3.1. Analysis of Scientific Research Output

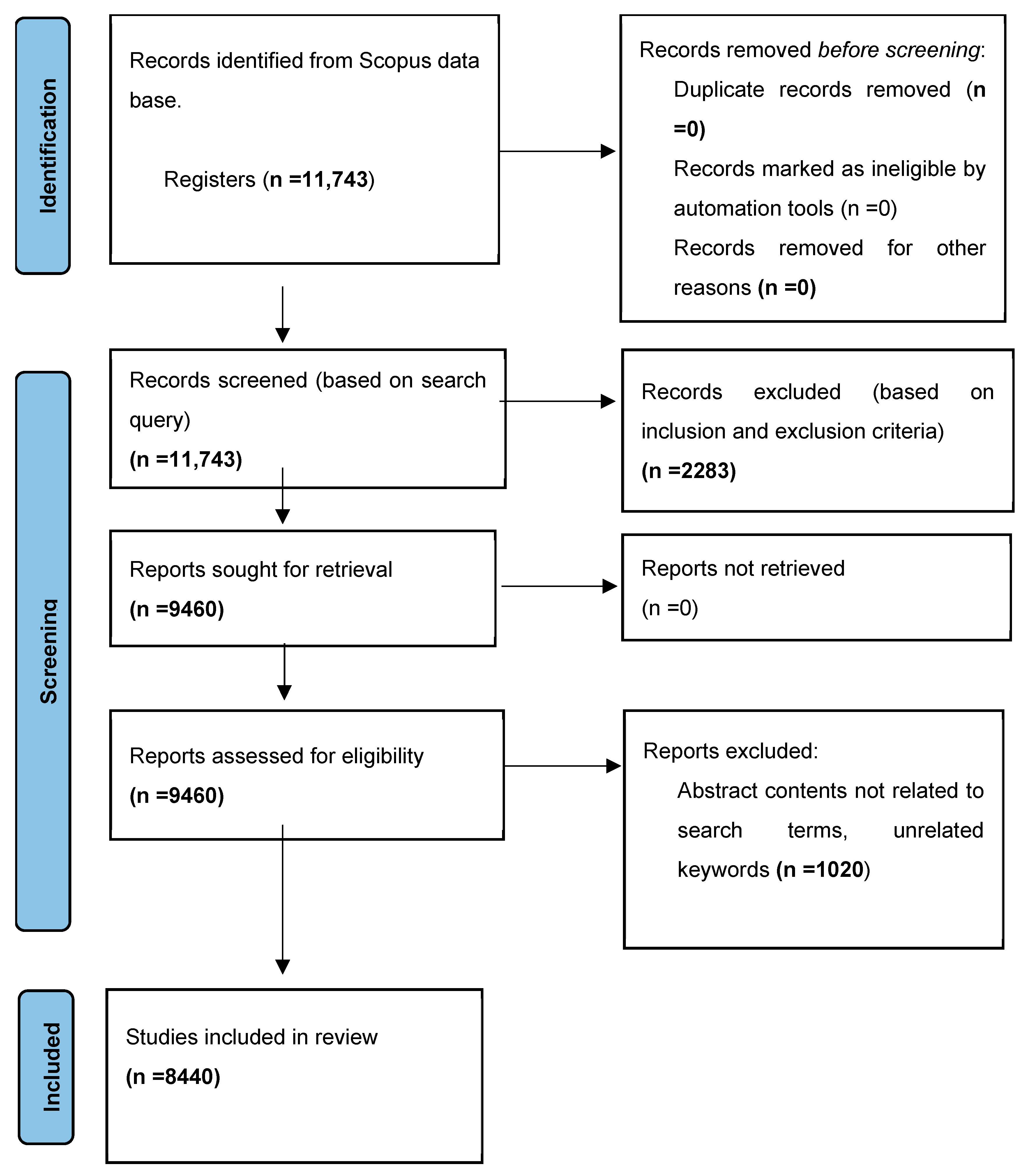

The results (see

Figure 2) show an increasing trend in the production output of research on gasification focused on hydrogen production over the past three decades, with over 60% of the research published between 1995 and 2025, peaking in 2024, with over 880 documents published on this topic. The trend also shows spikes in 2006, 2017, and 2024. This trend, although anecdotal, points to a ten-year cycle of increasing interest in hydrogen research. In fact, the International Energy Agency (IEA)’s 2024 Global Hydrogen Review shows that most hydrogen projects are expected to be delivered in 2027 [

1], demonstrating a possible surge in hydrogen research from 2027 to 2030. The COVID-19 pandemic may have influenced the marginal spike observed in 2019, as overall global research output increased due to increased remote worktimes under lockdown orders [

25,

26].

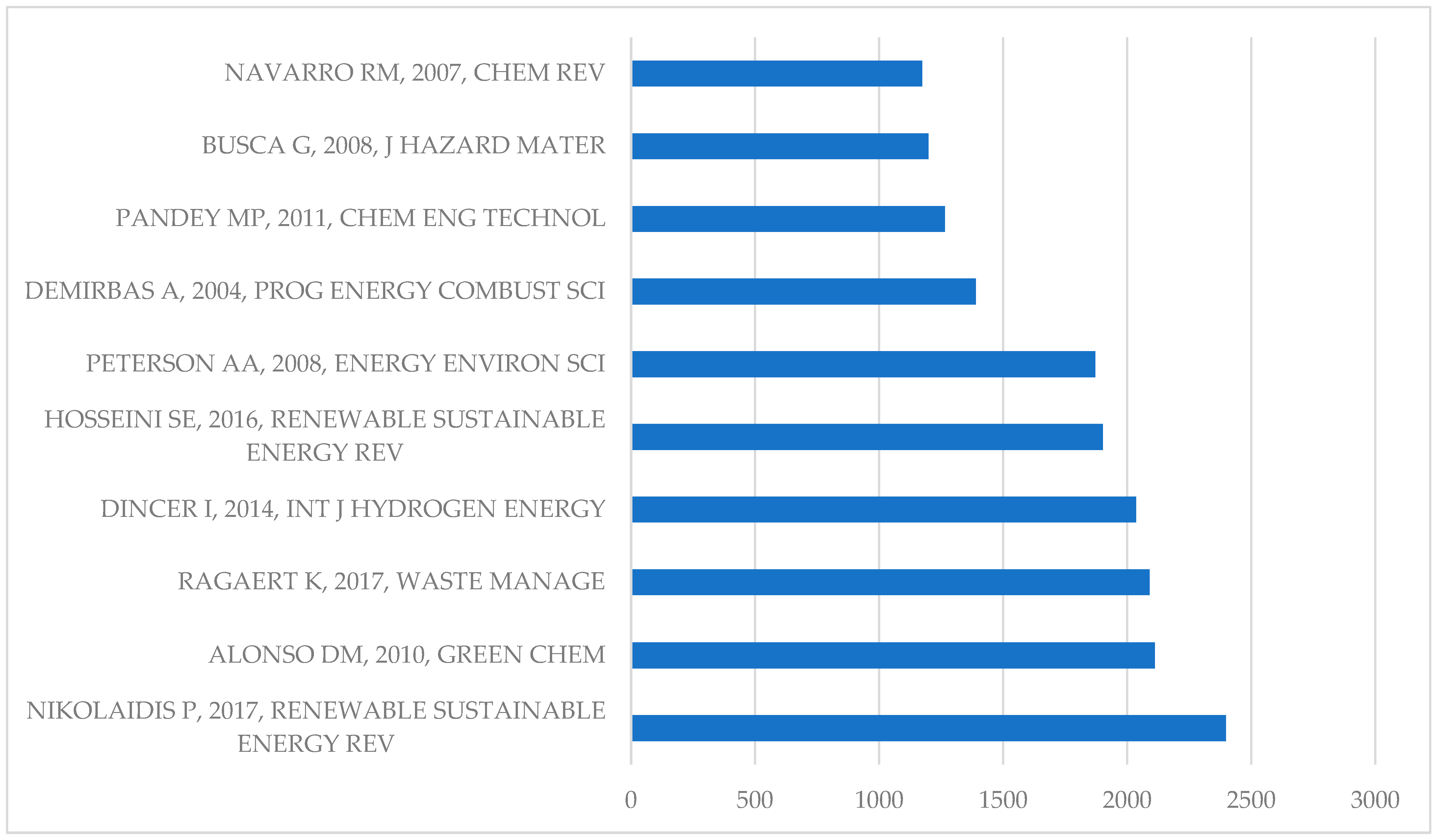

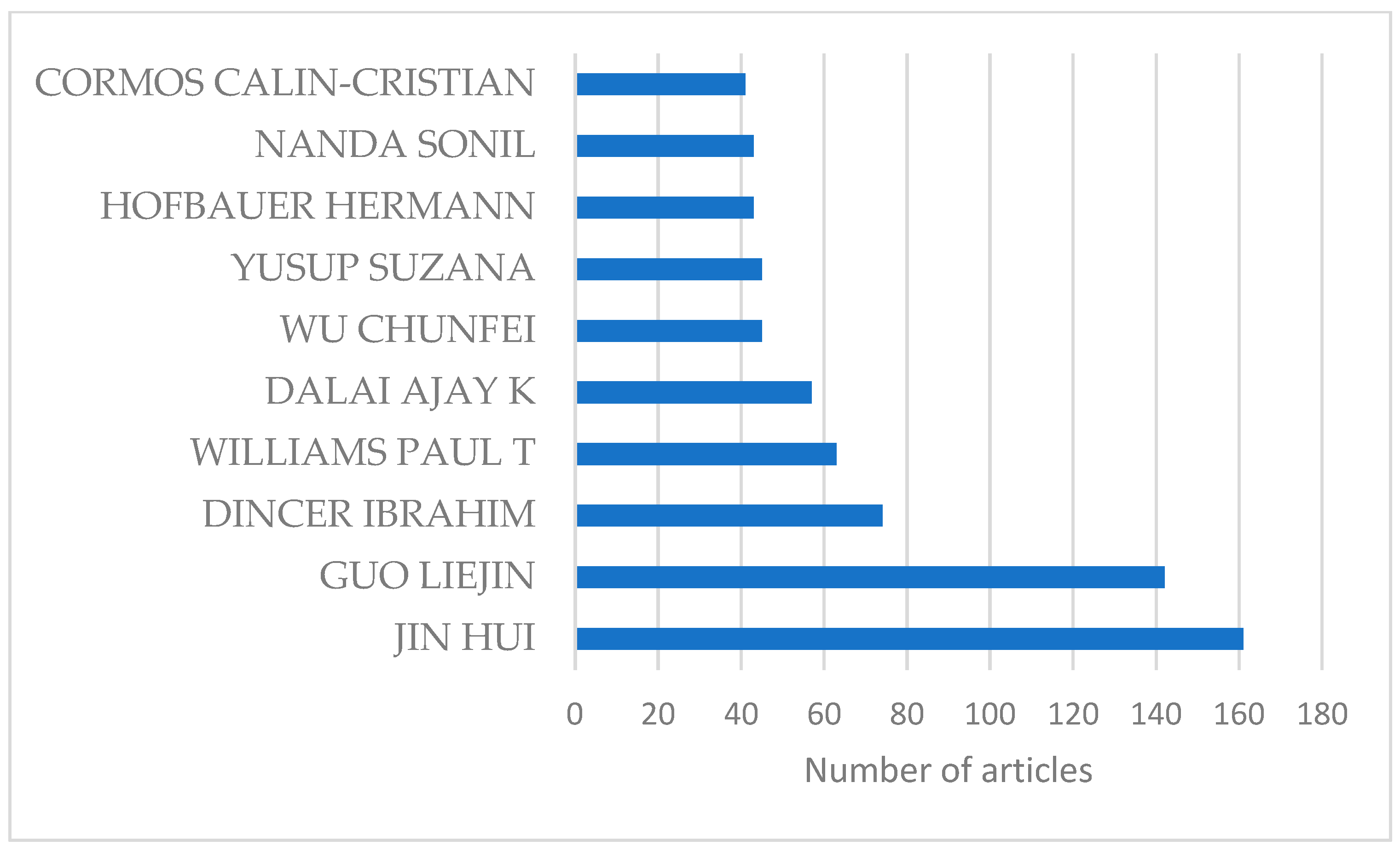

Figure 3 and

Figure 4 illustrate the most globally cited documents and the most relevant authors, respectively.

With a citation of over 2397, the paper by ref. [

15] is by far the most cited document on the topic under review. Their paper provided a comprehensive overview of hydrogen production processes, including thermochemical methods such as gasification. They concluded that gasification was among the most cost-competitive and efficient means of producing hydrogen (at a production cost of between USD 1.34 and USD 2.27/kg). Ref. [

27], whose paper emerged as the second most cited in the literature, evaluated the conversion of biomass to biofuels through catalysis and provided early support for the conversion of sugars to renewable hydrogen. The third most widely cited document, although focused on thermochemical conversion techniques, displays a slight deviation from the heavy emphasis of the literature on biomass, rather choosing to assess the feasibility of hydrogen generation from solid plastic gasification [

28].

The next most cited paper conducted a comprehensive assessment of hydrogen production methods, concluding that gasification and other thermochemical processes were preferred as long as efficiency was a priority [

29]. Ref. [

13] corroborated the cost-competitiveness of gasification for hydrogen production, with a distinct endorsement of biomass feedstocks, and highlighted the prospects of super-critical water gasification (SCWG) to further enhance efficiency.

A state-of-the-art overview of biomass technology [

30] with 804 citations reported that biomass gasification was a cost-effective means of producing hydrogen but concluded that a comprehensive review of the literature was missing. Other widely cited papers in the literature have reviewed gasification technology either with respect to different feedstocks, environmental impacts, or the state of the technology [

14,

18,

31,

32,

33,

34,

35,

36].

The top destinations for documents pertaining to the topic were published in the

International Journal of Hydrogen Energy and Energy, accounting for 1107 publications (representing nearly 13% of the literature) as shown in

Table 2. The distribution of publication on the subject matter supports Bradford’s law of scattering, which states that “if scientific journals are arranged in order of decreasing productivity of articles on a given subject, they may be divided into a nucleus of periodicals more particularly devoted to the subject and several groups or zones containing the same articles as the nucleus, when the number of periodicals in the nucleus and succeeding zones will be as 1: n: n

2, where “n” is a multiplier” [

37]. This law effectively posits that articles are majorly published in a concentrated few journals and that the rest are distributed over a large number of journals (see

Table 3).

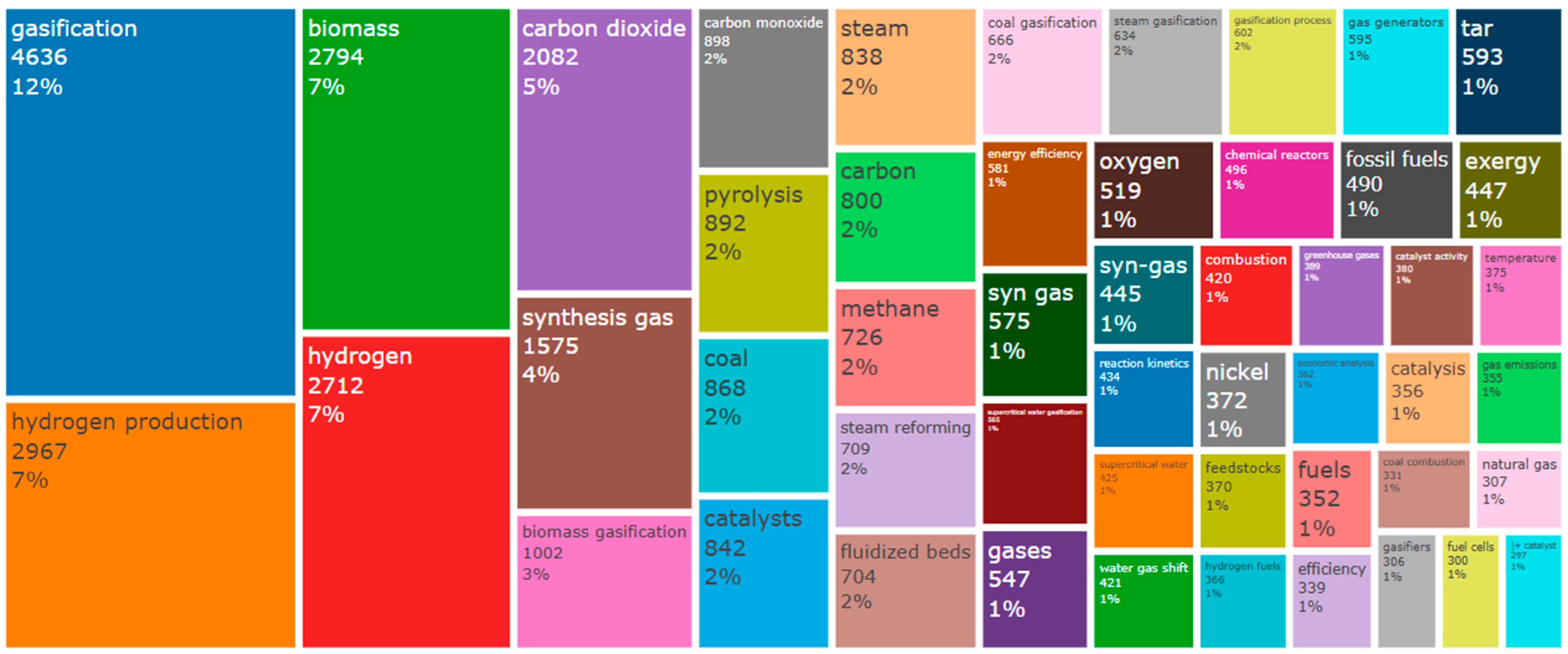

3.2. Keyword Tree Map

Figure 5 shows the prevalence of the keywords in the literature, demonstrating that the words “gasification”, “hydrogen production”, “hydrogen”, and “biomass” emerge as the most prevalent keywords, with “gasification” comprising 12% and the next top three prevalent keywords making up 7% of the keywords in the literature, respectively. The next most occurring keywords are “carbon dioxide” (5%), “synthetic gas”(4%), and “biomass gasification”(3%). Apart from the fact that these dominant keywords may be attributed to their use in direct search terms, the dominance of “gasification” and ‘hydrogen production” in the literature is also due to the positive prospects of biomass gasification as an efficient means of producing green hydrogen [

38,

39].

On the other hand, “coal combustion”, “feedstocks”, “water gas shift gasification”, “hydrogen fuels”, “fuel cells”, “super-critical water”, and “gas emissions” are among the least prevalent keywords in the literature, accounting for 1% each of the keywords. This depicts either a decline or the emergence of studies on these topics. For instance, while the low prevalence of “coal combustion” in the literature may be plausibly attributed to a declining interest in coal as a feedstock post-Paris Agreement [

40], the low prevalence of “feedstocks” could be attributed to the recent interest in exploring renewable feedstocks as alternatives to fossil fuels for gasification-derived bio-hydrogen [

41,

42].

It is observed that, while bio-hydrogen is gaining momentum as a sustainable and competitive alternative to fossil-derived hydrogen [

43,

44], the term “bio-hydrogen” does not occur in the tree map in

Figure 5. This is because, even though “bio-hydrogen” was part of the search term, this study focuses on hydrogen derived from gasification (a thermochemical process), whereas “bio-hydrogen” is a term often associated with hydrogen derived from biological processes such as anaerobic microbial digestion or fermentation [

45,

46].

3.3. Co-Occurrence Analysis

A co-occurrence network analysis (see

Table 4) reveals four main clusters. Cluster 1 shows the co-occurrence of keywords such as “biomass gasification”, “hydrogen production”, “biomass”, “steam gasification”, “chemical reactions”, and “syngas”, reflecting a focus on the process-oriented literature and revealing the strong interlinkage between gasification processes and hydrogen production in the literature. Some papers with a focus on feedstock have assessed the feasibility of Athabasca bitumen as a feedstock for hydrogen generation through super-critical water gasification, reporting significant hydrogen yields [

47]. Similarly, ref. [

48] reported the viability of biomass as an alternative feedstock for hydrogen production through gasification.

Cluster 2 comprises keywords such as “carbon dioxide”, “hydrogen”, “carbon monoxide”, “methane”, “synthetic gas”, “oxygen”, “gases”, and “gas generators”. This clearly illustrates a strong focus on the diverse products and bio-products of gasification processes.

Cluster 3 emphasises process optimisation techniques for improved efficiency. Keywords here include “catalysts”, “catalysts activity”, “supercritical water”, and “nickel”. Research with these keywords seeks to investigate the utility of various catalysts to improve biofuel yields and process efficiency. For instance, ref. [

49] reported increased hydrogen yield (90%) under optimised conditions of (360 °C, 0.5 g Ni-La catalyst loading, 0.5 g biomass and 10 min), emphasising the importance of an Ni-L catalyst in the gasification process. Other studies have also assessed the effect of various catalysts on optimising the gasification process for improved hydrogen yield [

50,

51].

The fourth cluster of keywords focuses on environmental assessment and cost–benefit analyses, featuring keywords such as “energy efficiency”, “economic analysis”, and “exergy”. Works in this cluster seek to evaluate the cost-competitiveness of using various feedstocks to produce hydrogen through gasification (see [

52,

53,

54]). Predictably, keywords on greenhouse gas emission analysis co-occur with keywords such as “coal combustion” and “natural gas”, as the literature here seeks to evaluate the emission profiles of fossil fuel feedstocks and their mitigation approaches.

The co-occurrence analysis, therefore, reveals four clusters of the literature on the subject matter: (1) the fundamentals of the gasification process for hydrogen production and the feasible feedstocks, as seen in [

18,

33,

55,

56,

57]; (2) the evaluation of products and bio-products of the gasification process, as reported by [

36]; (3) the thermochemical process optimisation for hydrogen production, as reported by refs. [

58,

59]; and (4) the emission and economic evaluation of the gasification process (see refs. [

60,

61,

62,

63,

64,

65,

66,

67,

68,

69,

70]).

3.5. Scientific Production and Collaboration by Country

Figure 6 illustrates the comparative scientific research output on hydrogen production through gasification. The map shows that the research output on the subject matter is concentrated within a few countries, illustrated by the dark shades. Thus, China, the United States of America, Germany, India, and the United Kingdom register substantial research outputs. The map conversely shows large parts of Africa, Central Asia, and some portions of Latin America in grey, signifying limited research activity on the subject matter. African countries with marginal research output include South Africa, Egypt, and Nigeria.

The concertation of research outputs in China and Europe is reflected in their hydrogen infrastructure maturity, as the two regions collectively host over 70% of global hydrogen capacity [

1].

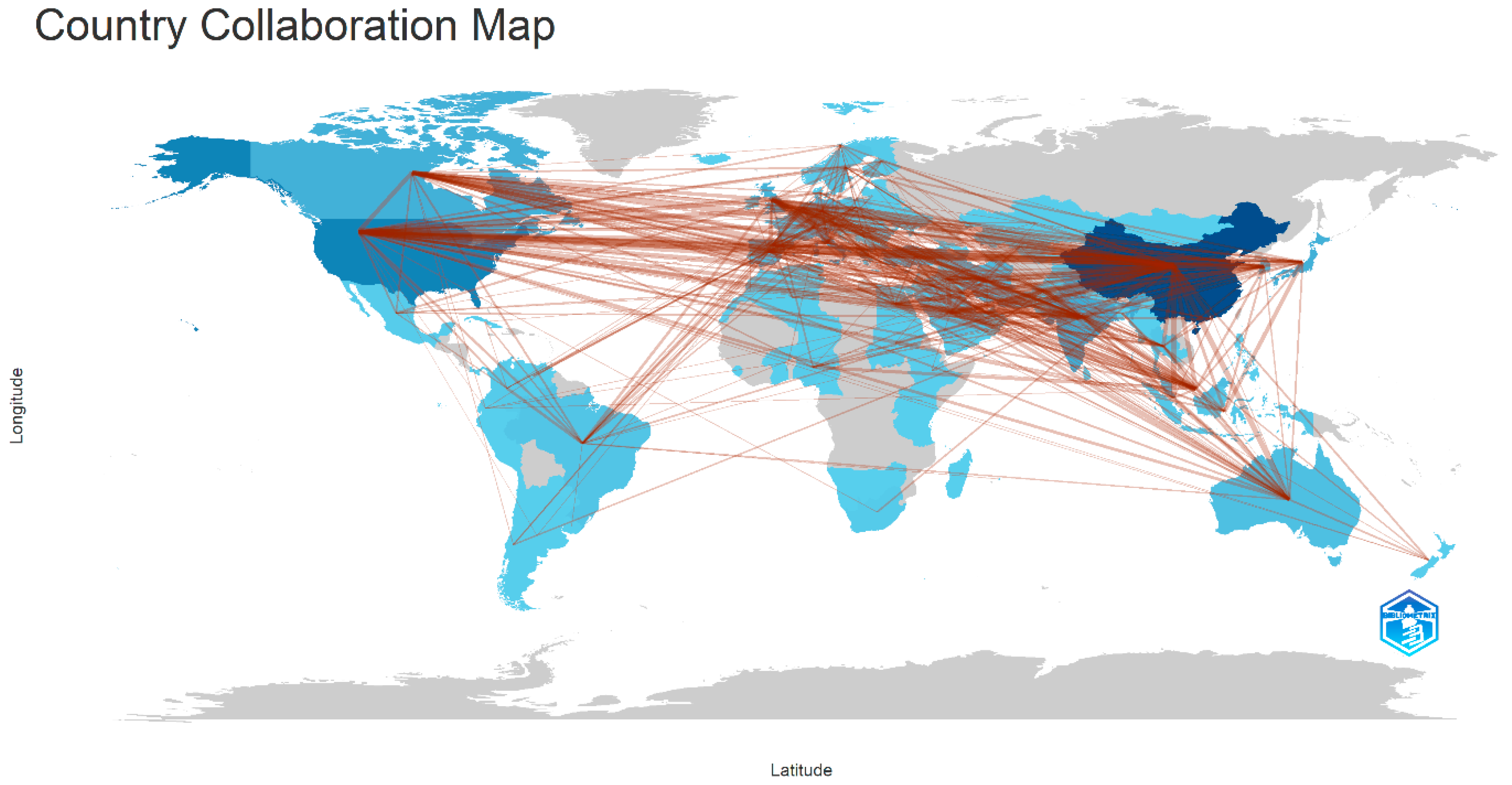

A country collaboration map (see

Figure 7) shows that countries with the highest density of research outputs tend to also exhibit the most collaborative links across the globe. Therefore, China, the United States, and countries in Europe host the densest research links, whereas the Global South demonstrates limited research collaborations, both inwardly and outwardly.

The limited research output in Africa may be attributed to the continent’s starved investment in research and development. For instance, Africa’s Gross Expenditure on R&D (GERD) is about 0.5% of GDP compared to a global average of 2.2% [

66]. Also, the number of researchers per million people in Africa (100 researchers per million) is far less than the global average of 1100 researchers per million people [

67]. This funding deficit is reflected in the continent’s heavy reliance on external funding sources to meet its research and development needs. Only 8 out of the 134 funding sponsors of Scopus-indexed African research output on the subject matter are located in Africa, namely the University of South Africa, the University of Johannesburg, Durban University of Technology (South Africa), Tshwane University of Technology (South Africa), the University of Cape Town (South Africa), the Council for Scientific and Industrial Research (South Africa), North-West University (South Africa), and the Kwame Nkrumah University of Science and Technology (Ghana). The remainder (including the top 10 funding institutions, as shown in

Table 6) are non-African.

This funding gap and limited research output notwithstanding, there are over one hundred (100) hydrogen projects at various phases of operation in Algeria, Angola, the Democratic Republic of Congo, Djibouti, Egypt, Kenya, Mauritania, Morocco, Mozambique, Namibia, Niger, South Africa, Uganda, and Zimbabwe. However, these projects are mainly focused on electrolytic water-splitting technology (95% of the projects), without any operational biomass-based hydrogen project as of 2024 [

68]. Comparatively, there are over 50 biomass-based hydrogen projects globally as of 2024, according to the International Energy Agency (see

Figure 8).

3.6. Research Trends

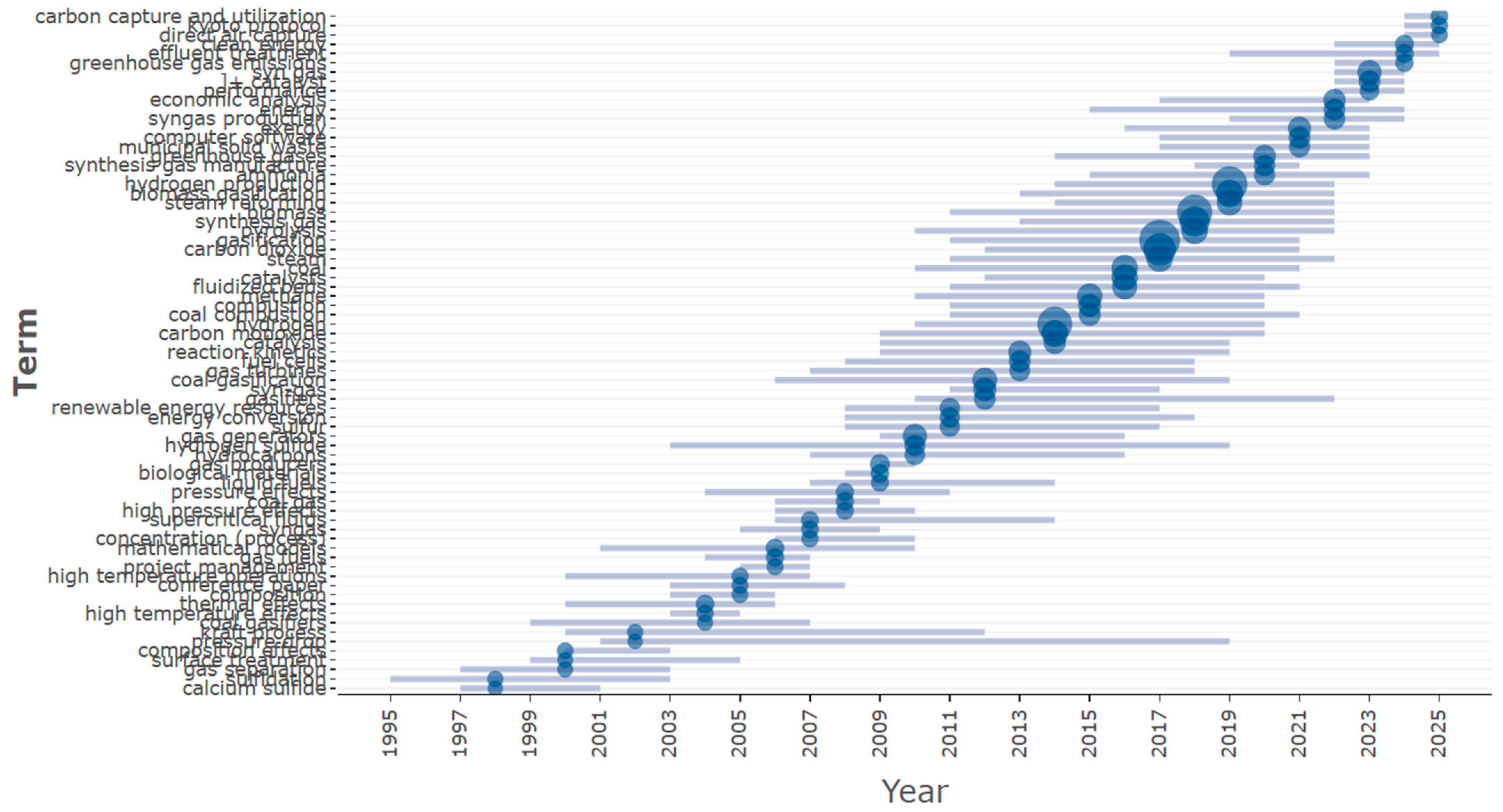

Figure 9 illustrates the evolution of research from 1995 to 2025. Four thematic timelines emerge in the literature, discussed below.

Fundamentals of thermochemical processes (1995–2002)

The literature within this period is characterised by keywords such as “sulphidation”, “pressure drop”, “combustion”, “high temperature effects”, and “gasifiers”. This emphasises a focus on technical feasibility and unravelling the science behind thermochemical processes. For instance, ref. [

69] developed a reduced nitrogen oxides model for industrial coal-firing boilers. Their study reports that the latter stages of the gasification process (such as gasification) were important for the formation of hydro-carbon radicals from leftover char. Also, ref. [

70] reported that the ammonia content in the resulting producer gas from a gasification process were most sensitive to the nitrogen content of the gasification fuel. Similar studies within this period assessed hydro-carbon yield from pyrolysis and gasification processes [

71], while other studies assessed the effects of various gasifying agents on the gasification process [

72,

73].

Notwithstanding the focus of the literature within the period on the thermodynamic fundamentals of gasification technology, the earliest appearance of the word “hydrogen” in the published literature within the period was in 1995, when ref. [

74] discussed the emergence of carbon as a hydrogen carrier. Their study expressed optimism about the generation of hydrogen from fossil fuels.

Process Optimisation and Feedstock Diversification (2003–2015).

This period represents the longest run where the trend shows a growing popularity of keywords such as “catalysts”, “concentration”, “thermal effects”, “mathematical modelling”, “biological materials”, “renewable energy resources”, and “reaction kinetics”. These keywords represent an evolution of the literature towards technical process optimisation and feedstock diversification beyond fossil fuel resources. Mathematical models and experimental set-ups have been designed to assess the effects of different operating conditions on the chemical properties of the resulting producer gas [

75,

76,

77,

78]. Some of these studies have established a positive correlation between temperature and hydrogen output from gasification processes, with CaO also reported to increase hydrogen yield by over 16% [

75]. Under high-pressure conditions, hydrogen yield is also reportedly increased using Ca(OH)

2 as a CO

2 absorbent [

79]. The absence of third-generation feedstocks, such as “algae”, in keyword evolution is largely because such feedstocks are usually treated through biochemical processes in lieu of the thermo-chemical (gasification) focus of this study, which is best suited for first- and second-generation feedstocks [

80,

81].

This period also demonstrates that the interest in diversifying the feedstock away from fossil fuels precedes the Paris Agreement, given the early, albeit limited, emergence of the literature seeking to assess the viability of renewable resources for hydrogen production via gasification [

75,

76].

Post-Paris Agreement Alignment (2016–2022).

The literature post-Paris Agreement sees a strong emergence of keywords such as “biomass gasification”, “municipal solid waste” (MSW), “hydrogen production”, and “economic analysis”. Improvements in gasification technology and incentives to transition to a low-carbon economy make municipal solid waste increasingly suitable and attractive for use in the thermo-chemical conversion of heterogenous waste such as municipal solid waste to hydrogen-rich syngas [

82,

83,

84,

85], with the possibility of reaching an energy efficiency of 57% [

84]. For instance, ref. [

85] reported that the organic component of municipal solid waste in parts of Western Norway can generate 2700 tonnes of hydrogen via gasification. Similarly, ref. [

86] found that waste generation in a typical city in Ghana (Cape Coast) has the potential of generating over 780,000 kg of bio-hydrogen, with the waste generated projected to increase by over 70% in the next 29 years.

Despite this enormous potential of MSW for hydrogen production, unsustainable waste management practices pose a major barrier [

86]. Lessons may be drawn from a four-stage strategy proposal for the management of crop residue encompassing stakeholder engagement, education, and capacity building and the development of integrated systems for the collection, storage, and transportation of biomass resources for hydrogen production [

87].

As established in the case of the gasification of other biomass feedstocks, higher gasification temperatures tend to improve hydrogen yield from MSW gasification. Ref. [

88] found that the gasification of municipal solid waste at higher temperatures (600 °C–800 °C) increases the hydrogen yield by 30–40 percent. An oxygen-steam gasifying agent, rather than pure oxygen, is advised for hydrogen-rich syngas production from MSW gasification [

88,

89]. Similarly, metal- and calcite-based catalysts, such as marbles, have proven to be effective in improving hydrogen yield from MSW gasification [

88,

89,

90].

Decarbonisation (2023–2025).

This period marks a deep decarbonisation focus. The keywords prevalent here include “carbon capture and utilisation” (CCU), “direct capture”, “Kyoto protocol”, “clean energy”, and “greenhouse gas emissions”. Whilst the earliest emergence of the literature on CCU-coupled hydrogen production from gasification between 1995 and 2025 was recorded in 2011 [

91], the period from 2023 to 2025 is particularly replete with the literature on the use of CCU as a carbon-abating approach in the thermochemical production of hydrogen from biomass. Thus, several studies have been performed on the lifecycle assessment (LCA) of bioenergy carbon capture and storage (BECCS) [

92,

93,

94,

95,

96]. A key finding from this emerging theme is the need for a standardised approach to conducting LCA on bioenergy production with CCS [

96].

3.7. Research Gaps

The review of the literature on hydrogen production through gasification reveals a scarcity of research on the specific context of Africa. This is demonstrated by the light colourisation of the region, as shown in

Figure 6 and

Figure 7. This is particularly relevant because the MSW generated in most African cities is composed of over 60% organic components [

97], whereas only about 44–60% of this waste is collected [

98] and only 1% of this waste is recovered [

87]. Comparatively, over 96% of MSW is reportedly collected in advanced countries [

99]. This gap provides an incentive for increased research to advance the hydrogen economy in emerging economies such as Africa.

Furthermore, while the literature features some studies on the evaluation of MSW gasification, most of the studies have treated MSW as a homogeneous resource, often overlooking the heterogeneity of MSW. For instance, some studies have focused on food waste [

18], while others have focused on livestock manure [

34] and crop residues [

87] as raw materials for hydrogen production via gasification. This calls for expansive studies to broaden the body of knowledge on the thermodynamic, chemical, and operational enablers of increased hydrogen production from municipal solid waste gasification.