3.1. Heat Transfer Mechanisms in Facade Cavities

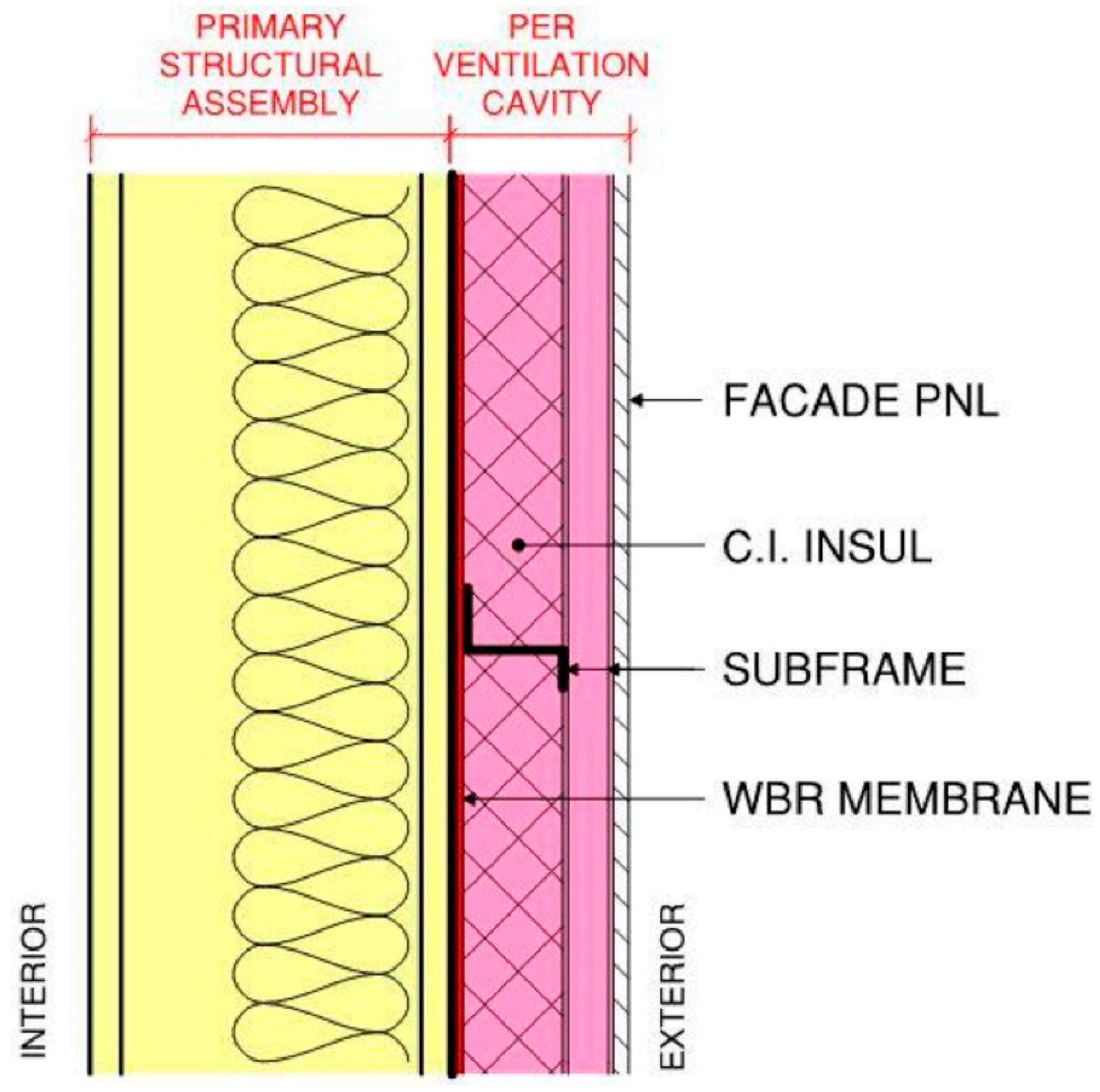

VF systems fundamentally alter the heat transfer pathways through a building envelope by introducing an air cavity between the outer cladding and the insulated inner wall. In this cavity, heat transfer occurs via conduction, convection, and radiation in a dynamic interplay distinct from a solid wall assembly. Conduction in a ventilated cavity is limited primarily to the solid components (cladding attachments and support brackets) rather than across the whole facade area [

35]. By contrast, in a conventional insulated wall (e.g., an ETICS system), conductive heat flow spans the entire wall surface, transmitting heat inward wherever insulation or thermal mass is contiguous [

36]. The ventilated cavity thus interrupts continuous conductive paths; heat must traverse the discontinuous metal fixings or thermal bridges, which occupy a small fraction of the facade area [

37]. This significantly reduces the effective conductive heat gain into the building, as illustrated in

Figure 4, where heat flow in a VF is largely confined to the discrete connectors instead of the whole wall plane. The thermal lag introduced by the ventilated layer further delays any residual conductive heat transfer, as the outer cladding and air gap absorb and dissipate heat before it reaches the inner wall. In essence, the ventilated cavity acts as a buffer that slows and reduces conductive heat flow. This is a key reason why VFs can keep the interior side cooler during hot periods and warmer during cold periods.

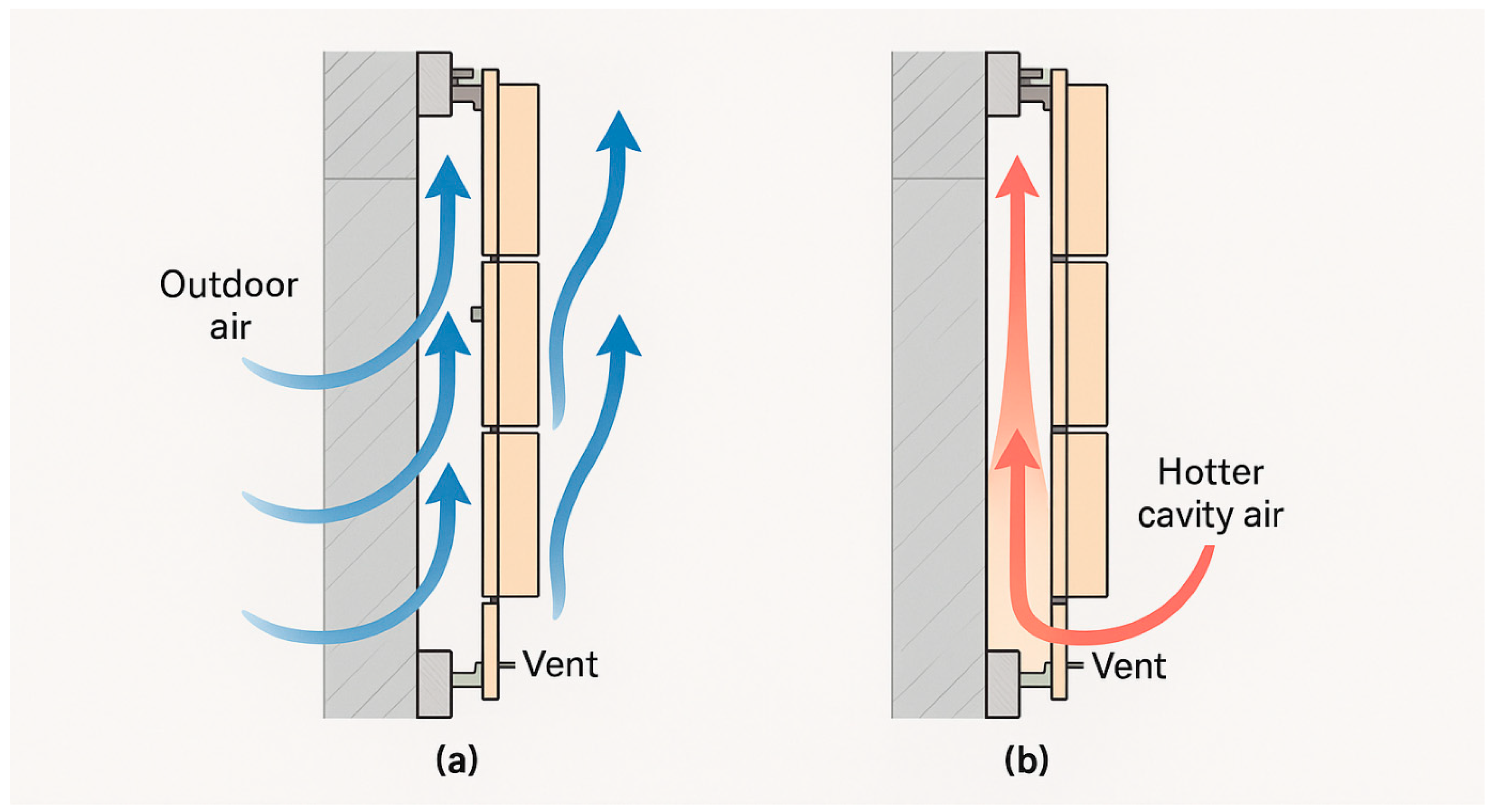

In the ventilated cavity, convection plays a dominant role in removing heat through buoyancy-driven airflow. When solar radiation heats the outer cladding and cavity air, the air’s density decreases, causing it to rise—a stack effect that induces upward airflow through the cavity [

38]. This buoyancy-driven ventilation carries away a significant portion of the absorbed heat before it can conduct inward, effectively cooling the cavity. Even in the absence of wind, a VF generates airflow solely by this buoyancy effect, directly proportional to the intensity of solar heating [

39]. Experiments and simulations show that the air velocity within the cavity under windless conditions is governed by the temperature difference (solar induced) between the cavity air and the outside environment [

40,

41]. As solar radiation increases, the buoyant flow becomes stronger, enhancing convective heat removal. In addition, any external wind will further drive convection: a wind pressure at the facade openings forces outside air into the cavity (at lower vents) and pulls heated air out (at upper vents). Studies have noted a clear correlation between external wind speed and the air speed inside the cavity [

42]. At higher wind velocities, convection in the cavity transitions from pure buoyancy-driven to a mixed or forced convection regime, which can equalise the performance of different cavity designs. For instance, at roughly 5 m/s wind, both open-joint and closed-joint VFs achieve similar heat removal efficiency, and the resulting indoor wall temperatures converge (differing by merely ~0.1 °C) [

43]. This indicates that beyond a certain airflow rate, convective cooling in the cavity reaches an effective maximum where additional wind offers diminishing returns.

Due to the continuous air exchange, the ventilated cavity also facilitates convective heat transfer coefficients at the interior surfaces that are higher than in a sealed air gap. According to Zhang et al. [

44], an unventilated air layer within wall assemblies can exhibit a thermal resistance of about 0.15 (m

2.K)/W, effectively reducing heat transfer through the building envelope. This value underscores the insulating capability of unventilated air gaps in building constructions. By contrast, an open ventilated cavity sustaining moderate airflow can have an order-of-magnitude higher convective heat transfer, effectively cancelling much of the insulation effect of the air layer [

45]. Field studies have shown that very high ventilation rates (on the order of 100 air changes per hour in the cavity) render the air gap’s thermal resistance nearly negligible, as the air temperature in the gap closely tracks the outdoor temperature [

46].

Likewise, radiative heat exchange in the cavity is mitigated by ventilation: the moving air continuously removes hot air and replaces it with cooler air, reducing the mean radiant temperature in the gap. Nonetheless, radiation between the hot inner face of the cladding and the cooler outer face of the insulation still occurs. High-emissivity surfaces in the cavity can radiatively transfer heat across the gap, but this is partly offset by the convective cooling of those surfaces by airflow. Some VF designs use low-emissivity (low-e) coatings on the cavity-facing side of the cladding or insulation to further cut down radiative heat transfer [

47]. The interplay between conduction, convection, and radiation is summarised in

Table 2, which categorises each heat transfer mode according to its pathway, influencing factors, and how it can be either enhanced or suppressed through design interventions such as cavity depth, material emissivity, and vent sizing. In summary, the cavity airflow concurrently convects heat out and cools the surfaces, while also limiting radiative exchange by lowering surface temperatures.

The stack effect in taller facades can amplify these convective processes. In multi-storey ventilated cavities, cooler air is drawn in at the bottom vent as warm air continuously rises and exits at the top, creating a self-sustaining upward airflow loop. This means the upper sections of a tall cavity often see higher air temperatures and velocities than the lower sections, especially under strong solar gain [

48]. Notably, researchers found that cavity air temperatures increase with height more markedly in an open-joint VF than in a closed-joint system [

49]. The open-joint configuration allows free entry of air along the height, producing a greater stack effect and thus a steeper temperature gradient up the wall. In contrast, a closed-joint (or limited inlet) design yields a more uniformly warm cavity but with less airflow, meaning heat is less effectively carried away. Paradoxically, although the closed cavity can become hotter internally, that heat is less rapidly dissipated, which can lead to slightly more heat transfer inward compared to an open joint under the same conditions [

50]. Designers must therefore balance cavity openness: open-jointed facades maximise convective cooling (with cavity air speeds up to five times higher than closed systems under identical conditions, whereas closed or baffled facades reduce rain ingress and may trap some heat (which can be useful in winter but is a liability in summer).

Figure 5 illustrates the airflow patterns for open- vs. closed-joint ventilated cavities. In the open-joint case, outdoor air freely enters at the base and through panel gaps, rushing upward and out, whereas in the closed-joint case, air enters only at designated vents, resulting in lower velocities and a hotter cavity air column.

Finally, the ventilated cavity introduces a thermal inertia and buffering effect, often termed thermal lag. During daytime solar exposure, part of the heat is absorbed by the cladding and cavity air, then vented out before reaching the inner wall. The inner wall experiences a delayed and reduced heat load, often peaking later in the day or not at all, compared to a wall without ventilation [

51]. At night, the outer cladding cools and can even draw heat out of the cavity (if the cladding reradiates to the cold sky), sometimes resulting in a reverse flow (cool air sinking). The net result is a moderation of interior wall temperature swings over the 24 h cycle [

52]. For example, Khadraoui et al. [

53] experimentally and numerically demonstrated that ventilated double-wall systems significantly moderate indoor temperature fluctuations during cold periods. In a hot-arid climate, the system enhanced thermal inertia and reduced heating energy consumption by up to 15%, confirming the buffering effect of natural convection within the cavity. This demonstrates how the interplay of conduction, convection, and radiation in a ventilated cavity collectively improves the thermal performance by damping heat flow peaks and leveraging natural forces (buoyancy and wind) to eject unwanted heat. In relation to these thermal improvements, different ventilation strategies, namely natural, forced, and hybrid, offer varying levels of effectiveness depending on climatic conditions and energy goals. As shown in

Table 3, natural ventilation provides energy-free airflow but is weather-dependent, while hybrid systems deliver the highest and most adaptive performance with minimal energy input. Understanding these trade-offs helps inform smarter design decisions for low-carbon buildings.

In summary, the physics of a VF cavity can be seen as a hybrid heat transfer system: conductive paths are minimised, convective airflow actively removes heat, and radiative exchange is mitigated by lower surface temperatures and potential low-e surfaces [

54]. Buoyancy-driven stack effect ventilation is the engine of heat removal in calm conditions, while wind can further augment convective cooling to the point of equalising performance across design variants at sufficient speeds. These mechanisms together explain why VFs significantly reduce heat flux entering the building, on the order of 25–30% less heat transfer compared to non-ventilated walls under summer conditions, according to multiple studies [

45]. By integrating these principles into design (e.g., sizing vents, selecting cladding with suitable emissivity, and providing an adequate cavity gap), modern VFs leverage physics to passively maintain better thermal control of the building envelope. These design elements are further detailed in

Table 4, which identifies key parameters such as cavity depth, vent area ratios, airflow velocity, and material emissivity. Each plays a critical role in defining the heat transfer balance, and collectively, they offer a roadmap for optimising facade thermal behaviour in both new builds and retrofits.

3.2. Cooling Load Reduction and Heating Efficiency

VFs are widely recognised for their ability to reduce cooling loads in buildings while also enhancing heating efficiency in cooler seasons. By intercepting and venting out a large fraction of incident solar heat, a VF dramatically cuts down the heat gain that would otherwise penetrate the building, thereby lowering the demand on cooling systems [

55]. At the same time, in cold weather or heating seasons, the ventilated cavity can be managed to improve thermal performance, for instance, by closing vents or recovering warmth from the cavity air, thus contributing to heating energy savings. This dual benefit has been demonstrated in both experimental studies and whole-building energy simulations over the past decade.

A VF acts as a passive cooling device for the building envelope. During hot periods, solar radiation that hits the outer cladding is largely dissipated by the ventilating air gap, preventing it from elevating the wall’s inner surface temperature. Empirical and simulation studies consistently report substantial reductions in the cooling energy required for buildings equipped with VFs. For example, Patania et al. [

56] found that in summer, VFs achieved over 40% energy saving in cooling needs compared to identical non-ventilated walls. Similarly, Gagliano et al. [

57] performed CFD analyses under summer design conditions and calculated a 47–51% reduction in heat flux through a VF relative to a non-VF. This roughly translates to nearly halving the cooling load attributable to envelope gains, a remarkable improvement.

Table 5 summarises several key studies reporting cooling load or heat gain reductions, illustrating that savings on the order of 20–55% are often achieved across different climates and facade configurations.

From these data, it is evident that VFs can often eliminate a very large portion of the cooling load that would be imposed by solar heating of walls. The highest savings (40–55%) tend to occur in hot climates and seasons with intense solar radiation, and on facades with high sun exposure (e.g., east and west orientations, which catch low-angle sun). For instance, a study in Italy found the peak cooling energy savings were for east- and west-facing walls in summer, reaching the 50%-plus range [

60]. In more moderate conditions or with some wind-driven mixing, the savings may be a bit lower (20–40%), but still significant. Even a 10% reduction in annual cooling electricity was observed in a real building in Valencia simply by using a ventilated rainscreen instead of a sealed facade, underlining that measurable gains occur in practice [

61]. It should be noted that these savings are passively achieved—i.e., without any mechanical power—which makes VFs an attractive strategy for low-carbon building design.

VFs prevent heat accumulation on the exterior wall by flushing hot air out. This leads to a lower exterior wall temperature on the inside in summer, as Naboni et al. [

62] observed in an experimental building in Milan. By keeping the wall’s inner surface cooler (often by several °C), the heat entering the room is delayed and diminished. Occupants or HVAC systems, therefore, face a much reduced thermal load. In many cases, the peak heat flux through the wall is shaved off and spread over a longer period (thermal lag), which also helps reduce peak cooling demand in the afternoon. In cooler seasons, a VF can be managed to improve heating performance, although the strategy differs from summer operation. If the cavity were left fully open in winter without sun, it could act as a thermal bypass, potentially increasing heat loss (since cold air would flush the cavity). However, several approaches allow VFs to benefit from heating efficiency:

On sunny winter days, the ventilated cavity can act as an additional insulation layer, capturing solar energy to warm the air, which then reduces heat transfer from the indoor space. Masi et al. [

63] conducted a year-long experimental monitoring in a Mediterranean climate and showed that an open-joint OVF system reduced winter heat fluxes by up to 85% compared to a non-insulated wall. The inner surface temperature remained close to or even higher than indoor air temperature in 18% of the winter observations, with a temperature increase of up to 2.7 °C. These findings confirm that the ventilated air cavity not only stabilises the wall surface temperature but also contributes positively to wintertime solar heat retention, effectively warming the inner wall layer and reducing the heating energy demand.

Closing or throttling vents: Many modern VFs (or DSFs) include operable vent closures. By closing the cavity openings in cold weather, the air gap becomes an enclosed insulating layer akin to trapped air insulation. This significantly increases thermal resistance and prevents cold air from drawing heat away. An OVF in “closed mode” essentially acts like an added exterior insulating blanket during winter nights, while still allowing an open mode on sunny days for solar collection. Saber et al. [

64] note that locations with low winter severity are most favourable, but even in colder climates, designers can adopt seasonal vent control to maximise benefits.

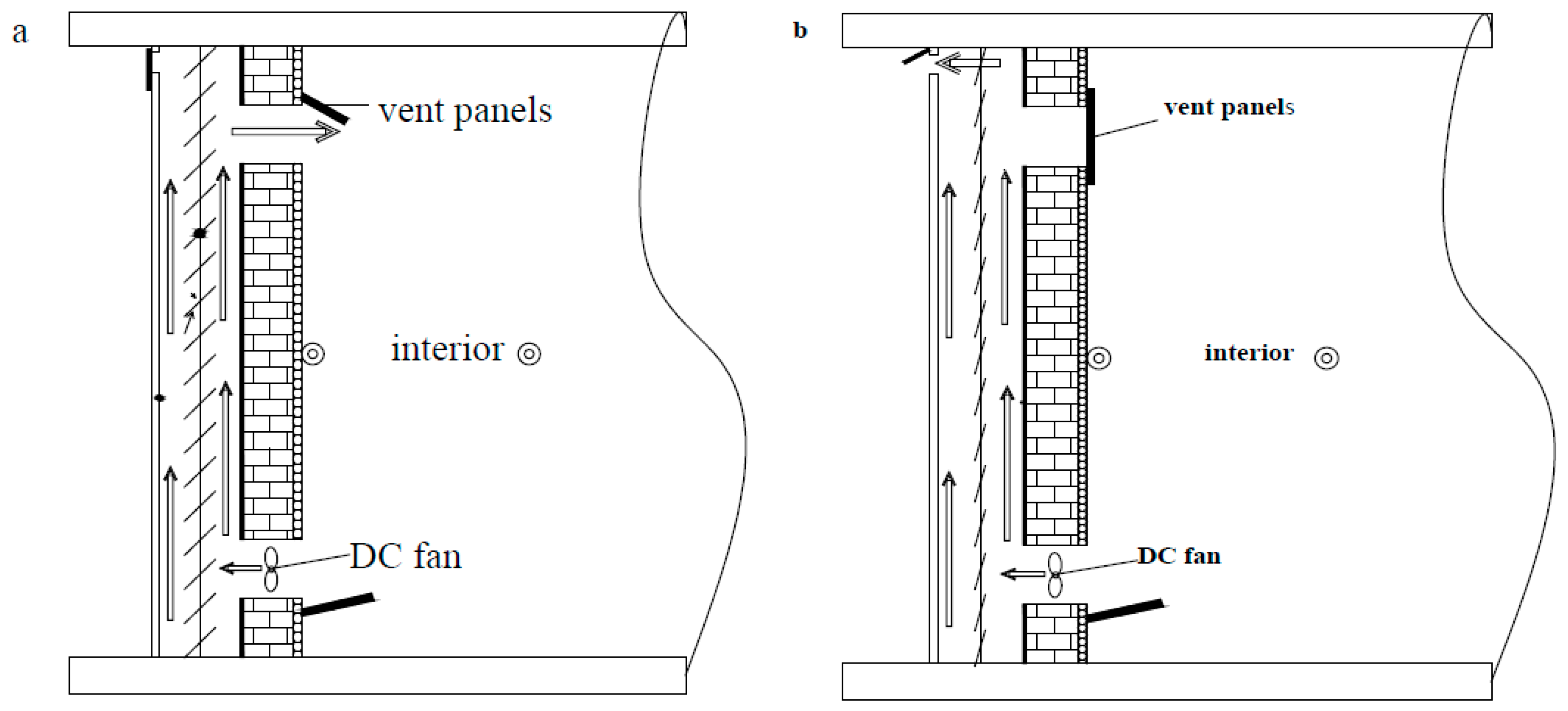

Heat recovery and supply air preheating: Beyond passive thermal buffering, advanced VFs can actively contribute to HVAC efficiency through heat recovery from the cavity air. For instance, Sukamto et al. [

65] numerically demonstrated that solar-heated air in the ventilated cavity can preheat supply air, with up to 90 W of heat exchange in winter, substantially reducing heating losses. Similarly, Rahiminejad and Khovalyg [

66] evaluated heat recovery from ventilated cavities behind passive and active facades, showing that the air space can deliver thermal gains exceeding 5000 kWh/day under optimal summer conditions. These findings support the integration of VFs into mechanical ventilation systems, enabling the captured solar heat to precondition fresh air before it enters the building. Diallo et al. [

67] extended this concept by simulating a hybrid facade system (E2VENT) using TRNSYS, revealing 16.5–23.5% primary energy savings across five European climates when heat recovery and latent storage are included. These results underline the significant potential of ventilated cavities as functional energy components, not merely thermal buffers, but active solar air heaters when properly coupled with HVAC systems.

Reducing thermal bridging and infiltration: VFs play a critical role in enhancing the thermal integrity of building envelopes by relocating the waterproofing layer and cladding to the exterior, thereby protecting the insulation from moisture ingress and temperature fluctuations. Van Linden and Van Den Bossche [

68] showed through hygrothermal simulations and rain infiltration tests that keeping the insulation layer dry is essential for maintaining thermal resistance; even minor water ingress can increase annual heat flux by up to 10.5% in shallow cavities. The air cavity in ventilated systems also acts as a wind pressure buffer, significantly reducing the differential pressure across the interior layers of the wall and thereby limiting air leakage and cold drafts, particularly in windy and cold climates. Furthermore, field studies by Colinart et al. [

69] on a retrofitted educational building in an oceanic climate demonstrated that VFs led to higher-than-expected thermal resistance values in winter, with stable hygrothermal conditions and reduced risk of condensation. Complementarily, Azkorra-Larrinaga et al. [

70] found that incorporating an open-VF increased the effective thermal resistance from 0.75 to 2.47 (°C.m

2)/W, whilst also decreasing air infiltration and heat absorption under solar load. Collectively, these results validate the role of VFs in reducing thermal bridging, preventing moisture accumulation, and improving heating efficiency and occupant comfort in diverse climatic conditions.

It is important to design VFs appropriately for the climate to maximise these dual-season gains. In predominantly hot climates, the emphasis is on maximising ventilation (open joints, large vents) to dump heat in summer, accepting that in the brief cool season, the facade might simply act as a sunscreen and light insulation. In mixed or cold climates, a more adaptive approach is needed: vents that can close, or hybrid modes where the facade sometimes operates like a closed cavity or even intentionally admits solar-heated air indoors. For instance, so-called Trombe wall integrations use ventilated air spaces with thermal mass to store and slowly release heat, which can outperform a purely VF in winter [

71]. The literature suggests that the most favourable climates for year-round energy benefit are those with high cooling loads and moderate winters (e.g., Mediterranean, subtropical), where the VF saves a lot in summer without incurring a big winter penalty. In very severe winter climates, VFs still provide summer savings, but designers may need to mitigate winter heat losses (through the methods above) to ensure net annual benefits [

72].

In summary, VFs substantially reduce cooling loads by venting away solar heat (commonly achieving 20–50% cooling energy savings, and they can also enhance heating efficiency through solar heat capture and insulating effects (with 10–20% heating savings in many cases, and much higher if integrated with heat recovery). These improvements have been demonstrated in both experimental test cells and occupied buildings across various climates. The combination of lower cooling demand and improved heating performance makes VFs a key technology for low-carbon buildings, as they reduce HVAC energy use in all seasons while relying predominantly on passive physical processes (natural convection and solar gains) rather than active energy input. In order to facilitate a comprehensive comparison of ventilated and advanced facade configurations,

Table 6 presents a detailed summary of their seasonal performance (in both cooling and heating modes), impact on thermal comfort, structural and economic considerations, and overall applicability across building types and climate zones. This comparative matrix serves to consolidate the various facade strategies examined in the literature, highlighting their relative strengths and limitations in an easily interpretable format.

3.3. Impact on Indoor Thermal Comfort

Beyond energy metrics, VFs have a pronounced influence on indoor thermal comfort, affecting parameters such as interior surface temperatures, temperature uniformity, and occupants’ thermal sensation indices (e.g., PMV, Predicted Mean Vote). By moderating the heat flow through external walls, VFs create more stable and comfortable indoor conditions for occupants. The study in different climates has evaluated how these facades alter the thermal environment inside buildings, finding generally positive impacts on comfort when properly implemented [

78].

One key comfort benefit is the improvement in temperature uniformity within the occupied space. In a room with a conventional facade, the interior surface of an external wall can become very hot in summer or very cold in winter, leading to discomfort for occupants near the wall and uneven temperature distribution (for instance, a hot zone near a sun-exposed wall, even if the thermostat is set lower). With a VF, the interior wall surface stays significantly closer to the indoor air temperature, avoiding extreme surface temperatures. Field measurements confirm that in summer, a VF can keep the inner wall surface several degrees cooler than it would be with a non-ventilated wall. A warmer wall in winter reduces the radiant heat loss from occupants’ bodies to the surroundings, thus improving comfort without needing to raise air temperature. In essence, VFs act to diminish the radiant asymmetry between indoor surfaces, which is a crucial factor in occupant comfort. An environment where all surfaces are near the air temperature feels more comfortable than one with a very cold wall and warm air, or vice versa [

79]. By maintaining wall surface temperatures closer to ideal levels, VFs help keep PMV values in the comfortable range with fewer complaints of draft or radiant discomfort [

80]. Whilst current VF systems increasingly incorporate automated and sensor-based controls, there is a notable gap in user-centric approaches that integrate occupant feedback into facade operation. Future research should explore human-in-the-loop (HITL) control strategies that dynamically adjust facade parameters, such as shading, ventilation rate, or glazing properties, based on real-time input from building occupants. These systems could leverage thermal comfort feedback, mobile interfaces, or wearable sensors to personalise indoor environments on maintaining energy efficiency. Such adaptive frameworks hold promise for optimising comfort satisfaction, especially in mixed-mode or naturally ventilated buildings where occupant behaviour plays a critical role.

Studies that explicitly calculate comfort metrics have reinforced these observations. In a hot-arid climate context, Fallahpour et al. [

81] employed a 3D quasi-steady CFD model and a multi-objective optimisation approach to analyse the impact of key geometric parameters of DSFs on indoor thermal conditions. By simulating airflow and temperature in a 6 × 8 × 2.8 m

3 test room equipped with a DSF, the authors demonstrated that parameters such as room air outlet height, DSF air outlet height, and interior glazing height are critical for achieving optimal airflow and minimising temperature differentials between indoor and outdoor environments. The optimised configuration reduced the indoor–outdoor temperature difference to as low as 1.04 °C and nearly eliminated reverse airflow, highlighting DSF’s strong potential to maintain thermal comfort in hot-arid zones. These findings underscore the effectiveness of DSF design in passively stabilising indoor temperatures, especially when geometric interactions are fully considered. This was achieved passively, indicating how effective the ventilated cavity was at smoothing out the indoor climate. Even during the cold desert night, the VF’s buffering effect meant the indoor temperature did not plummet as much, avoiding the discomfort of very low indoor operative temperature by morning.

Another comfort aspect is the reduction in thermal stratification and drafts. By design, VFs typically include a continuous air barrier on the interior wall, which improves air tightness. The wind pressure fluctuations on the building exterior are dampened by the ventilated cavity, the air in the cavity can move independently, so the pressure that reaches the inner wall is more uniform. This means less cold outside air is sucked into the room through cracks (reducing cold drafts) and less warm indoor air is pulled out. Enhanced airtightness and stable pressures contribute to more consistent indoor temperatures from floor to ceiling and fewer localised cold spots near the wall. Occupants thus experience a more uniform environment, which correlates with higher comfort satisfaction. In naturally ventilated buildings, the VF can also help channel intentional airflow in a controlled manner when windows are opened, rather than having unpredictable infiltration paths. By providing an intermediate ventilation space, it is possible to supply outdoor air more gradually or even pre-condition it in the cavity before it enters the occupied zone (some advanced systems draw room air into the cavity and exhaust it at the top, aiding ventilation without drafts) [

2]. All these effects mean that the indoor air velocity around occupants can be better managed. Typically, a ventilated opaque facade does not directly create indoor air movement (since the cavity is sealed from the room), but indirectly it prevents unwanted high-velocity infiltration jets. This is beneficial because it avoids discomfort due to cold drafts in winter, and in summer it ensures that if natural ventilation is used, it can be performed when needed for cooling rather than as an uncontrolled byproduct of wind pressure. In short, VFs contribute to a draft-free, stable environment, which is a cornerstone of thermal comfort.

It is important to note that VFs primarily address thermal comfort (temperature-based comfort). They also incidentally can contribute to better indoor air quality when integrated with ventilation systems (by providing pre-heated fresh air, or encouraging ventilation when needed), though a basic rainscreen facade by itself does not supply fresh air. Acoustically, the double-skin VF can reduce outside noise, which is another comfort facet (though outside our thermal focus) [

82]. Visually, OVFs do not affect daylight, but ventilated double-skin glazed facades can reduce glare by incorporating shading in the cavity, however, that strays into a different performance area. In conclusion, VFs enhance indoor thermal comfort by stabilising interior surface temperatures, reducing radiant heat asymmetry, and preventing unwanted drafts or hot spots. Studies across climates from tropical to arid to temperate show more hours within the comfort zone and improved comfort indices (lower PPD) when VF systems are in place. These comfort improvements complement the energy savings discussed earlier: a building that requires less active cooling/heating also tends to be one where occupants feel more comfortable naturally. By leveraging passive environmental control, VFs create indoor environments that are not only energy-efficient but also healthier and more pleasant for occupants, aligning with the goals of sustainable, high-performance buildings.

3.4. Performance in Different Climate Zones

The effectiveness of VFs can vary significantly across different climate zones, and successful designs often incorporate climate-responsive strategies to optimise performance. In this subsection, the VF performance in tropical, temperate, continental, and arid climates is compared, drawing on case studies and simulations from around the world. It is also discussed how design parameters are adapted to each climate for maximum benefit, and present comparative metrics (such as energy savings and interior temperature moderation) for these zones.

Tropical Climates (Hot-Humid): In tropical regions, buildings face year-round high temperatures, intense solar radiation, and often high humidity. The primary goal of a VF here is to minimise cooling loads and prevent overheating, as heating is rarely needed. Studies consistently show that OVFs can significantly cut heat gains in tropical climates [

83]. Recent investigations reinforce the effectiveness of ventilated and DSFs in tropical and subtropical regions by demonstrating significant reductions in cooling energy consumption through integrated passive and active strategies. Tognon et al. [

84] assess the use of operable windows and show that natural ventilation can reduce cooling loads by up to 30% in warm climates such as Italy and by 11% even in colder climates like Finland. Shading devices within naturally ventilated DSFs (NVDSFs) are also highly effective, delivering energy savings between 24% and 76%, with simulation studies in Egypt reporting up to 76% reductions during peak summer [

85,

86]. Further enhancements through photovoltaic integration in NVDSFs can lower energy consumption by 50% to 84% in subtropical settings, while the application of intelligent control strategies contributes additional savings of 4.5% to 45%, depending on system complexity and climatic context [

87,

88,

89,

90]. Several region-specific studies complement these findings. In the Mediterranean, Coma et al. [

91] demonstrate that green DSFs reduce annual cooling loads by approximately 33.8%. In Saudi Arabia, the application of PCMs achieves dual-seasonal benefits, cutting cooling loads by 5.6% and heating demands by 11.5% in Jeddah, and reducing heating demand by 40% in colder cities like Tabuk [

92]. Chan et al. [

93] find that reflective double-glazing systems in Hong Kong can cut cooling energy needs by 26% annually. In East Asian climates, Lee et al. [

94] show that PV-ventilated windows reduce cooling energy by 10%, while An et al. [

95] and Kang et al. [

96] demonstrate that solar-driven DSFs (SDSFs) achieve 6.5% to 50.1% reductions in both heating and cooling loads. Similarly, Khabir and Vakilinezhad [

97] report that optimised DSF configurations can yield up to 63% cooling energy savings in hot climate scenarios. A comprehensive case study in Dhahran by Rababa and Asfour [

98] explores 224 facade retrofit combinations using genetic algorithm optimisation. The most effective solution combines external thermal insulation composite systems (ETICS) for walls, low-emissivity Argon-filled glazing, and louvred shading, resulting in a 16% reduction in annual cooling electricity use with a 14.8-year payback period. Individually, external wall retrofits reduce cooling loads by 11.1–18%, while advanced glazing and window systems offer up to 8% further savings, confirming the value of integrated, locally adapted retrofit strategies in extremely hot environments. These collective findings underscore the growing importance of climate-responsive VF systems, particularly in regions where year-round solar and thermal stress dominate building energy performance.

Design strategies for tropical VFs emphasise maximal ventilation and solar reflection. This means larger or more numerous vent openings, sometimes even operable vents, to enhance airflow when solar gain is high. External cladding materials with low solar absorptance (light-coloured or reflective finishes) are preferred to reduce solar heating of the facade [

99]. Indeed, a study in a tropical climate suggests using lighter-colour claddings to further cut down cavity temperatures, especially if the facade has no insulation, the colour effect can be quite pronounced in reducing absorbed heat [

83]. Additionally, tropical designs may integrate sunshades or louvres in front of the ventilated cavity to block direct sun angles, thereby reducing the load on the cavity itself.

Temperate Climates: Temperate zones have moderate summers and winters, requiring both cooling and heating over the year. VFs in these climates must provide a balance of cooling relief in summer and not significantly penalise (or even aid) heating in winter. Many European countries (e.g., much of Italy, France, and coastal regions) and parts of North America fall into this category. In temperate climates, case studies often show annual energy savings from VFs in the range of 10–60%, depending on design and operation. For example, Raji et al. [

100] examined the impact of building envelope design on energy consumption in high-rise office buildings located in temperate climates. The study found that optimising parameters such as glazing type, window-to-wall ratio (around 50%), shading strategy, and roof design can reduce total energy use by up to 42%, with significant savings in heating and lighting energy. Another study in Spain (temperate/Mediterranean climate) by Peci and Ruiz [

101] found that the best locations for VFs were those with mild winters and ample sun, whereas very cold, cloudy winter sites saw less net benefit. This implies temperate coastal or southern regions gain more than temperate inland or northern areas with the same facade design. In Spain’s analysis of 12 cities, the VF saved energy in all, but cities with higher solar irradiation and moderate winter temperatures (e.g., Seville, Valencia) performed the best, whereas a cooler, cloudier city still saw savings but smaller. In hot-humid climates, the absence of systematic facade design guidance may hinder performance, and early-stage integration of climate-responsive strategies is essential [

102]. Moreover, naturally ventilated DSFs with hybrid or passive control systems can provide annual energy savings up to 47.9%, particularly effective in subtropical and tropical regions [

55]. Meanwhile, bio-based VFs demonstrate measurable cooling benefits and lifecycle sustainability in hot-arid climates, such as Dubai [

103].

Designers in temperate zones often incorporate seasonal adjustability in VFs. For instance, some systems include dampers that can partly close the cavity in winter to reduce ventilation heat losses. Others use a hybrid approach: in summer, the facade is fully ventilated; in winter, it operates like a static air layer or even a Trombe-wall-like collector if sunny. The OVF concept in temperate climates can be paired with thermal mass, e.g., a heavy inner wythe that soaks up daytime heat from the cavity when the sun is out and then releases it inward during the evening [

72]. Research in Italy has suggested that adding thermal mass in contact with the ventilated air gap (either as the inner wall or within the cavity) can reduce heat transfer and improve inertia in climates with significant daily temperature swings [

104]. Thus, a VF in a temperate climate might consist of an outer rain-screen (possibly glass or metal panels), a ventilated gap, and a heavy masonry inner wall: in summer the mass stays cool as heat is vented, in winter the mass can be slightly warmed by solar-heated cavity air if vents are selectively closed.

Continental Climates: These are characterised by hot summers and cold winters (large seasonal variation), typical of inland locations in mid-latitudes (e.g., Eastern Europe, Northern China, U.S. Midwest). Here, VFs face the challenge of providing strong performance in two opposite extremes. In summer, they function much like in temperate or even tropical climates, cutting down cooling loads effectively. In winter, however, if operated exactly the same (fully open), they could increase heating demand by venting away heat. Performance in continental climates thus heavily depends on management and design. The literature shows that in continental climates, VFs still yield net positive outcomes, especially if innovations are used. A climate-responsive VF system integrating PCMs and dynamic insulation was developed and validated for a continental climate with hot summers and cold winters. Simulation and prototype testing showed that the facade achieved fresh air pre-conditioning efficiencies between 60% and 75% in both heating and cooling seasons, effectively adapting to daily and seasonal thermal loads. Its thermal transmittance could be actively modulated via controlled airflow, enabling substantial cooling load reductions in summer while limiting heat loss during winter. The dual active–passive mechanism demonstrated significant potential in reducing HVAC dependence in retrofitted and new buildings alike [

105]. Experimental investigations conducted in a continental climate with hot summers and cold winters demonstrated that OVFs deliver markedly different thermal benefits depending on seasonal configuration. In summer, an open-joint design with ventilated cavities reduced cooling loads by up to 11.4%, while in winter, a closed-joint, restricted-ventilation configuration achieved heating load reductions of around 6.5%. To address the contrasting requirements of both seasons, an integrated facade configuration is proposed, combining bright external cladding, a 200 mm air cavity, and ventilation openings that operate seasonally, open in summer and are sealed in winter. These findings highlight the importance of climate-responsive facade operation, where adaptive control strategies can significantly enhance annual HVAC energy performance [

50].

In continental climates, climate-responsive strategies may include the following: automated vent closures based on temperature (to trap heat on cold days), integration of PCMs in the cavity to store solar heat for nighttime heating or using the cavity as a source of fresh air pre-heating on cold sunny days. Yang et al. [

106] investigated a ventilated DSF integrating dual-step PCMs in a temperate continental climate, demonstrating that daytime-only ventilation (1.09 m/s) combined with PCMs (melting points at 16 °C and 28 °C) achieved up to 91.4% ventilation efficiency and significantly reduced temperature fluctuations. Curpek and Hraska [

107] simulated a ventilated PV facade with PCM under continental conditions in Slovakia, showing that airflow and PCM layers reduced surface temperatures by up to 20 °C in summer and 12 °C in winter, and delayed peak thermal loads by over five hours. de Gracia et al. [

108] applied reinforcement learning control to a ventilated PCM facade and achieved energy, cost, and CO

2 emission reductions of 4.3%, 7.8%, and 16.7%, respectively, highlighting the benefits of intelligent, climate-adaptive operation. Similarly, Hu et al. [

109] experimentally showed that a PCM-enhanced ventilated window could reduce inlet air temperatures by 1.4 °C for 7 h (pre-cooling) and increase them by 2.0 °C for 12 h (pre-heating), achieving daily energy savings up to 1.6 MJ depending on seasonal application.

Arid Climates (Hot–Dry): Arid regions (deserts and semi-deserts) typically have very high solar gains and temperatures in the day but can have cool or even cold nights due to low humidity and clear skies (allowing radiative cooling). Examples include parts of the Middle East, North Africa, the southwest U.S., and inland Australia. VFs in these climates can be extremely beneficial for cooling during the day, while also helping with the unique diurnal swing. During the hot daytime, the ventilated cavity expels heat like a chimney, keeping the building cooler. At night, the outside air can be quite cool; a VF can either be closed to keep interior heat in (if heating is needed at night) or even continue venting to cool down the thermal mass of the building for the next day (night purging). The flexibility here is key.

Sotelo-Salas et al. [

110] experimentally validated a CFD model for an evaporative OVF under hot-arid climate conditions. Their simulation identified the optimal configuration as a 0.4 m air cavity, 25 μm water droplet size, and 0.6 m nozzle spacing, achieving a maximum cooling efficiency of 64.7% and reducing the inner wall surface temperature by 9.52 °C. Unlike porous-coated facades, this system performed efficiently without increasing indoor humidity. The results highlight its potential as a passive cooling strategy in extreme climates. Meanwhile, at night, because the ventilated wall assembly had released its heat quickly at sunset, the inner wall stayed warmer than the highly heat-loaded solid wall (which tended to release heat into the interior at night). As a result, the building with a VF needed much less nocturnal heating or stayed comfortable without heating for longer [

111].

Finally, architects often integrate climate-responsive facade elements in tandem with ventilation. For instance, in arid and tropical climates, combining VFs with shading devices (external louvres or greenery) yields even better performance: the shading cuts direct solar load, and the ventilated cavity handles the residual heat. In temperate and continental zones, integrating adaptive facades (that open/close, or include operable insulation or sunshades) can ensure the facade is always configured best for the season. An emerging concept is the “multi-skin adaptive VF”, which might include, say, a ventilated cavity plus a dynamic insulation layer that can slide or inflate in winter nights. These innovations point to a future where VFs are a component of a smart climate facade system, adjusting to weather in real time. In summary, VFs have demonstrated substantial performance improvements across all climate zones, but with varying emphases: tropical and arid climates reap very large cooling-focused benefits; temperate climates enjoy balanced benefits in both summer and winter with modest annual gains; continental climates can achieve good results with careful design (to maximise summer gains and mitigate winter losses). Climate-responsive design strategies, such as vent control, material choices, and integration with other passive systems, are crucial to unlocking the full potential of VFs in each climate. The versatility of this technology, able to address the extremes of a humid tropical day, a dry desert night, or a chilly continental morning, underlines why VFs are increasingly seen as a key solution for low-carbon, comfortable buildings worldwide. The comparative data and case studies confirm that, when properly tuned to their environment, VFs consistently enhance energy performance and indoor comfort across vastly different climate conditions.

Several unexpected or counterintuitive findings emerged across the reviewed literature. For instance, open-joint ventilated facades were found to outperform closed-joint systems in certain cold-weather scenarios, contradicting assumptions about airtightness and insulation. Similarly, poorly optimised ventilated cavities, especially those with insufficient depth or vent sizing, were shown to underperform even when compared to conventional insulated walls. While green facades demonstrated exceptional cooling benefits, they also caused excessive shading and underheating during colder months. In some cases, smart facades relying on automated control systems consumed more energy than passive ones due to sensor miscalibration or algorithmic inefficiencies. Likewise, Trombe wall applications, generally praised for passive heating, led to interior overheating during summer in the absence of proper shading control. These findings underscore the importance of climate-adaptive configuration, precise control strategies, and system-specific design to avoid performance setbacks and maximise the intended benefits of ventilated facade technologies.