Effect of Different Gelling Agents on the Properties of Wine Jellies Prepared from Aromatic Grape Varieties

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials for Jelly Production

2.2. Jelly Preparation

2.3. Instruments and Analytical Methods

2.4. Sensory Analysis

2.5. The Hypothesis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Analytical Evaluation of Wines and Jellies

Total Phenolic Content and Antioxidant Capacity

3.2. Sensory Evaluation of Wines and Jellies

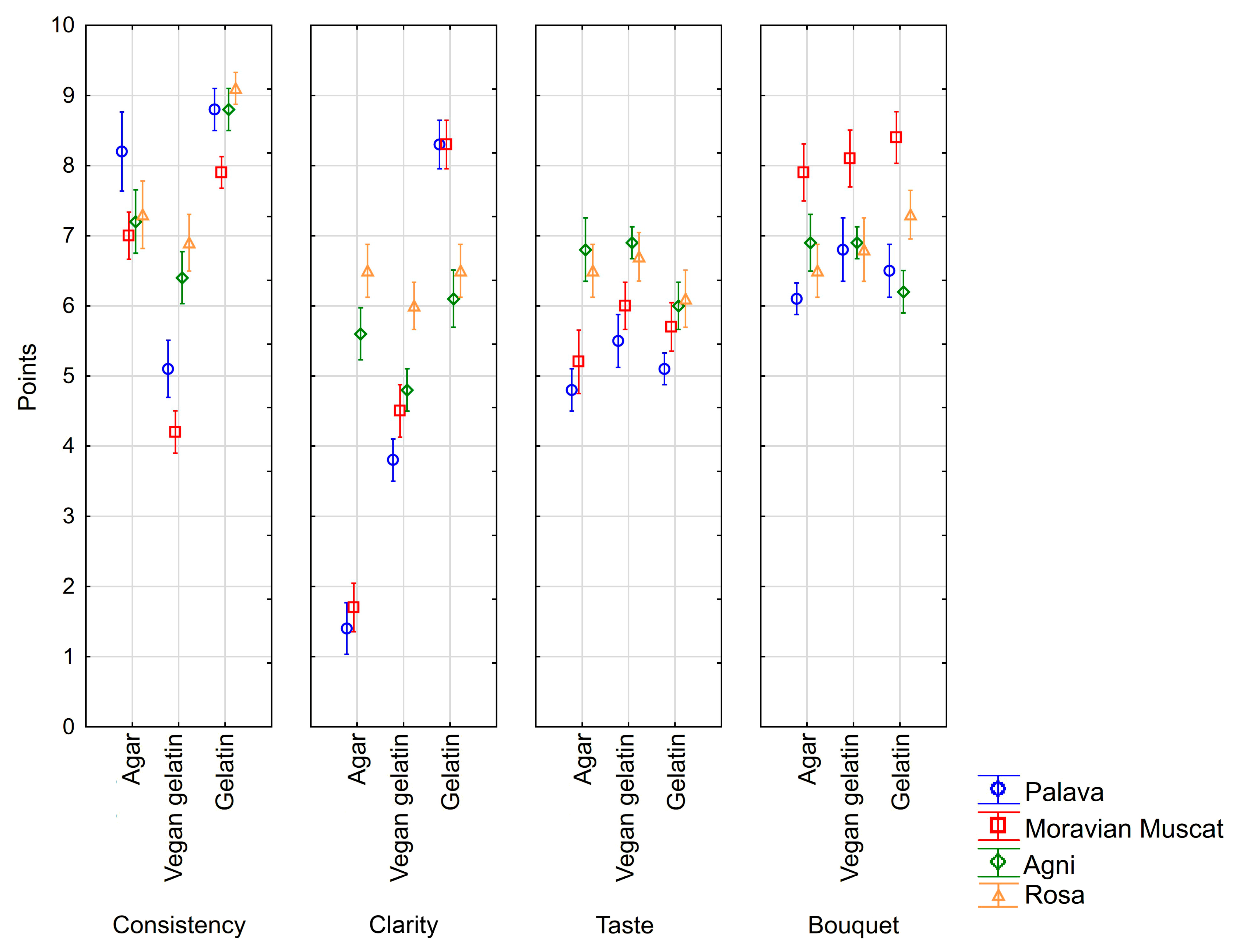

3.2.1. Comparison of Consistency

3.2.2. Comparison of Appearance—Clarity

3.2.3. Comparison of Taste

3.2.4. Comparison of Bouquet

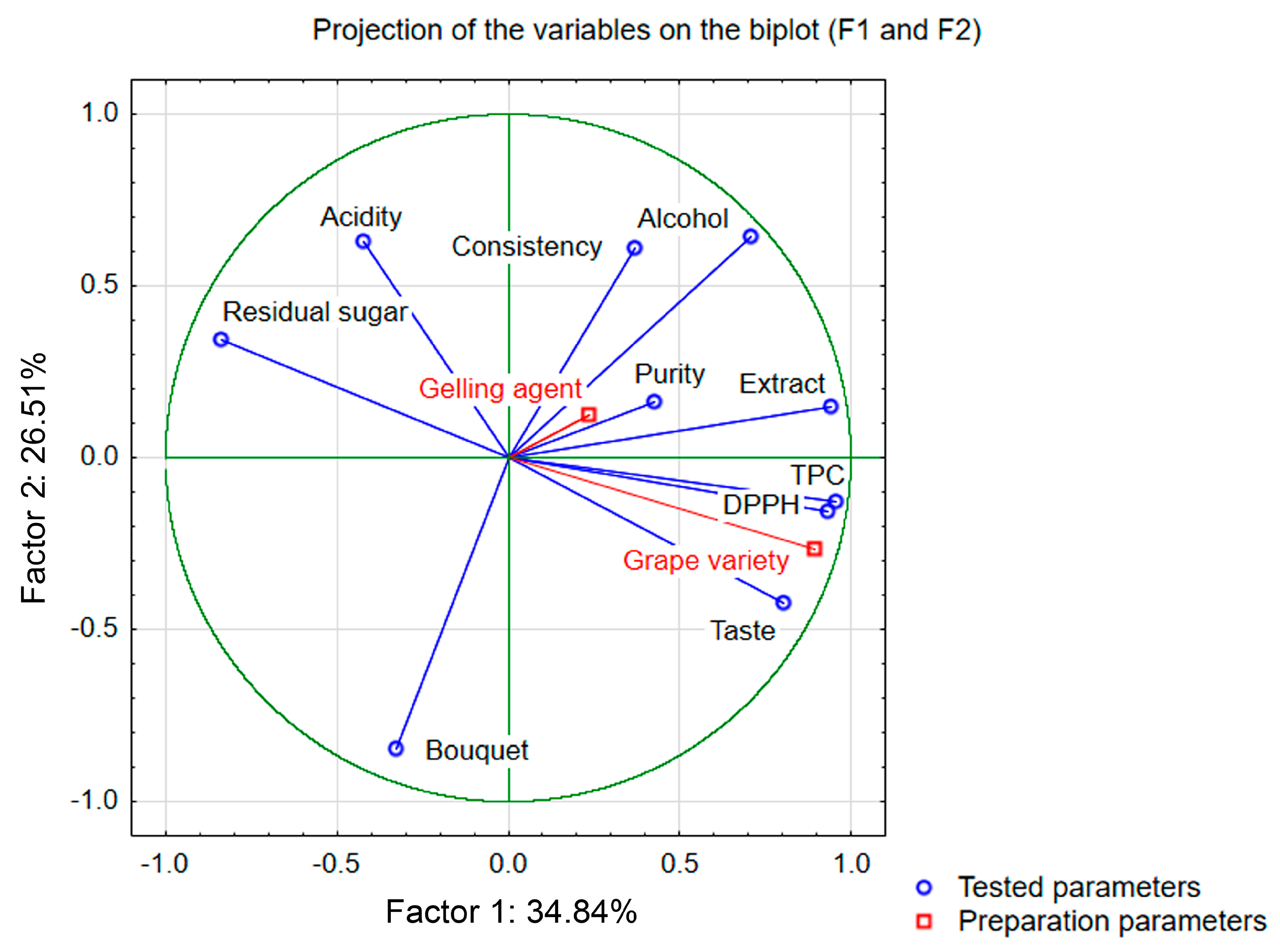

3.3. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAOSTAT. Food and Agriculture Organization of the United Nations (FAO). Statistics. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 7 May 2024).

- OIV. International Organization of Vine and Wine, Report: State of the World Vine and Wine Sector in 2023; OIV: Dijon, France, 2024; p. 21. Available online: https://www.Oiv.Int/sites/default/files/2024-04/oiv_state_of_the_world_vine_and_wine_sector_in_2023.pdf (accessed on 10 May 2024).

- Creasy, G.L. Viticulture: Grapevines and Their Management. In Encyclopedia of Applied Plant Sciences, 2nd ed.; Thomas, B., Murray, B.G., Murphy, D.J., Eds.; Academic Press: Oxford, UK, 2017; pp. 281–288. [Google Scholar]

- Venkitasamy, C.; Zhao, L.; Zhang, R.; Pan, Z. Chapter 6—Grapes. In Integrated Processing Technologies for Food and Agricultural By-Products; Pan, Z., Zhang, R., Zicari, S., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 133–163. [Google Scholar]

- Gubsky, S.; Artamonova, M.; Shmatchenko, N.; Piliugina, I.; Aksenova, E. Determination of total antioxidant capacity in marmalade and marshmallow. East. Eur. J. Enterp. Technol. 2016, 4, 43–50. [Google Scholar] [CrossRef]

- Aydin, M.; Arslan, D. Enhancing the formulation of pectin-based soft jelly type candy by using natural extracts and oligofructose. Taiwan. J. Agric. Chem. Food Sci. 2022, 60, 133–145. [Google Scholar] [CrossRef]

- Predanócyová, K.; Šedík, P. Honey market challenges: Flavored honey as healthy food choice for consumers. J. Microbiol. Biotechnol. Food Sci. 2024, 13, e11021. [Google Scholar] [CrossRef]

- Gümüs, T.; Kamer, D.D.A.; Kaynarca, G.B. Investigating the potential of wine lees as a natural colorant and functional ingredient in jelly production. J. Sci. Food Agric. 2024, 104, 1357–1366. [Google Scholar] [CrossRef]

- Bolotov, V.M.; Savvin, P.N.; Komarova, E.V.; Koshevarova, I.B. Effect of natural carotenoids and anthocyanins on properties of healthy food products. IOP Conf. Ser. Earth Environ. Sci. 2021, 640, 052001. [Google Scholar] [CrossRef]

- Kulichová, J.; Buaong, M.; Balík, J.; Híc, P.; Tríska, J.; Vrchotová, N. Juices enriched with phenolic extracts from grapes. Czech. J. Food Sci. 2018, 36, 261–267. [Google Scholar] [CrossRef]

- Nishiyama-Hortense, Y.P.O.; Rossi, M.J.P.; Shimizu-Marin, V.D.; Janzantti, N.S.; Gómez-Alonso, S.; Da-Silva, R.; Lago-Vanzela, E.S. Jelly candy enriched with BRS Violeta grape juice: Anthocyanin retention and sensory evaluation. Future Foods 2022, 6, 100179. [Google Scholar] [CrossRef]

- Mihalcea, L.; Barbu, V.; Enachi, E.; Andronoiu, D.G.; Râpeanu, G.; Stoica, M.; Dumitrascu, L.; Stanciuc, N. Microencapsulation of red grape juice by freeze drying and application in jelly formulation. Food Technol. Biotechnol. 2020, 58, 20–28. [Google Scholar] [CrossRef]

- Wan Chik, M.A.; Yusof, R.; Shafie, M.H.; Mohamed Hanaphi, R. The versatility of pectin: A comprehensive review unveiling its recovery techniques and applications in innovative food products. J. Food Meas. Charact. 2024, 18, 6101–6123. [Google Scholar] [CrossRef]

- Manev, Z.; Petkova, N. The influence of the concentration of gelling agents on the structural-mechanical properties of composite fruit jellies from pears. Bull. Transilv. Univ. Bras. Ser. II For. Wood Ind. Agric. Food Eng. 2024, 17, 163–176. [Google Scholar] [CrossRef]

- Sotolár, R.; Sotolárová, O.; Kumsta, M. Test of wine jelly. Kvas. Prum. 2018, 64, 71–75. [Google Scholar] [CrossRef]

- Kurt, A.; Bursa, K.; Toker, O.S. Gummy candies production with natural sugar source: Effect of molasses types and gelatin ratios. Food Sci. Technol. Int. 2022, 28, 118–127. [Google Scholar] [CrossRef] [PubMed]

- Aggarwal, P.; Padda, G.S.; Sidhu, J.S. Standardization of jelly preparation from grape: Guava blends. J. Food Sci. Technol. 1997, 34, 335–336. [Google Scholar]

- Vibhakara, H.S.; Bawa, A.S. Manufacturing jams and jellies. In Handbook of Fruits and Fruit Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 229–243. [Google Scholar]

- Braverman, J.B.S. Introduction to the Biochemistry of Foods; Elsevier Publishing Company: Amsterdam, The Netherlands, 1963. [Google Scholar]

- Kaewpetch, K.; Yolsuriyan, S.; Disayathanoowat, T.; Phokasem, P.; Jannu, T.; Renaldi, G.; Samakradhamrongthai, R.S. Influence of gelatin and propolis extract on honey gummy jelly properties: Optimization using d-optimal mixture design. Gels 2024, 10, 282. [Google Scholar] [CrossRef]

- El-Sayed, S.M.; El-Sayed, H.S.; Elgamily, H.M.; Youssef, A.M. Preparation and evaluation of yogurt fortified with probiotics jelly candy enriched with grape seeds extract nanoemulsion. J. Food Process. Preserv. 2022, 46, e16713. [Google Scholar] [CrossRef]

- Karadag, A.; Ozkan, K.; Sagdic, O. Development of microencapsulated grape juice powders using black ‘Isabel’ grape peel pectin and application in jelly formulation with enhanced in vitro bioaccessibility of anthocyanins. J. Food Sci. 2024, 89, 2067–2083. [Google Scholar] [CrossRef]

- Charoenphun, N.; Noonim, P.; Lekjing, S.g.; Nitikornwarakul, C.; Pham, N.H.; Venkatachalam, K. Physicochemical properties, antioxidant activity, and flavor profile of strawberry fruit-based novel drinking jelly made with gracilaria fisheri seaweed as a gelling agent at varying concentrations. Gels 2025, 11, 54. [Google Scholar] [CrossRef]

- Spinei, M.; Oroian, M. Characterization of băbească neagră grape pomace and incorporation into jelly candy: Evaluation of phytochemical, sensory, and textural properties. Foods 2024, 13, 98. [Google Scholar] [CrossRef]

- Budziak-Wieczorek, I.; Mašán, V.; Rząd, K.; Gładyszewska, B.; Karcz, D.; Burg, P.; Čížková, A.; Gagoś, M.; Matwijczuk, A. Evaluation of the quality of selected white and red wines produced from moravia region of czech republic using physicochemical analysis, ftir infrared spectroscopy and chemometric techniques. Molecules 2023, 28, 6326. [Google Scholar] [CrossRef]

- Laborde, M.B.; Tasca, J.E.; Barreto, G.P.; Pagano, A.M. Physicochemical characterization of pectin of rose grape red globe variety. J. Food Nutr. Res. 2020, 59, 323–331. [Google Scholar]

- Kalsi, G.; Hazarika, U.; Baruah, L.D.; Bordoloi, P.L.; Gogoi, M. Comprehensive review of carrageenan’s multifaceted role in health and food systems. Discov. Food 2025, 5, 115. [Google Scholar] [CrossRef]

- OIV. International Organization of Vine and Wine. Compendium of International Methods of Wine and Must Analysis; OIV: Dijon, France, 2012; p. 35. Available online: http://www.gie.uchile.cl/pdf/GIE_legislacion/Metodos%20Analisis_Vol.2.pdf (accessed on 10 May 2024).

- Rebelein, H. Vereinfachtes verfahren zur bestimmung des glycerins und butylenglykols in wein. Z. Lebensm. Unters. Forsch. 1957, 105, 296–311. [Google Scholar] [CrossRef]

- Bhat, N.R.; Desai, B.B.; Suleiman, M.K. Grapes and Raisins. In Handbook of Fruits and Fruit Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 447–459. [Google Scholar]

- Büyüktuncel, E.; Porgalı, E.; Çolak, C. Comparison of total phenolic content and total antioxidant activity in local red wines determined by spectrophotometric methods. Food Nutr. Sci. 2014, 5, 1660–1667. [Google Scholar] [CrossRef]

- Devi, D.N.; Darsih, C.; Yuniarti, N.; Ardiningtyas, B.; Laksitorini, M.D. Formulation and antioxidant activity of gotu kola jelly candy with plant-based polymers as a gelling agent. Maj. Obat Tradis. 2024, 29, 266–275. [Google Scholar] [CrossRef]

- Lam, Y.B.; Yusri, A.S.; Sarbon, N.M. Effect of gelling agents on the techno-functional, collagen bioavailability and phytochemical properties of botanic gummy jelly containing marine hydrolyzed collagen. Food Chem. Adv. 2025, 6, 100915. [Google Scholar] [CrossRef]

- Javorský, J.; Král, M.; Šnirc, M.; Árvay, J.; Tremlová, B.; Dordević, D. Characterization of moravian wines by selected chemical parameters. Separations 2021, 8, 89. [Google Scholar] [CrossRef]

- Porgalı, E.; Büyüktuncel, E. Determination of phenolic composition and antioxidant capacity of native red wines by high performance liquid chromatography and spectrophotometric methods. Food Res. Int. 2012, 45, 145–154. [Google Scholar] [CrossRef]

- Mitrevska, K.; Grigorakis, S.; Loupassaki, S.; Calokerinos, A.C. Antioxidant activity and polyphenolic content of north macedonian wines. Appl. Sci. 2020, 10, 2010. [Google Scholar] [CrossRef]

- Ma, T.T.; Sun, X.Y.; Gao, G.T.; Wang, X.Y.; Liu, X.Y.; Du, G.R.; Zhan, J.C. Phenolic characterisation and antioxidant capacity of young wines made from different grape varieties grown in helanshan donglu wine zone (China). S. Afr. J. Enol. Vitic. 2014, 35, 321–331. [Google Scholar] [CrossRef]

- Dóka, O.; Ficzek, G.; Simon, G.; Zsófi, Z.; Villangó, S.; Végvári, G. Quantification of total polyphenol content in wine lees by conventional optical and photoacoustic spectroscopy. OENO One 2023, 57, 257–264. [Google Scholar] [CrossRef]

- Mahsouli, L.; Lashkari, H. The feasibility of producing dessert containing grape juice concentrate, and evaluation of its physicochemical, microbial and sensory properties. Iran. Food Sci. Technol. Res. J. 2020, 16, 301–311. [Google Scholar] [CrossRef]

- Thakur, B.R.; Singh, R.K.; Handa, A.K. Chemistry and Uses of Pectin. Food Sci. Nutr. 1997, 37, 47–73. [Google Scholar]

- Acosta, O.; Víquez, F.; Cubero, E. Optimisation of low calorie mixed fruit jelly by response surface methodology. Food Qual. Prefer. 2008, 19, 79–85. [Google Scholar] [CrossRef]

- Horison, R.; Surini, S. Utilization of glucomannan-xanthan gum-carrageenan based co-processed excipients in the development of nutraceutical pomegranate (Punica granatum L.) peel extract jelly. J. Pharm. Pharmacogn. Res. 2025, 13, 774–786. [Google Scholar] [CrossRef]

- Menaka, U.; Wijesekara, I. Physico-chemical properties of agar extracted from Gracilariopsis longissima (formerly Gracilaria verrucosa) and development of plant-based food jellies. Food Chem. Adv. 2025, 6, 100938. [Google Scholar] [CrossRef]

- Farzaliev, E.B.; Ökten, S. Production and characterization of fruit jam with activated pectin using wild hawthorn puree (Crataegus monogyna Jacq.). Nat. Prod. Res. 2025, 39, 993–997. [Google Scholar] [CrossRef]

- Babaoglu Farzaliev, E.; Ökten, S. Pectin as a functional food ingredient in jelly marmalade. Nat. Prod. Res. 2025, 20, 1–6. [Google Scholar] [CrossRef]

| Wine Variety | Alcohol (% vol.) | Extract (g·L−1) | Titratable Acidity (g·L−1) | Residual Sugars (g·L−1) | pH | Glycerol (g·L−1) | Density (g·cm−1) | TPC (mg GAE·g−1) | DPPH (mg TEA·g−1) |

|---|---|---|---|---|---|---|---|---|---|

| Pálava | 12.02 ± 0.10 | 52.55 ± 0.22 | 7.58 ± 0.12 | 43 ± 3 | 3.33 ± 0.07 | 8.1 ± 0.5 | 0.97 ± 0.05 | 0.36 ± 0.04 | 0.25 ± 0.05 |

| Moravian Muscat | 11.59 ± 0.12 | 43.82 ± 0.23 | 5.62 ± 0.09 | 42.0 ± 2.2 | 3.12 ± 0.10 | 7.3 ± 0.4 | 0.90 ± 0.06 | 0.35 ± 0.04 | 0.29 ± 0.05 |

| Agni | 13.12 ± 0.13 | 28.61 ± 0.19 | 6.97 ± 0.09 | 4.9 ± 0.6 | 3.67 ± 0.09 | 8.7 ± 0.5 | 1.03 ± 0.08 | 1.6 ± 0.4 | 1.4 ± 0.3 |

| Rosa | 13.44 ± 0.16 | 31.17 ± 0.24 | 4.92 ± 0.08 | 3.4 ± 0.4 | 3.54 ± 0.09 | 8.8 ± 0.5 | 1.10 ± 0.09 | 1.9 ± 0.4 | 1.7 ± 0.3 |

| Wine Variety | Gelling Agent | Alcohol (% vol.) | Extract (g·L−1) | Acidity (g·L−1) | Residual Sugars (g·L−1) | Density (g·cm−1) | TPC (mg GAE·g−1) | DPPH (mg TEA·g−1) |

|---|---|---|---|---|---|---|---|---|

| Pálava | Agar | 7.06 ± 0.07 | 51.1 ± 0.4 | 7.5 ± 0.4 | 42.45 ± 0.23 | 1.09 ± 0.06 | 0.28 ± 0.04 | 0.29 ± 0.03 |

| Vegan gelatin | 6.74 ± 0.05 | 50.8 ± 0.5 | 7.1 ± 0.4 | 42.6 ± 0.3 | 1.03 ± 0.07 | 0.40 ± 0.04 | 0.38 ± 0.04 | |

| Gelatin | 7.54 ± 0.06 | 52.0 ± 0.4 | 7.6 ± 0.4 | 42.6 ± 0.3 | 1.03 ± 0.07 | 0.38 ± 0.04 | 0.31 ± 0.03 | |

| Moravian Muscat | Agar | 6.11 ± 0.06 | 41.6 ± 0.4 | 6.0 ± 0.4 | 41.59 ± 0.29 | 1.08 ± 0.08 | 0.28 ± 0.04 | 0.31 ± 0.03 |

| Vegan gelatin | 6.08 ± 0.06 | 43.5 ± 0.3 | 5.5 ± 0.3 | 41.7 ± 0.3 | 1.01 ± 0.09 | 0.37 ± 0.03 | 0.35 ± 0.04 | |

| Gelatin | 6.79 ± 0.06 | 42.9 ± 0.3 | 5.7 ± 0.4 | 41.8 ± 0.3 | 1.03 ± 0.08 | 0.36 ± 0.04 | 0.31 ± 0.03 | |

| Agni | Agar | 7.27 ± 0.08 | 69.0 ± 0.5 | 7.0 ± 0.4 | 41.0 ± 0.4 | 1.10 ± 0.08 | 0.88 ± 0.05 | 0.90 ± 0.06 |

| Vegan gelatin | 6.87 ± 0.07 | 68.0 ± 0.6 | 6.6 ± 0.4 | 41.1 ± 0.3 | 1.10 ± 0.08 | 1.85 ± 0.07 | 2.16 ± 0.10 | |

| Gelatin | 7.98 ± 0.08 | 70.0 ± 0.6 | 6.9 ± 0.4 | 40.86 ± 0.28 | 1.10 ± 0.08 | 1.61 ± 0.07 | 1.73 ± 0.09 | |

| Rosa | Agar | 7.59 ± 0.06 | 77.1 ± 0.6 | 5.4 ± 0.4 | 41.3 ± 0.3 | 1.20 ± 0.10 | 0.97 ± 0.05 | 0.91 ± 0.04 |

| Vegan gelatin | 7.21 ± 0.07 | 76.9 ± 0.6 | 4.89 ± 0.29 | 41.03 ± 0.29 | 1.11 ± 0.08 | 1.96 ± 0.07 | 2.04 ± 0.01 | |

| Gelatin | 8.15 ± 0.10 | 78.3 ± 0.7 | 5.0 ± 0.4 | 40.7 ± 0.3 | 1.10 ± 0.07 | 1.86 ± 0.08 | 1.83 ± 0.07 |

| Wine Variety | Sensory Evaluation | Gelling Agent | Consistency | Clarity | Taste | Bouquet |

|---|---|---|---|---|---|---|

| Pálava | 83.3 | Agar | 8.2 ± 0.25 df | 1.4 ± 0.16 c | 4.8 ± 0.13 c | 6.1 ± 0.10 b |

| Vegan gelatin | 5.1 ± 0.18 h | 3.8 ± 0.13 d | 5.5 ± 0.17 acd | 6.8 ± 0.20 abc | ||

| Gelatin | 8.8 ± 0.13 de | 8.3 ± 0.15 f | 5.1 ± 0.10 cd | 6.5 ± 0.17 ab | ||

| Moravian Muscat | 84.6 | Agar | 7.0 ± 0.15 ab | 1.7 ± 0.15 c | 5.2 ± 0.20 cd | 7.9 ± 0.18 de |

| Vegan gelatin | 4.2 ± 0.13 g | 4.5 ± 0.17 de | 6.0 ± 0.15 ab | 8.1 ± 0.18 d | ||

| Gelatin | 7.9 ± 0.10 cf | 8.3 ± 0.15 f | 5.7 ± 0.15 ad | 8.4 ± 0.16 d | ||

| Agni | 81.4 | Agar | 7.2 ± 0.20 ac | 5.6 ± 0.16 b | 6.8 ± 0.20 ef | 6.9 ± 0.18 ac |

| Vegan gelatin | 6.4 ± 0.16 b | 4.8 ± 0.13 e | 6.9 ± 0.10 f | 6.9 ± 0.10 ac | ||

| Gelatin | 8.8 ± 0.13 de | 6.1 ± 0.18 ab | 6.0 ± 0.15 ab | 6.2 ± 0.13 ab | ||

| Rosa | 82.9 | Agar | 7.3 ± 0.21 ac | 6.5 ± 0.17 a | 6.5 ± 0.17 bef | 6.5 ± 0.17 ab |

| Vegan gelatin | 6.9 ± 0.18 ab | 6.0 ± 0.15 ab | 6.7 ± 0.15 bef | 6.8 ± 0.20 abc | ||

| Gelatin | 9.1 ± 0.10 e | 6.5 ± 0.17 a | 6.1 ± 0.18 abe | 7.3 ± 0.15 ce |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sotolář, R.; Bača, P.; Mašán, V.; Vanýsek, P.; Burg, P.; Binar, T.; Sotolářová, O. Effect of Different Gelling Agents on the Properties of Wine Jellies Prepared from Aromatic Grape Varieties. Processes 2025, 13, 1893. https://doi.org/10.3390/pr13061893

Sotolář R, Bača P, Mašán V, Vanýsek P, Burg P, Binar T, Sotolářová O. Effect of Different Gelling Agents on the Properties of Wine Jellies Prepared from Aromatic Grape Varieties. Processes. 2025; 13(6):1893. https://doi.org/10.3390/pr13061893

Chicago/Turabian StyleSotolář, Radek, Petr Bača, Vladimír Mašán, Petr Vanýsek, Patrik Burg, Tomáš Binar, and Oldřiška Sotolářová. 2025. "Effect of Different Gelling Agents on the Properties of Wine Jellies Prepared from Aromatic Grape Varieties" Processes 13, no. 6: 1893. https://doi.org/10.3390/pr13061893

APA StyleSotolář, R., Bača, P., Mašán, V., Vanýsek, P., Burg, P., Binar, T., & Sotolářová, O. (2025). Effect of Different Gelling Agents on the Properties of Wine Jellies Prepared from Aromatic Grape Varieties. Processes, 13(6), 1893. https://doi.org/10.3390/pr13061893