Abstract

Close-distance coal seam mining in Danhou coal mine has caused serious deformation in the underlying soft rock roadways. The mechanism of this type of deformation is explored through theoretical analysis and numerical simulation, and corresponding control measures are proposed. Firstly, the mechanical model of abutment stress transfer along the underlying rock stratum is established, and the analytical solution of abutment stress at any point of the underlying rock stratum is derived. Secondly, the impact of upper working face mining on the underlying soft rock roadway is investigated through numerical simulation. Subsequently, the stress distribution characteristics of the surrounding rock of the rectangular roadway and straight- wall arch roadway are compared and analyzed. Finally, a support scheme for the underlying soft rock roadway is presented and implemented in engineering practice. Field engineering application results demonstrate that, after the combined support of high-strength bolts and grouting, the average deformation on both sides of the roadway is reduced by 63.4%, and the average floor heave is decreased by 93%. This indicates that the technology effectively controls the deformation of the surrounding rock in soft rock roadways during close-distance coal seam mining.

1. Introduction

With the growing demand for coal in China, coal mines are being extended, currently reaching depths of 10 to 25 m per year [1,2,3]. This trend has resulted in the underground environment exhibiting characteristics of “three highs and one disturbance,” leading to significant issues such as large deformations of the surrounding rock in the roadway [4]. The mining of close-distance coal seams is influenced by the dynamic pressure from the adjacent working face, making the stress distribution of the surrounding rock in the roadway more complex [5,6,7].

Many experts and scholars have conducted research on the deformation mechanisms of soft rock roadways in close-distance coal seams, and a series of results have been achieved. Ru et al. [8] argued that during the mining process of close-distance coal seams, the rotation of the fractured rock stratus in the upper coal seams causes an increase in the roof stress, resulting in creep failure of the underlying roadways. Zhang et al. [9] posited that the vertical stress of the coal pillars above the close-distance coal seam mining is the most important factor for the deformation of the underlying roadways. Zhang et al. [10] evaluated the damage characteristics of the underlying rock strata after the mining of the working face above the close-distance coal seam. Wang et al. [11] found that the peak stress of the lower coal seam increases with the increase in the peak stress in the goaf of the upper coal seam. Yang et al. [12] studied the roof collapse and movement law of the overlying strata in close-distance coal seam mining. Studies on the mechanism of deformation of soft rock roadways and the technology for controlling it mostly focus on single coalface roadways, while there are relatively few studies on the special geological condition of close-distance coal seams. Therefore, the research on constructing the mechanical model of underlying roadways with mining of the upper working face is relatively scarce, and the influence of the roadway’s cross-sectional size on the surrounding rock stress remains unclear. Through mechanical analysis and numerical simulation, the influence of abutment pressure generated by upper working face mining on the surrounding rock stress of the underlying soft rock roadway is examined. The influence of the cross-sectional size of the roadways on the surrounding rock stress is studied. A combined support scheme utilizing high-strength bolts and grouting is proposed. Wei et al. [13] discovered that the mining of upper coal seams in close-distance coal seams causes different stress deflection patterns in lower coal seams. Seki et al. [14] revealed the influence characteristics of coal pillar stress on the deformation and stress distribution of the soft rock tunnel floor. Nunes and Meguid [15] studied the influence of overlying hard rock layers on the deformation of soft rock tunnels.

In recent years, scholars worldwide have carried out extensive research on the stability control of soft rock roadways in close-distance coal seams. Wu et al. [16] proposed a combined support technology of “anchor-net-spray + 36U steel frame + full-section grouting”, which effectively controlled the deformation of the surrounding rock and the expansion of the plastic zone in the soft rock roadway of the close-distance coal seam. Liu et al. [17] proposed the support technology of “cable + mud affinity material grouting reinforcement”, which improved the integrity of the surrounding rock in the soft rock roadway of the close-distance coal seam. Zhang et al. [18] proposed a new coupling support technology of “bolt-net-cable + the bolt of bottom angle + flexible layer truss” for controlling the floor heave of soft rock roadways. Sakhno [19] found that the moisture content of the surrounding rock has a significant impact on the floor heave of soft rock roadways, and the floor heave was controlled through grouting reinforcement. Tian et al. [6] adopted deep- and shallow-hole coupling grouting to control large deformation of soft rock. Wang et al. [20] controlled the large deformation of soft rock roadways through concrete-filled steel tubes.

Research on the deformation mechanism of soft rock roadways has yielded numerous findings, and significant progress has been made in the control technology for the surrounding rock. Currently, the research on the mechanism of large deformation and control technology for soft rock roadways mostly focuses on single coalface roadways, while there are relatively few studies on the special geological condition of close-distance coal seams. Therefore, the research on constructing the mechanical model of the underlying roadways with mining of the upper working face is relatively scarce, and the influence of the roadway’s cross-sectional size on the surrounding rock stress is also underexplored. Through mechanical analysis and numerical simulation, the influence of abutment pressure generated by upper working face mining on the surrounding rock stress of the underlying soft rock roadway is examined. The influence of the cross-sectional size of the roadways on the surrounding rock stress is studied. A combined support scheme utilizing high-strength bolts and grouting is proposed, yielding positive results in engineering applications.

2. Engineering Background

2.1. Working Face Overview

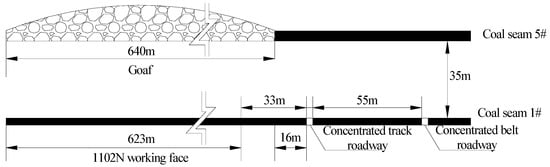

The main coal seams in the Danhou coal mine, from top to bottom, are coal seams 6#, 5#. and 1#. Currently, the coal seams 5# and 6# have been fully mined. The first mining face of the coal seam 1# is the working face, and the concentrated track roadway (CTR) is the preparation roadway for this working face. The geometric model of their relative spatial positions is shown in Figure 1. The horizontal distance between the CTR and the goaf edge of coal seam 5# is 16 m, and the horizontal distance between the CTR and the stop-mining line of coal seam 1# working face is 33 m. The distance between the coal seams 5# and 1# is 35 m.

Figure 1.

The positional relationship between the CTR and coal seam 5#. (AutoCAD 2010, Autodesk, Inc., San Francisco, CA, USA).

The working face is buried at a depth of about 400 m. The coal has a strength of 8.48 MPa and an average thickness of 3.2 m. The immediate roof is mudstone and siltstone with an average strength of 38.86 MPa and an average thickness of 7.5 m. The main roof is mudstone with a strength of 32.18 MPa and an average thickness of 16.0 m. The immediate floor is mudstone with a strength of 25.33 MPa and an average thickness of 9.3 m. The main floor is limestone with a strength of 47.71 MPa and an average thickness of 4.7 m. The clay minerals in the surrounding rock mainly include kaolinite, illite, and montmorillonite, and the absolute content of montmorillonite accounts for 38.65% of its total mineral composition. Montmorillonite has a strong water-absorbing and swelling property; therefore, 1# coal belongs to the soft rock with strong swelling properties.

2.2. Original Support and Deformation Characteristics of the Roadway

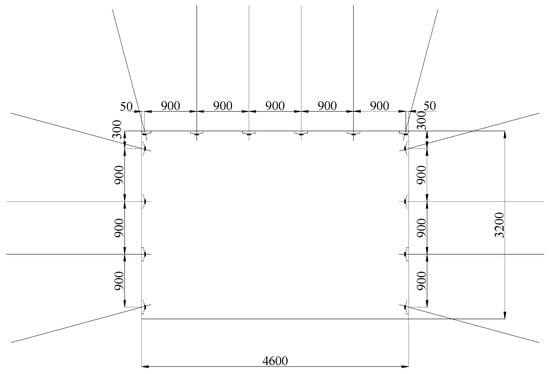

The CTR of the working face is excavated along the roof of coal 1#, and its cross-section is 4.6 × 3.2 m. The roof is supported by the bolt and steel belt, and the two sides are supported by the bolt and net. Six bolts and a 4.4 m W-shaped steel belt are installed in each row of the roof. The specification of the roof bolts is φ20 × 2200 mm. Four bolts are installed in each row at the side, with a specification of φ16 × 2000 mm. The row-and-column spacing of the bolts is 900 × 900 mm. The specific support is shown in Figure 2.

Figure 2.

Layout section of CTR of coal seam 1#.

As shown in Figure 3, after the excavation of the CTR, the local deformation on both sides is 0.4~1.5 m. Severe floor heave occurs in the floor. Generally, the deformation of the floor heave is about 1.0 m, and the local maximum deformation of the floor heave can reach 1.2 m. After re-leveling the deformed floor, the deformation of the floor heave again reached about 1.0 m within more than 10 days. The large deformation of the surrounding rock of the roadway was extremely prominent, seriously affecting the safe production and economic benefits of the coal mine.

Figure 3.

The deformation of the CTR on two sides. (a) The bolt failure; (b) the deformation of surrounding rock.

3. Deformation Mechanisms of Underlying Soft Rock Roadways in Close-Distance Coal Seam Mining

3.1. Mechanical Analysis of the Surrounding Rock of Underlying Roadways in Close-Distance Coal Seam Mining

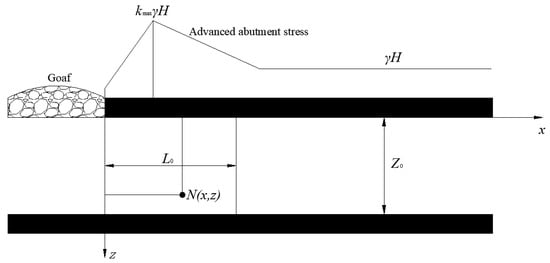

After the working face of the upper coal seam was mined, the advanced abutment stress compressed the underlying rock mass through the coal and then acted on the deep rock mass, thereby causing an abnormal increase in the stress of the surrounding rock and resulting in severe deformation and damage of the underlying roadways. Based on the relative spatial position of the coal seam, the mechanical model for stress transfer of the coal seam floor was established as shown in Figure 4.

Figure 4.

Mechanical model of the coal seam floor.

At present, the distribution functions and their ranges of abutment stress in the plastic and elastic zones have been solved by some scholars [21,22,23]. If the self-weight of the rock mass is not considered, the stress component of the abutment stress F at any point N of the floor is

where F is the abutment stress of the upper coal seam floor, MPa; σx is the horizontal normal stress, MPa; σz is the vertical normal stress, MPa; and τxz is the shear stress in the z direction, MPa.

- The calculation formula for the abutment stress in the plastic zone of the upper coal seam floor is as follows:where σxsd is the horizontal stress of the advanced abutment stress in the plastic zone at point N of the coal seam 5# floor, MPa; σzsd is the vertical stress of the advanced abutment stress in the plastic zone at point N of the coal seam 5# floor, MPa; τxzsd is the shear stress of the advanced abutment stress in the plastic zone at point N of the coal seam 5# floor, MPa; and x0 is the range of the limit balance zone of the advanced abutment stress, m.

- The calculation formula for the abutment stress in the elastic zone of the upper coal seam floor is as follows:where σxtd is the horizontal stress of the advanced abutment stress in the elastic zone at point N of the upper coal seam floor, MPa; σztd is the vertical stress of the advanced abutment stress in the elastic zone at point N of the upper coal seam floor, MPa; τxztd is the shear stress of the advanced abutment stress in the elastic zone at point N of the upper coal seam floor, MPa; and x’ is the influence range of the advanced abutment stress, m.

- The calculation formula for the abutment stress in the in situ stress zone of the upper coal seam floor is as follows:where σxyd is the horizontal stress of the abutment stress in the in situ stress zone at point N of the upper coal seam floor, MPa; σzyd is the vertical stress of the abutment stress in the in situ stress zone at point N of the upper coal seam floor, MPa; and τxzyd is shear stress of the abutment stress in the in situ stress zone at point N of the upper coal seam floor, MPa.

Based on Equations (2)–(4), the stress components generated by the advanced abutment stress in the upper coal seam floor are, respectively, as follows:

where σxcd is the horizontal stress of the advanced abutment stress at point N of the upper coal seam floor, MPa; σzcd is the vertical stress of the advanced abutment stress at point N of the upper coal seam floor, MPa; and τxzcd is shear stress of the advanced abutment stress at point N of the upper coal seam floor, MPa.

In conclusion, the calculation expressions for the vertical and horizontal stresses at any point in the upper coal seam floor under the action of the advanced abutment stress generated by coal mining are as follows:

According to the layout of the CTR and mining conditions of the upper coal seam, x0 = 10 m and x’ = 45 m, measured on the site. According to previous research results, the maximum concentration coefficient of the advanced abutment stress on the working face is generally kmax = 2–4 [24,25]. The bulk density is obtained based on experiments, and N0 = 2 MPa. kmax = 2, 3, 4, and related parameters are selected and substituted into Equation (6), respectively. The vertical stress curves at different floor depths are shown in Figure 5. It can be seen that the variations in the vertical stress distribution curves at different floor depths are similar. However, as the depth continuously increases, the influence of the advanced abutment stress on the floor continuously decreases. When the floor depth is relatively shallow, the vertical stress decreases more rapidly. With the increase in its depth, the attenuation rate of the vertical stress concentration coefficient decreases significantly. Meanwhile, as the floor depth increases, the peak point of vertical stress concentration continuously shifts away from the goaf, but the influence range of the stress does not change significantly. Therefore, when the close-distance coal seams are mined, in order to reduce the influence of mining dynamic stress in the upper coal seam, the layout depth of the roadway in the lower coal seam should be increased, and the distance between it and the edge of the goaf should also be increased.

Figure 5.

Vertical stress at different floor depths. (a) kmax = 2; (b) kmax = 3; (c) kmax = 4. (Origin2017, OriginLab, Northampton, MA, USA).

3.2. Numerical Analysis of Surrounding Rock of Underlying Roadways in Close-Distance Coal Seam Mining

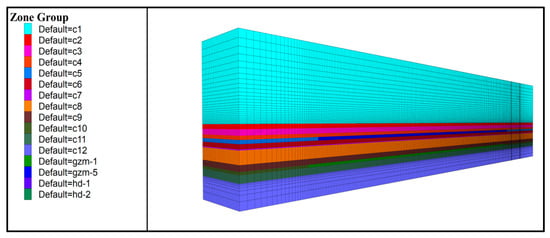

The FLAC3D numerical model was established based on the geological conditions of the working face, as shown in Figure 6. The size of the model (length × width × height) is 947 × 100 × 200 m. The model is divided into 12 layers, with a total of 973,236 nodes and 931,200 hexahedral elements, and the Mohr–Coulomb model is selected. An equivalent load of 6.075 MPa is applied at its top to simulate the weight of the overlying rock. The lateral stress coefficient of the model is 1.8, and the horizontal stress is 10.935 MPa. The horizontal displacements around the front, back, left, and right of the model and the three-directional displacements at the bottom boundary are constrained. In order to enhance the calculation accuracy of the numerical simulation, the mesh of the soft rock roadway is encrypted. The mesh size (length × width × height) of the roadway key area is 0.5 × 1.0 × 0.8 m. The mesh size of the other rock layer is 1.0 × 1.0 × 0.8 m. The rock mass strength parameters are shown in Table 1.

Figure 6.

Numerical model. (FLAC3D6.0, Itasca Consulting Group, Inc., Minneapolis, MN, USA).

Table 1.

The mechanical parameters of rock mass.

In order to reveal the deformation characteristics of the surrounding rock in the CTR, two working conditions were designed for the simulation experiment, as shown in Table 2. In working condition 1, the working face of coal seam 5# has not been mined, while the working face of coal seam 1# and the CTR have been excavated. In working condition 2, the working face of coal seam 5# has been mined, the working face of coal seam 1# and the CTR have been excavated. The horizontal distances between the CTR and the goaf edge of coal seam 5# are L0 = 6 m, 16 m, and 26 m, respectively (L0 = 16 m is the actual position of the CTR), and the vertical distances between it and coal seam 5# above are all 35 m. The comparison of working conditions 1 and 2 can reveal the difference in deformation characteristics of the CTR under the two conditions of mining and un-mining in the working face of coal seam 5#, so as to reveal the influence characteristics of the abutment stress generated by the mining in the working face of coal seam 5# on the deformation of the CTR.

Table 2.

Working conditions of numerical simulation.

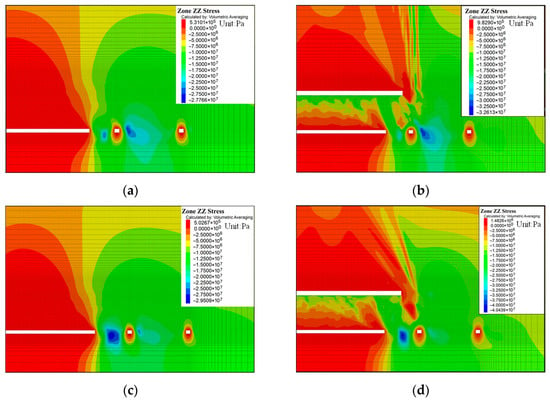

3.2.1. Vertical Stress Distribution of Surrounding Rock in the CTR Under Different Working Conditions

Cloud maps for the vertical stress of the surrounding rock of the CTR under different working conditions are shown in Figure 7. Before the coal seam 5# was mined, the mining influence of coal seam 1# has led to an increase in stress concentration on both sides of the CTR. The maximum stress concentration coefficients of the working conditions 1-1, 1-2, and 1-3 reached 2.70, 2.49, and 2.44, respectively, which were 1.78 to 1.98 times that before the mining of coal seam 1#. Hence, the concentrated stress on both sides of the CTR is asymmetrically distributed, and the mining influence of the coal seam 1# leads to a sudden increase in stress concentration on both sides of the CTR.

Figure 7.

The vertical stress cloud maps under different working conditions: (a) 1-1; (b) 2-1; (c) 1-2; (d) 2-2; (e) 1-3; (f) 2-3.

After the coal seam 5# was mined, the mining influence of the coal seam 1# led to a further increase in stress concentration on both sides of the CTR. Under the working conditions of 2-1, 2-2 and 2-3, the maximum stress concentration coefficients on both sides of the CTR are 3.20, 3.15 and 3.28, respectively, which are 1.7 to 2.0 times that before the mining of coal seam 1#. Therefore, the superimposed effect of the abutment stress formed by the mining of the coal seam 5# is significant.

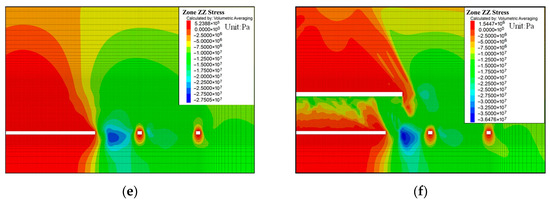

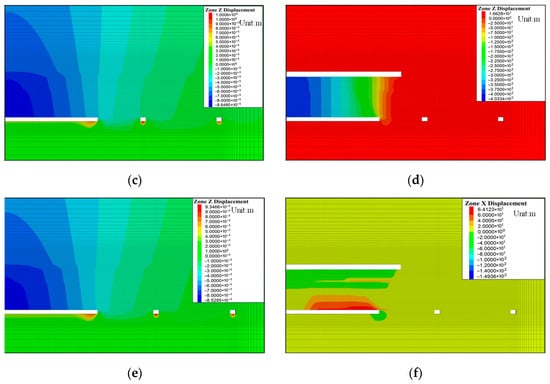

3.2.2. Vertical Displacement Distribution of Surrounding Rock in the CTR Under Different Working Conditions

As shown in Figure 8, under the condition 1-1, the maximum displacements of the roof, floor and the left and right sides of the CTR are 321 mm, 1120 mm, 844 mm and 643 mm, respectively. Compared with working condition 1-1, the roof displacement of the CTR in working conditions 1-2 and 1-3 decreased by 25.5% and 40.8%, respectively, the floor displacement decreased by 10.9% and 16.7%, respectively, the left side displacement decreased by 18.7% and 29.5%, respectively, and the right side displacement decreased by 16.5% and 25.2%, respectively. From the above data, it can be seen that without the mining influence of coal seam 5#, the convergence of the surrounding rock of the CTR shows an asymmetric feature. The floor displacement of the CTR is greater than that of the roof, and the displacement on the left side is greater than that on the right side.

Figure 8.

Cloud maps of vertical displacement of surrounding rock in the CTR under different working conditions: (a) 1-1; (b) 2-1; (c) 1-2; (d) 2-2; (e) 1-3; (f) 2-3.

Under the working condition 2-1, the maximum displacement of the left side of the CTR is 2781 mm, the right side is 923 mm, the roof is 951 mm, and the floor is 2784 mm. Compared with working conditions 2-1, the roof displacement of the CTR in working conditions 2-2 and 2-3 decreased by 47.1% and 70.8%, respectively, the floor displacement decreased by 26.0% and 60.1%, respectively, the left side displacement decreased by 38.8% and 73.4%, respectively, and the right side displacement decreased by 21.0% and 38.0%, respectively. Hence, under the mining influence of coal seam 5#, the convergence of the two sides and the roof to floor of the CTR shows a more obvious asymmetry.

Combined with the stress distribution characteristics, as the width of the coal pillar between the CTR and the goaf of the working face increases, significant changes occur in the stress and deformation on both sides of the CTR. This indicates that, under the mining influence of the coal seam 5#, the mine pressure in the CTR is more significant, and the deformation of the surrounding rock increases, manifested as severe floor heave and severe deformation on both sides, while the deformation of the roof is not prominent. Therefore, controlling the deformation of the surrounding rock in the CTR should focus on the floor and both sides.

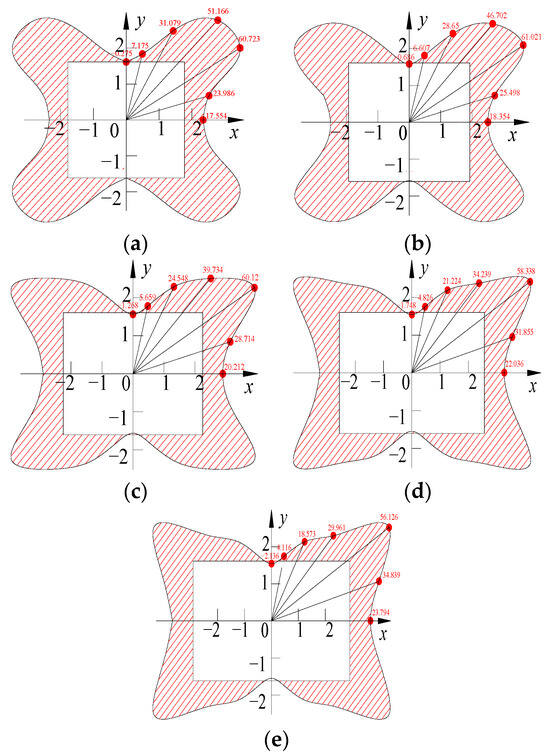

3.3. The Influence of Roadway Section Size on Surrounding Rock

Suppose the roadway is subjected to bidirectional unequal compressive stress, and the in situ stress of the horizontal and vertical directions is uniformly distributed [26]. The length of the roadway in the Z-axis direction is much larger than that in the other two directions. The force state is not considered. Therefore, the force situation at any section of the roadway is simplified to an axisymmetric planar stress problem [11,27,28]. The general mapping formula for the third-order conformal transformation of rectangular roadways is as follows [29]:

Finally, the calculation formula for the tangential stress around the rectangular roadway is obtained as follows:

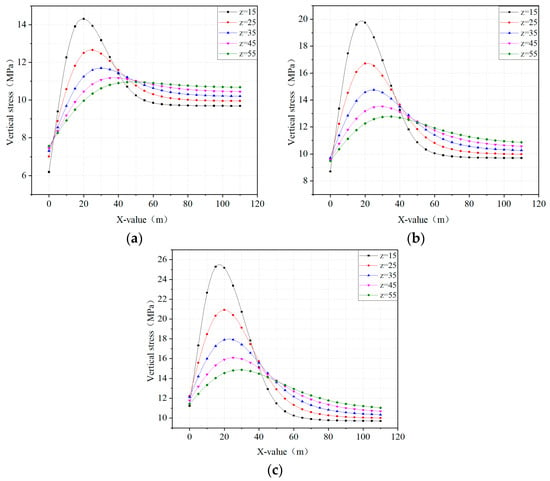

To study the influence of the cross-sectional size of the roadway on the stress distribution characteristics of the surrounding rock, the height of the roadway is fixed as 3.2 m, the lateral pressure coefficient λ is taken as 1.8, and the width-to-height ratios are 1.0, 1.2, 1.4, 1.6 and 1.8, respectively. Then, the values of R, c1 and c3 of the mapping function under different width-to-height ratios can be obtained. The corresponding values are submitted into Equation (8) to calculate the tangential stress at each point around the rectangular roadways with different width-to-height ratios when the λ is 1.8. Thus, the stress distribution maps of the surrounding rock of the rectangular roadways with different width-to-height ratios are drawn, as shown in Figure 9.

Figure 9.

The tangential stress distribution characteristics of the surrounding rock in roadways with different width-to-height ratios: (a) 1.0; (b) 1.2; (c) 1.4; (d) 1.6; (e) 1.8.

It can be known from this that the tangential stress around the rectangular roadway is closely related to the cross-sectional size of the roadway. When the λ is 1.8, the stress around rectangular roadways with different width-to-height ratios further increases. Tensile stress is generated in the middle of the roof and floor of the rectangular roadways, indicating that tensile failure has occurred here. The tensile stress increases with the increase in the width-to-height ratios. The roof angle and bottom angle, as well as the two sides, are in the compressive state. The compressive stress at the roof angle and bottom angle is greater than that at the two sides due to stress concentration. The compressive stress of both sides is greater than the in situ stress. When the width-to-height ratio is 1.0, it is 17.554 MPa; when the width-to-height ratio is 1.8, it is 23.794 MPa, with an increase of 35.5%. When the λ is 1.8, tensile stress occurs in the roof and floor, indicating that the λ has a significant influence on the stability of the roadway.

3.4. Analysis of the Main Controlling Factors for the Failure of Underlying Soft Rock Roadways in Close-Distance Coal Seam Mining

Combined with the geological conditions and mining conditions of the Danhou coal mine, through the analysis of mine pressure theory and mechanics, the main controlling factors of the failure of the CTR were found to be the following:

- (1)

- In situ stress

In situ stress is a necessary condition for the deformation of surrounding rock and the fundamental driving force for the deformation and failure of roadways. In addition, the roadway is affected by the high mining stress of the coal seam 5#, resulting in a relatively high stress concentration, which eventually leads to large deformation of the roadway.

- (2)

- The properties of surrounding rock

The properties of surrounding rock are the fundamental factors for the stability of the roadways. The floor of the CTR is thick-layered argillaceous soft rock, and the two sides are soft coal with low strength and weak thin interlayers. Therefore, the floor and two sides of CTR have become the weak links in the bearing structure of the surrounding rock.

- (3)

- Cross-section size

The size of the roadway section is an important factor affecting the stability of the roadway. Under the same conditions, the larger the roadway span, the higher the stress concentration degree on both sides of the roadway, and the wider the abutment stress distribution range. When the abutment stress exceeds the strength of the surrounding rock, it will inevitably lead to the failure of the surrounding rock.

To sum up, the floor of the CTR in coal seam 1# is thick-layered argillaceous soft rock, and the two sides are soft coal. The top and bottom corners of the rectangular roadways are affected by stress concentration and its compressive stresses are the largest. The abutment stress generated by the mining of coal seam 5# is transmitted to the CTR, resulting in a significant increase in its abutment stress. Multiple factors j ointly cause severe deformation of the surrounding rock in the CTR.

4. Research on Control Strategies for Underlying Soft Rock Roadways in Close-Distance Coal Seam Mining

4.1. Section Optimization Scheme for Soft Rock Roadways

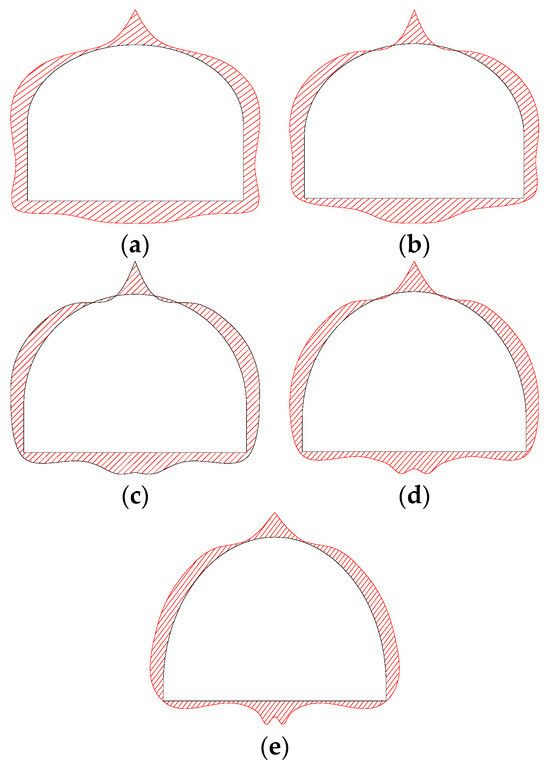

According to the deformation mechanisms of the underlying soft rock roadways in close-distance coal seam mining, it was initially believed that the rectangular roadways are not suitable for the geological conditions of the specific stress environment of coal seam 1#. Therefore, the tangential stress distribution law and surrounding rock stability of straight-wall arch roadways were studied.

Similarly to the calculation method of rectangular roadways, a mechanical model of bidirectional unequal pressure in the straight-wall arch roadways was established, and its conformal mapping function was determined [30,31,32]. The height of the roadway is 3.2 m, and the width-to-height ratios are 1.0, 1.2, 1.4, 1.6 and 1.8, respectively. When the λ is 1.8, the tangential stresses at each point around the roadway with different width-to-height ratios are calculated; the stress distribution of the surrounding rock of the roadway with different width-to-height ratios is shown in Figure 10.

Figure 10.

Tangential stress distribution characteristics of surrounding rock in the straight-wall arch roadways with different width-to-height ratios: (a) 1.0; (b) 1.2; (c) 1.4; (d) 1.6; (e) 1.8.

The tangential stress of the straight-wall arch roadways varies significantly near the roof and the floor. Especially within the range of 0° to 30° of the roof, the decrease in the tangential stress is relatively large. The tangential stress at the bottom angle and on both sides increases with the increase in the width-to-height ratios. Near the middle of the roadway floor, different changes in the tangential stress occur with the increase in the width-to-height ratios. When the width-to-height ratio is 1.0, the tangential stress in the middle of the floor is greater than that on both sides. When the width-to-height ratios are 1.4–1.8, the stress in the middle of the floor is less than that on both sides. When the width-to-height ratio is 1.2, the floor is subjected to uniform force and the tangential stress is relatively small.

Compared with rectangular roadways, the stability of straight-wall arch roadways is better, the tangential stress on the surrounding rock is smaller, and the stress concentration at the roof and on both sides is significantly improved. At the same time, it can avoid the tensile stress state of the floor. For roadways with a large lateral pressure coefficient and weak floor, straight-wall arch roadways are easier to maintain.

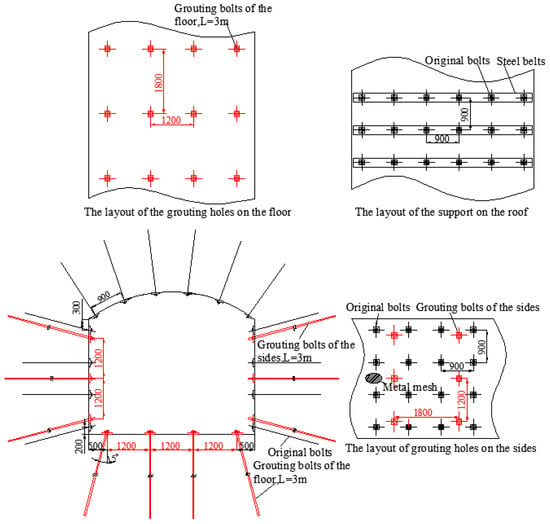

4.2. Support Optimization Scheme for Soft Rock Roadways

Low rock strength is the main factor for the severe deformation of the surrounding rock in the CTR [33]. Under the influence of high in situ stress, the fractures of the surrounding rock expand. The sliding of the fractured rock blocks cause their volume expansion [14]. Therefore, improving the stength of the surrounding rock in the roadway can significantly increase the stability of the roadway. Studies show that anchoring and grouting can effectively improve the mechanical properties of the surrounding rock, thereby reducing the deformation of the roadway [15,34,35]. Grouting can fill the joints and fissures in the surrounding rock and bond the rock masses on both sides of the structural plane together, thereby enhancing its strength. High prestressed support can suppress the discontinuous deformation of the surrounding rock in the anchoring area and reduce the reduction in the surrounding rock strength.

Based on the deformation mechanisms of the CTR, a technical scheme for optimizing the surrounding rock control of soft rock roadways is proposed. The shape of the roof is adjusted from the rectangle to circular-arc arch shape. The roof is supported by a combined approach of “high-strength bolts + steel belts”. The two sides adopt “high-strength bolts + metal meshes” as the basic support and “bolts + grouting” as the reinforcing support. Six bolts and a 4.8 m W-shaped steel strip are driven into each row of the roof. The bolts adopt φ22 × 2200 mm high preload bolts, with a preload of 100–120 kN and a spacing of 900 × 900 mm. Four bolts are driven into each row of the sides, and their models are the same as those on the roof. The side reinforcement support adopts φ25 × 3000 mm hollow grouting bolts, with a spacing of 1200 × 1800 mm. Three grouting bolts are arranged on each row of the two sides. The floor support adopts φ25 × 3000 mm hollow grouting bolts, with a spacing of 1200 × 1800 mm between grouting holes. Four grouting bolts are arranged in each row. The specific support is shown in Figure 11.

Figure 11.

Layout of support method of concentrated track roadway of coal seam 1#.

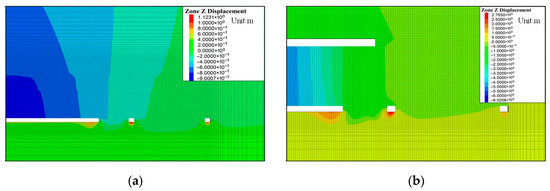

4.3. Numerical Analysis of the Optimization Scheme

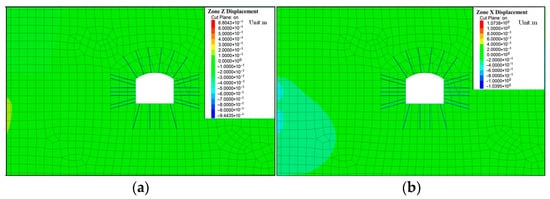

The FLAC3D numerical simulation was adopted to determine the rationality of the optimization scheme. The simulation results are shown in Figure 12. When this optimization scheme is adopted, the displacements of the roof and floor of the roadway are 81 mm and 96 mm, respectively, and the relative displacement of the two sides of the roadway is 187 mm. It can be seen that the optimization scheme meets the technical requirements of the mine, and this scheme is determined as the on-site engineering test scheme.

Figure 12.

Displacement of surrounding rock in the roadway: (a) vertical displacement; (b) horizontal displacement.

4.4. Monitoring Results of Deformation of Surrounding Rock

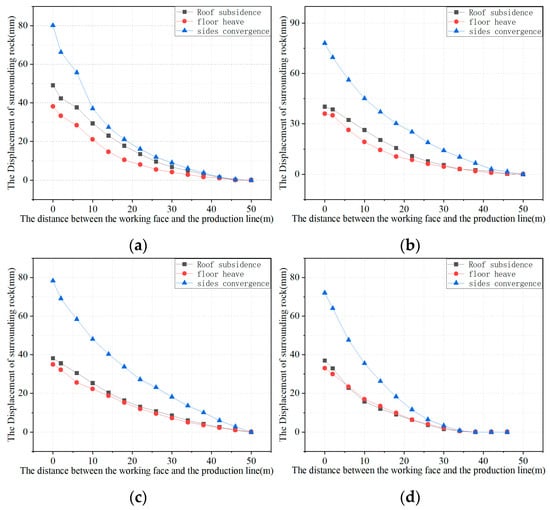

To evaluate the control effect of the optimization scheme on the surrounding rock of the roadway, the cross-point layout method was adopted to monitor the surface displacement of the roadway. A total of four monitoring stations were arranged in the CTR. The observation results of the surrounding rock deformation at each monitoring station are shown in Figure 13.

Figure 13.

Observation results of surrounding rock deformation: (a) Monitoring station 1#; (b) monitoring station 2#; (c) monitoring station 3#; (d) monitoring station 4#.

From station 1 to station 4, the average displacement of the roof is 41 mm, the average displacement of both sides is 75.5 mm, and the average displacement of the floor is 35.5 mm. Under the condition of new control technology for the surrounding rock, the average deformation on both sides of the CTR is reduced by 63.4%, and the average floor heave is reduced by 93.0%. The control effect of the surrounding rock of the roadway is remarkable. This indicates that this technology can effectively control the deformation of the surrounding rock of the CTR.

5. Conclusions

Based on the relative spatial geometric model of close-range coal seams in Danhou coal mines, a mechanical model for stress transfer from advanced support of the bottom plate in the goaf was established, and the law of support stress transfer was studied. Through numerical simulation, the stress distribution characteristics of the surrounding rock of close-to-roof (CTR) roadways were clarified. A technical implementation plan for high-strength, high-prestressed anchor bolt support and grouting reinforcement support was proposed, and on-site tests were conducted. The main conclusions are as follows:

- By considering the engineering geological conditions of the Danhou coal mine, a mechanical model of advance abutment stress transfer along the goaf floor was established. The theoretical analytical solution for vertical stress and horizontal stress at any point of the floor under the influence of advance abutment stress in close-distance coal seam mining was provided.

- The increase in abutment stress of the floor due to advance abutment stress transfer along the floor of the 5# coal seam resulted in further stress concentration of the surrounding rock of CTR in the 1# coal seam, leading to floor bulging and significant deformation on both sides.

- Numerical simulation results revealed significant changes in the stress and deformation of the surrounding rock with increasing distance between CTR and the goaf. The stress distribution exhibited an asymmetric–symmetric–asymmetric pattern, while the deformation showed an asymmetric distribution pattern that gradually decreased.

- The monitoring results of surrounding rock deformation demonstrated a 63.4% reduction in average deformation on both sides of CTR and a 93% decrease in average floor heave after implementing the new support scheme. This indicates that the technology effectively controls the deformation of the surrounding rock in soft rock roadways.

Author Contributions

Y.B.: conceptualization, data curation, writing—original draft. Y.L.: data curation, formal analysis. F.X.: conceptualization, formal analysis. L.Z.: data curation, formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kang, H.; Yang, J.; Jiang, P.; Gao, F.; Li, W.; Li, J.; Chen, H. Theory, technology and application of grouted bolting in soft rock roadways of deep coal mines. Int. J. Miner. Met. Mater. 2024, 31, 1463–1479. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, E.; Guo, Y.; Du, F.; Ding, K. Effect of loading rate on the mechanical and seepage characteristics of gas-bearing coal–rock and its mechanical constitutive model. Phys. Fluids 2024, 36, 026606. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, X.; Li, W.; Du, F.; Ma, J.; Qian, R.; Huo, N. Research on abutment stress distribution of roof–cutting coalface: Numerical simulation and field measurement. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 86. [Google Scholar] [CrossRef]

- Guo, Z.; Li, W.; He, M.; You, J.; Li, Y. Model test on failure mechanisms of deep high-stress soft rock roadways based on excavation compensation method. Eng. Fail. Anal. 2024, 160, 108161. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Guo, J.; Zhao, H. Experimental research on deformation failure process of roadway tunnel in fractured rock mass induced by mining excavation. Environ. Earth Sci. 2022, 81, 243. [Google Scholar] [CrossRef] [PubMed]

- Tian, M.; Gao, X.; Zhang, A.; Han, L.; Xiao, H. Study on the deformation failure mechanism and coupling support technology of soft rock roadways in strong wind oxidation zones. Eng. Fail. Anal. 2023, 156, 107840. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, K.; Du, F.; Guo, H.; Li, K.; Wang, Y. Mechanical-permeability characteristics of composite coal rock under different gas pressures and damage prediction model. Phys. Fluids 2024, 36, 0199545. [Google Scholar] [CrossRef]

- Ru, W.; Hu, S.; Ning, J.; Wang, J.; Gu, Q.; Guo, Y.; Zuo, J.; Wu, B. Study on the Rheological Failure Mechanism of Weakly Cemented Soft Rock Roadway during the Mining of Close-Distance Coal Seams: A Case Study. Adv. Civ. Eng. 2020, 2020, 8885849. [Google Scholar] [CrossRef]

- Zhang, J.; Zhuo, Q.; Yang, S.; Yang, T.; Wang, B.; Bai, W.; Wu, J.; Xie, S. Study on the Coal Pillar Weakening Technology in Close Distance Multi-Coal Seam Goaf. Energies 2022, 15, 6532. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, M.; Bai, J.; Yan, S.; Yu, X. Stability control of gob-side entry retained under the gob with close distance coal seams. Int. J. Min. Sci. Technol. 2021, 31, 321–332. [Google Scholar] [CrossRef]

- Wang, C.; Yao, H.; Huang, Y. Stability control of goaf-driven roadway surrounding rock under interchange remaining coal pillar in close distance coal seams. Energy Sci. Eng. 2024, 12, 2553–2567. [Google Scholar] [CrossRef]

- Yang, S.L.; Li, Q.; Yue, H.; Kong, D.Z.; Wu, G.Y.; Liu, F.Q. Study on Roof Deformation and Failure Law of Close Distance Coal Seams Mining Based on Digital Image Correlation. Exp. Tech. 2024, 48, 1005–1026. [Google Scholar] [CrossRef]

- Wei, X.-X.; Zhao, Z.-Q.; Wang, Y.-W.; Wang, X.-H.; Hui, Z.-L. Study on the law of stress distribution in the presence of remaining coal pillar in a close-distance coal seam and the reasonable location of the roadway. Sci. Rep. 2025, 15, 8737. [Google Scholar] [CrossRef]

- Seki, S.; Kaise, S.; Morisaki, Y.; Azetaka, S.; Jiang, Y. Model experiments for examining heaving phenomenon in tunnels. Tunn. Undergr. Space Technol. 2008, 23, 128–138. [Google Scholar] [CrossRef]

- Nunes, M.; Meguid, M. A study on the effects of overlying soil strata on the stresses developing in a tunnel lining. Tunn. Undergr. Space Technol. 2009, 24, 716–722. [Google Scholar] [CrossRef]

- Wu, J.; Jiao, J.; Zhou, S. Controlling large deformations in soft rock roadways with integrated anchor shotcrete and grouting techniques. Sci. Rep. 2024, 14, 28339. [Google Scholar] [CrossRef]

- Liu, Y.; Qiu, W.; Duan, D. Using Energy-Absorbing Dampers to Solve the Problem of Large Deformation in Soft-Rock Tunnels: A Case Study. Energies 2022, 15, 1916. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, T.-B.; Zhang, X.-T. Stability analysis and deformation control method of swelling soft rock roadway adjacent to chambers. Géoméch. Geophys. Geo-Energy Geo-Resour. 2023, 9, 91. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S. Numerical studies of floor heave mechanism and the effectiveness of grouting reinforcement of roadway in soft rock containing the mine water. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2023, 170, 105484. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, S.; Han, L.; Liu, Y.; Xue, B.; Li, J. Application research on composite support technology of concrete-filled steel tube support in high stress and large deformation soft rock roadway: A case study. Structures 2024, 60, 105814. [Google Scholar] [CrossRef]

- Li, W.; Guo, Y.; Liu, X.; Du, F.; Li, G.; Ma, Q. Failure mechanisms and reinforcement support of roadway in deep coal seam: A case study. Eng. Fail. Anal. 2024, 165, 108745. [Google Scholar] [CrossRef]

- Chen, Z.-Q.; He, C.; Wang, J.; Ma, C.-C. Time-dependent squeezing deformation mechanism of tunnels in layered soft-rock stratum under high geo-stress. J. Mt. Sci. 2021, 18, 1371–1390. [Google Scholar] [CrossRef]

- Liu, D.; Wang, F.; Hu, Q.; Huang, H.; Zuo, J.; Tian, C.; Zhang, D. Structural responses and treatments of shield tunnel due to leakage: A case study. Tunn. Undergr. Space Technol. 2020, 103, 103471. [Google Scholar] [CrossRef]

- Suchowerska, A.; Merifield, R.; Carter, J. Vertical stress changes in multi-seam mining under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2013, 61, 306–320. [Google Scholar] [CrossRef]

- Guo, Z.; Li, W.; Yin, S.; Yang, D.; Ma, Z. An Innovative Technology for Monitoring the Distribution of Abutment Stress in Longwall Mining. Energies 2021, 14, 475. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Zhang, D.; Yang, K.; Li, X.; Wang, D.; Li, Y. Experimental study of effect of liquid nitrogen cold soaking on coal pore structure and fractal characteristics. Energy 2023, 275, 127470. [Google Scholar] [CrossRef]

- Bai, Y.; Xin, H.; Xie, B.; Shen, K.; Yan, Y. Research on the interfacial bonding performance of novel composite L-shaped concrete-filled steel tubes. Struct. Des. Tall Spéc. Build. 2024, 33, e2108. [Google Scholar] [CrossRef]

- Lu, W.; Meng, L.; Li, S.; Xu, Y.; Wang, L.; Zhang, P.; Dou, S.; Sun, H. Study on progressive failure behavior and mechanical properties of tunnel arch support structures. Tunn. Undergr. Space Technol. 2023, 140, 105285. [Google Scholar] [CrossRef]

- Yang, W.; Wang, M.; Zhou, Z.; Li, L.; Yuan, Y.; Gao, C. A true triaxial geomechanical model test apparatus for studying the precursory information of water inrush from impermeable rock mass failure. Tunn. Undergr. Space Technol. 2019, 93, 105285. [Google Scholar] [CrossRef]

- Kusui, A.; Villaescusa, E.; Funatsu, T. Mechanical behaviour of scaled-down unsupported tunnel walls in hard rock under high stress. Tunn. Undergr. Space Technol. 2016, 60, 30–40. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, C.; Duan, K.; Zhang, Z.; Xiang, W. True Three-Dimensional Geomechanical Model Tests for Stability Analysis of Surrounding Rock During the Excavation of a Deep Underground Laboratory. Rock Mech. Rock Eng. 2019, 53, 517–537. [Google Scholar] [CrossRef]

- Zhu, G.-Q.; Feng, X.-T.; Zhou, Y.-Y.; Li, Z.-W.; Fu, L.-J.; Xiong, Y.-R. Physical Model Experimental Study on Spalling Failure Around a Tunnel in Synthetic Marble. Rock Mech. Rock Eng. 2019, 53, 909–926. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Chen, M.; Fang, G.; Wang, Y.-C.; Meng, B.; Li, Y.-H.; Jing, H.-W. Physical experiment and numerical modelling of tunnel excavation in slanted upper-soft and lower-hard strata. Tunn. Undergr. Space Technol. 2018, 82, 248–264. [Google Scholar] [CrossRef]

- Li, L.; Shang, C.; Chu, K.; Zhou, Z.; Song, S.; Liu, Z.; Chen, Y. Large-scale geo-mechanical model tests for stability assessment of super-large cross-section tunnel. Tunn. Undergr. Space Technol. 2021, 109, 103756. [Google Scholar] [CrossRef]

- Xu, G.; Wang, B.; Ma, G.; Du, J.; Chen, X.; Hou, Z. Study on the damage evolutional process of secondary tunnel lining under rheological effect of surrounding rock. Eng. Fail. Anal. 2022, 142, 103756. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).