Abstract

The propagation of high-frequency ultrasound waves will generate both physical and chemical effects as they propagate through a liquid medium, such as acoustic streaming, an acoustic fountain, and atomization. These phenomena are believed to be the main factors that contribute to the enhancement of mass transfer in the gas–liquid carbon dioxide (CO2) absorption system. Computational Fluid Dynamic (CFD) simulation is one of the powerful tools that can be used to model the complex hydrodynamic behavior induced by the propagation of ultrasound waves in the liquid medium. In this study, the ultrasonic irradiation forces were simulated via the momentum source term method using commercial CFD software (ANSYS Fluent V19.1). In addition, a parametric study was conducted to investigate the influences of absorber height and ultrasonic power on the hydrodynamic mixing performance. The simulation results indicated that enhanced mixing and a higher intensification factor were achieved with increased fountain flow velocity, particularly at the lowest absorber height and highest ultrasonic power. Conversely, the energy efficiency was improved with the increase of absorber height and decrease of ultrasonic power. To determine the optimal combination of absorber height and ultrasonic power, this trade-off between the energy efficiency and intensification in the ultrasonic-assisted absorption system (UAAS) is a crucial consideration during process scale-up.

1. Introduction

Natural gas has been a source of energy for many decades and its demand as a fuel has continuously increased worldwide. With the increase in natural gas demand, many countries have directed their focus to developing low-quality gas reserves that were uneconomical to be developed previously due to the lack of an economically feasible separation process. Among the low-quality gas reserves are high carbon dioxide (CO2) gas fields [1]. CO2 needs to be removed from natural gas not just for the sake of meeting the sales gas calorific value but also due to its corrosiveness in the presence of water, where it forms a weak acid [2].

Acid gas removal through the traditional absorption process using packed towers and bubble columns is the most mature process and has been commercialized for many decades [3]. It is more attractive as compared to other technologies due to low hydrocarbon losses and less pre-treatment required [4]. Even though packed and bubble columns have been used in industries for decades, this technology suffers from several drawbacks, such as high equipment corrosion rate, low CO2 loading capacity causing product off-spec, foaming, flooding, amine degradation, high energy consumption during regeneration, and large equipment size [5,6,7,8,9,10,11].

To overcome the limitations of the conventional acid gas absorption process, ultrasonic irradiation techniques that utilize high-frequency ultrasonic waves were explored to enhance the gas–liquid mass transfer during the absorption process [4,12,13,14,15]. Ultrasound waves are generated using a piezoelectric transducer, a device that produces an electric charge in response to applied mechanical stress on certain materials. Conversely, applying an electric field to these materials can induce mechanical displacement [16,17]. When an electric current is applied to the piezoelectric material, usually made from a crystal such as quartz or synthetic polycrystalline ceramic, the electric field will distort the crystal and force it to vibrate, producing ultrasonic waves. When the high-frequency ultrasonic waves propagate through the liquid medium, some of the ultrasound energy will be absorbed by the liquid medium, creating both physical and chemical effects such as acoustic streaming, acoustic cavitation, an acoustic fountain, and atomization [18]. These phenomena are believed to have caused the increase in mass transfer rate in the gas–liquid system due to the increase in local turbulence, enhanced mixing, and enhanced interfacial area for the absorption process to occur. Some of the ultrasound energy will be absorbed by the liquid medium, creating a momentum gradient and causing the acoustic streaming effect, while some will also be converted to heat energy. When the ultrasonic power and intensification are high enough to overcome the liquid threshold limit, an acoustic fountain will be formed followed by droplet atomization. Gas–liquid mass transfer in the form of gas absorption will occur at the gas–liquid interfacial area, which is further enhanced by the formation of an acoustic fountain and atomization. Acoustic streaming improves the mixing, and the jetting flow will increase the surface renewal rate at the gas–liquid interface, keeping the concentration gradient high for a more efficient gas–liquid mass transfer process.

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that assesses the physical phenomena that govern fluid flow using numerical analysis and data structures. It can help in solving complicated flow problems such as the phenomena of acoustic streaming in an ultrasonic-assisted absorption system (UAAS) that enhances the gas–liquid mixing and mass transfer. Recent studies have demonstrated that CFD modeling can effectively predict the hydrodynamics of gas–liquid two-phase flows, particularly the hydrodynamic behavior induced by the propagation of ultrasound waves in a liquid medium [18,19,20,21]. Researchers employ a numerical approach to characterize the propagation of high-frequency ultrasound waves by modeling the sound field distribution as a function of both time and space, in accordance with acoustic theory [22]. This simulation methodology has successfully elucidated the mechanisms underlying high-frequency ultrasonic wave propagation within liquid media [23,24,25,26,27]. For example, Abolhasani et al. have conducted a numerical study on the effect of high-frequency ultrasonic waves on the heat transfer rate [23]. Their simulation results indicated that a 1.7 MHz ultrasound wave could enhance fluid mixing and generate high-velocity flows, thereby promoting a more uniform temperature distribution within a vessel. Furthermore, the simulation outcomes were compared against experimental data, revealing a strong correlation with the experimental results, as the CFD modeling predicted the heater temperatures with a relative error of less than 1%.

However, this modeling approach is still not able to accurately model the formation of acoustic fountains and atomization. This limitation may arise from the assumption inherent in acoustic theory that acoustic forces are uniformly distributed across the transducer, which may not reflect the actual conditions. The direction of the ultrasound forces radiated from the transducer is significantly influenced by the vibration modes present in the transducer [28]. Since the acoustic fountain is usually observed to be formed at the center of the transducer, it is believed that the center-concentrated vibrating mode, which causes the force exerted at the center of the transducer to be higher as compared to its peripheral, is the main reason for these phenomena to occur. Therefore, existing acoustic theory models require refinement to account for the transducer’s vibration modes, which exhibit greater intensity at the center than at the periphery, resulting in higher radiated pressure at the center. Enhancing the acoustic theory to incorporate these factors is essential for accurately modeling the formation of acoustic fountains and atomization under high-frequency ultrasound waves. In this study, the objective is to develop a multiphase CFD model to study the hydrodynamic and mixing behavior of gas and liquid in a UAAS including the acoustic fountain. This UAAS utilizes a 1.7 MHz ultrasound wave for the CO2 absorption process. Using commercial CFD software (ANSYS Fluent V19.1, ANSYS Inc., Canonsburg, PA, USA), the Volume of Fluid (VOF) model was implemented to study the hydrodynamic and mixing behavior of gas and liquid in the UAAS. The momentum source method was selected, in which the ultrasonic irradiation force was defined as a momentum source within the fountain region. The accuracy of this method was evaluated in a validation study using the experimental data.

In addition, a numerical parametric study was conducted to investigate the influences of absorber height and ultrasonic power on the hydrodynamic performance. Under the parametric study, the computational geometry and meshing for the UAAS were established based on the lab-scale design of the UAAS absorber (16 transducers with multiple gas and liquid inlets). Nine simulation cases were performed based on the effect of absorber height and ultrasonic power. In the absorber height analysis, the height (based on gas region) varied from 37 mm (low) to 73 mm (medium) to 109 mm (high). For the ultrasonic power study, it varied from 5 to 9 to 13 W, respectively. The evaluation of each parameter was according to its phase interaction and tracer mixing. In addition, the results were also correlated with the performance based on an intensification factor and energy efficiency. Finally, the advantages and disadvantages of different absorber heights and ultrasonic power were discussed in terms of the intensification factor and energy efficiency, where a trade-off condition was revealed.

2. Fundamentals on CFD Theory

2.1. Governing Equations

The simulations were conducted using ANSYS Fluent V19.1 (ANSYS Inc., Canonsburg, PA, USA) and employed the multi-phase VOF model to track the liquid–liquid interface. A pressure-based solver was utilized with a transient time-step in a 3D domain, replicating the dimensions of the experimental setup. The Finite Volume Method (FVM) was employed in ANSYS Fluent, with results exhibiting significant dependency on mesh configuration. Domain meshing was refined through a grid sensitivity study, adjusting the number of cells to achieve optimal results. The second-order upwind and least squares cell-based gradient calculation schemes were respectively used for time marching of the momentum–continuity equations and the pressure gradient calculations. The continuity equation was solved to distinguish the phases by tracking the interface for the volume fraction of one of the phases. For the qth phase, Equation (1) represents the continuity equation, where is the mass transfer from phase q to phase p and is the mass transfer from phase p to phase q. In the current study, mass transfer was excluded. Therefore, the terms on the right-hand side of Equation (1) are equal to zero.

Equation (2) represents the single momentum equation solved throughout the domain, with the resulting field shared among the phases. This equation is volume fraction dependent on all phases through the properties of ρ and μ, as described in Equations (3) and (4), respectively.

The source term in Equation (2) is for the surface tension that uses the continuum surface force (CSF) model. This model was designed to incorporate surface tension into the VOF calculation, leading to the inclusion of a source term in the momentum equation. [29]. The pressure drops across the surface depend upon the surface tension coefficient, σ, and the surface curvature as measured by two radii in the orthogonal direction, R1 and R2, and are presented in Equation (5), where p1 and p2 are the pressures in the two fluids on either side of the interface.

In Ansys Fluent, a formulation of the CSF model was used, where the surface curvature was computed from local gradients in the surface normal at the interface. The surface tension can be expressed in terms of pressure difference across the surface. The force at the surface can be expressed as a volume force, Fvol, using the divergence theorem, as shown in Equation (6), where ρ is the volume-averaged density computed using Equation (3). This volume force is the source term that is added to the momentum equation.

The curvature, κ, is defined in terms of the divergence of the unit normal , as described in Equations (7) and (8).

n is the surface normal, defined as the gradient of , the volume fraction of the qth phase (see Equation (9)).

2.2. Solution Method: Momentum Source Term Method

In the momentum source term method, the acoustic irradiation force was introduced, imitating the amount of force generated by the ultrasonic transducer. The force was introduced in the model by defining a source term in the momentum equation followed by the acoustic irradiation force proposed by Lighthill et al. [30] in Equation (10):

where is the acoustic intensity, is the ultrasonic attenuation coefficient, is the diffusivity of sound, and is angular frequency, which is described in Equations (11)–(14), respectively.

The additional source term was written in a UDF and affected only the region of the fountain area, which will be further explained in the next section of the model validation.

2.3. VOF Model Validation

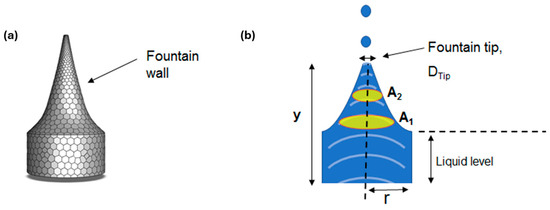

The model validation was conducted by comparing the simulation results calculated using the VOF model with the experimental results [12]. Only one ultrasonic transducer was used in the experimental setup without any sonotrode tip (also referred to as a horn tip); hence, the same setup was implemented in the simulation for the validation. As mentioned previously, the acoustic irradiation force was introduced as a source term. and it is located only within the fountain area, which is contained by the fountain wall, as shown in Figure 1a. The fountain wall has an opening at the bottom where the liquid can enter. There is another small opening at the top of the fountain (defined as the fountain tip), in which the liquid flows upward due to the acoustic irradiation force. The shape of the fountain was established based on the image captured during the experimental observation, as described in Figure 1b.

Figure 1.

(a) Shape of the fountain wall, and (b) description of the fountain geometry.

The main controlling parameter in the acoustic irradiation force was the acoustic intensity (see Equation (11)), which is correlated with the ultrasonic power and cross-sectional area, A. The cross-sectional area changed along the height of the fountain in the y-direction, using Equation (15), where r is the radius from the center of the fountain.

The radius has a constant value similar to the radius of a piezoelectric transducer up to the liquid level. Above the liquid level, the radius decreased exponentially, giving the shape of a fountain until its tip, following Equation (16). The decrease of the cross-sectional area increased the acoustic intensity, and this created an ultrasound focusing effect. The geometry of the fountain was a function of ultrasonic power, P, where the diameter of the fountain tip, DTip, changed with the ultrasonic power following Equation (17).

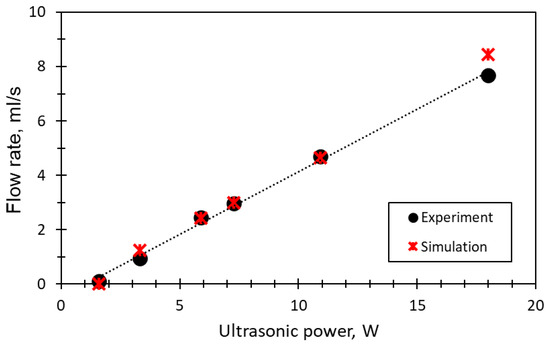

Figure 2 shows the fountain flow rate from experimental and simulation results at various ultrasonic power levels. The flow rate was measured at the fountain tip by multiplying the velocity and tip area. The flow rate increased as the ultrasonic power increased due to the increase of acoustic irradiation force. There was no fountain flow rate at a power below 1.6 W since the generated force was insufficient to trigger the ultrasonic fountain. The simulation results showed good agreement with the experimental results, especially in the middle power range between 5 and 12 W. Although the difference between the experimental and simulation results was obvious at a high power of 18 W, the average error was only 8%, which is considered to be acceptable.

Figure 2.

Comparison between experimental and validation results for a single transducer at different levels of ultrasonic power.

3. Simulation Boundary Conditions

3.1. Geometry and Meshing

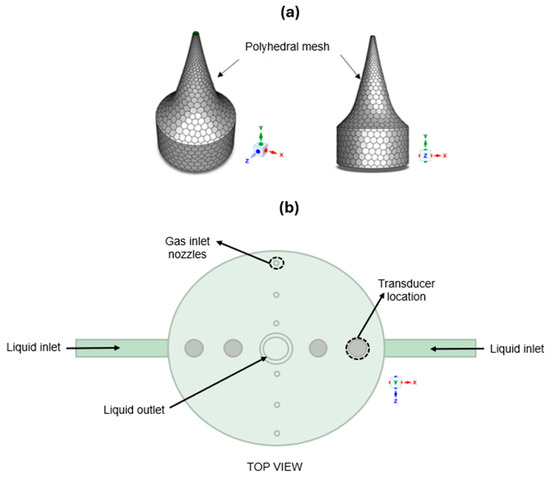

Figure 3 shows a detailed description of the geometry and meshing methodology. The computational geometry was based on the design of the UAAS absorber, which consists of 16 piezoelectric transducers that create 16 fountains. The geometry was meshed using polyhedral mesh, as shown in Figure 3a. Due to the confidentiality of the absorber’s internal design, only the schematic representative of the UAAS absorber is shown in Figure 4b. Two liquid inlets with a 0.6 cm diameter were located at the side of the absorber, and one liquid outlet with a 1.6 cm diameter was at the center of the absorber. The transducers (with a 1.1 cm diameter) were distributed at relatively the same distance from each other. Twenty-six (26) gas inlets (with a 0.15 cm diameter) were located at the bottom and distributed along with the transducer. There was a 1.6 cm diameter gas outlet at the top of the absorber.

Figure 3.

(a) Polyhedral mesh; (b) illustrative position of the ultrasonic transducer, liquid inlet, liquid outlet, and gas inlet nozzles.

Figure 4.

(a) The tip location where the mesh size was varied; meshing illustrations for (b) Mesh 1, (c) Mesh 2, and (d) Mesh 3.

For the boundary condition settings, both liquid and gas inlets were defined as a velocity inlet. The gas outlet was specified as a pressure outlet with a constant of 80 bar, while the liquid outlet was set as a mass flow outlet. Since the main objective of the current study involved hydrodynamic analysis without mass transfer, the materials used for the liquid and gas phases were water and air, respectively. Both the water and air inlets had the same velocity of 0.25 m/s, while the water mass flow outlet was 0.002 kg/s. In every simulation case, the sequence started with the initialization of data and the use of the patch function. The initialize function would fix all values inside the domain to zero, while the patch was used to set a specific value to a certain region. To make the simulation faster, the water phase was patched inside the fountains and bottom region of the absorber. Water was defined as the main phase, and gas as the secondary phase. The interfacial tension between water and air was constant at 0.0072 N/m, which was required for the body force formulation.

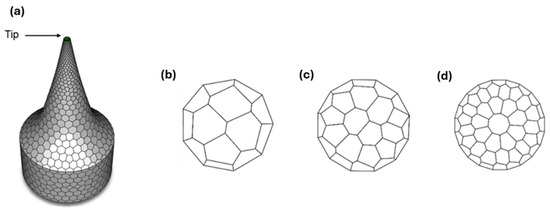

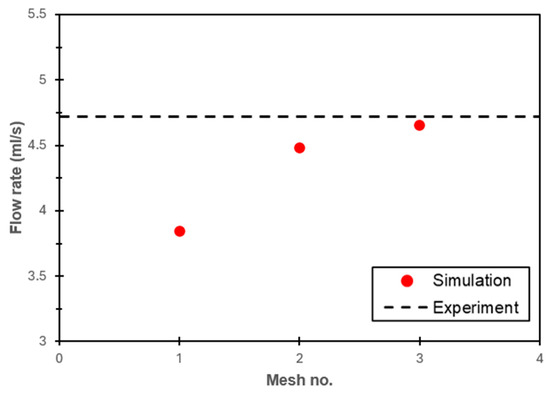

3.2. Mesh Sensitivity Analysis

The VOF model is very mesh-dependent, so the selection of a correct mesh size is important. Therefore, a mesh sensitivity analysis was performed to find the best mesh size that could give an accurate simulation result. The analysis was conducted using the same setup as the model validation, taking a single transducer at an ultrasonic power of 7 W. Three (3) different mesh sizes were used, and the meshing was focused only at the area of the fountain tip, where the velocity was most affected, when calculating the value of the flow rate. The meshing variations are shown in Figure 4.

Table 1 shows the detailed mesh characteristics in terms of minimum mesh size and number of nodes. Mesh 1 was the coarsest mesh, in that it has the least number of nodes and has the biggest minimum mesh size. The error was calculated by comparing the calculated flow rate using this meshing with the experimental value shown in the previous validation section. Figure 5 shows the comparison of different flow rate values at different meshing sizes, and the dashed line is the value from the experimental results.

Table 1.

Quantitative analysis of error at different meshing sizes compared with the experimental flow rate value.

Figure 5.

Flow rate values for different meshing values.

The value of the flow rate increased as the meshing was refined until Mesh 3. Theoretically, as the mesh is refined, it generally gives more accurate results [31]. In this case, the best result that gave the lowest error was from Mesh 3, with only 1% error. Hence, it was concluded that Mesh 3 was the optimum meshing size for this case, and it was be used for all the simulations in this study.

4. CFD Analysis

Computational Fluid Dynamics (CFD) is a very useful tool to investigate fluid characteristics and other fluid behaviors such as mixing and velocity profiles. Before examining the simulation results of UAAS technology, it is good to explain a few terms that are used to describe the CFD simulation results. In the current study, default hydrodynamic parameters which include volume fraction, velocity, and pressure were investigated. To give a better indication of the multiphase mixing performance, volume-averaged phase interaction and tracer mixing were defined. These parameters are explained in detail in the next section.

4.1. Volume Fraction

In the multiphase model, the volume fraction serves as a distinct parameter exclusively utilized within this framework. The Volume of Fluid (VOF) model employs the Euler–Euler approach, wherein the different phases are mathematically represented as interpenetrating continua. To account for the restriction that the volume of one phase cannot be occupied by another, the concept of phasic volume fraction was introduced. These volume fractions are considered continuous functions of space and time, with their sum equating to one. Conservation equations for each phase are formulated, resulting in a set of equations that exhibit a similar structure.

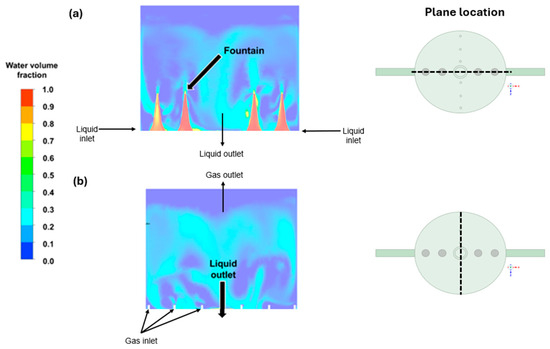

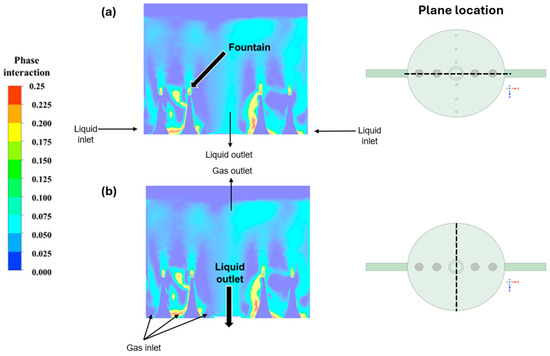

Figure 6 shows the example of the volume fraction result across the XZ plane of the UAAS absorber. Two locations were selected inside the absorber: Figure 6a shows the location across the horizontal x-axis, where four fountains can be observed, and Figure 6b shows the opposite direction across the vertical z-axis, where six gas inlets are visible within the plane axis. From the legend of the water volume fraction, the red color represents the water phase and the blue color signifies the air phase. In between these colors, there is a mixture of water and air volume fractions. The water was fed through two inlets from the bottom side of the absorber, and the excess amount of water flowed out through the water outlet of the absorber. As time passed, the ultrasonic momentum force inside the fountain pushed the liquid upward and distributed the liquid water in the air region where the mixture of water and air phase could be observed. This behavior also created a mixing where recirculation appeared in the air which helped in the mass transfer during absorption [14].

Figure 6.

Volume fraction fluid in the UAAS at different locations: (a) along the x-axis, and (b) along the z-axis.

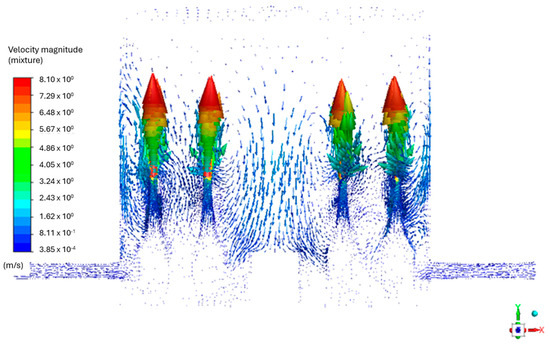

4.2. Velocity and Pressure Profile

The velocity and pressure profiles were studied to understand the hydrodynamic behavior in the UAAS absorber. Figure 7 shows the velocity vector inside the absorber. The size and color of the vector arrow indicate the velocity magnitude of the water–air mixture. In addition, the vector also shows the direction of velocity where the recirculation was observed. The highest velocity was located at the fountain tip, which was due to the focusing effect exerted by the ultrasonic irradiation force. High velocity created the recirculation zone inside the absorber, which helped in the distribution of the fluid mixture and subsequently enhanced the mixing of fluid [32].

Figure 7.

Velocity vector inside the UAAS absorber.

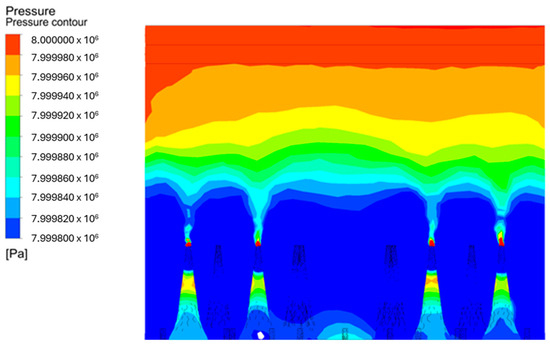

Figure 8 shows the pressure profile inside the absorber. A gradient of pressure is observed from the top to the bottom of the absorber. The highest pressure is located at the top of the absorber near the gas outlet. This occurred because the gas outlet was set at a constant 80 bar, which was according to the actual setup for a UAAS absorber. The difference in pressure inside the absorber was insignificant, which gave only a 200 Pa difference between the highest and lowest pressure values.

Figure 8.

Pressure profile inside the UAAS absorber.

4.3. Volume-Averaged Phase Interaction

Another important parameter to indicate the mass transfer performance is the volume-averaged phase interaction, . During multiphase mass transfer, the only region where mass transfer can occur is at the interfacial area between two phases. The phase interaction calculated in the simulation is related to this interfacial area. The phase interaction was calculated by multiplying the volume fraction between liquid and gas phases, as shown in Equation (18), where and are the liquid and gas phases, respectively.

Figure 9 shows the phase interaction profile inside the UAAS absorber. The maximum value of phase interaction would be 0.25 since the maximum phase interaction would only occur when the liquid and gas volume fraction is 0.5. In Figure 9, the highest phase interaction is observed at the water level and fountain tip where the contacts are at the maximum. As the water discharged from the fountain tip, the water phase was distributed within the air region and created a water–air mixture that contributed to the phase interaction value. To evaluate the overall mixing performance, the total phase interaction value was averaged with the overall volume domain. The parameter of volume-averaged phase interaction was used in the parametric study to make a comparison with other operating conditions such as the absorber height and ultrasonic power.

Figure 9.

Phase interaction of fluid in the UAAS at different locations: (a) along the x-axis, and (b) along the z-axis.

4.4. Liquid Tracer Mixing

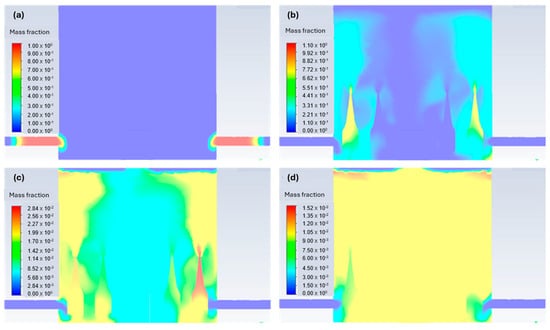

To investigate the mixing performance within the liquid phase, a tracer was introduced in the water inlet and injected into the UAAS absorber. The mixing performance was evaluated based on the tracer concentration that was diluted in the water as time passed. Figure 10 shows the evolution of tracer concentration in terms of mass fraction from the initial time until it reached perfect mixing. At the initial time of 0 s, the tracer shows a mass fraction of 1, indicating a pure concentration before mixing. As the tracer flowed into the water and through the transducer area, the tracer was pushed up through the fountain and distributed inside the air region. The mass fraction slowly decreased due to the dilution and distribution throughout the whole absorber chamber.

Figure 10.

The contour of tracer concentration at time (a) 0 s, (b) 0.5 s, (c) 1 s, and (d) 1.75 s.

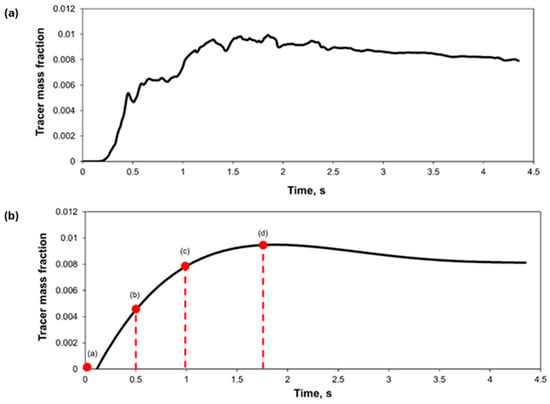

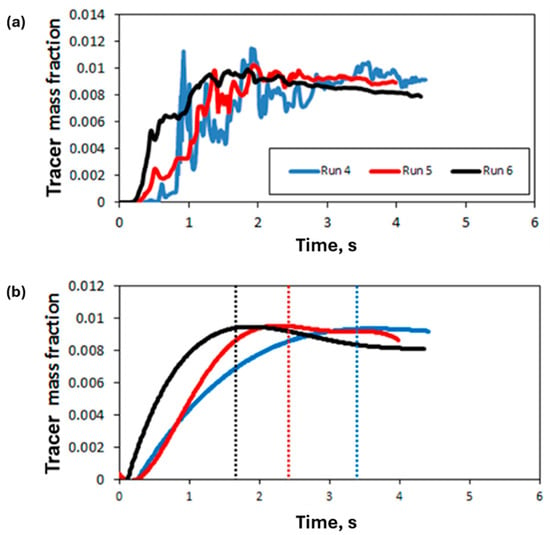

Figure 11a shows the raw data of the tracer mass fraction that were recorded at the water outlet. To smooth the plot line from the raw data, curve-fitting was used so that the data could be easily examined. Figure 11b shows the curve-fitting plot, and the red dashed line represents the time when Figure 10 was captured.

Figure 11.

(a) Raw data, and (b) curve-fitting data for the tracer mass fraction.

Based on Figure 11, the mass fraction of the tracer was zero at the initial time since no tracer was detected at the water outlet. The value increased over time until it reached the maximum value at a time of 1.75 s. At this time, the tracer became well mixed, and the mass fraction reduced slowly due to dilution from the incoming fresh water at the inlet. Theoretically, if the mixing were poor, the plot would show a plug-flow profile. In this profile, a pulse of instant increase of mass fraction would appear, following a constant value, and end with an abrupt decrease of tracer mass fraction that has almost zero value. However, the plug-flow profile was not observed in the UAAS absorber, which indicated a good mixing characteristic.

5. Parametric Study

In the parametric study, the absorber height and ultrasonic power were varied to investigate their influences on the hydrodynamic mixing performance. Table 2 demonstrates the simulation matrix for the parametric study, which consists of nine simulation runs based on different absorber heights and ultrasonic power. The absorber height varied from 37 mm to 73 mm to 109 mm. This height only refers to the height of the air region, while the other dimensions such as the water level were kept constant. The ultrasonic power was varied from 5 W to 9 W to 13 W.

Table 2.

Matrix for the parametric study.

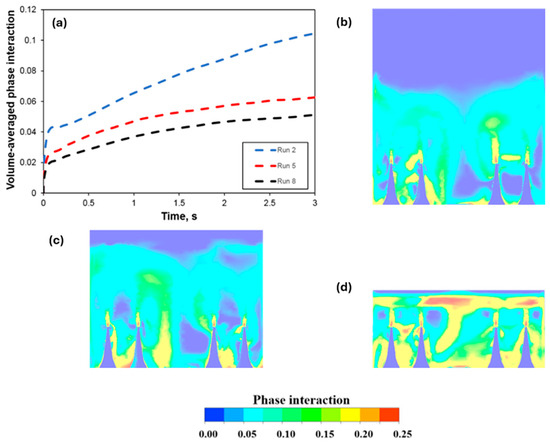

5.1. Analysis of Absorber Height

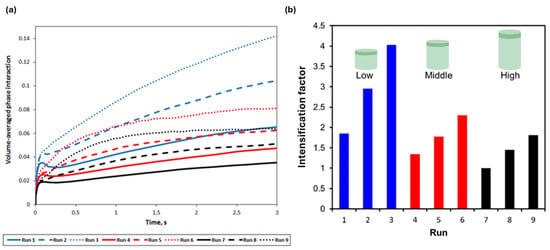

To facilitate the comparison analysis, the simulations with different absorber heights were analyzed based on a constant power (9 W—medium power), which was represented by runs 2, 5, and 8. Figure 12 shows the quantitative and qualitative analysis of the phase interaction at different absorber heights. The first evaluation of the mixing performance was the value of volume-averaged phase interaction. From the plot in Figure 12a, the absorber with the lowest height (Run 2) demonstrated the highest average phase interaction as compared to the absorber with the tallest height (Run 8). The difference in phase interaction can also be observed in the contour plot of phase interaction in Figure 12b–d.

Figure 12.

(a) Quantitative analysis of the comparison of phase interaction, and qualitative analysis of the phase interaction contour plot at time 3 s for cases (b) Run 8, (c) Run 5, and (d) Run 2.

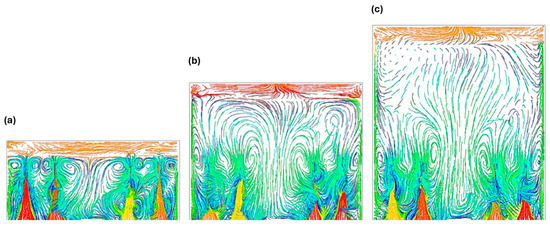

The absorber with the lowest height (Run 2) generated the highest phase interaction due to having the smallest volume, and it provided less space for the fluid to flow and created more intense mixing. The intense mixing also contributed to the formation of many recirculation zones that could be observed in the streamline profile, as shown in Figure 13 [33,34]. For the largest absorber volume (Run 8), the recirculation zones only appeared in the lower region of the absorber, with no recirculation zone at the upper part of the absorber. Hence, the smaller volume has the advantage of more intense mixing, which contributes to the highest phase interaction.

Figure 13.

Streamline profile for (a) Run 2, (b) Run 5, and (c) Run 8.

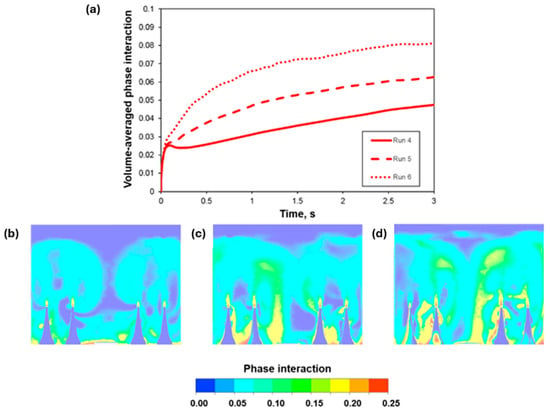

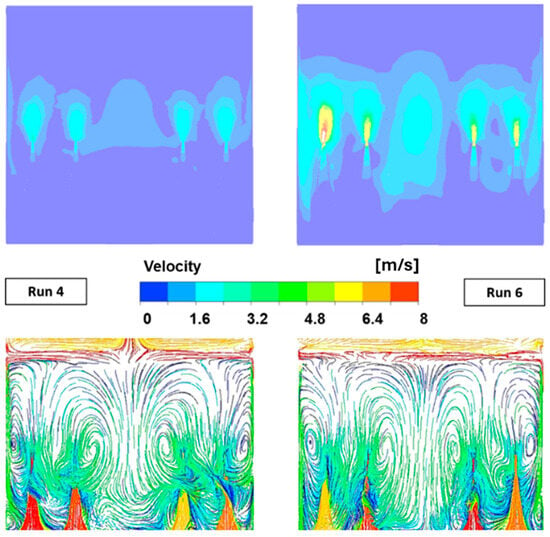

5.2. Analysis of Ultrasonic Power

To study the effect of ultrasonic power on the mixing performance, different ultrasonic powers of 5 W, 9 W, and 13 W were varied for the UAAS absorber with a constant height of 73 cm (medium height), which were represented by runs 4, 5, and 6, respectively. Figure 14 shows the volume-averaged phase interaction at different ultrasonic powers. Run 6 (absorber with the highest ultrasonic power) demonstrated the highest average phase interaction, in contrast with the lowest ultrasonic power case (Run 4). The increase in average phase interaction was mainly contributed by the increase in flow velocity from the fountain tip. Based on the explanation in the model validation section (see Figure 5), the fountain flow rate increased linearly with ultrasonic power [35]. Therefore, at the highest ultrasonic power, the fountain velocity was the highest, hence giving the highest mixing effect and, simultaneously, phase interaction value [14]. The difference in velocity profile at different ultrasonic powers is observable in the velocity contour plot shown in Figure 15. The streamline profiles showed very similar results between the lowest and highest ultrasonic powers because this parameter only resulted in significant differences at different absorber heights.

Figure 14.

(a) Quantitative analysis of the comparison of phase interaction, and qualitative analysis of the phase interaction contour plot at time 3 s for cases (b) Run 4, (c) Run 5, and (d) Run 6.

Figure 15.

Comparison of velocity contour and streamline profile between the lowest (Run 4) and the highest (Run 6) ultrasonic power.

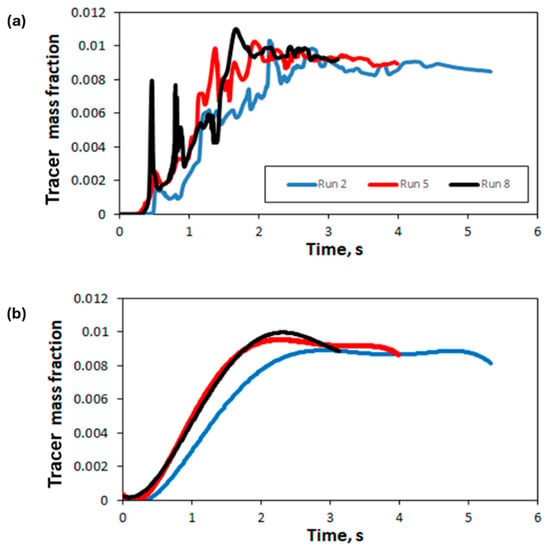

5.3. Analysis of Tracer Mixing

To analyze solvent mixing behavior, the liquid tracer mixing within the liquid phase was investigated. Figure 16 shows a comparison of tracer mass fraction measured at the water outlet at different simulation times. In the curve-fitting plot in Figure 16b, the peak of the tracer mass fraction indicates the time when it reached complete mixing. At different absorber heights, the peaks arrived at almost the same time, depicting that the influence of absorber height was not significant. However, at different ultrasonic powers, there was a significant difference in the complete mixing time. Figure 17 shows the tracer mass fraction trends at different ultrasonic powers. Run 6 (with the highest ultrasonic power) reached complete mixing in less than 2 s. The complete mixing time increased as the ultrasonic power decreased, and Run 4 (with the lowest ultrasonic power) required around 3.5 s to reach complete mixing. Fast mixing in the UAAS absorber at high ultrasonic power resulted from the high flow rate from the fountain tip and intense mixing. This observation was consistent with the previous finding during the phase interaction analysis [22,32].

Figure 16.

(a) Raw data, and (b) curve-fitting data at different absorber heights.

Figure 17.

(a) Raw data, and (b) curve-fitting data at different ultrasonic powers.

5.4. Intensification Factor and Energy Efficiency

To analyze the mixing behavior for absorption performance, the intensification factor (IF) was used to describe the enhancement of mass transfer of the ultrasonic absorber. A higher IF indicates the potential size reduction of the UAAS as compared to the conventional technology such as a packed bed column [4,14].

Figure 18 shows a summary of volume-averaged phase interaction and intensification factor for all cases from Run 1 to Run 9. Based on the above relationship in Equation (19), the absorber with the higher phase interaction will demonstrate a higher intensification factor. Therefore, Run 3 (with the lowest height and highest ultrasonic power) generated the highest phase interaction, which corresponded to the highest intensification factor. The lowest intensification factor was from Run 7, contributed by the lowest phase interaction due to its greatest height and lowest ultrasonic power, as explained earlier. These findings are depicted in Figure 18b.

Figure 18.

(a) Overall results of phase interaction, and (b) comparison in terms of intensification factor.

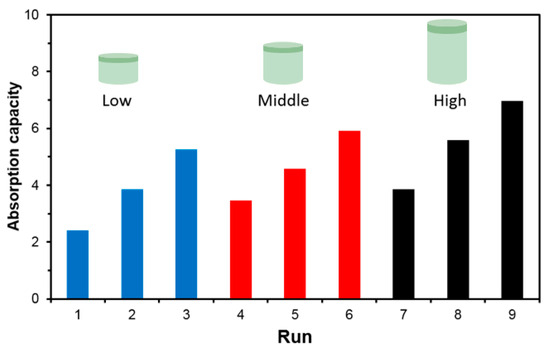

From a different perspective, the UAAS absorber height has a direct relationship with the absorption capacity. Assuming the liquid solvent has infinite absorption capacity and sorbate (gas) has an infinite amount in the absorber, the larger absorber has the advantage of absorbing more gases than the smaller absorber. The relative gas absorption capacity is calculated by multiplying the phase interaction with the absorber height, as shown in Equation (20).

This parameter describes the relative amount of gases that can be absorbed using a specific size of absorber and power. Figure 19 shows the relative gas absorption capacity at different absorber heights and ultrasonic power. Run 9 (with the highest absorber height and power) yielded the highest absorption capacity; in contrast, Run 1 (with the lowest absorber height and power) generated the lowest absorption capacity.

Figure 19.

Relative gas absorption capacity.

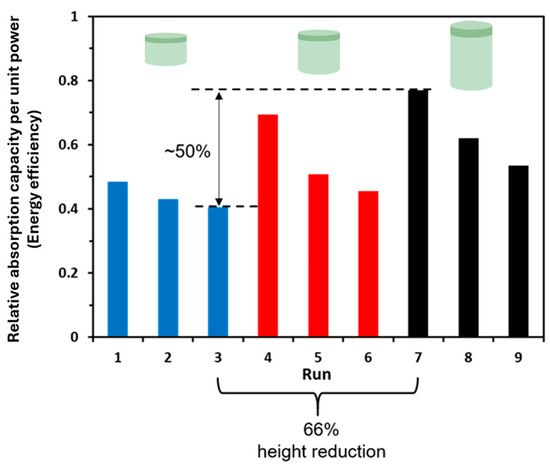

To evaluate the energy efficiency, a new term is used, which is defined as relative gas absorption capacity per ultrasonic power using the predefined absorption capacity, as shown in Equation (21):

Generally, this parameter indicates the energy efficiency of a process. Figure 20 shows the energy efficiency for different runs. Based on the results, the absorber with lower power demonstrated better energy efficiency than the case with higher power. In general, increase in height can increase the energy efficiency. For example, Run 7, which has the highest absorber height and lowest ultrasonic power, showed the highest energy efficiency; in contrast, Run 3 (with the lowest absorber height and highest power) demonstrated the lowest energy efficiency. Comparing the case with the highest (Run 7) and lowest (Run 3) energy efficiency, Run 7 was 50% more energy efficient than Run 3, yet Run 3 was 66% smaller as compared to Run 7. This explains the fact that although using a small absorber with a high power can increase the intensification factor, the disadvantage is lower energy efficiency.

Figure 20.

Energy efficiency comparison of different runs.

6. Analysis Summary

The parametric study discussed in the earlier section does not conclude any optimum value for the absorber height and ultrasonic power. However, there are advantages and disadvantages in terms of intensification factor and energy efficiency for each condition. Table 3 shows the summary analysis of the effect of absorber height. Based on the table, a UAAS with a lower absorber height has the advantage of a higher intensification factor due to its smaller absorber volume. However, at a lower height, the energy efficiency for the UAAS absorber would be lower. The UAAS with a higher absorber height has the advantage of having higher absorption capacity and higher energy efficiency, but a lower intensification factor. Therefore, there is a trade-off between intensification factor and energy efficiency for the effect of absorber height.

Table 3.

Advantages and disadvantages of the factor of absorber height.

Meanwhile, Table 4 summarizes the advantages and disadvantages in terms of intensification factor and energy efficiency for the effect of ultrasonic power. If a high intensification factor is the main aim of a process, higher ultrasonic power should be applied to the UAAS absorber because it could generate intense mixing and create higher phase interaction and mass transfer. As a trade-off, the UAAS absorber with the higher power has the disadvantage of lower energy efficiency. The best energy efficiency condition is at low ultrasonic power. Hence, the decision about the best configuration and operating condition should reflect the main objective of the desired process, either to obtain the highest intensification factor or energy efficiency.

Table 4.

Advantages and disadvantages for the factor of ultrasonic power.

7. Conclusions

Based on current CFD modeling and analysis, the hydrodynamics and mixing within the UAAS were successfully investigated. First, the chosen VOF model for the multiphase simulation was validated and showed a good agreement with the experimental data. Then, the mixing performance was evaluated based on the parameter of volume-averaged phase interaction and liquid tracer mixing. The profile of the velocity vector, streamline, and pressure were useful in explaining the mixing phenomenon.

In addition, a parametric study was conducted to examine the influence of absorber height and ultrasonic power on the intensification factor and energy efficiency. The absorber height influences the absorber volume, while ultrasonic power affects the flow rate and velocity of the fluids. Although no optimum condition was found, there are advantages and disadvantages for each parameter which can be summarized below:

- Run 7 (largest and lowest power) shows the highest energy efficiency

- Run 3 (smallest and highest power) shows the highest intensification factor

Hence, there is a trade-off between energy efficiency and intensification factor for the UAAS during the selection of optimum absorber configuration and operating condition, which is recommended to be considered and further evaluated especially for future technology scale-up.

Author Contributions

Conceptualization, A.M.T. and K.K.L.; methodology, A.M.T. and K.K.L.; software, A.M.T.; validation, A.M.T. and K.K.L.; formal analysis, K.K.L.; investigation, K.K.L.; writing—original draft preparation, A.M.T.; writing—review and editing, A.M.T., K.K.L., V.C.Q. and T.M.U.T.M.; visualization, A.M.T.; supervision, K.K.L. and T.M.U.T.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was technically supported by Universiti Teknologi PETRONAS, YUTP-PRG 2023 (015PBC-031) and PETRONAS Research Sdn Bhd (Master Research Agreement).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tay, W.H.; Lau, K.K.; Shari, A.M. High performance promoter-free CO2 absorption using potassium carbonate solution in an ultrasonic irradiation system. J. CO2 Util. 2017, 21, 383–394. [Google Scholar] [CrossRef]

- George, G.; Bhoria, N.; Alhallaq, S.; Abdala, A.; Mittal, V. Polymer membranes for acid gas removal from natural gas. Sep. Purif. Technol. 2016, 158, 333–356. [Google Scholar] [CrossRef]

- Faiz, R.; Li, K.; Al-marzouqi, M. H2S absorption at high pressure using hollow fibre membrane contactors. Chem. Eng. Process. 2014, 83, 33–42. [Google Scholar] [CrossRef]

- Yusof, S.M.M.; Lau, K.K.; Shariff, A.M.; Tay, W.H.; Mustafa, N.F.A.; Lock, S.S.M. Novel continuous ultrasonic contactor system for CO2 absorption: Parametric and optimization study. J. Ind. Eng. Chem. 2019, 79, 279–287. [Google Scholar] [CrossRef]

- Yu, C.; Huang, C.; Tan, C. A Review of CO2 Capture by Absorption and Adsorption. Aerosol Air Qual. Res. 2012, 12, 745–769. [Google Scholar] [CrossRef]

- Le Grange, P.; Sheilan, M.; Spooner, B. How to Limit Amine Systems Failures. Chem. Eng. 2017. Available online: https://www.researchgate.net/publication/343879575 (accessed on 14 June 2022).

- Sea, B.; Park, Y.; Lee, K. Comparison of Porous Hollow Fibers as a Membrane Contactor for Carbon Dioxide Absorption. J. Ind. Eng. Chem. 2002, 8, 290–296. [Google Scholar]

- deMontigny, D.; Tontiwachwuthikul, P.; Chakma, A. Comparing the Absorption Performance of Packed Columns and Membrane Contactors. Ind. Eng. Chem. Res. 2005, 44, 5726–5732. [Google Scholar] [CrossRef]

- Yeon, S.; Lee, K.; Sea, B.; Park, Y.-I.; Lee, K.-H. Application of pilot-scale membrane contactor hybrid system for removal of carbon dioxide from flue gas. J. Membr. Sci. 2005, 257, 156–160. [Google Scholar] [CrossRef]

- Lin, S.-H.; Chiang, P.-C.; Hsieh, C.-F.; Li, M.-H.; Tung, K.-L. Absorption of carbon dioxide by the absorbent composed of piperazine and 2-amino-2-methyl-1-propanol in PVDF membrane contactor. J. Chin. Inst. Chem. Eng. 2008, 39, 13–21. [Google Scholar] [CrossRef]

- Dindore, V.Y.; Brilman, D.W.F.; Feron, P.H.M.; Versteeg, G.F. CO2 absorption at elevated pressures using a hollow fiber membrane contactor. J. Membr. Sci. 2004, 235, 99–109. [Google Scholar] [CrossRef]

- Wee Horng, T. CO2 Absorption Using High Frequency Ultrasonic Irradiation: Experiment and Modeling. Ph.D Thesis, Universiti Teknologi PETRONAS, Seri Iskandar, Malaysia, 2017. [Google Scholar]

- Tay, W.H.; Lau, K.K.; Shariff, A.M. High frequency ultrasonic-assisted chemical absorption of CO2 using monoethanolamine (MEA). Sep. Purif. Technol. 2017, 183, 136–144. [Google Scholar] [CrossRef]

- Tamidi, A.M.; Lau, K.K.; Yusof, S.M.M.; Azmi, N.; Zakariya, S.; Patthi, U. Enhancement of CO2 Absorption Process Using High-Frequency Ultrasonic Waves. Sustainability 2023, 15, 11064. [Google Scholar] [CrossRef]

- Akbari, M.; Rahimi, M.; Faryadi, M. Gas—Liquid flow mass transfer in a T-shape microreactor stimulated with 1.7 MHz ultrasound waves. Chin. J. Chem. Eng. 2017, 25, 1143–1152. [Google Scholar] [CrossRef]

- Daquan, X. Physics of Ultrasound; The New York School of Regional Anesthesia: New York, NY, USA, 2022; Available online: https://www.nysora.com/topics/equipment/physics-of-ultrasound/#toc_REFERENCES (accessed on 14 June 2022).

- Gallego-Juarez, J.A. Piezoelectric ceramics and ultrasonic transducers. J. Phys. E 1989, 22, 804–816. [Google Scholar] [CrossRef]

- Qin, L.; Porfyrakis, K.; Tzanakis, I.; Grobert, N.; Eskin, D.G.; Fezzaa, K.; Mi, J. Multiscale interactions of liquid, bubbles and solid phases in ultrasonic fields revealed by multiphysics modelling and ultrafast X-ray imaging. Ultrason. Sonochemistry 2022, 89, 106158. [Google Scholar] [CrossRef]

- Niazi, S.; Hashemabadi, S.H.; Razi, M.M. CFD simulation of acoustic cavitation in a crude oil upgrading sonoreactor and prediction of collapse temperature and pressure of a cavitation bubble. Chem. Eng. Res. Des. 2014, 92, 166–173. [Google Scholar] [CrossRef]

- Guerrero, E.; Munoz, F.; Ratkovich, N. Comparison between Eulerian and VOF models for two-phase flow assessment in vertical pipes. CT&F-Cienc. Tecnol. Futuro 2017, 7, 73–84. [Google Scholar]

- Laborde, J.; Hita, A.; Caltagirone, J.; Gerard, A. Fluid dynamics phenomena induced by power ultrasounds. Ultrasonics 2000, 38, 297–300. [Google Scholar] [CrossRef]

- Cai, J.; Huai, X.; Yan, R.; Cheng, Y. Numerical simulation on enhancement of natural convection heat transfer by acoustic cavitation in a square enclosure. Appl. Therm. Eng. 2009, 29, 1973–1982. [Google Scholar] [CrossRef]

- Abolhasani, M.; Rahimi, M.; Dehbani, M.; Alsairafi, A.A. CFD Modeling of Heat Transfer by 1.7 MHz Ultrasound Waves. Numer. Heat Transf. Part A 2012, 62, 822–841. [Google Scholar] [CrossRef]

- Dehbani, M.; Rahimi, M.; Abolhasani, M.; Maghsoodi, A.; Afshar, P.G.; Dodmantipi, A.R.; Alsairafi, A.A. CFD modeling of convection heat transfer using 1.7 MHz and 24 kHz ultrasonic waves: A comparative study. Heat Mass Transf. 2014, 50, 1319–1333. [Google Scholar] [CrossRef]

- Abolhasani, M.; Rahimi, M.; Dehbani, M. CFD Modeling of Low, Medium and High Frequency Ultrasound Waves Propagation Inside a Liquid Medium. In Proceedings of the 4th National Conference on CFD Applications in Chemical & Petroleum Industries, Ahwaz, Iran, 16 May 2012. [Google Scholar]

- Parvizian, F.; Rahimi, M.; Faryadi, M.; Abdulaziz, A. Comparison between Mixing in Novel High Frequency Sonoreactor and Stirred Tank Reactor. Eng. Appl. Comput. Fluid Mech. 2012, 6, 295–306. [Google Scholar] [CrossRef]

- Parvizian, F.; Rahimi, M.; Hosseini, S.M.; Madaeni, S.; Alsairafi, A. The effect of high frequency ultrasound on diffusion boundary layer resistance in ion-exchange membrane transport. Desalination 2012, 286, 155–165. [Google Scholar] [CrossRef]

- Rahimi, M.; Movahedirad, S.; Shahhosseini, S. CFD study of the flow pattern in an ultrasonic horn reactor: Introducing a realistic vibrating boundary condition. Ultrason. Sonochemistry 2016, 35, 359–374. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Lighthill, J. Acoustic streaming. J. Sound Vib. 1978, 61, 391–418. [Google Scholar] [CrossRef]

- Mohd Laziz, A.; KuShaari, K.Z.; Azeem, B.; Yusup, S.; Chin, J.; Denecke, J. Rapid production of biodiesel in a microchannel reactor at room temperature by enhancement of mixing behaviour in methanol phase using volume of fluid model. Chem. Eng. Sci. 2020, 219, 115532. [Google Scholar] [CrossRef]

- Xu, Z.; Yasuda, K.; Koda, S. Numerical simulation of liquid velocity distribution in a sonochemical reactor. Ultrason. Sonochemistry 2013, 20, 452–459. [Google Scholar] [CrossRef]

- Absar, S.; Pasumarthi, P.; Choi, H. Numerical and experimental studies about the effect of acoustic streaming on ultrasonic processing of metal matrix nanocomposites (MMNCs). J. Manuf. Process. 2017, 28, 515–522. [Google Scholar] [CrossRef]

- Dong, Z.; Yao, C.; Zhang, Y.; Chen, G.; Yuan, Q.; Xu, J. Hydrodynamics and Mass Transfer of Oscillating Gas-Liquid Flow in Ultrasonic Microreactors. Am. Inst. Chem. Eng. 2016, 62, 1294–1307. [Google Scholar] [CrossRef]

- Tay, W.H.; Lau, K.K.; Shariff, A.M. High frequency ultrasonic assisted mass transfer for water batch reactor. ARPN J. Eng. Appl. Sci. 2016, 11, 1660–1665. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).