1. Introduction

With the growing emphasis on environmental sustainability and the pressing issue of energy shortages, the industrial sector has attracted considerable scrutiny due to its substantial share of global energy consumption [

1]. Current estimates suggest that approximately 20–50% of the energy input in industrial processes is expelled as waste heat, including exhaust gases, cooling water, heat from equipment surfaces, and thermal losses during product heating [

2]. This extensive thermal energy dissipation into the environment not only represents inefficiency but also poses environmental risks and heightens operational energy costs for enterprises. Thus, the recovery and utilization of waste heat are essential strategies for reducing greenhouse gas emissions and improving overall energy efficiency.

The Organic Rankine Cycle (ORC) represents an efficient method for recovering industrial waste heat in the medium and low-temperature range (100–250 °C), enabling the conversion of low-grade thermal energy into high-quality electrical energy [

3,

4]. During the thermoelectric conversion process, the ORC system harnesses industrial waste heat (or residual heat) to elevate the organic working fluid from a condensed state to a vaporized state, which then drives an expander (or turbine) to perform mechanical work, subsequently driving a generator to produce electricity [

5,

6]. In the context of escalating environmental pollution and the depletion of non-renewable resources, the ORC system offers several advantages, including a simple structure and high waste heat recovery efficiency, thus presenting significant potential for development and optimization [

7,

8].

One of the key research topics in this field is how to improve the performance and efficiency of ORC systems based on their basic thermoelectric conversion characteristics. Some scholars have focused on improving the hardware components of ORC systems and conducted related research and exploration work. Rohmah et al. evaluated the effect of different plate spacing on the total heat transfer area and pressure drop [

9]. Ravi et al. evaluated the performance of heat recovery by changing the protrusion method and geometric shape of the fins [

10]. Zhao et al. studied the working principle of a vortex expander and achieved an isentropic efficiency of 38% to 86% under laboratory conditions [

11].

Other scholars focus on the working fluid efficiency of ORC systems [

12]. By selecting different working fluids, the power generation efficiency of the ORC system can be improved. Quoilin et al. used a mixture of pure HCFC-365mfc and pure YR-1800 as the working substance [

13]. Compared with pure substances such as HC601, HFC245fa, and HFC134a, this mixture exhibits excellent performance during the cycling process.

Zhi et al. analyzed the effect of non-azeotropic mixtures on the performance of ORC systems [

14]. Wang et al. investigated the thermodynamic properties of ORC systems using a mixture of R245fa/R134a [

15]. Li et al. conducted a comprehensive energy analysis to optimize the ORC system of isobutane and isopentane mixtures [

16]. Research on improving the performance of ORC systems by changing the structure and working fluid is of great significance for enhancing system efficiency. However, these studies mainly focus on the impact of fluid and structural adjustments on system performance. In practical applications, how to quickly and effectively evaluate ORC conversion efficiency and evaluate system performance remains a key issue. The above research has explored the heat utilization and power generation efficiency of ORC system in terms of structural parameters and fluids, etc. With the development of technology, ORC technology and VCC technology have attracted the attention of scholars. Tomasz Suchocki [

17] introduced a combined ORC-VCC technology that uses ORC to recover waste heat and then further utilizes the heat through VCC, thereby achieving higher energy recovery efficiency. Zhiqi Wang [

18] established an experimental apparatus based on the coupling of the Organic Rankine Cycle (ORC) with the Vapor Compression Cycle (VCC). Off-design experiments were conducted under various cooling water temperatures and evaporation temperatures to gain a deeper understanding of the changes in system performance. The research results indicated that the cooling water temperature has a greater impact on the operational characteristics of the system than the cooling water flow rate. As the cooling water temperature decreases and its flow rate increases, the cooling capacity of the system increases, while the coefficient of performance remains relatively unchanged. With the increase in cooling water temperature, the isentropic efficiency of the expander and compressor increases to 74.8% and 72.5%, respectively. Xiaoxia Xia [

19] introduced two novel adjustable composition Organic Rankine Cycle systems combined with vapor compression refrigeration (ORC-VCR) and compared them with the traditional ORC-VCR. The results showed that whether the performance of the two new systems can be improved depends on which subsystem the saturated vapor enters after separation. For the CA-LORC-VVCR system (where the saturated vapor enters the VCR subsystem after separation), its thermodynamic and economic performance is better than that of the traditional T-ORC-VCR system, whereas for the CA-VORC-LVCR system (where the saturated vapor enters the ORC subsystem after separation), the situation is the opposite.

Net power generation is a key indicator of ORC systems, which can directly represent the final thermoelectric conversion results of the system, effectively evaluating the performance and efficiency of ORC systems. Therefore, it is of great significance to effectively and accurately measure and analyze net power generation. Many scholars have conducted extensive research on the net power generation of ORC systems and its influencing factors. Fiachi et al. compared and analyzed the thermoelectric conversion results of a 50kW centripetal turbine [

20]. Rayegan et al. proposed a screening method for working substances considering covariates such as net power generation, thermal efficiency, steam expansion ratio, and effective energy efficiency [

21]. Lv et al. introduced a conceptual ORC system and conducted thermal and economic analysis [

22]. Feng et al. proposed a multi-generation ORC system that achieved a net total energy output of 19.89 megawatts, with a net total energy efficiency of 52.77% and a total effective energy efficiency of 50.14% [

23].

Mustapic Nenad et al. studied the application of ORC systems in geothermal energy, using the principle of shunt [

24]. The ORC system achieved maximum net output power at heat source temperatures of 150 °C, 160 °C, 170 °C, and 180 °C. Additionally, Laghari et al. utilized R245fa/R600a as the working fluid to investigate energy efficiency and net output power by varying evaporator pressure [

25]. They found that the system achieved optimal performance when the evaporator pressure reached its maximum value, with a corresponding net output power of 2326 kW.

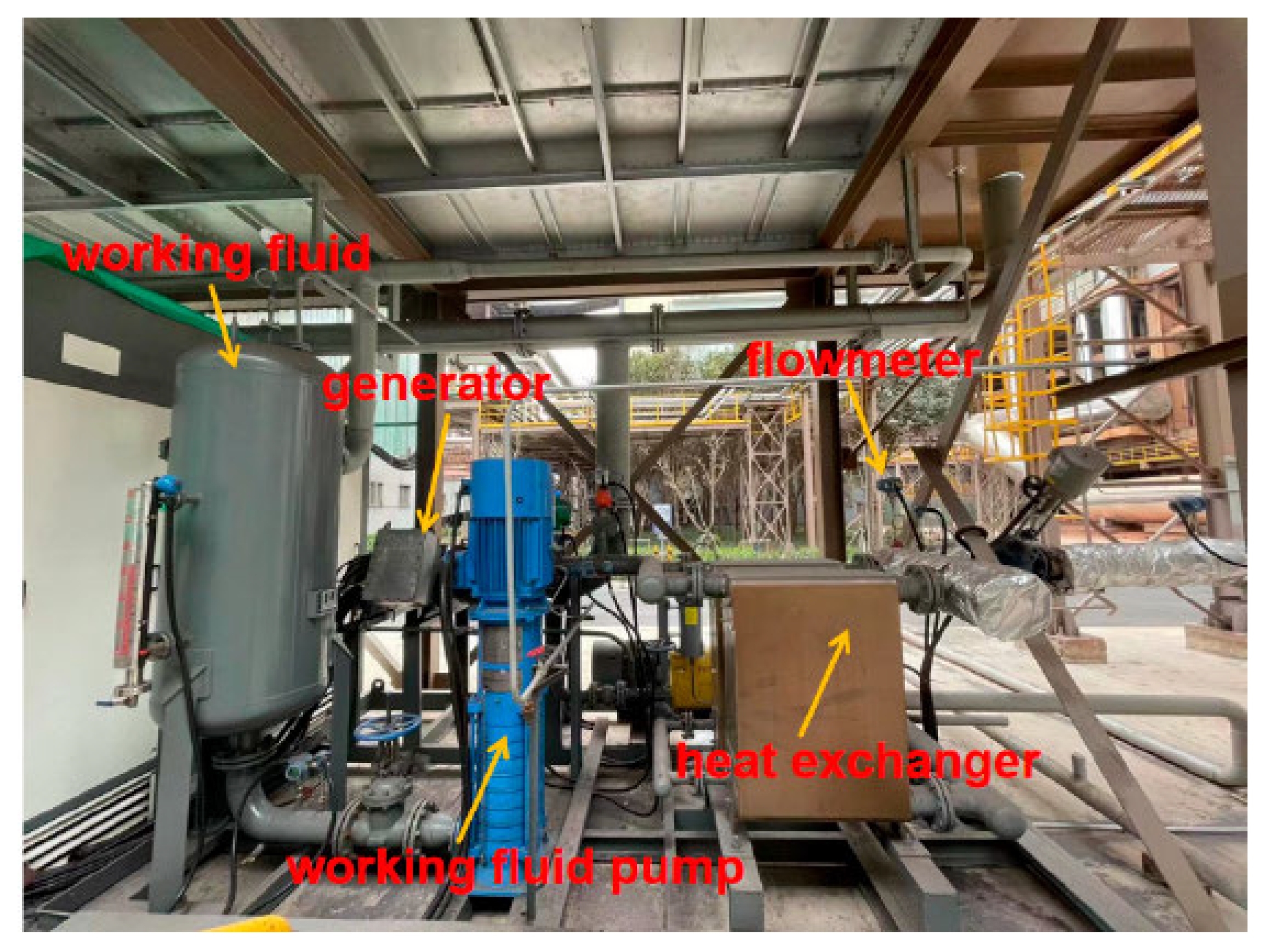

However, in current research results, net power generation is usually studied together with other parameters of ORC systems, and there are few reports on directly measuring and analyzing the net power generation of the system based on the power generation process. In addition, most generators in existing ORC systems adopt spiral mechanical contact structures [

26], which means that the generator rotor will be affected by friction during system operation, which will bring many adverse factors to the evaluation and analysis of system performance. In order to improve the waste heat utilization efficiency and power generation efficiency of the system, this study designed a magnetic levitation eddy current rotor ORC system and analyzed the net power generation during the low-temperature waste heat power generation process based on the system. The power generation efficiency and waste heat utilization rate of the system were calculated. Due to the use of magnetic levitation ORC system, it can effectively overcome the energy loss caused by mechanical friction in current ORC systems and analyze the performance of the system without considering frictional energy loss.

The organizational structure of this article is as follows:

Section 2 mainly introduces the relevant theories and analysis of net power generation.

Section 3 introduces the experimental system designed in this study.

Section 4 is about experiments and result analysis, and

Section 5 is the conclusion of this article.

2. Theoretical Analysis of Net Power Generation

In the Organic Rankine Cycle (ORC) system, industrial flue gas, which contains waste heat, is used to heat the organic working fluid from its condensed state to its vaporized form. The high-temperature steam then drives the expander (or turbine), which performs mechanical work, subsequently driving the generator to produce electricity. However, to ensure the ORC system operates efficiently, additional components such as a working fluid pump and cooling pump are required, which consume electrical energy during operation. Therefore, the net power generation of the ORC system is the difference between the electrical output from the generator and the energy consumed by the system’s auxiliary components, as expressed by the following equation [

2]:

where

represents the net power generation of the ORC system,

and

represent the electricity generation and electricity consumption (or power consumption) of the ORC system, respectively, and

denotes the operational time of the ORC system.

2.1. Electricity Generation Analysis of the ORC System

The electricity generation process of the ORC system is governed by the laws of thermodynamics, which means that during the process in which the expander is driven to generate electricity, the internal energy of the organic working fluid will change accordingly. Therefore, the organic working fluid in the ORC system exists in different states throughout the various stages of the cycle. The state of the working fluid is influenced by numerous factors, such as pressure, temperature, component composition, heat source temperature, and flow rate, which can be expressed as follows [

3]:

where

represents the state equation,

represents the functional relationship;

represent the pressure of the working fluid (unit is

), the temperature of the working fluid (unit is °C), the specific volume of the working fluid (unit is

), and the component content of the working fluid, respectively; and

represents other influencing factors such as heat source temperature and flow rate.

Based on Equation (2), under specific temperature

and pressure

conditions (that is, temperature

and pressure

are known quantities), the state of the work fluid can be further characterized by the specific enthalpy and specific entropy, which can be expressed as

where

and

represent the specific enthalpy and specific entropy of the working fluid, respectively.

According to Equations (2) and (3), the ORC system’s working fluid transitions between evaporation (heated by waste heat) and condensation (cooled by condensate), enabling steady electricity generation. This process can be modeled with a linear function correlating to the system’s operating time.

where

represents the slope of the linear function,

represents the running time of the ORC system, and

represents the electricity generation of the system at start-up.

Under actual operating conditions, the ORC power generation system is subject to various factors such as the operating environment, the characteristics of the flue gas, and the operational state of the system. These factors lead to a slight deviation between the actual electricity generation and the ideal (preset) electricity generation of the system. Furthermore, because the aforementioned influencing factors are difficult to detect and measure with high accuracy, the difference between actual and ideal electricity generation remains uncertain. In this paper, this discrepancy is represented by a random small quantity, and thus Equation (4) should be revised as follows:

where

represents the smaller random quantity corresponding to the electricity generation.

Based on Equation (5), during the operation of the ORC system, the corresponding electricity generation and system running time satisfy a functional relationship that increases approximately linearly. In other words, the electricity generation of the ORC system increases roughly in proportion to the running time.

2.2. Electricity Consumption Analysis of the ORC System

To ensure that the ORC system continues to generate electricity stably, some components within the system consume electrical energy during operation. This electricity consumption can be classified into two types, deterministic and indeterministic consumption, which are expressed as follows:

where

and

represent the deterministic electricity consumption and indeterministic electricity consumption, respectively.

Deterministic electricity consumption

primarily refers to the electricity consumed by components such as the working fluid pump, the cooling pump, and others during operation. Therefore, deterministic electricity consumption arises once the ORC system is started and increases steadily with the system’s running time. Additionally, these components may be affected by both internal and external factors during operation, such as mechanical fatigue and the operating environment, which can cause fluctuations in electricity consumption within a small range. Therefore, deterministic electricity consumption

can be expressed by a function that increases approximately linearly, as follows:

where

represents the slope of the linear function,

represents the running time of the ORC system,

represents the electricity consumption corresponding to the ORC system after start-up, and

is a small random quantity, which represents the fluctuation value of the deterministic electricity consumption in a small range.

For indeterministic electricity consumption

, it primarily arises from the frictional losses generated by the expander during the electricity generation process. Since these frictional losses are typically difficult to calculate with high accuracy, the corresponding electricity consumption is uncertain; that is, indeterministic electricity consumption

is a random variable that varies with the system’s running time. However, in the ORC system used in this study, because the expander employs a magnetic levitation vortex rotor structure, there is no direct mechanical contact between the generator rotors, meaning that the expander generates only minimal frictional losses during electricity generation. Therefore, in this paper, indeterministic electricity consumption

is represented by a random small quantity

that varies over time, expressed as

Based on Equations (6)–(8), the electricity consumption of the ORC system can be expressed as

where

is a smaller random quantity corresponding to the electricity consumption, which represents the fluctuation value of the electricity consumption in a smaller range.

Based on Equation (9), the corresponding electricity consumption during ORC system operation can be expressed as a function that includes the initial value and increases approximately linearly with running time.

2.3. Net Power Generation Analysis of ORC System

Based on Equations (1), (5), and (9), the net power generation of the ORC system can be expressed as

According to Equation (10), when the ORC system is just started, the electricity generation is less than the electricity consumption, that is,

is less than

. During the operation of the ORC system, although both the electricity generation and electricity consumption of the system increase with the operation time, the electricity generation increases faster than the electricity consumption, so

is more than

. In addition, for the two smaller random quantities

and

introduced in the electricity generation process and the electricity consumption process, their values are much smaller than the net power generation of the system. Therefore, the net power generation of the ORC system can be further modified and expressed as

where

represents the slope of the net power generation changing with time,

represents the relative electricity consumption (intercept) generated by the system at start-up, and

is the smaller random quantity corresponding to the net power generation, which represents the fluctuation value of the net power generation in a smaller range.

Based on Equation (11), the net power generation of the ORC system can be expressed as a function whose initial value is negative and increases approximately linearly with running time. Therefore, the electricity generation process of the ORC system can be divided into three stages: the stage where electricity generation is less than electricity consumption (with negative net power generation, that is, the net power generation of the system is mainly affected by electricity consumption), the stage where electricity generation is nearly equal to electricity consumption (with net power generation approaching zero), and the stage where electricity generation is more than electricity consumption (with positive net power generation).

4. Experiment and Result Analysis

In order to verify the theoretical accuracy of the net power generation analysis and explore the power generation efficiency of the system, this study utilized the constructed Maglev Vortex Rotor ORC system, with a steel smelter as the primary experimental site. The flue gas heat discharged after sintering served as the heat recovery source, and R245fa was used as the working fluid to conduct relevant experiments and analyses on the system’s net power generation. The parameters of R245fa were as follows: molecular weight was 134 g/mol, boiling point at 1 atm was 15.14 °C, critical temperature was 154.01 °C, critical pressure was 3.651 MPa, critical density was 516 kg/m

3, and safety classification was B1. The location and type of collection experiments used in the study are provided in

Table 3.

Under the actual working conditions, the experimental data recording period was 20 days, with a data recording interval of 10–20 s. During the experiment, the sintering flue gas was generated in the actual production process of the factory (specifically, the third sintering flue gas). Thus, the waste heat of the flue gas exhibited certain fluctuations at different time intervals, leading to variations in temperature, flow rate, and pressure when the flue gas entered the ORC system. In addition, the ambient temperature during the experimental period ranged from 10 °C to 20 °C, with adverse weather conditions such as precipitation, wind, and high temperatures. Therefore, the experimental equipment experienced certain differences in external conditions such as temperature and humidity. After the experimental equipment started, the experimental data were recorded continuously.

4.1. Analysis of Net Power Generation Process

4.1.1. Negative Net Power Generation Stage

The negative stage of net power generation occurs within 24 h after the ORC system’s start-up. During this time interval, the electricity consumption of the system exceeds the electricity generation.

Based on within 2 h after the ORC system is started, the corresponding electricity generation, electricity consumption, and net power generation are shown in

Figure 4. Regarding the experiment, some experimental parameters, including the heat source inlet temperature, heat source inlet pressure, and heat source outlet temperature, are listed in

Table 4.

Based on

Figure 4, within 2 h after the ORC system is started, the electricity generation is 272.2 kW·h. The electricity consumption ranges from 410.7 to 430.6 kW·h, and the average electricity consumption in this interval is 420.11 kW·h. The net power generation ranges from −158.4 to −138.5 kW·h, and the average net power generation in this interval is −147.91 kW·h. Furthermore, according to

Figure 4a, immediately after the ORC system is started, the electricity consumption increases approximately linearly with the running time to maintain the normal operation of the system components. However, electricity generation is limited due to factors such as system stability and environmental complexity.

From

Table 4, it can be seen that after the ORC system is just started, the inlet temperature of the heat source and the steam flow rate of the heat source are both small, the working liquid level and pump frequency are in an unstable state, and the pump pressure is close to 0. This means that there is less effective heat source (waste heat) entering the system, which means that in this situation, the heat source cannot effectively and stably drive the ORC system to generate electricity. Therefore, during this period, the power generation remains almost unchanged, and the corresponding power generation curve becomes almost horizontal. In addition, according to the power generation and consumption curves after the system is started, it can be clearly seen that during this period, the system’s power generation is low, power consumption is high, power generation is less than electricity consumption, and net power generation is negative.

4.1.2. Near-Zero Net Power Generation Stage

The stage when the net power generation is about zero (when the electricity consumption is almost equal to the power generation) occurs between 24 and 25 h after the ORC system is started. The corresponding power generation, electricity consumption, and net power generation are shown in

Figure 5. At this stage of the experiment, some parameters such as heat source inlet temperature, heat source inlet pressure, and heat source outlet temperature are shown in

Table 5.

Furthermore, this study performed linear fitting on the electricity generation, electricity consumption, and net electricity generation generated by the ORC system during this period. The slope values and goodness of fit of the linear fitting results are shown in

Table 6.

According to the experimental results shown in

Figure 5, during the 24th to 25th hour interval after the ORC system was started, its power generation ranged from 527 to 627.5 kW·h, with an average power generation of 594.88 kW·h. The power consumption of the system ranges from 544 to 573.5 kW·h, with an average of 558.25 kW·h (near the 50th record point in the interval, the power generation is approximately equal to the electricity consumption). The net power generation ranges from −17 to 99.5 kW·h, with an average of 36.63 kW·h (close to the 50th record point, with a net power generation of approximately 0 kW·h). Meanwhile, according to

Table 5, we can also see that the inlet temperature, outlet temperature, steam flow rate, and working liquid level of the heat source are relatively stable. Compared to the data listed in

Table 4, both pump pressure and pump frequency have increased. This implies that the heat source (waste heat) entering the ORC system is relatively uniform and stable, which means that under these conditions, the ORC system can begin to effectively supply power to the outside.

In addition, according to the fitting results shown in

Table 6, the slope of power generation (0.6174) exceeds that of power consumption (0.123), indicating that although both power generation and power consumption increase with the increase in system operation time, the growth rate of power generation is faster. In addition, the net power generation slope is 0.4944 (greater than 0), and the corresponding the R-squared and adjusted R-squared values is 0.9956, close to 1. Therefore, within this interval, there is a transitional phase of positive and negative net power generation in the ORC system, and after the 50th record point, the net power generation increases approximately linearly with the system operating time.

4.1.3. Positive Net Power Generation Stage

After running the ORC system for 25 h, the net power generation becomes positive. During this period, the power consumption of the system is less than the generated electricity. This article mainly analyzes the relevant data of two time periods: running time between 25 and 26 h and running time between 264 and 408 h.

Running Time Between 25th and 26th Hours

At the 25th to 26th hour after the ORC system is started, its power generation, electricity consumption, and net power generation are shown in

Figure 6. During the experimental process, some experimental parameters (heat source inlet temperature, inlet pressure, outlet temperature, etc.) are shown in

Table 7.

Further, the electricity generation, electricity consumption, and net power generation generated by the ORC system in this interval are linearly fitted, respectively, in this paper. The slope value and goodness of fit after linear fitting are shown in

Table 8.

According to the experimental results shown in

Figure 6, within the time interval of the 25th to 26th hour after the ORC system is started, the power generation ranges from 673.9 to 878.4 kW·h, with an average of 776.36 kW·h. The range of electricity consumption is 573.5 to 617 kW·h, with an average of 595.04 kW·h. The net power generation range is 100.4 to 261.9 kW·h, with an average of 181.31 kW·h. Meanwhile, according to

Table 7, the inlet temperature and outlet temperature of the heat source, steam flow rate of the heat source, working liquid level, pump pressure, and pump frequency are all effectively stable. This means that the heat source (waste heat) entering the ORC system is uniformly stable, and the ORC system can effectively and stably generate electricity under these conditions.

In addition, according to the fitting results shown in

Table 8, the slope value of electricity generation (0.5852) exceeds that of electricity consumption (0.1257), indicating that both electricity generation and consumption increase with the system’s running time, although the growth rate of electricity generation is faster. Meanwhile, the slope value of net power generation is 0.4595 (greater than 0), and the corresponding R-square and adjusted R-square values are 0.9995 and 0.9995 (approaching 1), respectively. Therefore, the net power generation of the ORC system in this interval is positive and increases approximately linearly with the system running time.

Running Time Between 264th and 408th Hour

Within the time interval of the 264th to 408th hours after the ORC system is started (with a time interval of 144 h), the corresponding power generation, electricity consumption, and net power generation are shown in

Figure 7. During this period, the relevant experimental parameters (heat source inlet temperature, heat source inlet pressure, heat source outlet temperature, etc.) are shown in

Table 9.

Further, the electricity generation, electricity consumption, and net power generation generated by the ORC system in this interval are linearly fitted, respectively, in this paper. The slope value and goodness of fit after linear fitting are shown in

Table 10.

According to the experimental results shown in

Figure 7, within the time interval of the 264th to 408th hours after the start of the ORC system, the power generation was 41,534–75,128 kW·h, and the average power generation during this period was 58,469 kW·h. The electricity consumption ranges from 8100.7 to 14,375 kW·h. The net power generation is 33,433–60,754 kW·h, and the average net power generation in the interval is 47,236 kW·h.

Meanwhile, according to the data shown in

Table 9, the inlet and outlet temperatures of the heat source, steam flow rate, working liquid level, pump pressure, and pump frequency are all relatively stable. Consistent with the data in

Table 7, this means that the heat source (waste heat) entering the ORC system is uniformly stable, and the ORC is in a stable working state. The ORC system can effectively and stably generate electricity under these heat source conditions. In addition, compared with

Table 7, the experimental parameter values shown in

Table 9 (such as inlet and outlet temperatures of the heat source) are larger, resulting in higher power generation and net power generation. This indicates that when the ORC system has a higher heat source temperature and flow rate, more waste heat will enter the system, and the ORC system will generate more net electricity (power generation).

In addition, according to the fitting results shown in

Table 10, the slope value of electricity generation (0.7234) is more than that of electricity consumption (0.1354). That is, both electricity generation and electricity consumption increase with the running time of the system, but the growth rate of electricity generation is faster. Meanwhile, the slope value of net power generation is 0.5881 (more than 0), and the corresponding R-square and adjusted R-square values are 0.9997 (approaching 1). Therefore, the net power generation of the ORC system in this interval is positive and increases approximately linearly with the system running time.

4.1.4. Analysis of Net Power Generation

According to the actual operating conditions and the complete experimental period (from system start-up to the 20th day), the corresponding power generation, power consumption, and net power generation of the ORC system are shown in

Figure 8.

In addition, this article linearly fitted the power generation, power consumption, and net power generation of the ORC system throughout the entire experimental interval. The slope values and goodness of fit after linear fitting are shown in

Table 11.

According to the experimental results shown in

Figure 8, during the entire experimental period (from system start-up to the 20th day), the power generation was 272.2–86,793 kW·h, with an average power generation of 42,742 kW·h. The electricity consumption ranges from 410.7 to 16,503 kW·h, with an average of 8353.4 kW·h. The net power generation ranges from −186.9 to 70,290 kW·h, with an average net power generation of 3438.9 kW·h. In addition, according to the fitting results shown in

Table 11, the slope value of power generation (0.731) is greater than the slope value of electricity consumption (0.1348). Both power generation and electricity consumption increase with the increase in system operation time, but the growth rate of power generation is faster. At the same time, the slope value of net power generation is 0.5962 (greater than 0), and the corresponding R-squared sum adjusted R-squared value is 0.9999 (close to 1).

Based on the above experimental results, it can be seen that the power generation process of the ORC system constructed in this study can be divided into three stages: the stage where the power generation is less than the electricity consumption (net power generation is negative), the transition period where the power generation is basically equal to the electricity consumption (net power generation is about 0), and the stage where the power generation is greater than the electricity consumption (net power generation is positive). Meanwhile, in the above three stages, the net power generation of the ORC system increases approximately linearly with the system operating time. The above experiment indicates that the net power generation of the ORC system can be represented by a function, which has an initial negative value and increases approximately linearly with running time. That is, the net power generation of the ORC system is negative at the beginning of start-up (the power generation is less than the power consumption), and increases approximately linearly with the running time of the system.

4.2. Main Factors Affecting the System and Performance Evaluation

4.2.1. The Influence of Temperature and Flow Rate on the Performance of the System

From the above experiment, it can be seen that the temperature and flow rate of steam are the main factors affecting power generation efficiency. In order to investigate the net power generation efficiency of the proposed ORC system, this study used measured experimental data to explore the effects of different steam temperatures and flow rates on the system’s power generation.

Firstly, based on the recorded steam temperature data, we selected the range of steam temperature from 140 to 170 degrees after the system stabilized for research. The average method was used to calculate the output power of the same heat source at different steam temperatures, and the experimental results are shown in

Figure 9.

From

Figure 9, it can be seen that as the steam temperature increases, and the power generation gradually increases. This is because as the temperature of steam increases, the heat exchange between steam and working fluid in the exchanger is relatively sufficient, and the energy exchange rate per unit time is higher, and at this time, the energy carried by the working fluid is also more, so that the power generation and power generation also increase.

According to the Carnot theorem, the upper limit of a system’s efficiency is determined by the temperatures of the heat source and the cold sink. Specifically, the higher the temperature of the heat source, the higher the Carnot efficiency. This principle illustrates the direct impact of the heat source temperature on efficiency. In an Organic Rankine Cycle (ORC) system, the organic working fluid is heated from a liquid to a gaseous state and then expands through a turbine to perform work. When the temperature of the heat source increases, the working fluid obtains more heat in the evaporator, thereby entering the turbine at a higher temperature and pressure. This allows the turbine to operate under more efficient conditions, effectively reducing irreversible losses. Specifically, higher inlet temperatures and pressures help to increase the isentropic efficiency of the turbine, thereby increasing the output of mechanical work. Since the working fluid flows at a higher temperature, its heat transfer efficiency is higher, and losses are relatively minimal. Therefore, as the heat source temperature increases, the power generation capacity also increases.

The heat exchange per unit time in the evaporator varies at different steam flow rates. Based on the recorded data, this study also used the average method to calculate the output power of the same heat source at different flow rates. The results are shown in

Figure 10.

From

Figure 10, it can be seen that as the steam flow rate increases, the heat exchange capacity in the evaporator increases, and the heat obtained by the working fluid increases, resulting in an increase in enthalpy at the outlet of the organic working fluid and an increase in evaporation pressure. Therefore, as the work carried out by the turbine increases, the power generated also increases.

An increase in flow rate can enhance the heat transfer efficiency between the heat source and the organic working fluid. In the evaporator, an increased heat source flow rate means that more heat is transferred to the working fluid within a unit of time, thereby more quickly heating the fluid from a liquid to a gaseous state. This not only improves the efficiency of heat transfer but also reduces the dwell time of the heat source in the evaporator, minimizing heat loss. A higher heat source flow rate can also heat the organic working fluid more uniformly, reducing the occurrence of localized overheating or underheating. Uniform heating can decrease the temperature gradient of the working fluid in the evaporator, ensuring that the fluid enters the expander with a higher specific enthalpy drop, thus increasing the output of mechanical work. Therefore, as the flow rate increases, the power generation capacity of the system also increases.

4.2.2. System Performance Evaluation

The performance evaluation indicators of low-temperature waste heat power generation systems mainly include efficiency of waste heat power generation, waste heat utilization efficiency, etc. The efficiency of waste heat power generation refers to the ratio of the power generated by a low-temperature waste heat power generation system to the heat effectively utilized by the heat exchanger. The following formula can be used to represent it:

where

is the generating power of the system;

is the flow rate of the mass;

is the enthalpy of organic work at the exit of the heat exchanger;

is the enthalpy of organic work at the heat exchanger; and

is the efficiency of waste heat power generation.

According to Formula (12), the waste heat power generation efficiency of the Maglev Vortex Rotor ORC system designed in this study is 10.03%.

4.2.3. Comparison of Magnetic Levitation ORC Systems

In traditional Organic Rankine Cycle (ORC) systems, expanders and pumps are typically equipped with mechanical bearings, which generate mechanical friction and sealing leaks during operation. This friction not only consumes energy but also causes equipment wear and heat generation, thereby reducing the overall efficiency of the system. Moreover, mechanical friction can decrease the isentropic efficiency of expanders and pumps, while sealing leaks can reduce the circulation flow of the working fluid, further decreasing the power generation efficiency of the system.

In contrast, magnetic levitation technology suspends the rotor in the air using a magnetic field, completely eliminating mechanical contact. This innovative technology significantly reduces mechanical friction and sealing leaks, thereby greatly improving the thermodynamic efficiency of the system. Specifically, the isentropic efficiency of magnetic levitation expanders and pumps is significantly higher than that of traditional mechanical bearing expanders [

27]. Therefore, magnetic levitation ORC systems are clearly superior to traditional ORC systems in terms of efficiency and reliability.

Furthermore, the performance comparison between the method presented in this paper and traditional ORC systems is shown in

Table 12.

Table 12 presents the heat-to-power conversion efficiencies of ORC systems from different studies. By comparing these data, one can observe the impact of different research methods on system efficiency. The current magnetic levitation ORC system achieves an efficiency of 10.03%, which is higher than the thermal efficiencies reported in references [

28,

29,

30]. This demonstrates the superior performance of the magnetic levitation ORC system.