Correlation Between Plume Emission and Material Modifications in Fiber Laser Processing of Titanium

Abstract

1. Introduction

2. Experimental Details

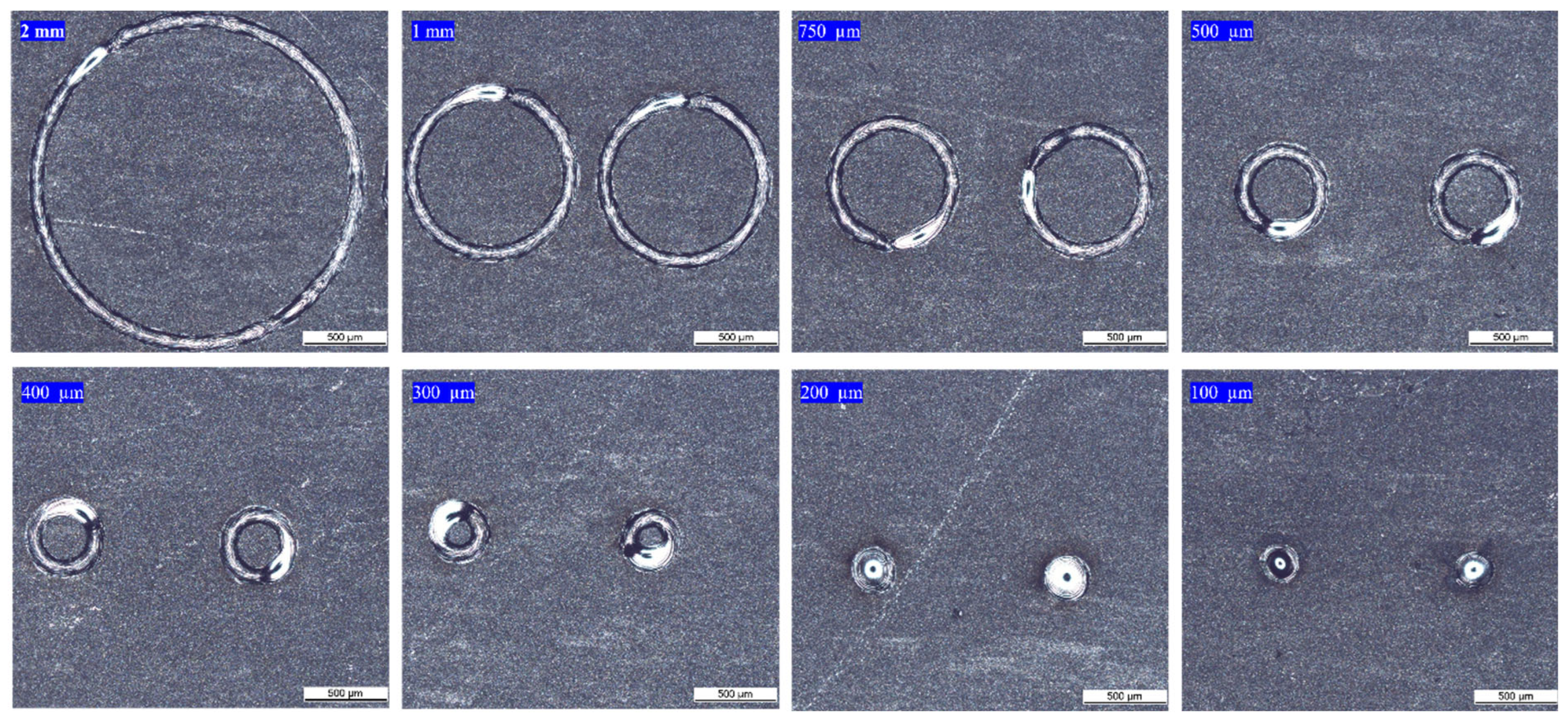

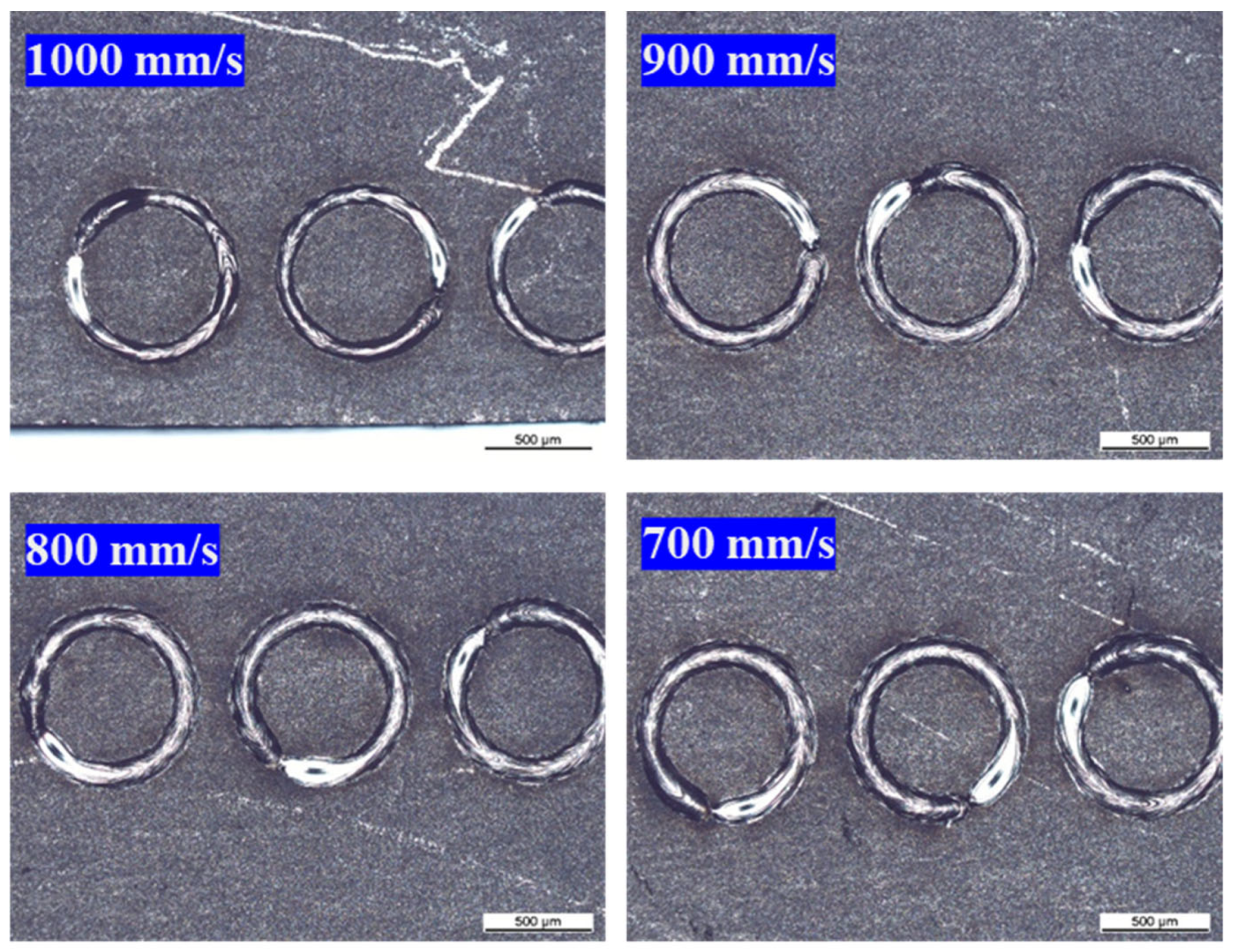

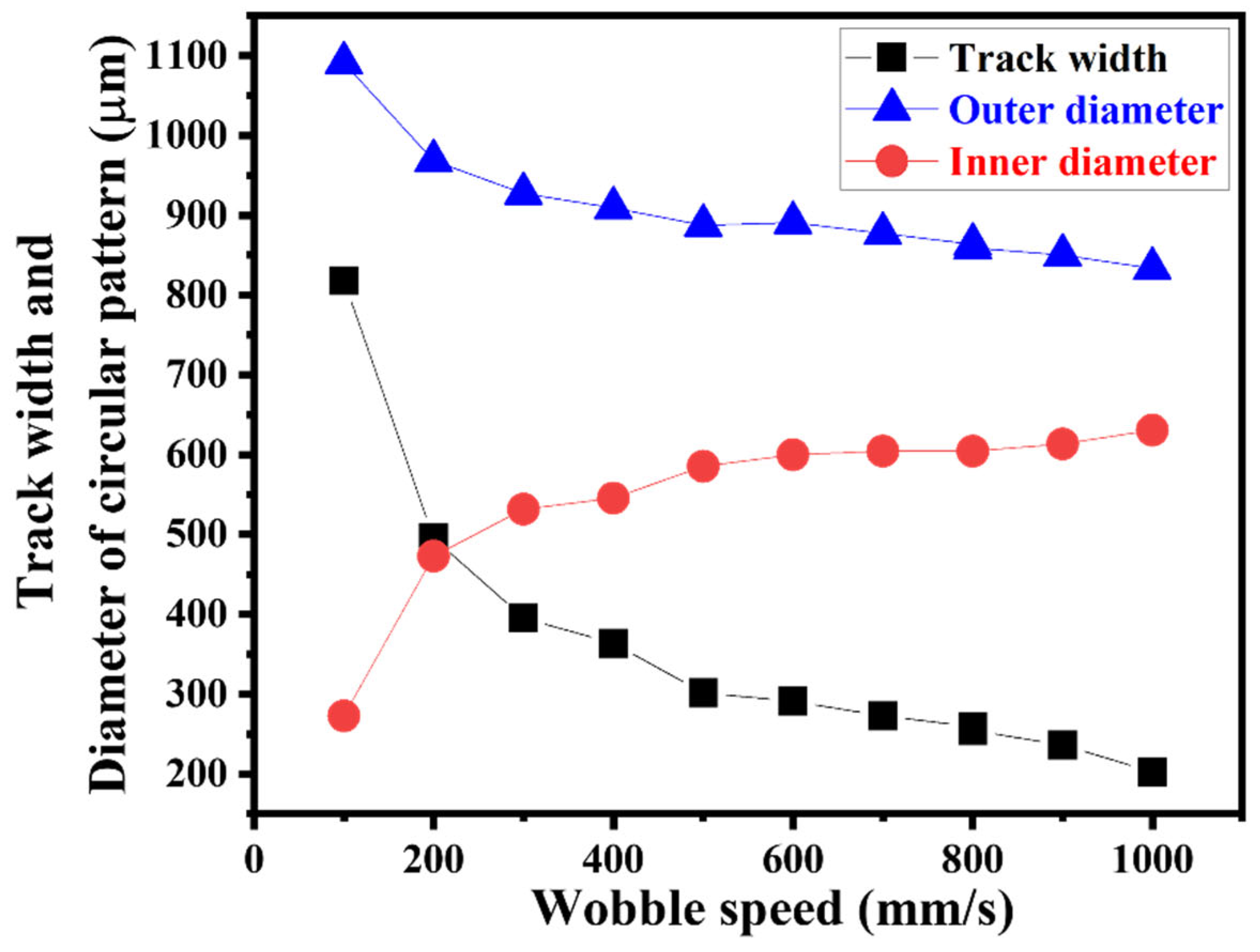

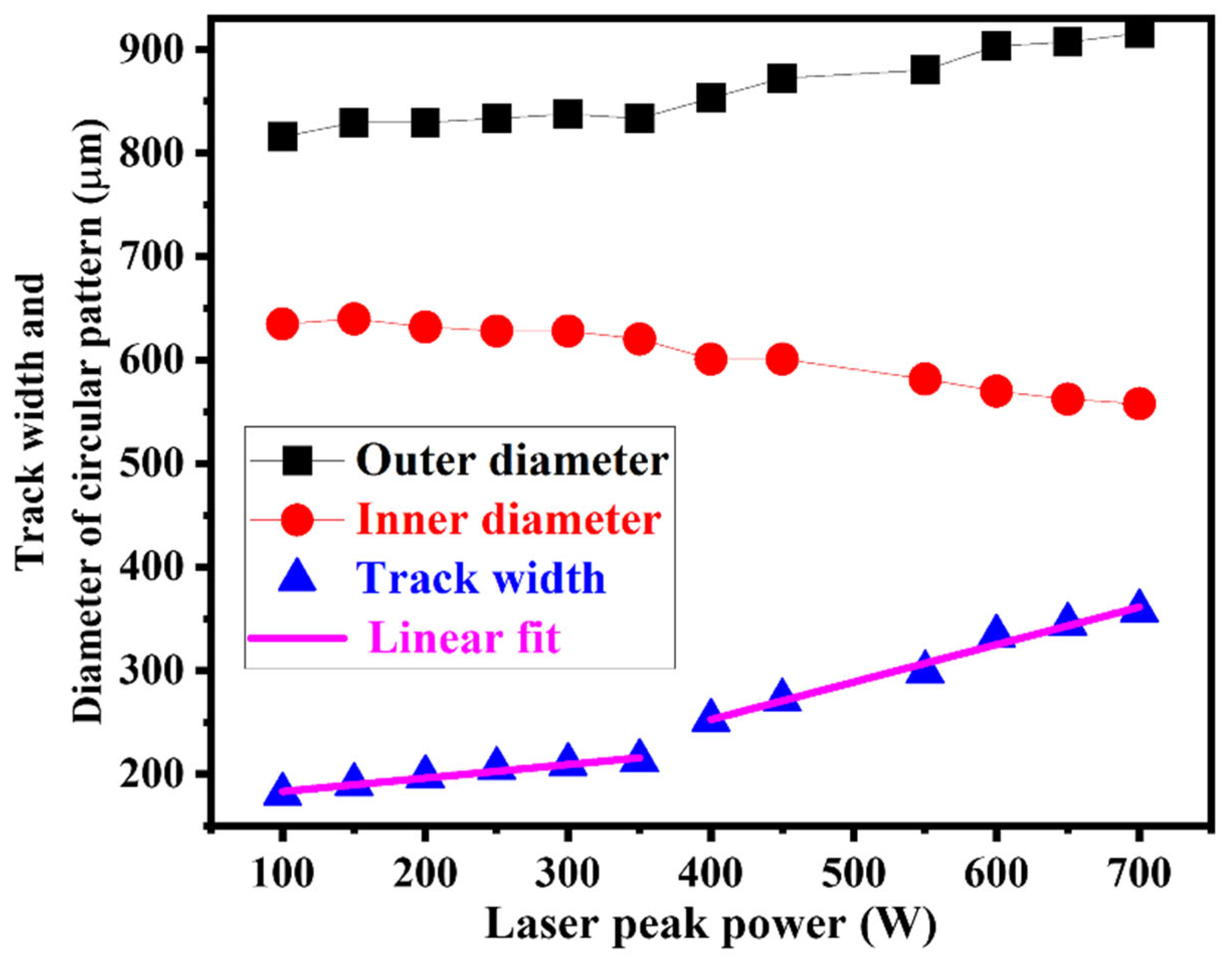

3. Results

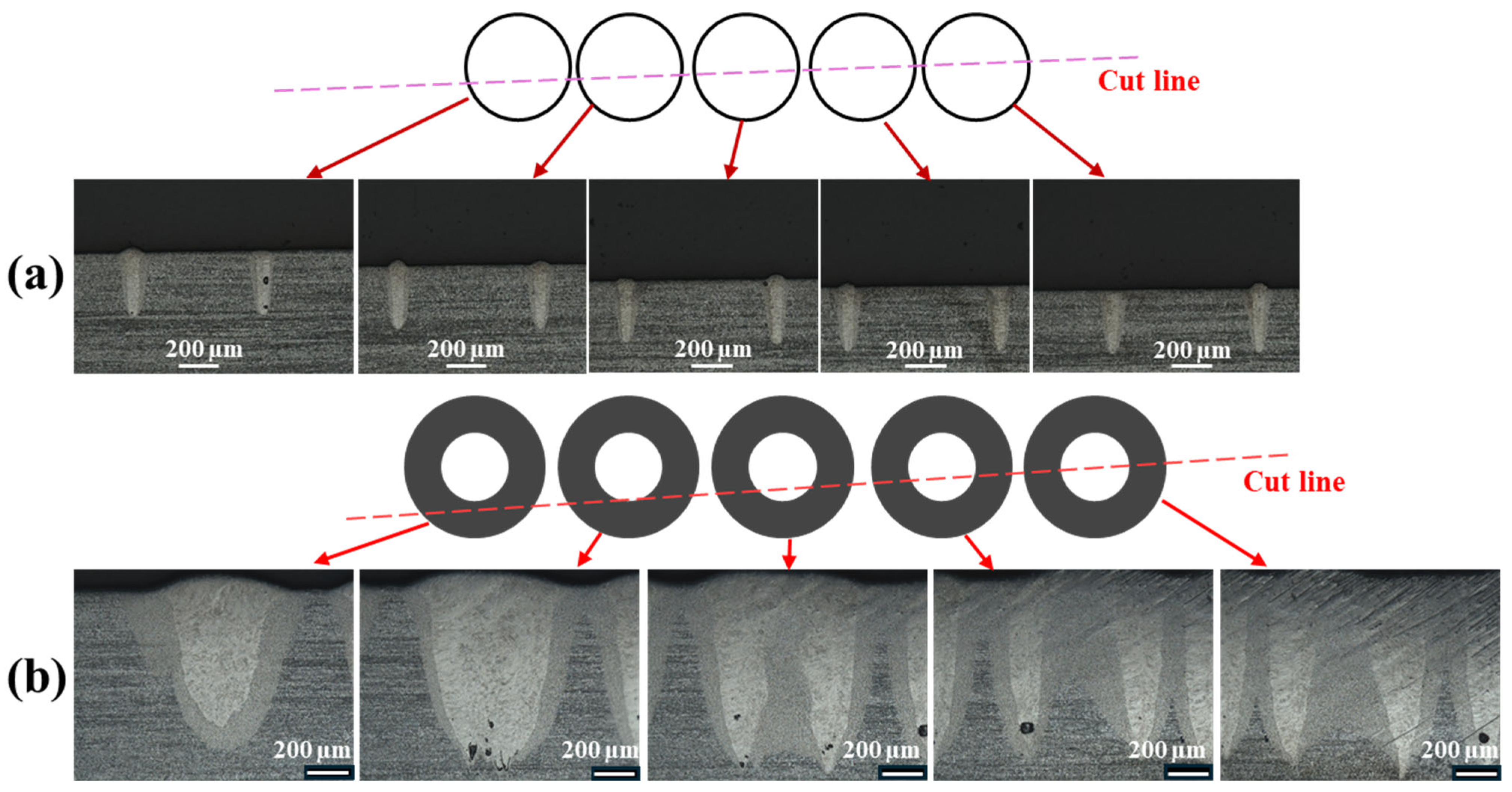

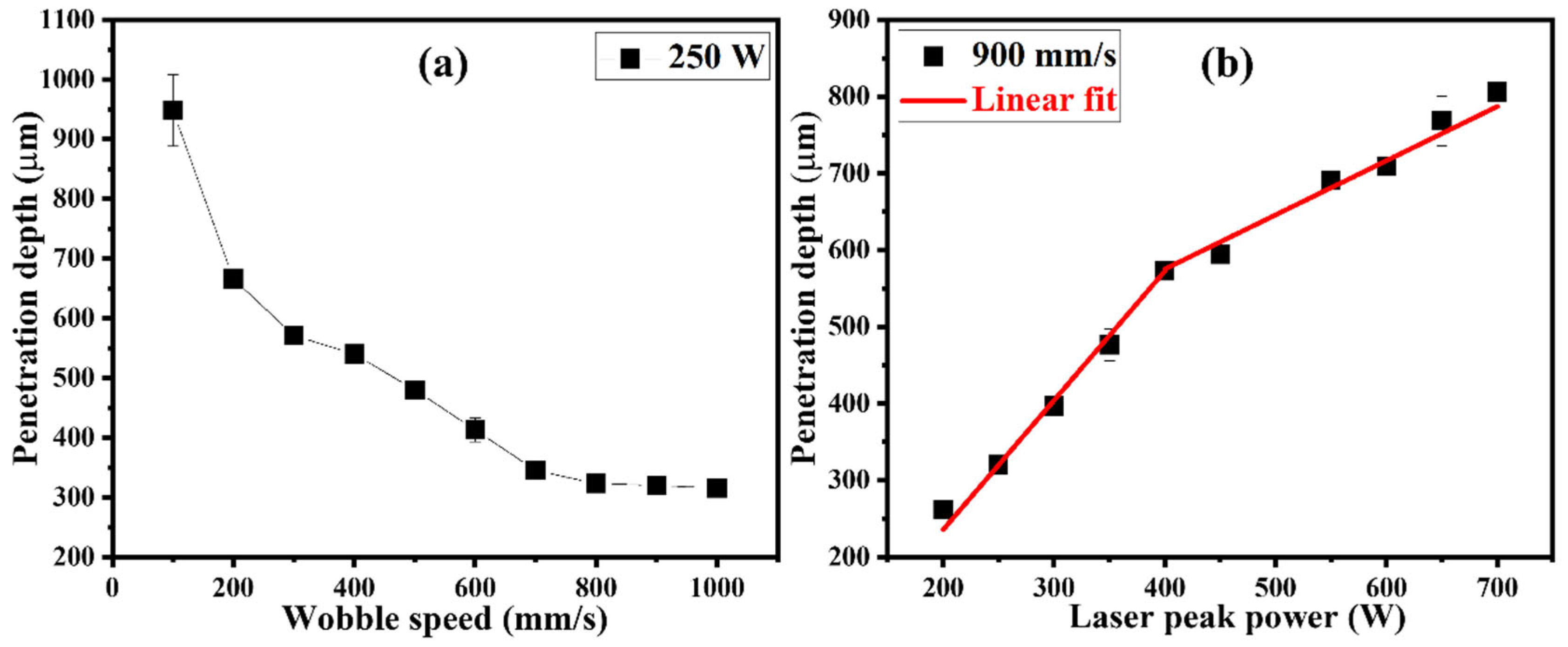

3.1. Cross-Sectional Analysis

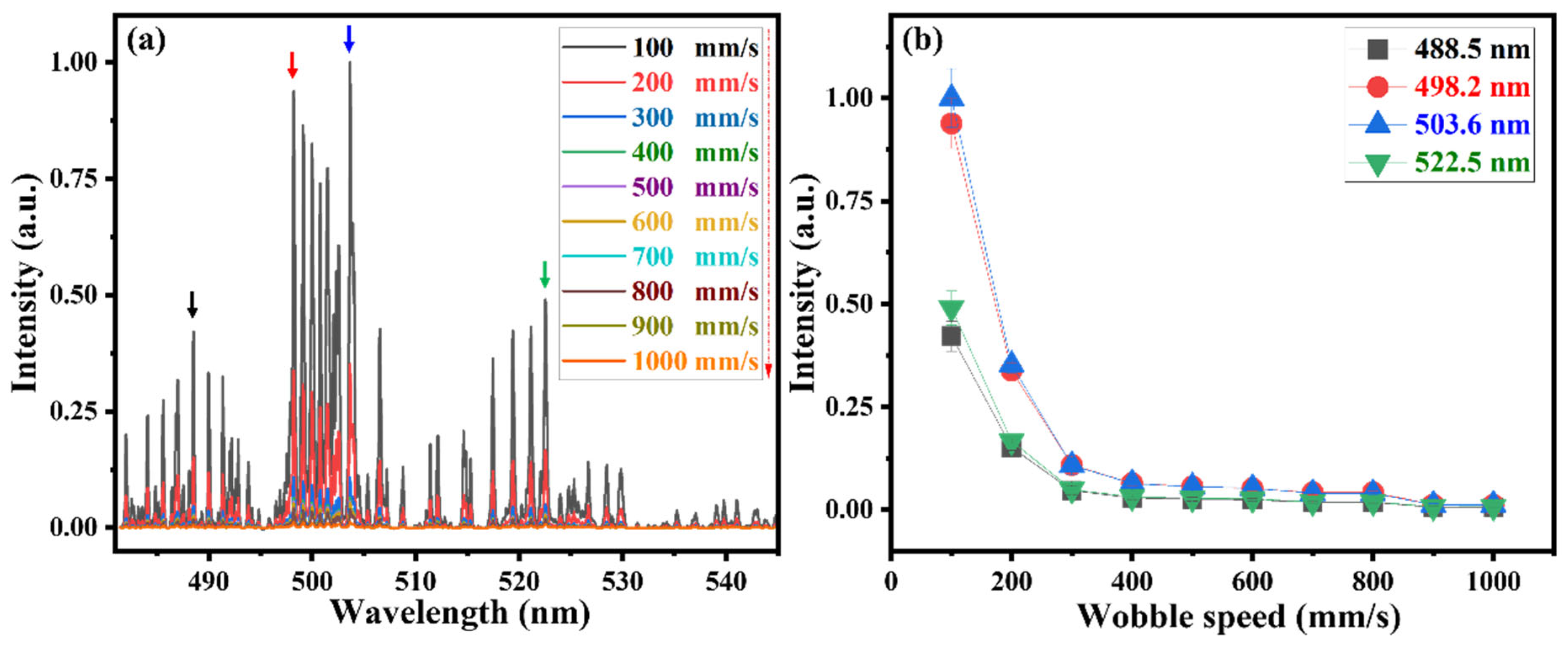

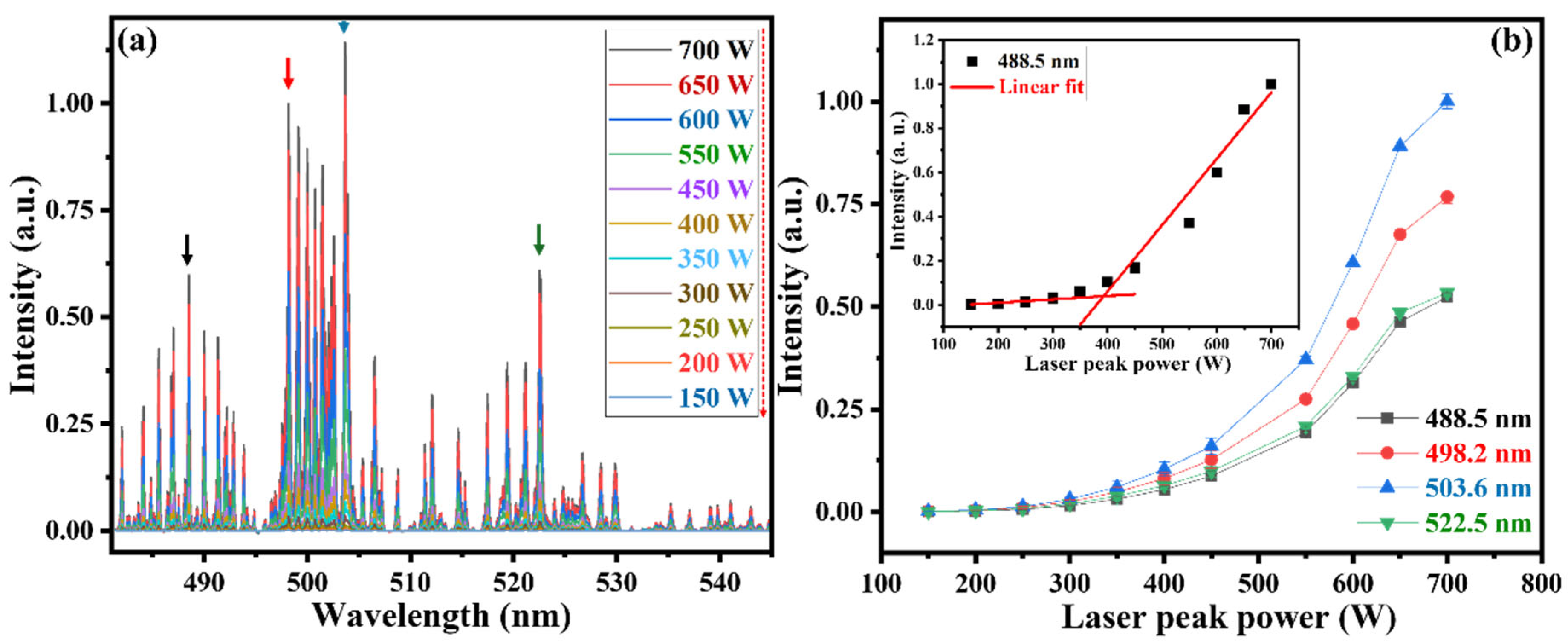

3.2. Optical Emission Spectroscopy

4. Discussion

5. Conclusions

- Track width and penetration depth increase with a decreasing wobble speed and increasing laser peak power;

- A critical transition point was identified at around 400 W of laser peak power, indicating a shift in the material’s response characteristics;

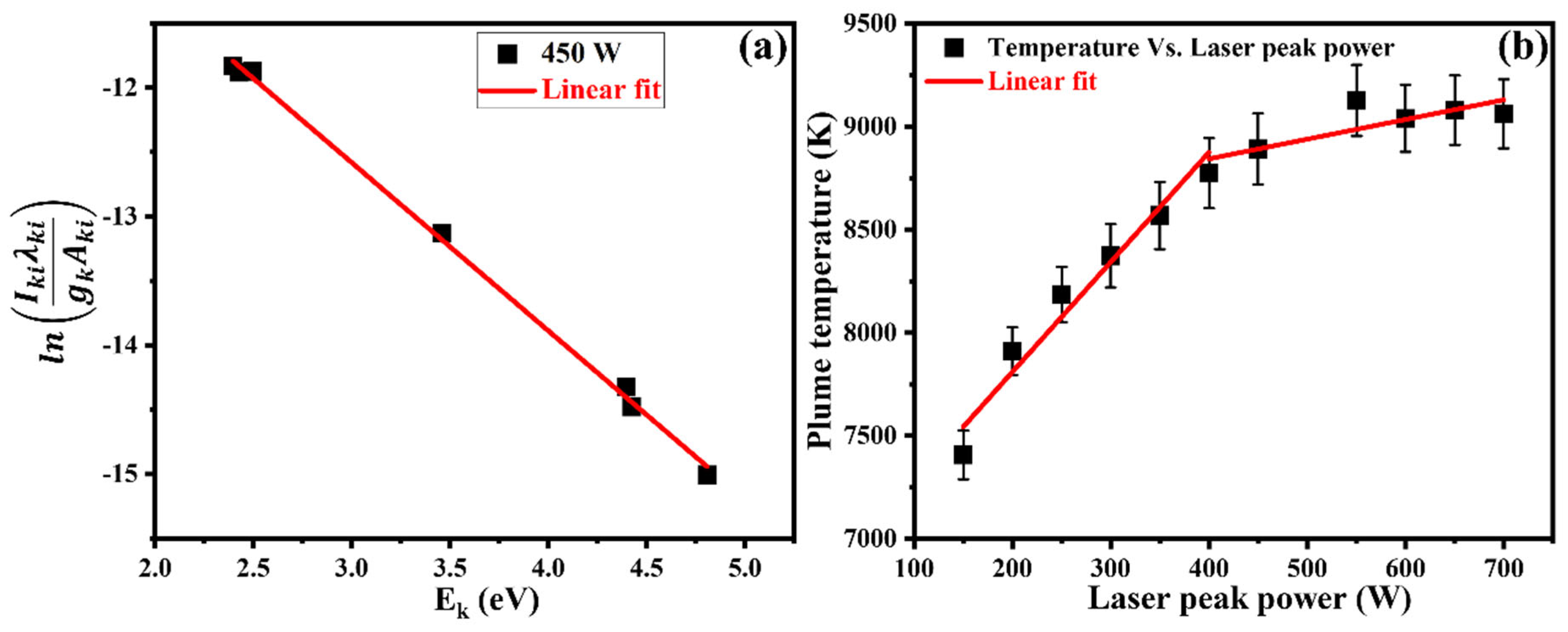

- Plume temperature rises with increasing laser peak power, but its variation with wobble speed is negligible;

- Emission line intensities from OES strongly correlate with the extent of material modification, suggesting the feasibility of predictive modeling using multivariate statistics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brown, M.S.; Arnold, C.B. Fundamentals of Laser-Material Interaction and Application to Multiscale Surface Modification. In Laser Precision Microfabrication; Springer Series in Materials Science; Sugioka, K., Meunier, M., Piqué, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 35, pp. 91–120. [Google Scholar] [CrossRef]

- Shin, Y.C.; Wu, B.; Lei, S.; Cheng, G.J.; Yao, Y.L. Overview of Laser Applications in Manufacturing and Materials Processing in Recent Years. J. Manuf. Sci. Eng. 2020, 142, 110818-1. [Google Scholar] [CrossRef]

- DePond, P.J.; Fuller, J.C.; Khairallah, S.A.; Angus, J.R.; Guss, G.; Matthews, M.J.; Martin, A.A. Laser-metal interaction dynamics during additive manufacturing resolved by detection of thermally induced electron emission. Commun. Mater. 2020, 1, 92. [Google Scholar] [CrossRef]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A review on laser beam welding of titanium alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 1071–1098. [Google Scholar] [CrossRef]

- Gao, X.-L.; Zhang, L.-J.; Liu, J.; Zhang, J.-X. A comparative study of pulsed Nd: YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 559, 14–21. [Google Scholar] [CrossRef]

- Yunlian, Q.; Ju, D.; Quan, H.; Liying, Z. Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater. Sci. Eng. A 2000, 280, 177–181. [Google Scholar] [CrossRef]

- Li, M.; Xiao, R.; Zou, J.; Wu, Q.; Xu, J. Correlation between plume fluctuation and keyhole dynamics during fiber laser keyhole welding. J. Laser Appl. 2020, 32, 022010-1–022010-7. [Google Scholar] [CrossRef]

- Ahn, J.; Chen, L.; Davies, C.M.; Dear, J.P. Parametric optimisation and microstructural analysis on high power Yb-fibre laser welding of Ti–6Al–4V. Opt. Laser Eng. 2016, 86, 156–171. [Google Scholar] [CrossRef]

- Frey, C.; Beyel, A.; Wahl, J.; Twiehaus, T.; Olschok, S.; Hagenlocher, C.; Graf, T.; Reisgen, U. Interdependence of metal vapor plume and melt pool dynamics during laser beam welding under vacuum. J. Laser Appl. 2024, 36, 042008. [Google Scholar] [CrossRef]

- Mohanta, A.; Leistner, M.; Leparoux, M. Effect of plume dynamics on surface contamination during interaction of millisecond infrared fiber laser with titanium. Opt. Laser Eng. 2022, 153, 106996. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Shao, X.; Gong, S.; Xiao, J. Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: Local evaporation, plume swing and gas entrapment into porosity. Opt. Laser Eng. 2016, 82, 28–40. [Google Scholar] [CrossRef]

- Wang, J.; Wang, C.; Meng, X.; Hu, X.; Yu, Y.; Yu, S. Study on the periodic oscillation of plasma/vapour induced during high power fiber laser penetration welding. Opt. Laser Technol. 2012, 44, 67–70. [Google Scholar] [CrossRef]

- Luo, Y.; Zhu, L.; Han, J.; Xie, X.; Wan, R.; Zhu, Y. Study on the acoustic emission effect of plasma plume in pulsed laser welding. Mech. Syst. Signal Process 2019, 124, 715–723. [Google Scholar] [CrossRef]

- Xie, L.; Shi, W.; Wu, T.; Gong, M.; Cai, D.; Han, S.; He, K. Effect of Dynamic Preheating on the Thermal Behaviour and Mechanical Properties of Laser-Welded Joints. Materials 2022, 15, 6159. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Ren, H.; Liu, Z.; Huang, F.; Xia, G.; Long, Y. In-situ monitoring system for weld geometry of laser welding based on multi-task convolutional neural network model. Measurement 2022, 204, 112138. [Google Scholar] [CrossRef]

- Cai, W.; Wang, J.Z.; Jiang, P.; Cao, L.C.; Mi, G.Y.; Zhou, Q. Application of sensing techniques and artificial intelligence-based methods to laser welding real-time monitoring: A critical review of recent literature. J. Manuf. Process 2020, 57, 1–18. [Google Scholar] [CrossRef]

- Kang, S.; Shin, J. In-situ monitoring of Al/Cu dissimilar laser welding process using optical emission spectroscopy (OES). Opt. Laser Technol. 2024, 176, 110893. [Google Scholar] [CrossRef]

- Mohanta, A.; Kung, P.; Thareja, R.K. Exciton-exciton scattering in vapor phase ZnO nanoparticles. Appl. Phys. Lett. 2015, 106, 013108. [Google Scholar] [CrossRef]

- Shah, L.H.; Khodabakhshi, F.; Gerlich, A. Effect of beam wobbling on laser welding of aluminum and magnesium alloy with nickel interlayer. J. Manuf. Process 2019, 37, 212–219. [Google Scholar] [CrossRef]

- Asirvatham, M.C.; Collins, S.; Masters, I. Laser wobble welding of steel to Aluminum busbar joints for Li-ion battery packs. Opt. Laser Technol. 2022, 151, 108000. [Google Scholar] [CrossRef]

- Mohanta, A.; AlAmeri, R.; Leparoux, M.; Matras, G.; Kasmi, C. In-situ investigation of laser interaction with AlMg5 and Ti6Al4V alloys using spectroscopy and high-speed imaging for laser manufacturing. Opt. Eng. 2024, 63, 064104-1–064104-11. [Google Scholar] [CrossRef]

- Mohanta, A.; Leparoux, M. Spectroscopic investigation of laser produced plasma of carbon nanotube reinforced AlMg5 metal matrix nanocomposites. Opt. Lasers Eng. 2019, 121, 37–45. [Google Scholar] [CrossRef]

- Li, X.; Xie, J.; Zhou, Y. Effect of oxygen contamination in the argon shielding gas in laser welding of commercially pure titanium thin sheet. J. Mat. Sci. 2005, 40, 3437–3443. [Google Scholar] [CrossRef]

- Hornik, P.; Sebestova, H.; Novotny, J.; Mrna, L. Laser beam oscillation strategy for weld geometry variation. J. Manuf. Process 2022, 84, 216–222. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology (NIST). Atomic Spectra Database. Available online: https://www.nist.gov/pml/atomic-spectra-database (accessed on 23 May 2025).

- Gao, M.; Chen, C.; Hu, M.; Guo, L.; Wang, Z.; Zeng, X. Characteristics of plasma plume in fiber laser welding of aluminum alloy. Appl. Surf. Sci. 2015, 326, 181–186. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohanta, A.; Leparoux, M. Correlation Between Plume Emission and Material Modifications in Fiber Laser Processing of Titanium. Processes 2025, 13, 1761. https://doi.org/10.3390/pr13061761

Mohanta A, Leparoux M. Correlation Between Plume Emission and Material Modifications in Fiber Laser Processing of Titanium. Processes. 2025; 13(6):1761. https://doi.org/10.3390/pr13061761

Chicago/Turabian StyleMohanta, Antaryami, and Marc Leparoux. 2025. "Correlation Between Plume Emission and Material Modifications in Fiber Laser Processing of Titanium" Processes 13, no. 6: 1761. https://doi.org/10.3390/pr13061761

APA StyleMohanta, A., & Leparoux, M. (2025). Correlation Between Plume Emission and Material Modifications in Fiber Laser Processing of Titanium. Processes, 13(6), 1761. https://doi.org/10.3390/pr13061761