Design and Fabrication of Customizable Urban Furniture Through 3D Printing Processes

Abstract

1. Introduction

2. The Role of Customization in Public Space Design

2.1. The Need for Adaptable, User-Centric Urban Environments and the Role of Customization in Enhancing Accessibility and Inclusivity

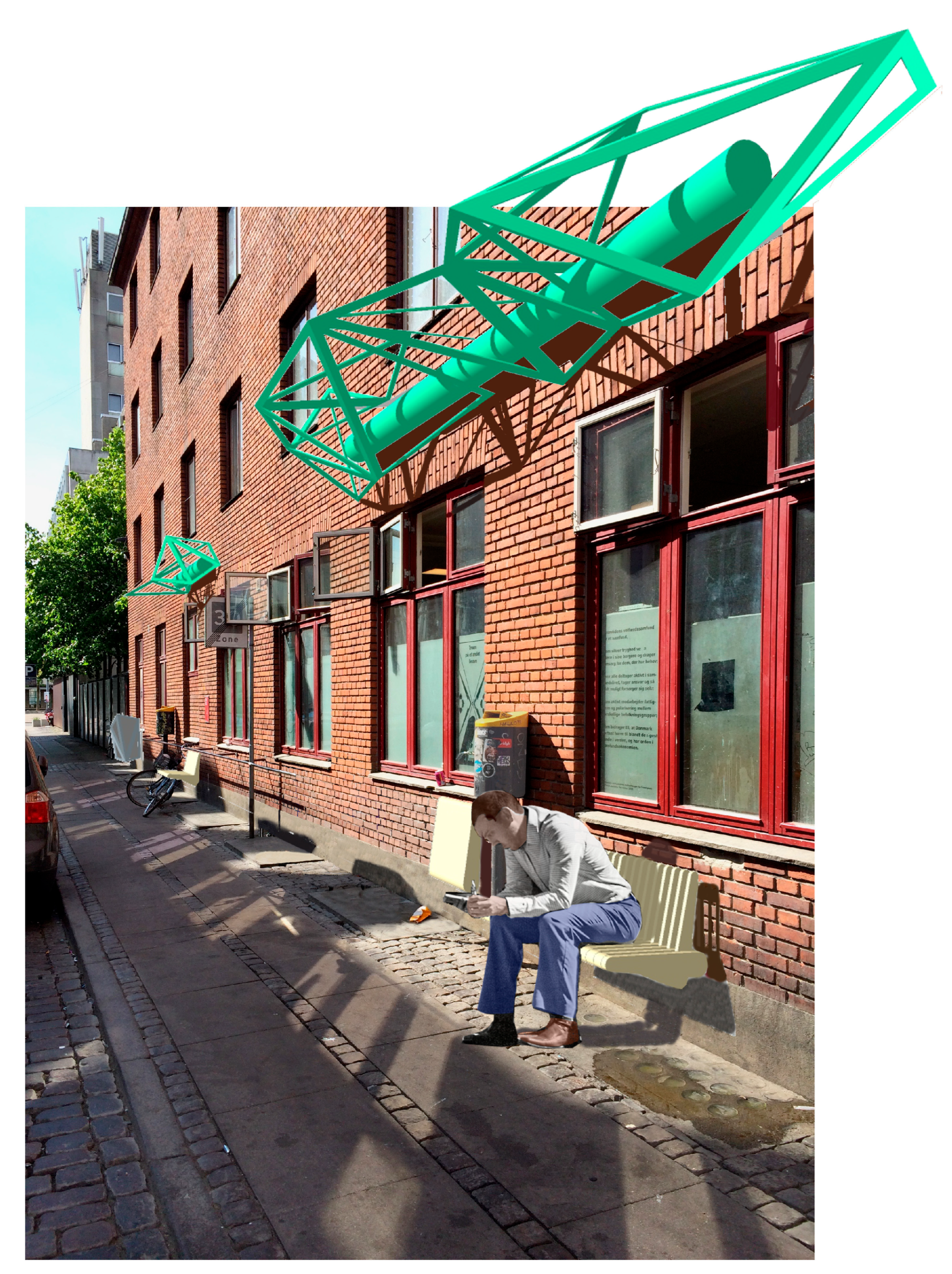

2.2. Case Studies on Community-Driven Design Approaches

3. Three-Dimensional Printing Technologies for Urban Furniture Fabrication

3.1. Overview of Additive Manufacturing Techniques Relevant to Urban Furniture

3.2. Comparison of FDM, SLA, SLS, and Other Methods for Large-Scale Production

3.3. Advancements in Hybrid Manufacturing for Structural Integrity

4. Materials for 3D-Printed Urban Furniture

4.1. Sustainable and Eco-Friendly Materials

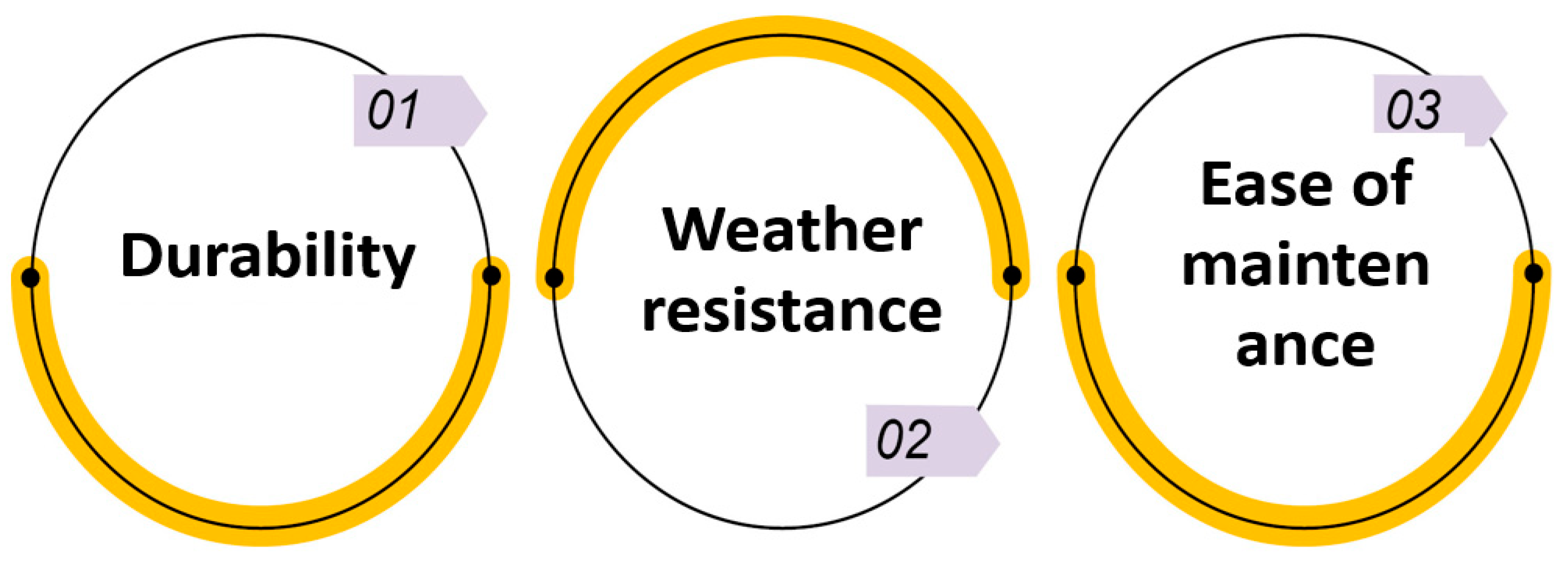

4.2. Performance Characteristics

4.3. Innovations in Smart and Self-Healing Materials for Public Use

5. Innovations in Post-Processing Techniques

5.1. Ergonomics and Comfort

5.2. Aesthetic and Cultural Integration

5.3. Modularity and Scalability

5.4. Challenges and Mitigation Strategies

6. Implementation and Real-World Applications

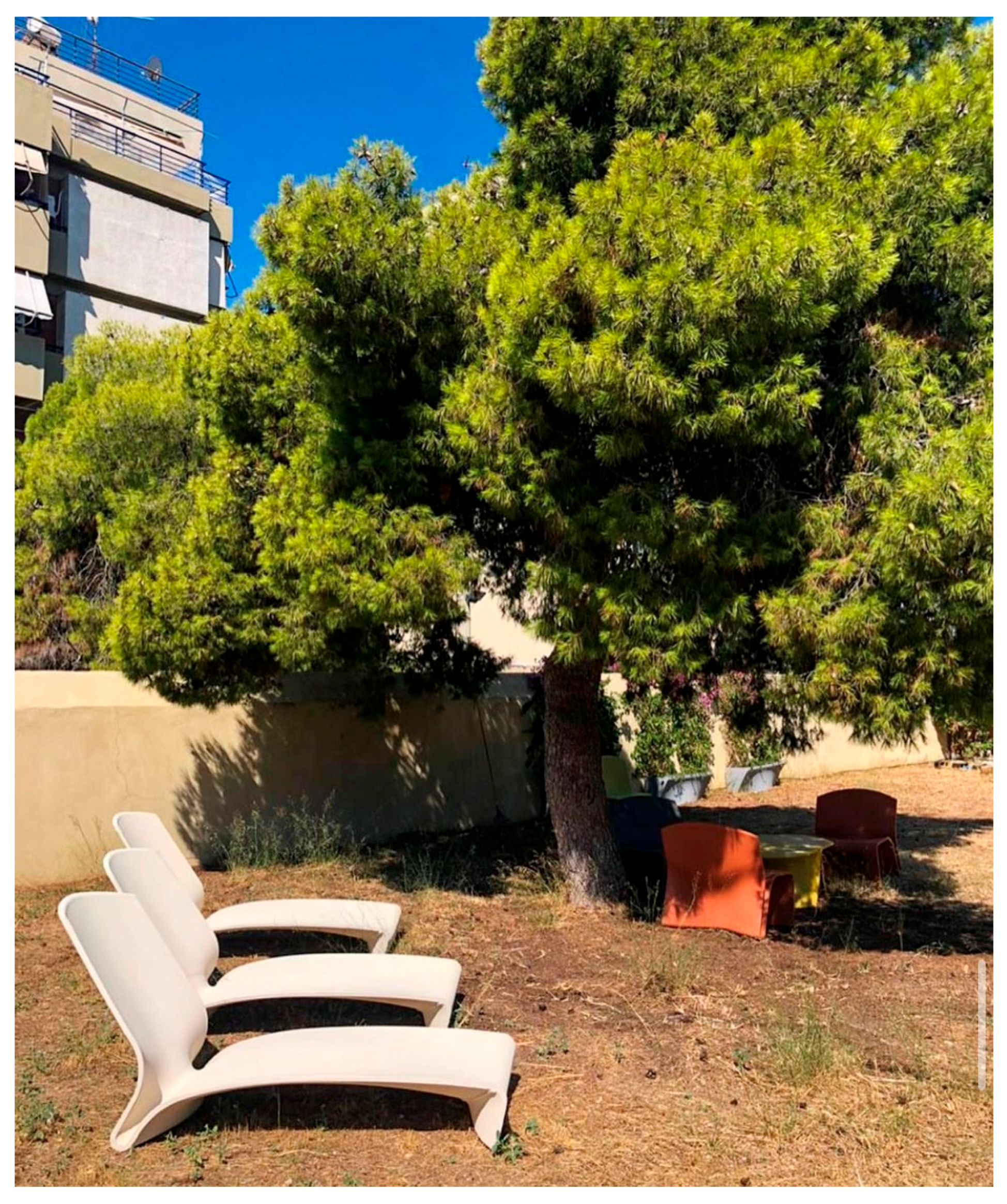

6.1. Case Studies of Cities Adopting 3D-Printed Urban Furniture

6.2. Benefits for Rapid Prototyping and Iterative Design Improvements

6.3. Stakeholder Involvement: Municipalities, Designers, and Community Participation

7. Challenges and Future Directions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bolkaner, M.K.; İnançoğlu, S.; Asilsoy, B. A Study on Urban Furniture: Nicosia Old City. Eur. J. Sustain. Dev. 2019, 8, 1. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Łacka, A.; Wiza, W. Material, Functional, and Aesthetic Solutions for Urban Furniture in Public Spaces. Sustainability 2022, 14, 16211. [Google Scholar] [CrossRef]

- Fusaro, G.; D’Alessandro, F.; Baldinelli, G.; Kang, J. Design of Urban Furniture to Enhance the Soundscape: A Case Study. Build. Acoust. 2018, 25, 61–75. [Google Scholar] [CrossRef]

- Siu, K.W.M. Pleasurable Products: Public Space Furniture with Userfitness. J. Eng. Des. 2005, 16, 545–555. [Google Scholar] [CrossRef]

- Rinaldi, A.; Viviani, S.; Busciantella-Ricci, D. Urban Furniture Design Strategies to Build Healthy and Inclusive Neighborhoods. Sustainability 2025, 17, 859. [Google Scholar] [CrossRef]

- Sipahi, S.; Sipahi, M. Raw Material Stage Assessment of Seating Elements as Urban Furniture and Eco-Model Proposals. Sustainability 2024, 16, 4163. [Google Scholar] [CrossRef]

- Uslu, E.; Bölükbaşı, A.E. Urban Furniture in Historical Process. J. Hist. Cult. Art Res. 2019, 8, 425. [Google Scholar] [CrossRef]

- Askarizad, R.; He, J. The Role of Urban Furniture in Promoting Gender Equality and Static Social Activities in Public Spaces. Ain Shams Eng. J. 2025, 16, 103250. [Google Scholar] [CrossRef]

- Arruda, A.; Moroni, I.; Bezerra, P.; Silva, P.; de Paiva, R.B.F. Practical Urban: The Urban Furniture and Its Relationship with the City. In Advances in Ergonomics Modeling, Usability & Special Populations; Springer International Publishing: Cham, Switzerland, 2017; pp. 413–423. ISBN 9783319416847. [Google Scholar]

- Yasar, D. Urban Furniture in the Framework of Economic, Social, and Environmental Sustainability. Str. Art Urban Creat. 2023, 9, 74–80. [Google Scholar] [CrossRef]

- Srinivas, D.; Boddepalli, U.; Dey, D.; Choaudhary, B.; Panda, B.; Sitharam, T.G.; Ranjani, G.I.S. Development of Outdoor Furniture Using 3D Concrete Printing. In Research and Innovation for Sustainable Development Goals; Springer Nature: Singapore, 2024; pp. 51–61. ISBN 9789819758692. [Google Scholar]

- Petrova, B.; Jivkov, V. Application of 3D Printing Technology in Furniture Construction. Materials 2024, 17, 4848. [Google Scholar] [CrossRef]

- Kim, S.; Shin, Y.; Park, J.; Lee, S.-W.; An, K. Exploring the Potential of 3D Printing Technology in Landscape Design Process. Land 2021, 10, 259. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D Printing: Making an Innovative Technology Widely Accessible through Makerspaces and Outsourced Services. Mater. Today 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Romani, A.; Rognoli, V.; Levi, M. Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability 2021, 13, 7269. [Google Scholar] [CrossRef]

- Antreas, K.; Piromalis, D. Employing a Low-Cost Desktop 3D Printer: Challenges, and How to Overcome Them by Tuning Key Process Parameters. Int. J. Mech. Appl. 2021, 10, 11–19. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 3D and 4D Printing as Integrated Manufacturing Methods of Industry 4.0. Am. J. Eng. Appl. Sci. 2023, 16, 12–22. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Zhou, L.; Xu, J.; Wang, J.; Sang, Z. Progress of Standardization of Urban Infrastructure in Smart City. Standards 2022, 2, 417–429. [Google Scholar] [CrossRef]

- Derrible, S. Urban Infrastructure Is Not a Tree: Integrating and Decentralizing Urban Infrastructure Systems. Environ. Plan. B Urban Anal. City Sci. 2017, 44, 553–569. [Google Scholar] [CrossRef]

- Kantaros, A.; Zacharia, P.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations. Appl. Sci. 2025, 15, 3719. [Google Scholar] [CrossRef]

- Siu, K.W.M.; Wong, K.S.L. Flexible Design Principles: Street Furniture Design for Transforming Environments, Diverse Users, Changing Needs and Dynamic Interactions. Facilities 2015, 33, 588–621. [Google Scholar] [CrossRef]

- Susanto, D.; Ilmiani, A.N. Flexible Furniture: A Design Strategy for Multiuse yet Limited Space in the Urban Kampung. In Proceedings of the 2018 2nd International Conference on Smart Grid and Smart Cities (ICSGSC), Kuala Lumpur, Malaysia, 12–14 August 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Schraml, C.; Färber, M. Reviving Public Space through Socially Sustainable Urban Furniture. UXUC User Exp. Urban Creat. 2024, 6, 72–87. [Google Scholar] [CrossRef]

- van Hees, M.; Oskam, I.; Bocken, N. Motives, Drivers and Barriers to Urban Upcycling: Insights from Furniture Upcycling in the Netherlands. J. Clean. Prod. 2025, 486, 144485. [Google Scholar] [CrossRef]

- Al-Saud, K.; AlAli, R.; Al saud, A.; Abouelela, A.; Shehab, R.; Moneim, D.; Hamid, A. Exploring the Aesthetic and Functional Aspects of Recycled Furniture in Promoting Sustainable Development: An Applied Approach for Interior Design Students. Sustainability 2024, 16, 4003. [Google Scholar] [CrossRef]

- Pei, X.; Italia, M.; Melazzini, M. Enhancing Circular Economy Practices in the Furniture Industry through Circular Design Strategies. Sustainability 2024, 16, 6544. [Google Scholar] [CrossRef]

- Urban, W.; Łukaszewicz, K.; Krawczyk-Dembicka, E. Development Process of Customised Products, Supported by Technologies, a Case of Tailor-Made Furniture. In Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 90–104. ISBN 9783030993092. [Google Scholar]

- Gómez-Carmona, O.; Sádaba, J.; Casado-Mansilla, D. Enhancing Street-Level Interactions in Smart Cities through Interactive and Modular Furniture. J. Ambient Intell. Humaniz. Comput. 2022, 13, 5419–5432. [Google Scholar] [CrossRef]

- Gulten, A.; Yildirim, B.; Unal, M. Analysis of the Historically Compatibility of AI-Assisted Urban Furniture Design Using the Semantic Differentiation Method: The Case of Elazığ Harput. Sustainability 2025, 17, 3402. [Google Scholar] [CrossRef]

- Gómez-Carmona, O.; Casado-Mansilla, D.; López-de-Ipiña, D. Multifunctional Interactive Furniture for Smart Cities. Proceedings 2018, 2, 1212. [Google Scholar] [CrossRef]

- Itair, M.; Shahrour, I.; Hijazi, I. The Use of the Smart Technology for Creating an Inclusive Urban Public Space. Smart Cities 2023, 6, 2484–2498. [Google Scholar] [CrossRef]

- Klaus, P.; Edwards, K.; Norvik, D.; Manthiou, A.; Luong, V.H. Inclusive Servicescapes: The Imperative of Universal Design Principles. J. Serv. Mark. 2024, 38, 1089–1098. [Google Scholar] [CrossRef]

- Hanna, I.; Parvaresh, P. Investigating AI’s Role in Enhancing Multi-Sensory Experiences in Public Spaces. Acad. Res. Community Publ. 2024, 8, 12–30. [Google Scholar] [CrossRef]

- De Siqueira, G.; Malaj, S.; Hamdani, M. Digitalization, Participation and Interaction: Towards More Inclusive Tools in Urban Design—A Literature Review. Sustainability 2022, 14, 4514. [Google Scholar] [CrossRef]

- Szaszák, G.; Kecskés, T. Universal Open Space Design to Inform Digital Technologies for a Disability-Inclusive Place-Making on the Example of Hungary. Smart Cities 2020, 3, 1293–1333. [Google Scholar] [CrossRef]

- Culturally Enriched Communities Have a Seat: Participatory Design from an Architect’s Point of View—The Men’s Home. Available online: https://cec-design.com/have-a-seat-participatory-design-from-an-architects-point-of-view-the-mens-home/ (accessed on 23 April 2025).

- File:Mændenes Hjem.Jpg—Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:M%C3%A6ndenes_hjem.jpg (accessed on 23 April 2025).

- Sobral, L. Co-Created Street Furniture as a Catalyst for Urban Culture and Public Life. Available online: https://www.hackingurbanfurniture.net/fileadmin/user_upload/HUF/Research/HUF%20article%20%E2%80%93%20Co-created%20Street%20Furniture%20as%20a%20Catalyst%20for%20Urban%20Culture%20and%20Public%20Life%20%20%282%29.pdf (accessed on 23 April 2025).

- Carra, M.; Levi, N.; Sgarbi, G.; Testoni, C. From Community Participation to Co-Design: “Quartiere Bene Comune” Case Study. J. Place Manag. Dev. 2018, 11, 242–258. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Kantaros, A.; Katsantoni, M.; Ganetsos, T.; Petrescu, N. The Evolution of Thermoplastic Raw Materials in High-Speed FFF/FDM 3D Printing Era: Challenges and Opportunities. Materials 2025, 18, 1220. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Soulis, E.; Petrescu, F.I.T.; Ganetsos, T. Advanced Composite Materials Utilized in FDM/FFF 3D Printing Manufacturing Processes: The Case of Filled Filaments. Materials 2023, 16, 6210. [Google Scholar] [CrossRef]

- Przekop, R.E.; Konieczna, R.; Głowacka, J.; Sztorch, B.; Głowacki, M.; Kotecka, B. 3D Printing in Art: Use of Thermoplastics and Ceramics—The Current State and Limitations Resulting from the Possibilities of Technology. Prog. Addit. Manuf. 2025, 10, 5851–5881. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process Phenomena and Material Properties in Selective Laser Sintering of Polymers: A Review. Materials 2021, 15, 183. [Google Scholar] [CrossRef]

- Arrigo, R.; Frache, A. FDM Printability of PLA Based-Materials: The Key Role of the Rheological Behavior. Polymers 2022, 14, 1754. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Singh, S.; Kaur, D.; Singh, M.; Balu, R.; Mehta, A.; Vasudev, H. Challenges and Issues in Manufacturing of Components Using Polymer-Based Selective Laser Sintering (SLS): A Review. Int. J. Interact. Des. Manuf. (IJIDeM) 2024. [Google Scholar] [CrossRef]

- Sebbe, N.P.V.; Fernandes, F.; Sousa, V.F.C.; Silva, F.J.G. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals 2022, 12, 1874. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. Current Trends and Research Opportunities in Hybrid Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 623–648. [Google Scholar] [CrossRef]

- Kurniawan, B.K.; Ezran, M.; Pramono, A.; Pratomo, A.; Maulana, F.I.; Mohamed, M. IoT in the Development of Smart Furniture Prototypes for Confined Urban Residential Areas: A Systematic Review. In Proceedings of the 2024 International Conference on Informatics, Multimedia, Cyber and Information System (ICIMCIS), Jakarta, Indonesia, 20–21 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 283–288. [Google Scholar]

- Kantaros, A.; Bimis, A.; Karalekas, D. In Situ Characterization of Residual Strains in Layered Manufacturing. In Proceedings of the 5th International Conference on Materials Integrated Non Destructive Testing (IC-MINDT-2013), Athens, Greece, 20–22 May 2013. [Google Scholar]

- Puzatova, A.; Shakor, P.; Laghi, V.; Dmitrieva, M. Large-Scale 3D Printing for Construction Application by Means of Robotic Arm and Gantry 3D Printer: A Review. Buildings 2022, 12, 2023. [Google Scholar] [CrossRef]

- Patel, R.; Desai, C.; Kushwah, S.; Mangrola, M.H. A Review Article on FDM Process Parameters in 3D Printing for Composite Materials. Mater. Today 2022, 60, 2162–2166. [Google Scholar] [CrossRef]

- Mróz, A.; Szymański, M.; Koch, P.; Pawlicki, M.; Meller, A.; Przekop, R.E. The Influence of Surface Texture of Elements Made of PA6-Based Composites on Anti-Graffiti Effect of Paint Coating. Materials 2024, 17, 1951. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-Curing 3D Printing Technique and Its Challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Manoj Prabhakar, M.; Saravanan, A.K.; Haiter Lenin, A.; Jerin leno, I.; Mayandi, K.; Sethu Ramalingam, P. A Short Review on 3D Printing Methods, Process Parameters and Materials. Mater. Today 2021, 45, 6108–6114. [Google Scholar] [CrossRef]

- Natarajan, J.; Cheepu, M.; Yang, C.-H. (Eds.) Advances in Additive Manufacturing Processes; Bentham Science: Sharjah, United Arab Emirates, 2021; ISBN 9789815036336. [Google Scholar]

- Yehia, H.M.; Hamada, A.; Sebaey, T.A.; Abd-Elaziem, W. Selective Laser Sintering of Polymers: Process Parameters, Machine Learning Approaches, and Future Directions. J. Manuf. Mater. Process. 2024, 8, 197. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.; Ungureanu, L.; Munteanu, I. Post-Production Finishing Processes Utilized in 3D Printing Technologies. Processes 2024, 12, 595. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Ruiz, J.E.; Ukar, E.; Lamikiz, A. Latest Developments in Industrial Hybrid Machine Tools That Combine Additive and Subtractive Operations. Materials 2018, 11, 2583. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.; Shi, J.; Tian, H.; Zhao, Y. Evaluation and Optimization of a Hybrid Manufacturing Process Combining Wire Arc Additive Manufacturing with Milling for the Fabrication of Stiffened Panels. Appl. Sci. 2017, 7, 1233. [Google Scholar] [CrossRef]

- Grzesik, W.; Ruszaj, A. Hybrid Manufacturing Processes: Physical Fundamentals, Modelling and Rational Applications; Springer Nature: Cham, Switzerland, 2021; ISBN 9783030771065. [Google Scholar]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid Processes in Additive Manufacturing. J. Manuf. Sci. Eng. 2018, 140, 060801. [Google Scholar] [CrossRef]

- Cruz, P.; Figueiredo, B.; Oliveira, I.; Lopes, J.V.; Freitas, P. A New Breed of Sustainable Augmented Urban Furniture. Designing for Extrusion-Based Additive Manufacturing. Available online: https://www.cees2023.uc.pt/projectos/cees2023/atas/pdfs/ID074.pdf (accessed on 23 April 2025).

- Valette, E.; El-Haouzi, H.B.; Demesure, G.; Boucinha, V. Toward an Anthropocentric Approach for Hybrid Control Architectures: Case of a Furniture Factory. In Service Orientation in Holonic and Multi-Agent Manufacturing; Springer International Publishing: Cham, Switzerland, 2019; pp. 145–155. ISBN 9783030030025. [Google Scholar]

- Ma, J.; Li, Z.; Zhao, Z.-L.; Xie, Y.M. Creating Novel Furniture through Topology Optimization and Advanced Manufacturing. Rapid Prototyp. J. 2021, 27, 1749–1758. [Google Scholar] [CrossRef]

- Zeyin, S.; Jinghan, Q.; Hao, Z.; Shu, X. Human-Centered Generative AI Framework in Intelligent Construction: A Case Study on Furniture Manufacturing Design. Available online: https://publications.ibpsa.org/proceedings/asim/2024/papers/P09_asim2024_1220.pdf (accessed on 23 April 2025).

- Wiederspahn, P.; Kana, P. Furniture Urbanism: A Pedagogy for Fabrication and Social Engagement. Empower 2022. [Google Scholar] [CrossRef]

- Zhu, Z.; Dhokia, V.G.; Nassehi, A.; Newman, S.T. A Review of Hybrid Manufacturing Processes—State of the Art and Future Perspectives. Int. J. Comput. Integr. Manuf. 2013, 26, 596–615. [Google Scholar] [CrossRef]

- Meyer, K. Next Generation Small Urban Manufacturing: Apprentices’ Perspective on Location Factors, Mixed-Use, and Shared Spaces. Urban Plan. 2023, 8, 236–248. [Google Scholar] [CrossRef]

- Cruz, R.; Pombo, F. Trade Fairs from 2016 to 2022: Trends of Flexible and Modular Furniture for Hybrid Working Sceneries. In Springer Series in Design and Innovation; Springer Nature: Cham, Switzerland, 2024; pp. 327–364. ISBN 9783031435157. [Google Scholar]

- Siddiqui, M.A.S.; Rabbi, M.S.; Ahmed, R.U.; Billah, M.M. Biodegradable Natural Polymers and Fibers for 3D Printing: A Holistic Perspective on Processing, Characterization, and Advanced Applications. Clean. Mater. 2024, 14, 100275. [Google Scholar] [CrossRef]

- Bora, L.V.; Vadaliya, K.S.; Bora, N.V. Sustainable Feedstocks for 4D Printing: Biodegradable Polymers and Natural Resources. Green Mater. 2024, 12, 192–208. [Google Scholar] [CrossRef]

- Elessawy, N.A.; El Shakhs, A.; Fahmy El-Saka, M.; Youssef, M.E.; Youssef, B.A.B.; Malek Ali, M.A. Sustainable and Eco-Friendly 3D Printing Filament Fabricated from Different Recycled Solid Wastes and Evaluate Its Impact on Interior and Furniture Design. Results Eng. 2024, 23, 102428. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Niemelä, M.; Ebrahimzadeh Sepasgozar, S.M.; Lai, T.Y.; Su, W.; Reddy, K.R.; Shirowzhan, S.; Sepasgozar, S.; Marroquin, F.A. Three-Dimensional Printing Using Recycled High-Density Polyethylene: Technological Challenges and Future Directions for Construction. Buildings 2018, 8, 165. [Google Scholar] [CrossRef]

- Hassan, M.; Mohanty, A.K.; Misra, M. 3D Printing in Upcycling Plastic and Biomass Waste to Sustainable Polymer Blends and Composites: A Review. Mater. Des. 2024, 237, 112558. [Google Scholar] [CrossRef]

- Anwajler, B.; Zdybel, E.; Tomaszewska-Ciosk, E. Innovative Polymer Composites with Natural Fillers Produced by Additive Manufacturing (3D Printing)-A Literature Review. Polymers 2023, 15, 3534. [Google Scholar] [CrossRef]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef] [PubMed]

- Luhar, S.; Suntharalingam, T.; Navaratnam, S.; Luhar, I.; Thamboo, J.; Poologanathan, K.; Gatheeshgar, P. Sustainable and Renewable Bio-Based Natural Fibres and Its Application for 3D Printed Concrete: A Review. Sustainability 2020, 12, 10485. [Google Scholar] [CrossRef]

- Billings, C.; Siddique, R.; Sherwood, B.; Hall, J.; Liu, Y. Additive Manufacturing and Characterization of Sustainable Wood Fiber-Reinforced Green Composites. J. Compos. Sci. 2023, 7, 489. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. A Review of Natural Fiber-Based Filaments for 3D Printing: Filament Fabrication and Characterization. Materials 2023, 16, 4052. [Google Scholar] [CrossRef]

- Khilji, I.A.; Chilakamarry, C.R.; Surendran, A.N.; Kate, K.; Satyavolu, J. Natural Fiber Composite Filaments for Additive Manufacturing: A Comprehensive Review. Sustainability 2023, 15, 16171. [Google Scholar] [CrossRef]

- Lee, C.H.; Padzil, F.N.B.M.; Lee, S.H.; Ainun, Z.M.A.; Abdullah, L.C. Potential for Natural Fiber Reinforcement in PLA Polymer Filaments for Fused Deposition Modeling (FDM) Additive Manufacturing: A Review. Polymers 2021, 13, 1407. [Google Scholar] [CrossRef]

- Afshar, A.; Wood, R. Development of Weather-Resistant 3D Printed Structures by Multi-Material Additive Manufacturing. J. Compos. Sci. 2020, 4, 94. [Google Scholar] [CrossRef]

- Saavedra-Rojas, F.A.; Bhandari, S.; Lopez-Anido, R.A. Environmental Durability of Bio-Based and Synthetic Thermoplastic Composites in Large-Format Additive Manufacturing. Polymers 2024, 16, 787. [Google Scholar] [CrossRef]

- Yu, W.; Yuan, T.; Yao, Y.; Deng, Y.; Wang, X. PLA/Coffee Grounds Composite for 3D Printing and Its Properties. Forests 2023, 14, 367. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green Composites Based on PLA and Agricultural or Marine Waste Prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, T.H.; Lim, H.S. A study on the importance and application of 3D printing technology for street furniture manufacturing. J. Korea Acad. Ind. Coop. Soc. 2020, 21, 509–517. [Google Scholar] [CrossRef]

- El Shakhs, A.; Elessawy, N.A.; El-Saka, M.F.; Hassan, G.E.; Ali, M.A.M. Developing Eco-Friendly 3D-Printing Composite Filament: Utilizing Palm Midrib to Reinforce High-Density Polyethylene Matrix in Design Applications. Polymers 2024, 16, 1135. [Google Scholar] [CrossRef]

- Mistretta, M.C.; La Mantia, F.P.; Titone, V.; Botta, L.; Pedeferri, M.; Morreale, M. Effect of Ultraviolet and Moisture Action on Biodegradable Polymers and Their Blend. J. Appl. Biomater. Funct. Mater. 2020, 18, 228080002092665. [Google Scholar] [CrossRef]

- Colucci, G.; Sacchi, F.; Bondioli, F.; Messori, M. Fully Bio-Based Polymer Composites: Preparation, Characterization, and LCD 3D Printing. Polymers 2024, 16, 1272. [Google Scholar] [CrossRef]

- Ci, S.; Liang, J.; Li, J.; Zhou, Y.; Sun, X. Microstructure and Tensile Properties of DD32 Single Crystal Ni-Base Superalloy Repaired by Laser Metal Forming. J. Mater. Sci. Technol. 2020, 45, 23–34. [Google Scholar] [CrossRef]

- Grassi, G.; Lupica Spagnolo, S.; Paoletti, I. Fabrication and Durability Testing of a 3D Printed Façade for Desert Climates. Addit. Manuf. 2019, 28, 439–444. [Google Scholar] [CrossRef]

- Liberski, A.; Garita, R.; Kot, R. Design, Manufacturing and Analysis of Smart Furniture. QScience Connect 2019, 2019, 4. [Google Scholar] [CrossRef]

- Vincent Transforming Urban Furniture with Industrial 3D Printing and Polymaker’s Materials. Available online: https://ceadgroup.com/transforming-urban-furniture-with-industrial-3d-printing-and-polymakers-materials/ (accessed on 24 April 2025).

- Alzarooni, M.A. Exploring the Adoption of 3D Printing for Reducing Capital and Operational Costs of Façades in Office Buildings. Master’s Thesis, The British University in Dubai, Dubai, United Arab Emirates, 2019. [Google Scholar]

- Rouf, S.; Raina, A.; Irfan Ul Haq, M.; Naveed, N.; Jeganmohan, S.; Farzana Kichloo, A. 3D Printed Parts and Mechanical Properties: Influencing Parameters, Sustainability Aspects, Global Market Scenario, Challenges and Applications. Adv. Ind. Eng. Polym. Res. 2022, 5, 143–158. [Google Scholar] [CrossRef]

- Şatiroğlu, E.; Dinçer, D.; Korgavuş, B. Urban Furniture İn the Context of Sustanainable Materials. Kent Akad. 2023, 16, 566–576. [Google Scholar] [CrossRef]

- Lesovik, V.; Fediuk, R.; Amran, M.; Vatin, N.; Timokhin, R. Self-Healing Construction Materials: The Geomimetic Approach. Sustainability 2021, 13, 9033. [Google Scholar] [CrossRef]

- De Nardi, C.; Gardner, D.; Jefferson, A.D. Development of 3D Printed Networks in Self-Healing Concrete. Materials 2020, 13, 1328. [Google Scholar] [CrossRef] [PubMed]

- Shah, K.W.; Huseien, G.F. Biomimetic Self-Healing Cementitious Construction Materials for Smart Buildings. Biomimetics 2020, 5, 47. [Google Scholar] [CrossRef] [PubMed]

- Walter, M.; Lengsfeld, K.; Borschewski, D.; Albrecht, S.; Kölsch, P.; Pretsch, T.; Krus, M.; Lehmann-Brauns, S. Shape Memory Polymer Foam for Autonomous Climate-Adaptive Building Envelopes. Buildings 2022, 12, 2236. [Google Scholar] [CrossRef]

- Marturano, V.; Cerruti, P.; Giamberini, M.; Tylkowski, B.; Ambrogi, V. Light-Responsive Polymer Micro- and Nano-Capsules. Polymers 2016, 9, 8. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Transforming Object Design and Creation: Biomaterials and Contemporary Manufacturing Leading the Way. Biomimetics 2024, 9, 48. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Stiubianu, G.-T.; Bele, A.; Bargan, A.; Potolinca, V.O.; Asandulesa, M.; Tugui, C.; Tiron, V.; Hamciuc, C.; Dascalu, M.; Cazacu, M. All-Polymer Piezo-Composites for Scalable Energy Harvesting and Sensing Devices. Molecules 2022, 27, 8524. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, Z.; Ren, L.; Liu, Q.; Ren, L.; Yang, X.; Zhou, X. Advances in 4D Printed Shape Memory Polymers: From 3D Printing, Smart Excitation, and Response to Applications. Adv. Mater. Technol. 2022, 7, 2101568. [Google Scholar] [CrossRef]

- Aradoaei, M.; Ciobanu, R.C.; Schreiner, C.; Paulet, M.; Caramitu, A.R.; Pintea, J.; Baibarac, M. Three-Dimensional Printable Flexible Piezoelectric Composites with Energy Harvesting Features. Polymers 2023, 15, 2548. [Google Scholar] [CrossRef]

- Son, T.H.; Weedon, Z.; Yigitcanlar, T.; Sanchez, T.; Corchado, J.M.; Mehmood, R. Algorithmic Urban Planning for Smart and Sustainable Development: Systematic Review of the Literature. Sustain. Cities Soc. 2023, 94, 104562. [Google Scholar] [CrossRef]

- Xi, L.; Zhang, M.; Zhang, L.; Lew, T.T.S.; Lam, Y.M. Novel Materials for Urban Farming. Adv. Mater. 2022, 34, e2105009. [Google Scholar] [CrossRef] [PubMed]

- Lupu, A.; Gradinaru, L.M.; Gradinaru, V.R.; Bercea, M. Diversity of Bioinspired Hydrogels: From Structure to Applications. Gels 2023, 9, 376. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ding, T. A Review on the Current State of Microcapsule-Based Self-Healing Dental Composites. J. Funct. Biomater. 2024, 15, 165. [Google Scholar] [CrossRef] [PubMed]

- Self-Healing Construction Materials: Fundamentals, Monitoring and Large Scale Applications; Kanellopoulos, A., Norambuena-Contreras, J., Eds.; Springer Nature: Cham, Switzerland, 2021; ISBN 9783030868796. [Google Scholar]

- Fiorati, A.; Linciano, C.; Galante, C.; Raucci, M.G.; Altomare, L. Bioactive Hydrogels: Design and Characterization of Cellulose-Derived Injectable Composites. Materials 2021, 14, 4511. [Google Scholar] [CrossRef]

- Hossain, M.R.; Sultana, R.; Patwary, M.M.; Khunga, N.; Sharma, P.; Shaker, S.J. Self-Healing Concrete for Sustainable Buildings. A Review. Environ. Chem. Lett. 2022, 20, 1265–1273. [Google Scholar] [CrossRef]

- Paramés-González, A.; Prieto-Lage, I.; Gutiérrez-Santiago, A. 3D Printing in Fitting Furniture to Student Anthropometry. Zenodo 2020, 5, 76–89. [Google Scholar] [CrossRef]

- Leimer, K.; Winkler, A.; Ohrhallinger, S.; Musialski, P. Pose to Seat: Automated Design of Body-Supporting Surfaces. Comput. Aided Geom. Des. 2020, 79, 101855. [Google Scholar] [CrossRef]

- Rossi, E.; Di Nicolantonio, M.; D’Onofrio, A.; Massacesi, R. 3D-Printed Inclusive Modular System for Underprivileged Communities. In Proceedings of the AHFE 2019 International Conference on Additive Manufacturing, Modeling Systems and 3D Prototyping, Washington, DC, USA, 24–28 July 2019. [Google Scholar]

- Akinwande, F.; Akanbi, O.; Akindele, S. Computer-Aided Ergonomics Design and Comparative Analysis of Waiting Chairs at a Health Centre. Int. J. Ind. Syst. Eng. 2022, 42, 338. [Google Scholar] [CrossRef]

- Krzyżaniak, Ł.; Smardzewski, J.; Prekrat, S. Numerical Modelling of Stiffness of RTA Furniture with New Externally Invisible and Dismountable Joints. Drv. Ind. 2020, 71, 209–214. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Pallis, E.; Papoutsidakis, M. Biomimetic Additive Manufacturing: Engineering Complexity Inspired by Nature’s Simplicity. Biomimetics 2025, 10, 453. [Google Scholar] [CrossRef] [PubMed]

- Krapež Tomec, D.; Kariž, M. Use of Wood in Additive Manufacturing: Review and Future Prospects. Polymers 2022, 14, 1174. [Google Scholar] [CrossRef] [PubMed]

- Martoïa, F.; Orgéas, L.; Dumont, P.J.J.; Bloch, J.-F.; Flin, F.; Viguié, J. Crumpled Paper Sheets: Low-Cost Biobased Cellular Materials for Structural Applications. Mater. Des. 2017, 136, 150–164. [Google Scholar] [CrossRef]

- Santana, L.; Lino Alves, J.; da Costa Sabino Netto, A. A Study of Parametric Calibration for Low Cost 3D Printing: Seeking Improvement in Dimensional Quality. Mater. Des. 2017, 135, 159–172. [Google Scholar] [CrossRef]

- Amaya, J.L.; Ramírez, E.A.; Maldonado, G.F.; Hurel, J. Detailed Design Process and Assembly Considerations for Snap-Fit Joints Using Additive Manufacturing. Procedia CIRP 2019, 84, 680–687. [Google Scholar] [CrossRef]

- De-Miguel-Sánchez, M.; Gutiérrez-Pérez, N. A Methodology to Make Cultural Heritage More Accessible to People with Visual Disabilities through 3d Printing. Disegnarecon 2024, 17, 4-1–4-11. [Google Scholar]

- Grey, R.; Sinha, S.; de Vries, C.M. Universal Design Analysis for Improving the Usability of Fused Filament Fabrication 3D Printers. In Proceedings of the 34th International Conference on Design Theory and Methodology (DTM), St. Louis, MO, USA, 14–17 August 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 6. [Google Scholar]

- Engel, C.; Müller, K.; Constantinescu, A.; Loitsch, C.; Petrausch, V.; Weber, G.; Stiefelhagen, R. Travelling More Independently: A Requirements Analysis for Accessible Journeys to Unknown Buildings for People with Visual Impairments. In Proceedings of the 22nd International ACM SIGACCESS Conference on Computers and Accessibility, Online, 26–28 October 2020; ACM: New York, NY, USA, 2020. [Google Scholar]

- Huang, W.; Abdul Rahman, A.R.; Gill, S.S.; Raja Ahmad Effendi, R.A.A. Furniture Design Based on Cultural Orientation: A Thematic Review. Cogent Arts Humanit. 2025, 12, 2442811. [Google Scholar] [CrossRef]

- Sharif, A.A. User Activities and the Heterogeneity of Urban Space: The Case of Dahiyat Al Hussein Park. Front. Arch. Res. 2020, 9, 837–857. [Google Scholar] [CrossRef]

- Miranda, A.E. Urban Furniture Design, Identity, and Collective Memory. Int. J. Architecton. Spat. Environ. Des. 2019, 13, 57–68. [Google Scholar] [CrossRef]

- Mahshid Mehreganfar, N.K.M. Development of Urban Furniture Design Inspired by Nature; Case Study: Street Benches. J. Iran. Archtecture Urban. (JIAU) 2022, 14, 143–158. [Google Scholar] [CrossRef]

- Ismail, R.M.; Megahed, N.A.; Shahda, M.M.; Eltarabily, S. Bio-Inspired Design: Leveraging Nature for Enhanced Ecosystem Services. Arch. Eng. Des. Manag. 2025, 1–32. [Google Scholar] [CrossRef]

- Chen, Y.; Dang, B.; Wang, C.; Wang, Y.; Yang, Y.; Liu, M.; Bi, H.; Sun, D.; Li, Y.; Li, J.; et al. Intelligent Designs from Nature: Biomimetic Applications in Wood Technology. Prog. Mater. Sci. 2023, 139, 101164. [Google Scholar] [CrossRef]

- Rashdan, W.; Ashour, A.F. Biophilic Design: An Experiment in Teaching Furniture Design Studio. Int. J. Art Des. Educ. 2025. [Google Scholar] [CrossRef]

- Rinaldi, A.; Caon, M.; Khaled, O.A.; Mugellini, E. Designing Urban Smart Furniture for Facilitating Migrants’ Integration: The Co-Design Workshop as Approach for Supporting Inclusive Design. In Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2019; pp. 461–470. ISBN 9783319960708. [Google Scholar]

- Allahdadi, M. Explaining the Criteria of Designing Urban Furniture and Landscape, with a Cultural-Social Design Approach. J. Hist. Cult. Art Res. 2017, 6, 165. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, C. Design of Street Furniture for Famous Historical and Cultural Cities in the View of Cultural and Technological Integration—A Case Study on the Design of Bus Shelter in Bozhou. MATEC Web Conf. 2018, 237, 03011. [Google Scholar] [CrossRef][Green Version]

- Kargar, R.; Ghassemi, M. Urban Furniture and Leisure of Citizens (Case Study of Sabzevar Urban Parks). Available online: https://www.ojceu.ir/main/attachments/article/51/J.%20Civil%20Eng.%20Urban.,%206%20(2)%2040-47,%202016.pdf (accessed on 24 April 2025).

- Qiao, B.; Sun, Q.; He, H. A Crowdsourcing Method for 3D Furniture Based on Parameterized Template. J. Phys. Conf. Ser. 2021, 1952, 032029. [Google Scholar] [CrossRef]

- Mueller, J.; Lu, H.; Chirkin, A.; Klein, B.; Schmitt, G. Citizen Design Science: A Strategy for Crowd-Creative Urban Design. Cities 2018, 72, 181–188. [Google Scholar] [CrossRef]

- Nishikawa, H.; Schreier, M.; Ogawa, S. User-Generated versus Designer-Generated Products: A Performance Assessment at Muji. Int. J. Res. Mark. 2013, 30, 160–167. [Google Scholar] [CrossRef]

- Prawata, A. Creative User Generated Urbanism. Procedia Soc. Behav. Sci. 2015, 184, 232–239. [Google Scholar] [CrossRef][Green Version]

- Thesis Submitted To, A. Design for Pv-Integrated Smart Urban Furniture. Available online: https://www.proquest.com/openview/edba20a2175b78ad72b981631d415977/1?cbl=2026366&diss=y&pq-origsite=gscholar (accessed on 24 April 2025).

- Ling, T.-Y.; Yen, N.; Lin, C.-H.; Chandra, W. Critical Thinking in the Urban Living Habitat: Attributes Criteria and Typo-Morphological Exploration of Modularity Design. J. Build. Eng. 2021, 44, 103278. [Google Scholar] [CrossRef]

- Yalçın, E. Micro Living Spaces and the Furniture Industry. Int. J. Sports Technol. Sci. 2024, 2, 105–122. [Google Scholar]

- View of Module and Modularity—Variations and Application Scales in Contemporary Times. Available online: https://www.agathon.it/agathon/article/view/367/435 (accessed on 24 April 2025).

- Rimmer, M. Automating Fab Cities: 3D Printing and Urban Renewal. In Automating Cities; Springer: Singapore, 2021; pp. 255–272. ISBN 9789811586699. [Google Scholar]

- Liu, W.; Md Ishak, S.M.; Yahaya, M.F. Enhancing Mobility and Sustainability: An Origami-Based Furniture Design Approach for Young Migrants. Sustainability 2024, 17, 164. [Google Scholar] [CrossRef]

- Zuo, Z.; De Corte, W.; Huang, Y.; Chen, X.; Zhang, Y.; Li, J.; Zhang, L.; Xiao, J.; Yuan, Y.; Zhang, K.; et al. Propelling the Widespread Adoption of Large-Scale 3D Printing. Nat. Rev. Mater. 2023, 9, 754–756. [Google Scholar] [CrossRef]

- Baharuldin, K.; Abdullah, M.E.Z.; Anwar, M.F.M.; Harun, M.H. Sustainable Furniture Joints: Leveraging Fused Deposition Modeling (FDM) for Eco-Friendly Design. BIO Web Conf. 2024, 131, 05015. [Google Scholar] [CrossRef]

- Zainal Abdullah, M.E.; Abdul Hamid, N.H.; Jaafar, J.; Mohd Anwar, M.F.; Sukri, S.N.D. FLUX 2.0: Sustainable Furniture Production with Modular 3D Printed Joinery System. BIO Web Conf. 2023, 73, 05007. [Google Scholar] [CrossRef]

- Messages, K. Modular 3D Printing Construction: Towards Affordable, Adjustable and Climate- Resilient Housing. Available online: https://sdgs.un.org/sites/default/files/2022-05/2.4.4-14-van%20den%20Bergh%20-Modular%203D%20printing%20construction.pdf (accessed on 24 April 2025).

- Yang, S.; Du, P. The Application of 3D Printing Technology in Furniture Design. Sci. Program. 2022, 2022, 1960038. [Google Scholar] [CrossRef]

- Teixeira, J.; Schaefer, C.O.; Rangel, B.; Maia, L.; Alves, J.L. A Road Map to Find in 3D Printing a New Design Plasticity for Construction—The State of Art. Front. Arch. Res. 2023, 12, 337–360. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- Montes, J.O.; Olleros, F.X. Local On-Demand Fabrication: Microfactories and Online Manufacturing Platforms. J. Manuf. Technol. Manag. 2020, 32, 20–41. [Google Scholar] [CrossRef]

- Madrigal, J.; Jeong, S. Personalization Process of 3D Printed Products Using Parametric Design. Arch. Des. Res. 2022, 35, 31–47. [Google Scholar] [CrossRef]

- Arvaniti-Pollatou, M. Print Your City by the New Raw. Available online: https://www.archisearch.gr/green-design/print-your-city-by-the-new-raw-greek-citizens-design-3d-printed-street-furniture-from-household-plastic-waste (accessed on 24 April 2025).

- Salloum Stanbuly, N. Reducing Construction Waste through Urban Furniture: An Experimental and Multi-Criteria Exploration of Fine Recycled Aggregates for 3D Printed Concrete. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2023. [Google Scholar]

- Chiappelli, J. Designing Functional 3d Printed Furniture Made from Plastic Waste for Developing Countries through Circular Economy Principles. Master’s Thesis, University of Rhode Island, Kingston, RI, USA, 2024. [Google Scholar]

- Mason, H. Urban Furniture Project Demonstrates Green Potential for Composite 3D Printing and Recycled Materials. Available online: https://www.compositesworld.com/articles/urban-furniture-project-demonstrates-green-potential-for-composite-3d-printing-and-recycled-materials (accessed on 25 April 2025).

- NexNet Dubai Municipality Installs 40 3D Printed Seats in Uptown Mirdif and Al Khazzan Parks. Available online: https://www.dm.gov.ae/2024/07/08/dubai-municipality-installs-40-3d-printed-seats-in-uptown-mirdif-and-al-khazzan-parks (accessed on 24 April 2025).

- Rodríguez-Parada, L.; De la Rosa, S.; Pardo-Vicente, M.Á.; Méndez-Salgueiro, J.R.; Mayuet, P.F. Generation and Characterization Metrology of Textures for Design of Urban Furniture with Recycled Material—A Case of Study for Additive Manufacturing. Key Eng. Mater. 2023, 958, 139–147. [Google Scholar] [CrossRef]

- BlueCycle Gifted an Outdoors Lounge to Paidopoli Agia Varvara. Available online: https://www.muminstitute.org/news/i-bluecycle-dorise-epipla-exoterikou-chorou-gia-tin-paidopoli-agia-varvara/ (accessed on 25 April 2025).

- Goldberg, D.M.; Deane, J.K.; Rakes, T.R.; Rees, L.P. 3D Printing Technology and the Market Value of the Firm. Inf. Syst. Front. 2022, 24, 1379–1392. [Google Scholar] [CrossRef]

- Fernandez Cordero, A.; Moreno Sanchez, D.; Molina Rubio, S.I. Urban Furniture Design through the Implementation of Artificial Intelligence and Additive Manufacturing. Dyna 2025, 100, 130–136. [Google Scholar] [CrossRef]

- Chen, C.C.; Yang, W.Z.; Teng, H.M.; Liao, S.S.; Tsao, C.C. Study on the Application of 3D Printing to Wooden Furniture Connectors. J. Phys. Conf. Ser. 2023, 2631, 012006. [Google Scholar] [CrossRef]

- Jeong, J.; Park, H.; Lee, Y.; Kang, J.; Chun, J. Developing Parametric Design Fashion Products Using 3D Printing Technology. Fash. Text. 2021, 8, 22. [Google Scholar] [CrossRef]

- Murphy, A.R.; Floresca, E.A.; Fu, K.K.; Linsey, J.S. Comparing Parallel and Iterative Prototyping Strategies during Engineering Design. Res. Eng. Des. 2022, 33, 173–190. [Google Scholar] [CrossRef]

- Demirel, S.; Kuvel, N.T.; Çava, K.; Aslan, M. The Performance of 3d Printed Dowel with Three Different Surface Designs in Furniture Joints. Turk. J. For. 2023, 25, 100–106. [Google Scholar] [CrossRef]

- Stanko, M.A.; Allen, B.J. Disentangling the Collective Motivations for User Innovation in a 3D Printing Community. Technovation 2022, 111, 102387. [Google Scholar] [CrossRef]

- Hegedus, T.; Kreuter, P.; Kismarczi-Antalffy, A.A.; Demeter, T.; Banyai, D.; Vegh, A.; Geczi, Z.; Hermann, P.; Payer, M.; Zsembery, A.; et al. User Experience and Sustainability of 3D Printing in Dentistry. Int. J. Environ. Res. Public Health 2022, 19, 1921. [Google Scholar] [CrossRef]

- Ibach, M.K. Printing Utopia: The Domain of the 3D Printer in the Making of Commons-Based Futures. Des. Cult. 2022, 15, 323–344. [Google Scholar] [CrossRef]

- Moilanen, J.; Vadén, T. 3D Printing Community and Emerging Practices of Peer Production. First Monday 2013, 18, e4271. [Google Scholar] [CrossRef]

- Farmer, S. Communities of Saint Martin: Legend and Ritual in Medieval Tours; Cornell University Press: Ithaca, NY, USA, 2019; ISBN 9781501740619. [Google Scholar]

- Tetsuka, H.; Shin, S.R. Materials and Technical Innovations in 3D Printing in Biomedical Applications. J. Mater. Chem. B Mater. Biol. Med. 2020, 8, 2930–2950. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-Material Additive Manufacturing of Sustainable Innovative Materials and Structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef]

- Ben-Ner, A.; Siemsen, E. Decentralization and Localization of Production: The Organizational and Economic Consequences of Additive Manufacturing (3D Printing). Calif. Manag. Rev. 2017, 59, 5–23. [Google Scholar] [CrossRef]

- Ihl, C.; Piller, F. 3D Printing as Driver of Localized Manufacturing: Expected Benefits from Producer and Consumer Perspectives. In Progress in IS; Springer International Publishing: Cham, Switzerland, 2016; pp. 179–204. ISBN 9783319316840. [Google Scholar]

- Srai, J.S.; Graham, G.; Hennelly, P.; Phillips, W.; Kapletia, D.; Lorentz, H. Distributed Manufacturing: A New Form of Localised Production? Int. J. Oper. Prod. Manag. 2020, 40, 697–727. [Google Scholar] [CrossRef]

- Ivkić, I.; Buhmann, T.; List, B. A Cost-Benefit Analysis of Additive Manufacturing as a Service. arXiv 2025, arXiv:2502.05586. [Google Scholar] [CrossRef]

- Eriksson, H.; Harrie, L. Versioning of 3D City Models for Municipality Applications: Needs, Obstacles and Recommendations. ISPRS Int. J. Geoinf. 2021, 10, 55. [Google Scholar] [CrossRef]

- de Souza, E.A.; Borges, P.H.R.; Stengel, T.; Nematollahi, B.; Bos, F.P. 3D Printed Sustainable Low-Cost Materials for Construction of Affordable Social Housing in Brazil: Potential, Challenges, and Research Needs. J. Build. Eng. 2024, 87, 108985. [Google Scholar] [CrossRef]

- Wolfs, R.; Bos, D.; Salet, T. Lessons Learned of Project Milestone: The First 3D Printed Concrete House in the Netherlands. Mater. Today 2023. [Google Scholar] [CrossRef]

- Xin, L. 3D Printing Technology Based on the Development Model of Cultural and Creative Products on University Campuses. Scalable Comput. Pract. Exp. 2024, 25, 2721–2727. [Google Scholar] [CrossRef]

- Yan, M. From Tradition to Innovation: Integrating 3D Printing in the Creation of Wooden Artistic and Furniture Products. Int. J. Mater. Sci. Technol. Stud. 2024, 1, 32–38. [Google Scholar] [CrossRef]

- Domljan, D.; Lukež, N.; Vlaović, Z. Sustainable Furniture Design for Rural Tourist Accommodation Inspired by the Heritage of Istria. Sustainability 2025, 17, 1415. [Google Scholar] [CrossRef]

- Norouzi, B.; Kinnula, M.; Iivari, N. Making Sense of 3D Modelling and 3D Printing Activities of Young People: A Nexus Analytic Inquiry. In Proceedings of the Proceedings of the 2021 CHI Conference on Human Factors in Computing Systems, Yokohama, Japan, 8–13 May 2021; ACM: New York, NY, USA, 2021. [Google Scholar]

- Beltagui, A.; Sesis, A.; Stylos, N. A Bricolage Perspective on Democratising Innovation: The Case of 3D Printing in Makerspaces. Technol. Forecast. Soc. Change 2021, 163, 120453. [Google Scholar] [CrossRef]

- Villanueva Orbaiz, M.L.; Arce-Urriza, M. The Role of Active and Passive Resistance in New Technology Adoption by Final Consumers: The Case of 3D Printing. Technol. Soc. 2024, 77, 102500. [Google Scholar] [CrossRef]

- To, T.T.; Al Mahmud, A.; Ranscombe, C. Teaching Sustainability Using 3D Printing in Engineering Education: An Observational Study. Sustainability 2023, 15, 7470. [Google Scholar] [CrossRef]

- Lundgren, H. Participatory Design of a 3D-Printed Furniture Concept for Learning Spaces: A Study of Large-Scale Additive Manufacturing Opportunities and Limitations. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2021. [Google Scholar]

- Keskin, G.; Hasirci, D. Innovative Participatory Design Method Using Social Media and Online Platforms. New Des. Ideas 2024, 8, 50–80. [Google Scholar] [CrossRef]

- Peinado-Santana, S.; Hernández-Lamas, P.; Bernabéu-Larena, J.; Cabau-Anchuelo, B.; Martín-Caro, J.A. Public Works Heritage 3D Model Digitisation, Optimisation and Dissemination with Free and Open-Source Software and Platforms and Low-Cost Tools. Sustainability 2021, 13, 13020. [Google Scholar] [CrossRef]

- Berman, A.; Thakare, K.; Howell, J.; Quek, F.; Kim, J. HowDIY: Towards Meta-Design Tools to Support Anyone to 3D Print Anywhere. In Proceedings of the 26th International Conference on Intelligent User Interfaces, College Station, TX, USA, 14 April 2021; ACM: New York, NY, USA, 2021. [Google Scholar]

- Lube, T.; Staudacher, M.; Hofer, A.-K.; Schlacher, J.; Bermejo, R. Stereolithographic 3D Printing of Ceramics: Challenges and Opportunities for Structural Integrity. Adv. Eng. Mater. 2023, 25, 2200520. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Soltani, P.; Weinberg, K.; Reinicke, T. Structural Integrity of Adhesively Bonded 3D-Printed Joints. Polym. Test. 2021, 100, 107262. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. Fracture Behavior of Intact and Defected 3D-Printed Parts. Procedia Struct. Integr. 2021, 31, 105–110. [Google Scholar] [CrossRef]

- García, H.; López Pola, T. Health and Safety in 3D Printing: Article. Int. J. Occup. Environ. Saf. 2022, 6, 14–25. [Google Scholar] [CrossRef]

- Jarža, L.; Čavlović, A.O.; Pervan, S.; Španić, N.; Klarić, M.; Prekrat, S. Additive Technologies and Their Applications in Furniture Design and Manufacturing. Drv. Ind. 2023, 74, 115–128. [Google Scholar] [CrossRef]

- Mora, S.; Pugno, N.M.; Misseroni, D. 3D Printed Architected Lattice Structures by Material Jetting. Mater. Today 2022, 59, 107–132. [Google Scholar] [CrossRef]

- Baz, B.; Aouad, G.; Kleib, J.; Bulteel, D.; Remond, S. Durability Assessment and Microstructural Analysis of 3D Printed Concrete Exposed to Sulfuric Acid Environments. Constr. Build. Mater. 2021, 290, 123220. [Google Scholar] [CrossRef]

- Moelich, G.M.; Kruger, P.J.; Combrinck, R. A Plastic Shrinkage Cracking Risk Model for 3D Printed Concrete Exposed to Different Environments. Cem. Concr. Compos. 2022, 130, 104516. [Google Scholar] [CrossRef]

- Groslambert, S.; Léonard, A.; Courard, L. Life Cycle Assessment of 3D Printed Furniture Using Fine Recycled Aggregates—CIRMAP Project. Available online: https://hal.science/hal-03880968v1/document (accessed on 25 April 2025).

- Jiang, W.; Lu, D.; Zhao, N. A New Design Approach: Applying Optical Fiber Sensing to 3D-Printed Structures to Make Furniture Intelligent. Sustainability 2023, 15, 16715. [Google Scholar] [CrossRef]

- Yu, H.; Wen, B.; Zahidi, I.; Fai, C.M.; Madsen, D.Ø. Constructing the Future: Policy-Driven Digital Fabrication in China’s Urban Development. Results Eng. 2024, 22, 102096. [Google Scholar] [CrossRef]

- Wang, B.T.; Rimmer, M. 3D Printing and Housing: Intellectual Property and Construction Law. In Automating Cities; Springer: Singapore, 2021; pp. 113–140. ISBN 9789811586699. [Google Scholar]

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.; Ndlovu, L. 3d Printing for Sustainable Low-Income Housing in South Africa: A Case for the Urban Poor. J. Green Build. 2021, 16, 129–141. [Google Scholar] [CrossRef]

- Suvanjumrat, C.; Chansoda, K.; Chookaew, W. Additive Manufacturing Advancement through Large-Scale Screw-Extrusion 3D Printing for Precision Parawood Powder/PLA Furniture Production. Clean. Eng. Technol. 2024, 20, 100753. [Google Scholar] [CrossRef]

- Tuazon, B.J.; Dizon, J.R.C. Additive Manufacturing Technology in the Furniture Industry: Future Outlook for Developing Countries. Adv. Sustain. Sci. Eng. Technol. 2024, 6, 02403024. [Google Scholar] [CrossRef]

- Gonzales Castillo, P. Crafting and 3D Printing Shop Business Plan. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2024. [Google Scholar]

- Wang, Y.; Surip, S.S. Optimizing Sustainable Furniture Design through the Application of Agricultural Waste Straw: An Operational Research Approach. Oper. Res. Eng. Sci. Theor. Appl. 2024, 7. Available online: https://oresta.org/menu-script/index.php/oresta/article/view/800 (accessed on 5 June 2025).

- Prończuk, A.; Mertz-Revol, C.; Hinzpeter, J.; Smeets, J.; Chmielik, M.; Duarte, A.J.; Malheiro, B.; Ribeiro, C.; Justo, J.; Silva, M.F.; et al. Smart Adjustable Furniture—An EPS@ISEP 2023 Project. In Proceedings of the TEEM 2023, Bragança, Portugal, 25 October 2023; Springer Nature: Singapore, 2024; pp. 913–922, ISBN 9789819718139. [Google Scholar]

- Nageb Fewella, L. The Behavioral Smart Furniture and Its Relevance to Family Emotional Dynamics. Ain Shams Eng. J. 2024, 15, 103030. [Google Scholar] [CrossRef]

- Krejcar, O.; Maresova, P.; Selamat, A.; Melero, F.J.; Barakovic, S.; Husic, J.B.; Herrera-Viedma, E.; Frischer, R.; Kuca, K. Smart Furniture as a Component of a Smart City—Definition Based on Key Technologies Specification. IEEE Access 2019, 7, 94822–94839. [Google Scholar] [CrossRef]

- Maulana, F.I.; Kurniawan, B.K.; Pramono, A.; Purnomo, A.; Abdulah, M.E.B.Z.; Mohamed, M. Internet of Things for Smart Furniture: A Systematic Review. In Proceedings of the 2024 International Conference on ICT for Smart Society (ICISS), Bandung, Indonesia, 4–5 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Frischer, R.; Krejcar, O.; Maresova, P.; Fadeyi, O.; Selamat, A.; Kuca, K.; Tomsone, S.; Teixeira, J.P.; Madureira, J.; Melero, F.J. Commercial ICT Smart Solutions for the Elderly: State of the Art and Future Challenges in the Smart Furniture Sector. Electronics 2020, 9, 149. [Google Scholar] [CrossRef]

- Fewella, L.N. Smartification Furniture Manufacturing: A Furniture Prototype with Thermal-Based Sensors (Visions and Challenges). Results Eng. 2024, 24, 103508. [Google Scholar] [CrossRef]

- Jleilaty, S.; Ammounah, A.; Abdulmalek, G.; Nouveliere, L.; Su, H.; Alfayad, S. Distributed Real-Time Control Architecture for Electrohydraulic Humanoid Robots. Robot. Intell. Autom. 2024, 44, 607–620. [Google Scholar] [CrossRef]

- Qi, W.; Xu, X.; Qian, K.; Schuller, B.W.; Fortino, G.; Aliverti, A. A Review of AIoT-Based Human Activity Recognition: From Application to Technique. IEEE J. Biomed. Health Inform. 2025, 29, 2425–2438. [Google Scholar] [CrossRef]

| 3D Printing Technology | Description | Key Benefits for Urban Furniture | Materials Used |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Uses thermoplastic filament extruded through a heated nozzle, layer by layer. | Cost-effective, widely accessible, suitable for functional components, rapid prototyping. | PLA, ABS, PETG, nylon |

| Stereolithography (SLA) | Utilizes liquid resin cured by ultraviolet light to create high-precision models. | High resolution, smooth surface finish, ideal for intricate designs, aesthetic appeal. | Photopolymer resins |

| Selective Laser Sintering (SLS) | Fuses powdered materials using a laser, creating strong, robust structures. | Strong mechanical properties, durable, suitable for outdoor applications, functional furniture. | Nylon, metal powders, polymers |

| Hybrid Manufacturing | Combines 3D printing with traditional techniques (e.g., injection molding, CNC machining). | Enhanced structural integrity, scalable, efficient material usage, customizable. | Varies by hybrid method (plastics, metals, composites) |

| Material Type | Description | Key Advantages | Challenges | Examples |

|---|---|---|---|---|

| Recycled Plastics | Plastics sourced from post-consumer or industrial waste, such as rPET, rHDPE, and rPLA. | Reduces plastic waste, cost-effective, supports circular economy, and lowers environmental impact. | Limited weather resistance for long-term outdoor use, potential loss of material strength after recycling. | Recycled PET (rPET), rHDPE, rPLA |

| Biodegradable Polymers | Materials like PLA derived from renewable resources such as corn starch or sugarcane. | Biodegradable, low carbon footprint, derived from renewable sources. | Limited durability and weather resistance compared to conventional plastics. | PLA, PHA (Polyhydroxyalkanoates) |

| Natural Fiber Composites | Combinations of biodegradable polymers (such as PLA) with natural fibers like hemp, flax, or bamboo. | Renewable, lightweight, improved mechanical properties, and aesthetic appeal. | Sensitivity to moisture, UV degradation, and limited strength in some cases. | Hemp–PLA, Bamboo-PLA composites |

| Bio-based Resins | Resins derived from plant-based sources, offering a more sustainable alternative to petroleum-based resins in SLA 3D printing. | Derived from renewable resources, reduced environmental impact in production. | Potential limitations in strength and durability under harsh conditions, less widely available. | Plant-based SLA resins |

| Design Consideration | Key Aspects | Impact on Urban Furniture |

|---|---|---|

| Ergonomics and Comfort | Anthropometric customization, pressure distribution, flexible structures | Enhances user experience, reduces physical strain, improves accessibility |

| Aestheticand Cultural Integration | Parametric design, biomimetic forms, cultural motifs | Strengthens cultural identity, improves visual harmony, fosters community engagement |

| Modularity | Interlocking components, reconfigurable layouts, easy disassembly | Allows for adaptability, facilitates repairs, extends furniture lifespan |

| Scalability | Large-format 3D printing, scalable designs from benches to pavilions | Enables urban customization, supports diverse public space applications |

| Sustainability | Recycled materials, circular economy principles, material optimization | Reduces environmental impact, promotes longevity, aligns with green urban planning |

| Aspect | Conventional Manufacturing | 3D Printing (Additive Manufacturing) | Source(s) |

|---|---|---|---|

| Typical Materials | Metals (cast iron, steel), concrete, treated wood | Thermoplastics (PLA, PETG), recycled polymers, composites (natural fibers, filled filaments) | Sipahi & Sipahi (2024); Prashar et al. (2023); Kantaros et al. (2023) [Advanced Composite Materials] [6,43,157] |

| Average Lifespan | 10–20 years with regular maintenance (painting, anti-corrosion) | 5–15 years depending on polymer durability, UV exposure, protective coatings | Grassi et al. (2019) [3D-printed façade durability]; Afshar & Wood (2020); Saavedra-Rojas et al. (2024) [85,86,94] |

| Production Lead Time | Typically 2–6 weeks (mold making, casting, assembly, finishing) | 1–5 days for direct fabrication; on-demand, localized production | Zuo et al. (2023) [Large-scale 3D printing adoption]; Kantaros et al. (2024) [Post-Processing] [60,151] |

| Unit Cost | High for custom molds and small batches; cost-efficient for mass production | More cost-effective for custom or small series; cost depends on material and printer amortization | Alzarooni (2019) [3D Printing for façade cost reduction]; Montes & Olleros (2020) [Local on-demand fabrication] [97,158] |

| Customization | Limited: new mold for each variant increases costs | High: geometry easily adjusted in CAD; parametric design supports personalization | Madrigal & Jeong (2022); Yang & Du (2022); Biyun Qiao et al. (2021) [141,155,159] |

| Sustainability Aspects | Traditional processes generate waste (e.g., excess concrete, scrap metals); recycling can be complex | Recycled polymers, upcycled plastic waste, circular economy concepts; local production reduces transport footprint | Arvaniti-Pollatou (Print Your City); Salloum Stanbuly (2023); Chiappelli (2024) [160,161,162] |

| Maintenance Needs | Periodic repainting, anti-rust treatment for metal; wood needs weatherproofing | Monitoring UV degradation, applying protective coatings; modular repairs possible with digital files | Afshar & Wood (2020); Saavedra-Rojas et al. (2024); Mason (CompositesWorld) [85,86,163] |

| Challenge | Description | Future Directions/Potential Solutions |

|---|---|---|

| Structural Integrity and Safety Compliance | Risk of material weakness due to novel layer-based manufacturing; variable mechanical properties. |

|

| Environmental Exposure and Durability | UV degradation, moisture, and mechanical wear affect longevity. |

|

| Regulatory Compliance | Lack of standards for AM infrastructure complicates approval processes. |

|

| Economic Feasibility | High costs of materials, equipment, and specialized labor. |

|

| Integration of Smart Technologies | Increased complexity and cost; concerns about power, protection, and data privacy. |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Ganetsos, T.; Kanetaki, Z.; Stergiou, C.; Pallis, E.; Papoutsidakis, M. Design and Fabrication of Customizable Urban Furniture Through 3D Printing Processes. Processes 2025, 13, 2492. https://doi.org/10.3390/pr13082492

Kantaros A, Ganetsos T, Kanetaki Z, Stergiou C, Pallis E, Papoutsidakis M. Design and Fabrication of Customizable Urban Furniture Through 3D Printing Processes. Processes. 2025; 13(8):2492. https://doi.org/10.3390/pr13082492

Chicago/Turabian StyleKantaros, Antreas, Theodore Ganetsos, Zoe Kanetaki, Constantinos Stergiou, Evangelos Pallis, and Michail Papoutsidakis. 2025. "Design and Fabrication of Customizable Urban Furniture Through 3D Printing Processes" Processes 13, no. 8: 2492. https://doi.org/10.3390/pr13082492

APA StyleKantaros, A., Ganetsos, T., Kanetaki, Z., Stergiou, C., Pallis, E., & Papoutsidakis, M. (2025). Design and Fabrication of Customizable Urban Furniture Through 3D Printing Processes. Processes, 13(8), 2492. https://doi.org/10.3390/pr13082492