Utilisation of Different Types of Glass Waste as Pozzolanic Additive or Aggregate in Construction Materials

Abstract

1. Introduction

2. Research Methods

3. Results and Discussion

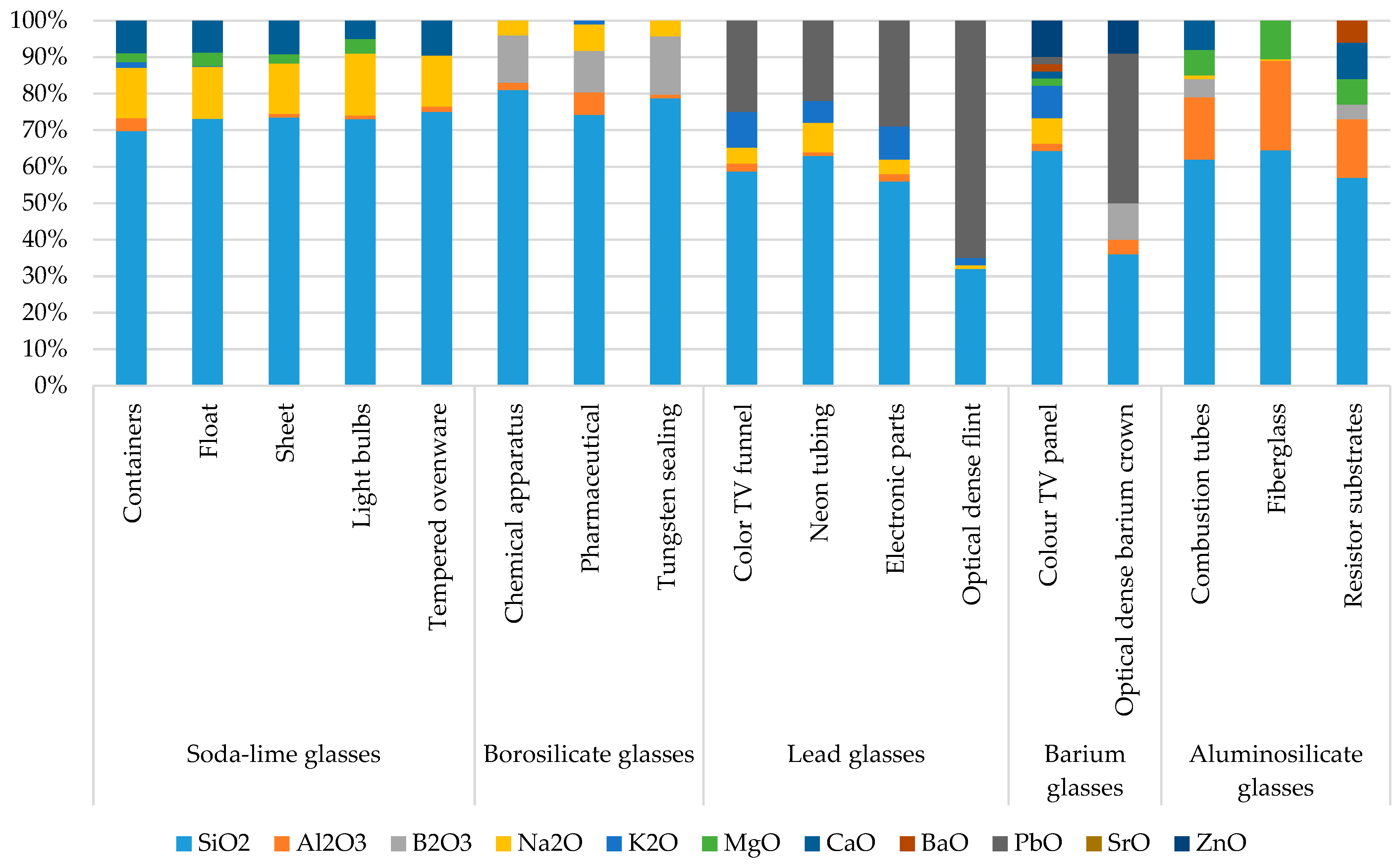

3.1. Chemical and Physical Properties of Different Types of GW

3.2. The Influence of Different Particle Size Glass Waste on the Properties of Cementitious Materials

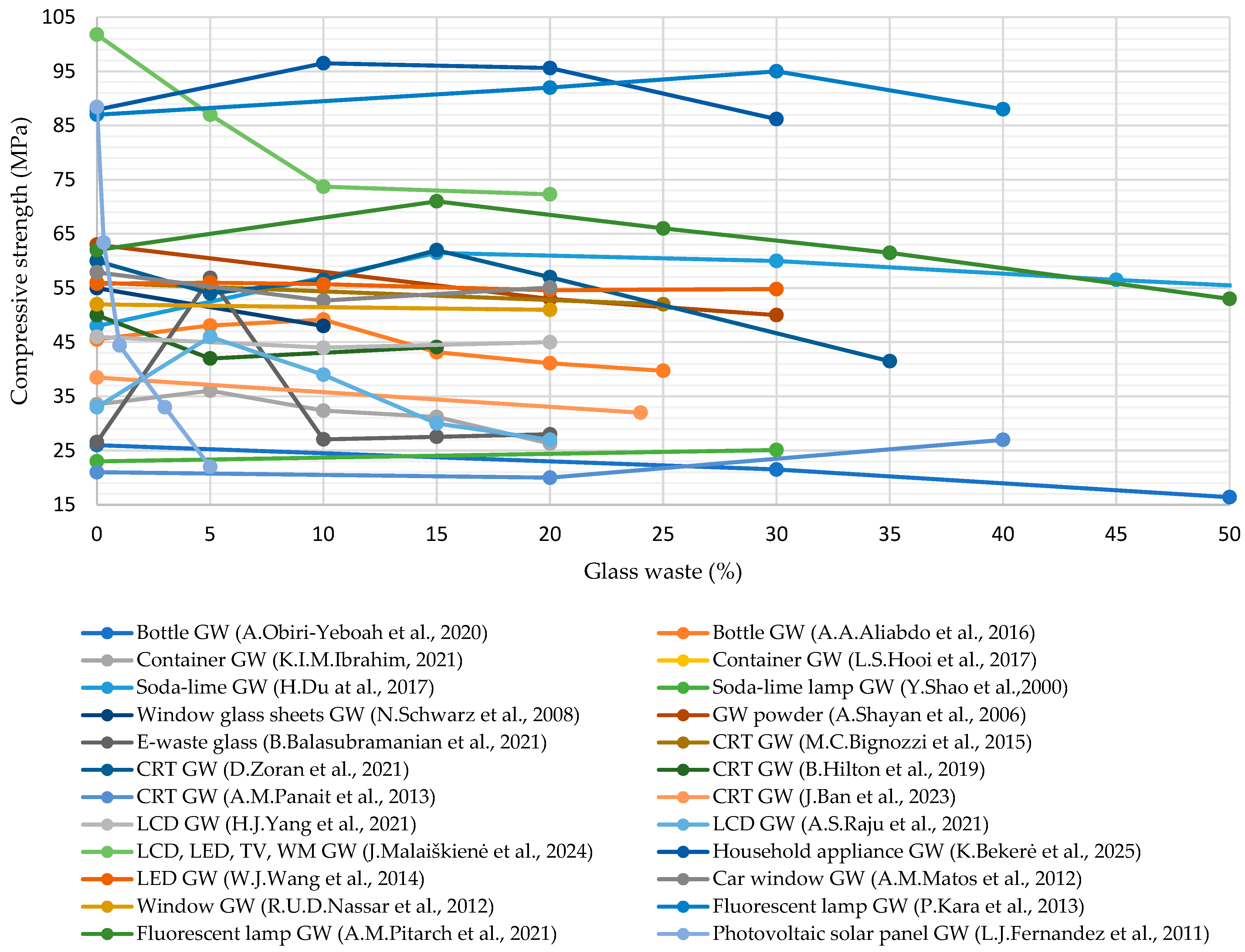

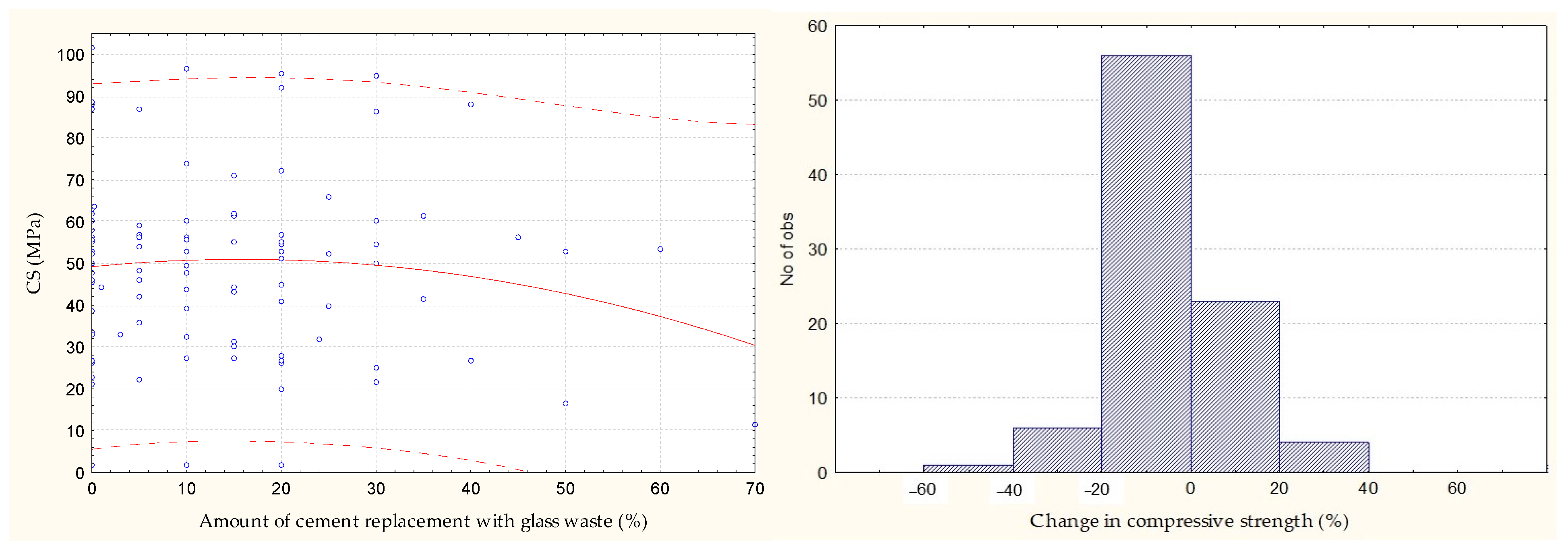

3.2.1. Influence of Cement-Sized Glass Waste, Used as a Partial Binder Replacement, on the Properties of Cementitious Materials

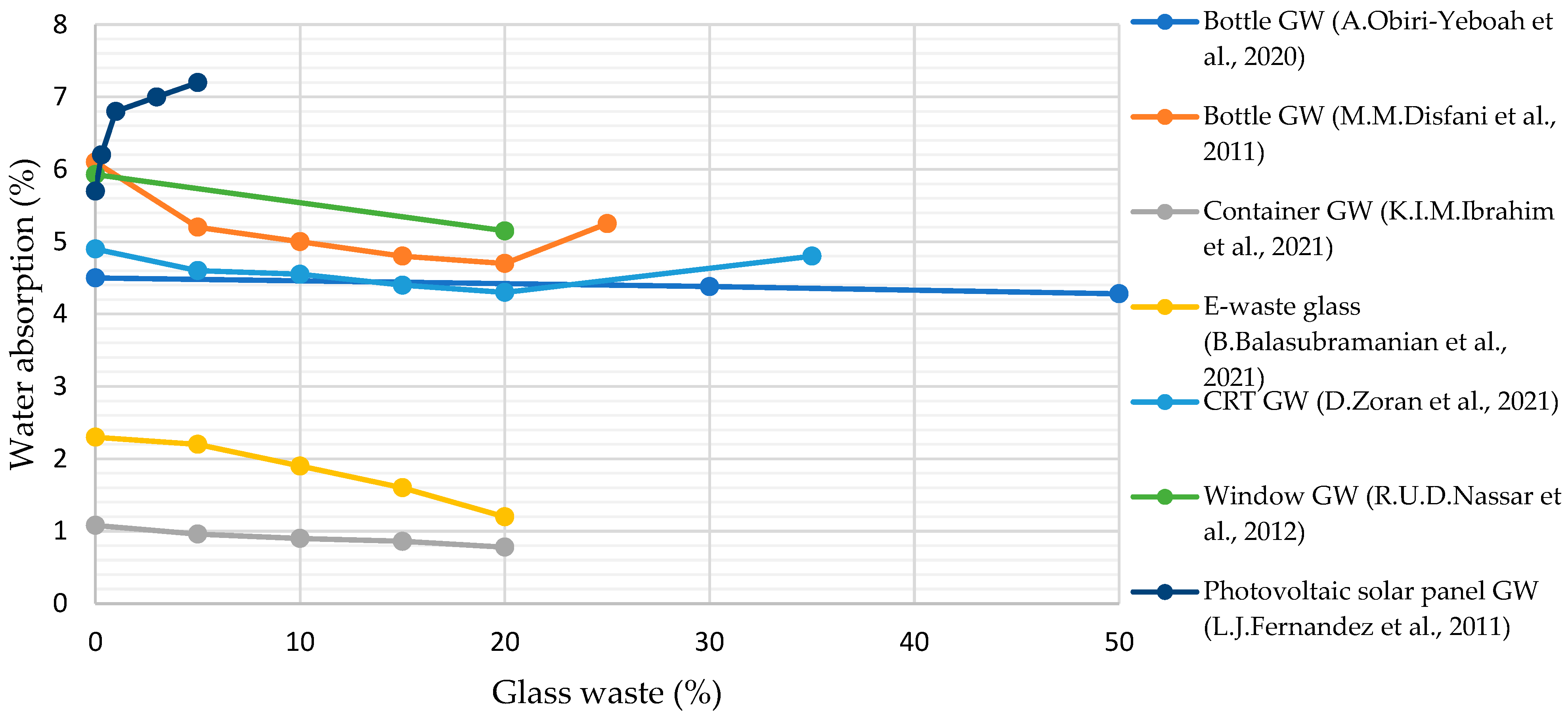

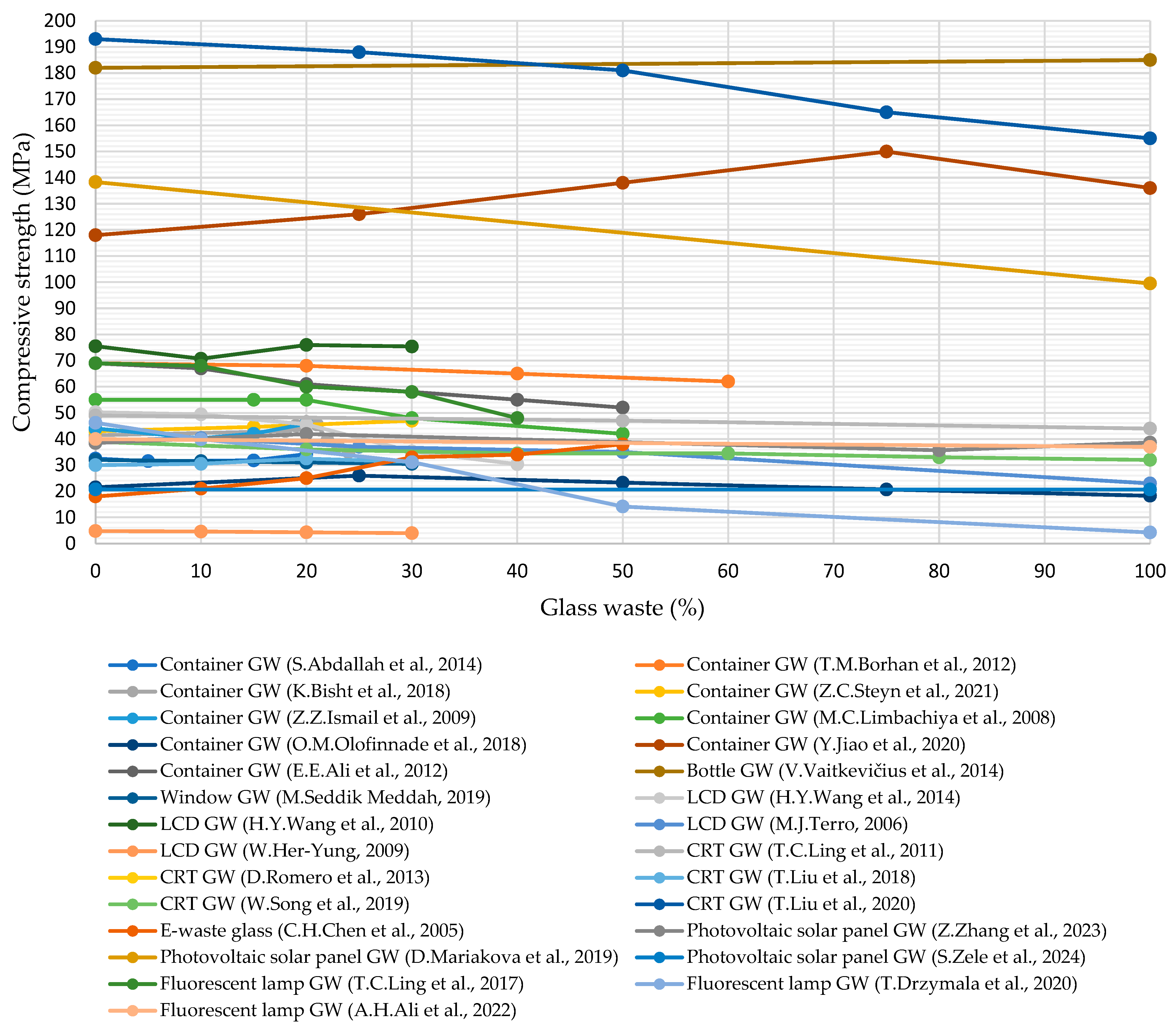

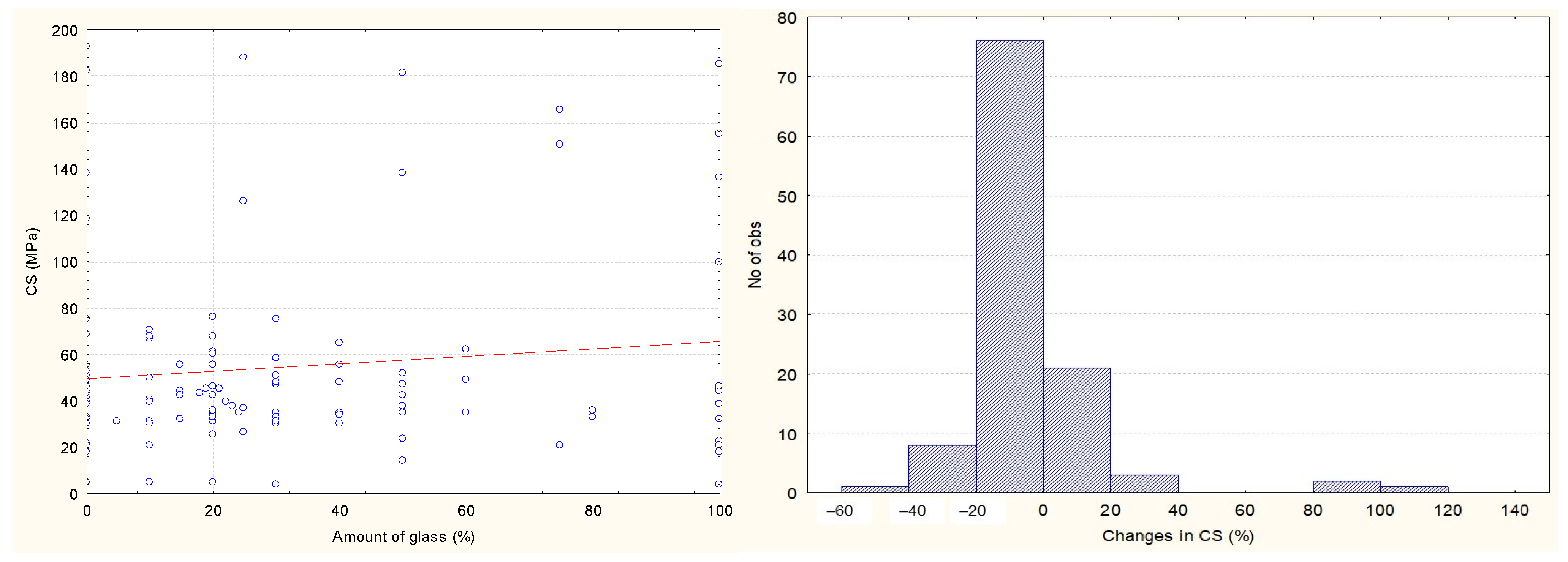

3.2.2. Influence of Fine Aggregate-Sized Particles, Used as a Partial Fine Aggregate Replacement, in Cementitious Materials

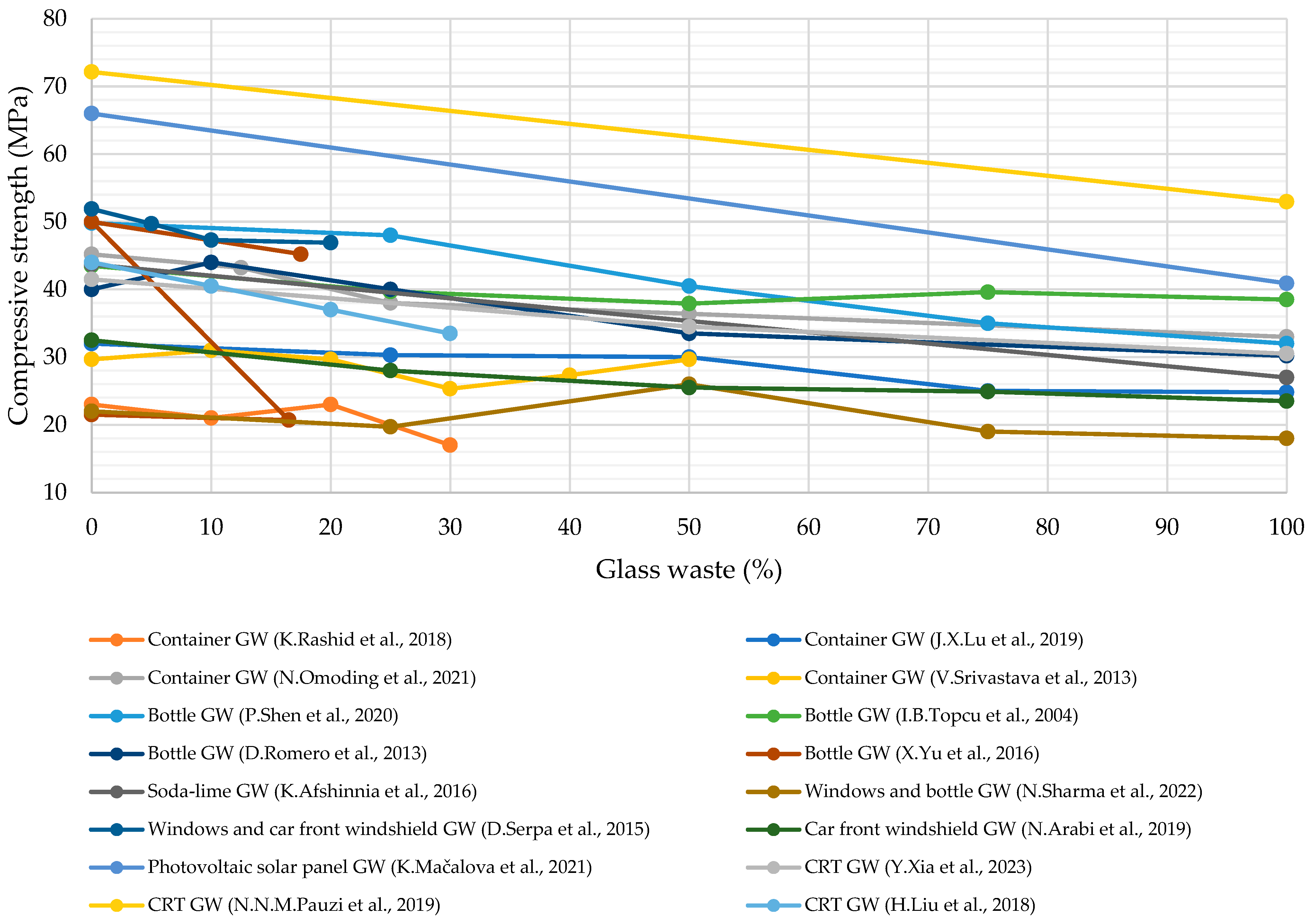

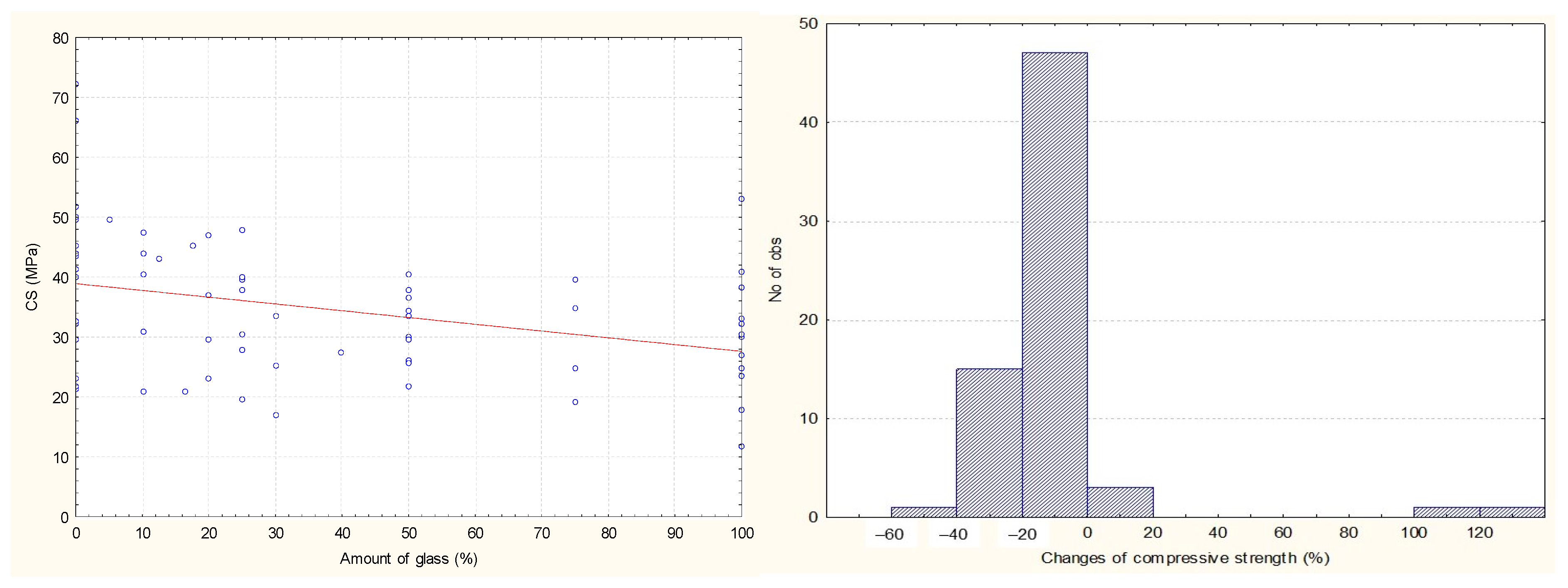

3.2.3. Influence of Coarse Aggregate-Sized Particles, Used as a Natural Coarse Aggregate Replacement, on the Properties of Concrete

3.3. The Possibilities of GW Utilisation in Asphalt Concrete

3.4. The Possibilities of Glass Waste Utilisation in Ceramic Materials

4. Conclusions

- A comprehensive review of the literature and research findings reveals a clear correlation between the prevalence of consumerism and the increasing volume of GW disposed of in landfills. The recycling rate for glass varies depending on the type of glass, with an average of up to 50% for certain types. Given the extensive development of the concrete industry on a global scale, it would be advantageous to utilise various types of GW in the production of concrete or other cementitious materials, thus substituting for a portion of the cement or natural aggregates. The article also mentions the potential use of GW in the production of asphalt concrete and ceramics. Research indicates that GW has a considerable propensity to be utilised in a diverse array of mixtures, thus contributing to the improvement of sustainable waste management practices and the development of infrastructure.

- A comprehensive review of the scientific literature has revealed controversial trends in the properties of cementitious materials. It is proposed that approximately 10–20% of the cement be replaced with a dispersed fine glass cement additive. This additive acts as a pozzolanic agent, which has been shown to improve the technological and mechanical properties of cementitious materials. It has also been shown to improve the resistance of these materials to various chemical influences and to increase their durability, particularly after a longer curing time of 56–90 days. However, depending on the type of GW used, its chemical composition, crystallinity, and other factors, the properties of cementitious materials can deteriorate due to the higher air content, agglomeration of dispersed particles, reactions of harmful chemical elements, and possible leaching.

- Replacement of a portion of fine aggregate has shown that, under certain circumstances, the workability of cementitious materials can be improved because of reduced water penetration and the smooth surface of GW particles. However, in certain cases, increased friction between particles can lead to a reduction in fluidity. The mechanical properties of the material may be enhanced as a result of the finer particles’ capacity to function as a pozzolanic additive and/or microfiller. For example, when 75% of the sand was replaced with container GW, the compressive strength of fine-grained concrete increased by about 30%. The density of the material depends on the density of the glass itself, and there are instances where the density of cementitious materials may increase or decrease. The effect on the mechanical properties in this case depends on the mineral composition of the particles and adhesion to the cementitious matrix. It has been established that GW particles with a higher amorphous content have the capacity to trigger ASR. Therefore, this study must be carried out. In this instance, the results of the lead leaching tests demonstrated that Pb remained within the material’s structure and was only minimally leached.

- When coarse aggregate in concrete is replaced by coarse GW, a decrease in density and deterioration of mechanical properties are commonly observed. This is primarily due to the inadequate bonding between glass and the cementitious matrix, as well as the elevated amount of entrapped air. It has been established that workability is subject to deterioration in relation to the dimensions and configuration of the particles, in addition to the elevated levels of air incorporated. It has been demonstrated that, conversely, abrasion resistance is prone to deterioration; concurrently, however, thermal conductivity is reduced.

- The utilisation of waste glass in asphalt concrete constitutes a viable and eco-friendly approach; however, it is imperative to evaluate the amount of waste glass that can be incorporated and its inherent characteristics to ensure optimal pavement durability and safety. The size and content of the glass particles in the mix can produce a variety of benefits, including improved pavement reflectivity, increased coefficient of friction, and increased resistance to skids, which can ultimately improve road safety. Furthermore, the positive impact of bitumen and polymer-coated glass fibre has been observed on the durability and moisture resistance of asphalt. However, an increase in glass content above 20% has been found to result in a decrease in the resistance of the pavement to rutting and an increase in its susceptibility to moisture. This phenomenon can be attributed to weaker adhesion between the glass particles and the binder. However, the utilisation of certain types of waste glass, such as CRT glass, has been demonstrated to curtail the migration of hazardous substances into the environment.

- The incorporation of different GW (containerised lime–sodium glass cullet, CRT waste, TV screen glass, etc.) has a substantial impact on the physical, thermal, and mechanical properties of the ceramic products. Optimal results with a GW content of up to 25% were achieved, which decreased water absorption, improved bulk density and mechanical strength, especially when fired at 1100 °C to 1150 °C. The addition of more GW resulted in detrimental effects, including reduced compaction, increased firing shrinkage, and adverse impacts on the exterior appearance of the tiles. Furthermore, it was determined that the fineness of the glass powder, as well as the particle size of the waste material, played a crucial role in improving the compressive strength and overall properties of the clay bricks fired. The findings support the feasibility of integrating GW into the production of ceramic materials as part of sustainable construction practices, reducing waste and improving material performance. However, it is evident that there is a limit to the amount of GW that can be incorporated without compromising the quality of the final product.

- In order to fully harness the potential of GW in construction materials, future research must address the current uncertainties and technical challenges associated with its use. In cementitious materials, the inconsistent effects of GW on mechanical and durability properties highlight the need to study the influence of the chemical composition, mineralogy, and particle morphology of GW. It is imperative that research efforts are directed toward the optimisation of GW particle size, shape, and surface texture. Furthermore, exploration of surface treatments is necessary to enhance the bond with the cement matrix. The incorporation of additional cementitious materials should also be explored in order to mitigate the ASR and enhance performance. In the context of asphalt applications, improving the performance of GW-modified mixtures requires optimisation of the gradation, the implementation of surface treatments to increase the adhesion of the binder, and the refinement of compaction methodologies. It is imperative that environmental safety, particularly the leaching behaviour of e-waste glass, be rigorously assessed. The development of standardised design guidelines is imperative to ensure durability, performance, and environmental sustainability. In ceramic production, future efforts might focus on optimising the composition and quantity of GW, meticulously controlling firing conditions, and augmenting densification through the use of additives or nucleating agents. It is imperative to pay particular attention to the fineness of the particles and the phase development at elevated temperatures in order to ensure the maintenance of mechanical strength and the minimisation of defects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| GW | Glass waste |

| CS | Compressive strength |

| C-S-H | Calcium hydrosilicates |

References

- Esquinas, A.R.; Ledesma, E.F.; Otero, R.; Jiménez, J.R.; Fernández, J.M. Mechanical Behaviour of Self-Compacting Concrete Made with Non-Conforming Fly Ash from Coal-Fired Power Plants. Constr. Build. Mater. 2018, 182, 385–398. [Google Scholar] [CrossRef]

- Sobolev, K.; Türker, P.; Soboleva, S.; Iscioglu, G. Utilization of Waste Glass in ECO-Cement: Strength Properties and Microstructural Observations. Waste Manag. 2007, 27, 971–976. [Google Scholar] [CrossRef] [PubMed]

- Kazmi, D.; Serati, M.; Williams, D.J.; Qasim, S.; Cheng, Y.P. The Potential Use of Crushed Waste Glass as a Sustainable Alternative to Natural and Manufactured Sand in Geotechnical Applications. J. Clean. Prod. 2021, 284, 124762. [Google Scholar] [CrossRef]

- Premathilaka, K.K.W.; Liyanapathirana, D.S.; Leo, C.J.; Hu, P. Application of Recycled Waste Glass to Replace Traditional Quarried Aggregates: A Comprehensive Review. J. Build. Eng. 2024, 86, 108846. [Google Scholar] [CrossRef]

- Mohajerani, A.; Vajna, J.; Cheung, T.H.H.; Kurmus, H.; Arulrajah, A.; Horpibulsuk, S. Practical Recycling Applications of Crushed Waste Glass in Construction Materials: A Review. Constr. Build. Mater. 2017, 156, 443–467. [Google Scholar] [CrossRef]

- Wang, H.Y. A Study of the Effects of LCD Glass Sand on the Properties of Concrete. Waste Manag. 2009, 29, 335–341. [Google Scholar] [CrossRef]

- Esmaeili, J.; Oudah Al-Mwanes, A. A Review: Properties of Eco-Friendly Ultra-High-Performance Concrete Incorporated with Waste Glass as a Partial Replacement for Cement. Mater. Today Proc. 2021, 42, 1958–1965. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency; Glass: Material-Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/glass-material-specific-data (accessed on 22 March 2025).

- Recovery. Recycling Technology Worldwide; Glass Recycling–Current Market Trends. Available online: https://www.recovery-worldwide.com/en/artikel/glass-recycling-current-market-trends-3248774.html (accessed on 22 March 2025).

- Dong, W.; Li, W.; Tao, Z. A Comprehensive Review on Performance of Cementitious and Geopolymeric Concretes with Recycled Waste Glass as Powder, Sand or Cullet. Resour. Conserv. Recycl. 2021, 172, 105664. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N. An Overview on the Reuse of Waste Glasses in Alkali-Activated Materials. Resour. Conserv. Recycl. 2019, 144, 297–309. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of Landfill Wastes (Tyres, Plastics and Glass) in Construction—A Review on Global Waste Generation, Performance, Application and Future Opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global Status of Recycling Waste Solar Panels: A Review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Tian, X.; Chen, X.; Ren, L.; Geng, C. A Review of End-of-Life Crystalline Silicon Solar Photovoltaic Panel Recycling Technology. Sol. Energy Mater. Sol. Cells 2022, 248, 111976. [Google Scholar] [CrossRef]

- Maani, T.; Celik, I.; Heben, M.J.; Ellingson, R.J.; Apul, D. Environmental Impacts of Recycling Crystalline Silicon (c-SI) and Cadmium Telluride (CDTE) Solar Panels. Sci. Total Environ. 2020, 735, 138827. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Saad Agwa, I. Effect of Ferrosilicon and Silica Fume on Mechanical, Durability, and Microstructure Characteristics of Ultra High-Performance Concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Mariaková, D.; Mocová, K.A.; Fořtová, K.; Pavlů, T.; Hájek, P. Waste Glass Powder Reusability in High-Performance Concrete: Leaching Behavior and Ecotoxicity. Materials 2021, 14, 4476. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ali, H.; Khaled, M.M.; Al-Aqeeli, N.; Abu-Dheir, N.; Varanasi, K.K. Influence of Dust and Mud on the Optical, Chemical, and Mechanical Properties of a Pv Protective Glass. Sci. Rep. 2015, 5, 15833. [Google Scholar] [CrossRef] [PubMed]

- Shayan, A.; Xu, A. Value-Added Utilisation of Waste Glass in Concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Shi, C.; Zheng, K. A Review on the Use of Waste Glasses in the Production of Cement and Concrete. Resour. Conserv. Recycl. 2007, 52, 234–247. [Google Scholar] [CrossRef]

- Saltan, M.; Öksüz, B.; Uz, V.E. Use of Glass Waste as Mineral Filler in Hot Mix Asphalt. Sci. Eng. Compos. Mater. 2015, 22, 271–277. [Google Scholar] [CrossRef]

- Kazmi, D.; Williams, D.J.; Serati, M. Waste Glass in Civil Engineering Applications—A Review. Int. J. Appl. Ceram. Technol. 2020, 17, 529–554. [Google Scholar] [CrossRef]

- Delbari, S.A.; Hof, L.A. Glass Waste Circular Economy—Advancing to High-Value Glass Sheets Recovery Using Industry 4.0 and 5.0 Technologies. J. Clean. Prod. 2024, 462, 142629. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 Emissions from Cement Production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Ogundairo, T.O.; Adegoke, D.D.; Akinwumi, I.I.; Olofinnade, O.M. Sustainable Use of Recycled Waste Glass as an Alternative Material for Building Construction—A Review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012073. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Alexandre, J.; Zanelato, E.B.; Marvila, M.T. Influence of Incorporation of Glass Waste on the Rheological Properties of Adhesive Mortar. Constr. Build. Mater. 2017, 148, 359–368. [Google Scholar] [CrossRef]

- Stefanidou, M.; Anastasiou, E.; Mantziou, O.; Mpougla, E.; Vasiliou, E.; Konti, P.D.; Antoniadis, K. Incorporation of Glass Particles in High-Performance Mortars. Waste Biomass Valorization 2016, 7, 879–883. [Google Scholar] [CrossRef]

- Omran, A.F.; Etienne, D.M.; Harbec, D.; Tagnit-Hamou, A. Long-Term Performance of Glass-Powder Concrete in Large-Scale Field Applications. Constr. Build. Mater. 2017, 135, 43–58. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical Behaviour of Ground Waste Glass When Used as Partial Cement Replacement in Mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Chandra Paul, S.; Šavija, B.; Babafemi, A.J. A Comprehensive Review on Mechanical and Durability Properties of Cement-Based Materials Containing Waste Recycled Glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.H.; Thomas, M.D.A. Alkali–Silica Reaction: Current Understanding of the Reaction Mechanisms and the Knowledge Gaps. Cem. Concr. Res. 2015, 76, 130–146. [Google Scholar] [CrossRef]

- Farshad, R.; Hamed, M.; Gregor, F. Investigating the Alkali-Silica Reaction of Recycled Glass Aggregates in Concrete Materials. J. Mater. Civ. Eng. 2010, 22, 1201–1208. [Google Scholar] [CrossRef]

- Guo, P.; Meng, W.; Nassif, H.; Gou, H.; Bao, Y. New Perspectives on Recycling Waste Glass in Manufacturing Concrete for Sustainable Civil Infrastructure. Constr. Build. Mater. 2020, 257, 119579. [Google Scholar] [CrossRef]

- Dhir, R.K.; Dyer, T.D.; Tang, M.C. Alkali-Silica Reaction in Concrete Containing Glass. Mater. Struct. 2009, 42, 1451–1462. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass Waste as Supplementary Cementing Materials: The Effects of Glass Chemical Composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Kelly, T. Crushed Cement Concrete Substitution for Construction Aggregates—A Materials Flow Analysis; U.S. Geological Survey: Reston, VA, USA, 1998.

- Koehnken, L.; Rintoul, M.S.; Goichot, M.; Tickner, D.; Loftus, A.C.; Acreman, M.C. Impacts of Riverine Sand Mining on Freshwater Ecosystems: A Review of the Scientific Evidence and Guidance for Future Research. River Res. Appl. 2020, 36, 362–370. [Google Scholar] [CrossRef]

- Sand, Rarer than One Thinks. Env. Dev. 2014, 11, 208–218. [CrossRef]

- Arulrajah, A.; Ali, M.M.Y.; Disfani, M.M.; Piratheepan, J.; Bo, M.W. Geotechnical Performance of Recycled Glass-Waste Rock Blends in Footpath Bases. J. Mater. Civ. Eng. 2013, 25, 653–661. [Google Scholar] [CrossRef]

- EN 12457-2; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size Below 4 mm (without or with Size Reduction). European Standards s.r.o.: Brussel, Belgium, 2003.

- EN 12350-2; Testing Fresh Concrete—Part 2: Slump Test. European Standards s.r.o.: Brussel, Belgium, 2019.

- EN 12390-2; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. European Standards s.r.o.: Brussel, Belgium, 2019.

- EN 12390-7; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. European Standards s.r.o.: Brussel, Belgium, 2019.

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Standards s.r.o.: Brussel, Belgium, 2019.

- EN 12390-8; Testing Hardened Concrete—Part 8: Depth of Penetration of Water Under Pressure. European Standards s.r.o.: Brussel, Belgium, 2019.

- ASTM C 1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2012.

- EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Standards s.r.o.: Brussel, Belgium, 2016.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Standards s.r.o.: Brussel, Belgium, 2020.

- EN 1097-3; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. European Standards s.r.o.: Brussel, Belgium, 2002.

- EN 1097-6; Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar. European Standards s.r.o.: Brussel, Belgium, 2002.

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). European Standards s.r.o.: Brussel, Belgium, 2002.

- Epure, C.; Munteanu, C.; Istrate, B.; Harja, M.; Buium, F. Applications of Recycled and Crushed Glass (RCG) as a Substitute for Natural Materials in Various Fields—A Review. Materials 2023, 16, 5957. [Google Scholar] [CrossRef]

- Grambow, B. Corrosion of Glass. In Uhlig’s Corrosion Handbook; Wiley-Interscience: Hoboken, NJ, USA, 2011; pp. 399–419. ISBN 9780470872864. [Google Scholar]

- Nasier, S. Utilization of Recycled Form of Concrete, E-Wastes, Glass, Quarry Rock Dust and Waste Marble Powder as Reliable Construction Materials. Mater. Today Proc. 2021, 45, 3231–3234. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.H.; Kazi, N. Waste Glass Powder as Partial Replacement of Cement for Sustainable Concrete Practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- De Castro, S.; De Brito, J. Evaluation of the Durability of Concrete Made with Crushed Glass Aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- Góra, J.; Franus, M.; Barnat-Hunek, D.; Franus, W. Utilization of Recycled Liquid Crystal Display (LCD) Panel Waste in Concrete. Materials 2019, 12, 2941. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.K.; Yang, H.J. Utilization of Liquid Crystal Display (LCD) Waste Glass Powder as Cementitious Binder in Mortar for Enhancing Neutron Shielding Performance. Constr. Build. Mater. 2021, 270, 121859. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- Lee, W.H.; Lin, Y.W.; Lin, K.L. Optimization of Synthesis Parameters for the Preparation of Zeolite by Reusing Industrialwaste as Raw Material: Sandblasting Waste and Solar Panel Waste Glass. Solid. State Sci. 2023, 143, 107277. [Google Scholar] [CrossRef]

- Ojovan, M.I.; Lee, W.E.; Kalmykov, S.N. Immobilisation of Radioactive Wastes in Glass. In An Introduction to Nuclear Waste Immobilisation, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 319–368. [Google Scholar] [CrossRef]

- Yang, H.J.; Usman, M.; Hanif, A. Suitability of Liquid Crystal Display (LCD) Glass Waste as Supplementary Cementing Material (SCM): Assessment Based on Strength, Porosity, and Durability. J. Build. Eng. 2021, 42, 102793. [Google Scholar] [CrossRef]

- Wang, W.J.; Wang, C.D.; Lee, T.C.; Chang, C.C. Characterization of a Mortar Made with Cement and Sludge from the Light-Emitting Diode Manufacturing Process. Constr. Build. Mater. 2014, 56, 106–112. [Google Scholar] [CrossRef]

- Su, N.; Chen, J.S. Engineering Properties of Asphalt Concrete Made with Recycled Glass. Resour. Conserv. Recycl. 2002, 35, 259–274. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Bo, M.W.; Hankour, R. Recycled Crushed Glass in Road Work Applications. Waste Manag. 2011, 31, 2341–2351. [Google Scholar] [CrossRef] [PubMed]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of Waste Glass Powder in the Production of Cement and Concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Castro-Cardona, C.; Bastidas-Vallejo, S.; Romero-Bustos, S.; Moreno-Piraján, J.C.; Murillo-Acevedo, Y.S.; Serrano-Romero, R.O. Evaluation of the Physical and Mechanical Properties of Modified Concrete with Recycled Crushed Glass, Using a Proportion Adjustment with the Method ACI 211.1. Constr. Build. Mater. 2021, 313, 125378. [Google Scholar] [CrossRef]

- Siddika, A.; Hajimohammadi, A.; Ferdous, W.; Sahajwalla, V. Roles of Waste Glass and the Effect of Process Parameters on the Properties of Sustainable Cement and Geopolymer Concrete—A State-of-the-Art Review. Polymers 2021, 13, 3935. [Google Scholar] [CrossRef]

- Chesner, W.H.; Collins, R.J.; MacKay, M.H.; Emery, J. User Guidelines for Waste and Byproduct Materials in Pavement Construction; Recycled Materials Resource Center: Madison, WI, USA, 2002. [Google Scholar]

- Zele, S.; Joshi, A.; Gogate, N.; Marathe, D.; Shitole, A. Experimental Investigation on Utilization of Crushed Solar Panel Waste as Sand Replacement in Concrete. Sol. Energy 2024, 269, 112338. [Google Scholar] [CrossRef]

- Lin, Y.W.; Lee, W.H.; Lin, K.L. A Novel Approach for Preparing Ecological Zeolite Material from Solar Panel Waste Lass and Sandblasting Waste: Microscopic Characteristics and Humidity Control Performance. J. Mater. Res. Technol. 2022, 19, 4128–4140. [Google Scholar] [CrossRef]

- Callaghan, J.; Wright, J.; Goosen, R. Determined to Succeed: Researching Student Stories of Resilience. J. Aust. N. Z. Stud. Serv. Assoc. 2013, 42, 1–11. [Google Scholar]

- Obiri-Yeboah, A.; Ghadafi, A.M.; Domfeh, M.K.; Nyantakyi, E.K.; Mohammed, G.A.; Kwame Obeng-Ahenkora, N. Partial Replacement of Cement with Glass Bottle Waste Powder in Concrete for Sustainable Waste Management: A Case Study of Kumasi Metropolitan Assembly, Ashanti Region, Ghana. J. Civ. Eng. Res. 2020, 10, 29–38. [Google Scholar]

- Ibrahim, K.I.M. Recycled Waste Glass Powder as a Partial Replacement of Cement in Concrete Containing Silica Fume and Fly Ash. Case Stud. Constr. Mater. 2021, 15, e00630. [Google Scholar] [CrossRef]

- Hooi, L.S.; Min, P.J. Potential of Substituting Waste Glass in Aerated Light Weight Concrete. Procedia Eng. 2017, 171, 633–639. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Properties of High Volume Glass Powder Concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on Concrete Containing Ground Waste Glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Schwarz, N.; Cam, H.; Neithalath, N. Influence of a Fine Glass Powder on the Durability Characteristics of Concrete and Its Comparison to Fly Ash. Cem. Concr. Compos. 2008, 30, 486–496. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Performance of Glass Powder as a Pozzolanic Material in Concrete: A Field Trial on Concrete Slabs. Cem. Concr. Res. 2006, 36, 457–468. [Google Scholar] [CrossRef]

- Balasubramanian, B.; Gopala Krishna, G.V.T.; Saraswathy, V.; Srinivasan, K. Experimental Investigation on Concrete Partially Replaced with Waste Glass Powder and Waste E-Plastic. Constr. Build. Mater. 2021, 278, 122400. [Google Scholar] [CrossRef]

- Zoran, D.; Grdić, G.; Aleksandar, G.; Topličić, T.; Curčić, C.; Jure, Z.; Srboljub, N.; Ristić, R.; Fantilli, P. Durability Properties of Concrete Supplemented with Recycled CRT Glass as Cementitious Material. Materials 2021, 14, 4421. [Google Scholar] [CrossRef]

- Hilton, B.; Bawden, K.; Winnebeck, K.; Chandrasiri, C.; Ariyachandra, E.; Peethamparan, S. The Functional and Environmental Performance of Mixed Cathode Ray Tubes and Recycled Glass as Partial Replacement for Cement in Concrete. Resour. Conserv. Recycl. 2019, 151, 104451. [Google Scholar] [CrossRef]

- Panait, A.M.; Badanoiu, A.; Georgescu, M.; Stoleriu, S. Cementitious Composites with Glass Waste from Recycling of Cathode Ray Tubes. Mater. Struct. 2013, 46, 2135–2144. [Google Scholar] [CrossRef]

- Ban, J.; Lu, J.X.; Peng, L.; Du, H.; Yao, J.; Poon, C.S. Efficient Utilization of Waste CRT Glass in Low Carbon Super-Sulfated Cement Mortar. Cem. Concr. Compos. 2023, 139, 105037. [Google Scholar] [CrossRef]

- Raju, A.S.; Anand, K.B.; Rakesh, P. Partial Replacement of Ordinary Portland Cement by LCD Glass Powder in Concrete. Mater. Today Proc. 2021, 46, 5131–5137. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Bekerė, K. Impact of Electronic Waste Glass on the Properties of Cementitious Materials. Buildings 2024, 14, 1218. [Google Scholar] [CrossRef]

- Bekerė, K.; Malaiškienė, J.; Škamat, J. An Analysis of a Cement Hydration Process Using Glass Waste from Household Appliances as a Supplementary Material. Processes 2025, 13, 840. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of Mortar Using Waste Glass Powder as Cement Replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Nassar, R.U.D.; Soroushian, P. Strength and Durability of Recycled Aggregate Concrete Containing Milled Glass as Partial Replacement for Cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Kara, P.; Korjakins, A.; Kovalenko, K. The Usage of Fluorescent Waste Glass Powder in Concrete. Constr. Sci. 2013, 13, 26–32. [Google Scholar] [CrossRef][Green Version]

- Pitarch, A.M.; Reig, L.; Gallardo, A.; Soriano, L.; Borrachero, M.V.; Rochina, S. Reutilisation of Hazardous Spent Fluorescent Lamps Glass Waste as Supplementary Cementitious Material. Constr. Build. Mater. 2021, 292, 123424. [Google Scholar] [CrossRef]

- Fernández, L.J.; Ferrer, R.; Aponte, D.F.; Fernández, P. Recycling Silicon Solar Cell Waste in Cement-Based Systems. Sol. Energy Mater. Sol. Cells 2011, 95, 1701–1706. [Google Scholar] [CrossRef]

- Jain, J.A.; Neithalath, N. Chloride Transport in Fly Ash and Glass Powder Modified Concretes—Influence of Test Methods on Microstructure. Cem. Concr. Compos. 2010, 32, 148–156. [Google Scholar] [CrossRef]

- Wang, C.C.; Wang, H.Y. Assessment of the Compressive Strength of Recycled Waste LCD Glass Concrete Using the Ultrasonic Pulse Velocity. Constr. Build. Mater. 2017, 137, 345–353. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of Waste Glass Powder as a Supplementary Cementitious Material (SCM) on Physical and Mechanical Properties of Cement Paste under High Temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Saccani, A.; Bignozzi, M.C. An Insight in the Behavior of Glasses with Different Chemical Composition to Be Used in Cementitious Composites as Aggregates or Reactive Fillers. In Proceedings of the 13th International Conference on Alkali-Aggregate Reactions in concrete, Trondheim, Norway, 16–20 June 2008. [Google Scholar]

- Saccani, A.; Bignozzi, M.C. ASR Expansion Behavior of Recycled Glass Fine Aggregates in Concrete. Cem. Concr. Res. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S. Alkali-Activated Binder with Waste Photovoltaic Glass Powder and Blast Furnace Slag as Precursors: Performance Study, Shrinkage- Reducing Technology and Mechanism Analysis. J. Non Cryst. Solids 2023, 609, 122263. [Google Scholar] [CrossRef]

- Walczak, P.; Małolepszy, J.; Reben, M.; Szymański, P.; Rzepa, K. Utilization of Waste Glass in Autoclaved Aerated Concrete. Procedia Eng. 2015, 122, 302–309. [Google Scholar] [CrossRef]

- Abdallah, S. Characteristics of Concrete with Waste Glass as Fine Aggregate Replacement. Int. J. Web Eng. Technol. 2014, 2, 11–17. [Google Scholar]

- Borhan, T.M. Properties of Glass Concrete Reinforced with Short Basalt Fibre. Mater. Des. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P.V. Sustainable Production of Concrete Containing Discarded Beverage Glass as Fine Aggregate. Constr. Build. Mater. 2018, 177, 116–124. [Google Scholar] [CrossRef]

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete Containing Waste Recycled Glass, Plastic and Rubber as Sand Replacement. Constr. Build. Mater. 2021, 269, 121242. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Recycling of Waste Glass as a Partial Replacement for Fine Aggregate in Concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef]

- Limbachiya, M.C. Bulk Engineering and Durability Properties of Washed Glass Sand Concrete. Constr. Build. Mater. 2009, 23, 1078–1083. [Google Scholar] [CrossRef]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Ngene, B.U.; Akinwumi, I.I.; Ofuyatan, O. Strength and Microstructure of Eco-Concrete Produced Using Waste Glass as Partial and Complete Replacement for Sand. Cogent Eng. 2018, 5, 1483860. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Guo, M.; Zhang, L.; Ning, H.; Liu, S. Mechanical and Fracture Properties of Ultra-High Performance Concrete (UHPC) Containing Waste Glass Sand as Partial Replacement Material. J. Clean. Prod. 2020, 277, 123501. [Google Scholar] [CrossRef]

- Ali, E.E.; Al-Tersawy, S.H. Recycled Glass as a Partial Replacement for Fine Aggregate in Self Compacting Concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Vaitkevičius, V.; Šerelis, E.; Hilbig, H. The Effect of Glass Powder on the Microstructure of Ultra High Performance Concrete. Constr. Build. Mater. 2014, 68, 102–109. [Google Scholar] [CrossRef]

- Seddik Meddah, M. Use of Waste Window Glass as Substitute of Natural Sand in Concrete Production. Proc. IOP Conf. Ser. Mater. Sci. Eng. Inst. Phys. Publ. 2019, 603, 032011. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zeng, H.H.; Wu, J.Y. A Study on the Macro and Micro Properties of Concrete with LCD Glass. Constr. Build. Mater. 2014, 50, 664–670. [Google Scholar] [CrossRef]

- Wang, H.Y.; Huang, W.L. Durability of Self-Consolidating Concrete Using Waste LCD Glass. Constr. Build. Mater. 2010, 24, 1008–1013. [Google Scholar] [CrossRef]

- Terro, M.J. Properties of Concrete Made with Recycled Crushed Glass at Elevated Temperatures. Build. Environ. 2006, 41, 633–639. [Google Scholar] [CrossRef]

- Her-Yung, W. A Study of the Engineering Properties of Waste LCD Glass Applied to Controlled Low Strength Materials Concrete. Constr. Build. Mater. 2009, 23, 2127–2131. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. Properties of Architectural Mortar Prepared with Recycled Glass with Different Particle Sizes. Mater. Des. 2011, 32, 2675–2684. [Google Scholar] [CrossRef]

- Romero, D.; James, J.; Mora, R.; Hays, C.D. Study on the Mechanical and Environmental Properties of Concrete Containing Cathode Ray Tube Glass Aggregate. Waste Manag. 2013, 33, 1659–1666. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Qin, S.; Zou, D.; Song, W. Experimental Investigation on the Durability Performances of Concrete Using Cathode Ray Tube Glass as Fine Aggregate under Chloride Ion Penetration or Sulfate Attack. Constr. Build. Mater. 2018, 163, 634–642. [Google Scholar] [CrossRef]

- Song, W.; Zou, D.; Liu, T.; Teng, J.; Li, L. Effects of Recycled CRT Glass Fine Aggregate Size and Content on Mechanical and Damping Properties of Concrete. Constr. Build. Mater. 2019, 202, 332–340. [Google Scholar] [CrossRef]

- Liu, T.; Wei, H.; Zou, D.; Zhou, A.; Jian, H. Utilization of Waste Cathode Ray Tube Funnel Glass for Ultra-High Performance Concrete. J. Clean. Prod. 2020, 249, 119333. [Google Scholar] [CrossRef]

- Chen, C.H.; Huang, R.; Wu, J.K.; Yang, C.C. Waste E-Glass Particles Used in Cementitious Mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Zhang, Z.; Pethati Mudiyanselage Don, J.; Mendis, P.; Lumantarna, E.; Sofi, M. Recycling of End-of-Life Photovoltaic Panels Glass into Concrete. In Proceedings of the Concrete Institute of Australia’s Biennial National Conference, Perth, Australia, 10–13 September 2023. [Google Scholar]

- Mariaková, D.; Jirkalová, Z.; Laiblová, L. Waste Glass as a Replacement for Fine Fraction in High-Performance Concrete. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2019, 660, 012033. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. Spent Fluorescent Lamp Glass as a Substitute for Fine Aggregate in Cement Mortar. J. Clean. Prod. 2017, 161, 646–654. [Google Scholar] [CrossRef]

- Drzymala, T.; Zegardlo, B.; Tofilo, P. Properties of Concrete Containing Recycled Glass Aggregates Produced of Exploded Lighting Materials. Materials 2020, 13, 226. [Google Scholar] [CrossRef]

- Ali, H.A.; Lu, J.X.; Sun, K.; Poon, C.S. Valorization of Spent Fluorescent Lamp Waste Glass Powder as an Activator for Eco-Efficient Binder Materials. Constr. Build. Mater. 2022, 352, 129020. [Google Scholar] [CrossRef]

- Lu, J.-X.; Duan, Z.-H.; Poon, C.S. Combined Use of Waste Glass Powder and Cullet in Architectural Mortar. Cem. Concr. Compos. 2017, 82, 34–44. [Google Scholar] [CrossRef]

- Toufik, C.; Ghrieb, A.; Abadou, Y. Influence of Recycled Display Glass E-Waste on Ternary Dune Sand Mortar Engineering Properties. Mag. Concr. Res. 2023, 75, 1117–1133. [Google Scholar] [CrossRef]

- Hafiz, A. Use of Waste Glass in Geopolymer Based Repairing Materials. Ph.D. Thesis, Hong Kong Polytechnic University, Hong Kong, China, 2023. [Google Scholar]

- Vicent, M.; Criado, M.; García-Ten, J. Alkali-Activated Materials Obtained from Asphalt Fillers and Fluorescent Lamps Wastes. J. Clean. Prod. 2019, 215, 343–353. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Use of Waste Glass as Sand in Mortar: Part I–Fresh, Mechanical and Durability Properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Topçu, I.B.; Canbaz, M. Properties of Concrete Containing Waste Glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effects of Recycled Fine Glass Aggregates on the Properties of Dry-Mixed Concrete Blocks. Constr. Build. Mater. 2013, 38, 638–643. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C. Studies on Expansion Properties in Mortar Containing Waste Glass and Fibers. Cem. Concr. Res. 2004, 34, 1145–1152. [Google Scholar] [CrossRef]

- Polley, C.; Cramer, S.M.; Cruz, R.V. de la Potential for Using Waste Glass in Portland Cement Concrete. J. Mater. Civ. Eng. 1998, 10, 210–219. [Google Scholar] [CrossRef]

- Najm, H.M.; Ahmad, S. Civil and Environmental Engin Eering Reports The Use Of Waste Ceramic Optimal Concrete For A Cleaner And Sustainable Environment-A Case Study Of Mechanical Properties. Civ. Environ. Eng. Rep. 2022, 32, 85–115. [Google Scholar] [CrossRef]

- Sami, Y.; Al-Kamaki, S. Behavior of Concrete Made of Recycled Pet Waste and Confined with Cfrp Fabrics. Master’s Thesis, University of Duhok, Duhok, Iraq, 2014. [Google Scholar]

- Qaidi, S. Ultra-High-Performance Fiber-Reinforced Concrete: Fresh Properties. Case Stud. Constr. Mater. 2022, 17, e01265. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part II: Hydration and Microstructure. Case Stud. Constr. Mater. 2022, 17, e01289. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on Mechanical Properties of Concrete Containing Waste Glass Aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Değirmenci, N.; Yılmaz, A.; Çakır, Ö.A. Utilization of Waste Glass as Sand Replacement in Cement Mortar. Indian. J. Eng. Mater. Sci. 2011, 18, 303–308. [Google Scholar]

- Ali, M.H.; Dinkha, Y.Z.; Haido, J.H. Mechanical Properties and Spalling at Elevated Temperature of High Performance Concrete Made with Reactive and Waste Inert Powders. Eng. Sci. Technol. Int. J. 2017, 20, 536–541. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Improvement in Concrete Behavior with Fly Ash, Silica-Fume and Coconut Fibres. Constr. Build. Mater. 2019, 203, 174–187. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Use of Limestone Powder during Incorporation of Pb-Containing Cathode Ray Tube Waste in Self-Compacting Concrete. J. Environ. Manag. 2013, 128, 931–940. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. Use of CRT Funnel Glass in Concrete Blocks Prepared with Different Aggregate-to-Cement Ratios. Green. Mater. 2014, 2, 43–51. [Google Scholar] [CrossRef]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Cost Assessment; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Qaidi, S.M.A. Ultra-High-Performance Fiber-Reinforced Concrete: Durability Properties; University of Duhok: Duhok, Iraq, 2022. [Google Scholar]

- Ling, T.C.; Poon, C.S. Feasible Use of Recycled CRT Funnel Glass as Heavyweight Fine Aggregate in Barite Concrete. J. Clean. Prod. 2012, 33, 42–49. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ahmed, H.U.; Rafiq, S.; Sor, N.H.; Ibrahim, D.F.; Qaidi, S.M.A. Performance of Self-Compacting Mortars Modified with Nanoparticles: A Systematic Review and Modeling. Clean. Mater. 2022, 4, 100086. [Google Scholar] [CrossRef]

- He, X.; Yuhua, Z.; Qaidi, S.; Isleem, H.F.; Zaid, O.; Althoey, F.; Ahmad, J. Mine Tailings-Based Geopolymers: A Comprehensive Review. Ceram. Int. 2022, 48, 24192–24212. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. Effects of Particle Size of Treated CRT Funnel Glass on Properties of Cement Mortar. Mater. Struct. /Mater. Constr. 2013, 46, 25–34. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Hussain, A.; Chu, S.H. Effect of Silica-Fume Content on Performance of CaCO3 Whisker and Basalt Fiber at Matrix Interface in Cement-Based Composites. Constr. Build. Mater. 2021, 300, 124046. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Earthquake-Resistant Brick Masonry Housing for Developing Countries: An Easy Approach. In Proceedings of the NZSEE 2017 Conference, Wellington, New Zealand, 27–29 April 2017. [Google Scholar]

- Zhang, N.; Yan, C.; Li, L.; Khan, M. Assessment of Fiber Factor for the Fracture Toughness of Polyethylene Fiber Reinforced Geopolymer. Constr. Build. Mater. 2022, 319, 126130. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Aisheh, Y.I.A.; Qaidi, S.M.A.; Tayeh, B.A. Experimental and Simulation Study on the Impact Resistance of Concrete to Replace High Amounts of Fine Aggregate with Plastic Waste. Case Stud. Constr. Mater. 2022, 17, e01324. [Google Scholar] [CrossRef]

- Almeshal, I.; Al-Tayeb, M.M.; Qaidi, S.M.A.; Abu Bakar, B.H.; Tayeh, B.A. Mechanical Properties of Eco-Friendly Cements-Based Glass Powder in Aggressive Medium. Mater. Today Proc. 2022, 58, 1582–1587. [Google Scholar] [CrossRef]

- Emad, W.; Mohammed, A.S.; Bras, A.; Asteris, P.G.; Kurda, R.; Muhammed, Z.; Hassan, A.M.T.; Qaidi, S.M.A.; Sihag, P. Metamodel Techniques to Estimate the Compressive Strength of UHPFRC Using Various Mix Proportions and a High Range of Curing Temperatures. Constr. Build. Mater. 2022, 349, 128737. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled Waste Glass as Fine Aggregate Replacement in Cementitious Materials Based on Portland Cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Properties of Concrete Contains Mixed Colour Waste Recycled Glass as Sand and Cement Replacement. Constr. Build. Mater. 2008, 22, 713–720. [Google Scholar] [CrossRef]

- Yildizel, S.A.; Tayeh, B.A.; Calis, G. Experimental and Modelling Study of Mixture Design Optimisation of Glass Fibre-Reinforced Concrete with Combined Utilisation of Taguchi and Extreme Vertices Design Techniques. J. Mater. Res. Technol. 2020, 9, 2093–2106. [Google Scholar] [CrossRef]

- Al Saffar, D.M.; Tawfik, T.A.; Tayeh, B.A. Stability of Glassy Concrete under Elevated Temperatures. Eur. J. Environ. Civ. Eng. 2022, 26, 3157–3168. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part IV: Durability Properties, Cost Assessment, Applications, and Challenges. Case Stud. Constr. Mater. 2022, 17, e01271. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Ahmed, S.N.; Hamah Sor, N.; Ahmed, M.A.; Qaidi, S.M.A. Thermal Conductivity and Hardened Behavior of Eco-Friendly Concrete Incorporating Waste Polypropylene as Fine Aggregate. Mater. Today Proc. 2022, 57, 818–823. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Faraj, R.H.; Qaidi, S.M.A.; Mohammed, A.A. Compressive Strength of Geopolymer Concrete Modified with Nano-Silica: Experimental and Modeling Investigations. Case Stud. Constr. Mater. 2022, 16, e01036. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, S.Y.; Yang, E.I. Evaluation of Durability of Concrete Substituted Heavyweight Waste Glass as Fine Aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal Properties of Cement Mortars Containing Waste Glass Aggregate and Nanosilica. Procedia Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Wang, W.C.; Chen, B.T.; Wang, H.Y.; Chou, H.C. A Study of the Engineering Properties of Alkali-Activated Waste Glass Material (AAWGM). Constr. Build. Mater. 2016, 112, 962–969. [Google Scholar] [CrossRef]

- Wang, C.C.; Wang, H.Y.; Chen, B.T.; Peng, Y.C. Study on the Engineering Properties and Prediction Models of an Alkali-Activated Mortar Material Containing Recycled Waste Glass. Constr. Build. Mater. 2017, 132, 130–141. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. A Comparative Study on the Feasible Use of Recycled Beverage and CRT Funnel Glass as Fine Aggregate in Cement Mortar. J. Clean. Prod. 2012, 29–30, 46–52. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Concrete with Recycled Glass as Fine Aggregates. ACI Mater. J. 2014, 111, 47–57. [Google Scholar]

- Ling, T.C.; Poon, C.S.; Kou, S.C. Feasibility of Using Recycled Glass in Architectural Cement Mortars. Cem. Concr. Compos. 2011, 33, 848–854. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D.; Hajimohammadi, A. Effect of Recycled Glass Fines on Mechanical and Durability Properties of Concrete Foam in Comparison with Traditional Cementitious Fines. Cem. Concr. Compos. 2019, 99, 120–129. [Google Scholar] [CrossRef]

- Topçu, I.B.; Boǧa, A.R.; Bilir, T. Alkali–Silica Reactions of Mortars Produced by Using Waste Glass as Fine Aggregate and Admixtures Such as Fly Ash and Li2CO3. Waste Manag. 2008, 28, 878–884. [Google Scholar] [CrossRef] [PubMed]

- Jin, W.; Meyer, C.; Baxter, S. “Glascrete”-Concrete with Glass Aggregate. ACI Struct. J. 2000, 97, 208–213. [Google Scholar]

- Idir, R.; Cyr, M.; Tagnit-Hamou, A. Use of Fine Glass as ASR Inhibitor in Glass Aggregate Mortars. Constr. Build. Mater. 2010, 24, 1309–1312. [Google Scholar] [CrossRef]

- Prezzi, M.; Monteiro, P.J.M.; Sposito, G. The Alkali-Silica Reaction, Part I: Use of the Double-Layer Theory to Explain the Behavior of Reaction-Product Gels. ACI Mater. J. 1997, 94, 10–17. [Google Scholar]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of Recycled Waste Glass Sand as Partial Replacement of Sand in Concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Yang, C.C.; Huang, R.; Yeih, W.; Sue, I.C. Aggregate Effect on Elastic Moduli of Cement-Based Composite Materials. J. Mar. Sci. Technol. 1995, 3, e2500. [Google Scholar] [CrossRef]

- Rashid, K.; Hameed, R.; Ahmad, H.A.; Razzaq, A.; Ahmad, M.; Mahmood, A. Analytical Framework for Value Added Utilization of Glass Waste in Concrete: Mechanical and Environmental Performance. Waste Manag. 2018, 79, 312–323. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.X.; Yan, X.; He, P.; Poon, C.S. Sustainable Design of Pervious Concrete Using Waste Glass and Recycled Concrete Aggregate. J. Clean. Prod. 2019, 234, 1102–1112. [Google Scholar] [CrossRef]

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of Using Recycled Waste Glass Coarse Aggregates on the Hydrodynamic Abrasion Resistance of Concrete. Constr. Build. Mater. 2021, 268, 121177. [Google Scholar] [CrossRef]

- Srivastava, V.; Gautam, S.P.; Agarwal, V.C.; Mehta, P.K. Glass Wastes as Coarse Aggregate in Concrete. J. Environ. Nanotechnol. 2013, 3, 67–71. [Google Scholar] [CrossRef]

- Shen, P.; Zheng, H.; Liu, S.; Lu, J.X.; Poon, C.S. Development of High-Strength Pervious Concrete Incorporated with High Percentages of Waste Glass. Cem. Concr. Compos. 2020, 114, 103790. [Google Scholar] [CrossRef]

- Yu, X.; Tao, Z.; Song, T.Y.; Pan, Z. Performance of Concrete Made with Steel Slag and Waste Glass. Constr. Build. Mater. 2016, 114, 737–746. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of Combined Use of Ground Glass Powder and Crushed Glass Aggregate on Selected Properties of Portland Cement Concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, P.; Parashar, A.K. Use of Waste Glass and Demolished Brick as Coarse Aggregate in Production of Sustainable Concrete. Mater. Today Proc. 2022, 62, 4030–4035. [Google Scholar] [CrossRef]

- Serpa, D.; De Brito, J.; Pontes, J. Concrete Made with Recycled Glass Aggregates: Mechanical Performance. Mater. J. 2015, 112, 29–38. [Google Scholar] [CrossRef]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of Recycled Materials in Development of Self-Compacting Concrete: Mixing Recycled Concrete Aggregates—Windshield Waste Glass Aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Máčalová, K.; Václavík, V.; Dvorský, T.; Figmig, R.; Charvát, J.; Lupták, M. The Use of Glass from Photovoltaic Panels at the End of Their Life Cycle in Cement Composites. Materials 2021, 14, 6655. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Shi, D.; Wang, J.; Zhao, Y.; Yu, K.; Liu, Y.; Cui, H.; Wang, L. Value-Added Recycling of Cathode Ray Tube Funnel Glass into High-Performance Radiation Shielding Concrete. Resour. Conserv. Recycl. 2023, 199, 107252. [Google Scholar] [CrossRef]

- Pauzi, N.N.M.; Jamil, M.; Hamid, R.; Abdin, A.Z.; Zain, M.F.M. Influence of Spherical and Crushed Waste Cathode-Ray Tube (CRT) Glass on Lead (Pb) Leaching and Mechanical Properties of Concrete. J. Build. Eng. 2019, 21, 421–428. [Google Scholar] [CrossRef]

- Liu, H.; Shi, J.; Qu, H.; Ding, D. An Investigation on Physical, Mechanical, Leaching and Radiation Shielding Behaviors of Barite Concrete Containing Recycled Cathode Ray Tube Funnel Glass Aggregate. Constr. Build. Mater. 2019, 201, 818–827. [Google Scholar] [CrossRef]

- Stehlík, M.; Knapová, J.; Kostka, V. Possibilities of Use of Glass Recyclate from Photovoltaic Panels for Concrete Masonry Units. IOP Conf. Ser. Mater. Sci. Eng. 2019, 549, 012006. [Google Scholar] [CrossRef]

- He, S.Y.; Diao, Y.; He, H.Z.; Wang, J.; Yang, Y.; Li, L. Flexural Performance in Concrete-Filled Steel Tubes with Waste Glass Aggregate: Role of Replacement Ratios and Structural Enhancements. Constr. Build. Mater. 2025, 463, 140083. [Google Scholar] [CrossRef]

- Dilek, U. Effects of Manufactured Sand Characteristics on Water Demand of Mortar and Concrete Mixtures. J. Test. Eval. 2015, 43, 562–573. [Google Scholar] [CrossRef]

- Donza, H.; Cabrera, O.; Irassar, E.F. High-Strength Concrete with Different Fine Aggregate. Cem. Concr. Res. 2002, 32, 1755–1761. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Gnappi, G.; Moriconi, G.; Montenero, A. Reuse of Ground Waste Glass as Aggregate for Mortars. Waste Manag. 2005, 25, 197–201. [Google Scholar] [CrossRef] [PubMed]

- Poutos, K.H.; Alani, A.M.; Walden, P.J.; Sangha, C.M. Relative Temperature Changes within Concrete Made with Recycled Glass Aggregate. Constr. Build. Mater. 2008, 22, 557–565. [Google Scholar] [CrossRef]

- Cho, W.J.; Kwon, S.; Choi, J.W. The Thermal Conductivity for Granite with Various Water Contents. Eng. Geol. 2009, 107, 167–171. [Google Scholar] [CrossRef]

- Disfani, M.M.; Arulrajah, A.; Younus Ali, M.M.; Bo, M.W. Fine Recycled Glass: A Sustainable Alternative to Natural Aggregates. Int. J. Geotech. Eng. 2011, 5, 255–266. [Google Scholar] [CrossRef]

- Surendran, H.; Akhas, P.K. Properties of High-Performance Concrete Incorporating Toughened Glass Waste Coarse Aggregate: An Experimental Study. Structures 2024, 60, 105897. [Google Scholar] [CrossRef]

- Yang, Q.; Fan, Z.; Yang, X.; Hao, L.; Lu, G.; Fini, E.H.; Wang, D. Recycling Waste Fiber-Reinforced Polymer Composites for Low-Carbon Asphalt Concrete: The Effects of Recycled Glass Fibers on the Durability of Bituminous Composites. J. Clean. Prod. 2023, 423, 138692. [Google Scholar] [CrossRef]

- Yu, M.; Jin, D.; Liu, Y.; You, Z.; Li, Y. Performance Evaluation of Surface Treatment Waste Glass as Aggregate in Asphalt Mixture. Case Stud. Constr. Mater. 2024, 21, e03767. [Google Scholar] [CrossRef]

- Phan, T.M.; Kang, S.P.; Vo, H.V.; Park, D.W. Evaluation on Performances of Cold Asphalt Mixture Containing Recycled Waste Glass and Red Mud. Case Stud. Constr. Mater. 2024, 20, e03194. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, M.; Wu, S.; Yang, T.; Zhang, J.; Zhao, Y. Effect of Waste Glass Aggregate on Performance of Asphalt Micro-Surfacing. Constr. Build. Mater. 2021, 307, 125133. [Google Scholar] [CrossRef]

- Jin, D.; Wang, J.; You, L.; Ge, D.; Liu, C.; Liu, H.; You, Z. Waste Cathode-Ray-Tube Glass Powder Modified Asphalt Materials: Preparation and Characterization. J. Clean. Prod. 2021, 314, 127949. [Google Scholar] [CrossRef]

- West, R.C.; Page, G.C.; Murphy, K.H. Evaluation of Crushed Glass in Asphalt Paving Mixtures. Astm Spec. Tech. Publ. 1993, 1193, 117. [Google Scholar]

- Tucci, A.; Esposito, L.; Rastelli, E.; Palmonari, C.; Rambaldi, E. Use of Soda-Lime Scrap-Glass as a Fluxing Agent in a Porcelain Stoneware Tile Mix. J. Eur. Ceram. Soc. 2004, 24, 83–92. [Google Scholar] [CrossRef]

- Andreola, F.; Barbieri, L.; Karamanova, E.; Lancellotti, I.; Pelino, M. Recycling of CRT Panel Glass as Fluxing Agent in the Porcelain Stoneware Tile Production. Ceram. Int. 2008, 34, 1289–1295. [Google Scholar] [CrossRef]

- Andreola, F.; Barbieri, L.; Bondioli, F.; Lancellotti, I.; Miselli, P.; Ferrari, A.M. Recycling of Screen Glass into New Traditional Ceramic Materials. Int. J. Appl. Ceram. Technol. 2010, 7, 909–917. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, W.K.; Chang, T.C.; Lee, C.H.; Lin, C.H. Recycling Thin Film Transistor Liquid Crystal Display (TFT-LCD) Waste Glass Produced as Glass–Ceramics. J. Clean. Prod. 2009, 17, 1499–1503. [Google Scholar] [CrossRef]

- Zaid, M.H.M.; Matori, K.A.; Abdul Aziz, S.H.; Kamari, H.M.; Wahab, Z.A.; Fen, Y.W.; Alibe, I.M. Synthesis and Characterization of Low Cost Willemite Based Glass–Ceramic for Opto-Electronic Applications. J. Mater. Sci. Mater. Electron. 2016, 27, 11158–11167. [Google Scholar] [CrossRef]

- Xi, C.; Zheng, F.; Xu, J.; Yang, W.; Peng, Y.; Li, Y.; Li, P.; Zhen, Q.; Bashir, S.; Liu, J.L. Preparation of Glass-Ceramic Foams Using Extracted Titanium Tailing and Glass Waste as Raw Materials. Constr. Build. Mater. 2018, 190, 896–909. [Google Scholar] [CrossRef]

- Xin, Y.; Kurmus, H.; Mohajerani, A.; Dallol, Y.; Lao, Y.; Robert, D.; Pramanik, B.; Tran, P. Recycling Crushed Waste Beer Bottle Glass in Fired Clay Bricks. Buildings 2021, 11, 483. [Google Scholar] [CrossRef]

- Darweesh, H.H.M. Recycling of Glass Waste in Ceramics—Part I: Physical, Mechanical and Thermal Properties. SN Appl. Sci. 2019, 1, 1274. [Google Scholar] [CrossRef]

- Abdeen, H.H.; Shihada, S.M. Properties of Fired Clay Bricks Mixed with Waste Glass. J. Sci. Res. Rep. 2017, 13, 1–9. [Google Scholar] [CrossRef]

- Ali, A.; Hanif, F.; Ali, N.; Nadeem, M.; Rashid, M.U. Mutations in Burnt-Clay Brick Properties Attributable to Waste Glass. Mehran Univ. Res. J. Eng. Technol. 2021, 40, 898–905. [Google Scholar] [CrossRef]

| Type of Glass | Replacement of Cement, % | Slump | Porosity % | Density | Chloride Permeability | ASR | References |

|---|---|---|---|---|---|---|---|

| Bottle glass | 30, 50, 70 | ↓ | [73] | ||||

| 5, 10, 15, 20, 25 | ↑ | [66] | |||||

| Soda-lime glass | 15, 30, 45, 60 | ↑ | [76] | ||||

| Window glass sheets | 10 | ↓ | [78] | ||||

| Industrial glass | 10, 20 | ↓ | [93] | ||||

| E-waste glass | 20 | ↑↓ | ↓ | [80] | |||

| CRT glass | 5, 10, 15, 20, 35 | ↓ | ↓ | [81] | |||

| CRT and mixed container glass (MRF) | 20 | ↓ | [82] | ||||

| LCD glass | 5, 10, 15, 20, 30 | ↓ | ↓ | [85,94] | |||

| LCD, LED TV screen and washing machine glass (WM) | 5, 10, 20 | ↓↑ | ↓ | [86] | |||

| Household appliance glass | 10, 20, 30 | ↓ | ↓ | [87] | |||

| Milled window glass | 20 | ↑ | ↑ | [89] | |||

| Fluorescent lamp glass | 20, 30, 40 | ↓ | [90] | ||||

| Photovoltaic solar panel glass | 0,3, 1, 3, 5 | ↓ | [92] |

| Type of Glass | Replacement of Sand, % | Particle Size | Slump | Porosity | Density | Chloride Permeability | ASR | Elasticity | Flexural Strength | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Container glass | 5, 10, 15, 20 | <4.75 mm | ↓ | ↓ | [100] | |||||

| 20, 40, 60 | <4.76 mm | ↑ | [101] | |||||||

| 0, 18, 19, 20, 21, 22, 23, 24 | 150–600 µm | ↑ | ↓ | ↑ | [102] | |||||

| 15, 30 | <4.75 mm | ↑ | ↓ | [103] | ||||||

| 10, 15, 20 | 0.15–4.75 mm | ↓ | ↓ | ↑ | [104] | |||||

| 15, 20, 30, 50 | <5 mm | ↓ | [105] | |||||||

| Container glass | 25, 50, 70, 100 | <5 mm | ↓ | [106] | ||||||

| 25, 50, 75, 100 | <600 μm | ↑ | ↓↑ | [107] | ||||||

| 10, 20, 30, 40, 50 | 0.075–5 mm | ↓ | ↓ | ↓ | [108] | |||||

| LCD glass | 20, 40, 60, 80 | <4.75 mm | ↓ | ↓ | [111] | |||||

| 10, 20, 30 | <3.37 mm | ↑ | ↓ | ↓↑ | [112,113] | |||||

| CRT glass | 50, 100 | <5 mm | ↑ | ↓ | ↓ | [115] | ||||

| 20, 40, 60, 80, 100 | <4.75 mm | ↓ | ↓ | [118] | ||||||

| 25, 50, 75, 100 | 0.6–1.18 mm | ↑ | ↓↑ | [119,126] | ||||||

| Various e-waste glass | 10, 20, 30, 40, 50 | <4.75 mm | ↓ | [120] | ||||||

| 5, 10, 15, 20 | <4.75 mm | ↓ | ↑ | [127] | ||||||

| Photovoltaic solar panel glass | 20, 80, 100 | <4.75 mm | ↓ | [121] | ||||||

| 100 | <4.75 mm | ↑ | [122] | |||||||

| Fluorescent lamp glass | 10, 20, 30, 40 | <1.18 mm | ↑ | ↓ | [123] | |||||

| 10, 30, 50, 100 | <2 mm, 2–8 mm | ↑ | ↑ | ↓ | [124] | |||||

| 100 | ∼10–20 μm | ↓ | [125,128] | |||||||

| 12.5, 25, 37.5, 100 | <100 μm | ↑ | [129] |

| Type of Glass | Replacement of Sand, % | Particle Size | Slump | Porosity | Density | Pb Leaching | ASR | Elasticity | Flexural Strength | References |

|---|---|---|---|---|---|---|---|---|---|---|

| Container glass | 10, 20, 30 | <20 mm | ↓ | ↓ | [179] | |||||

| 25, 50, 75, 100 | 2.36–10 mm | ↓ | ↓ | [180] | ||||||

| Container glass | 12,5, 25, 50, 100 | 10–20 mm | ↓ | ↑↓ | [181] | |||||

| Bottle glass | 25, 50, 75, 100 | 2.36–5 mm | ↓↑ | ↓ | [183] | |||||

| 25, 50, 75, 100 | 4–16 mm | ↓ | ↑ | [131] | ||||||

| 10, 25, 50, 100 | 10–19 mm | ↑ | [116] | |||||||

| Bottle glass | 16.5, 17.5 | 4.9–16 mm | ↓ | ↑ | [184] | |||||

| Soda-lime glass | 100 | 4.75–9.5 mm | ↓ | ↑ | ↓ | [185] | ||||

| Windows and bottle glass | 25, 50, 75, 100 | <20 mm | ↓ | [186] | ||||||

| Windows and car front windshield glass | 5, 10, 20 | 4–11.2 mm | ↑↓ | [187] | ||||||

| Car front windshield glass | 25, 50, 75, 100 | 3–16 mm | ↓ | [188] | ||||||

| Photovoltaic solar panel glass | 100 | <10 mm | ↓ | ↓ | [189] | |||||

| 50, 100 | <8 mm | ↓ | [193] | |||||||

| CRT glass | 50, 100 | <20 mm | ↓ | ↑ | ↑ | ↑ | [190] | |||

| CRT glass | 100 | 4.75–19 mm | ↑ | ↓↑ | ↓ | [191] | ||||

| 10, 20, 30 | 4–10 mm | ↑ | ↓ | ↑ | ↑ | ↓ | [147,192] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bekerė, K.; Malaiškienė, J. Utilisation of Different Types of Glass Waste as Pozzolanic Additive or Aggregate in Construction Materials. Processes 2025, 13, 1613. https://doi.org/10.3390/pr13051613

Bekerė K, Malaiškienė J. Utilisation of Different Types of Glass Waste as Pozzolanic Additive or Aggregate in Construction Materials. Processes. 2025; 13(5):1613. https://doi.org/10.3390/pr13051613

Chicago/Turabian StyleBekerė, Karolina, and Jurgita Malaiškienė. 2025. "Utilisation of Different Types of Glass Waste as Pozzolanic Additive or Aggregate in Construction Materials" Processes 13, no. 5: 1613. https://doi.org/10.3390/pr13051613

APA StyleBekerė, K., & Malaiškienė, J. (2025). Utilisation of Different Types of Glass Waste as Pozzolanic Additive or Aggregate in Construction Materials. Processes, 13(5), 1613. https://doi.org/10.3390/pr13051613