Measuring the Effects of Gas Pressure and Confining Pressures on Coal: In the View of Time–Frequency Evolutionary Properties and Crack Propagation Behavior

Abstract

1. Introduction

2. Test Setups and Systems

2.1. Test Systems

2.2. Coal Sample Preparation and Determination of Basic Mechanical Parameters

2.3. Experimental Procedure

3. Results and Discussion

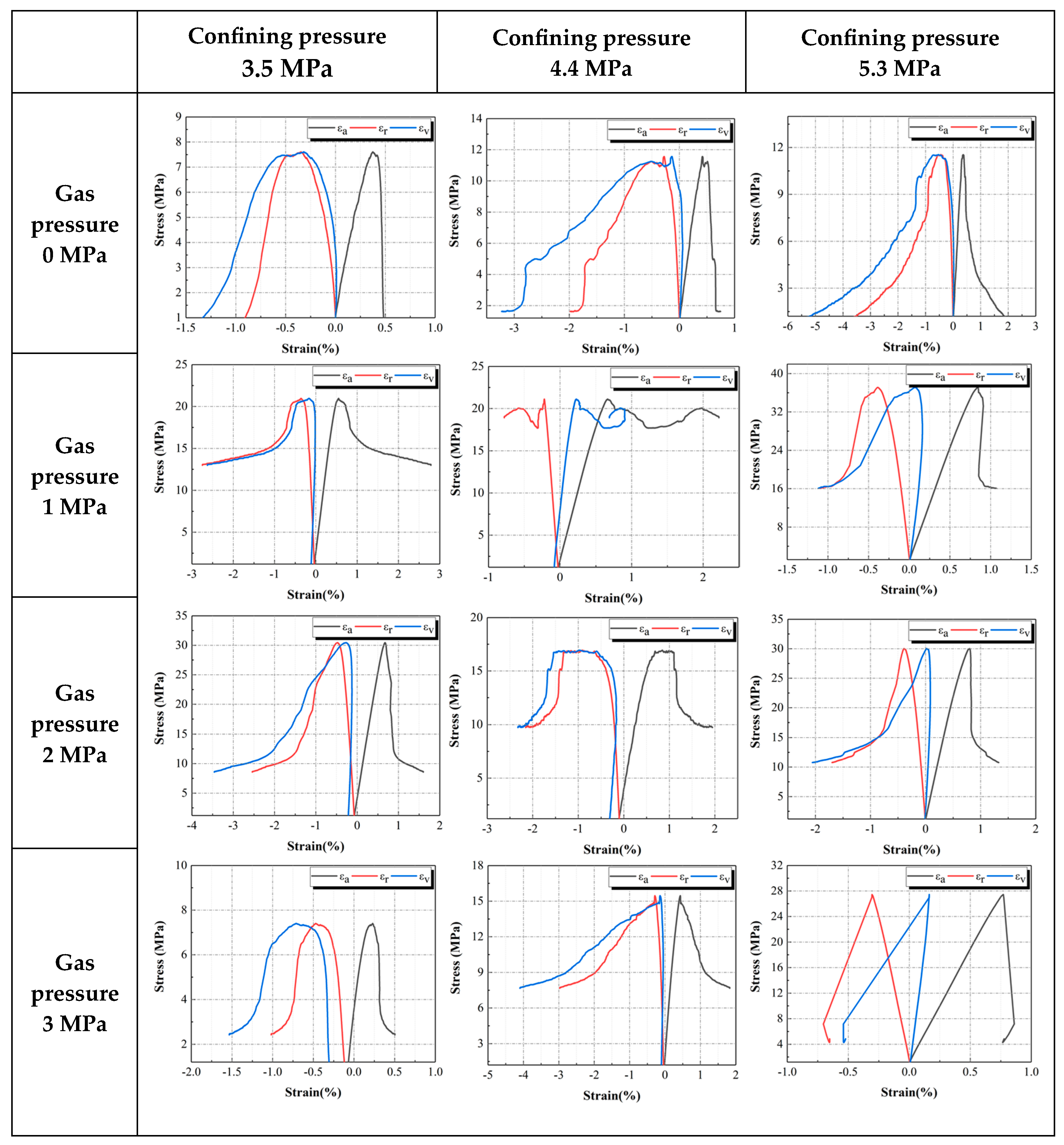

3.1. Stress–Strain Relationships and Failure Characterization

3.2. Characteristic Parameter Analysis of Damage

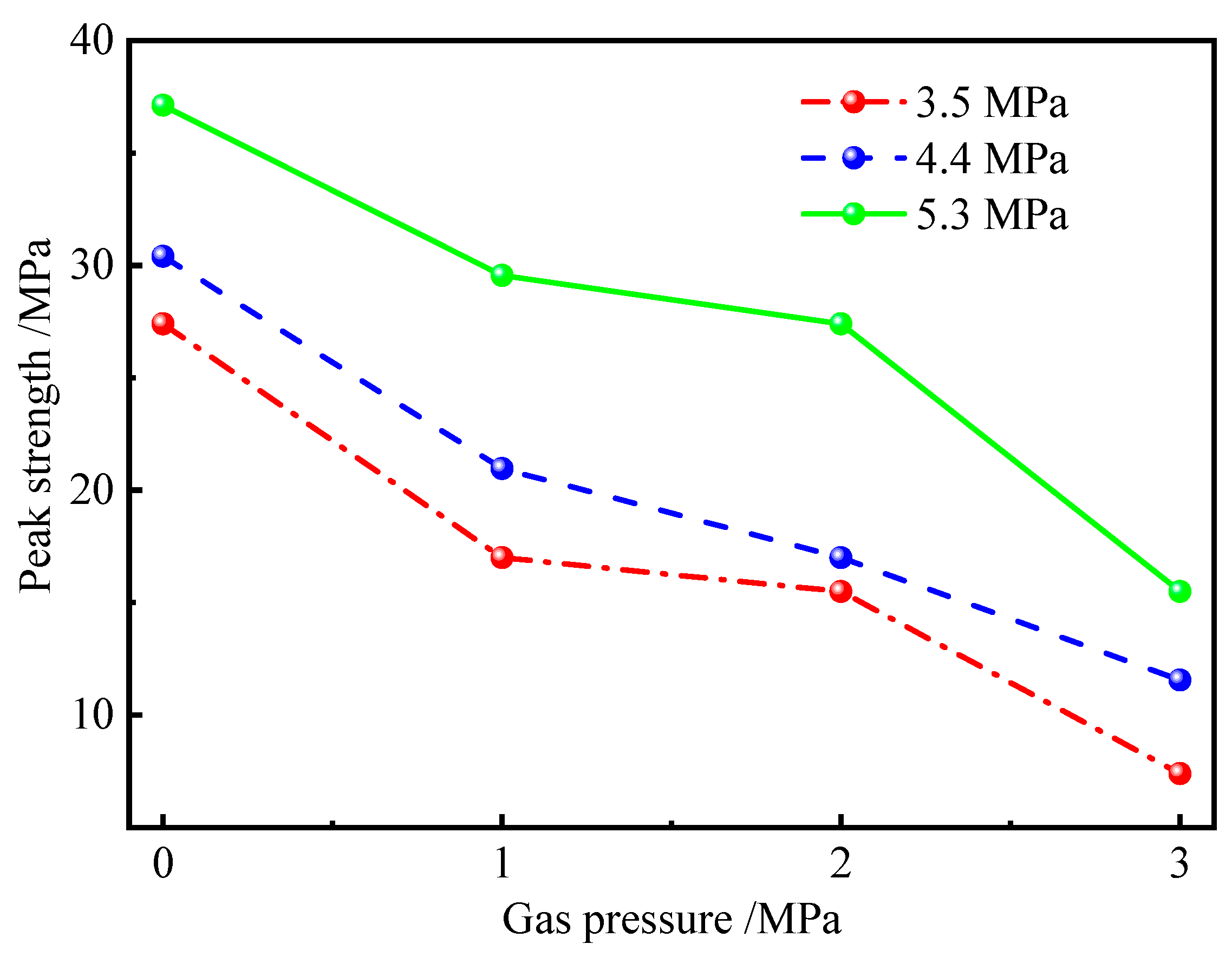

3.2.1. Peak Strength

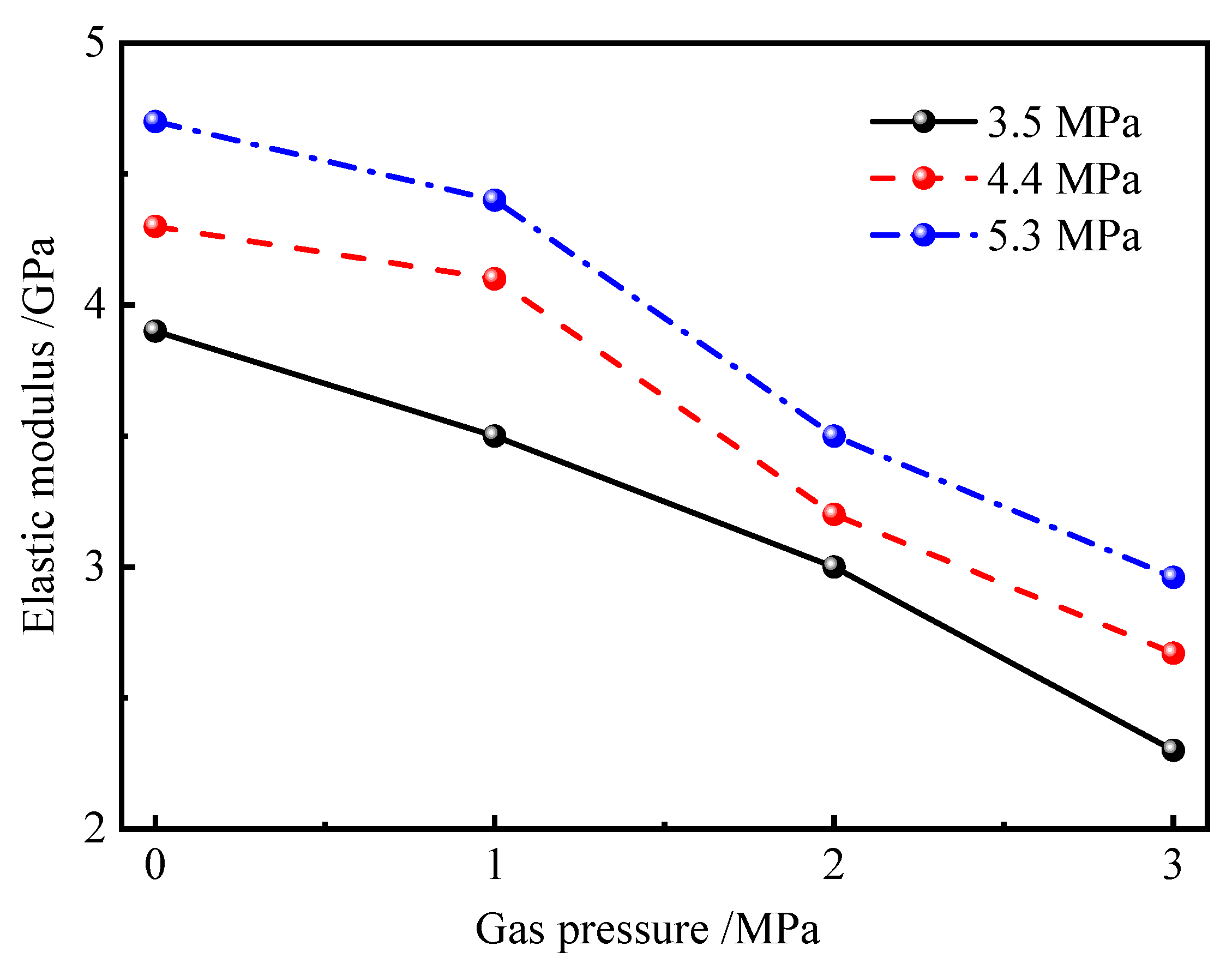

3.2.2. Elastic Modulus

3.3. Time–Frequency Evolution Analysis of AE

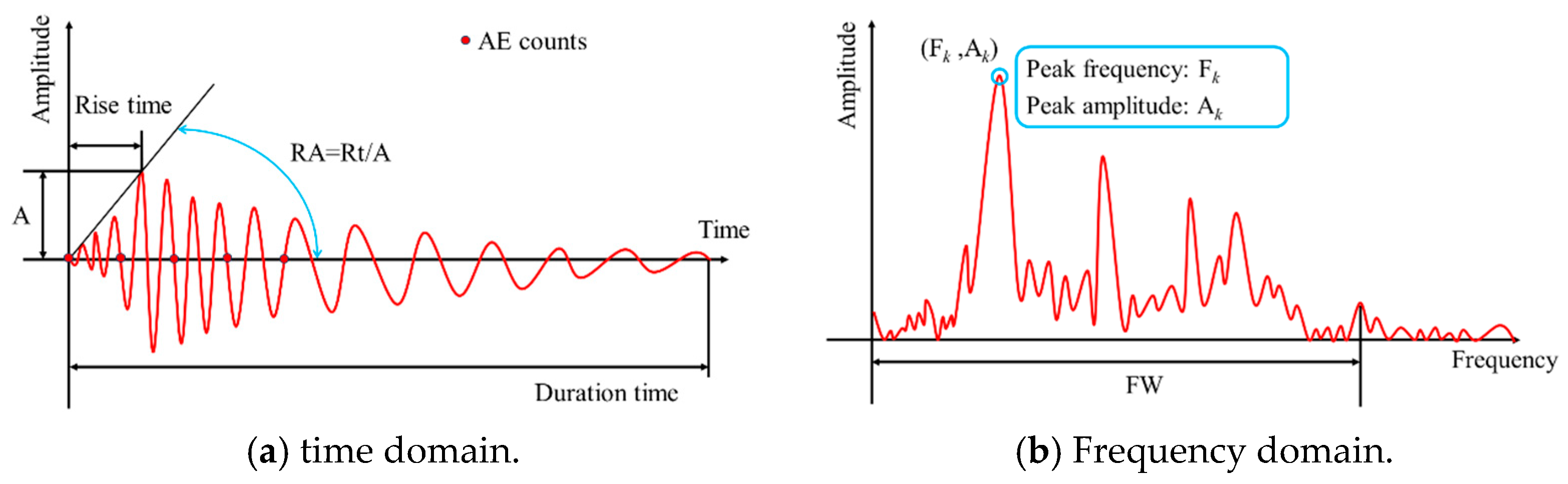

3.3.1. Introduction of AE Parameters

3.3.2. AE b-Value Analysis

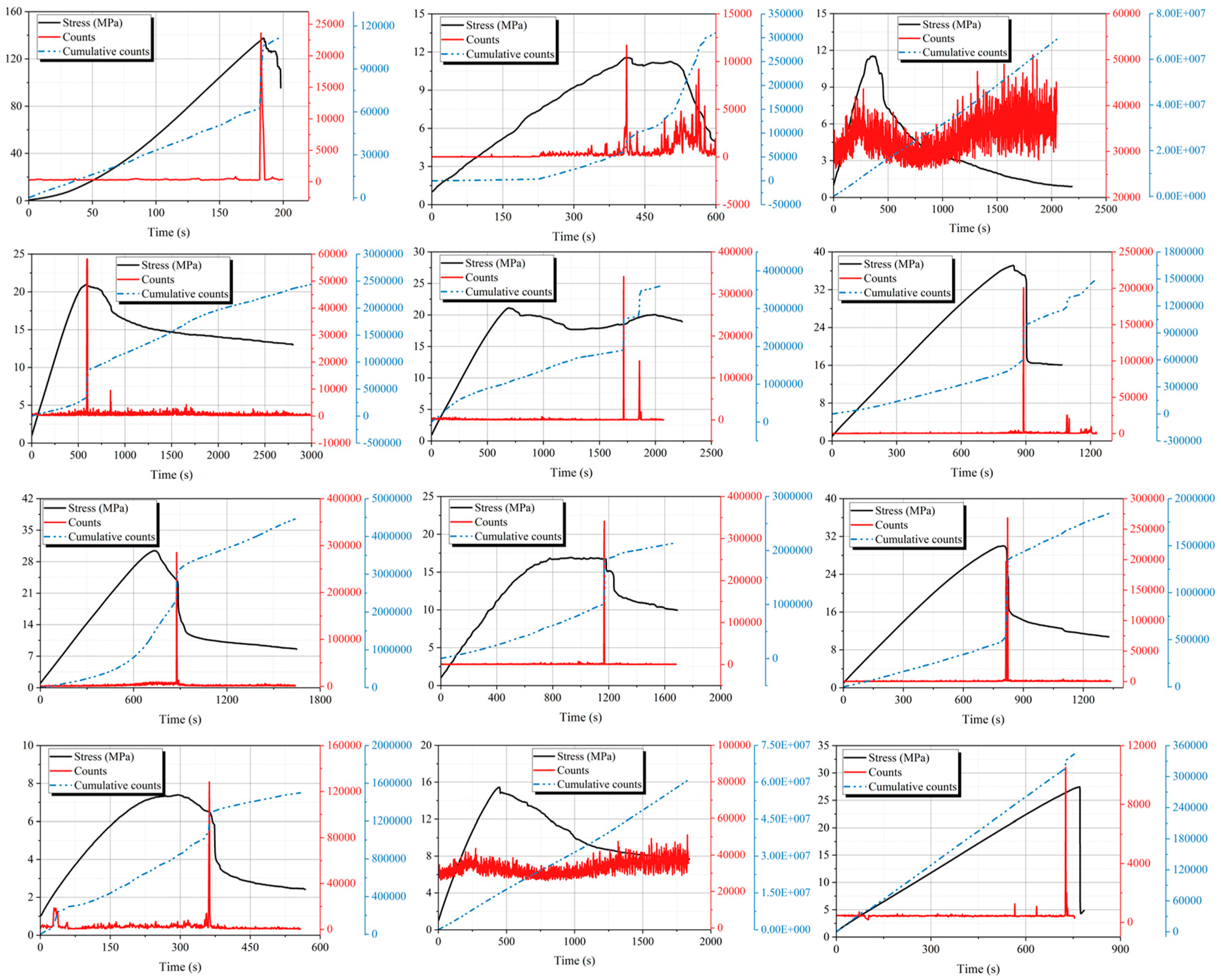

3.3.3. AE Count and Cumulative Count Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Dong, H.; Guo, Y.; Zhao, W.; Shao, B.; Yan, Z.; Wu, J.; Guan, L. Gas drainage performance evaluation in coal under non-uniform stress with different moisture content: Analysis, simulation and field verification. Fuel 2021, 305, 121489. [Google Scholar] [CrossRef]

- Yuan, L. Challenges and countermeasures for high quality development of China’s coal industry. China Coal 2020, 46, 6–12. (In Chinese) [Google Scholar]

- Meng, H.; Yang, Y.; Hou, W.; An, F.; Guo, H.; Li, X.; Wang, F.; Pang, L.; Zhang, R.; Chen, L.; et al. The role of coal strength in coal and gas outbursts. Phys. Fluids 2025, 37, 036636. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Mu, C.M.; Xu, D.K.; Li, Z.Q. Energy action mechanism of coal and gas outburst induced by rockburst. Shock Vib. 2021, 2021, 5553914. [Google Scholar] [CrossRef]

- Zhu, J.B.; Ma, B.W.; Xie, H.P.; Gao, F.; Zhou, H.W.; Zhou, C.T.; Zheng, F.R. Differences and connections between mining seismicity and coal bursts in coal mines and preliminary study on coal bursts induced by mining seismicity. J. China Coal Soc. 2022, 47, 3396–3409. (In Chinese) [Google Scholar]

- Liu, Y.; Cao, S.; Li, Y.; Guo, P.; Zhang, Z. Analysis of the Evolution of AE Sequence Correlation Dimensions During the Destruction Process of Coal Bodies Containing Methane. J. Chongqing Univ. 2012, 35, 108–114. (In Chinese) [Google Scholar]

- Cao, S.; Guo, P.; Liu, Y.; Zhang, Z.; Li, Y. Experimental study on the evolution of cracks during coal body destruction. J. China Univ. Min. Technol. 2013, 42, 725–730. (In Chinese) [Google Scholar]

- Yao, B.; Ma, Q.; Wei, J.; Ma, J.; Cai, D. Effect of protective coal seam mining and gas extraction on gas transport in a coal seam. Int. J. Min. Sci. Technol. 2016, 26, 637–643. [Google Scholar] [CrossRef]

- Chen, W.; Konietzky, H.; Tan, X.; Frühwirt, T. Pre-failure damage analysis for brittle rocks under triaxial compression. Comp. Geotech. 2016, 74, 45–55. [Google Scholar] [CrossRef]

- Zhang, M.W.; Meng, Q.B.; Liu, S.D. Energy evolution characteristics and distribution laws of rock materials under triaxial cyclic loading and unloading compression. Adv. Mater. Sci. Eng. 2017, 2017, 5471571. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.B.; Xu, J.; Gao, Z.; Chen, S.; Wang, B. Study on triaxial compression damage evolution characteristics of coal based on energy dissipation. China J. Rock Mech. Eng. 2021, 40, 1614–1627. (In Chinese) [Google Scholar]

- Liu, Y.; Yin, G.; Li, M.; Zhang, D.; Deng, B.; Liu, C.; Lu, J. Anisotropic mechanical properties and the permeability evolution of cubic coal under true triaxial stress paths. Rock Mech. Rock Eng. 2019, 52, 2505–2521. [Google Scholar] [CrossRef]

- Xu, J.K.; Zhou, R.; Song, D.Z.; Li, N.; Zhang, K.; Xi, D.Y. Deformation and damage dynamic characteristics of coal-rock materials in deep coal mines. Int. J. Damage Mech. 2017, 28, 58–78. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, M.Z.; Zhang, R.; Peng, G.Y.; Wang, W.Y.; Li, A.Q. Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Zhao, Y.; Konietzky, H.; Herbst, M. Damage evolution of coal with inclusions under triaxial compression. Rock Mech. Rock Eng. 2021, 54, 5319–5336. [Google Scholar] [CrossRef]

- Zhang, B.A.; Li, X.M.; Zhang, D.M. Study on mechanical and permeability characteristics of containing gas coal-rock under conventional triaxial compression. Geotech. Geol. Eng. 2021, 39, 5775–5786. [Google Scholar] [CrossRef]

- Xiao, Z.; Wang, C.; Wang, G.; Jiang, Y.; Yu, J. An improved apparent permeability model considering full pore pressure range, variable intrinsic permeability and slippage coefficient. Int. J. Min. Sci. Technol. 2022, 32, 1233–1244. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Z.; Wang, E.; Kong, X.; Feng, X.; Liu, Y.; Wang, D.; Zhang, C. A new method for determining coal seam permeability based on a gas–solid coupling model and PSO+ LM hybrid optimization algorithm. Nat. Resour. Res. 2023, 32, 1265–1282. [Google Scholar] [CrossRef]

- Wei, J.; Su, E.; Xu, G.; Yang, Y.; Han, S.; Chen, X.; Chen, H.; An, F. Comparative analysis of permeability rebound and recovery of tectonic and intact coal: Implications for coalbed methane recovery in tectonic coal reservoirs. Energy 2024, 301, 131702. [Google Scholar] [CrossRef]

- Tang, Y.; Li, B.; Li, J.; Ding, Y.; Zeng, X.; Cao, J. Modeling apparent permeability of coal: Incorporation of slippage effect and gas pressure decline. Phys. Fluids 2025, 37, 053605. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, K.; Du, F.; Guo, H.; Li, K.; Wang, Y. Mechanical-permeability characteristics of composite coal rock under different gas pressures and damage prediction model. Phys. Fluids 2024, 36, 036615. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, E.; Guo, Y.; Du, F.; Ding, K. Effect of loading rate on the mechanical and seepage characteristics of gas-bearing coal–rock and its mechanical constitutive model. Phys. Fluids 2024, 36, 026606. [Google Scholar] [CrossRef]

- Hu, J.; Guo, Y.; Chen, X.; Chen, X.; Yang, T. Interfacial contact characteristics and energy evolution of gas-bearing coal seams at different shear rates. Phys. Fluids 2024, 36, 096620. [Google Scholar] [CrossRef]

- Kovari, K. Suggested methods for determining the strength of rock materials in triaxial compression. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 15, 47–51. [Google Scholar]

- Qiu, X.; Xu, J.; Xu, W.; Xiao, S.; Wang, F.; Yuan, J. Characterization of fatigue damage mechanism of asphalt mixtures with acoustic emission. Constr. Build. Mater. 2020, 240, 117961. [Google Scholar] [CrossRef]

- Gutenberg, B.; Richter, C.F. Frequency of Earthquakes in California. Nature 1944, 156, 371. [Google Scholar] [CrossRef]

- Colombo, I.S.; Main, I.G.; Forde, M.C. Assessing damage of reinforced concrete beam using “b-value” analysis of acoustic emission signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, Y.; Xia, C.; Liu, H.; Xie, Q.; Zhong, Y. Influence of specimen size on granite fracture characteristics and acoustic emission phenomena under mode I loading conditions. Theor. Appl. Fract. Mech. 2023, 128, 104106. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, L.; Wan, X.; Tang, Y.; Liu, Q.; Li, W.; Liao, J. Synthesis and Characterization of a Temperature-Sensitive Microcapsule Gelling Agent for High-Temperature Acid Release. ACS Omega 2024, 9, 20849–20858. [Google Scholar] [CrossRef]

- Wibberley, C.A.J.; Yielding, G.; Di Toro, G. Recent advances in the understanding of fault zone internal structure: A review. Geol. Soc. 2008, 299, 5–33. [Google Scholar] [CrossRef]

- Goebel, T.H.W.; Becker, T.W.; Schorlemmer, D.; Stanchits, S.; Sammis, C.; Rybacki, E.; Dresen, G. Identifying fault heterogeneity through map** spatial anomalies in acoustic emission statistics. J. Geophys. Res. Solid Earth 2012, 117, B03310. [Google Scholar] [CrossRef]

- Lei, X.; Ma, S. Laboratory acoustic emission study for earthquake generation process. Earthq. Sci. 2014, 27, 627–646. [Google Scholar] [CrossRef]

| Experimental Mode | Confining Pressure (MPa) | Gas Pressure (MPa) |

|---|---|---|

| Conventional triaxial compression | 3.5 | 0 |

| 1 | ||

| 2 | ||

| 3 | ||

| 4.4 | 0 | |

| 1 | ||

| 2 | ||

| 3 | ||

| 5.3 | 0 | |

| 1 | ||

| 2 | ||

| 3 |

| ID | Feature | Units | Description |

|---|---|---|---|

| 1 | Amplitude | dB, V | The maximum voltage peak in the waveform |

| 2 | Energy | J | The measurement area of waveform envelope |

| 3 | Counts | / | The number of times the transient voltage exceeds the threshold in the duration |

| 4 | Rise time | μs | Tine from start of signal to maximum amplitude |

| 5 | Rise angle | / | tan−1 (Amplitude/Rise time) |

| 6 | RA value | V × μs−1 | Rise time/amplitude |

| 7 | Duration time | μs | Signal duration time |

| 8 | Average frequency | kHz | |

| 9 | Peak frequency | kHz | The point with the highest amplitude measured in the frequency distribution |

| 10 | Frequency centroid | kHz | |

| 11 | Initiation frequency | kHz | Average frequency from signal onset to maximum amplitude |

| 12 | Weighted peak frequency | kHz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Jiang, J.; Deng, Z.; Wang, Y.; Duan, Z.; Ren, W.; Li, Y.; Zhang, G. Measuring the Effects of Gas Pressure and Confining Pressures on Coal: In the View of Time–Frequency Evolutionary Properties and Crack Propagation Behavior. Processes 2025, 13, 2493. https://doi.org/10.3390/pr13082493

Tian Y, Jiang J, Deng Z, Wang Y, Duan Z, Ren W, Li Y, Zhang G. Measuring the Effects of Gas Pressure and Confining Pressures on Coal: In the View of Time–Frequency Evolutionary Properties and Crack Propagation Behavior. Processes. 2025; 13(8):2493. https://doi.org/10.3390/pr13082493

Chicago/Turabian StyleTian, Yufei, Junjun Jiang, Zhigang Deng, Yin Wang, Zhuoran Duan, Weiguang Ren, Yunpeng Li, and Guanghui Zhang. 2025. "Measuring the Effects of Gas Pressure and Confining Pressures on Coal: In the View of Time–Frequency Evolutionary Properties and Crack Propagation Behavior" Processes 13, no. 8: 2493. https://doi.org/10.3390/pr13082493

APA StyleTian, Y., Jiang, J., Deng, Z., Wang, Y., Duan, Z., Ren, W., Li, Y., & Zhang, G. (2025). Measuring the Effects of Gas Pressure and Confining Pressures on Coal: In the View of Time–Frequency Evolutionary Properties and Crack Propagation Behavior. Processes, 13(8), 2493. https://doi.org/10.3390/pr13082493