Study on Air Injection to Enhance Coalbed Gas Extraction

Abstract

1. Introduction

2. Thermal-Hydraulic-Solid Coupling Model for Air-ECGE

- (1)

- The coal is homogeneous and isotropic, and the gas in the coalbed is evenly distributed;

- (2)

- The constitutive relation of stress and strain satisfies elastic mechanics; the compressive state of stress and strain is negative, while the tensile state is positive;

- (3)

- The gas in the coalbed is ideal gas, and the influence of temperature change on gas dynamic viscosity is ignored;

- (4)

- Regardless of the chemical adsorption of oxygen on coal, the adsorption of a gas on coal meets the Langmuir adsorption equilibrium equation.

2.1. Gas Migration Control Equation

2.2. Stress Control Equation of the Coal Seam

2.3. Control Equation of the Coalbed Temperature Field

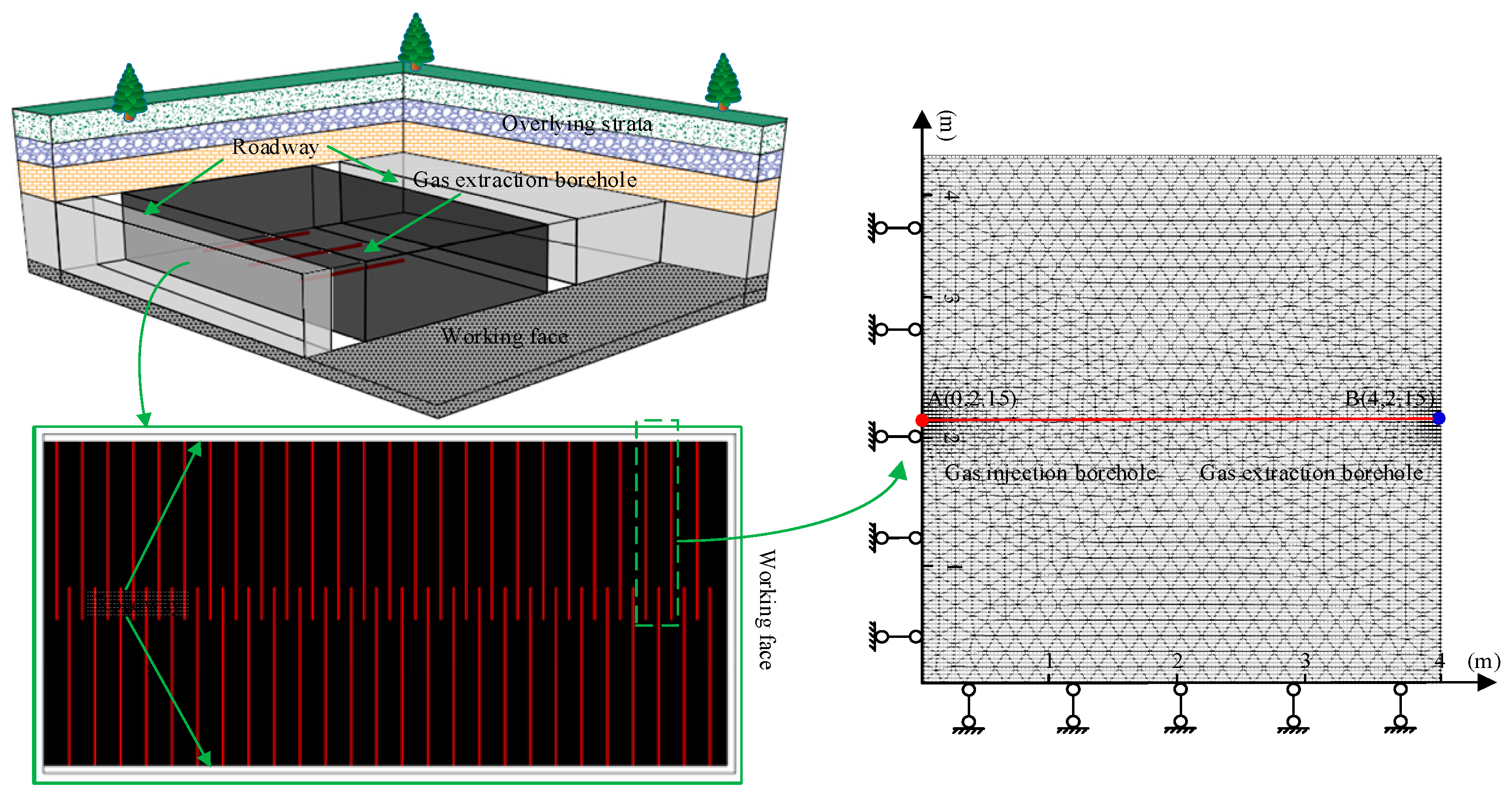

3. Numerical Simulation of Air-ECGE

3.1. Numerical Model and Solution Conditions

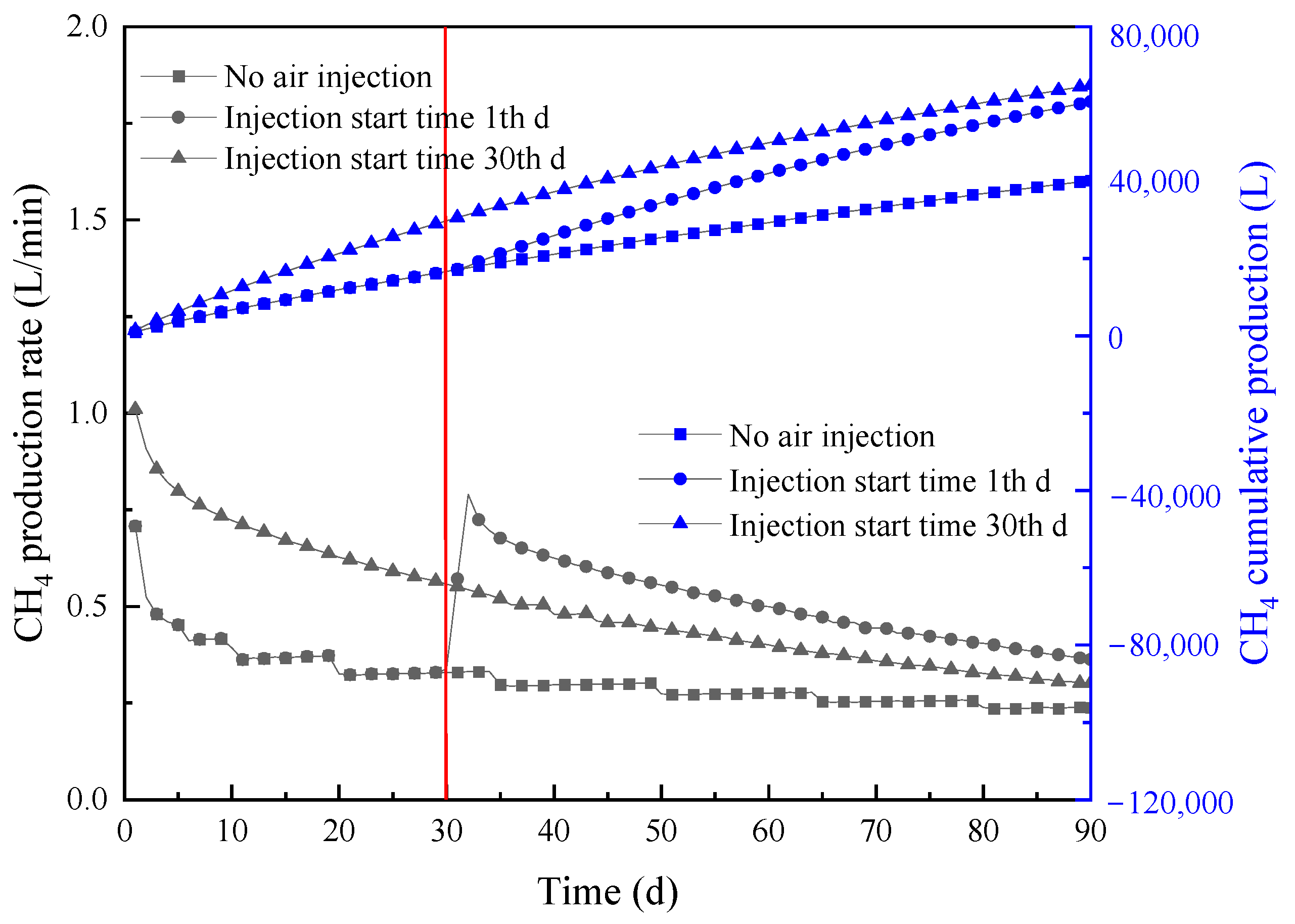

3.2. The Influence of Air Injection into the Coalbed for Coalbed Gas Extraction

3.3. Effect of Injection Pressure on Air-ECGE

3.4. Effect of Borehole Spacing on Air-ECGE

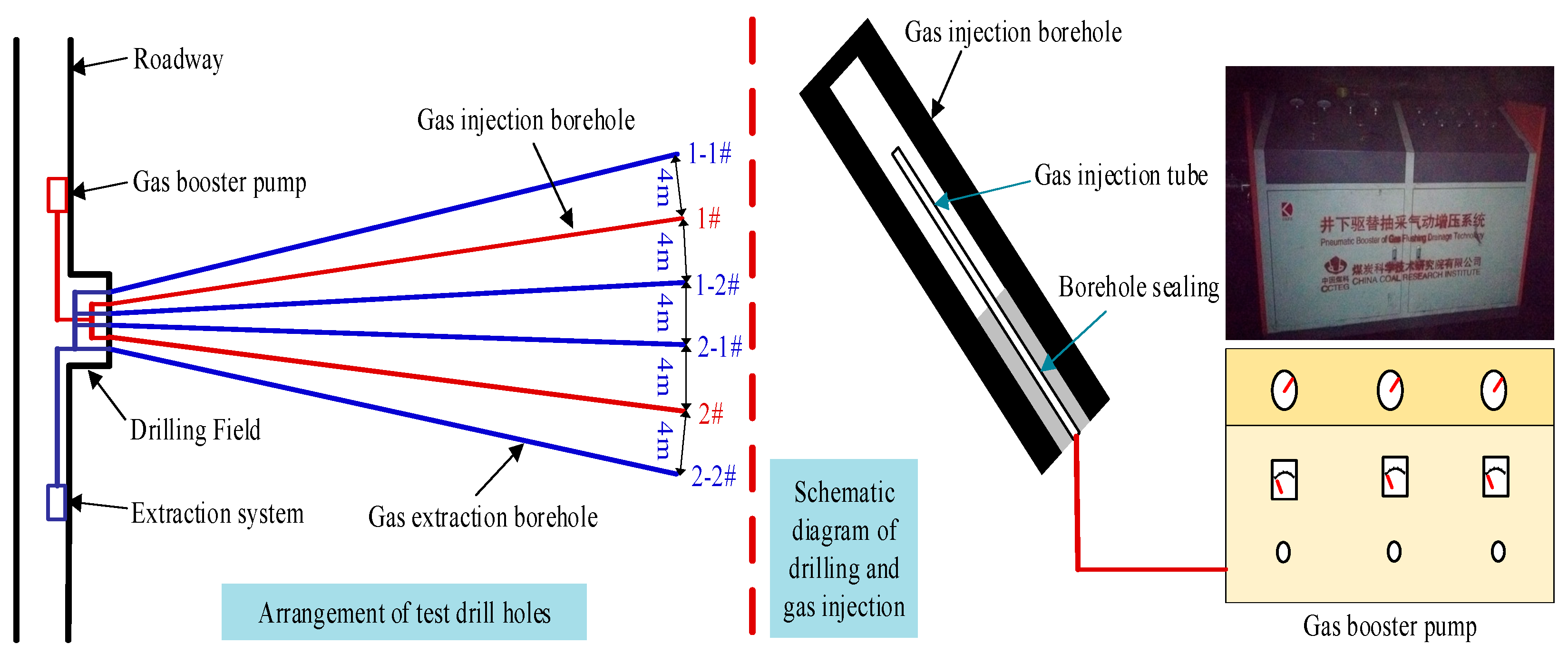

4. Field Test of Air-ECGE in Liuzhuang Mine

5. Discussion

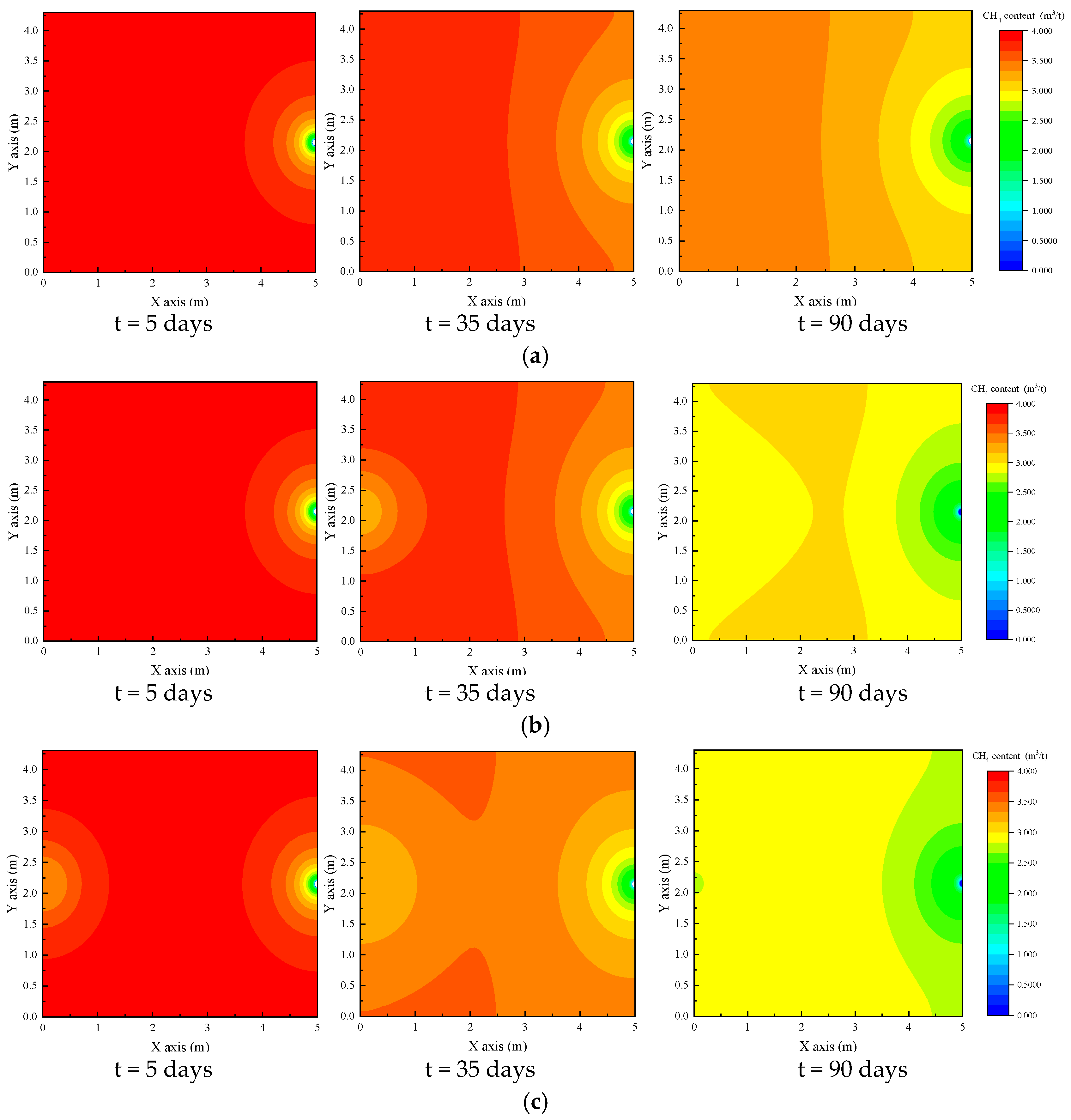

- (1)

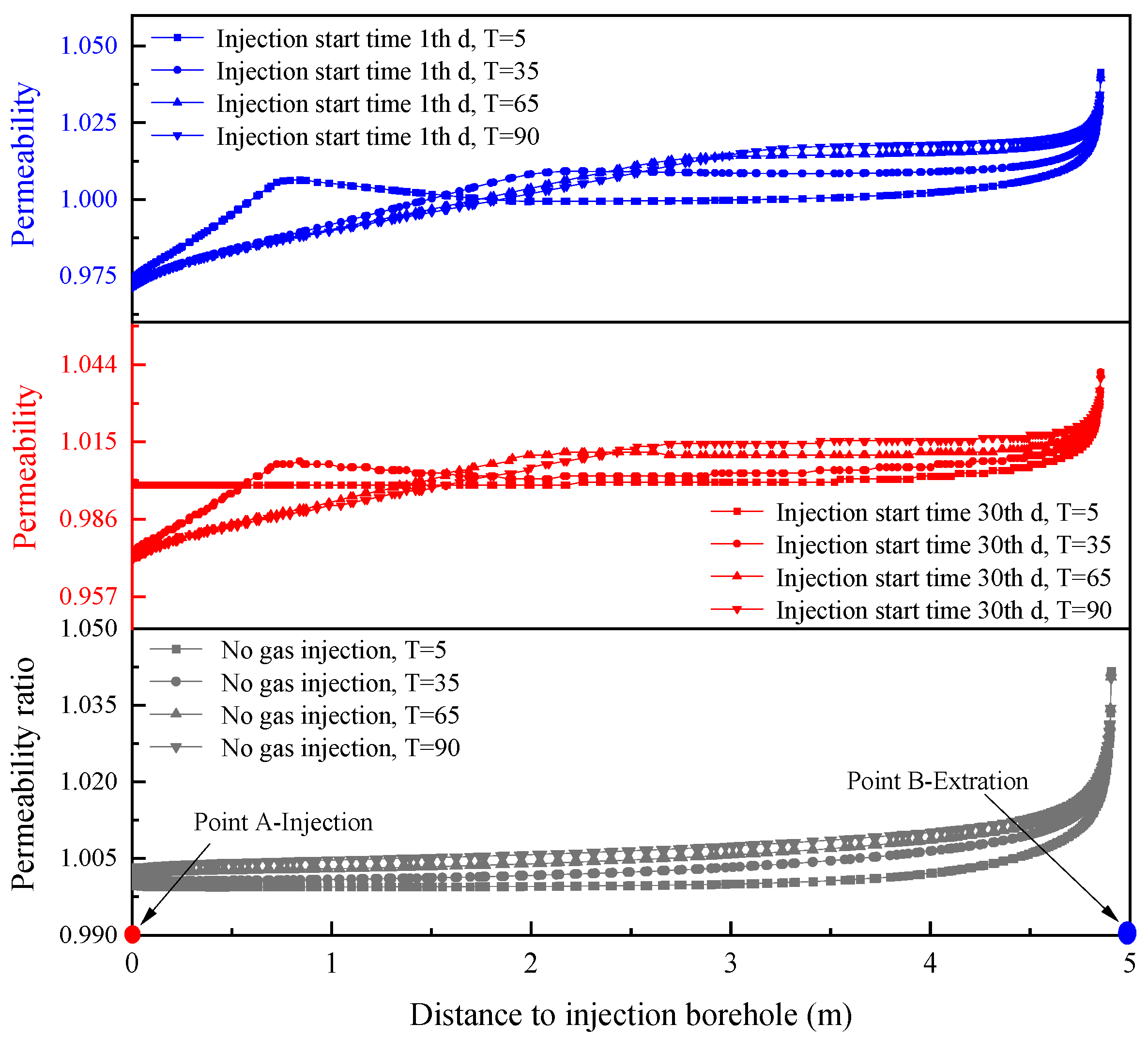

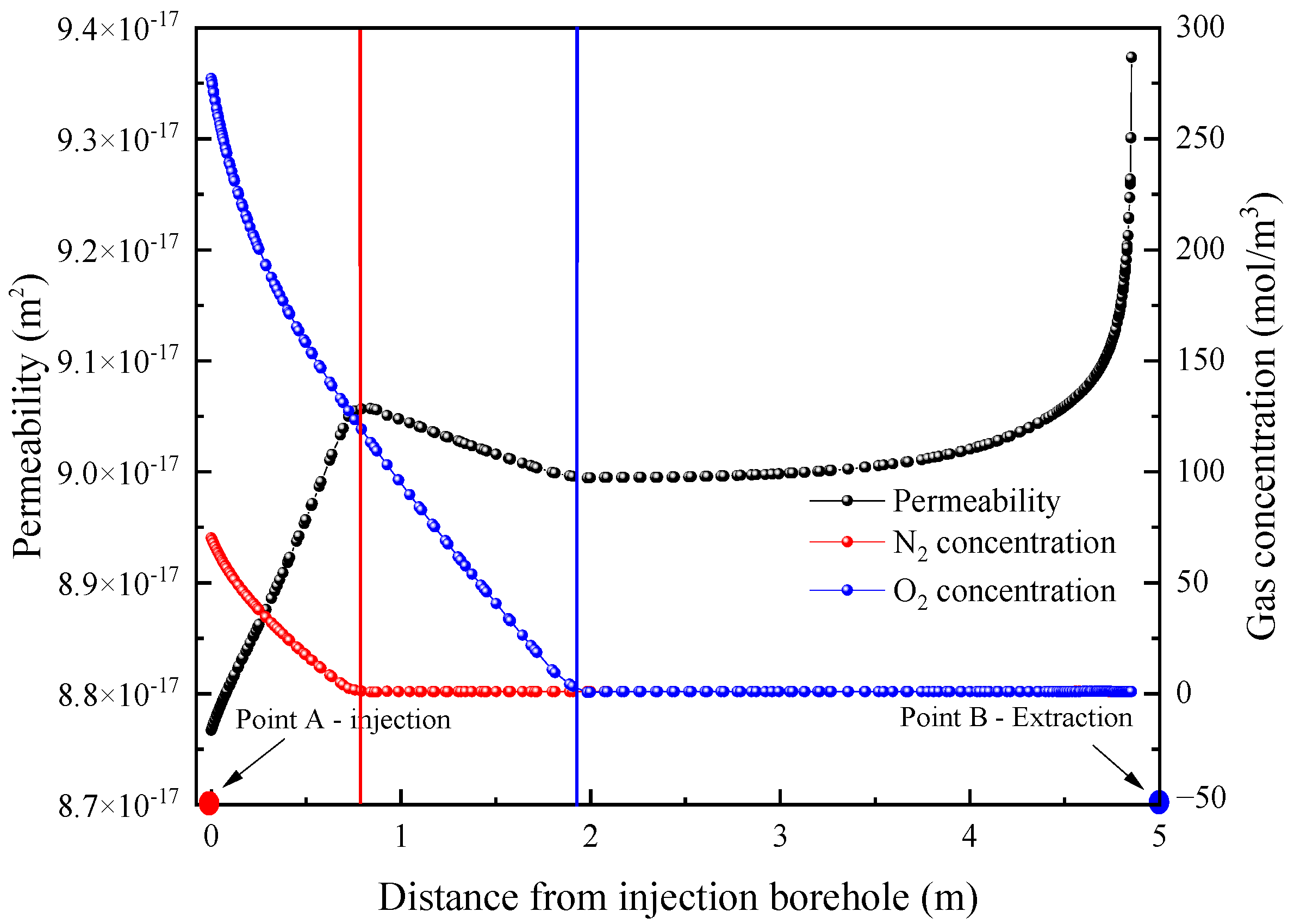

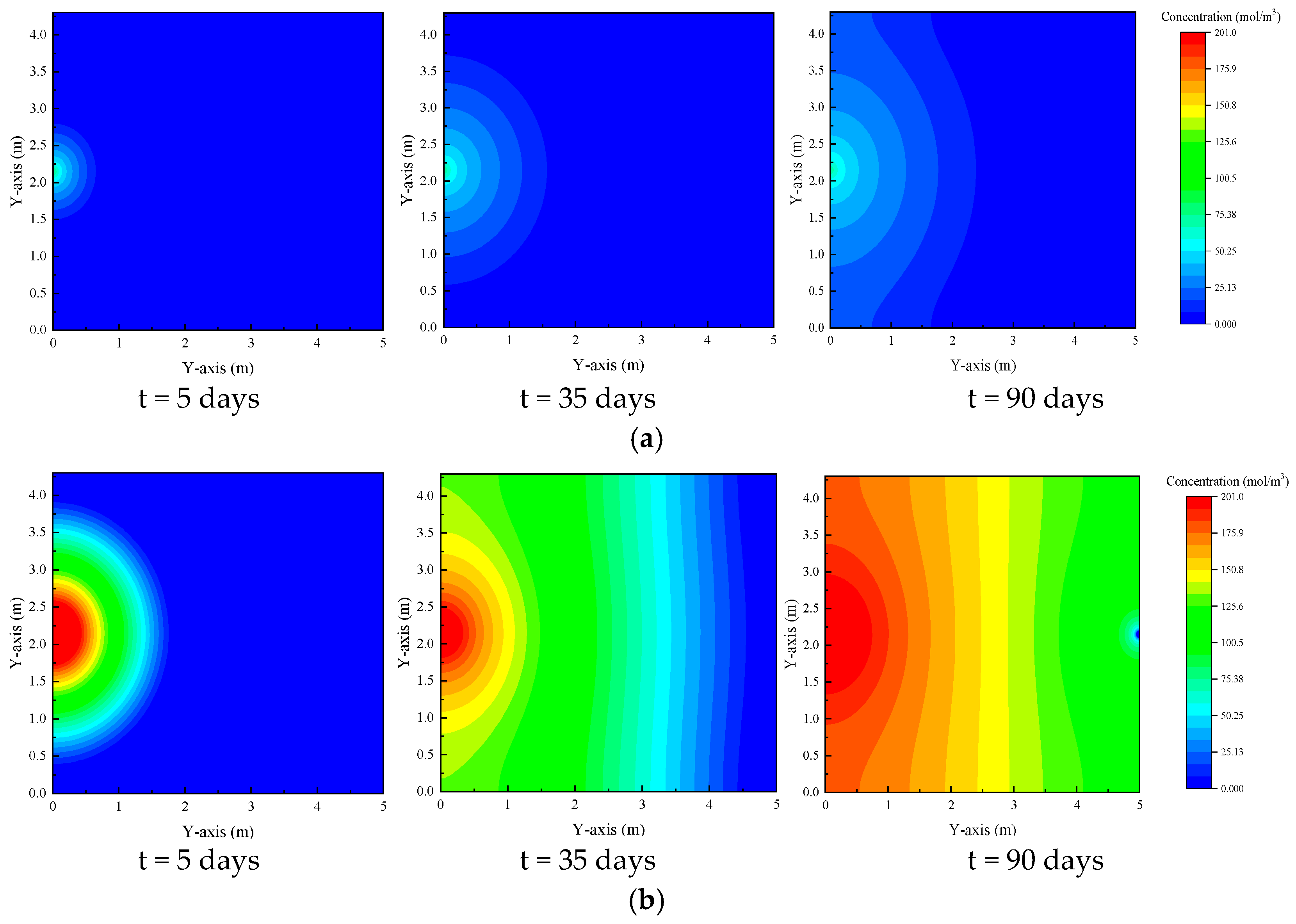

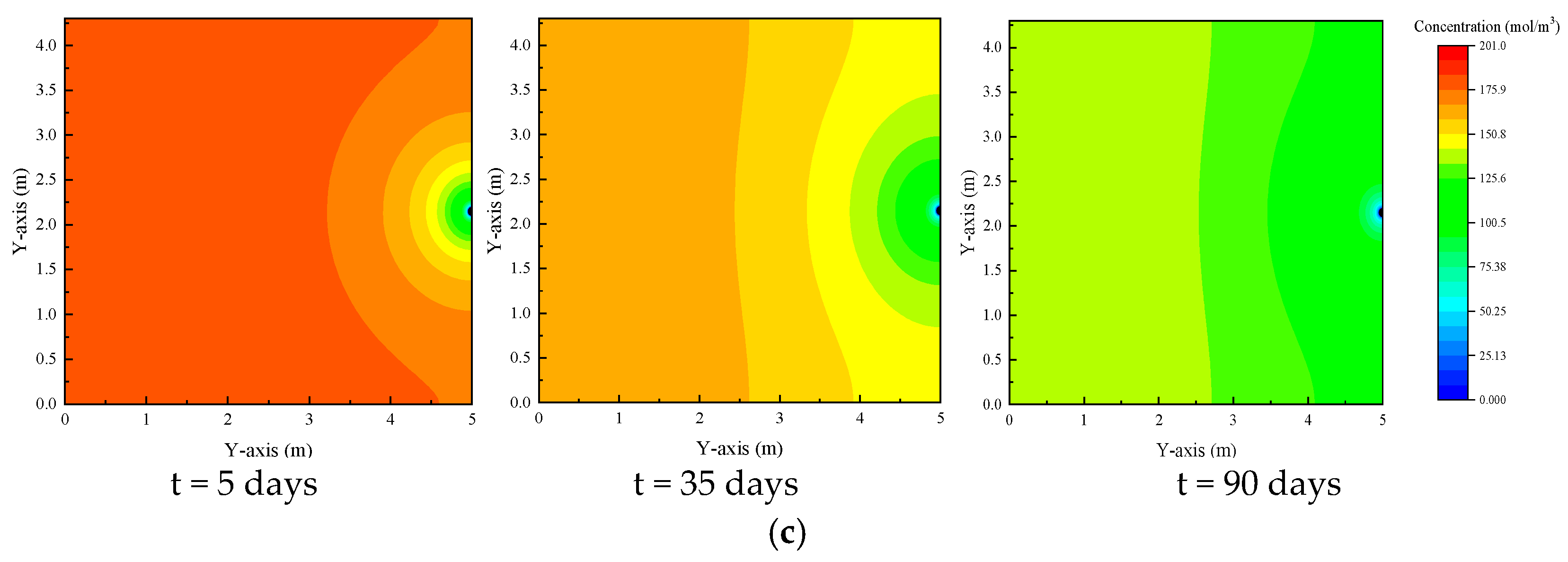

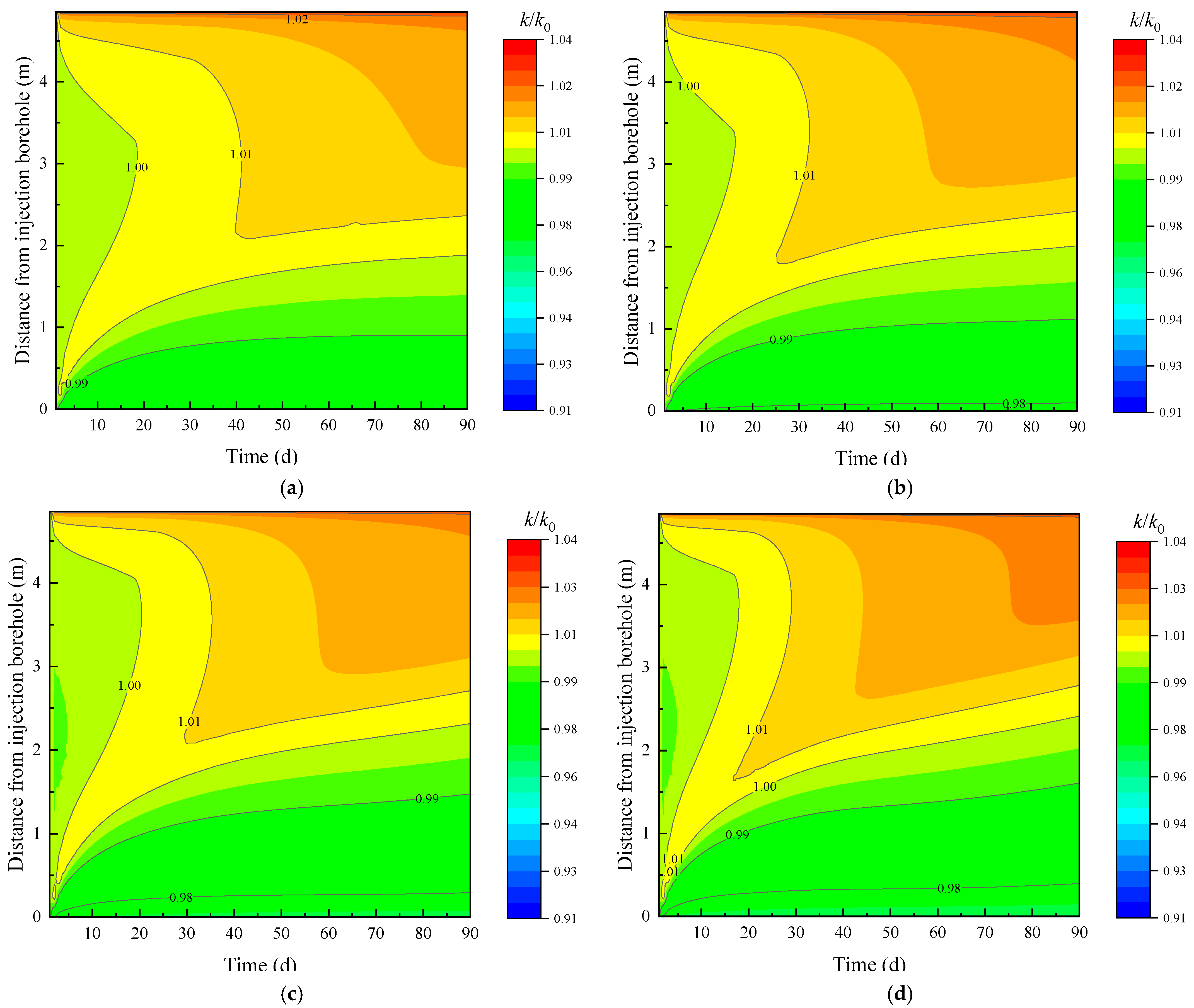

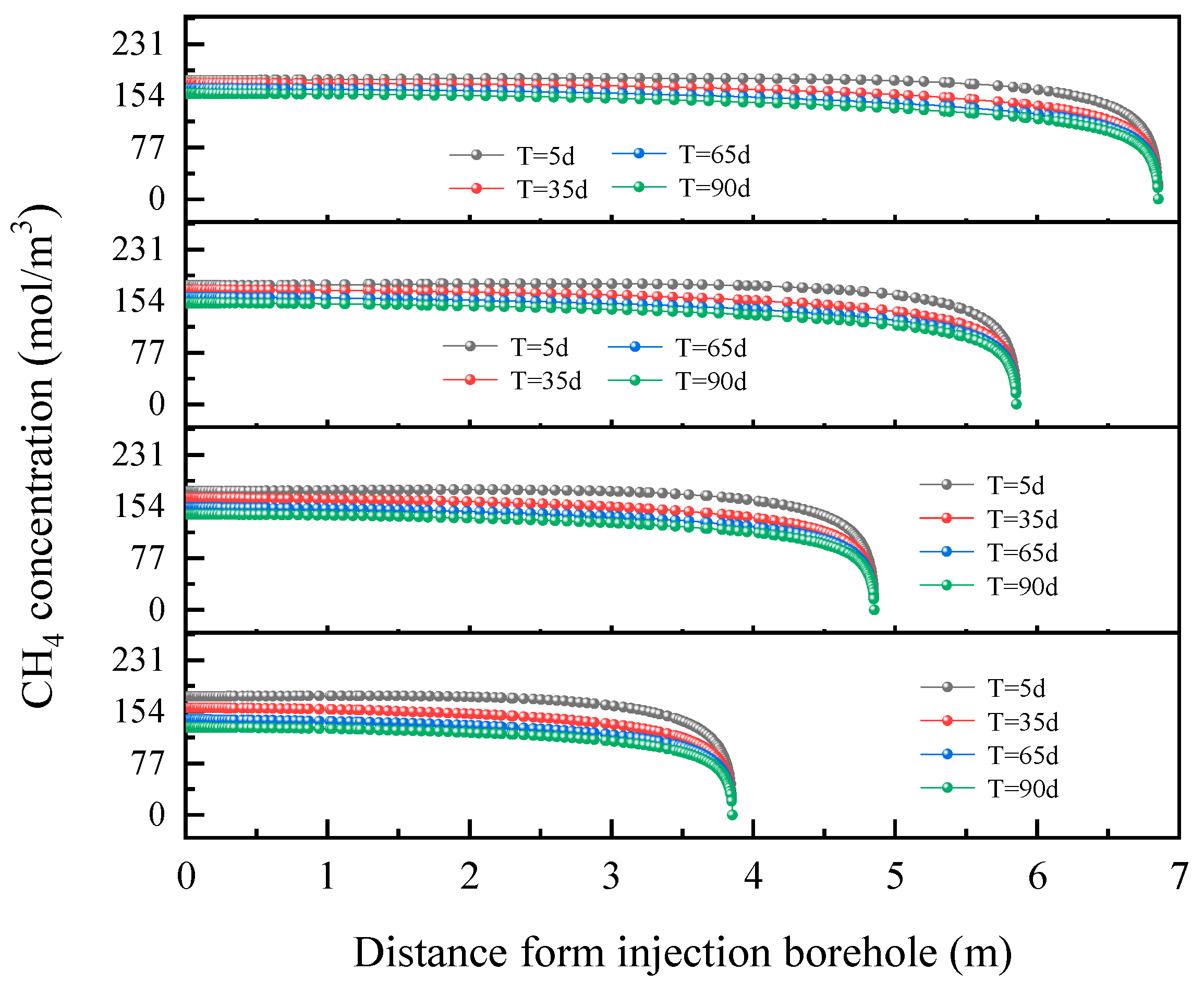

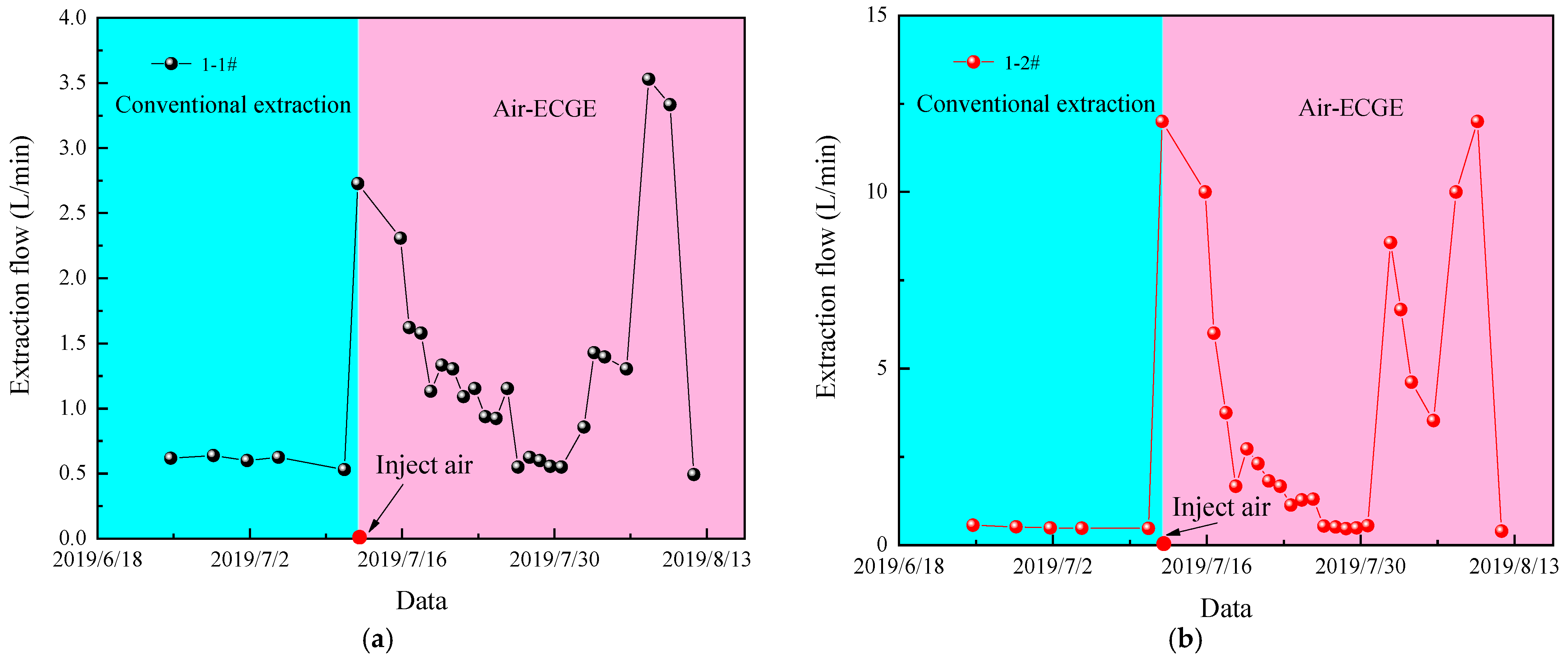

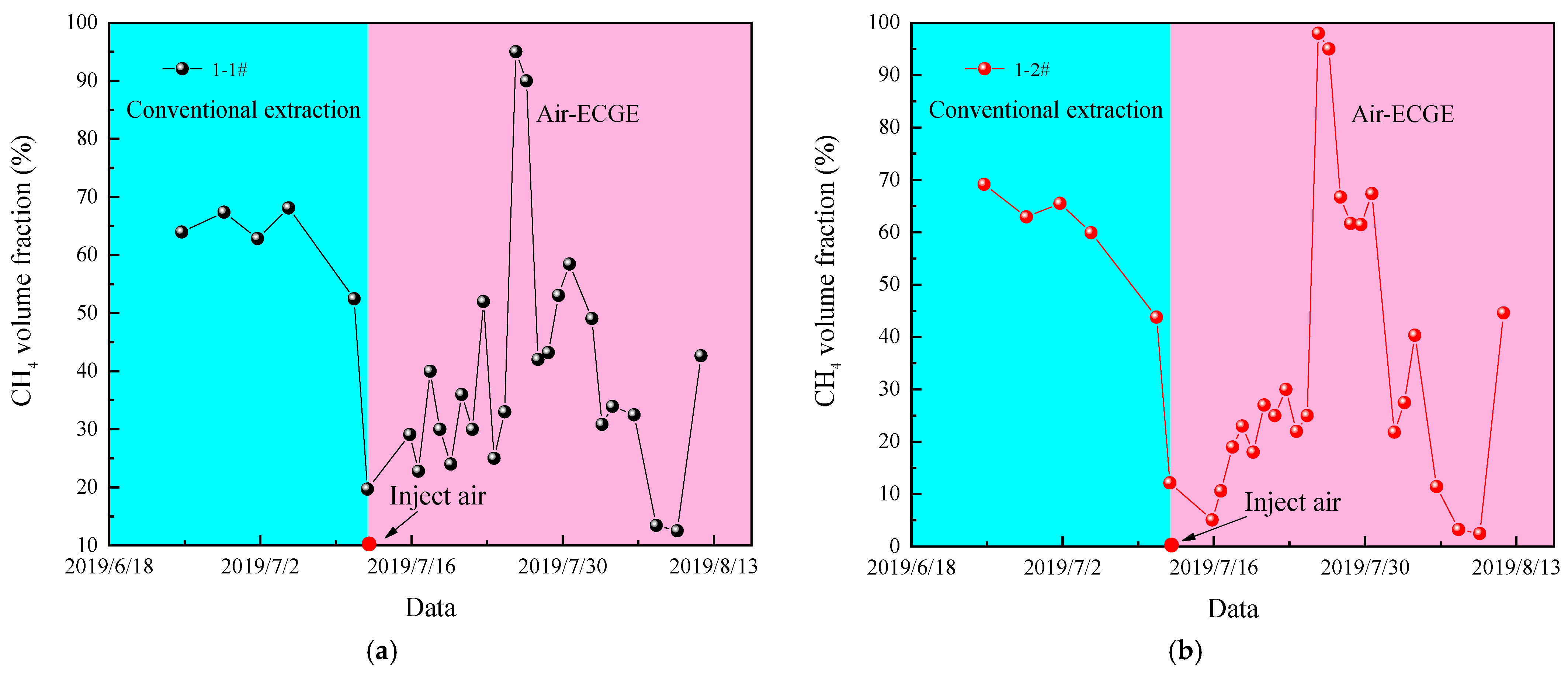

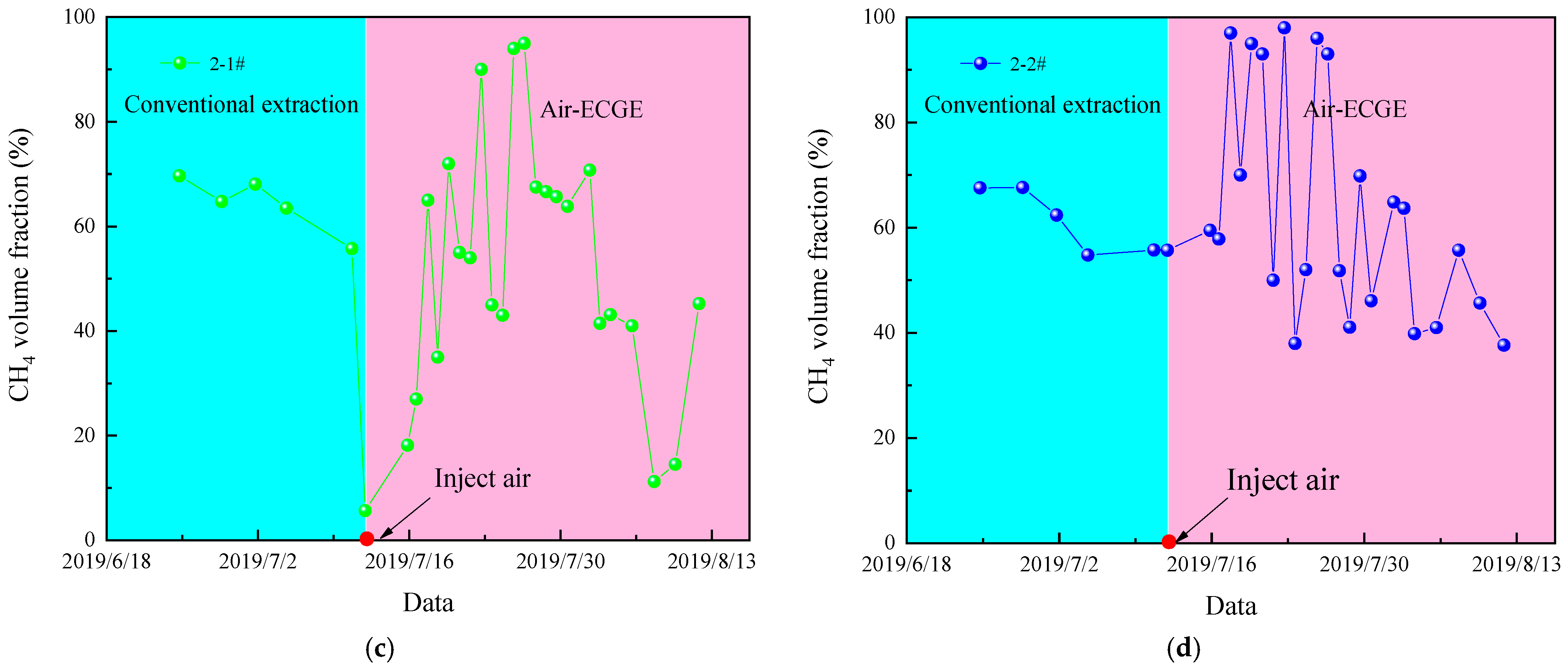

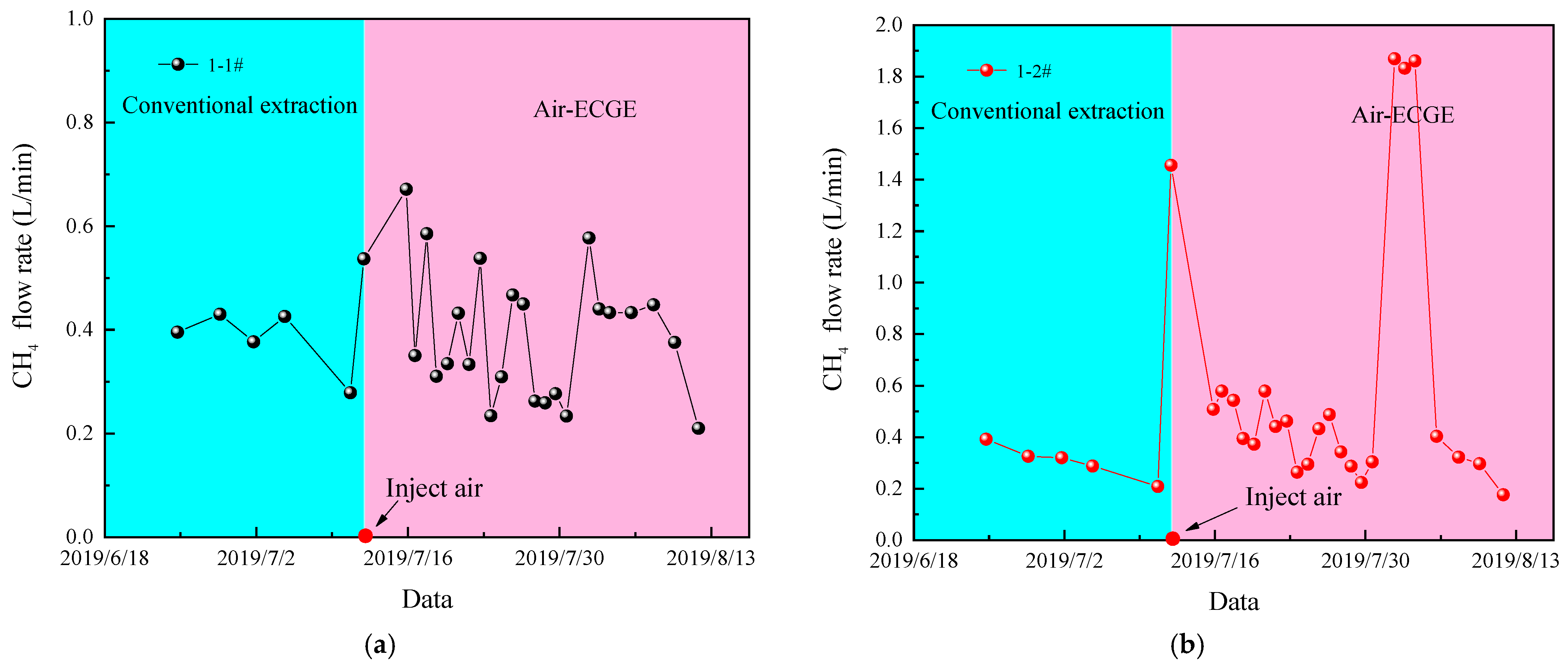

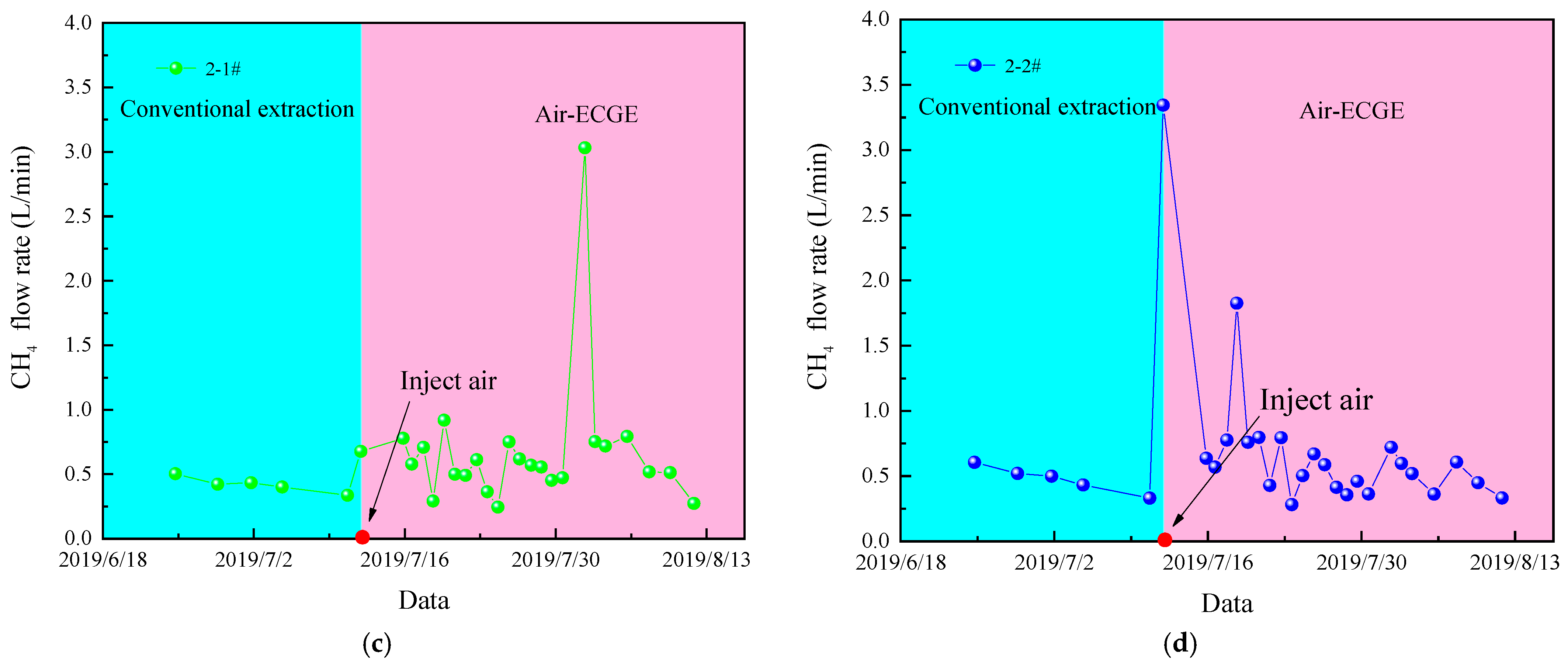

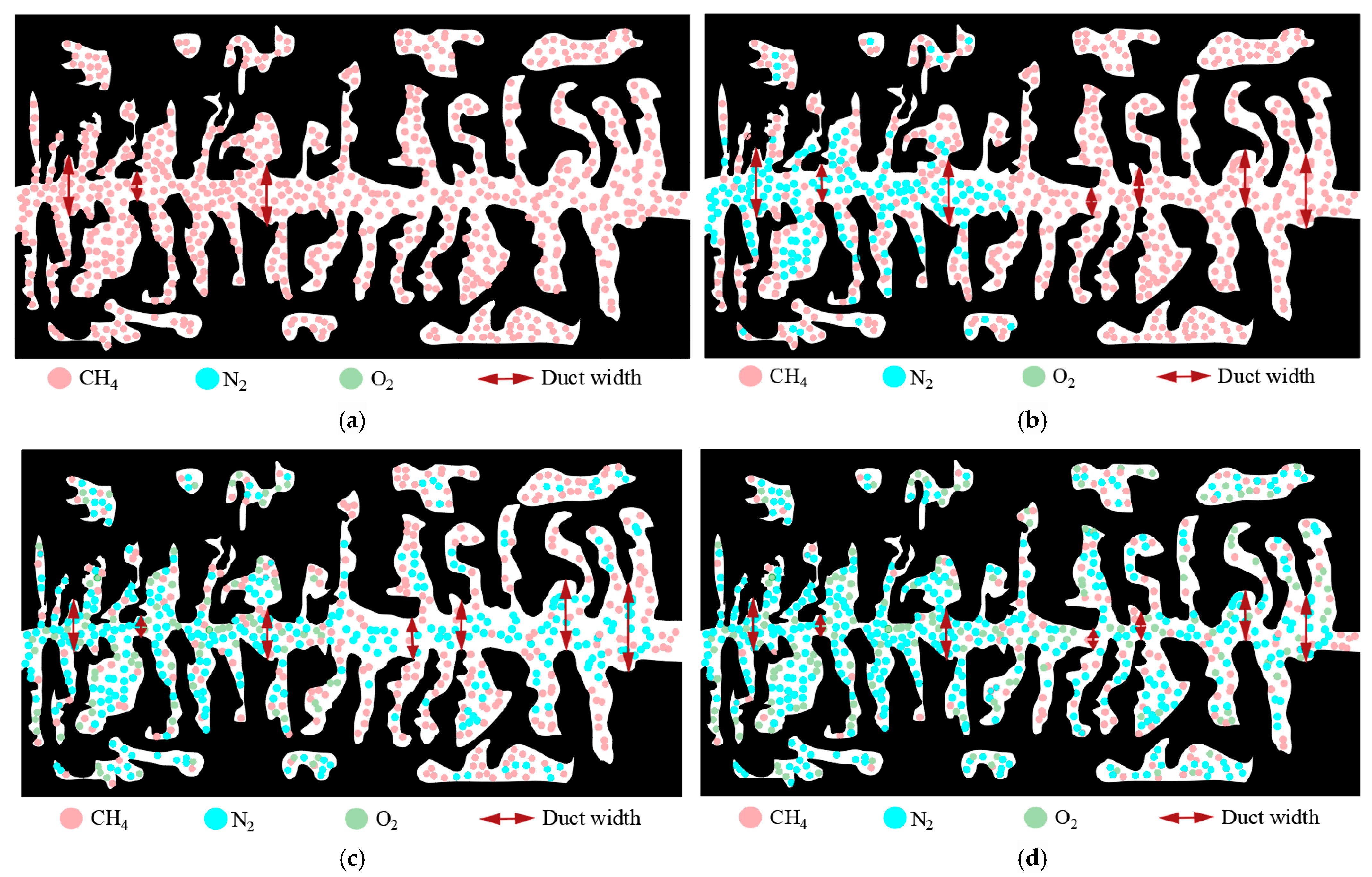

- Owing to the high content of N2 in the air and the relatively low adsorption capacity of N2 on coal, the migration speed of N2 inside the coal is faster than that of O2, and the coal around the gas injection borehole is first affected by N2. High-pressure N2 compresses the coal skeleton, increasing the width of the coal duct and the permeability. Moreover, high-pressure N2 increases the internal pressure difference of the coal body, promotes gas migration, and increases the extraction efficiency of methane (Figure 18a,b).

- (2)

- When O2 affects the coal body, owing to the strong adsorption of O2 on the coal body, the coal skeleton expands, the pores of the coal body become smaller, and the permeability decreases. However, O2 can displace more CH4, further promoting the extraction of coalbed methane (Figure 18c,d).

- (3)

- As shown in previous studies focusing on surface well coalbed methane drainage, the injection gas pressure typically exceeds 6 MPa. In contrast, this field test achieved effective results with only 0.8 MPa injection pressure. The key reason lies in the substantial difference in well spacing: surface operations require 100–300 m between injection and production wells, whereas coal mine underground drilling allows a spacing of merely 1–6 m between boreholes. This compact configuration enables efficient gas drainage with lower pressure. Although studies indicate higher injection pressures enhance drainage effectiveness, China’s underground air compressors are restricted to a maximum outlet pressure of 2.5 MPa per safety regulations, with pipeline pressure typically maintained below 1.0 MPa. This critical safety measure prevents gas leaks from endangering personnel in underground workings.

- (4)

- Not all areas within coal mines are suitable for Air-ECGE technology implementation. First, specific coal seam characteristics are a prerequisite: if geological structures are well-developed, it may cause inadvertent connectivity between injection boreholes, extraction boreholes, or underground roadways. This scenario would allow injected gas to flow directly into extraction points or tunnels, significantly compromising its effectiveness in enhancing coal seam gas drainage. Second, regarding underground infrastructure: large-scale implementation requires high-capacity air compressors, which typically exceed 3.5 m in length and 3 tons in weight. Mines must therefore possess adequate transport capacity for such equipment along with sufficient clearance for installation in confined underground spaces.

- (5)

- Since the technology involves injecting high-pressure air into boreholes, its core equipment requirement is specifically air compressors. Currently, certified air compressors suitable for underground coal mine operations carry an approximate price tag of $75,000. Notably, engineering materials employed are standard consumables routinely used in mine production, incurring no significant additional material costs. Mine implementation would require only one additional air compressor operator. Critical safety protocols must be established: Mine operators should enhance underground safety training programs with emphasis on strictly prohibiting unauthorized disconnection of injection pipelines to prevent high-pressure hazards. Furthermore, the efficacy of Air-ECGE technology is highly dependent on optimal borehole design and precise gas injection parameter selection. Consequently, systematic technical training for relevant personnel is imperative, with projected training expenditures estimated at $100,000. Although this technology entails additional costs, it can significantly enhance the efficiency of coalbed methane extraction, ensure production safety during coal mining, reduce accident rates, and improve coal production efficiency in mines. From this perspective, its application ultimately lowers operational costs for mines and enhances corporate profits.

6. Conclusions

- (1)

- The results show that injecting high-pressure air into a coalbed can effectively promote gas desorption and gas migration within the coalbed, greatly improving the efficiency of coalbed gas extraction.

- (2)

- Owing to the large pressure gradient that can lead to fast coalbed gas seepage, the gas production rate of the extraction borehole is directly proportional to the gas injection pressure. The spacing of the boreholes limits the influence range of the gas injection: the larger the spacing, the larger the influence range, and the higher the gas extraction rate of the extraction borehole.

- (3)

- After injecting air into the Liuzhuang coal mine coalbed, the extraction flow rate and concentration of gas from the extraction boreholes both increased significantly. A certain delay effect was observed in the gas injection effect, and the gas extraction flow rate only decreased after a period of time post gas injection stoppage.

- (4)

- This study only conducted field trials of Air-ECGE technology under one borehole layout configuration. However, multiple types of boreholes exist in underground coal mines, such as cross-measure boreholes and long boreholes exceeding 300 m. The effectiveness of Air-ECGE technology under these scenarios requires further investigation. Furthermore, injecting air into coal seams may reduce the methane extraction concentration from underground boreholes. Currently, most mines utilize the extracted methane gas, and a decrease in concentration could impose limitations on its utilization. Therefore, the Air-ECGE process requires further optimization to ensure increased methane extraction while maintaining concentration. Achieving a balance between increasing the absolute methane yield and maintaining extraction concentration constitutes a critical future research direction for this technology.

- (5)

- Due to the O2-rich nature of air, prolonged injection into spontaneous combustion-prone coal seams carries the risk of triggering spontaneous combustion, potentially leading to mine fires. Therefore, ensuring the safety of such coal seams during Air-ECGE application represents a critical research topic for subsequent studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yiting, D. The Coal Industry Structure Is Better and the Background Color Is Greener. People’s Daily, 28 February 2022; 2003–2005. [Google Scholar]

- Guo, Y.; Wang, K.; Du, F.; Guo, H.; Li, K.; Wang, Y. Mechanical-Permeability Characteristics of Composite Coal Rock under Different Gas Pressures and Damage Prediction Model. Phys. Fluids 2024, 36, 1–13. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, E.; Guo, Y.; Du, F.; Ding, K. Effect of Loading Rate on the Mechanical and Seepage Characteristics of Gas-Bearing Coal-Rock and Its Mechanical Constitutive Model. Phys. Fluids 2024, 36, 1–12. [Google Scholar] [CrossRef]

- Shu, L.; Wang, K.; Liu, Z.; Zhao, W.; Zhu, N.; Lei, Y. A Novel Physical Model of Coal and Gas Outbursts Mechanism: Insights into the Process and Initiation Criterion of Outbursts. Fuel 2022, 323, 124305. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent Developments in Coal Mine Methane Extraction and Utilization in China: A Review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, J.; Shen, C.; Zhang, Q.; Sun, C. Technology and Application of Pressure Relief and Permeability Increase by Jointly Drilling and Slotting Coal. Int. J. Min. Sci. Technol. 2012, 22, 545–551. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, W.; Chen, J.; Xiao, X.; Li, Y.; Zhao, X. Simulation of Hydraulic Fracturing Using Particle Flow Method and Application in a Coal Mine. Int. J. Coal Geol. 2014, 121, 1–13. [Google Scholar] [CrossRef]

- Yun, J.; Xu, F.; Liu, L.; Zhong, N.; Wu, X. New Progress and Future Prospects of CBM Exploration and Development in China. Int. J. Min. Sci. Technol. 2012, 22, 363–369. [Google Scholar] [CrossRef]

- Yan, T.; Li, W.; Bi, X. An Experimental Study of Fracture Initiation Mechanisms During Hydraulic Fracturing. Pet. Sci. 2011, 8, 87–92. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Zou, Q.; Zhu, C.; Guo, C.; Li, J. Investigation on Mechanical Properties and Damage Evolution of Coal after Hydraulic Slotting. J. Nat. Gas Sci. Eng. 2015, 24, 489–499. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Elsworth, D.; Chen, Z.; Connell, L.; Pan, Z. Dual Poroelastic Response of a Coal Seam to CO2 Injection. Int. J. Greenh. Gas Control 2010, 4, 668–678. [Google Scholar] [CrossRef]

- Walker, P.L.; Geller, I. Change in Surface Area of Anthracite on Heat Treatment. Nature 1956, 178, 1001. [Google Scholar] [CrossRef]

- White, C.M.; Smith, D.H.; Jones, K.L.; Goodman, A.L.; Jikich, S.A.; LaCount, R.B.; DuBose, S.B.; Ozdemir, E.; Morsi, B.I.; Schroeder, K.T. Sequestration of Carbon Dioxide in Coal with Enhanced Coalbed Methane Recovery—A Review. Energy Fuels 2005, 19, 659–724. [Google Scholar]

- Bai, X.; Zhang, D.; Zeng, S.; Zhang, S.; Wang, D.; Wang, F. An Enhanced Coalbed Methane Recovery Technique Based on CO2 Phase Transition Jet Coal-Breaking Behavior. Fuel 2020, 265, 2–3. [Google Scholar] [CrossRef]

- Zheng, S.; Yao, Y.; Elsworth, D.; Liu, D.; Cai, Y. Dynamic Fluid Interactions during CO2-Enhanced Coalbed Methane and CO2 Sequestration in Coal Seams. Part 1: CO2-CH4 Interactions. Energy Fuels 2020, 34, 8274–8282. [Google Scholar] [CrossRef]

- Fan, N.; Wang, J.; Deng, C.; Fan, Y.; Mu, Y.; Wang, T. Numerical Study on Enhancing Coalbed Methane Recovery by Injecting N2/CO2 Mixtures and Its Geological Significance. Energy Sci. Eng. 2020, 8, 1104–1119. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G.; Ranathunga, A.S.; Koay, A.Y.J.; Zhao, J.; Choi, S.K. Optimization of Enhanced Coal-Bed Methane Recovery Using Numerical Simulation. J. Geophys. Eng. 2015, 12, 90–107. [Google Scholar] [CrossRef]

- Ross, H.E.; Hagin, P.; Zoback, M.D. CO2 Storage and Enhanced Coalbed Methane Recovery: Reservoir Characterization and Fluid Flow Simulations of the Big George Coal, Powder River Basin, Wyoming, USA. Int. J. Greenh. Gas Control 2009, 3, 773–786. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Faaij, A.P.C.; Turkenburg, W.C.; van Bergen, F.; Pagnier, H.J.M.; Barzandji, O.H.M.; Wolf, K.H.A.A.; Ruijg, G.J. CO2 Enhanced Coalbed Methane Production in the Netherlands. Energy 2002, 27, 647–674. [Google Scholar] [CrossRef]

- Vishal, V.; Mahanta, B.; Pradhan, S.P.; Singh, T.N.; Ranjith, P.G. Simulation of CO2 Enhanced Coalbed Methane Recovery in Jharia Coalfields, India. Energy 2018, 159, 1185–1194. [Google Scholar] [CrossRef]

- Wong, S.; Law, D.; Deng, X.; Robinson, J.; Kadatz, B.; Gunter, W.D.; Ye, J.; Feng, S.; Fan, Z. Enhanced Coalbed Methane and CO2 Storage in Anthracitic Coals—Micro-Pilot Test at South Qinshui, Shanxi, China. Int. J. Greenh. Gas Control 2007, 1, 215–2228. [Google Scholar] [CrossRef]

- Zhou, F.; Hou, W.; Allinson, G.; Wu, J.; Wang, J.; Cinar, Y. A Feasibility Study of ECBM Recovery and CO2 Storage for a Producing CBM Field in Southeast Qinshui Basin, China. Int. J. Greenh. Gas Control 2013, 19, 26–40. [Google Scholar] [CrossRef]

- Fan, Y.; Deng, C.; Zhang, X.; Li, F.; Wang, X.; Qiao, L. Numerical Study of CO2-Enhanced Coalbed Methane Recovery. Int. J. Greenh. Gas Control 2018, 76, 12–23. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Chen, Z.; Luo, M.; Song, Y.; Zhang, H. Modelling and Optimization of Enhanced Coalbed Methane Recovery Using CO2/N2 Mixtures. Fuel 2019, 253, 1114–1129. [Google Scholar] [CrossRef]

- Vishal, V.; Ranjith, P.G.; Singh, T.N. CO2 Permeability of Indian Bituminous Coals: Implications for Carbon Sequestration. Int. J. Coal Geol. 2013, 105, 36–47. [Google Scholar] [CrossRef]

- Jasinge, D.; Ranjith, P.G.; Choi, S.K. Effects of Effective Stress Changes on Permeability of Latrobe Valley Brown Coal. Fuel 2011, 90, 1292–1300. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, X.; Fan, C.; Bai, G. Coal Permeability Evolution Triggered by Variable Injection Parameters during Gas Mixture Enhanced Methane Recovery. Energy 2022, 252, 124065. [Google Scholar] [CrossRef]

- Fan, Z.; Fan, G.; Zhang, D.; Zhang, L.; Zhang, S.; Liang, S.; Yu, W. Optimal Injection Timing and Gas Mixture Proportion for Enhancing Coalbed Methane Recovery. Energy 2021, 222, 119880. [Google Scholar] [CrossRef]

- Mirzaeian, M.; Hall, P.J.; Jirandehi, H.F. Study of Structural Change in Wyodak Coal in High-Pressure CO2 by Small Angle Neutron Scattering. J. Mater. Sci. 2010, 45, 5271–5281. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G.; Choi, S.K.; Airey, D.; Weniger, P. Estimation of Gas Adsorption Capacity in Coal: A Review and an Analytical Study. Int. J. Coal Prep. Util. 2012, 32, 25–55. [Google Scholar] [CrossRef]

- Fan, Y.; Shu, L.; Huo, Z.; Hao, J.; Li, Y.; Guo, X. Research on Coalbed Methane Microscopic Seepage Characteristics of Medium and High-Rank Coal. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–13. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.; Wang, Y. Laboratory Study of the Displacement Coalbed CH4 Process and Efficiency of CO2 and N2 Injection. Sci. World J. 2014, 242947, 1–9. [Google Scholar] [CrossRef]

- Mazzotti, M.; Pini, R.; Storti, G. Enhanced Coalbed Methane Recovery. J. Supercrit. Fluids 2009, 47, 619–627. [Google Scholar] [CrossRef]

- Balan, H.O.; Gumrah, F. Enhanced Coalbed Methane Recovery with Respect to Physical Properties of Coal and Operational Parameters. J. Can. Pet. Technol. 2009, 48, 56–61. [Google Scholar] [CrossRef]

- Fan, Y.; Deng, C.; Zhang, X.; Li, F.; Wang, X. Numerical Study of Multi-Branch Horizontal Well Coalbed Methane Extraction. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1342–1350. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Wei, J.; Liu, X. Optimum Structure of a Laval Nozzle for an Abrasive Air Jet Based on Nozzle Pressure Ratio. Powder Technol. 2020, 364, 343–362. [Google Scholar] [CrossRef]

- Liu, S.; Ji, H.; Han, D.; Guo, C. Experimental Investigation and Application on the Cutting Performance of Cutting Head for Rock Cutting Assisted with Multi-Water Jets. Int. J. Adv. Manuf. Technol. 2018, 94, 2715–2728. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental Investigation of N2 Injection to Enhance Gas Drainage in CO2-Rich Low Permeable Seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Cheng, Y.; Nemcik, J.; Wang, G. Cyclic N2 Injection for Enhanced Coal Seam Gas Recovery: A Laboratory Study. Energy 2019, 188, 116115. [Google Scholar] [CrossRef]

- Li-Wei, C.; Tian-Hong, Y.; Hong-Min, Y.; Li-Guo, W. Time Characteristics of the Influence Radius by Injecting N2 to Displace Coalbed Methane: A Case Study. Geofluids 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Yang, X.; Wang, G.; Du, F.; Jin, L.; Gong, H. N2 Injection to Enhance Coal Seam Gas Drainage (N2-ECGD): Insights from Underground Field Trial Investigation. Energy 2022, 239, 122247. [Google Scholar] [CrossRef]

- Yıldız, T.D. Loss of Profits Occurring Due to the Halting of Mining Operations Arising from Occupational Accidents or Reasons Related to Legislation. Gospod. Surowcami Miner./Miner. Resour. Manag. 2021, 37, 153–176. [Google Scholar] [CrossRef]

- Kahraman, M.M. Analysis of Mining Lost Time Incident Duration Influencing Factors Through Machine Learning. Min. Metall. Explor. 2021, 38, 1031–1039. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Bulk modulus of coal (E) | 2786 MPa | Bulk modulus of coal skeleton (Es) | 8147 MPa |

| Poisson’s ratio of coal (v) | 0.35 | Coal skeleton density (ρs) | 1375 kg/m3 |

| Density of coal (ρ) | 1289 kg/m3 | Density of N2 at standard condition (ρga2) | 1.25 kg/m3 |

| Density of CH4 at standard condition (ρga1) | 0.716 kg/m3 | Initial porosity of coal (φ0) | 0.032 |

| Density of O2 at standard condition (ρga3) | 1.429 kg/m3 | Initial temperature of coalbed (T0) | 308 K |

| Initial Langmuir volume constant of CH4 (VL1) | 0.0223 m3/kg | Initial Langmuir pressure constant of CH4 (PL1) | 1.85 MPa |

| Initial Langmuir volume constant of N4 (VL2) | 0.0183 m3/kg | Initial Langmuir pressure constant of CH4 (PL2) | 3.01 MPa |

| Initial Langmuir volume constant of O2 (VL3) | 0.0401 m3/kg | Initial Langmuir pressure constant of O2 (PL3) | 2.05 MP |

| Pressure correction factor (d1) | 0.071 1/MPa | Temperature correction factor (d2) | 0.021 1/K |

| Dispersion coefficient of CH4 (D1) | 3.6 × 10−12 m2/s | Dispersion coefficient of N2 (D2) | 2.8 × 10−12 m2/s |

| Dispersion coefficient of O2 (D3) | 6.2 × 10−12 m2/s | Specific heat capacity of coal skeleton (Cs) | 1280 J/(kg·K) |

| Constant specific heat capacity of CH4 (Cv1) | 1624 J/(kg·K) | Constant specific heat capacity of N2 (Cv2) | 741 J/(kg·K) |

| Constant specific heat capacity of O2 (Cv3) | 918 J/(kg·K) | Thermal conductivity of coal skeleton (λs) | 0.171 W/(m·K) |

| Thermal conductivity of CH4 (λg1) | 0.031 W/(m·K) | The thermal conductivity of N2 (λg2) | 0.025 W/(m·K) |

| Thermal conductivity of O2 (λg3) | 0.024 W/(m·K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Y.; Shu, L.; Song, X.; Gong, H. Study on Air Injection to Enhance Coalbed Gas Extraction. Processes 2025, 13, 1882. https://doi.org/10.3390/pr13061882

Fan Y, Shu L, Song X, Gong H. Study on Air Injection to Enhance Coalbed Gas Extraction. Processes. 2025; 13(6):1882. https://doi.org/10.3390/pr13061882

Chicago/Turabian StyleFan, Yongpeng, Longyong Shu, Xin Song, and Haoran Gong. 2025. "Study on Air Injection to Enhance Coalbed Gas Extraction" Processes 13, no. 6: 1882. https://doi.org/10.3390/pr13061882

APA StyleFan, Y., Shu, L., Song, X., & Gong, H. (2025). Study on Air Injection to Enhance Coalbed Gas Extraction. Processes, 13(6), 1882. https://doi.org/10.3390/pr13061882