1. Introduction

Launch vehicles and spacecraft using liquid propellants are crucial for the success of space missions. The core component of these vehicles is the liquid-propellant rocket engine (LRE), which plays a vital role in ensuring efficient propulsion and maneuverability in space. LREs with the capacity of deep thrust modulation or deep throttling have the potential to significantly enhance the performance of launch vehicles, such as efficiently improving the payload capacity, the orbit-entering accuracy, and the orbital-transfer flexibility [

1]. Deep throttling is also a crucial technology for enabling speed control, hovering and soft landing of spacecraft, capabilities that are essential for the recycle of reusable spacecraft, space rendezvous and planet exploration [

2,

3].

Throttleable LREs were originally developed in Germany in the late 1930s [

4]. Subsequently, throttling technology has continued to evolve and has been successfully applied to many high-thrust engines across various space programs. Notably, it has been employed in the Space Shuttle Main Engine, which played a crucial role in NASA’s Space Shuttle Program. Additionally, the YF-100 engine used on the Long March 5 rocket and the Merlin-1D engine employed by SpaceX’s Falcon 9 rocket have both benefited from the throttling technology [

5,

6,

7,

8]. The approaches to achieve regulating thrust could be mainly divided into two categories: changing the turbine power and pump head via various regulation devices in the feed system or adjusting the pressure drop across the injectors in the thrust [

9]. Dressler [

10] summarized nine throttling techniques for LREs in detail and introduced the implementation of deep-throttling methods, including a movable-element injector, a coaxial pintle injector and a cavitating Venturi flow control valve, on the Apollo Lunar Module Descent Engine. Casiano et al. [

11] discussed and compared eight approaches to throttling, including high-pressure-drop systems, dual-injector manifolds, gas injection, multiple chambers, pulse modulation, throat throttling, movable injector components, and hydro-dynamically dissipative injectors. In addition, researchers have continued to promote the development of variable thrust technology and optimization design research. Fukushima et al. [

12] reported on the development status of the LE-5B LOX/LH

2 engine, which was designed with a thrust range of 60% to 100%. Greene et al. [

13] designed a LOX/GH

2 swirl injector that used a dual LOX manifold for a 10:1 throttling range. The performance of the injector under steady-state and transient conditions was tested and analyzed. Alliot et al. [

14] illustrated the progress of the VINCI upper stage cryogenic engine, which could modulate thrust between 72% and 100% of the rated level by arranging two bypass valves on the pipeline to regulate the turbine flow. Gromski et al. [

15] conducted pintle injector testing on the TR202 engine (a LOX/LH

2 expander cycle engine) and achieved 10:1 throttle capability, which could support the deep-throttling cryogenic pintle technology. Nardi and Pimenta [

16] and Kazuki and Shinji [

17] also experimentally studied the atomization characteristics, combustion behaviors and optimal design of key parameters of the pintle injector. Melcher et al. [

18] analyzed the test data of the Project Morpheus LOX/LCH

4 main engine, which is a pressure-fed cryogenic engine using an impinging element injector design with 4:1 throttling. Combustion instabilities might be triggered at low chamber pressure during the start sequence, which could be mitigated via a higher-chamber pressure start sequence. Cui et al. [

19] proposed a system scheme of the LOX/LCH4 cryogenic variable thrust liquid rocket engine that uses a motor pump and developed the computation models of all subassemblies to obtain the state and structural parameter distributions.

However, a large-range variable thrust capability would significantly impact the throttling behavior and the operation of the rocket engines. Especially at low-thrust condition, mainly because of the low chamber pressure and insufficient injector pressure drop to sustain good atomization and mixing of the propellants, instabilities such as whistling, howling, rough burning and chugging might occur [

20]. Gas injection is regarded as one of the applicable methods to maintain a high injector pressure drop over a wide throttling range.

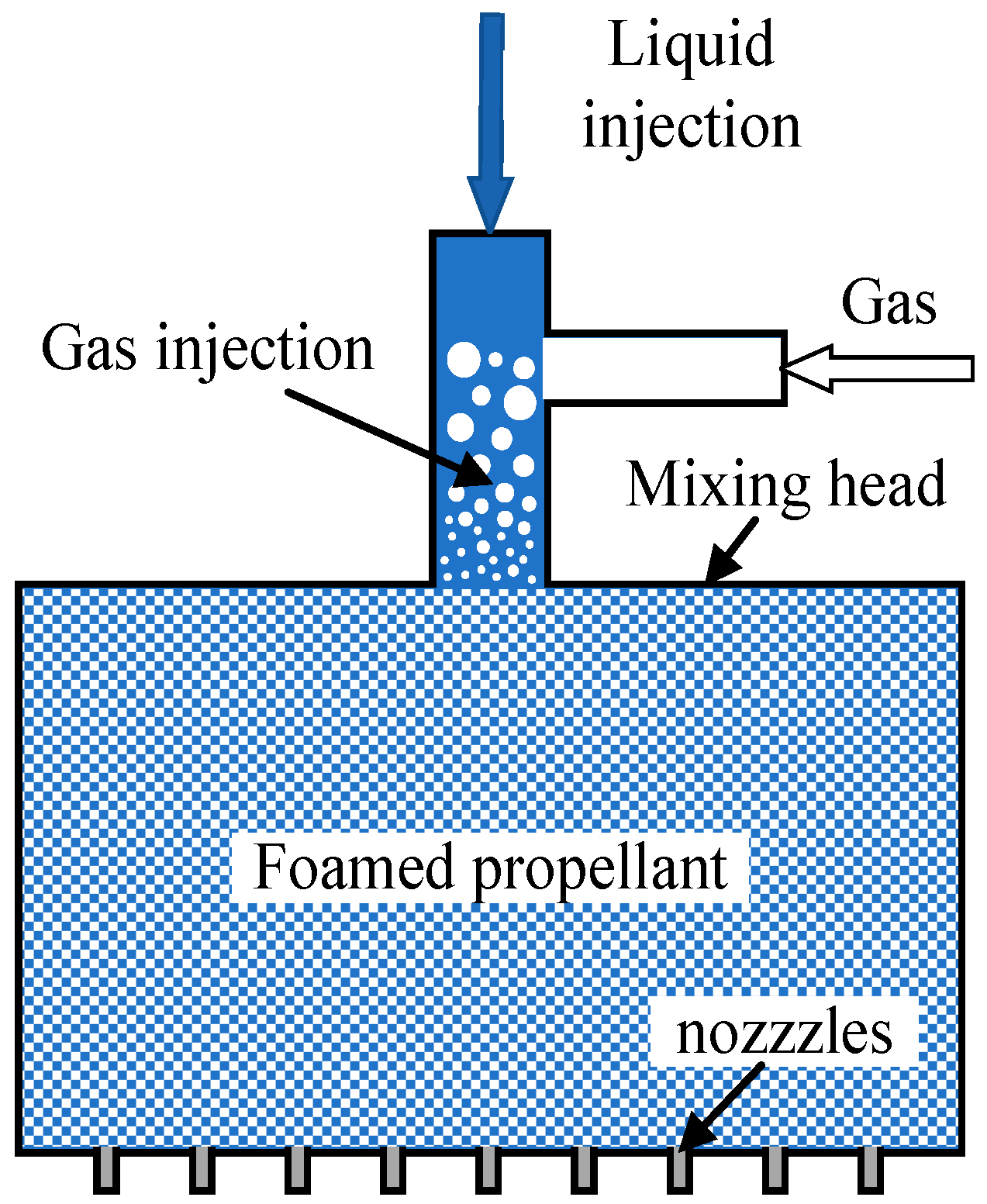

Figure 1 illustrates the gas injection process: before reaching the mixing head of the injector, a small amount of inert, insoluble gas is injected into the main flow of the liquid propellant, foaming the propellant and reducing the bulk density of the propellant. Without affecting the mass flow rate of the liquid propellant, the injector pressure drop could be increased as the effective density of the bulk propellant decreases, thereby enhancing the chug stability margin, thrust range and performance of fixed-geometry injectors at low engine flow rates [

11]. In theory, continuous density variation of the injected gas–liquid mixture could be achieved by injecting matched gas; therefore, continuously varying the rocket thrust is feasible [

21].

Gunter and Fahrenholz [

22] theoretically and experimentally investigated the effect of secondary gas injection into the nozzle throat on thrust modulation and vector control. Tests on a modified RL10A-1 showed that chugging over the entire 10-to-1 throttling range could be eliminated by injecting gaseous oxygen or helium into the liquid oxygen propellant line at the manifold inlet flange [

23]. A thrust modulation range of 35 to 1 with a small amount of gaseous nitrogen injection has been demonstrated for a bipropellant attitude control system without combustion instability, indicating a good efficiency of this method over a wide throttling range, without requiring complicated mechanical devices [

24]. In addition, this throttling technique has also been successfully verified on the Rocketdyne SE-10 engine with a 10:1 deep-throttling capacity by using helium gas injection under low-thrust conditions [

25]. Tan et al. [

26] have proposed a combined depth thrust regulation scheme for a 1200 kN LOX/kerosene rocket engine, which combined gas generator fuel flow regulator adjustment, main turbine inlet gas diversion, oxidizer main path throttling and gas injection to improve the pressure drop of the injector. A thrust regulation ratio of 10:1 was demonstrated by simulation. However, these studies merely demonstrated the effectiveness of the gas injection process in maintaining stability under low-thrust conditions, without providing more detailed data or conducting an in-depth analysis of its characteristics.

In summary, although the gas injection technique has been proposed for over 50 years in LREs for deep throttling, fundamental studies focusing on this method remain rather limited. In this paper, the head cavity of a certain type gas generator of kerosene was selected as the study object. An open-cycle experimental apparatus was designed and built to investigate the effect of gas injection on the pressure drop characteristics of the gas generator under conditions far below its rated working state. Factors including the flow rate, gas type and liquid type were tested and compared. The foamed gas–liquid mixture and its atomization under different gas injection conditions were also visually observed. This work could provide fundamental data for understanding the principles and characteristics of gas injection and promote its mature application in the development of deep-throttling technology.

2. Experiment Setups

In order to make clear the effect of gas injection on the pressure drop characteristics of the head cavity of the gas generator, an experimental apparatus, as shown in

Figure 2, has been specially designed and built. The system setup is shown in

Figure 3, which mainly consists of a gas flow path, a liquid flow path, a gas–liquid two-phase mixing section, a tested head cavity and a measurement section.

The gas was supplied by the high-pressure gas cylinders. Its flow rate was controlled by the pressure-reducing valve and the control valve. A piston pump (RTX 100–120 N, 0~100 L/min, manufactured by Tuochuang, Nantong, China) was used to supply the liquid from the supplying container. The flow rate of the liquid could be changed by controlling the working frequency (0~1450 rpm) of the piston pump. Both the gas and liquid pipelines were fitted with a check valve to prevent backflow between them.

The core part of the test object, including the structure and dimensions of the mixing chamber, the bent pipe and the head cavity were designed based on to the real structure of the gas generator of a certain type of liquid oxygen/kerosene engine in China. As detailed in

Figure 3 on the right, within the mixing chamber, the gas is injected into the liquid flow in a vertical direction. The internal plug structure could intensify the mixture of the gas and liquid phases. The mixed state of the gas–liquid flow could be observed through the visual segment, which was made of high borosilicate glass, with an inner diameter of 20 mm, a height of 80 mm and a thickness of 15 mm. The head cavity was formed by the void between the upper and bottom plates, which were connected by bolts. A total of 61 nozzles were installed on the bottom plate using threaded connection. Except for one nozzle, which was arranged in the center, 60 nozzles were arranged in 4 staggered circular rows along the radius, with 6, 12, 18 and 24 nozzles in each row, respectively. The nozzles were of the centrifugal type, with two 1.5 mm tangential throats, which were designed and manufactured with certain structural simplifications compared to the actual nozzle structure in the real system.

To measure the parameters of the liquid and gas flow, at the inlet side of the mixture chamber, a temperature sensor, a pressure transmitter and a flowmeter were arranged on the liquid pipeline and the gas pipeline, respectively. At the outlet side of the mixture chamber, the temperature and the pressure of the mixing two-phase flow were also measured. Meanwhile, three press-leading tubes were arranged along the radius direction of the head cavity to obtain the pressure distribution within the head cavity. PT100 (−100~200 °C, ±0.2 °C) was used for temperature measurement. Pressure was measured using a Senex-DG1300 pressure transmitter, with a measuring range of 0–1.5 MPa and a measuring accuracy of 0.5% F.S. As for the measurement of flow rate, a turbine flowmeter with the range of 0–10 m

3/h and the accuracy degree of 0.5% F.S. was used for liquid side, while a thermal mass flowmeter (YK-TMF-F-20F6E02D12L, 13~125 kg/h, 0.5% F.S.) was used for the gas side. A Keithley 7700 data acquisition device was employed for data logging. In addition, the flow state within the visual pipe and the outlet of the nozzles was observed using a high-definition camera with a resolution ratio of 2560 × 1440 and a frame rate of 120 fps. The installed positions of each sensor are roughly marked in

Figure 3, and the detailed annotations are listed in

Table 1.

It should be noted that, in order to observe the fluid state at the nozzle outlet, an open-loop circulation system was adopted. On the other hand, due to the safety strength limit of the glass visualization section, the test pressure did not exceed 1 MPa, which is significantly lower than the working pressure in the actual rocket engine. In other words, this experiment was conducted under more severe low-thrust conditions.

Considering the volatility and ignitability of kerosene, white oil and water were used as the substitute working liquids. Meanwhile, in view of the alternative gas that might be used in the actual operation of the engines, gaseous helium (GHe) and gaseous nitrogen (GN

2) were chosen as the blowing gases. The main thermophysical parameters (under room conditions) of the kerosene and the four working media are listed in

Table 2. In comparison, the properties of white oil are more similar to those of kerosene, and the results of white oil could be qualitatively used to evaluate the pressure drop and emulsification characteristics of kerosene in the gas injection process. The parameters under other working conditions could be obtained from REFPROP [

27].

3. Results and Discussion

Tests with single-phase liquid flow were conducted as the benchmark, and the pressure drop performance of the target head cavity, as well as the phase state of the flowing fluid under different gas injection conditions, was investigated and compared.

3.1. Singe-Phase-Liquid Condition

Figure 4a displays the pressure data measured by each pressure measurement point at different volume flow rates when only single-phase liquid white oil flowed through the system. It can be observed that, due to pressure loss caused by the flow of viscous fluid, the pressure at each location in the system decreases along the flow direction. Specifically, the pressures in the upstream liquid pipe (

Pl) and gas pipe (

Pg) are consistently higher than the pressure after the mixing chamber (

Pm), and the pressure within the injector head cavity (

Ph) remains the lowest. Furthermore, as the flow rate varies, the pressures at different positions within the head cavity (

Ph-ir,

Ph-mr and

Ph-or) are nearly identical, indicating a negligible pressure gradient within this region. In other words, the pressure drop through the internal flow passages of the head cavity is significantly smaller compared to that across the nozzles, suggesting that the head cavity can be considered a region of uniform pressure under single-phase liquid flow conditions.

From

Figure 4a, it is evident that the pressure at each position consistently increases according to a power function as the flow rate increases. According to the fundamental principles of fluid mechanics, the local flow resistance of single-phase fluid should adhere to the following relationship [

28]:

where Δ

p is the pressure drop,

K is the pressure loss coefficient, which is determined by the shape and size of the flow structure and is also influenced by the flow,

ρ is the fluid density,

V is the velocity,

A is the cross-sectional area of the flow path,

Q is the volume flow rate. To further validate this correlation, three representative positions are chosen in

Figure 4b to illustrate the variation of local pressure with the square of flow rate. It can be seen that each pressure exhibits a clear linear relationship with the square of the flow rate, which aligns precisely with the relationship described by Equation (1). Meanwhile, the strong linearity demonstrated in

Figure 4b, where the coefficient of determination (R

2) consistently exceeds 0.995, provides further evidence of the accuracy and stability of the experimental measurement.

The same single-phase liquid flow tests were also conducted using water as the working fluid. As shown in

Figure 5, pressure data from the liquid pipe

Pl, the mixture chamber

Pm and the middle ring within the head cavity

Ph-mr are selected as representatives to illustrate the pressure variation at the same locations for the water and white oil conditions, respectively. The results show that the pressure change trend of the water flow closely resembles that of white oil, indicating a theoretical adherence to Equation (1) again. The key difference is that, at the same position under the same flow rate, the pressure of water is consistently higher than that of the white oil flow condition. This is attributed to the higher density of water, which corresponds to a greater pressure loss, as described by Equation (1).

3.2. Liquid with Gas Injection

Tests with GHe gas injection were initially carried out based on the case where the volume flow rate of white oil was 6.9 L/min.

Figure 6 presents the pressure changes at typical positions when injecting different amounts of gas into the white oil. It can be seen that, when the flow rate is small, the pressure drop of the single-phase liquid flow is slight, while the pressure level at each typical position increases significantly after the gas injection. Moreover, as the mass of gas injection increases, so does the pressure at each position, clearly demonstrating the effectiveness of pressurization through gas injection.

The total pressure drop in the measurement section of this experimental system can be mainly decomposed into three components: the pressure drop across the mixing chamber (approximated as

Pl-

Pm), the inlet region of the head cavity (approximated as

Ph-mr-

Pm) and the nozzles (approximated as

Ph-mr-

Pa). From

Figure 4a, it can be seen that the largest pressure drop always occurs across the nozzles for the single-phase liquid flow conditions because nozzles are the key resistance component for fuel atomization. After gas injection, the pressure drop across all three components increases, particularly in the head cavity and nozzles, indicating a notably higher pressure drop for the two-phase fluid compared to the single-phase fluid. This phenomenon is primarily attributed to the increased volumetric flow rate of the gas–liquid mixed fluid caused by gas injection, leading to a corresponding rise in the pressure drop of the two-phase fluid. Furthermore, with gas injection, the pressures at all three measurement points in the head cavity remain very closely aligned, indicating a uniform and stable distribution of the mixed fluid within the mixing chamber. In view of the slight difference of the pressure distribution within the head cavity, the pressure at the middle ring

Ph-mr is selected as the representative of the head cavity pressure for the following discussion. After injecting 1.06 g/s and 5.5 g/s of GHe, the head cavity pressure increases to 1.34 times and 3.3 times that under the no-gas-injection condition, respectively.

Figure 7 exhibits the phase characteristics at the inlet of the head cavity and the outlet of the nozzles corresponding to the variable gas injection conditions, as shown in

Figure 6. It can be seen that, for the single-phase liquid phase flow condition (

Qm_g,He = 0 g/s), full flow of the liquid could be achieved at the inlet of the head cavity when the flow rate is very low, at 6.9 L/min, and the flow of single-phase white oil appears transparent and colorless. At the nozzle outlets, the liquid outflow appears as several liquid columns, lacking any atomization effect. This indicates that, similar to the low-thrust condition in LRE operation, when the flow rate of fuel is excessively low, the flow parameters may no longer meet the performance requirements of nozzles. A significant deviation from the nozzle’s design conditions can degrade the fuel atomization effect, which directly impacts combustion performance and, consequently, engine operation under low-thrust conditions. After injecting a small amount of gas (see diagrams for condition

Qm_g,He = 1.06 g/s), a mixture flow of gas and liquid could be observed at the inlet section of the head cavity, albeit with relatively low uniformity. Additionally, some improvement in atomization effect at the nozzle outlets was noticeable, although intermittent, non-atomized liquid columns persisted. As the amount of injected gas increases, the degree of gas–liquid mixing and the atomization effect both continuously increase. As shown by the diagrams for the condition of

Qm_g,He = 5.50 g/s, a relatively uniform gas–liquid mixture resembling a milky white fluid could be observed at the head cavity inlet. Other visual investigations have found the similar results: video footage of the manifold showed that the bubbles were too fine to see and appeared as a fog; therefore, some researchers also referred to this process as emulsification [

22]. Meanwhile, at the nozzle outlets, the fluid is observed to be dispersed into small droplets, indicating good atomization of white oil. In combination with the results shown in

Figure 6, it can be found that an increasing amount of gas injection leads to a continuous rise in head cavity pressure, while also gradually optimizing the degree of emulsification and atomization. Therefore, it can be inferred that for a specific gas generator, the head cavity pressure (

Ph-mr) or the nozzle pressure drop (

Ph-mr-

Pa) is directly correlated with the nozzle’s atomization effect and could thus serve as an indicator of the nozzle’s atomization performance.

3.3. Effects of Flow Rate

After determining the pressurization effect of gas injection, a further analysis was conducted to compare the impact of gas injection under varying liquid flow rates, as depicted in

Figure 8. It shows that, as the flow rate of liquid increases, the pressure at each typical position under gas injection condition significantly surpasses that under the single-phase liquid condition. Furthermore, the pressure rise induced by the same amount of gas injection also increases with a higher liquid flow rate. For example, at liquid flow rates of 6.9 L/min, 20.7 L/min, 34.5 L/min and 48.3 L/min, the pressure within the head cavity under the gas injection condition (

Qm_g,He = 2.46–2.49 g/s) increases by 3.25 kPa, 8.67 kPa, 16.16 kPa and 25.69 kPa over that under single-phase liquid condition, respectively.

The phase distribution at the inlet section of the head cavity under corresponding working conditions is provided in

Figure 9. It can be observed that, as the liquid flow rate increases, the mixing degree of the gas–liquid two-phase flow improves continuously. This indicates that an increased liquid flow rate could also enhance the uniformity of the gas–liquid mixture, thereby improving the emulsification effect. Hence, it can be inferred that both the flow rates of gas and liquid influence the mixing degree of the gas–liquid two-phase flow. A higher flow rate of either liquid or gas would result in a stronger disturbance on the mixed fluid, leading to a better mixing uniformity of the two-phase flow.

Figure 9 also illustrates the comparison of phase distribution at the nozzle outlets under varying liquid flow rates, with and without gas injection. In the case of single-phase liquid flow, increasing the liquid flow rate leads to a progressive transition in phase distribution: from long liquid columns to shorter, discontinuous liquid columns; then to short liquid columns accompanied by large droplets; and eventually to small, discontinuous droplets. This demonstrates an improved atomization effect of the nozzles with increasing liquid flow rate. However, it should be noted that due to the open experimental system utilized in this study, the pressure of the head cavity and the flow rate of the working medium are significantly lower than those found in actual operating conditions of LREs. Therefore, even at a liquid flow rate of 48.3 L/min, the atomization effect remains weak since this flow condition is still far below the rated working condition of the nozzles.

After injecting 2.46~2.49 g/s of GHe, the atomization effect at the nozzle outlets is significantly improved. At a liquid flow rate of 6.9 L/min, nearly all the fluid at the nozzle outlet transitions from liquid columns to small droplets. As the liquid flow rate increases, unstable emulsified fluid parcels gradually appear at the nozzle outlets, dispersed into smaller droplets. The formation of fluid parcels can be explained by the fact that, when the amount of gas injection remains constant, the disturbance caused by the injected gas is relatively greater at lower liquid flow rates compared to higher ones. In other words, the gas–liquid mixture at a lower liquid flow rate, which is of a smaller mixing density, is more susceptible to atomization by the same amount of gas injection. At higher liquid flow rates, although the increased head cavity pressure enhances nozzle atomization and produces smaller droplets, the relative effect of the same gas injection on the mixture is diminished. This reduction is due to the lower gas volume fraction in the emulsion, causing the flow to behave more like a single-phase liquid through the nozzles. Consequently, unstable columns or parcels similar to those observed under single-phase liquid conditions are formed.

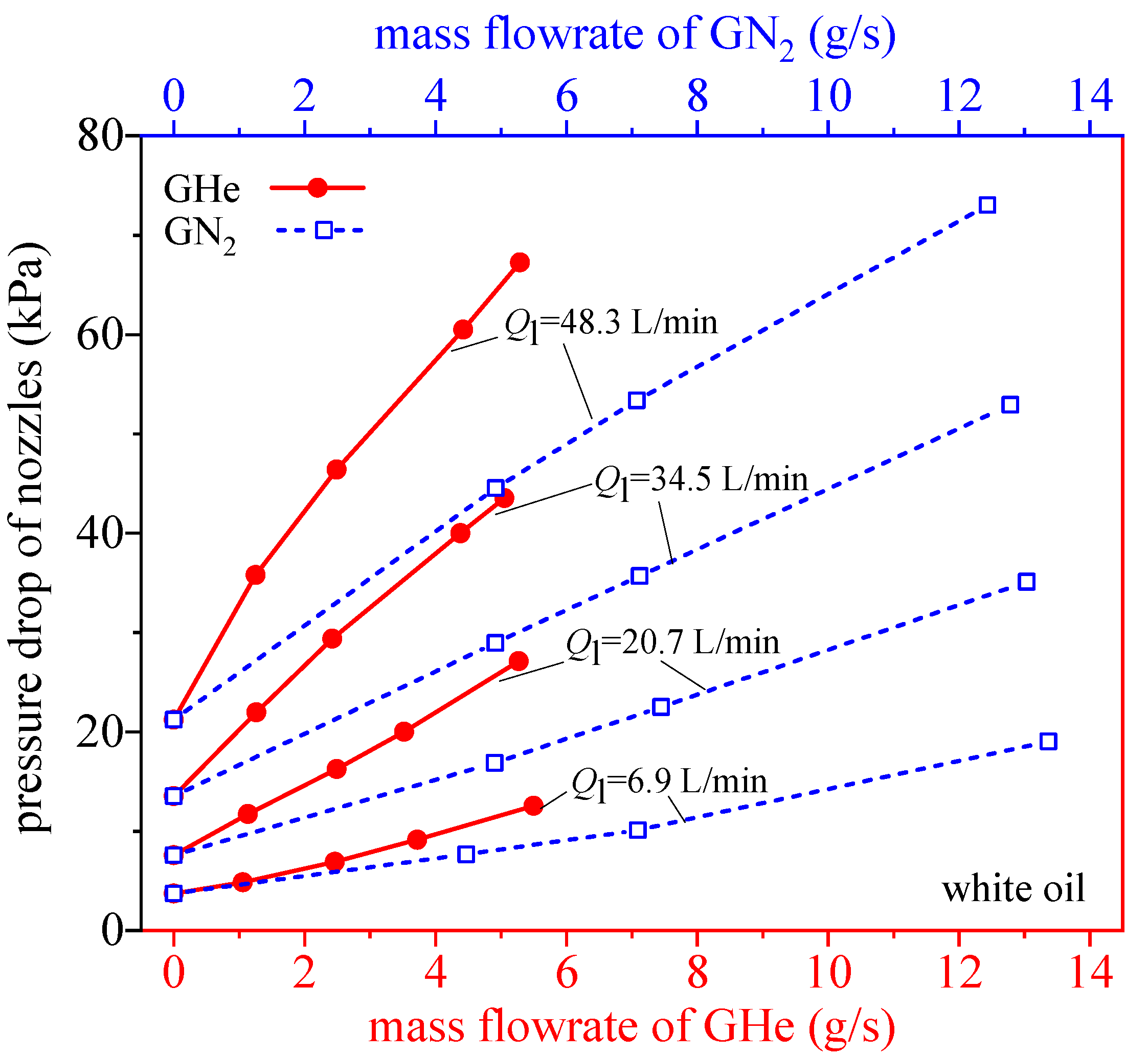

Improving the nozzle atomization effect is the goal of gas injection technology. Based on the above analysis, under the same liquid flow rate, the pressure of the head cavity or the pressure drop of nozzles is positively correlated with the atomization effect. Therefore, the nozzle pressure drop is used as an indicator parameter, and the variation trend of the nozzle pressure drop under different flow rates of liquid and gas is displayed in

Figure 10. It can be seen that, consistent with the previous findings discussed, an increase in liquid and gas flow will result in a higher nozzle pressure drop. In addition, for any given liquid flow condition, there is a relatively clear linear relationship between the nozzle pressure drop and the gas injection rate. The right coordinate of

Figure 10 demonstrates the multiple relation between the nozzle pressure drop under different working conditions and that under the single-phase liquid condition. It can be noted that, as the amount of gas injection increases, the ratio of the nozzle pressure drop with gas injection to that without gas injection also increases linearly. Furthermore, an intriguing discovery is that, despite different liquid flow rates, the pressurization effect caused by a certain amount of gas injection results in nearly constant multiplicative increases in nozzle pressure drop. For instance, across liquid flow rates ranging from 6.9 L/min to 48.3 L/min, injecting approximately 1 g/s GHe consistently causes the nozzle pressure drop to increase by a factor of about 1.5, while injecting approximately 5.5 g/s GHe would consistently result in a pressure drop increase by a factor of about 3.3. Henceforth, if a greater pressurization or atomization effect is desired, a higher gas injection rate would be necessary.

3.4. Effects of Gas Type

Considering the potential use of nitrogen as a gas source in the operational processes of launch vehicles and LREs, a comparative test was also conducted using GN

2 as an injecting gas to determine the most suitable gas type for the gas injection technology.

Figure 11 illustrates the changes in nozzle pressure drop after injecting GHe and GN

2 at varying flow rates of white oil, respectively. It could be seen that the pressure drop across the nozzles in the GN

2 injection process also increases with the GN

2 flow rate, similar that in the GHe injection process. However, compared to the GHe injection condition, the pressurization effect caused by injecting the same mass of GN

2 is obviously weaker. Injecting approximately 5 g/s of GHe and GN2 into the main flow at a liquid flow rate of 34.5 L/min, the corresponding nozzle pressure drops are about 43.5 kPa and 28.9 kPa, respectively. This is mainly due to the smaller molecular weight and density of GHe. In other words, the volume flow rate of GHe is much higher than that of GN

2 at the same mass flow rate and pressure, being able to reduce the mixing density and increase the volume flow rate of the mixed fluid, ultimately resulting in a greater pressure drop across the nozzles.

The comparison between the injection conditions of GN

2 and GHe could be further explored by analyzing the phase distribution diagrams presented in

Figure 12. As depicted in

Figure 12a,b, at gas flow rates of approximately 5 g/s for both GN

2 and GHe, a non-uniform gas–liquid distribution could be observed from the inlet section of the head cavity for the GN

2 injection condition under two different liquid flow rates, indicating inferior mixing uniformity and emulsification compared to that under the GHe injection condition. On the other hand, larger droplets and more liquid columns or parcels are observed from the outlet section of the nozzles for the GN

2 injection condition, indicating a weaker atomization effect of the mixed fluid than that with GHe injection. Additionally,

Figure 12c presents the phase distributions when injecting a higher flow rate of GN

2, where the emulsification effect and nozzle atomization effect of the mixed fluid are both improved when the injecting amount of GN

2 is increased to about 13 g/s. This is consistent with the trend illustrated in

Figure 7 for GHe injection conditions that the emulsification effect and nozzle atomization effect both improve with higher gas injecting rates. Furthermore, when compared to

Figure 12a, there is a stronger alignment between the emulsification and nozzle atomization effects of the mixed fluid, and the corresponding nozzle pressure drop is also more closely depicted in

Figure 11, which further supports the positive correlation between the nozzle pressure drop and the nozzle atomization effect, as previously concluded.

3.5. Effects of Liquid Type

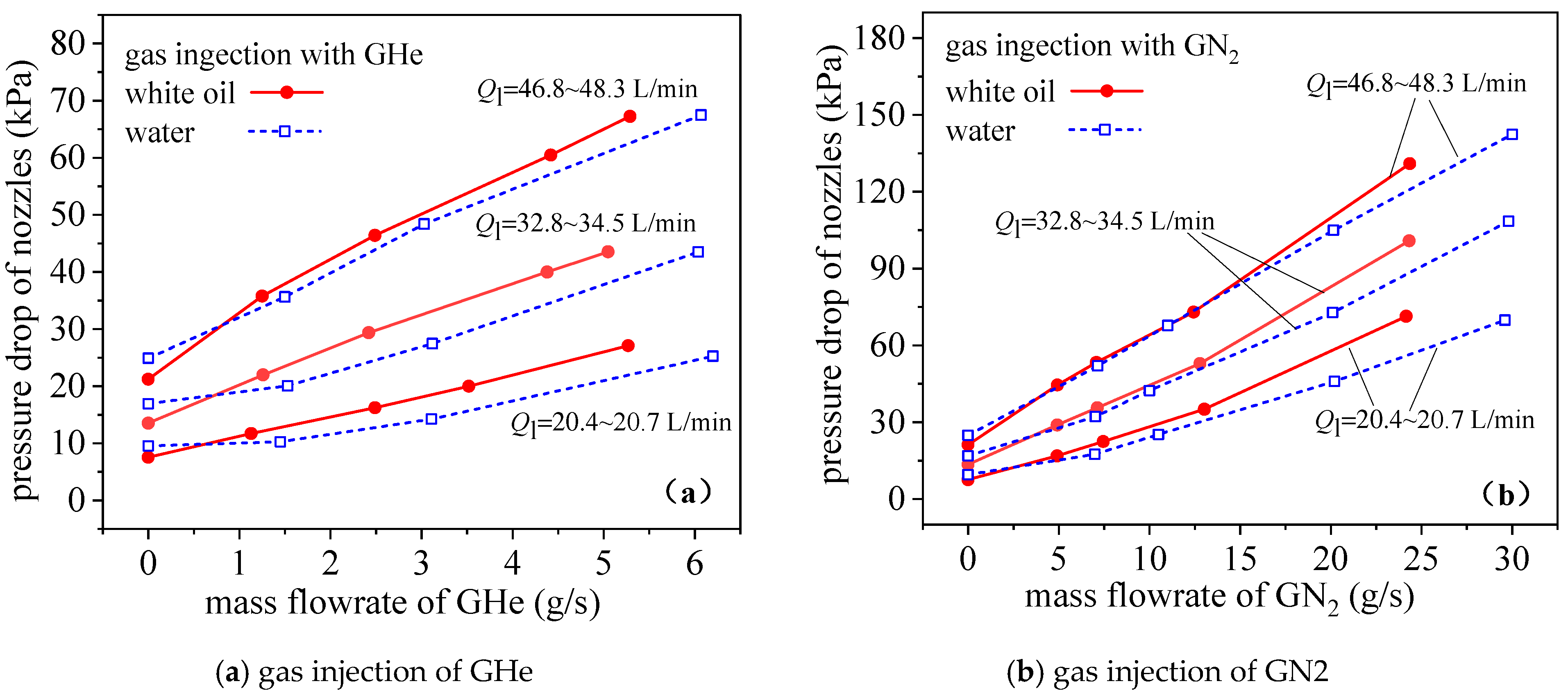

Figure 13a,b illustrate the variations in pressure drop of white oil and water flowing through the nozzles with GHe and GN

2 injection, respectively. It can be seen that, similar to the results observed for white oil flow, the injection of GHe and GN

2 also exerts a significant pressurization effect on the water flow process, with this effect increasing as the amount of injected gas increases. At the same time, for the water flow condition, GHe injection also demonstrates superior pressurization effects compared to GN

2 injection under equivalent mass flow rates of injected gas.

The difference is that the pressure drop across nozzles in water flow cases is consistently lower than that of white oil flow cases, which contrasts with the behavior observed in single-phase liquid flow cases. Despite the greater pressure drop associated with the denser water shown in

Figure 5, the pressure drop in gas–liquid two-phase flow is even more complex. It may depend not only on the flow rate and density of the mixed fluid but also on the phase distribution or interphase interactions.

Figure 14a,b show the gas–liquid phase distribution at the inlet section of head cavity and outlet of nozzles under different flow rates of water and white oil, with the same flow rate of GN

2 injection. It can be seen that, at the same liquid flow rate condition, the white oil flow always exhibits a more uniform milky white fluid state at the inlet section of the head cavity, indicating a better mixing uniformity compared to the water flow condition. Although there is little difference in droplet size and liquid column structure at the nozzle outlets between the white oil and water flows, their mixed fluid states differ significantly. The white oil with gas injection presents a milky white color, while the water flow with gas injection becomes nearly transparent after passing through the nozzles. This indicates that, in white oil flow cases, the fluid remains a relatively stable emulsified gas–liquid mixture, whereas in water flow cases, the gas and liquid phases tend to separate after passing through the nozzles. In other words, compared to white oil, water is less likely to be dispersed by gas injection into a uniform and stable emulsion, resulting in a reduced pressurization effect. This difference between different liquids may be attributed to variations in liquid viscosity, surface tension or contact angle, and requires further comprehensive research and argumentation.

Furthermore, it is important to acknowledge that the limited number of variable-condition tests conducted for only two liquids and two gases in this study has resulted in a restricted range of data parameters obtained during the measurement. For instance, some crucial parameters such as gas-phase proportion at different cross-sectional positions, gas–liquid phase flow velocity and the velocity difference between phases are not available in this measurement. Therefore, while some influence laws of core parameters on the nozzle pressure drop, emulsification, and atomization effects have been identified based on the existing results, it is currently not feasible to establish a universal quantitative law or generate dimensionless parameters to symbolize the gas injection performance under different conditions. In order to elucidate the more quantitative relationship characteristics between different parameters and performance for gas injection technology, more systematic variable-condition tests need to be conducted in the next stage along with necessary numerical calculations as supplement.

4. Conclusions

As one of the applicable methods to maintain the injector pressure drop for deep throttling of LERs, the gas injection process and its effects on the performance of a gas generator under low-thrust conditions are experimentally investigated in this paper. The main conclusions are listed as follows:

- (1)

The feasibility and effectiveness of using gas injection to pressurize the head cavity and improve nozzle atomization under low-thrust conditions was demonstrated through tests conducted on an open-cycle system. Injecting 5.5 g/s of GHe into a white oil flow rate of 6.9 L/min, the head cavity pressure increases to 3.3 times that under the no-gas-injection condition. Meanwhile, the fluid transits from transparent to milky white at the head cavity inlet, and from liquid columns to small droplets at the nozzle outlets after gas injection.

- (2)

As the injection amount of gas and the flow rate of liquid increase, the pressure drop across the nozzles, the degree of gas–liquid mixing and the atomization effect all improve accordingly. For any given liquid flow rate, there is a relatively clear linear relationship between the nozzle pressure drop and the gas injection rate. Despite varying liquid flow rates, a fixed amount of gas injection results in nearly constant multiplicative increase in the nozzle pressure drop.

- (3)

The pressure drop across the nozzles also increases with an increase in GN2’s flow rate, similar to that in the GHe injection process. However, compared to the GHe injection conditions, injecting the same mass of GN2 could result in a noticeably weaker pressurization effect. It can be considered that the gas with a smaller molecular weight is recommended to use as the injected gas for the gas injection process.

- (4)

Gas injection also produces a significant pressurization effect on the water flow process, with this effect intensifying as the amount of injected gas increases. However, in water flow cases, which are characterized by higher density and smaller viscosity, the pressure drop across nozzles is consistently lower than that in white oil flow cases. Moreover, the uniformity and stability of the gas–liquid mixed fluid are poorer in water flow cases, where the gas and liquid phases tend to separate after passing through the nozzles.

It should be noted that this paper investigated the gas injection performance of an actual engine head cavity structure; however, several limitations must be acknowledged. For example, to enable visual observation, an open cycle was employed in this experiment, restricting the testing conditions to low-pressure conditions and precluding wide-ranging tests at the engine’s actual operating pressure. Furthermore, the observation results provided only qualitative insights into the atomization difference of the nozzle before and after gas injection, without yielding quantitative data. Additionally, due to safety considerations, an alternative working fluid was utilized, which could not fully capture the quantitative gas injection characteristics of kerosene. These limitations are targeted for improvement in future research efforts.