Evaluation Method of Key Controlling Factors for Productivity in Deep Coalbed Methane Reservoirs—A Case Study of the 8+9# Coal Seam in the Eastern Margin of the Ordos Basin

Abstract

1. Evaluation Methodology for Key Controlling Factors

1.1. Grey Relational Analysis

1.2. Random Forest Methodology

1.3. Principal Component Analysis–Entropy Weight Method

1.3.1. Principal Component Analysis

1.3.2. Entropy Weight Method

1.4. Fuzzy Mathematics Comprehensive Evaluation

2. Case Study: 8+9# Coal Seam in the Eastern Margin of the Ordos Basin

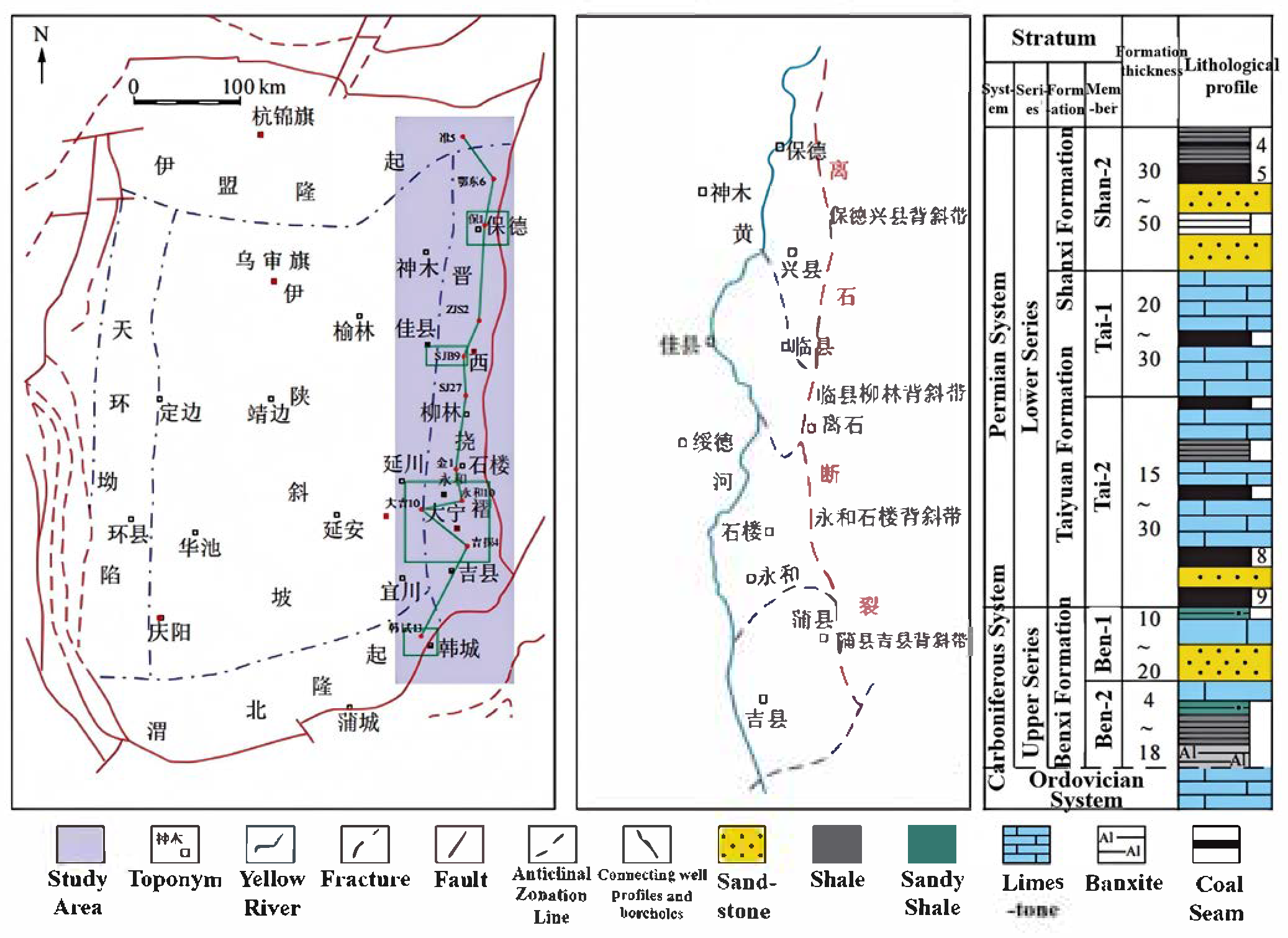

2.1. Regional Geological Setting

2.2. Analysis of Key Productivity Controls

2.2.1. Data Preprocessing

- ①

- When the coefficient is 1, it indicates a perfect positive linear relationship between the two variables, meaning that as one variable increases, the other increases in a fixed proportion.

- ②

- When the coefficient is −1, it indicates a perfect negative linear relationship, meaning that as one variable increases, the other decreases in a fixed proportion.

- ③

- When the coefficient is close to 0, it suggests little to no linear relationship between the two variables.

2.2.2. Comprehensive Geological–Engineering Factor Analysis

2.2.3. Univariate Factor Analysis Validation

3. Highlights

- A comprehensive analysis method for main controlling factors of production capacity is proposed, which integrates grey relational analysis, random forest, and principal component analysis-entropy weight method.

- The key geological and engineering controlling factors for the productivity of deep coalbed methane in the 8+9# coal seams on the eastern margin of the Ordos Basin have been clarified.

- Formulate a differentiated development strategy: for Block A, form a “geology-led, engineering-regulated” plan; for Block B, propose a “engineering supplementation for geological deficiencies” strategy.

- This analysis method still has certain limitations. The accuracy of its analysis results can be further improved by integrating more advanced feature evaluation methods.

4. Conclusions and Findings

- This study analyzed Pearson correlations and comprehensive influence degrees between average cumulative gas production, peak gas production, and multiple geological/engineering parameters using data from 38 directional wells in the 8+9# deep coalbed methane reservoir of the Ordos Basin’s eastern margin. The key controlling factors for average cumulative production were identified as gas content, vertical thickness, and GSI value among geological parameters, and proppant intensity, pad fluid ratio, and proppant volume among engineering parameters.

- By integrating grey correlation analysis, principal component analysis-entropy weight method, and random forest algorithm through fuzzy mathematics, we developed a comprehensive evaluation methodology for identifying key productivity controls in deep CBM reservoirs, which provides a scientific basis for future fracturing design optimization.

- Although the comprehensive evaluation method proposed in this study integrates three single methods, it still has certain limitations. Specifically, this method is more suitable for analyzing continuous data. When dealing with discrete data, preprocessing such as recoding may be required to convert it into a continuous form; however, this process might overlook the actual meaning of discrete values and potentially reduce the accuracy of the analysis. In addition, since this method combines three independent technologies for analyzing controlling factors, it can also be integrated with newer and more advanced analytical methods. Nevertheless, before conducting such integration, the advantages and disadvantages of the newly added method must be carefully evaluated to determine whether it can complement those of the current framework; otherwise, the accuracy of the final results may be compromised.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, J.P. China’s CBM exploration and production and associated technologicaladvancements: A review and reflections. Coal Geol. Explor. 2025, 53, 114–127. [Google Scholar] [CrossRef]

- Jiang, S.H.; Shi, S.Z.; Zhao, K.; Liu, Y.C.; Yao, X.J.; Shi, J.X.; Xie, D.S. Prospect and development direction of deep coal and coalbed methane exploration. Sci. Technol. Rev. 2023, 41, 106–113. [Google Scholar] [CrossRef]

- Huang, Z.W.; Li, G.F.; Yang, R.Y.; Li, G.S. Review and development trends of coalbed methane exploitation technology in China. J. China Coal Soc. 2022, 47, 3212–3238. [Google Scholar] [CrossRef]

- Yan, T.T.; Deng, Z.Y.; Wu, P.; Gao, G.S.; Chang, S.L.; Fu, X.Y.; Meng, Y.J.; Liu, Y.F. Characteristics and Key Control Factors of Coalbed Methane Well Productivity in the Yangjiapo Block, Eastern Linxing District, Ordos Basin. Geoscience 2024, 38, 1545–1556. [Google Scholar] [CrossRef]

- Chen, Z.L.; Wang, Y.H.; Liu, X.; Cui, B. Critical technologies and geology-engineering integration practices for deep CBM production in the Yanchuannan CBM field. Coal Geol. Explor. 2025, 53, 143–151. [Google Scholar] [CrossRef]

- Zeng, F.H.; Hu, D.G.; Zhang, Y.; Guo, J.C.; Tian, F.C.; Zhang, B.T. Research on Data-Driven Intelligent Optimization of Fracturing Treatment Parameters for Shale Oil Horizontal Wells. Pet. Drill. Tech. 2023, 51, 78–87. [Google Scholar] [CrossRef]

- Gou, B.; Wang, C.; Yu, T.; Wang, K. Fuzzy logic and grey clustering analysis hybrid intelligence model applied to candidate-well selection for hydraulic fracturing in hydrocarbon reservoir. Arab. J. Geosci. 2020, 13, 975. [Google Scholar] [CrossRef]

- Verma, A.K.; Singh, T.N. A neuro-fuzzy approach for prediction of longitudinal wave velocity. Neural Comput. Appl. 2013, 22, 1685–1693. [Google Scholar] [CrossRef]

- Rios, E.H.; Azeredo, R.B.d.V.; Moss, A.K.; Pritchard, T.N.; Domingues, A.B.G. Estimating the Permeability of Rocks by Principal Component Regressions of NMR and MICP Data. Petrophysics 2022, 63, 442–453. [Google Scholar] [CrossRef]

- Kong, X.W.; Xie, X.; Wang, C.W. Evaluation of geological engineering factors for productivity of deep CBM well after fracturing based on grey correlation method. Pet. Reserv. Eval. Dev. 2023, 13, 433–440. [Google Scholar] [CrossRef]

- Wang, L.J. Evaluation of Effectiveness and Main Control Factors after Segmented Multi-Cluster Fracturing in Horizontal Wells of Tight Conglomerate Reservoirs. Master’s Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar] [CrossRef]

- Zhang, S.K.; Chen, Z. Status and Prospect of Artificial Intelligence Application in Fracturing Technology. Pet. Drill. Tech. 2023, 51, 69–77. [Google Scholar] [CrossRef]

- Han, Y.D. Productivity Prediction of Multiple-Fractured Horizontal Wells in Tight Reservoirs Based on Machine Learning. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2023. [Google Scholar]

- Ma, J.; Shi, S.; Chen, J.; Zhang, J.; He, X.; Li, X.; Guo, D. Optimization of fracture design for horizontal wells in Mahu region based on machine learning. J. Shenzhen Univ. 2021, 38, 621–627. [Google Scholar] [CrossRef]

- Xiao, H.; Zhou, L.L.; Zhou, W.H.; Luo, H.; Cha, J.H. Analysis of main controlling factors of initial productivity of gas wells in the Longwangmiao Formation Gas reservoir of Longnvsi Block. Complex Hydrocarb. Reserv. 2023, 16, 335–342. [Google Scholar] [CrossRef]

- Su, H.; Li, R.X.; Deng, H.C.; Qin, Y.W.; Fu, M.Y.; He, J.H.; Zeng, Q.G.; Song, L.K.; Zhang, J.W. Comprehensive evaluation of geological and engineering factors affecting fracturing effectiveness in tight sandstone reservoirs. Pet. Geol. Exp. 2024, 46, 1349–1361. [Google Scholar] [CrossRef]

- Zhang, J.S. Ultra-deep Fractured Low-porosity Sandstone Gas Reservoir Intelligent Evaluation Study of Production Capacity. Master’s Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, R.B.; Xu, H.T.; Zhao, Y.Z.; Sun, Z.Q.; Yang, F.X.; Zhan, H.Y.; Li, H.B.; Lv, S.Y. Application of CNN⁃LSTM based on physical model constraint and attention mechanism in in⁃situ combustion production prediction. Pet. Geol. Oilfield Dev. Daqing 2025, 44, 90. [Google Scholar] [CrossRef]

- Fu, Y.X.; Tan, C.Q.; Hou, B.; Zheng, X.M.; Yang, Y.X.; Pan, J.Y. Evaluation of Controlling Factors of Low Production and Low Efficiency Wells Based on Principal Component Analysis and Grey Correlation. J. Chongqing Univ. Sci. Technol. 2023, 25, 23–28+51. [Google Scholar] [CrossRef]

- Khanal, A.; Khoshghadam, M.; Lee, W.J.; Nikolaou, M. New forecasting method for liquid rich shale gas condensate reservoirs with data driven approach using principal component analysis. J. Nat. Gas Sci. Eng. 2017, 38, 621–637. [Google Scholar] [CrossRef]

- Hu, J.; Xu, B.; Chen, Z.; Zhang, H.; Cao, J.; Wang, Q. Hazard and risk assessment for hydraulic fracturing induced seismicity based on the Entropy-Fuzzy-AHP method in Southern Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2021, 90, 103908. [Google Scholar] [CrossRef]

- Zuo, C.; Wang, W.; Qi, Y.; Cui, X.C. Evaluation of Coal Mine Emergency Management Ability Based on Entropy Weight Method and BP Neural Network. J. Shanxi Datong Univ. 2024, 40, 116–120. [Google Scholar] [CrossRef]

- Ju, Y.; Wu, G.; Wang, Y.; Liu, P.; Yang, Y. 3D Numerical Model for Hydraulic Fracture Propagation in Tight Ductile Reservoirs, Considering Multiple Influencing Factors via the Entropy Weight Method. Spe J. 2021, 26, 2685–2702. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Chen, Q.G. Research and Application of Risk Assessment for Hydraulic Workover Rig Equipment Based on Fuzzy Mathematics. China Heavy Equip. 2023, 45–49. [Google Scholar] [CrossRef]

- Zhou, K.; Sun, F.; Yang, C.; Qiu, F.; Wang, Z.; Xu, S.; Chen, J. Evaluation of Deep Coalbed Methane Potential and Prediction of Favorable Areas within the Yulin Area, Ordos Basin, Based on a Multi-Level Fuzzy Comprehensive Evaluation Method. Processes 2024, 12, 820. [Google Scholar] [CrossRef]

- Sun, J.; Han, S.; Liu, S.; Lin, J.; Li, F.; Liu, G.; Shi, P.; Teng, H. Key Controlling Factors of Deep Coalbed Methane Reservoir Characteristics in Yan’an Block, Ordos Basin: Based on Multi-Scale Pore Structure Characterization and Fluid Mobility Research. Processes 2025, 13, 2382. [Google Scholar] [CrossRef]

- He, D.F.; Bao, H.P.; Kai, B.Z.; Wei, L.B.; Xu, Y.H.; Ma, J.H.; Cheng, Y. Critical tectonic modification periods and its geologic features of Ordos Basin and adjacent area. Acta Pet. Sin. 2021, 42, 1255–1269. [Google Scholar] [CrossRef]

- Jia, A.L.; Wei, Y.S.; Guo, Z.; Wang, G.T.; Meng, D.W.; Huang, S.Q. Development status and prospect of tight sandstone gas in China. Nat. Gas Ind. B 2022, 9, 467–476. [Google Scholar] [CrossRef]

- Liu, J.Z.; Zhu, G.H.; Liu, Y.C.; Chao, W.W.; Du, J.; Yang, Q.; Mi, H.G.; Zhang, S.R. Breakthrough, future challenges and countermeasures of deep coalbed methane in the eastern margin of Ordos Basin:a case study of Linxing-Shenfu block. Acta Pet. Sin. 2023, 44, 1827–1839. [Google Scholar] [CrossRef]

- Niu, X.B.; Zhao, W.B.; Shi, Y.H.; Hu, X.Y.; Du, X.W. Natural gas accumulation conditions and exploration potential of Benxi Formation in Ordos Basin. Acta Pet. Sin. 2023, 44, 1240–1257. [Google Scholar] [CrossRef]

- Liu, X.B.; Tao, S.Z.; Yang, X.C.; Chen, Y.Y.; Liu, Z.Y.; Pei, X.B.; Wang, L.F.; Yi, W.; Feng, J.Q.; Zhang, T.; et al. Accumulation mechanisms and resource potential of helium in coal measures:A case study of the eastern margin of the Ordos Basin. Coal Geol. Explor. 2024, 52, 49–66. [Google Scholar] [CrossRef]

- Fu, J.H.; Wei, X.S.; Ren, J.F. Distribution and genesis of large-scale Upper Palaeozoic lithologic gas reservoirs on Yi-Shaan Slope. Pet. Explor. Dev. 2008, 35, 664–667+691. [Google Scholar] [CrossRef]

- Li, G.Z. Contribution and Its Prediction Model of Production Strata for Joint CMG Mining: A Case from Linxing-Shenfu Area in Ordos Basin, China. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar] [CrossRef]

- Ye, Z.L.; Gong, X.P.; Hu, M.; Shang, B. Analysis of the correlation between coal spontaneous combustion gas products and microscopic groups. Coal Technol. 2024, 43, 246–250. [Google Scholar] [CrossRef]

| Sample | Perforation Thickness | Effective Perforation Count | Proppant Volume | Clean Fluid Volume | Pumping Rate | Vertical Thickness | Proppant Intensity | Fluid Intensity | Pad Fluid Ratio | Slurry Volume | Displacement Volume | Average Sand Ratio | Flowback Ratio | Density | GSI | Gas Content |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit | m | piece | m3 | m3 | m3/min | m | m2 | m2 | % | m3 | m3 | % | % | g/cm3 | - | m3/t |

| 1 | 5 | 80 | 314 | 2881.6 | 17 | 17.4 | 18.04 | 165.6 | 28.8% | 2053.8 | 27.0 | 14.8% | 13.2% | 1.27 | 64.5 | 5.9 |

| 2 | 3 | 48 | 211.5 | 1981.4 | 18 | 10.6 | 19.95 | 186.9 | 23.7% | 1536.9 | 28.3 | 14.7% | 4.6% | 1.27 | 44.9 | 11.1 |

| 3 | 3.5 | 56 | 301.9 | 2754.8 | 18 | 13.6 | 22.19 | 202.5 | 22.7% | 2028.3 | 31.1 | 14.6% | 10.7% | 1.47 | 61.2 | 17.04 |

| Method | Weight (Average Cumulative Production) | Weight (Peak Production) |

|---|---|---|

| Grey Correlation Analysis | 0.416 | 0.447 |

| Random Forest Method | 0.343 | 0.295 |

| PCA–Entropy Weight Method | 0.241 | 0.258 |

| Method | Weight (Average Cumulative Production) | Weight (Peak Production) |

|---|---|---|

| Grey Correlation Analysis | 0.408 | 0.415 |

| Random Forest Method | 0.368 | 0.357 |

| PCA–Entropy Weight Method | 0.224 | 0.228 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Cui, J.; An, Q.; Zeng, F.; Wen, H.; Hu, J.; Li, Y.; Lan, T. Evaluation Method of Key Controlling Factors for Productivity in Deep Coalbed Methane Reservoirs—A Case Study of the 8+9# Coal Seam in the Eastern Margin of the Ordos Basin. Processes 2025, 13, 2850. https://doi.org/10.3390/pr13092850

Zhang S, Cui J, An Q, Zeng F, Wen H, Hu J, Li Y, Lan T. Evaluation Method of Key Controlling Factors for Productivity in Deep Coalbed Methane Reservoirs—A Case Study of the 8+9# Coal Seam in the Eastern Margin of the Ordos Basin. Processes. 2025; 13(9):2850. https://doi.org/10.3390/pr13092850

Chicago/Turabian StyleZhang, Shaopeng, Jiashuo Cui, Qi An, Fanbang Zeng, Haitao Wen, Jiachen Hu, Yu Li, and Tian Lan. 2025. "Evaluation Method of Key Controlling Factors for Productivity in Deep Coalbed Methane Reservoirs—A Case Study of the 8+9# Coal Seam in the Eastern Margin of the Ordos Basin" Processes 13, no. 9: 2850. https://doi.org/10.3390/pr13092850

APA StyleZhang, S., Cui, J., An, Q., Zeng, F., Wen, H., Hu, J., Li, Y., & Lan, T. (2025). Evaluation Method of Key Controlling Factors for Productivity in Deep Coalbed Methane Reservoirs—A Case Study of the 8+9# Coal Seam in the Eastern Margin of the Ordos Basin. Processes, 13(9), 2850. https://doi.org/10.3390/pr13092850