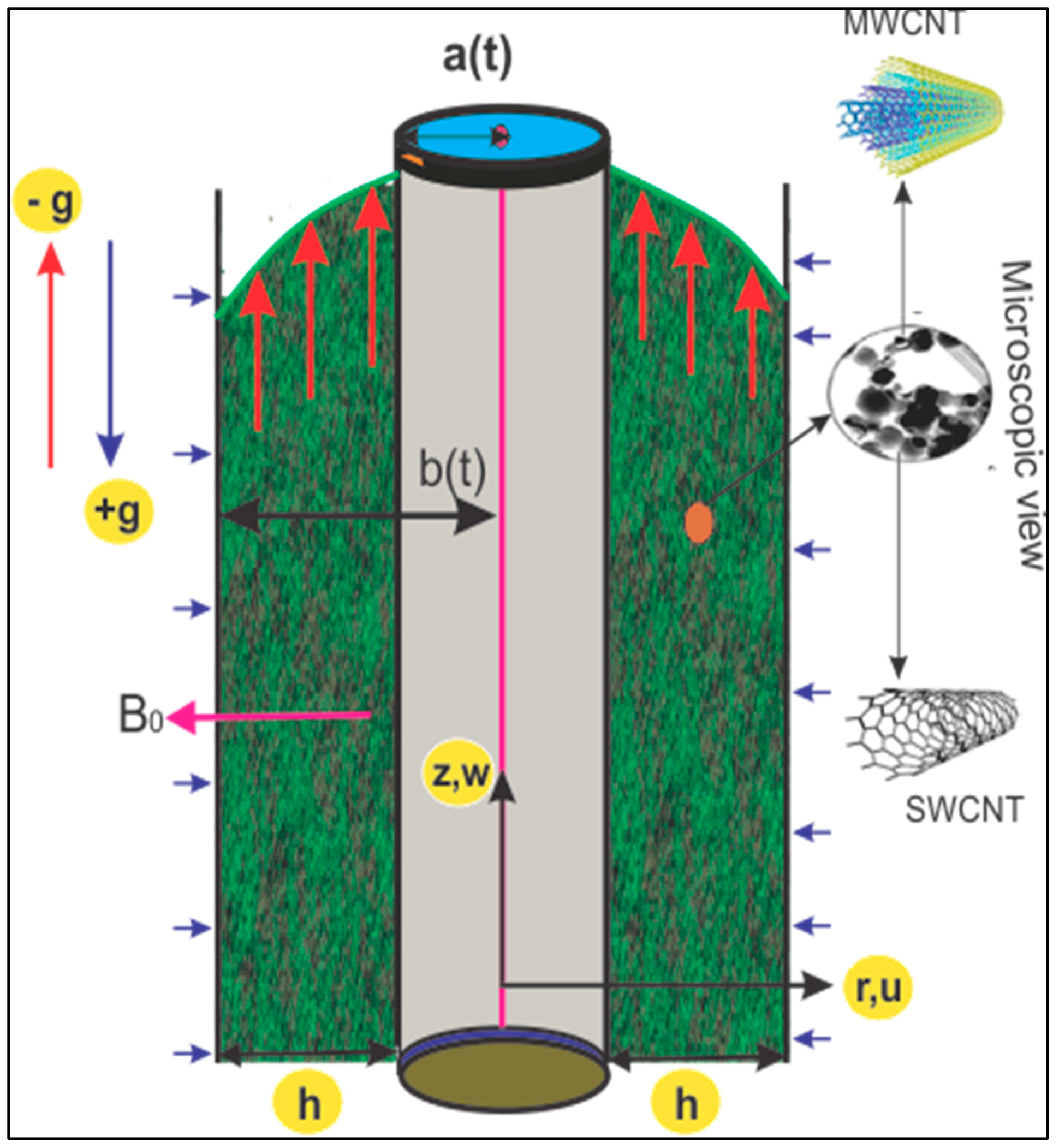

The two-dimensional unsteady flow of water-based carbon nanotubes is sprayed over a vertical stretching cylinder with radius

The

-axis is considered along the cylinder and

are chosen along the radial direction. The cylinder is stretched with the stretching velocity

along the

-direction, such that the radius of the cylinder remains identical, as shown in

Figure 1. The radius of the cylinder lies in the range between

and

. The gravity force

shows the downward effect and

shows the upward effect during stretching. The single and multiwalled carbon nanotubes SWCNTs/MWCNTs and their microscopic view are also shown in

Figure 1. The thickness of the liquid film above the free surface is assumed as

. The constant

shows the stretching and

is used for the shrinking of the surface. The term

stands for the time. A constant magnetic field

is applied in the radial direction.

The basic flow equations are:

The velocity components

are directed in the

directions,

stands for the pressure term,

stands for the temperature field. Moreover,

and

are the density, viscosity, thermal expansion coefficient, heat capacitance and thermal conductivity of carbon nanotubes respectively. The radiative heat flux

was taken from Roseland approximations. The boundary conditions of the above-stated problem are

where

stands for the unsteady radius of the tube and

is the range of the thin nanofluid.

is the suction/ injection velocity, the thickness of the liquid film is denoted by

is the surface temperature. The temperature at the liquid film surface is taken as

Where

is taken from the literature [

30,

31].

is known as the reference temperature such that

.

The density, viscosity, heat capacitance and thermal conductivity of the CNTs are specified in the

Appendix.

Introducing the similarity transformations to transform the basic governing equations into the dimensionless form as:

The similarity variables defined in Equation (7) have been used in Equations (1)–(6). The continuity equation satisfied automatically and the rest of the equations are:

Using the similarity transformation, the boundary conditions for the flow problem can be written as:

where

is the Reynolds number,

is the unsteadiness parameter,

is the Prandtl number,

is the Radiation parameter,

is the Magnetic parameter,

is the Grashof number and are defined as:

The pressure distribution term is evaluated from Equation (2) as follows

The velocity

is a function of the nanofluid thickness

and is defined as:

The non-dimensional forms of skin friction coefficient and heat transfer rate are defined as [

32,

33,

34]:

3. OHAM Solution

In this section, the non-linear flow models in Equations (8) and (9) has been solved analytically through the Optimal homotopy analysis method (OHAM). This method has a tendency to find the solution of nonlinear ordinary differential equations up to 20th–30th order approximation. For this purpose, the BVPh 2.0 package, as mentioned in [

44,

45,

46], is utilized to obtain the 10th order approximations for which the residual error is minimized. This package was introduced in a renowned book “Homotopy Analysis Method” [

44]. The basic theory of this method is to minimize the total average squared residuals and find out the consistent local optimal convergence control parameters. The OHAM BVP 2.0 package has the tendency to obtain the suitable range of the parameters for the proposed problem, as obtained in [

46].

The linear operators

and

are defined as:

The general outcomes of the

and

are:

According to the BVPh 2.0 package of OHAM, as explained in [

44,

45,

46], Equations (8) and (9) are written as

According to Liao [

35] and Gul and Firdous [

36], the total squared residual error is defined by

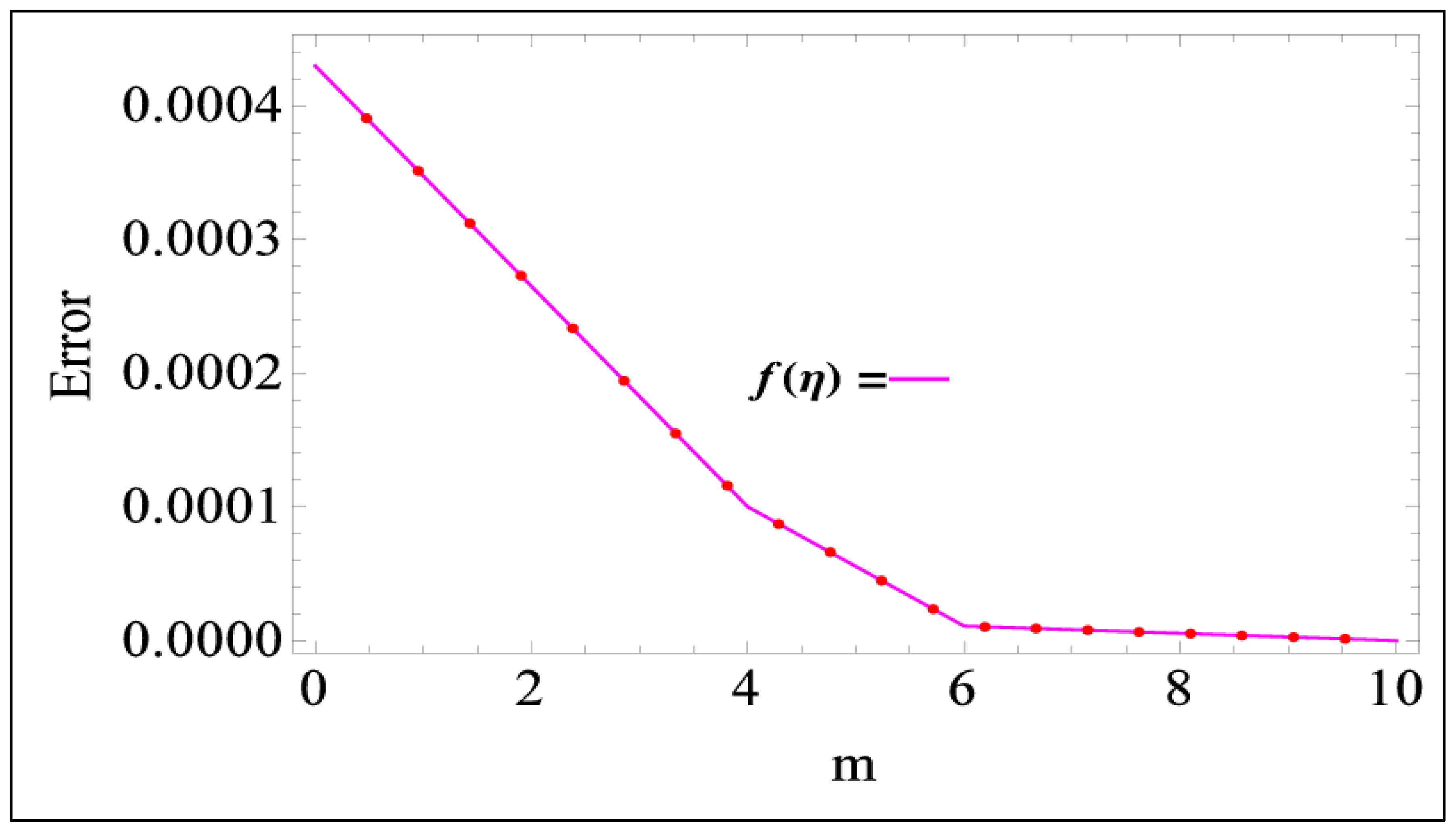

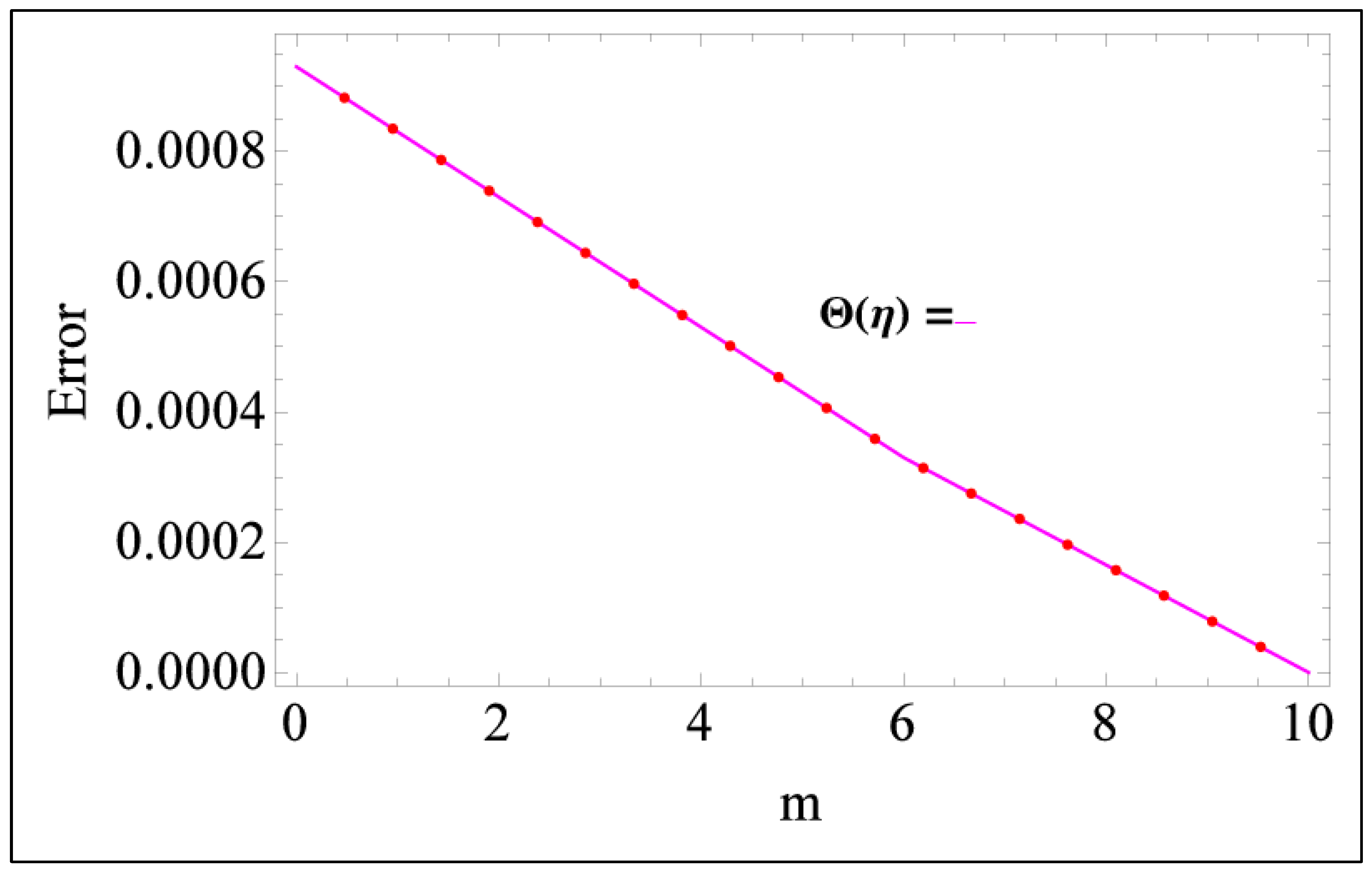

The total residual error

in the form of auxiliary parameters has been exhibited in

Figure 2 and

Figure 3 for the velocity and temperature profiles respectively. The numerical values of the optimal convergence control constraints

have been archived in case of the SWCNTs-water while

have been obtained in the case of MWCNTs-water. To inculcate the accuracy of the obtained results, one can find the required range of the embedding parameters involved in the problem. Due to this importance, the range of the physical constraints involved in the modeled problem has been calculated and presented in

Figure 4 and

Figure 5.

4. Results and Discussion

A comprehensive analysis of the unsteady flow of the CNTs-water nanofluid spray over the surface of a vertical cylinder is studied. The dimensionless velocity, temperature and pressure profiles for both (SWCNT’s) and (MWCNT’s) nanofluids are investigated.

The stepwise detailed discussion of the OHAM method convergence, velocity field, temperature profile, pressure distribution, and spray rate are as follows:

4.1. Residual Error

The optimal values of the auxiliary constraints

and

are determined to control and stabilize the OHAM solution. The geometry of the problem is depicted in

Figure 1. The total residual error is exhibited in

Figure 2 and

Figure 3 for the dimensionless velocity and temperature fields. They authenticate strong convergence of this method. The numerical values of the optimal convergence control constraints

have been archived in case of the SWCNTs-water while

have been obtained in case of MWCNTs-water.

4.2. Velocity Profile

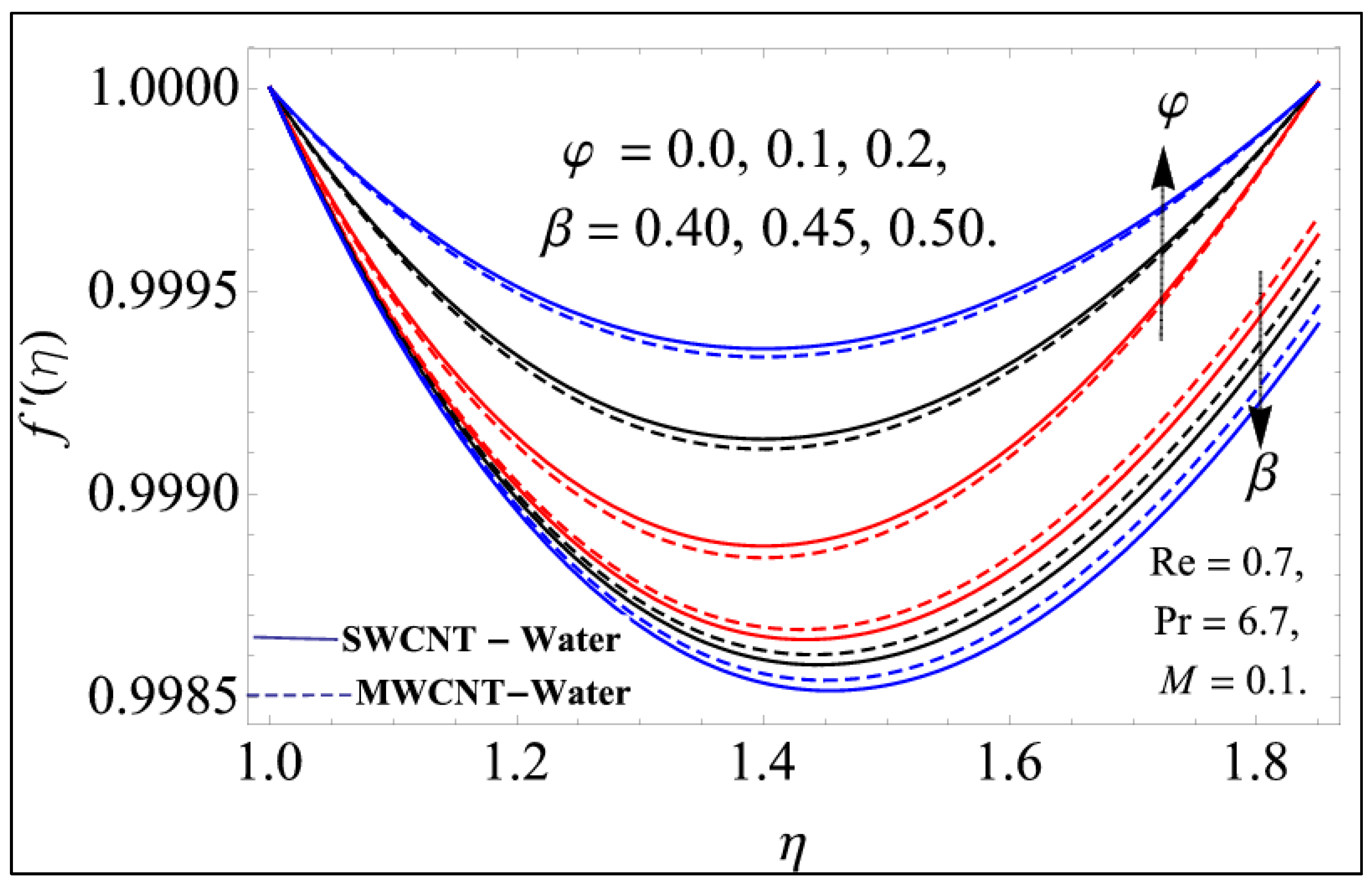

The striking features in the sprayed pattern on the surface of a stretching cylinder are the depth of the nano liquid film and the nanoparticle volume fraction for both types of CNTs.

In the first phase, attention was paid to the impact of the thickness parameter due to its important role during spray coating. The velocity of fluid quickly varies with the variation of liquid film thickness . The thin liquid flow moves quickly while the thick liquid comparatively moves slower.

From

Figure 4, it is obvious that the velocity declines with larger values of

. The growing thickness enhances the mass of the nanofluid, therefore, the fluid flow declines. The enhancement of the spray rate and radial velocity

is assumed to vary with the thinning liquid film and this effect is clear in the SWCNTs due to its physical properties as compared to the MWCNTs.

The nanoparticle volume fraction has an important role in the thermal applications. The larger amount of the nanoparticle volume fraction reduces the internal cohesive forces among the molecules of the liquid and as a result the viscous forces become feeble to stop the flow. Therefore, the larger the value of , the larger will be the radial velocity and this effect is comparatively strong in case of SWCNTs.

The effects of

and

on the dimensionless velocity are shown in

Figure 5. The vertical cylinder is stretched equally in the upper and lower directions. Therefore, the Grashof number

is treated positive and negative in the momentum boundary layer equation. The radial velocity of the nano liquid film for the larger amount of the Grashof number gradually towards the free surface. While the radial velocity decline using the negative value of

which shows the opposite impact against the natural convection. The influence of

depicts the change in the fluid velocity and shown in the same

Figure 5.

The thickness of the momentum boundary-layer increases for larger values of the parameter which indicates the decline in the velocity field and this effect is almost the same for both sorts of CNTs.

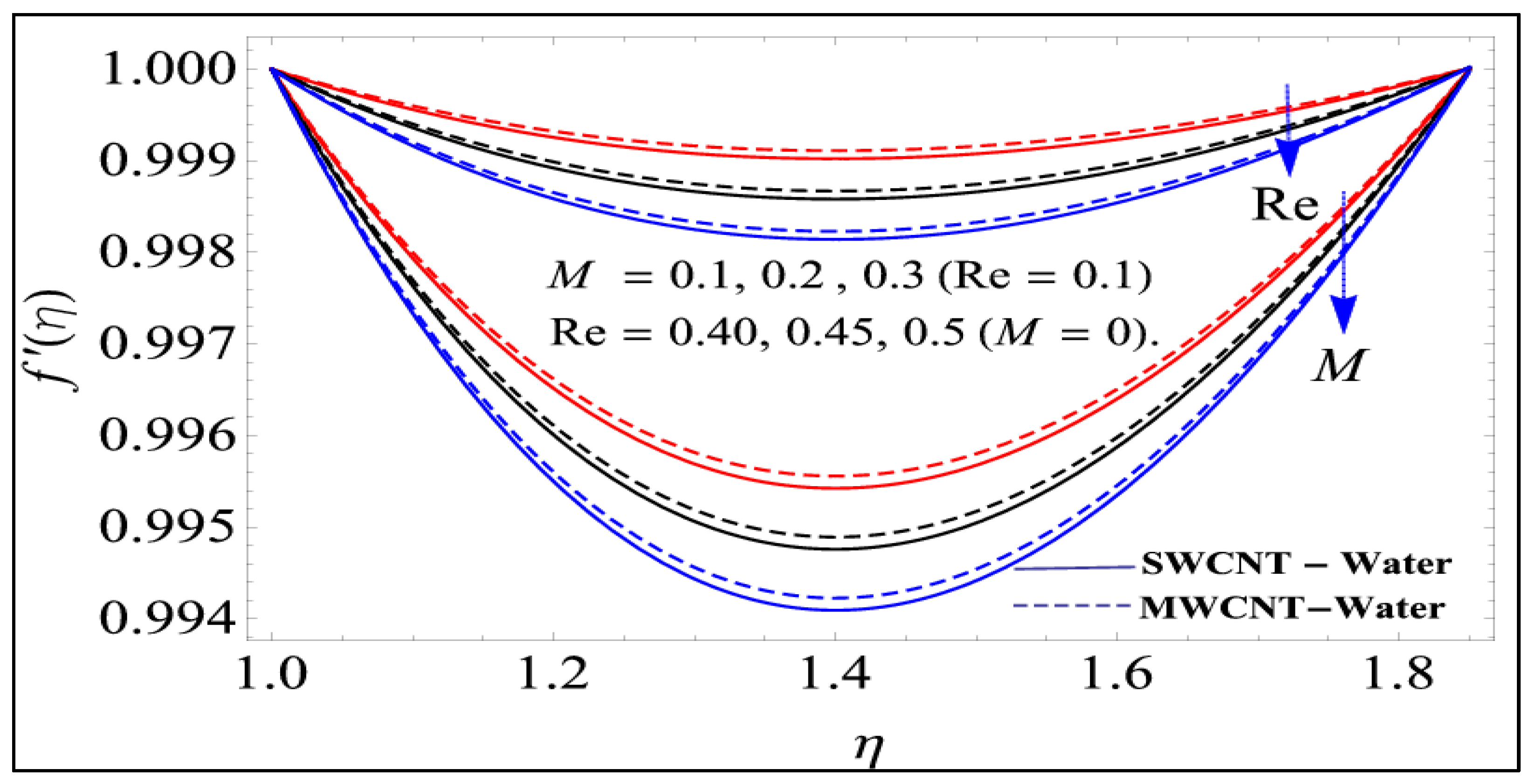

The impact of the Reynolds number

and magnetic parameter

on the dimensionless velocity is presented in

Figure 6. It is observed that the radial velocity goes to decline for the larger values of

. Physically,

, expresses the ratio among the inertia forces and viscous forces and the larger value of the

boosted the inertial force. Therefore, the larger amount of

retards the radial and the motion declines slowly.

Furthermore, the strong inertial forces packed the atoms/molecules of the nano liquid-tightly and do not allow them to flow. The impact of the inertial forces is relatively strong in the SWCNTs. The spray pattern retarded for the higher values of . In fact, the execution of the magnetic field of the spray pattern produces a resistive force called the Lorentz force and this force to produce the retardation in the motion of the fluid. Due to the physical properties of the SWCNTs, this impact is comparatively strong.

4.3. Temperature Profile

The main objective of the current research is the thermal study which has a prominent application in the heating of the cylinder. The carbon nanotubes CNTs plays a vital role to enhance the thermal properties of the surface during spray phenomenon. The thickness

of the liquid film has an important role in heat transfer. The temperature distribution decelerates for the larger values of

which is demonstrated in

Figure 7. The thin liquid is proficient for the transmission of energy while thick liquid depreciates energy transport. Physically, the mass of the fluid rises with the greater quantity of the thick liquid which reduces the dimensionless temperature. The heat can easily penetrate in the thin liquids as compared to the thick liquids. Therefore, the larger quantity of the thickness parameter

decelerates the temperature field and this effect is almost the same for both CNTs.

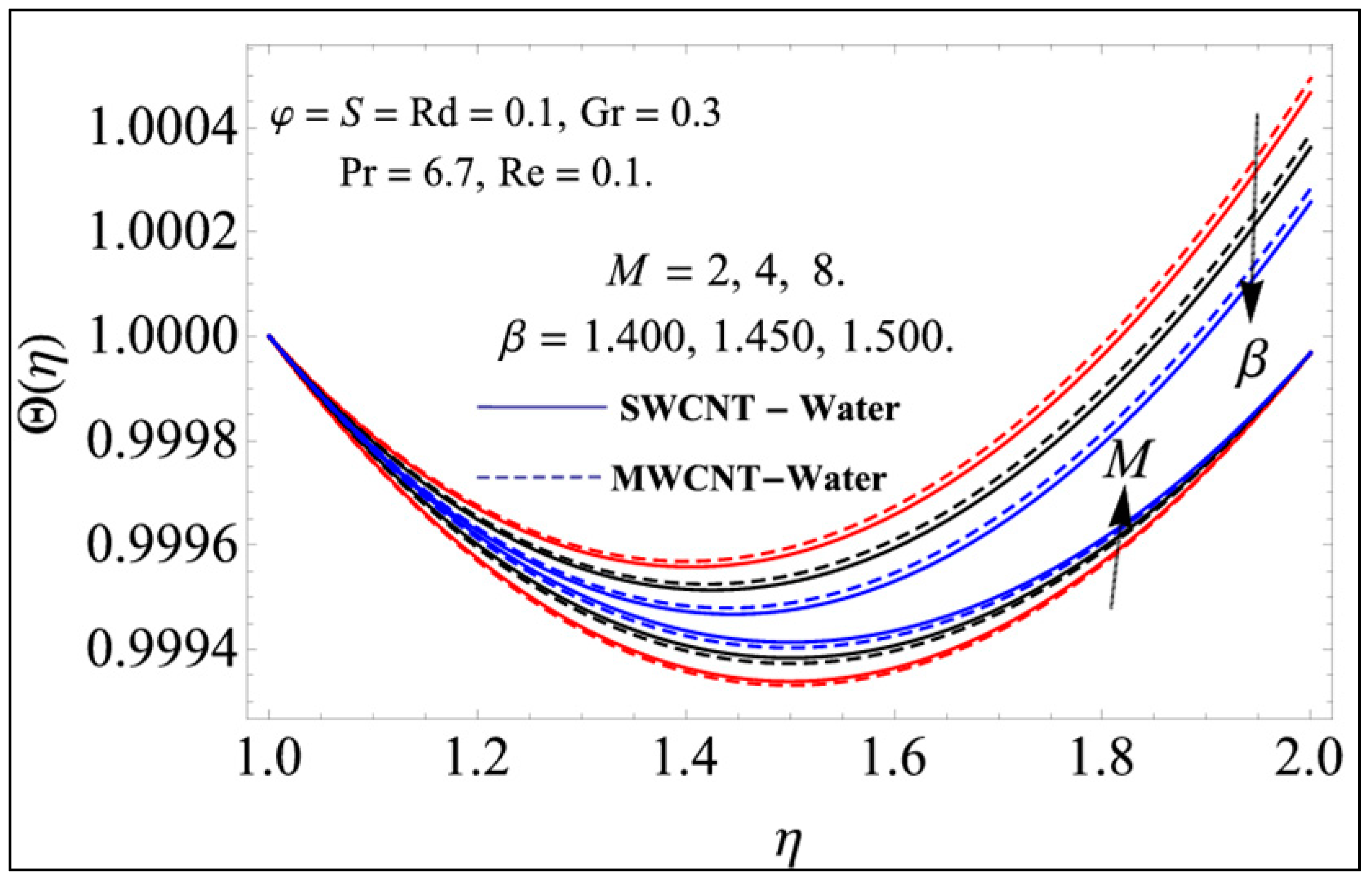

The larger value of

increases the dimensionless temperature as shown in

Figure 7. The application of the magnetic field imply that the resistive force generated by the magnetic field, known as the Lorentz force, is responsible for the enhancement of temperature. The transverse magnetic field controls and bounds the boundary layer, whereas the Lorentz force supports the temperature profile; this effect is the same for both CNTs.

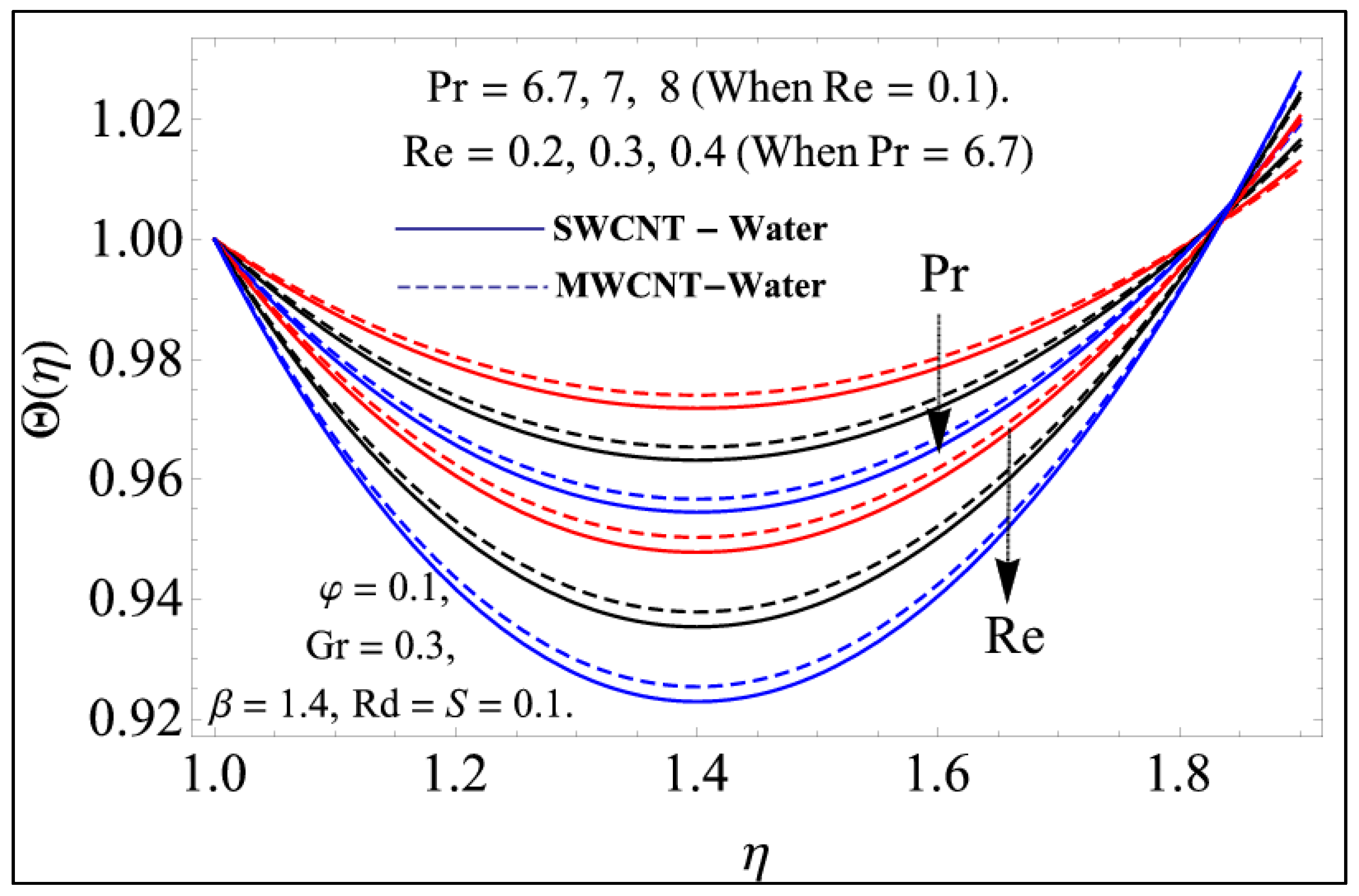

Figure 8 predicts the effects of the Prandtl number

and Reynolds number

on the dimensionless temperature

. The maximum cooling is attained with the larger values of

and this influence is hastier for the CNTs. In fact,

, is the ratio of momentum diffusivity to thermal diffusivity. The fluids having low

, are capable for the higher heat transfer rate. Therefore, the larger value of the Prandtl number diffuses temperature field. Similarly, the temperature distribution depreciates for the larger values of

displayed in the

Figure 8. The Reynolds number implies that the dominant inertial forces differs the viscous forces. Due to the strong inertial forces, the molecules and atoms of the nano liquid are tightly bounded which requires more energy to collapse them. The decline effect due to the larger value of the Reynolds number is comparatively faster in the SWCNTs.

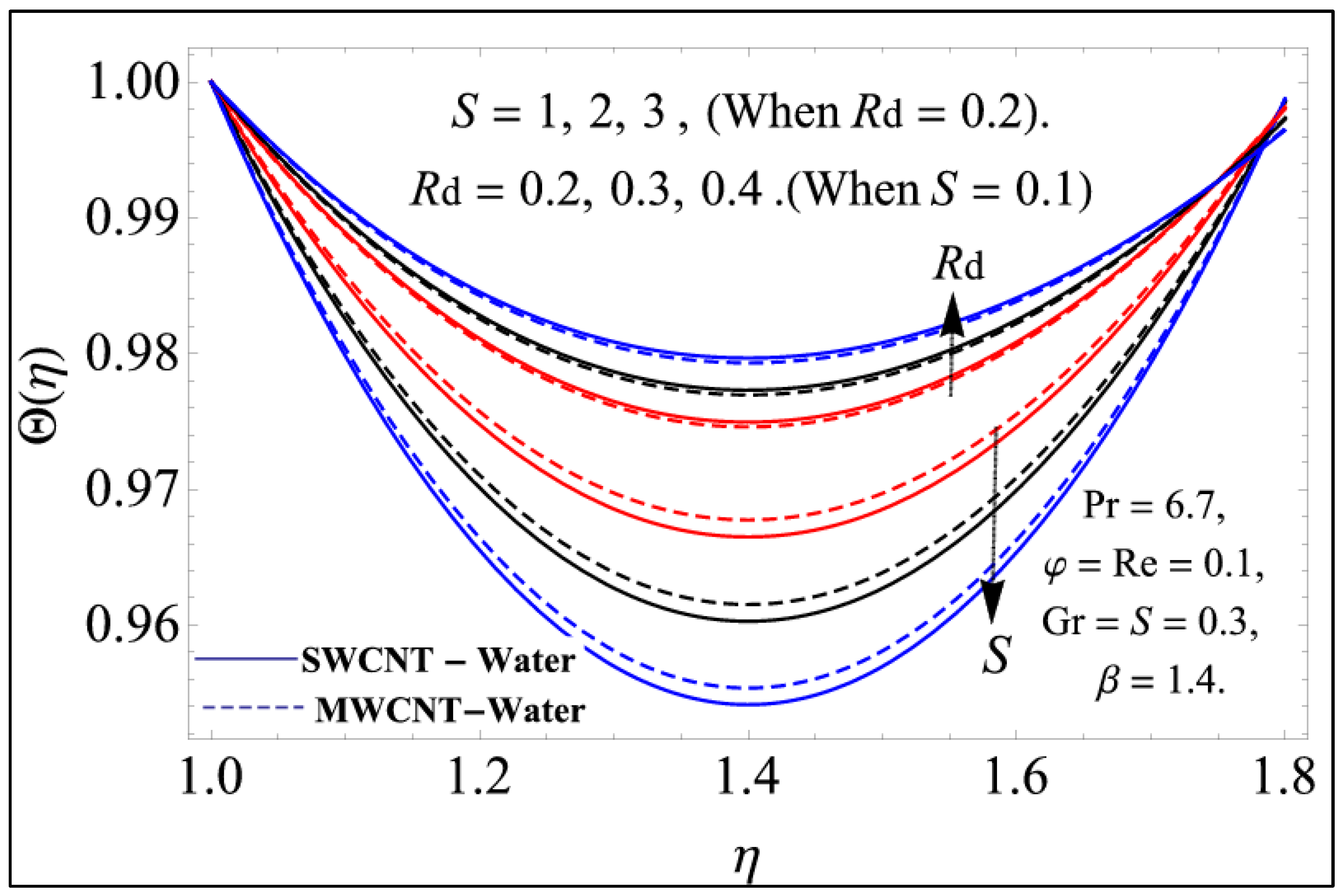

The impact of the unsteady parameter

and radiation parameter

on the dimensionless temperature is displayed in

Figure 9. The unsteadiness parameter

has the inverse relation to the stretching constraint of the temperature field. Therefore, the larger value of the parameter

declines the temperature field. The larger value of thermal radiation

, enhances the nanofluid temperature. Physically, the higher values of the radiation parameter produce a sufficient capacity of heating to the CNTs to enhance the temperature field. Due to excellent physical properties of the SWCNTs, the thermal radiation is more effective in the SWCNTs as compared to the MWCNTs.

4.4. Pressure Distribution

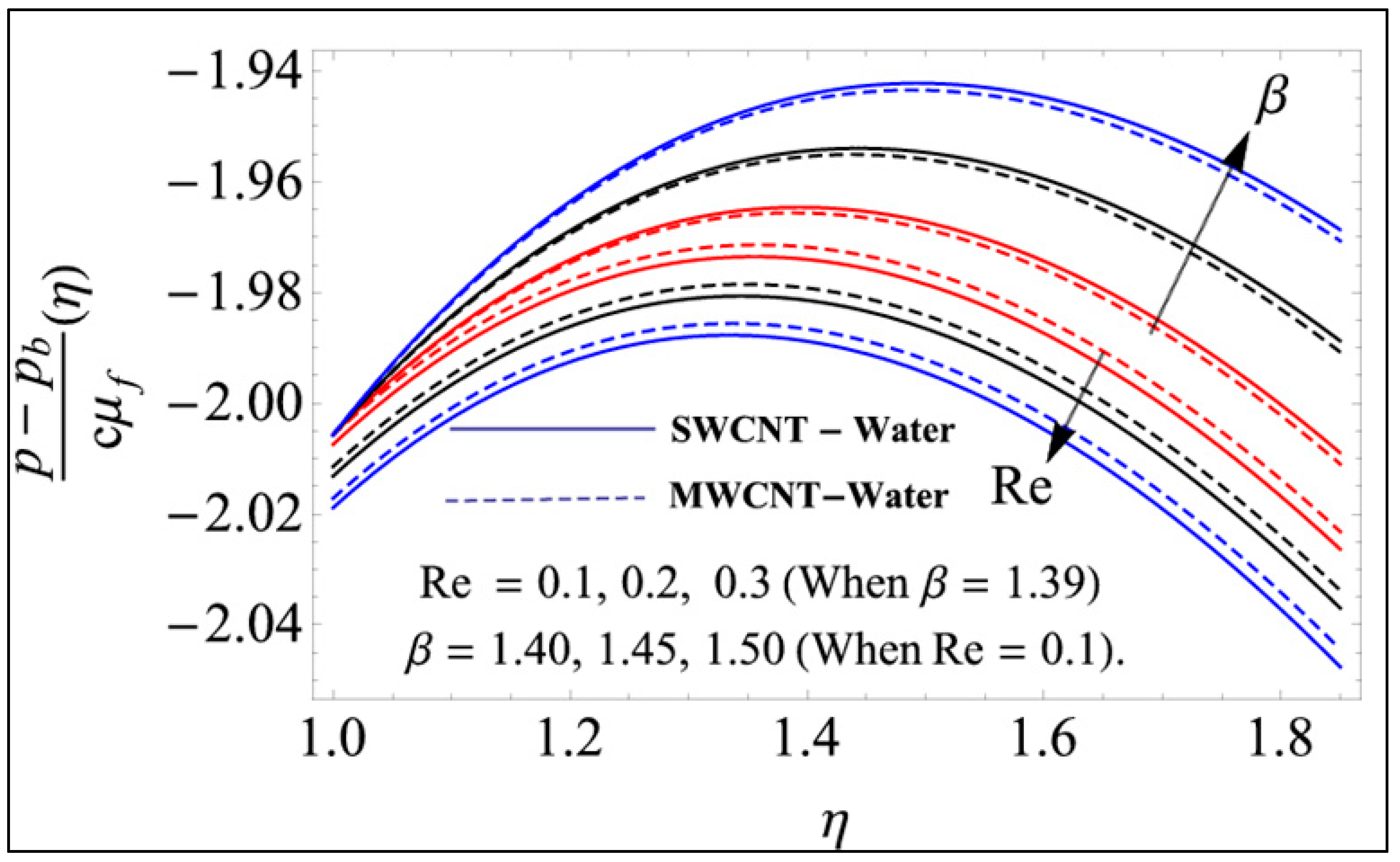

The pressure term has an important factor in the spray pattern.

Figure 10 specifies that pressure distribution which increases for the larger values of the thickness parameter

. Physically, more pressure is required for the thick boundary layer as compared to the thinning liquids during spray phenomenon. The pressure distribution boosts up with the larger thickness parameter

and extra power is essential to stun the stress spawned due to the greater thickness of the nano liquid film. This effect is observed relatively strong in the SWCNTs.

The greater values of the Reynolds number

decline the pressure term as it is illustrated in

Figure 10. Due to the inertial forces, the pressure inevitably goes at the lowest rate in the broad way of motion. The particles of the nano liquid are tightly packed and more pressure is required for the fluid motion.

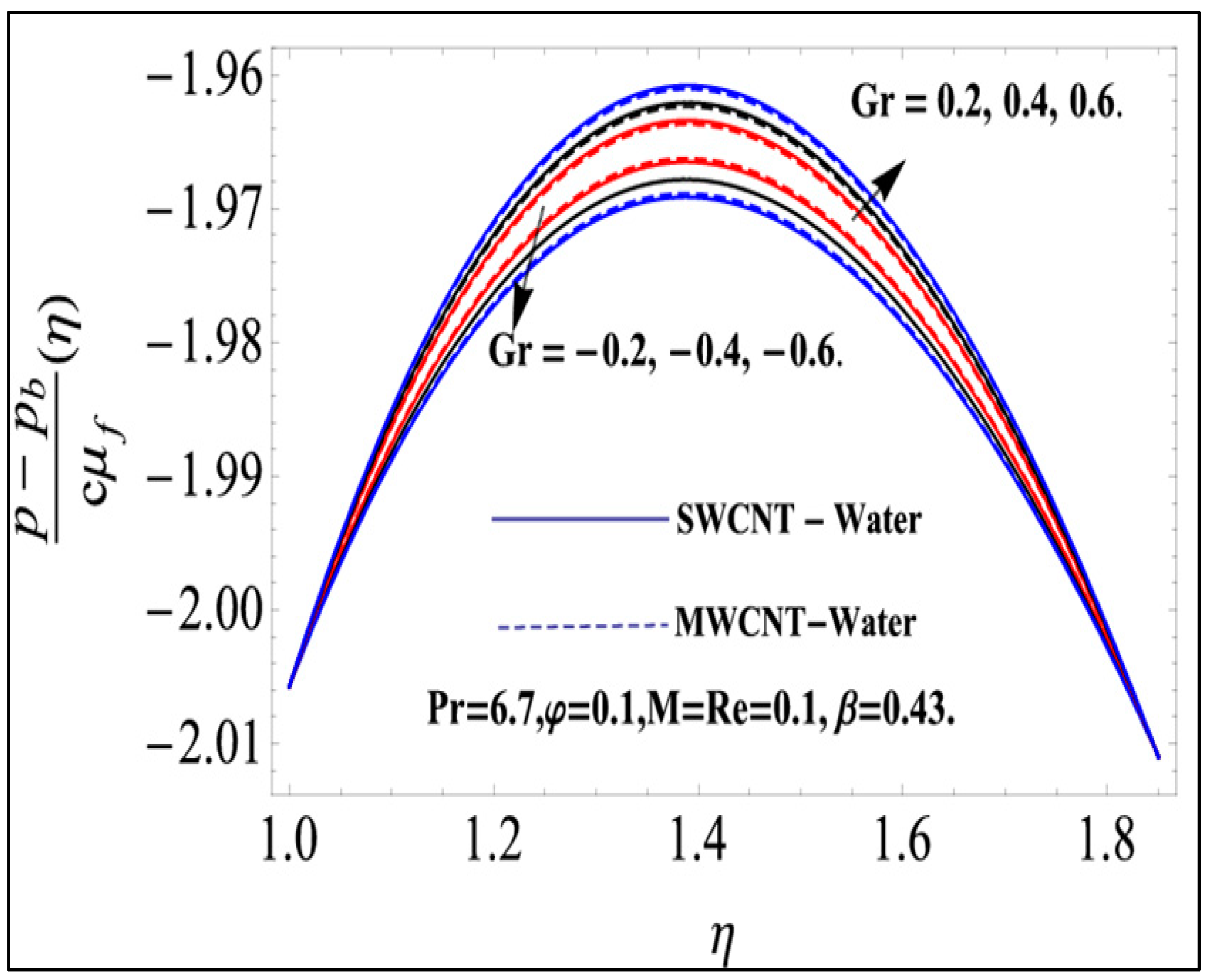

The impact of the natural convection parameter

on the pressure distribution is displayed in

Figure 11 for positive and negative values. The pressure distribution increases with the positive values of the Grashof number

and decline with the negative values of

. Since the vertical cylinder stretches equally up and down, the natural convection is observed in the same pattern. In the upward direction

and during downward direction

. The larger values of

enhances the pressure distribution while its negative value causes to decrease the fluid motion and pressure distribution as well.

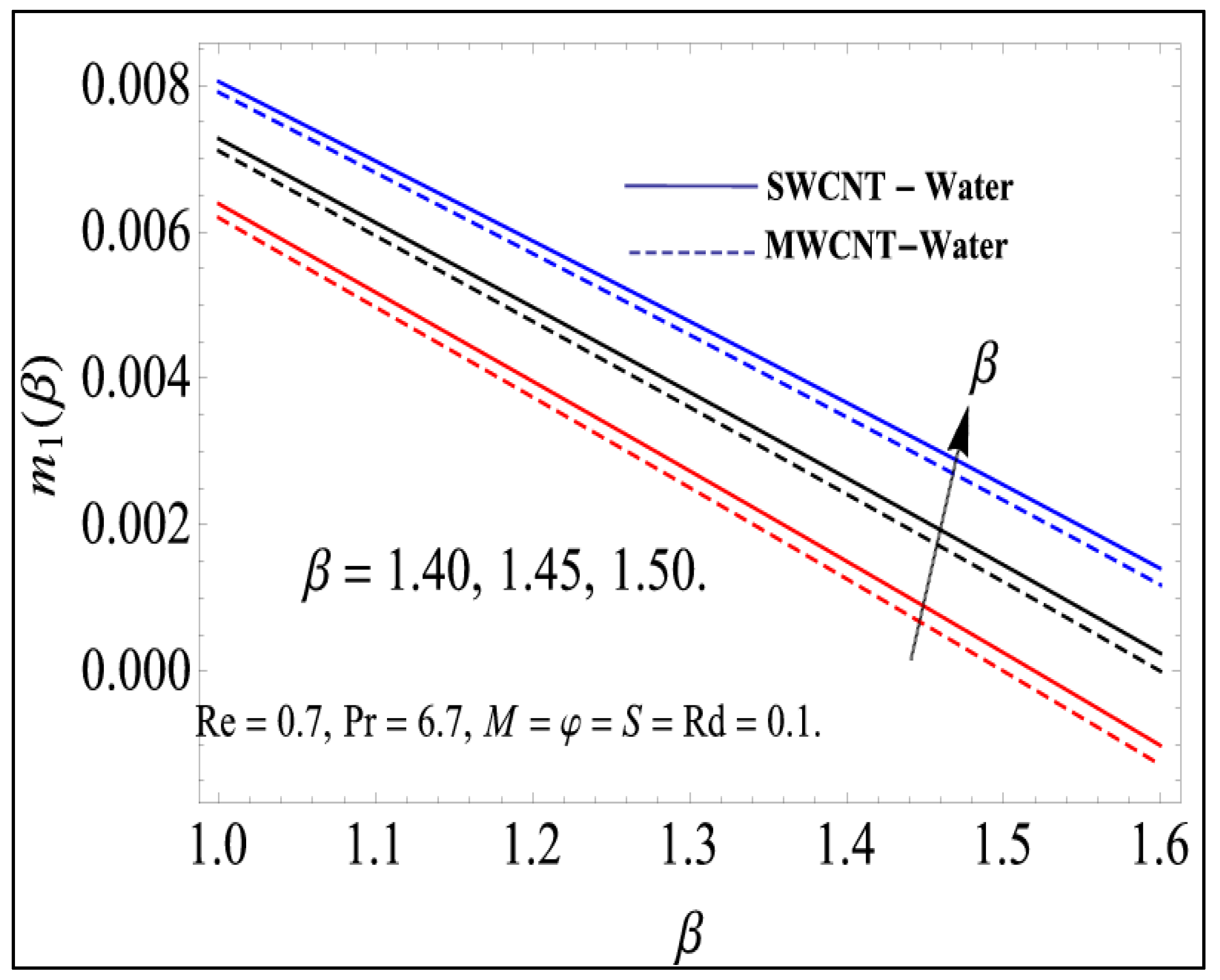

4.5. Spray Distribution

The spray rate or spray distribution is the essential part of the painting phenomenon and the uniform spray distribution is the important factor of this manifestation. The vertical and stretching cylinder is sprayed by a nanofluid for the thermal applications and protecting the paint.

Figure 12 displays the mass flux

which is a function of the thickness parameter

. It is obvious that the mass flux enhances the size of the film

. For the constant spray rate, the deposition velocity needs to be uniform and much-closed impact observed for both sorts of CNTs.

The impact of the normalized spray rate

, which is the function of the film size

is illustrated in

Figure 13. The normalized spray rate

is increasing with the larger values of the thickness parameter

. In fact, the thinning liquids need low spray rate and the normalized spray rate rises with thicker liquids. Again, this effect is almost the same for the SWCNTs and MWCNTs.

4.6. Skin Friction and Nusselt Number

Table 1 indicates the thermophysical properties of the base liquid and solid carbon nanotubes. The residual errors for SWCNTs/MWCNTs-Water are presented in

Table 2. The influence of the unsteadiness constraint

, Reynolds number

and Grashof number

versus the local skin friction are scrutinized in

Table 3. The large values of

and

raises the skin friction coefficient

. In fact, the larger values of these parameters enhance the friction force to increase the skin friction. The larger values of the Grashof number

reduces the friction force and therefore, the skin friction decline. These effects are comparatively stronger in the case of the SWCNTs.

The influence of the unsteadiness parameter

, Reynolds number

, and Grashof number

on the heat transfer rate (Nusselt number), is scrutinized in

Table 4.

The larger values of the parameters and enhances the heat transfer rate. The effects of these parameters are more effective in the case of SWCNTs.