Enhancing the Reliability and Durability of Micro-Sensors Using the Taguchi Method

Abstract

1. Introduction

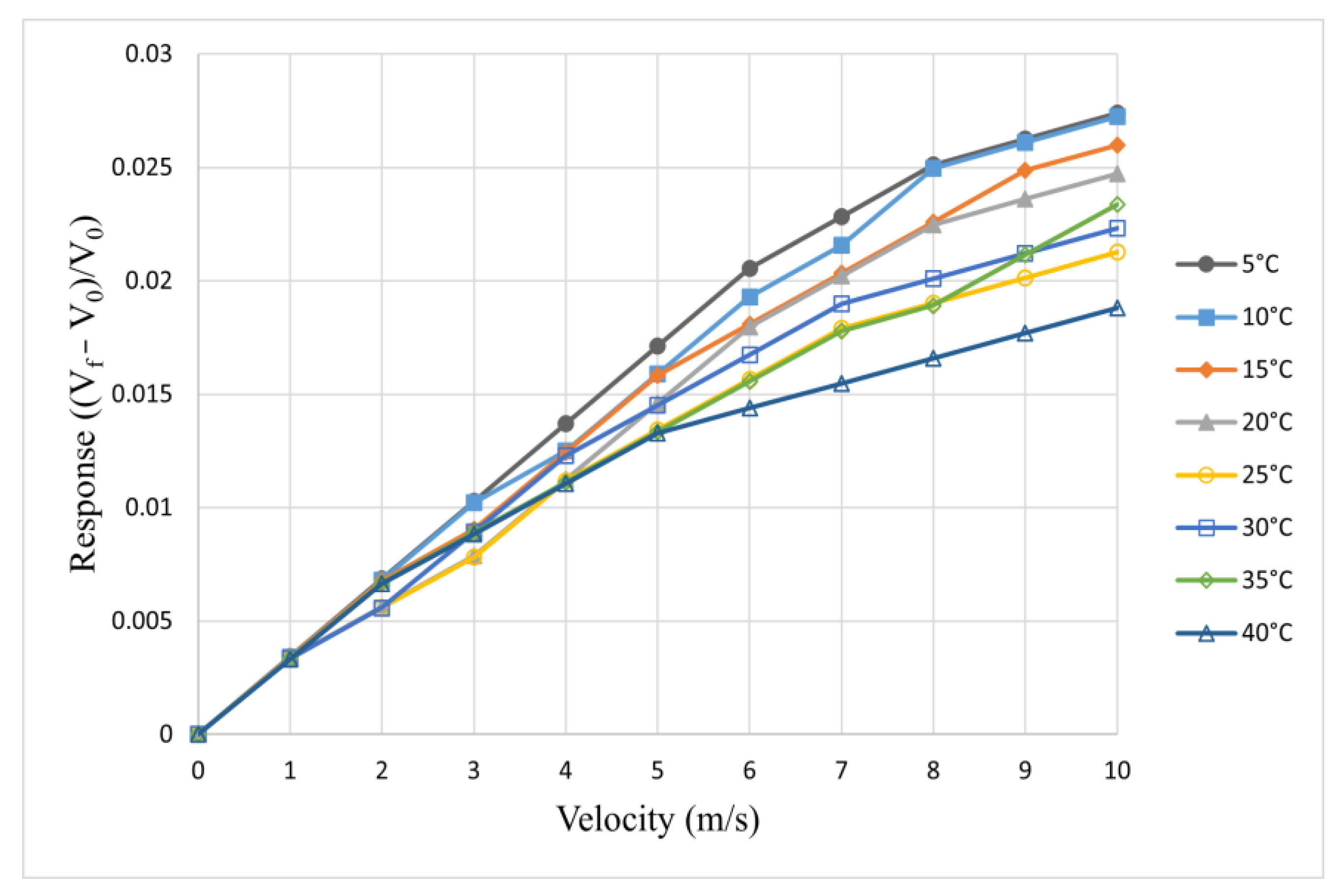

1.1. Micro-Velocity Sensor

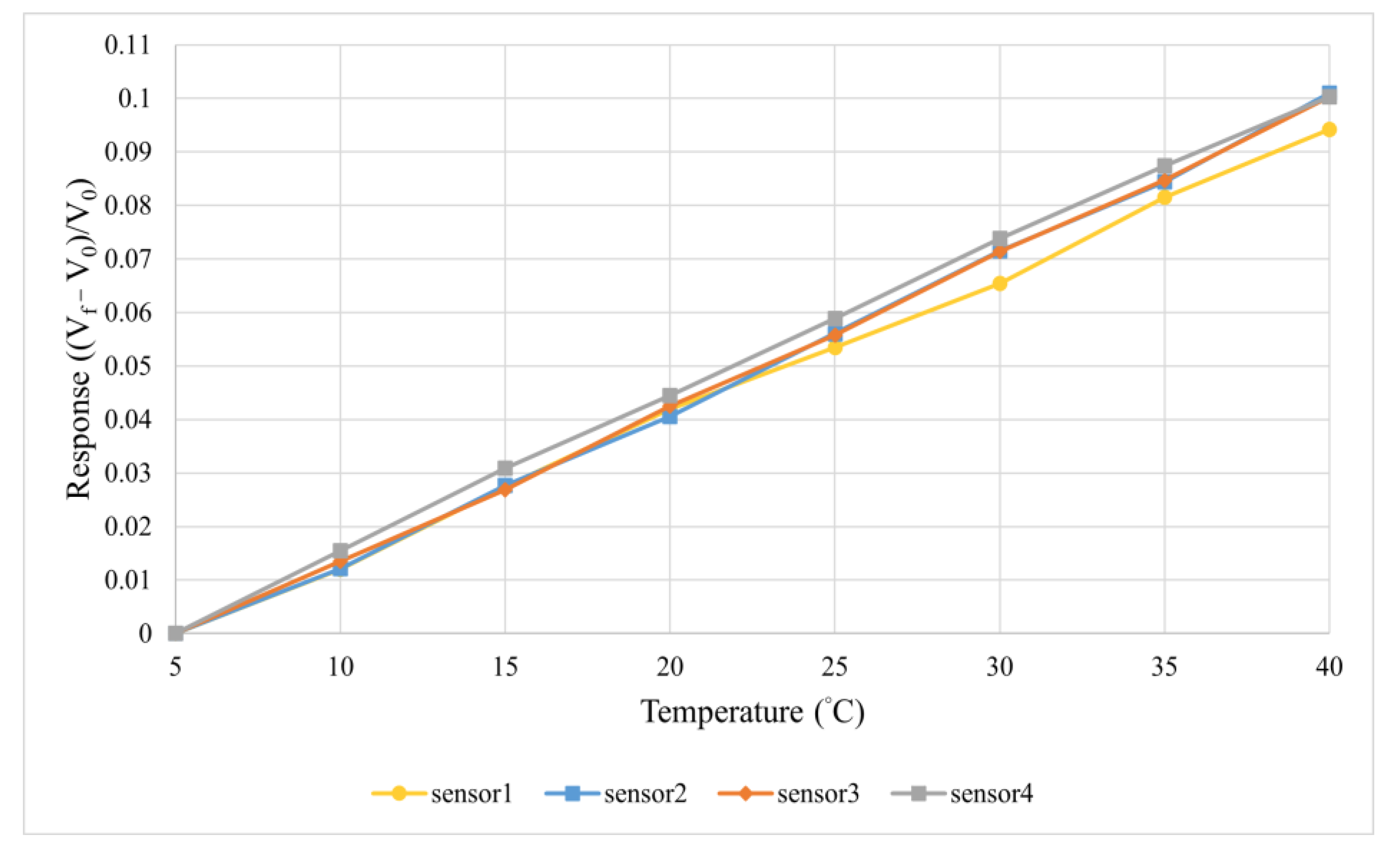

1.2. Micro-Temperature Sensor

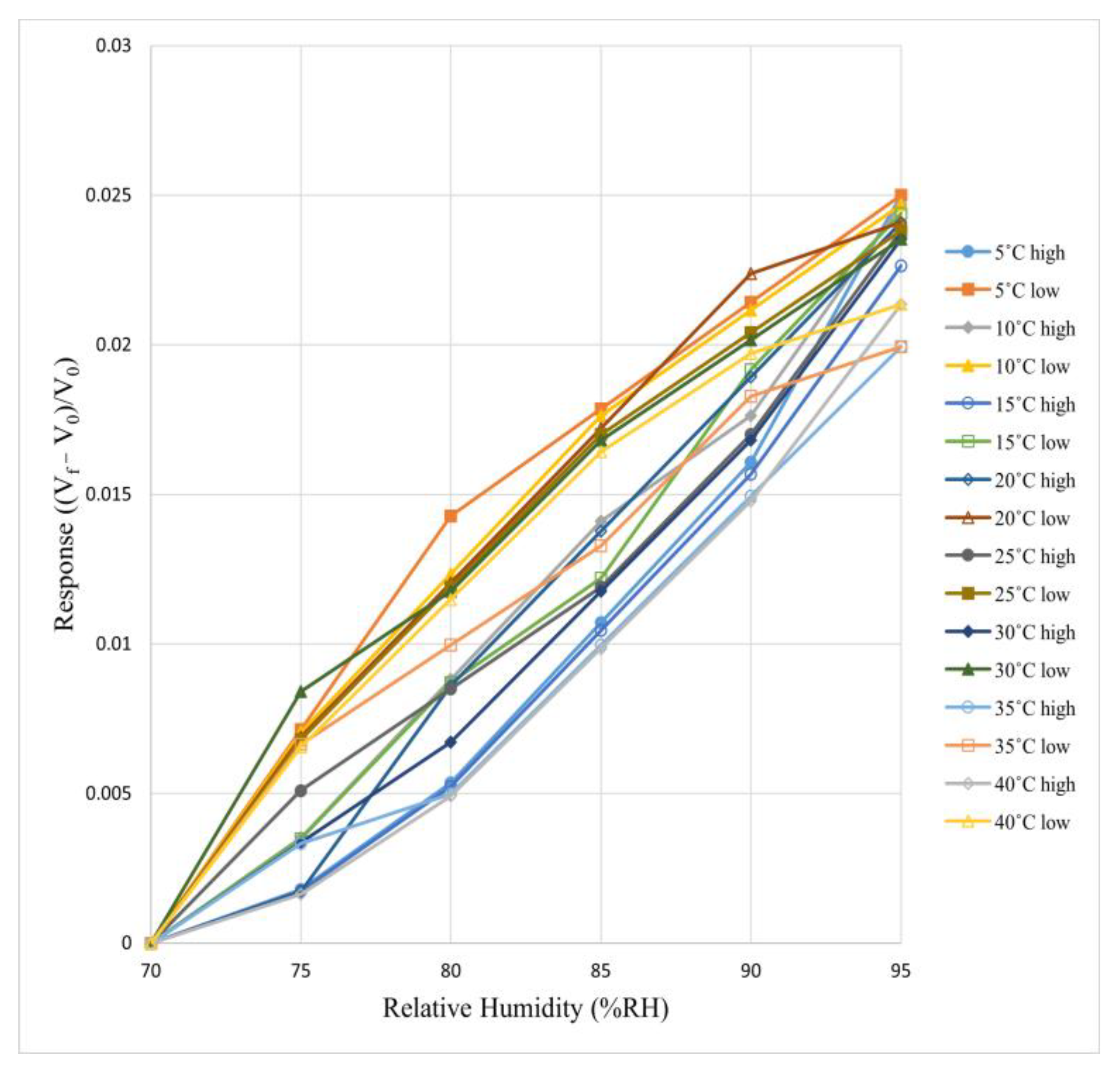

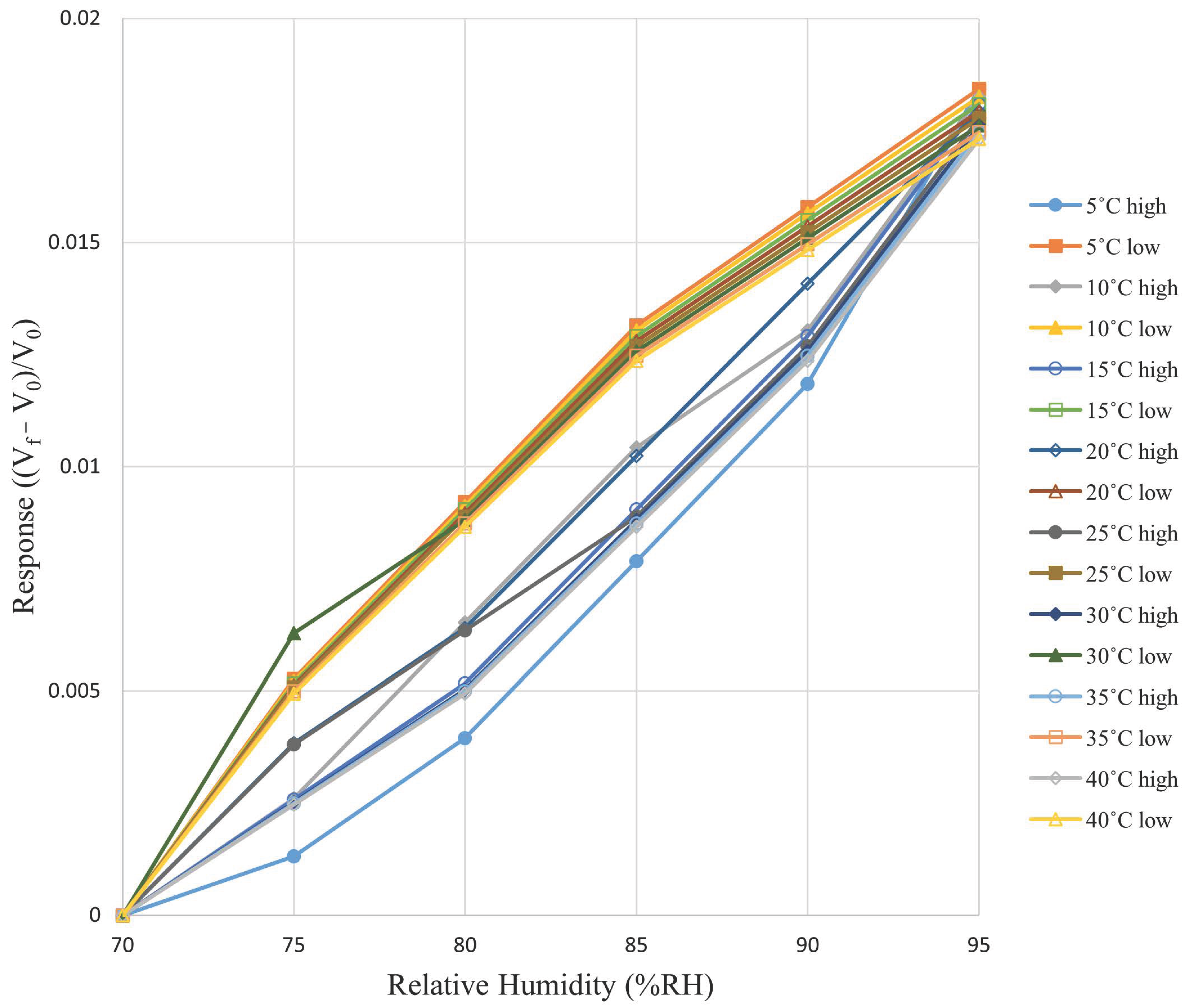

1.3. Micro-Humidity Sensor

2. Research Methods

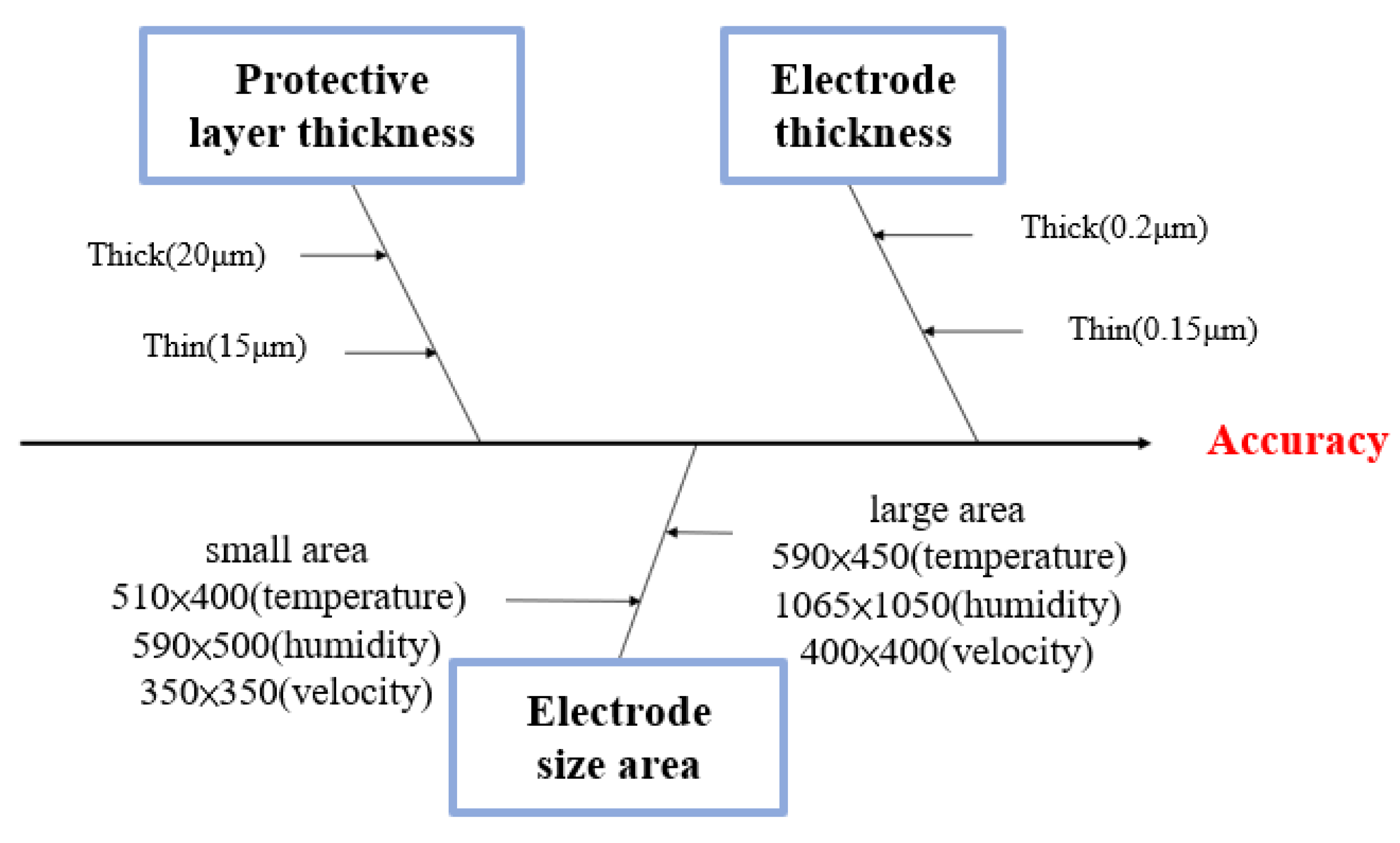

2.1. Integration of a Three-in-One Micro-Sensor with the Taguchi Method

2.2. Design and Principle of the Integrated 3-in-1 Micro-Sensor

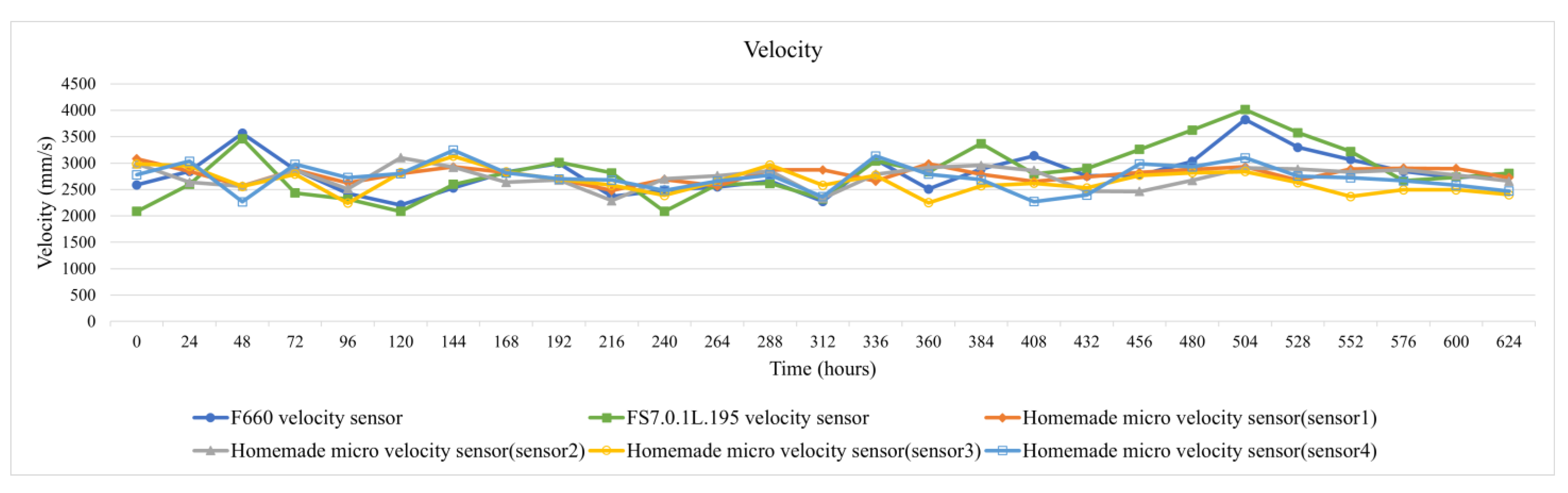

2.3. Micro-Velocity Sensor

2.4. Micro-Temperature Sensor

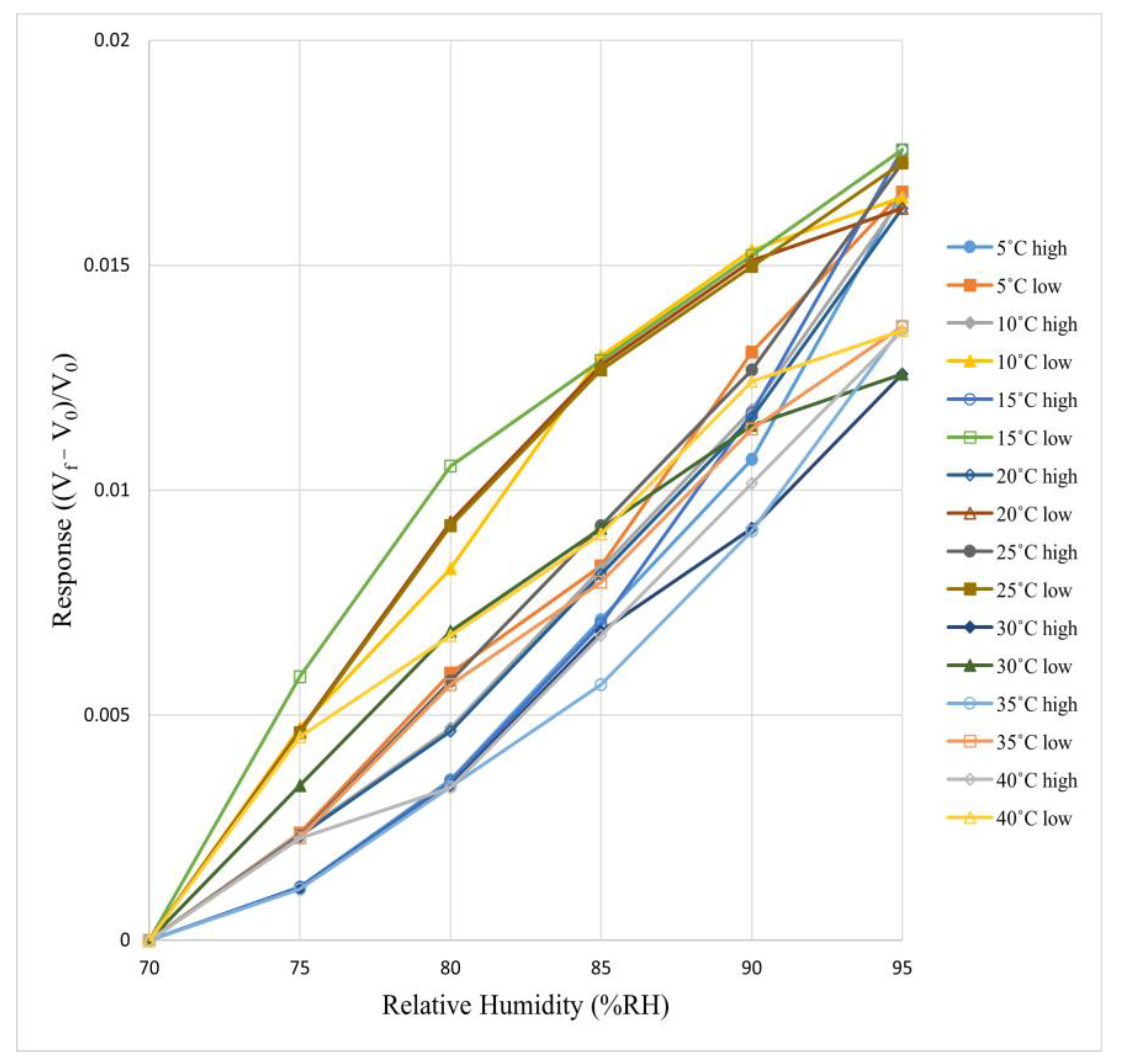

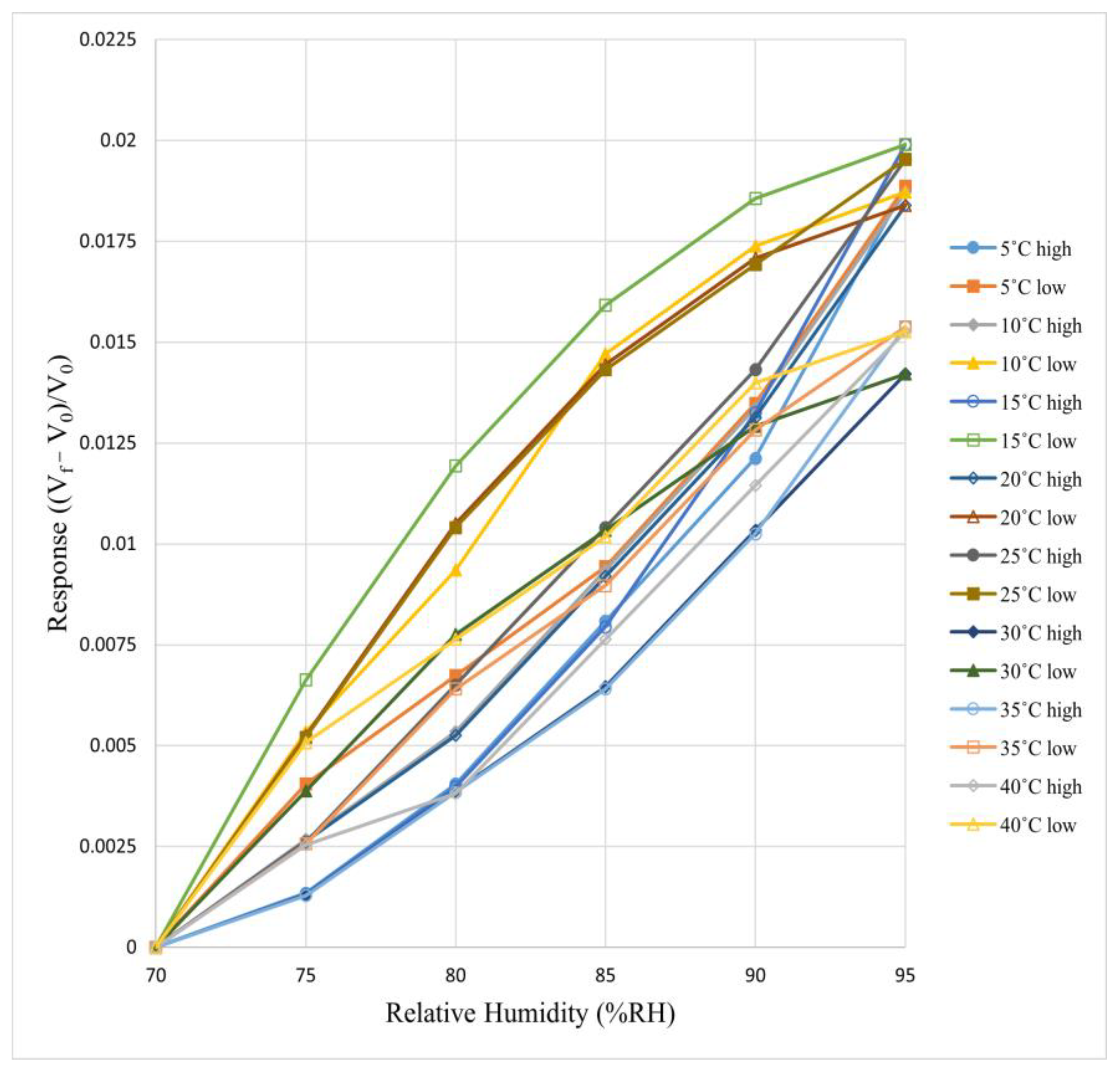

2.5. Micro-Humidity Sensor

2.6. Integration of the Three-in-One Micro-Sensor

2.7. Fabrication Process of the Integrated Three-in-One Micro-Sensor

2.8. Calibration of the Integrated Three-in-One Micro-Sensor

3. Results and Discussion

3.1. Back-End Integration of Integrated Three-in-One Micro-Sensor with FPC

3.2. Integrated Three-in-One Micro-Sensor Packaging

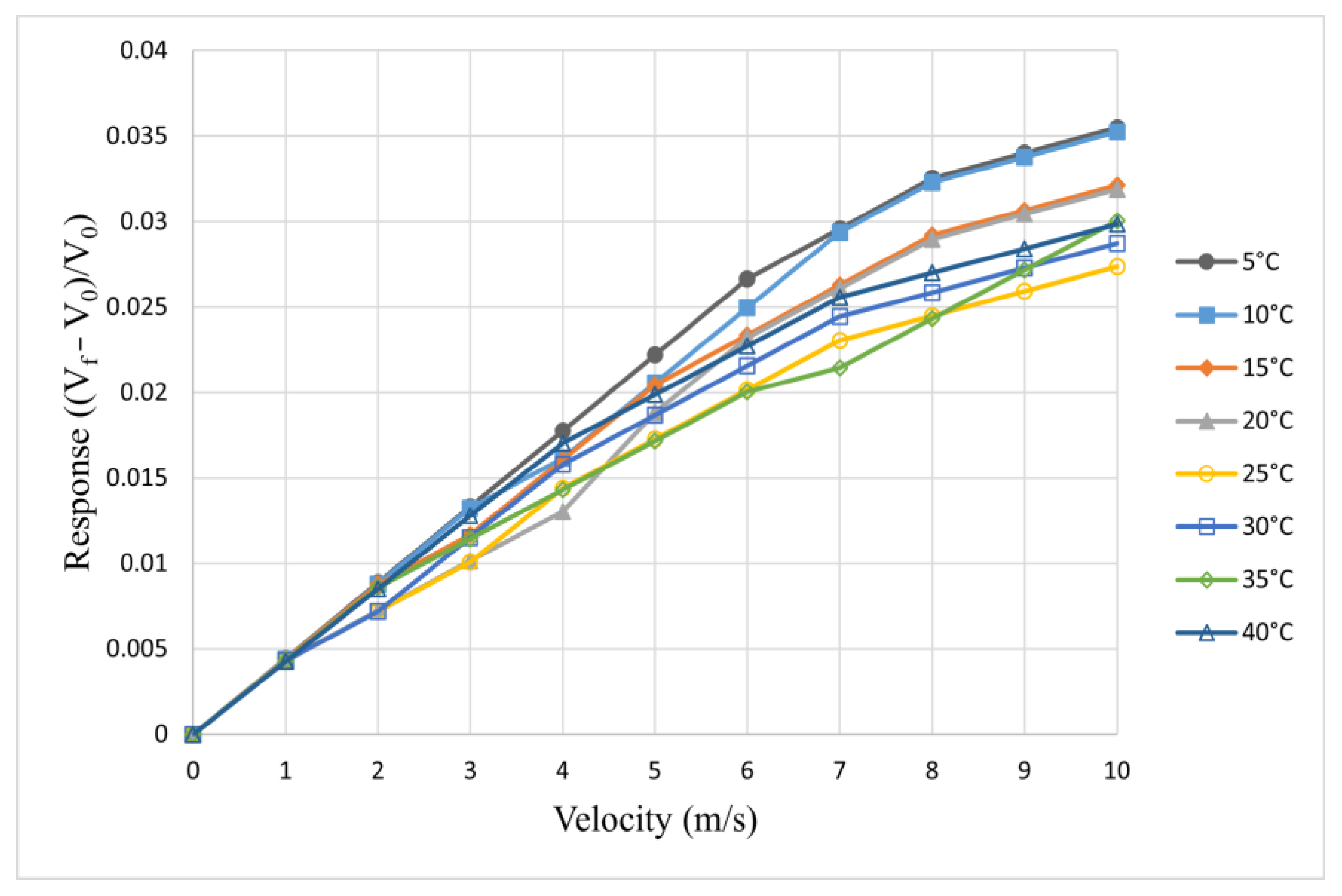

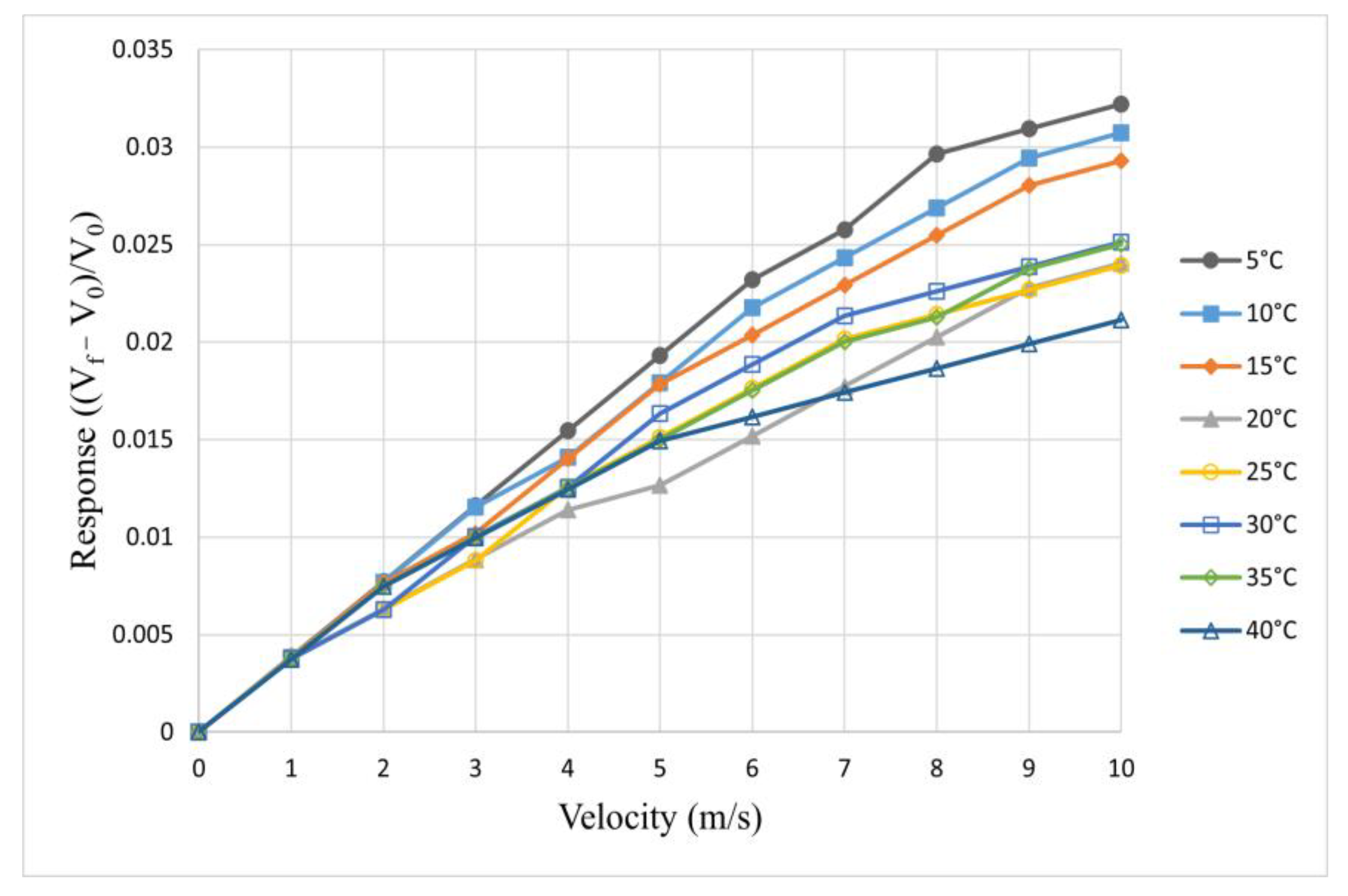

3.3. Performance Comparison of the Four Sets of Self-Made Integrated Three-in-One Micro-Sensors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- JMP. Introduction to Design of Experiments (DOE): Classic Screening Design and Full Factorial Design. 2021. Available online: https://community.jmp.com/t5/JMP-Blog/%E5%AF%A6%E9%A9%97%E8%A8%AD%E8%A8%88-DOE-%E5%85%A5%E9%96%80%E7%B6%93%E5%85%B8%E7%AF%A9%E9%81%B8%E8%A8%AD%E8%A8%88%E8%88%87%E5%85%A8%E5%9B%A0%E5%AD%90%E8%A8%AD%E8%A8%88/ba-p/423195 (accessed on 8 October 2021).

- Jankovic, A.; Chaudhary, G.; Goia, F. Designing the design of experiments (DOE)—An investigation on the influence of different factorial designs on the characterization of complex systems. Energy Build. 2021, 250, 111298. [Google Scholar] [CrossRef]

- Bell, S. Experimental design. Int. Encycl. Hum. Geogr. 2009, 10, 672–675. [Google Scholar] [CrossRef]

- Wang, Z.; Yi, Z.; Qin, M.; Huang, Q.-A.; Zhou, Z.-F. Linearity and sensitivity analysis of MEMS thermal wind sensor via analytical model. IEEE Trans. Instrum. Meas. 2023, 72, 1109–1118. [Google Scholar] [CrossRef]

- Agrawal, V.K.; Patel, R.; Boolchandani, D.; Varma, T.; Rangra, K. Sensitivity and reliability enhancement of a MEMS based wind speed sensor. Microelectron. Reliab. 2020, 104, 2714–2720. [Google Scholar] [CrossRef]

- Xu, Q.; Lu, Y.; Zhao, S.; Hu, N.; Jiang, Y.; Li, H.; Wang, Y.; Gao, H.; Li, Y.; Yuan, M.; et al. A wind vector detecting system based on triboelectric and photoelectric sensors for simultaneously monitoring wind speed and direction. Nano Energy 2021, 89, 106382. [Google Scholar] [CrossRef]

- Yi, Z.; Wang, Y.; Qin, M.; Huang, Q. Research on dust effect for mems thermal wind sensors. Sensors 2023, 23, 5533. [Google Scholar] [CrossRef] [PubMed]

- Yi, Z.; Wan, Y.; Qin, M.; Huang, Q.-A. Quadruple sensitivity improvement for wind speed sensor using dual-layer bended inductors. Sens. Actuators A Phys. 2020, 303, 111786. [Google Scholar] [CrossRef]

- Mu, Y.; Liu, M.; Ma, Z.; Zhang, J. Resistance characteristic analysis based study on a novel damper torque airflow sensor for VAV terminals. Build. Environ. 2020, 175, 106813. [Google Scholar] [CrossRef]

- Ligęza, P. Static and dynamic parameters of hot-wire sensors in a wide range of filament diameters as a criterion for optimal sensor selection in measurement process. Measurement 2020, 151, 107177. [Google Scholar] [CrossRef]

- Hao, L.; Xiao, X.; Wu, Y.; Zhang, K.; Li, R.; Tian, H.; Ma, Y.; Ma, L. Fast response temperature sensor based on reduced graphene oxide through electron beam direct writing. Sens. Actuators A Phys. 2024, 376, 115669. [Google Scholar] [CrossRef]

- Miao, F.; Zhang, X.; Tao, B.; Zhang, P. Wireless chipless RFID temperature and humidity sensor based on Fe2O3-Co3O4/SnO2/rGO composites. Mater. Sci. Eng. B 2024, 307, 117549. [Google Scholar] [CrossRef]

- Lin, S.; Wang, F.; Qu, Y.; Han, X.; Zhang, Y. Discharge splicing-free ultra-highly sensitive fiber-optic temperature sensor based on PDMS and the Vernier effect. Sens. Actuators A Phys. 2024, 376, 115653. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, X.; Li, Y.; Qin, Z.; Pang, Y.; Liu, Z. Simultaneous measurement of relative humidity and temperature based on forward Brillouin scattering in polyimide-overlaid fiber. Sens. Actuators B Chem. 2021, 348, 130702. [Google Scholar] [CrossRef]

- Pan, J.; Liu, S.; Zhang, H.; Lu, J. A flexible temperature sensor array with polyaniline/graphene–polyvinyl butyral thin film. Sensors 2019, 19, 4105. [Google Scholar] [CrossRef] [PubMed]

- Tursunniyaz, M.; Meredith, A.; Andrews, J. Aerosol jet printed resistive temperature sensors with high sensitivity. Sens. Actuators A Phys. 2023, 364, 114777. [Google Scholar] [CrossRef]

- Tursunniyaz, M.; Agarwal, V.; Meredith, A.; Andrews, J. Hybrid nanomaterial inks for printed resistive temperature sensors with tunable properties to maximize sensitivity. Nanoscale 2023, 1, 166118–166129. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, Z.; Fang, Z.; Liu, Z.; Zhu, Y.; Du, L. High-performance FBAR humidity sensor based on the PI film as the multifunctional layer. Sens. Actuators B Chem. 2020, 308, 127694. [Google Scholar] [CrossRef]

- Mu, Y.; Jin, P.; Zheng, L.; Wang, C.; Hou, Y.; Liu, W.; Si, L.; Liu, Z. An enhanced MEMS-based polyimide capacitive-type relative-humidity sensor with halloysite nanotube as a modifier. Microchem. J. 2023, 191, 108934. [Google Scholar] [CrossRef]

- Li, Z.; Dong, B.; Chen, E.; Li, Y.; Zhao, W.; Wang, Y.; Gao, C. High sensitivity FBG humidity sensor coated with graphene and polyimide films. Opt. Fiber Technol. 2021, 66, 102635. [Google Scholar] [CrossRef]

- Zhu, J.; Cao, Y.; Chen, H.; Fan, B.; Zou, X.; Cheng, J.; Zhang, C. Rapid-response humidity sensors based on ultra-thin films stacked with single-layer graphene oxide. Results Chem. 2024, 7, 101444. [Google Scholar] [CrossRef]

- Che, X.Y.; Mei, S.X.; Zhao, W.; Zhang, Y.C.; Zhang, X.M.; Cui, Z.; Fu, P.; Pang, X.C.; Liu, M.Y.; Ye, Y. Thermoplastic polyamide elastomer based flexible humidity sensor for breath monitoring. Mater. Des. 2023, 235, 112438. [Google Scholar] [CrossRef]

- Zhang, H.-W.; Xu, X.; Huang, M.-L.; Wang, Y.-S.; Xu, Z.-Q.; Feng, Z.-S.; Zhang, Y. Interlayer cross-linked MXene enables ultra-stable printed paper-based flexible sensor for real-time humidity monitoring. Chem. Eng. J. 2024, 495, 153343. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Shieh, J.-S.; Chen, J.; Wang, X.-W.; Liu, C.-K.; Wei, C.-H. The application of a self-made integrated three-in-one microsensor and commercially available wind speed sensor to the cold air pipe of the heating, ventilation, and air conditioning in a factory for real-time wireless measurement. Sensors 2023, 23, 4471. [Google Scholar] [CrossRef] [PubMed]

- Keshavarzi, M.; Hasani, J.Y. Design and optimization of fully differential capacitive MEMS accelerometer based on surface micromachining. Microsyst. Technol. 2019, 25, 1369–1377. [Google Scholar] [CrossRef]

| Electrode Area (μm) | Electrode Thickness (μm) | Protective Layer Thickness (μm) | |

|---|---|---|---|

| Sensor 1 | 510 × 400 (temperature) 590 × 500 (humidity) 350 × 350 (velocity) | 0.2 | 20 |

| Sensor 2 | 510 × 400 (temperature) 590 × 500 (humidity) 350 × 350 (velocity) | 0.15 | 15 |

| Sensor 3 | 590 × 450 (temperature) 1065 × 1050 (humidity) 400 × 400 (velocity) | 0.2 | 15 |

| Sensor 4 | 590 × 450 (temperature) 1065 × 1050 (humidity) 400 × 400 (velocity) | 0.15 | 20 |

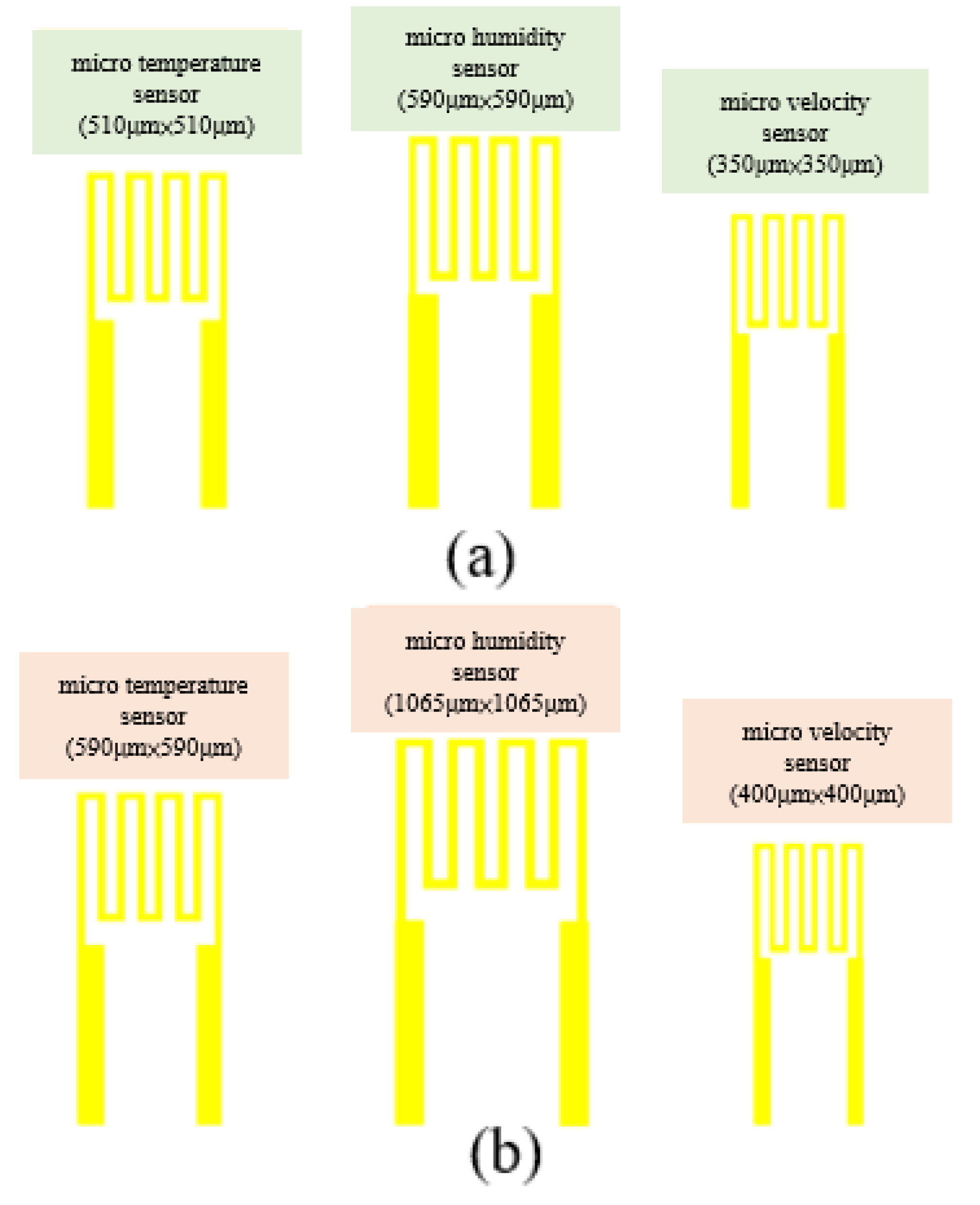

| Micro-temperature sensor |  | This study uses a Resistance Temperature Detector (RTD) with a snake-shaped electrode to increase resistance. The temperature-sensitive resistance material is gold (Au), which has stable chemical properties, a simple manufacturing process, and high linearity. |

| Micro-humidity sensor |  | This study uses a resistive humidity sensor. Its electrode type is an interdigitated electrode structure. There is a moisture-sensing material film (PI 9305, Fujifilm, Tokyo, Japan) above the electrode. When the moisture absorbed by the moisture-sensing film increases, its dielectric constant It will also increase as the ambient humidity increases. The moisture-sensitive film material is PI 9305, which has stable chemical properties and high linearity in moisture-sensing characteristics. |

| Micro-velocity sensor |  | This study uses a snake-shaped hot-wire micro-velocity sensor. The main measurement structure of the hot-wire micro-velocity sensor is a resistance heater. The power supply is used to provide a constant voltage input to generate a heat source so that the electrode becomes a resistance heater, generating stable temperature field. When the gas increases with the wind speed and the heat is taken away, the resistance value of the heater will decrease accordingly. The resistance material is gold (Au), which has stable chemical properties, a simple manufacturing process, and high linearity. |

| F660 | FS7.0.1L.195 | Integrated Three-in-One Micro-Sensor | |

|---|---|---|---|

| Sensing range | 0.15~20 m/s | 0~100 m/s | 0.15~20 m/s |

| Accuracy | ±5% | <3% | ±3% |

| Response time | 400 ms | 200 ms | 1 ms |

| Measuring physical quantities | Velocity and temperature | Velocity | Velocity, temperature, and humidity |

| price | NT4000 | NT560 | NT535 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-Y.; Shieh, J.-S.; Huang, G.-Q.; Liu, C.-K.; Cox, N.; Chou, C.-H. Enhancing the Reliability and Durability of Micro-Sensors Using the Taguchi Method. Processes 2025, 13, 2852. https://doi.org/10.3390/pr13092852

Lee C-Y, Shieh J-S, Huang G-Q, Liu C-K, Cox N, Chou C-H. Enhancing the Reliability and Durability of Micro-Sensors Using the Taguchi Method. Processes. 2025; 13(9):2852. https://doi.org/10.3390/pr13092852

Chicago/Turabian StyleLee, Chi-Yuan, Jiann-Shing Shieh, Guan-Quan Huang, Chen-Kai Liu, Najsm Cox, and Chia-Hao Chou. 2025. "Enhancing the Reliability and Durability of Micro-Sensors Using the Taguchi Method" Processes 13, no. 9: 2852. https://doi.org/10.3390/pr13092852

APA StyleLee, C.-Y., Shieh, J.-S., Huang, G.-Q., Liu, C.-K., Cox, N., & Chou, C.-H. (2025). Enhancing the Reliability and Durability of Micro-Sensors Using the Taguchi Method. Processes, 13(9), 2852. https://doi.org/10.3390/pr13092852