Relationship Between Density and Structure of Lignins Obtained from Different Feedstocks Pretreated with Protic Ionic Liquids

Abstract

1. Introduction

2. Materials and Methods

2.1. Lignins

2.2. Skeletal Density

2.3. Bulk Density

2.4. Particle Size

2.5. Two-Dimensional-HSQC

2.6. 31P-NMR

3. Results

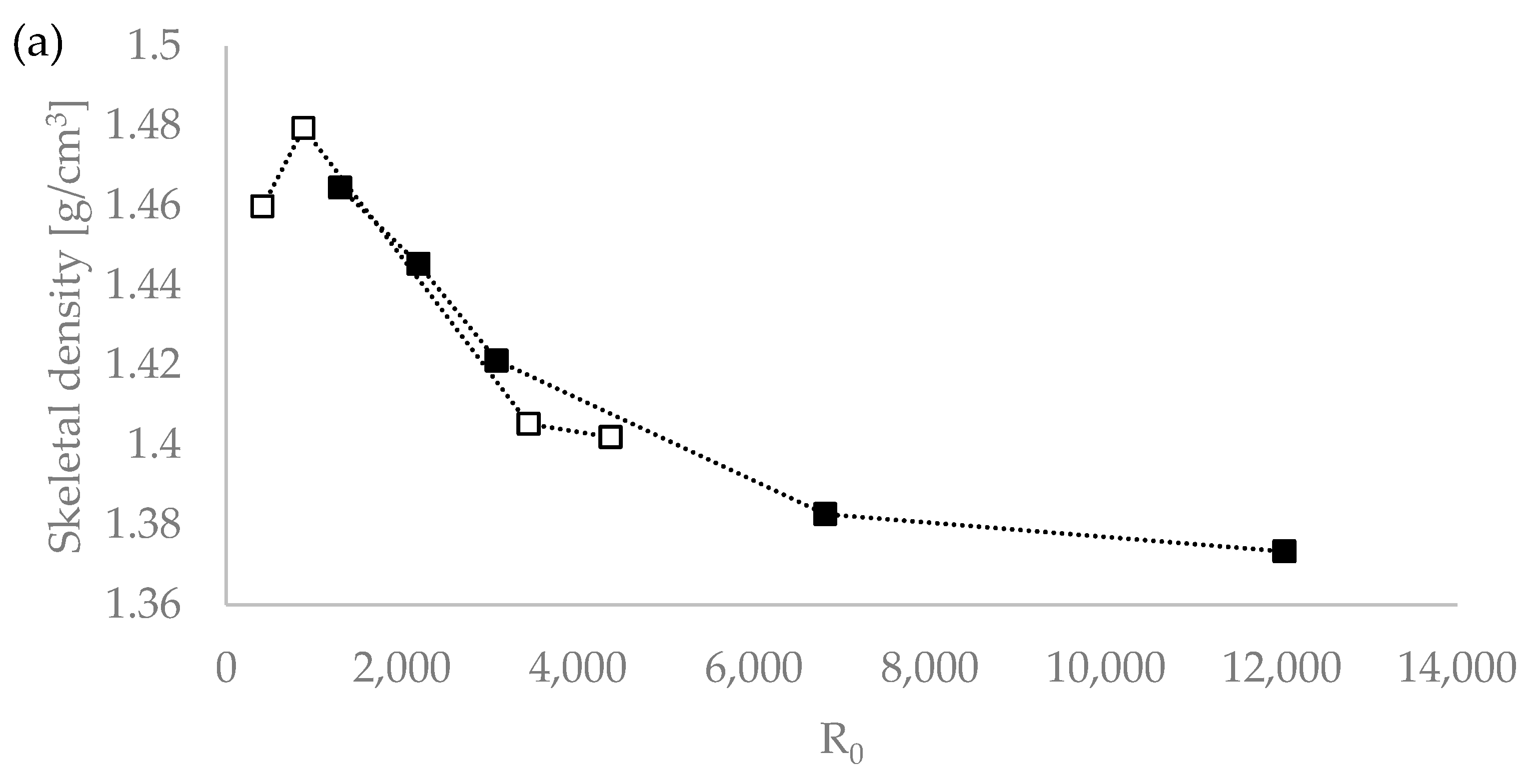

3.1. Density

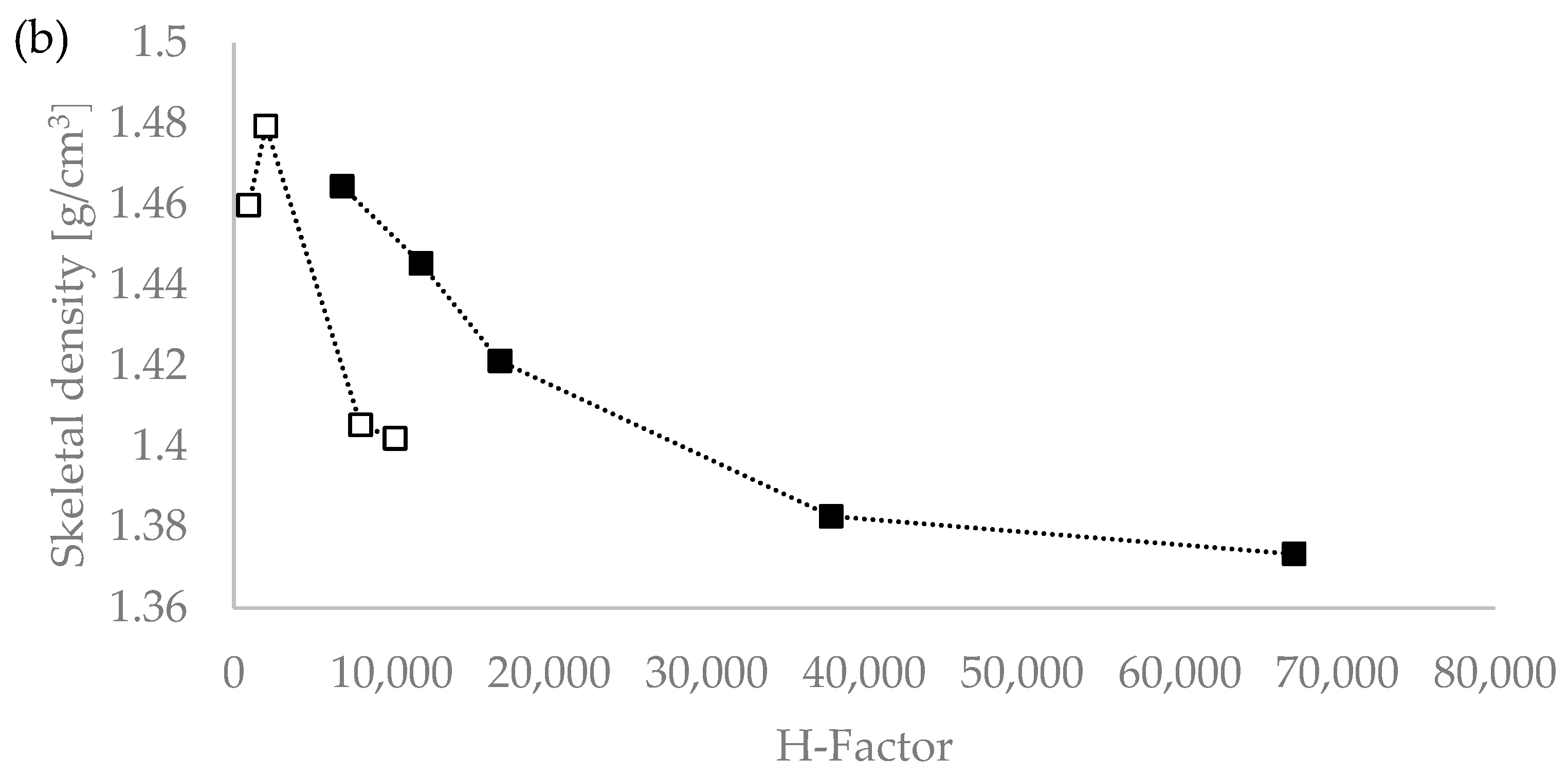

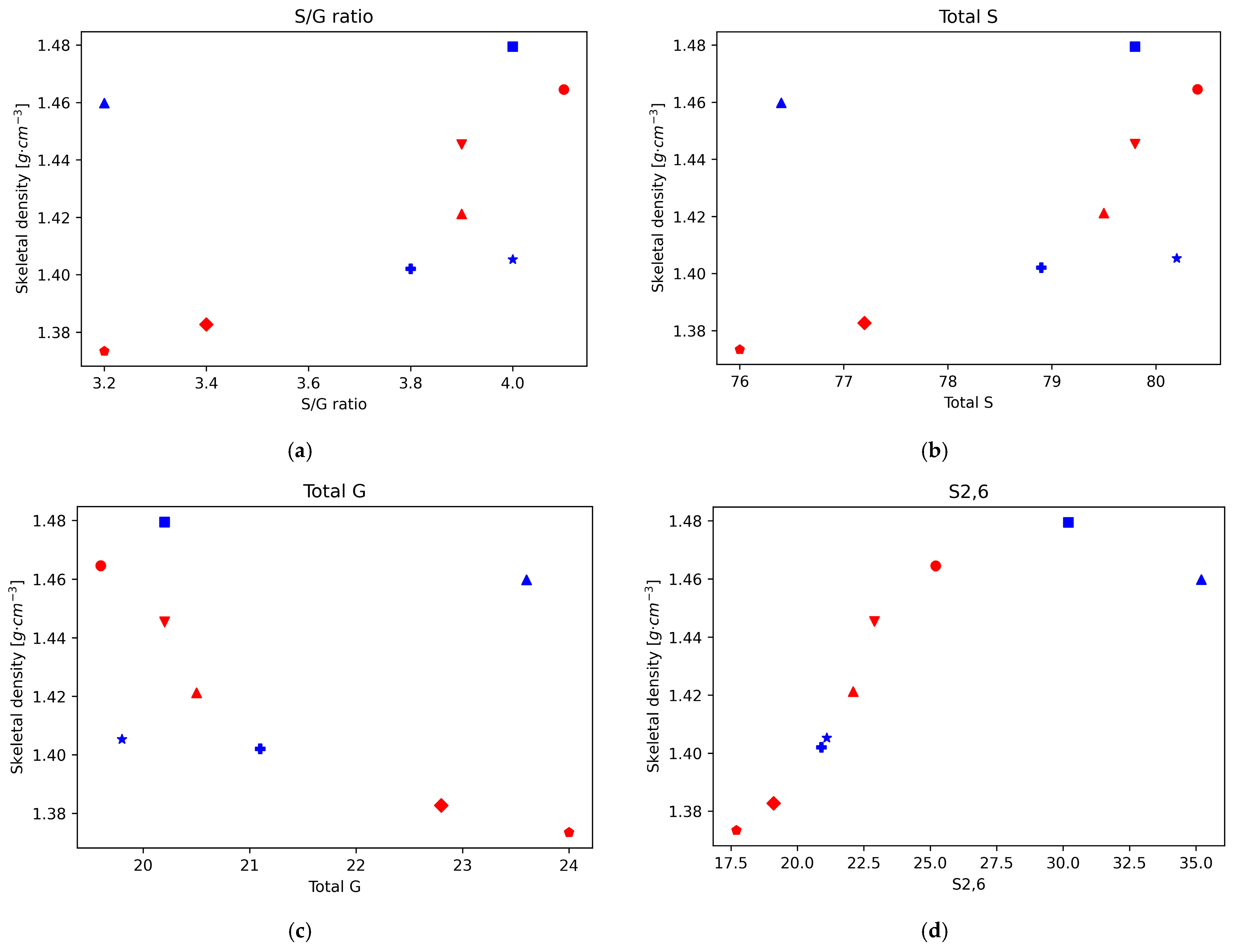

3.2. Density and Chemical Structure Correlations

3.3. 31P-NMR

3.4. Particle Size

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 31P-NMR | Phosphorus 31 nuclear magnetic resonance |

| 2D-HSQC | Two-dimensional heteronuclear quantum coherence |

| ρ | Density |

| Da | Daltons |

| DI | De-ionized |

| M. | Mixed |

| MW | Molecular weight |

| [MEA][OAc] | Monoethanol ammonium acetate |

| [DMBA][HSO4] | N,N-Dimethyl butylammonium hydrogen sulphate |

| R0 | Severity factor |

| rpm | Rotations per minute |

| Std Dev | Standard deviation |

| 31P-NMR | Phosphorus 31 nuclear magnetic resonance |

References

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem. 2013, 15, 550–583. [Google Scholar] [CrossRef]

- Weigand, L.; Mostame, S.; Brandt-Talbot, A.; Welton, T.; Hallett, J.P. Effect of pretreatment severity on the cellulose and lignin isolated from Salix using ionoSolv pretreatment. Faraday Discuss. 2017, 202, 331–349. [Google Scholar] [CrossRef] [PubMed]

- Yoo, C.G.; Ragauskas, A. (Eds.) Opportunities and challenges of lignin utilization. In Lignin Utilization Strategies: From Processing to Applications; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2021; Volume 1377, pp. 1–12. [Google Scholar] [CrossRef]

- Chambon, C.L.; Fitriyanti, V.; Verdía, P.; Yang, S.M.; Hérou, S.; Titirici, M.-M.; Brandt-Talbot, A.; Fennell, P.S.; Hallett, J.P. Fractionation by Sequential Antisolvent Precipitation of Grass, Softwood, and Hardwood Lignins Isolated Using Low-Cost Ionic Liquids and Water. ACS Sustain. Chem. Eng. 2020, 8, 3751–3761. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Hyman, D.; Payne, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Wolfe, J. Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process Samples; National Renewable Energy Laboratory: Golden, CO, USA, 2008; Volume XXV, pp. 233–253. [Google Scholar]

- Voitkevich, O.V.; Kabo, G.J.; Blokhin, A.V.; Paulechka, Y.U.; Shishonok, M.V. Thermodynamic properties of plant biomass components. Heat capacity, combustion energy, and gasification equilibria of lignin. J. Chem. Eng. Data 2012, 57, 1903–1909. [Google Scholar] [CrossRef]

- Tolbert, A.; Akinosho, H.; Khunsupat, R.; Naskar, A.K.; Ragauskas, A.J. Characterization and analysis of the molecular weight of lignin for biorefining studies. Biofuels Bioprod. Biorefining 2014, 8, 836–856. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Yoo, C.G.; Meng, X.; Pu, Y.; Ragauskas, A.J. The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: A comprehensive review. Bioresour. Technol. 2020, 301, 122784. [Google Scholar] [CrossRef]

- Koutsoukos, S.; Philippi, F.; Malaret, F.; Welton, T. A review on machine learning algorithms for the ionic liquid chemical space. Chem. Sci. 2021, 12, 6820–6843. [Google Scholar] [CrossRef]

- Nakasu, P.Y.; Barbará, P.V.; Firth, A.E.; Hallett, J.P. Pretreatment of biomass with protic ionic liquids. Trends Chem. 2022, 4, 175–178. [Google Scholar] [CrossRef]

- Nakasu, P.Y.S.; Clarke, C.J.; Rabelo, S.C.; Costa, A.C.; Brandt-Talbot, A.; Hallett, J.P. Interplay of acid–base ratio and recycling on the pretreatment performance of the protic ionic liquid monoethanolammonium acetate. ACS Sustain. Chem. Eng. 2020, 8, 7952–7961. [Google Scholar] [CrossRef]

- Ovejero-Pérez, A.; Rigual, V.; Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Effect of autohydrolysis and ionosolv treatments on eucalyptus fractionation and recovered lignin properties. RSC Adv. 2023, 13, 10338–10348. [Google Scholar] [CrossRef] [PubMed]

- Brandt-Talbot, A.; Gschwend, F.J.V.; Fennell, P.S.; Lammens, T.M.; Tan, B.; Weale, J.; Hallett, J.P. An economically viable ionic liquid for the fractionation of lignocellulosic biomass. Green Chem. 2017, 19, 3078–3102. [Google Scholar] [CrossRef]

- Chambon, C.L.; Chen, M.; Fennell, P.S.; Hallett, J.P. Efficient Fractionation of Lignin- and Ash-Rich Agricultural Residues Following Treatment With a Low-Cost Protic Ionic Liquid. Front. Chem. 2019, 7, 246. [Google Scholar] [CrossRef] [PubMed]

- Demuner, I.F.; Colodette, J.L.; Demuner, A.J.; Jardim, C.M. Biorefinery review: Wide-reaching products through kraft lignin. BioResources 2019, 14, 7543–7581. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Pourhashem, G.; Ullah, A.H.; Bajwa, S.G. A concise review of current lignin production, applications, products and their environmental impact. Ind. Crop. Prod. 2019, 139, 111526. [Google Scholar] [CrossRef]

- Ruwoldt, J.; Opedal, M.T. Green materials from added-lignin thermoformed pulps. Ind. Crop. Prod. 2022, 185. [Google Scholar] [CrossRef]

- Widjaya, E.R.; Chen, G.; Bowtell, L.; Hills, C. Gasification of non-woody biomass: A literature review. Renew. Sustain. Energy Rev. 2018, 89, 184–193. [Google Scholar] [CrossRef]

- Malaret, F.; Gschwend, F.J.V.; Lopes, J.M.; Tu, W.-C.; Hallett, J.P. Eucalyptus red grandis pretreatment with protic ionic liquids: Effect of severity and influence of sub/super-critical CO2 atmosphere on pretreatment performance. RSC Adv. 2020, 10, 16050–16060. [Google Scholar] [CrossRef]

- Pu, Y.; Cao, S.; Ragauskas, A.J. Application of quantitative 31P NMR in biomass lignin and biofuel precursors characterization. Energy Environ. Sci. 2011, 4, 3154–3166. [Google Scholar] [CrossRef]

- ISO 17828:2025; Solid Biofuels—Determination of Bulk Density, 2nd ed. International Organization for Standardization: London, UK, 2025. Available online: https://www.iso.org/standard/84596.html (accessed on 30 April 2025).

- ASTM D3766-08(2018); Standard Terminology Relating to Catalysts and Catalysis. ASTM International: West Conshohocken, PA, USA, 2024. Available online: https://store.astm.org/d3766-08r18.html (accessed on 30 April 2025).

- Wypych, A. (Ed.) Front Matter. In Databook of Adhesion Promoters; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Michelsen, F.A.; Foss, B.A. A comprehensive mechanistic model of a continuous Kamyr digester. Appl. Math. Model. 1996, 20, 523–533. [Google Scholar] [CrossRef]

- Chen, L.; Xin, J.; Ni, L.; Dong, H.; Yan, D.; Lu, X.; Zhang, S. Conversion of lignin model compounds under mild conditions in pseudo-homogeneous systems. Green Chem. 2016, 18, 2341–2352. [Google Scholar] [CrossRef]

- Zhang, L.; LeBoeuf, E.J. A molecular dynamics study of natural organic matter: 1. Lignin, kerogen and soot. Org. Geochem. 2009, 40, 1132–1142. [Google Scholar] [CrossRef]

- Barbosa, B.M.; Vaz, S.; Colodette, J.L.; de Siqueira, H.F.; da Silva, C.M.S.; Cândido, W.L. Effects of kraft lignin and corn residue on the production of eucalyptus pellets. BioEnergy Res. 2023, 16, 484–493. [Google Scholar] [CrossRef]

- Elniski, A.; Dongre, P.; Bujanovic, B.M. Lignin Use in Enhancing the Properties of Willow Pellets. Forests 2023, 14, 2041. [Google Scholar] [CrossRef]

- D’Amour, R. Modèle Réactionnel de La Dépolymérisation Hydrolytique de La Cellulose En Cellulose Microcristalline; Université de Sherbrooke: Sherbrooke, QC, Canada, 2001. [Google Scholar]

- Overend, R.P.; Chornet, E. Fractionation of lignocellulosics by steam-aqueous pretreatments. Phil. Trans. R. Soc. Lond. A 1987, 321, 523–536. [Google Scholar] [CrossRef]

- Joseph, P.; Opedal, M.T.; Moe, S.T. The O-factor: Using the H-factor concept to predict the outcome of organosolv pretreatment. Biomass Conv. Bioref. 2023, 13, 6727–6736. [Google Scholar] [CrossRef]

- Wyman, C.E.; Yang, B. Combined Severity Factor for Predicting Sugar Recovery in Acid-Catalyzed Pretreatment Followed by Enzymatic Hydrolysis. In Hydrothermal Processing in Biorefineries; Ruiz, H.A., Hedegaard Thomsen, M., Trajano, H.L., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 161–180. [Google Scholar] [CrossRef]

- Ovejero-Pérez, A.; Rigual, V.; Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Acidic depolymerization vs ionic liquid solubilization in lignin extraction from eucalyptus wood using the protic ionic liquid 1-methylimidazolium chloride. Int. J. Biol. Macromol. 2020, 157, 461–469. [Google Scholar] [CrossRef]

- Stücker, A.; Podschun, J.; Saake, B.; Lehnen, R. A novel quantitative31P NMR spectroscopic analysis of hydroxyl groups in lignosulfonic acids. Anal. Methods 2018, 10, 3481–3488. [Google Scholar] [CrossRef]

- Brandt, A.; Chen, L.; van Dongen, B.E.; Welton, T.; Hallett, J.P. Structural changes in lignins isolated using an acidic ionic liquid water mixture. Green Chem. 2015, 17, 5019–5034. [Google Scholar] [CrossRef]

- Posoknistakul, P.; Tangkrakul, C.; Chaosuanphae, P.; Deepentham, S.; Techasawong, W.; Phonphirunrot, N.; Bairak, S.; Sakdaronnarong, C.; Laosiripojana, N. Fabrication and Characterization of Lignin Particles and Their Ultraviolet Protection Ability in PVA Composite Film. ACS Omega 2020, 5, 20976–20982. [Google Scholar] [CrossRef]

- Tsvetkov, M.V.; Salganskii, E.A. Lignin: Applications and Ways of Utilization (Review). Russ. J. Appl. Chem. 2018, 91, 1129–1136. [Google Scholar] [CrossRef]

- Boschetti, W.T.N.; Lopes, A.D.C.P.; Ribeiro, R.A.; Reyes, R.Q.; Carneiro, A.d.C.O. Kraft lignin as an additive in pine and eucalyptus particle composition for briquette production. Rev. Arvore 2019, 43. [Google Scholar] [CrossRef]

- Setter, C.; Costa, K.L.S.; de Oliveira, T.J.P.; Mendes, R.F. The effects of kraft lignin on the physicomechanical quality of briquettes produced with sugarcane bagasse and on the characteristics of the bio-oil obtained via slow pyrolysis. Fuel Process. Technol. 2020, 210, 106561. [Google Scholar] [CrossRef]

- Findorák, R.; Legemza, J.; Fröhlichová, M.; Fabriciová, G.; Džupková, M. New utilization of specific biomass: Lignin in the iron ore sintering process. Metals 2020, 10, 1170. [Google Scholar] [CrossRef]

- González-Muñoz, M.J.; Alvarez, R.; Santos, V.; Parajó, J.C. Production of hemicellulosic sugars from Pinus pinaster wood by sequential steps of aqueous extraction and acid hydrolysis. Wood Sci. Technol. 2012, 46, 271–285. [Google Scholar] [CrossRef]

- Li, J.; Galebach, P.H.; Johnson, J.K.; Fredriksen, T.; Wittrig, A.; Bai, X.; Yang, H.; Huber, G.W. Supercritical methanol depolymerization and hydrodeoxygenation of pyrolytic lignin over reduced copper porous metal oxides. Green Chem. 2020, 22, 8403–8413. [Google Scholar] [CrossRef]

| Lignin Sample | Extraction Method | ρ (g/cm3) | Std Dev (g/cm3) | ρbulk (cm3/g) | Std Dev (g/cm3) |

|---|---|---|---|---|---|

| European softwood | Kraft | 1.3604 | 0.0038 | 0.4729 | 0.0048 |

| Lineo Prime | Kraft | 1.3547 | 0.0015 | 0.4622 | 0.0060 |

| Soda wheat lignin | Soda pulping | 1.3370 | 0.0017 | 0.4976 | 0.0086 |

| Spruce lignin | ionoSolv (145 °C, 30′) | 1.3831 | 0.0075 | 0.4255 | 0.0119 |

| Eucalyptus | ionoSolv (120 °C, 120′) | 1.4598 | 0.0053 | 0.1475 | 0.0115 |

| Eucalyptus | ionoSolv (120 °C, 240′) | 1.4193 | 0.0065 | 0.1538 | 0.0027 |

| Eucalyptus | ionoSolv (120 °C, 900′) | 1.4053 | 0.0027 | 0.3472 | 0.0094 |

| Eucalyptus | ionoSolv (120 °C, 1140′) | 1.4020 | 0.0012 | 0.2977 | 0.0084 |

| Eucalyptus | ionoSolv (150 °C, 60′) | 1.3708 | 0.0112 | 0.0944 | 0.0023 |

| Eucalyptus | ionoSolv (150 °C, 90′) | 1.4454 | 0.0050 | 0.1135 | 0.0027 |

| Eucalyptus | ionoSolv (150 °C, 120′) | 1.4098 | 0.0034 | 0.1456 | 0.0176 |

| Eucalyptus | ionoSolv (150 °C, 246′) | 1.3827 | 0.0020 | 0.3234 | 0.0095 |

| Eucalyptus | ionoSolv (150 °C, 422′) | 1.3734 | 0.0016 | 0.5302 | 0.0048 |

| Pre-extracted eucalyptus | ionoSolv ([MEA][OAc], 150 °C, 60′) | 1.3550 | 0.0072 | - | - |

| Pre-extracted eucalyptus | ionoSolv ([MEA][OAc], 150 °C, 90′) | 1.3765 | 0.1090 | - | - |

| Miscanthus | ionoSolv (150 °C, 45′) | 1.3594 | 0.0027 | - | - |

| Miscanthus | ionoSolv (150 °C, 65′) | 1.3670 | 0.0035 | - | - |

| Miscanthus | ionoSolv (150 °C, 90′) | 1.3547 | 0.0013 | - | - |

| Lignin | Aliphatic (mmol/g) | β-5′ | 4-O-5′ | 5-5′ | Syringyl | Guaiacyl | Para-Hydroxy-Pheny |

|---|---|---|---|---|---|---|---|

| M. softwood Kraft | 166.99 | 25.98 | 7.12 | 40.23 | - | 102.25 | 10.69 |

| Wheat straw Soda | 182.60 | 21.06 | 10.37 | 73.86 | 90.51 | 37.71 | |

| Spruce ionoSolv—145 °C | 121.71 | 0 | 0 | 0 | 0 | 81.14 | 0 |

| M. soft. ionoSolv—150 °C | 198.31 | 57.20 a | 0 | 135.14 | 0 | ||

| Eucalyptus ionoSolv—120 °C | 224.40 | 123.83 b | 60.03 | 0 | |||

| Eucalyptus ionoSolv—150 °C | 131.69 | 396.63 b | 146.46 | 0 | |||

| Miscanthus ionoSolv—150 °C | 142.69 | 36.77 a | 102.14 | 145.83 | 88.31 | ||

| Biomass | Bulk Density (g/cm3) | Particle Size (mm) | Reference |

|---|---|---|---|

| Kraft lignin | 0.427 | 0.149–0.177 | [39] |

| Kraft lignin | 0.520 | 0.18 | [40] |

| Technical hydrolysed lignin | 0.93–1.0 | 0.5–25.0 | [41] |

| Kraft lignin | 0.4–0.5 | 0.010–0.200 | [42] |

| Maple wood | 0.25 | 0.177–0.354 | [43] |

| Kraft softwood lignin | 0.4729 | 0.13–1.258 | This work |

| Kraft LineoTM lignin | 0.4622 | 0.36–1.445 | This work |

| Soda wheat lignin | 0.4976 | 0.01–1.091 | This work |

| Spruce ionoSolv (145°/30 min) | 0.4255 | 0.01–1.445 | This work |

| Eucalyptus ionoSolv (120°/240 min) | 0.1538 | 0.05–0.138 | This work |

| Eucalyptus ionoSolv (150°/90 min) | 0.1135 | 0.03–0.549 | This work |

| Eucalyptus ionoSolv (150°/120 min) | 0.1456 | 0.01–0.417 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malaret, F.; Nakasu, P.Y.S.; Verdía Barbará, P.; Hopson, C.; Hallett, J. Relationship Between Density and Structure of Lignins Obtained from Different Feedstocks Pretreated with Protic Ionic Liquids. Processes 2025, 13, 1848. https://doi.org/10.3390/pr13061848

Malaret F, Nakasu PYS, Verdía Barbará P, Hopson C, Hallett J. Relationship Between Density and Structure of Lignins Obtained from Different Feedstocks Pretreated with Protic Ionic Liquids. Processes. 2025; 13(6):1848. https://doi.org/10.3390/pr13061848

Chicago/Turabian StyleMalaret, Francisco, Pedro Y. S. Nakasu, Pedro Verdía Barbará, Cynthia Hopson, and Jason Hallett. 2025. "Relationship Between Density and Structure of Lignins Obtained from Different Feedstocks Pretreated with Protic Ionic Liquids" Processes 13, no. 6: 1848. https://doi.org/10.3390/pr13061848

APA StyleMalaret, F., Nakasu, P. Y. S., Verdía Barbará, P., Hopson, C., & Hallett, J. (2025). Relationship Between Density and Structure of Lignins Obtained from Different Feedstocks Pretreated with Protic Ionic Liquids. Processes, 13(6), 1848. https://doi.org/10.3390/pr13061848