Applications of Intelligent Models in Processes in the Construction Industry: Systematic Literature Review

Abstract

1. Introduction

- RQ1: What are the technologies of Industry 4.0 that were used in the construction industry?

- RQ2: What are the benefits and advantages of using these technologies?

- RQ3: What are the obstacles that slow down the adoption of these technologies?

- RQ4: What research gaps and future directions are identified in the existing literature?

Importance of Digital Technologies

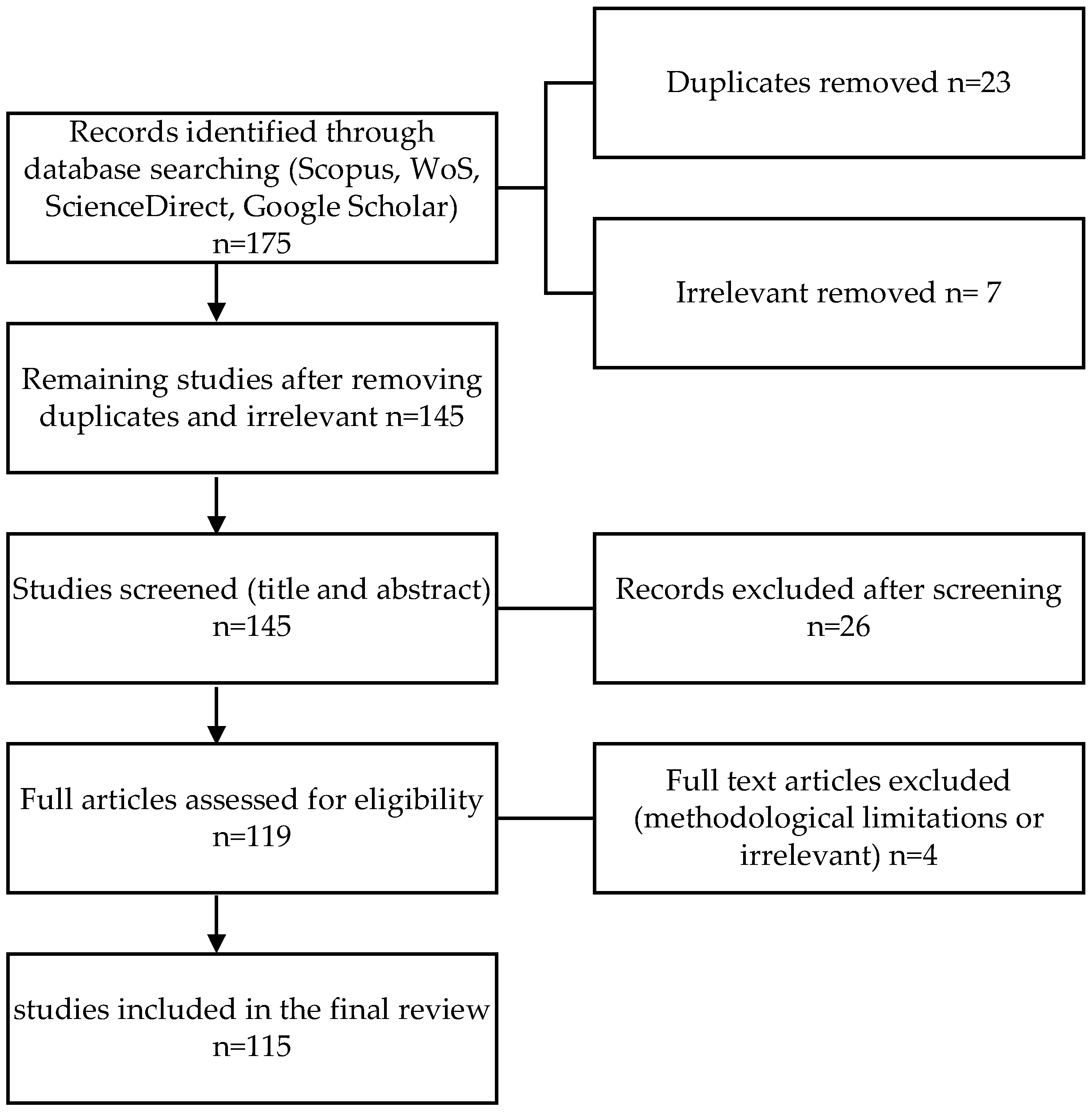

2. Methodology

3. Results

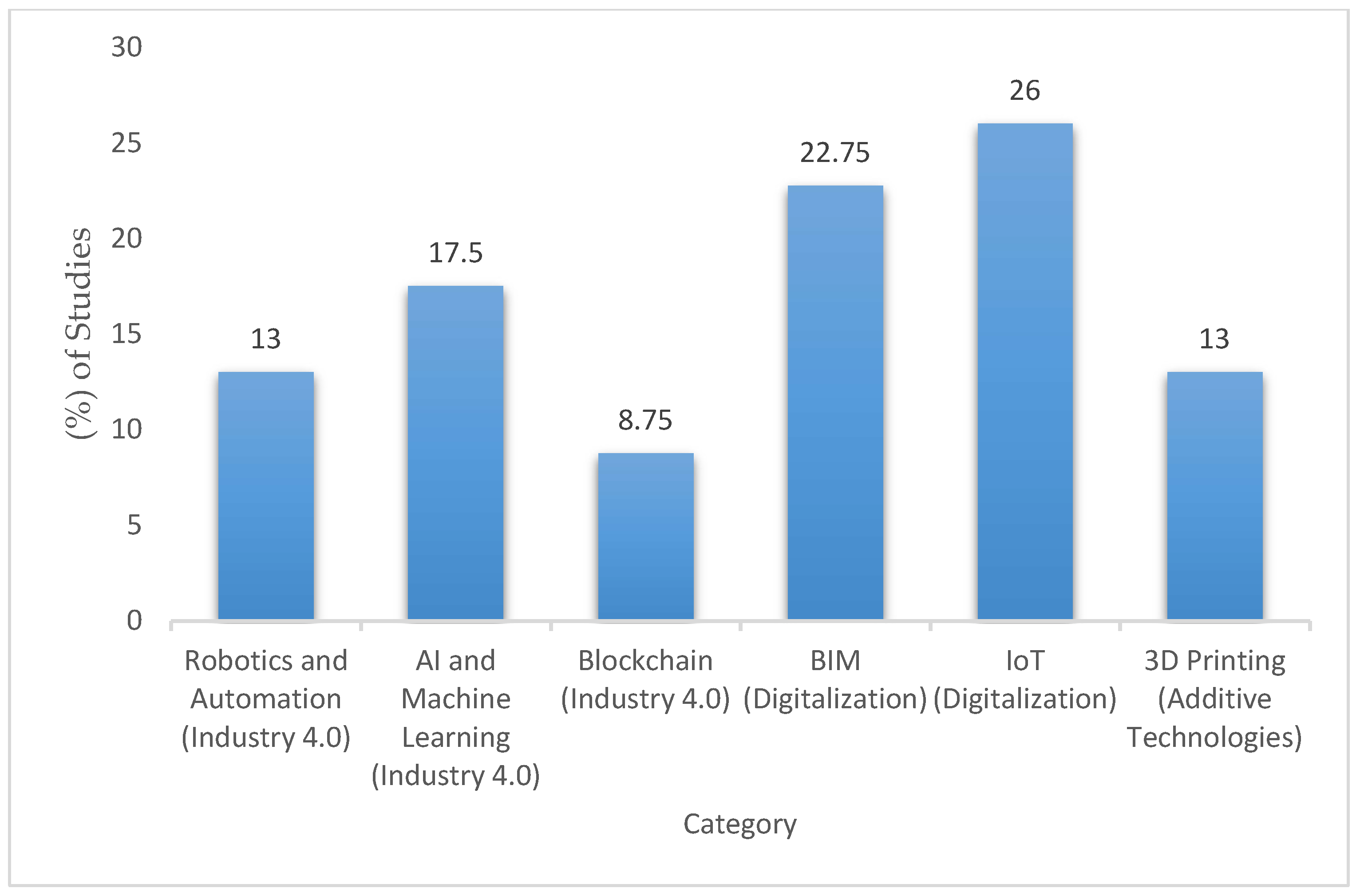

3.1. Industry 4.0 in Construction—Results Summary

3.2. Digitalization and Internet of Things (IoT)—Results Summary

3.3. Additive Technologies (3D Printing)—Results Summary

3.4. Summary of Findings

4. Industry 4.0 in Construction: An Overview

4.1. Definition and Core Principles

4.2. Industry 4.0 in Construction—Benefits

4.3. Industry 4.0 in Construction—Challenges

5. Digitalization and Internet of Things (IoT)

5.1. Digitalization in Construction

5.2. IoT Applications in Construction

5.3. Digitalization and Internet of Things (IoT)—Benefits

5.4. Digitalization and Internet of Things (IoT)—Challenges

6. Additive Technologies (3D Printing)

6.1. Current Uses of 3D Printing in Construction

6.2. Additive Technologies (3D Printing)—Benefits

6.3. Additive Technologies (3D Printing)—Challenges

7. Discussion

7.1. Consistency with Prior Research

7.2. Contrasts with Previous Studies

7.3. Limitations and Methodological Differences

7.4. Contribution of This Review

7.5. Implications for Research and Practice

8. Recommendations and Future Directions

8.1. Recommendations for Practitioners

8.2. Recommendations for Researchers

8.3. Future Research Directions

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smithies, G.; Papi, G.; Mcgillycuddy, E.; Mcgillycuddy, E. The blueprint of digital advancement: A study of construction technology implementation. Proc. Inst. Civ. Eng. Civ. Eng. 2025, 178, 104–117. [Google Scholar] [CrossRef]

- Zhu, H.; Hwang, B.-G.; Ngo, J.; Tan, J.P.S. Applications of Smart Technologies in Construction Project Management. J. Constr. Eng. Manag. 2022, 148, 04022010. [Google Scholar] [CrossRef]

- Radivojević, M.; Šahinagić-Isović, M.; Kozić, M.; Radivojević, D. Real-Time Intelligent Information Systems to Support More Efficient Work of Construction Companies. In Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2021; Volume 233, pp. 539–548. [Google Scholar] [CrossRef]

- Zhao, J.; Olivieri, H.; Seppänen, O.; Peltokorpi, A.; Badihi, B.; Lundström, P. Data analysis on applying real time tracking in production control of construction. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 10–13 December 2017; pp. 573–577. [Google Scholar] [CrossRef]

- Vacanas, Y.; Themistocleous, K.; Agapiou, A.; Hadjimitsis, D. Building Information Modelling (BIM) and Unmanned Aerial Vehicle (UAV) technologies in infrastructure construction project management and delay and disruption analysis. In Proceedings of the Third International Conference on Remote Sensing and Geoinformation of the Environment, Paphos, Cyprus, 16–19 March 2015; Volume 9535, pp. 93–103. [Google Scholar] [CrossRef]

- Radman, K.; Jelodar, M.B.; Lovreglio, R.; Ghazizadeh, E.; Wilkinson, S. Digital technologies and data-driven delay management process for construction projects. Front. Built Environ. 2022, 8, 1029586. [Google Scholar] [CrossRef]

- Pérez, Y.; Ávila, J.; Sánchez, O. Influence of BIM and Lean on mitigating delay factors in building projects. Results Eng. 2024, 22, 102236. [Google Scholar] [CrossRef]

- Zhang, Z.; Wei, Z.; Court, S.; Yang, L.; Wang, S.; Thirunavukarasu, A.; Zhao, Y. A Review of Digital Twin Technologies for Enhanced Sustainability in the Construction Industry. Buildings 2024, 14, 1113. [Google Scholar] [CrossRef]

- Skibniewski, M.J. The Present and Future of Smart Construction Technologies. Engineering 2025, 44, 21–23. [Google Scholar] [CrossRef]

- Wang, G. Innovative Applications and Benefit Analysis of Financial Informationization and Intelligence in the Construction Industry. J. Prog. Eng. Phys. Sci. 2024, 3, 9–17. [Google Scholar] [CrossRef]

- Khodak, V. Analysis of the Development Level of Smart Technologies in Construction Business Management. Odessa Natl. Univ. Herald. Econ. 2024, 29, 102. [Google Scholar] [CrossRef]

- Wang, K. Research on Intelligent Construction Technology Based on Green Concepts. In Proceedings of the 2024 International Conference on Naval Architecture and Ocean Engineering, Beijing, China, 22–24 November 2024; Volume 606, p. 04009. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, H.; Wang, Y.; Yang, Z.; Wang, Q.; Zhang, H. A hybrid building information modeling and collaboration platform for automation system in smart construction. Alex. Eng. J. 2024, 88, 80–90. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing Industry 4.0 on the Construction Site: Challenges and Opportunities. IEEE Trans. Industr. Inform. 2021, 17, 746–756. [Google Scholar] [CrossRef]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Shahin, M.; Chen, F.F.; Bouzary, H.; Krishnaiyer, K. Integration of Lean practices and Industry 4.0 technologies: Smart manufacturing for next-generation enterprises. Int. J. Adv. Manuf. Technol. 2020, 107, 2927–2936. [Google Scholar] [CrossRef]

- Begić, H.; Galić, M. A Systematic Review of Construction 4.0 in the Context of the BIM 4.0 Premise. Buildings 2021, 11, 337. [Google Scholar] [CrossRef]

- Maloney, W.F. Construction Product/Service and Customer Satisfaction. J. Constr. Eng. Manag. 2002, 128, 522–529. [Google Scholar] [CrossRef]

- Wickramanayake, N.D.; Jayalath, J.A.C.D.; Kulatunga, U.; Siriwardhana, S.D. Limitations of traditional building materials for sustainable construction in Sri Lanka. FARU J. 2024, 11, 96–104. [Google Scholar] [CrossRef]

- Jayasinghe, J.D.S.S.; Hadiwattege, C.; Ilangakoon, I.W.M.A.D. Addressing traditional HRM challenges in the construction industry: Insights from modern HRM literature. In Proceedings of the 12th World Construction Symposium, Columbo, Sri Lanka, 9–10 August 2024; pp. 92–104. [Google Scholar] [CrossRef]

- Zhou, H.; Chang, J. Planning and Construction Strategies for Infrastructure in Traditional Villages of the Grand Canal from the Perspective of Villager Needs. Buildings 2024, 14, 3560. [Google Scholar] [CrossRef]

- Okereke, R.A.; Ihekweme, N.M.; Adegboyega, A.A. Impact of Traditional Procurement System on Construction Project Delivery. J. Proj. Manag. Pract. 2022, 2, 23–38. [Google Scholar] [CrossRef]

- Takhtravanchi, M.; Pathirage, C. Knowledge integration challenges and critical success factors within construction traditional procurement system. Knowl. Perform. Manag. 2018, 2, 24–37. [Google Scholar] [CrossRef][Green Version]

- Syed Basheer, S.; Jeeva, R. Avoiding Challenges in the Construction Industry. Int. J. Res. Publ. Rev. 2024, 5, 5587–5597. [Google Scholar] [CrossRef]

- Yang, H.; Shen, J.; Jiang, Y.; Lu, F. Research on the application of smart sites: Research hub of Huzhou Qilitang Project Project for Example. Highlights Sci. Eng. Technol. 2024, 86, 217–226. [Google Scholar] [CrossRef]

- Cameli, S.A. 3D Printing of Cities: Is Urban Planning Ready? Plan. Theory Pract. 2019, 20, 776–784. [Google Scholar] [CrossRef]

- Bettemir, Ö.H.; Sonmez, R. Hybrid Genetic Algorithm with Simulated Annealing for Resource-Constrained Project Scheduling. J. Manag. Eng. 2014, 31, 04014082. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Critical design factors for minimising waste in construction projects: A structural equation modelling approach. Resour. Conserv. Recycl. 2018, 137, 302–313. [Google Scholar] [CrossRef]

- Carvajal-Arango, D.; Bahamón-Jaramillo, S.; Aristizábal-Monsalve, P.; Vásquez-Hernández, A.; Botero, L.F.B. Relationships between lean and sustainable construction: Positive impacts of lean practices over sustainability during construction phase. J. Clean. Prod. 2019, 234, 1322–1337. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Cillari, G.; Ricciardi, P.; Miino, M.C.; Torretta, V.; Rada, E.C.; Abbà, A. The Production of Sustainable Concrete with the Use of Alternative Aggregates: A Review. Sustainability 2020, 12, 7903. [Google Scholar] [CrossRef]

- Guo, B.H.W.; Yiu, T.W.; González, V.A. Predicting safety behavior in the construction industry: Development and test of an integrative model. Saf. Sci. 2016, 84, 1–11. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges. Renew. Sustain. Energy Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef]

- Chuang, S.Y.; Sahoo, N.; Lin, H.W.; Chang, Y.H. Predictive Maintenance with Sensor Data Analytics on a Raspberry Pi-Based Experimental Platform. Sensors 2019, 19, 3884. [Google Scholar] [CrossRef] [PubMed]

- Alagarsamy, S.; Ramdas, R. Unlocking innovation and sustainability: Lessons from Dubai Expo 2020 for business transformation. CASE J. 2024, 21, 673–692. [Google Scholar] [CrossRef]

- Hewavitharana, S.; Perera, S.; Jin, X.; Seneviratne, K.; Bamdad, K. Application of Blockchain in Procurement and Management of Building Services: A Critical and Systematic Review. J. Inf. Technol. Constr. 2024, 29, 635–661. [Google Scholar] [CrossRef]

- Rastogi, S. Construction 4.0: The 4th Generation Revolution. In Proceedings of the Indian Lean Construction Conference, Chennia, India, 28–29 July 2017. [Google Scholar]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A. Identification of coordination factors affecting building projects performance. Alex. Eng. J. 2016, 55, 2689–2698. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Rivera, F.M.-L.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2020, 28, 689–711. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences, Koloa, HI, USA, 5–8 January 2016; Volume 2016, pp. 3928–3937. [Google Scholar] [CrossRef]

- Ahmadisheykhsarmast, S.; Senji, S.G.; Sonmez, R. Decentralized tendering of construction projects using blockchain-based smart contracts and storage systems. Autom. Constr. 2023, 151, 104900. [Google Scholar] [CrossRef]

- Pullagura, L.; Brahma, B.; Kumari, N.V.; Ravikumar, L.; Katta, S.K.G.; Chiwariro, R. Industry 4.0 Design Principles, Technologies, and Applications. In Computational Intelligence in Industry 4.0 and 5.0 Applications Trends, Challenges and Applications; Auerbach Publications: Boca Raton, FL, USA, 2025; pp. 357–388. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors 2020, 20, 3046. [Google Scholar] [CrossRef]

- Karmakar, A.; Delhi, V.S.K. Construction 4.0: What we know and where we are headed? J. Inf. Technol. Constr. 2021, 26, 526–545. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Irfan, M.; Sreenivasan, P.; Rabbani, M.B.A. Health and Safety Improvement through Industrial Revolution 4.0: Malaysian Construction Industry Case. Sustainability 2023, 15, 201. [Google Scholar] [CrossRef]

- Heigermoser, D.; de Soto, B.G.; Abbott, E.L.S.; Chua, D.K.H. BIM-based Last Planner System tool for improving construction project management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Fabiha Fatima, A.; Syed, S.; Muhammad Tariq, B.; Sumayya, O.; Ijaz, A.; Munir Hayet, K.; Muhammad, B. Revolutionizing Construction through Enhanced Project Management and Sustainability with Industry 4.0 Technologies. J. Innov. Technol. 2024, 2024, 1–9. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Shukla, V.; Islam, N.; Manghat, S. Construction Industry 4.0 and Sustainability: An Enabling Framework. IEEE Trans. Eng. Manag. 2024, 71, 1–19. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating major challenges for industry 4.0 adoption among construction companies. Eng. Constr. Archit. Manag. 2022, 29, 1470–1503. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Sendanayake, H.; Nawarathna, A.; Fernando, N. Exploring opportunities and challenges in integrating industry 4.0 for advancements in the Sri Lankan construction sector. In Proceedings of the 12th World Construction Symposium, Columbo, Sri Lanka, 9–10 August 2024; pp. 470–480. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, V.; Verma, P.; Kandasamy, J. Identification and severity assessment of challenges in the adoption of industry 4.0 in Indian construction industry. Asia Pac. Manag. Rev. 2023, 28, 299–315. [Google Scholar] [CrossRef]

- Kim, S.; Chang, S.; Castro-Lacouture, D. Dynamic Modeling for Analyzing Impacts of Skilled Labor Shortage on Construction Project Management. J. Manag. Eng. 2019, 36, 04019035. [Google Scholar] [CrossRef]

- Akinosho, T.D.; Oyedele, L.O.; Bilal, M.; Ajayi, A.O.; Delgado, M.D.; Akinade, O.O.; Ahmed, A.A. Deep learning in the construction industry: A review of present status and future innovations. J. Build. Eng. 2020, 32, 101827. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Safapour, E.; Silwal, A. Workforce-Related Challenges of Construction 4.0 Technologies in the Architectural, Engineering, and Construction Industry. In Computing in Civil Engineering 2023: Visualization, Information Modeling, and Simulation, Proceedings of the ASCE International Conference on Computing in Civil Engineering 2023, Corvallis, OR, USA, 25–28 June 2023; ASCE: Reston, VA, USA; pp. 622–629. [CrossRef]

- Almatari, H.A.Q.; Chan, M.; Masrom, M.A.N. Factors inhibiting the adoption of industrial revolution 4.0 in Malaysian construction industry. Smart Sustain. Built Environ. 2024, 13, 1041–1065. [Google Scholar] [CrossRef]

- Osunsanmi, T.O.; Oke, A.E.; Aigbavboa, C.O. Barriers for the Adoption of Incorporating RFID with Mobile Technology for Improved Safety of Construction Professionals. In The Construction Industry in the Fourth Industrial Revolution; Springer: Cham, Switzerland, 2020; pp. 297–304. [Google Scholar] [CrossRef]

- Singh, A.; Misra, S.C. Identifying Challenges in the Adoption of Industry 4.0 in the Indian Construction Industry. In Advances in Intelligent Systems and Computing; Springer: Singapore, 2021; Volume 1198, pp. 380–398. [Google Scholar] [CrossRef]

- Pham, V.H.S.; Dau, T.D.; Tran, L.A. Exploring the Challenges of the Implementation Technology 4.0 on Enterprises Operating in the Construction Sector in Vietnam. In The International Conference on Sustainable Civil Engineering and Architecture; Springer: Singapore, 2024; Volume 442, pp. 483–497. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Tuhaise, V.V.; Tah, J.H.M.; Abanda, F.H. Technologies for digital twin applications in construction. Autom. Constr. 2023, 152, 104931. [Google Scholar] [CrossRef]

- Klinc, R.; Turk, Ž. Construction 4.0—Digital Transformation of One of the Oldest Industries. Econ. Bus. Rev. 2019, 21, 4. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Rossi, A.; Vila, Y.; Lusiani, F.; Barsotti, L.; Sani, L.; Ceccarelli, P.; Lanzetta, M. Embedded smart sensor device in construction site machinery. Comput. Ind. 2019, 108, 12–20. [Google Scholar] [CrossRef]

- Jain, S.; Sanchez, G.; Taruna, S.; Sharma, D.K. An IoT-Based Framework for Enhanced Construction Material Management and Tracking. Int. J. Recent Innov. Trends Comput. Commun. 2023, 11, 1579–1586. [Google Scholar] [CrossRef]

- Anjum, K.N.; Luz, A.L.A. Investigating the Role of Internet of Things (IoT) Sensors in Enhancing Construction Site Safety and Efficiency. Int. J. Adv. Eng. Manag. 2024, 6, 463–470. [Google Scholar] [CrossRef]

- Kumar, G.S.A.; Roy, A.; Singh, R.; Gehlot, A.; Iqbal, M.I.; Akram, S.V. A Comprehensive Approach to Real-time Site Monitoring and Risk Assessment in Construction Settings using Internet of Things and Artificial Intelligence. Int. J. Electr. Electron. Eng. 2023, 10, 112–126. [Google Scholar] [CrossRef]

- Agarwal, A.; Tanwar, A.; Singh, R.; Garg, V.; Gehlot, A. Arduino- and IoT-Based Tools and Inventory Tracking System in Construction Sites. In Intelligent Communication, Control and Devices; Advances in Intelligent Systems and Computing; Springer: Singapore, 2018; Volume 624, pp. 1677–1686. [Google Scholar] [CrossRef]

- Louis, J.; Dunston, P.S. Integrating IoT into operational workflows for real-time and automated decision-making in repetitive construction operations. Autom. Constr. 2018, 94, 317–327. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. A Concept for Automated Construction Progress Monitoring: Technologies Adoption for Benchmarking Project Performance Control. Arab. J. Sci. Eng. 2019, 44, 4993–5008. [Google Scholar] [CrossRef]

- Patil, D.T.; Bhaumik, A. Efficiency of Internet of Things (IoT)-Enabled Systems in Reducing Construction Cost. In Proceedings of the 3rd IEEE International Conference on Computational Intelligence and Knowledge Economy, ICCIKE 2023, Dubai, United Arab Emirates, 9–10 March 2023; pp. 408–413. [Google Scholar] [CrossRef]

- Chakareski, J. UAV-IoT for Next Generation Virtual Reality. IEEE Trans. Image Process. 2019, 28, 5977–5990. [Google Scholar] [CrossRef]

- Idries, A.; Mohamed, N.; Jawhar, I.; Mohamed, F.; Al-Jaroodi, J. Challenges of developing UAV applications: A project management view. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; pp. 1–10. [Google Scholar] [CrossRef]

- Khoury, H.; Salhab, D.; Antar, S. A review on internet of things solutions for enhancing construction equipment fleet productivity. In Proceedings of the Creative Construction Conference 2018, Ljubljana, Slovenia, 30 June–3 July 2018; pp. 971–978. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J. Times-series data augmentation and deep learning for construction equipment activity recognition. Adv. Eng. Inform. 2019, 42, 100944. [Google Scholar] [CrossRef]

- Alzubi, K.M.; Alaloul, W.S.; Al Salaheen, M.; Qureshi, A.H.; Musarat, M.A.; Alawag, A.M. Reviewing the Applications of Internet of Things in Construction Projects. In Proceedings of the 2022 International Conference on Decision Aid Sciences and Applications, DASA 2022, Chiangrai, Thailand, 23–25 March 2022; pp. 169–173. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Santos, R.S.D.; Assayag, E.S. Internet of Things (IoT) Applied in Construction Industry: A Systematic Review. Int. J. Eng. Technol. Manag. Res. 2022, 9, 23–29. [Google Scholar] [CrossRef]

- da Costa, C.A.; Pasluosta, C.F.; Eskofier, B.; da Silva, D.B.; da Rosa Righi, R. Internet of Health Things: Toward intelligent vital signs monitoring in hospital wards. Artif. Intell. Med. 2018, 89, 61–69. [Google Scholar] [CrossRef]

- Yang, X.; Yu, Y.; Shirowzhan, S.; Sepasgozer, S.; Li, H. Automated PPE-Tool pair check system for construction safety using smart IoT. J. Build. Eng. 2020, 32, 101721. [Google Scholar] [CrossRef]

- Nyamuchiwa, K.; Lei, Z.; Aranas, C. Cybersecurity Vulnerabilities in Off-Site Construction. Appl. Sci. 2022, 12, 5037. [Google Scholar] [CrossRef]

- Parn, E.A.; Edwards, D. Cyber threats confronting the digital built environment: Common data environment vulnerabilities and block chain deterrence. Eng. Constr. Archit. Manag. 2019, 26, 245–266. [Google Scholar] [CrossRef]

- Turk, Ž.; de Soto, B.G.; Mantha, B.R.K.; Maciel, A.; Georgescu, A. A systemic framework for addressing cybersecurity in construction. Autom. Constr. 2022, 133, 103988. [Google Scholar] [CrossRef]

- Jamlus, N.D.F.; Haron, R.C. The Challenges of the Internet of Things (IoT) in the Context of Construction Cost Management. J. Archit. Plan. Constr. Manag. 2024, 14, 20–36. [Google Scholar] [CrossRef]

- Samonte, M.J.C.; Algabre, M.M.; Angeles, C.J.H.; Rosa, A.J.D.D. Securing IoT Ecosystems: Integration Challenges and Architectural Solutions. In Proceedings of the 2024 IEEE 7th International Conference on Computer and Communication Engineering Technology (CCET), Beijing, China, 16–18 August 2024; pp. 170–174. [Google Scholar] [CrossRef]

- Thandekkattu, S.G.; Ayem, G.T.; Rakshit, S.; Thandekkattu, S.G.; Ayem, G.T.; Rakshit, S. Data Management and Analytics in the Internet of Things (IoT). In Designing Sustainable Internet of Things Solutions for Smart Industries; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 209–228. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and trends in Internet of Things (IoT) research: Future applications in the construction industry. Eng. Constr. Archit. Manag. 2021, 28, 457–481. [Google Scholar] [CrossRef]

- Kanan, R.; Elhassan, O.; Bensalem, R. An IoT-based autonomous system for workers’ safety in construction sites with real-time alarming, monitoring, and positioning strategies. Autom. Constr. 2018, 88, 73–86. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Puzatova, A.; Shakor, P.; Laghi, V.; Dmitrieva, M. Large-Scale 3D Printing for Construction Application by Means of Robotic Arm and Gantry 3D Printer: A Review. Buildings 2022, 12, 2023. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Freire, T.; Brun, F.; Mateus, A.; Gaspar, F. 3D Printing Technology in the Construction Industry. In Sustainability and Automation in Smart Constructions, Proceedings of the International Conference on Automation Innovation in Construction (CIAC-2019), Leiria, Portugal, 7–8 November 2019; Advances in Science, Technology & Innovation; Springer: Cham, Switzerland, 2021; pp. 157–167. [Google Scholar] [CrossRef]

- Tafazzoli, M.; Naeijian, F.; Naqvi, S.F.N.; Tafazzoli, M.; Naeijian, F.; Naqvi, S.F.N. 3D Printing in Highway Construction, Opportunities and Challenges. In Recent Topics in Highway Engineering—Up-to-Date Overview of Practical Knowledge; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Varghese, F.; Jayan, R. 3D printing building technology—The game changing future technology. In Proceedings of the 2024 2nd International Conference on Green Building, Milan, Italy, 22–24 May 2024; Volume 546, p. 02005. [Google Scholar] [CrossRef]

- Yin, J.; Suo, Y.; Lv, T.; Ma, K.; Wang, X.; Zhang, Z. Application of 3D Printing Technology in the Construction Industry and Its Development Prospects. In Proceedings of the 2021 International Conference on Smart Technologies and Systems for Internet of Things (STS-IOT 2021), Shanghai, China, 26–27 November 2021; Volume 2. [Google Scholar] [CrossRef]

- Ghosh, B.; Karmakar, S. 3D Printing Technology and Future of Construction: A Review. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Jaipur, India, 11–12 August 2023; Volume 1326, p. 012001. [Google Scholar] [CrossRef]

- Braichenko, S.; Kharit, O.; Shevchuk, M.; Husar, K.; Kyzymyshyn, L. Technological Aspects of using 3D Printing Software in Construction. WSEAS Trans. Syst. 2024, 23, 249–261. [Google Scholar] [CrossRef]

- Domingues, T.; Cachaço, A.; Sousa, P.J.; Carneiro, F.; Silva, J.; Eslami, S.; Moreira, P.M. Development of a custom setup for additive manufacturing of high-performance thermoplastics. Procedia Struct. Integr. 2022, 37, 847–856. [Google Scholar] [CrossRef]

- Shahzad, Q.; Umair, M.; Waqar, S. Bibliographic analysis on 3D printing in the building and construction industry: Printing systems, material properties, challenges, and future trends. J. Sustain. Constr. Mater. Technol. 2022, 7, 198–220. [Google Scholar] [CrossRef]

- Abdul, M.; Malallah, K. Challenges, New Approaches, and Potential Future Paths for Three-Dimensional Printing (3DP) in Building Project: A Reviews. Al-Rafidain J. Eng. Sci. 2025, 3, 113–128. [Google Scholar] [CrossRef]

- Tabassum, T.; Mir, A.A. A review of 3d printing technology-the future of sustainable construction. Mater. Today Proc. 2023, 93, 408–414. [Google Scholar] [CrossRef]

| Technology/Theme | (%) of Studies | Key Benefits | Main Challenges |

|---|---|---|---|

| Robotics and Automation (Industry 4.0) | 13 | Performs repetitive/high-risk tasks; improves safety and productivity | High cost of adoption, workforce adaptation, and technical limits |

| AI and Machine Learning (Industry 4.0) | 17.5 | Predictive analytics, risk management, automated decision support | Data availability, skilled workforce shortage, and model generalization |

| Blockchain (Industry 4.0) | 8.75 | Transparency in supply chains, smart contracts, and trust in data | Lack of regulation, interoperability issues, and adoption reluctance |

| BIM (Digitalization) | 22.75 | Collaboration, cost/time accuracy, and digital project management | Interoperability, training requirements, and resistance to adoption |

| IoT (Digitalization) | 26 | Real-time monitoring, predictive maintenance, safety tracking | Cybersecurity risks, data overload, privacy issues, and integration challenges |

| 3D Printing (Additive Technologies) | 13 | Sustainability, reduced waste, faster project delivery, and innovative designs | High equipment cost, regulatory gaps, lack of skilled operators |

| Technology | Primary Impact Areas | Impact Level | Cost Profile | Adoption Level | Maturity/Readiness | Typical Time to Value | Common Barriers | % of 115 |

|---|---|---|---|---|---|---|---|---|

| IoT (Digitalization) | Real-time monitoring, safety, asset tracking, predictive maintenance, and site logistics | High | Moderate CAPEX (sensors, gateways); OPEX for connectivity/cloud | High (widely piloted and scaled on sites) | High (proven building blocks; integration still needed) | Short (weeks, months once instrumentation is deployed) | Cybersecurity, privacy, data overload, and change management | 26 |

| BIM (Digitalization) | Design coordination; planning; cost and schedule control; collaboration | High | Moderate High CAPEX (licenses); training/time investment; integration services | High (standard practice in many regions/projects) | High (mature platforms and workflows) | Short Medium (benefits realized after model setup and team onboarding) | Interoperability across tools; skill gaps; resistance to process change | 22.75 |

| 3D Printing (Additive) | Rapid prototyping; on-site/off-site printed elements; efficiency; waste reduction | Moderate High | High CAPEX (printers, materials); specialized expertise; certification/QA costs | Low Moderate (limited large-scale deployments) | Medium (emerging standards; maturing hardware/processes) | Medium Long (pilot-to-scale transition needed; permitting/codes) | Codes/standards immaturity; high upfront cost; operator skills; supply chain | 13 |

| Reference | Topic Focus | Research Method | Key Findings | Challenges/Limitations | Region | Research Gap |

|---|---|---|---|---|---|---|

| [44] | Industry 4.0 | Triangulation (Literature Review + Industry Analysis) | Outlined implications of digitalization in construction; proposed framework for Construction 4.0. | Fragmentation, resistance to change, and lack of standards. | Global | Need for detailed practical implementation strategies for Construction 4.0. |

| [65] | Use of deep learning in construction | Review | Deep learning enhances automation and decision-making in construction. | Data scarcity and model generalization issues. | Global | Real-world implementation |

| [66] | Artificial intelligence in construction | review | Highlights growing potential of AI in automating tasks and enhancing efficiency | Data availability and lack of a skilled workforce | Global | Real-world implementation |

| [37] | IoT-BIM integration in prefabrication | System development and case study | IoT-BIM improves coordination and efficiency in on-site assembly | Technical complexity and data management | China | Scalable real-world validation |

| [81] | IoT in workflow automation | System architecture and case study | IoT enables real-time automation in repetitive construction tasks | Integration into existing workflows | USA | Broader application scenarios |

| [92] | IoT-based safety verification system | System prototype and testing | Smart IoT can automate PPE tool matching to improve safety | Limited testing environments | China | Broader field deployment |

| [102] | 3D printing with concrete extrusion | Literature-based roadmap | Identifies technical, material, and process priorities for 3DCP | Material consistency, process control | UK/Europe | Standardization and testing |

| [105] | 3D printing in the construction industry | Critical literature review | Highlights benefits, barriers, and future potential of 3D printing | Material limitations, lack of standards | Global/China | Real-world implementation case |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eid, A.E.; Hayder, G.; Alhussian, H. Applications of Intelligent Models in Processes in the Construction Industry: Systematic Literature Review. Processes 2025, 13, 2866. https://doi.org/10.3390/pr13092866

Eid AE, Hayder G, Alhussian H. Applications of Intelligent Models in Processes in the Construction Industry: Systematic Literature Review. Processes. 2025; 13(9):2866. https://doi.org/10.3390/pr13092866

Chicago/Turabian StyleEid, Abdallah Elsayed, Gasim Hayder, and Hitham Alhussian. 2025. "Applications of Intelligent Models in Processes in the Construction Industry: Systematic Literature Review" Processes 13, no. 9: 2866. https://doi.org/10.3390/pr13092866

APA StyleEid, A. E., Hayder, G., & Alhussian, H. (2025). Applications of Intelligent Models in Processes in the Construction Industry: Systematic Literature Review. Processes, 13(9), 2866. https://doi.org/10.3390/pr13092866