Energy Saving and Low-Cost-Oriented Design Processes of Blank’s Dimensions Based on Multi-Objective Optimization Model

Abstract

1. Introduction

2. Establishment of Blank Dimension Design Using Multi-Objective Optimization Model

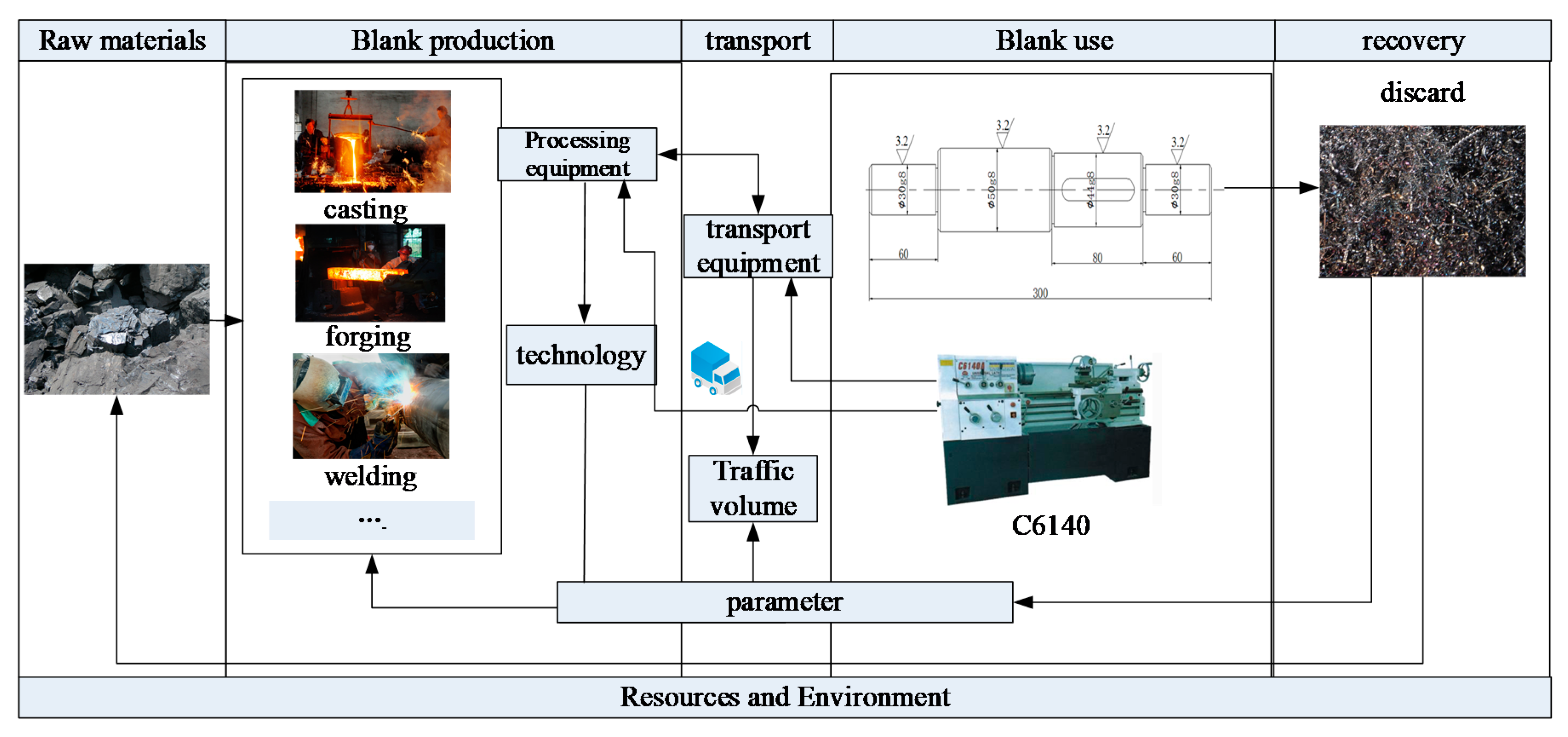

2.1. Impacts of Blank Dimension Design on Energy Consumption and Cost

2.2. Energy Objective

2.3. Cost Objective

3. Constraints

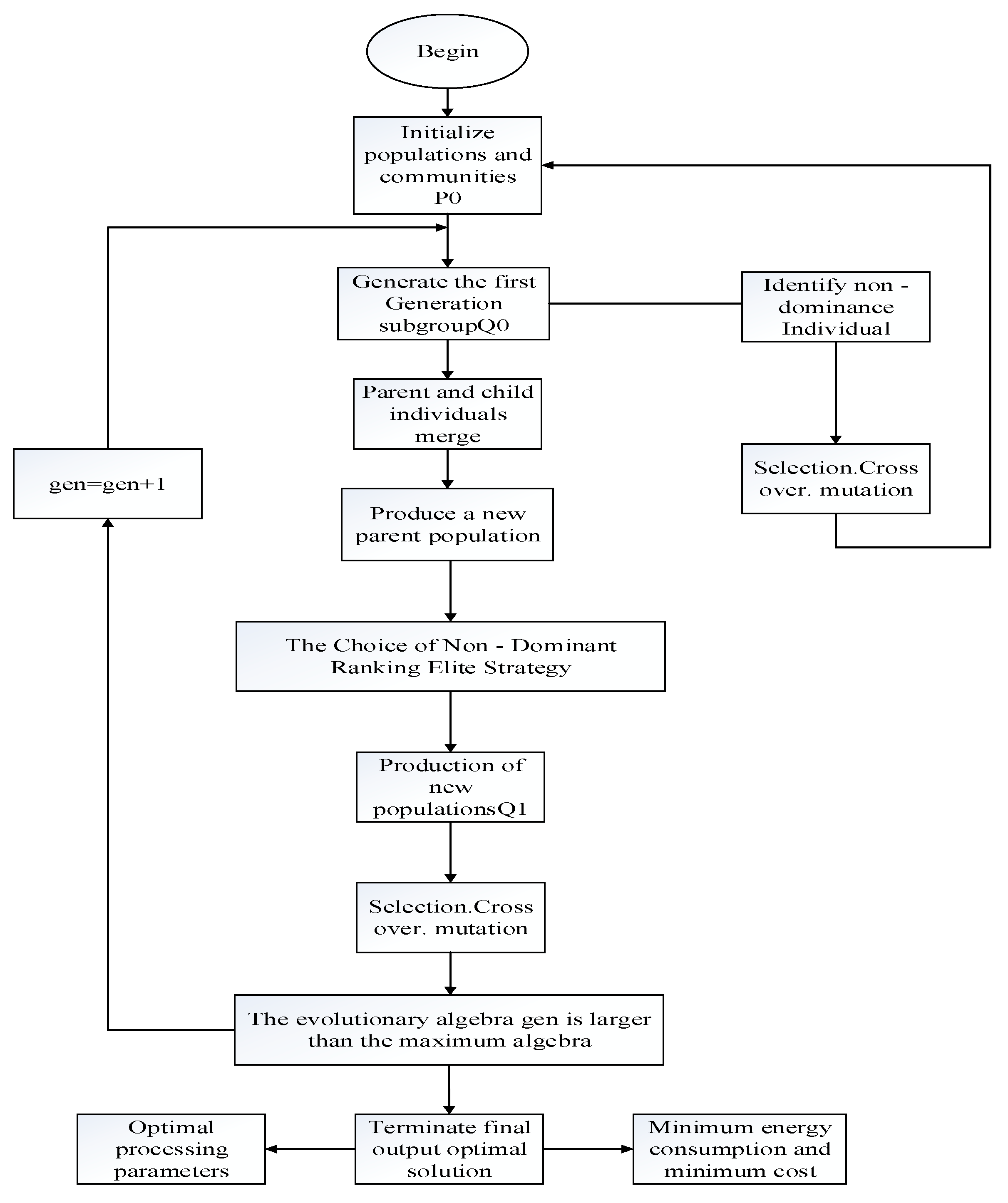

4. Solving Optimization Model Based on NSGA-II

4.1. Analysis of NSGA-II Algorithm

4.2. Basic Parameter Setting of NSGA-II

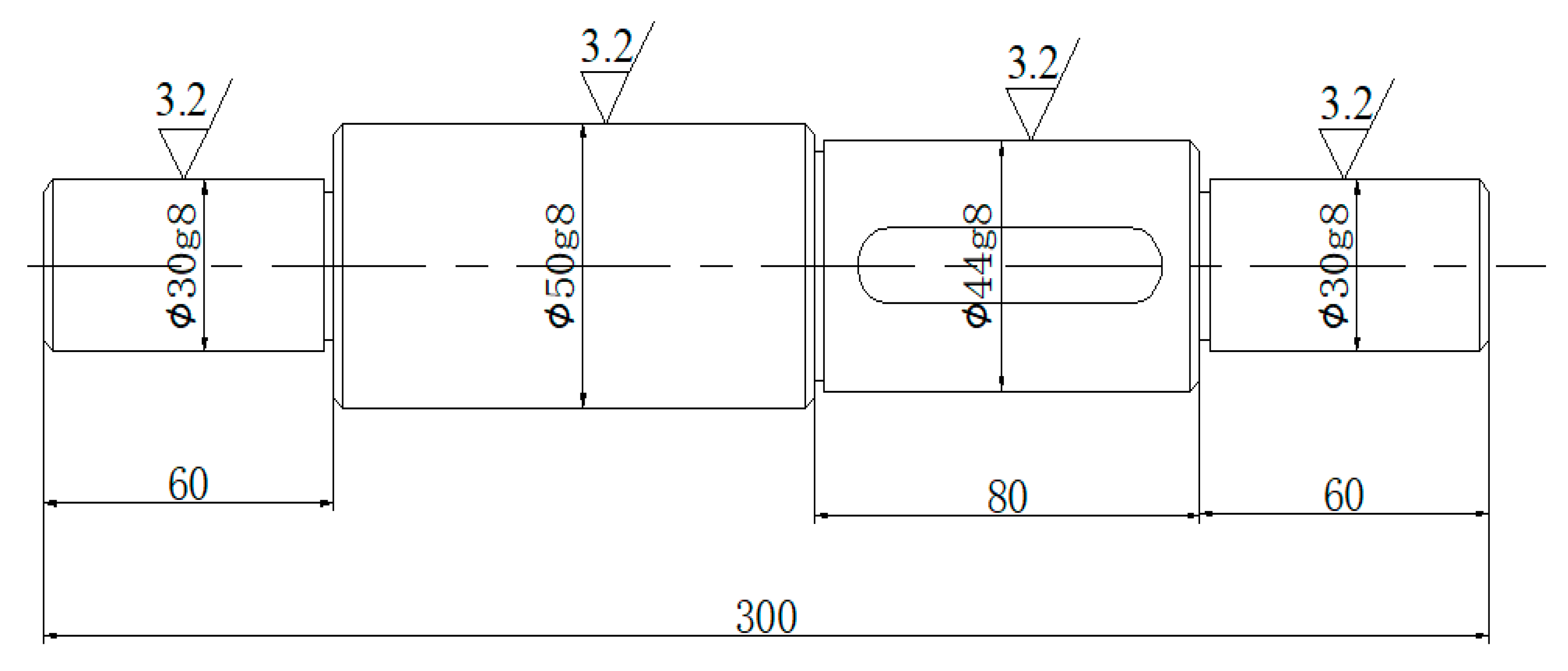

4.3. Background of the Optimization Problem

4.4. Experimental Conditions

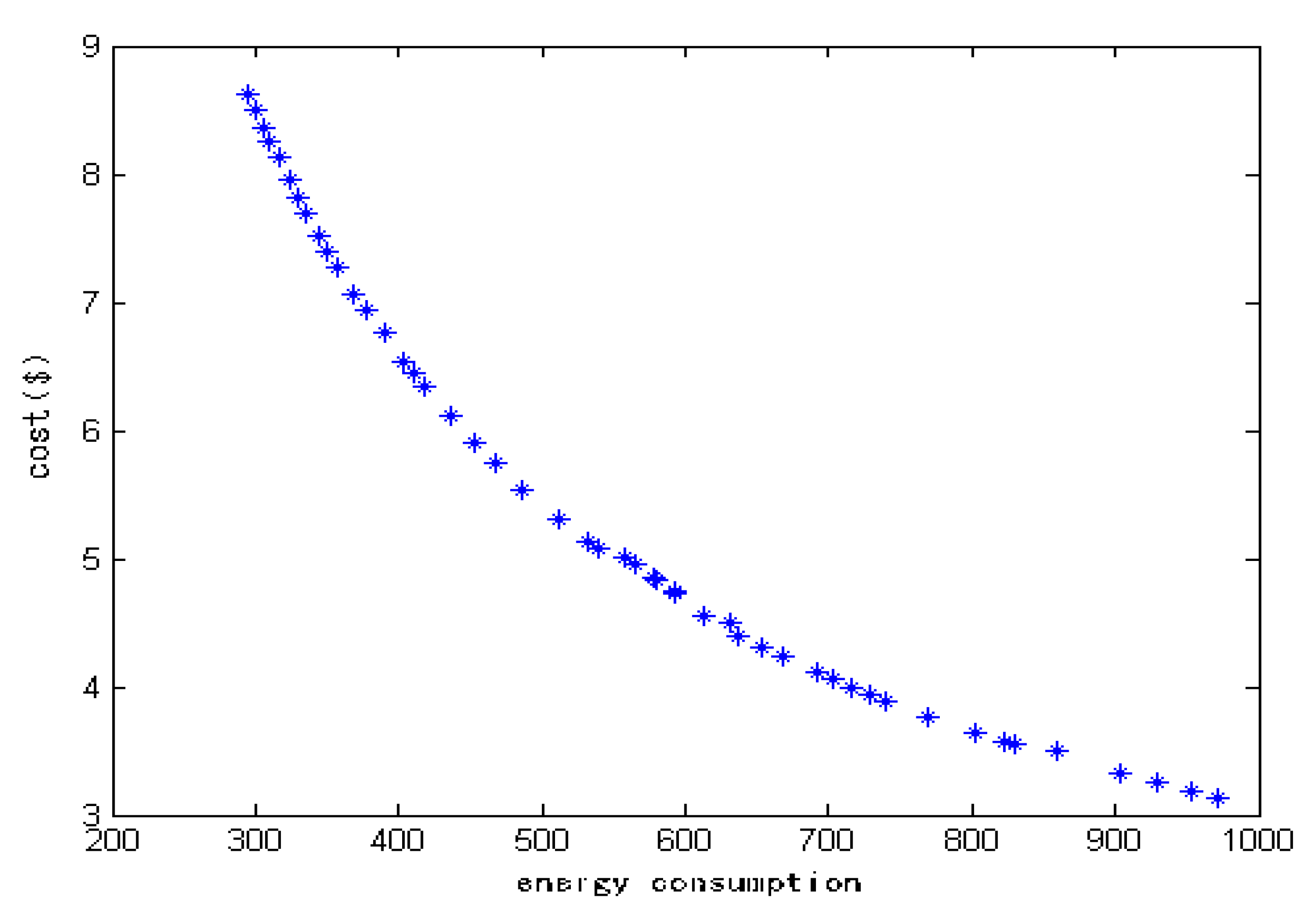

4.5. Simulation Results

4.6. Discussion and Practical Implications

4.7. Comparison of the Proposed Method and Methods in the Literature

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Y.; Ke, J.; Ni, C.C.; McNeil, M.; Khanna, N.Z.; Zhou, N.; Fridley, D.; Qiqiang, L. A comparative study of energy consumption and efficiency of Japanese and Chinese manufacturing industry. Energy Policy 2014, 70, 45–56. [Google Scholar] [CrossRef]

- Fei, L.; Peiji, L.; Congbo, L.; Junbo, T.; Wei, C. The Statue and Difficult Problems of Research on Energy Efficiency of Manufacturing Systems. J. Mech. Eng. 2017, 53, 1–11. [Google Scholar] [CrossRef]

- Xiuben, Z. Machinery Technology; Machinery Technology: Beijing, China, 2012. [Google Scholar]

- Yumei, H.; Wasim, L.; Ghulam, M.S.; Nadeem, L.; Yasir, A.S.; Arooj, F. Measuring Energy Efficiency and Environmental Performance: A Case of South Asia. Process 2019, 7, 325. [Google Scholar] [CrossRef]

- Kuwabara, T.; Si, W.H. PC-based blank design system for deep-drawing irregularly shaped prismatic shells with arbitrarily shape flange. J. Mater. Process. Tech. 1997, 63, 89–94. [Google Scholar] [CrossRef]

- Lee, C.H.; Huh, H. Three dimensional multi-step inverse analysis for the optimum blank design in sheet metal forming processes. J. Mater. Process. Tech. 1998, 80–81, 76–82. [Google Scholar] [CrossRef]

- Qian, D.S.; Lin, H. Blank design optimization for stepped-section profile ring rolling. Sci. China Tech. Sci. 2010, 53, 1612–1619. [Google Scholar] [CrossRef]

- Kitayama, S.; Natsume, S.; Yamazaki, K.; Yamazaki, K.; Han, J.; Uchida, H. Numerical optimization of blank shape considering flatness and variable blank holder force for cylindrical cup deep drawing. Int. J. Adv. Manuf. Tech. 2016, 85, 2389–2400. [Google Scholar] [CrossRef]

- Padmanabhan, R.; Oliveira, M.C.; Baptista, A.J.; Alves, J.L.; Menezes, L.F. Blank design for deep drawn parts using parametric NURBS surfaces. J. Mater. Process. Tech. 2009, 209, 2402–2411. [Google Scholar] [CrossRef][Green Version]

- Ku, T.W.; Lim, H.J.; Han, H.C.; Hwang, S.M.; Beom, S.K. Implementation of backward tracing scheme of the FEM to blank design in sheet metal forming. J. Mater. Process. Tech. 2001, 111, 90–97. [Google Scholar] [CrossRef]

- Shim, H.B. Digital tryout based on the optimal blank design toward realization of beadles stamping. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1514–1520. [Google Scholar] [CrossRef]

- Chamekh, A.; Benrhaiem, S.; Khaterchi, H.; BelHadjSalah, H.; Hamnli, R. An optimization strategy based on a metamodel applied for the prediction of the initial blank shape in a deep drawing process. Int. J. Adv. Manuf. Tech. 2010, 50, 93–100. [Google Scholar] [CrossRef]

- Liu, Y.L.; Chen, W.L.; Ding, L.P.; Wang, X.P. Response surface methodology based on support vector regression for polygon blank shape optimization design. Int. J. Adv. Manuf. Tech. 2013, 66, 1397–1405. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.; Liu, C.; Wei, F.; Ma, M.; Jia, S.; Jiang, Z.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. Sci. Total. Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; Liu, C.; Zhang, C.; Ma, M.; Rao, W.; Li, W.; He, K.; Gao, M. Developing the ecological compensation criterion of industrial solid waste based on energy for sustainable development. Energy 2018, 157, 940–948. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Lai, K.; Li, L.; Cunha, J.; Hu, L. Energy performance certification in mechanical manufacturing industry: A review and analysis. Energy Convers. Manag. 2019, 186, 415–432. [Google Scholar] [CrossRef]

- Congbo, L.; Song, F.; Xingzheng, C. Multi-objective CNC gear hobbing parameters optimization model for high efficiency and energy saving. Comput. Integr. Manuf. Syst. 2018, 5, 1–17. [Google Scholar]

- Yongtang, L.; Huiping, Q.; Jianhua, F. Theoretical and Process Analyses on the Cast-blank Rolling Forming of 42CrMo Bearing Rings. J. Mech. Eng. 2014, 50, 77–85. [Google Scholar]

- Wang, Q.; Liu, F.; Wang, X. Multi-objective optimization of machining parameters considering energy consumption. Int. J. Adv. Manuf. Tech. 2014, 71, 1133–1142. [Google Scholar] [CrossRef]

- Li, X.; Huang, X.; Liu, J.; Liu, F. Optimization Simulation for Job-shop scheduling for Reducing Manufacturing Energy Consumption. J. Syst. Simul. 2016, 28, 114–120. [Google Scholar]

- Wei, Y.; Zhang, H.; Jiang, Z.G.; Hon, K.K.B. Multi-objective optimization of arc welding parameters: The trade-offs between energy and thermal efficiency. J. Clean. Prod. 2016, 140, 1842–1849. [Google Scholar] [CrossRef]

- Albertelli, P.; Keshari, A.; Matta, A. Energy oriented multi cutting parameter optimization in face milling. J. Clean. Prod. 2016, 137, 1602–1618. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Chen, P. Energy-efficient multi-pass turning operation using multi-objective backtracking search algorithm. J. Clean. Prod. 2016, 137, 1516–1531. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K.S. Prediction and optimization of machining parameters for minimizing power consumption and surface roughness in machining. J. Clean. Prod. 2014, 83, 151–164. [Google Scholar] [CrossRef]

- Na, Z.; Xuguang, J.; Wei, W.; Lei, W. Multi-objective optimization of bar pass and Simulation of continuous rolling process. In Proceedings of the Seventh Symposium on Pressure Processing Equipment of Metallurgical Equipment Branch of China Metal Society, Hangzhou, China, 18–20 September 2017; pp. 135–139. [Google Scholar]

- Liu, S.; Liu, F.; Xie, J.; Wang, Q.L. Energy Forecasting Method for CNC MachineT during Its Working Time. Patent Application No. 201210131766, 28 April 2012. [Google Scholar]

- Xiao, Y.; Zhang, H.; Jiang, Z. An approach for blank dimension design considering energy consumption. Int. J. Adv. Manuf. Tech. 2016, 87, 1229–1235. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology: Machining; China Machinery Press: Beijing, China, 2004. [Google Scholar]

- Yang, Y.; Cao, L.; Wang, C.; Zhou, Q.; Jiang, P. Multi-objective process parameters optimization of hot-wire laser welding using ensemble of meta models and NSGA-II. Robot. Comput. Integr. Manuf. 2018, 53, 141–152. [Google Scholar] [CrossRef]

- Esfe, M.H.; Hajmohammad, M.H.; Sina, N.; Afrand, M. Optimization of thermo physical properties of Al2O3/water-EG (80:20) nanofluids by NSGA-II. Phys. E Low Dimens. Syst. Nanostructures 2018, 103, 264–272. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Gong, Q.; Chen, X. Energy Saving and Low-Cost-Oriented Design Processes of Blank’s Dimensions Based on Multi-Objective Optimization Model. Processes 2019, 7, 811. https://doi.org/10.3390/pr7110811

Xiao Y, Gong Q, Chen X. Energy Saving and Low-Cost-Oriented Design Processes of Blank’s Dimensions Based on Multi-Objective Optimization Model. Processes. 2019; 7(11):811. https://doi.org/10.3390/pr7110811

Chicago/Turabian StyleXiao, Yongmao, Qingshan Gong, and Xiaowu Chen. 2019. "Energy Saving and Low-Cost-Oriented Design Processes of Blank’s Dimensions Based on Multi-Objective Optimization Model" Processes 7, no. 11: 811. https://doi.org/10.3390/pr7110811

APA StyleXiao, Y., Gong, Q., & Chen, X. (2019). Energy Saving and Low-Cost-Oriented Design Processes of Blank’s Dimensions Based on Multi-Objective Optimization Model. Processes, 7(11), 811. https://doi.org/10.3390/pr7110811