Abstract

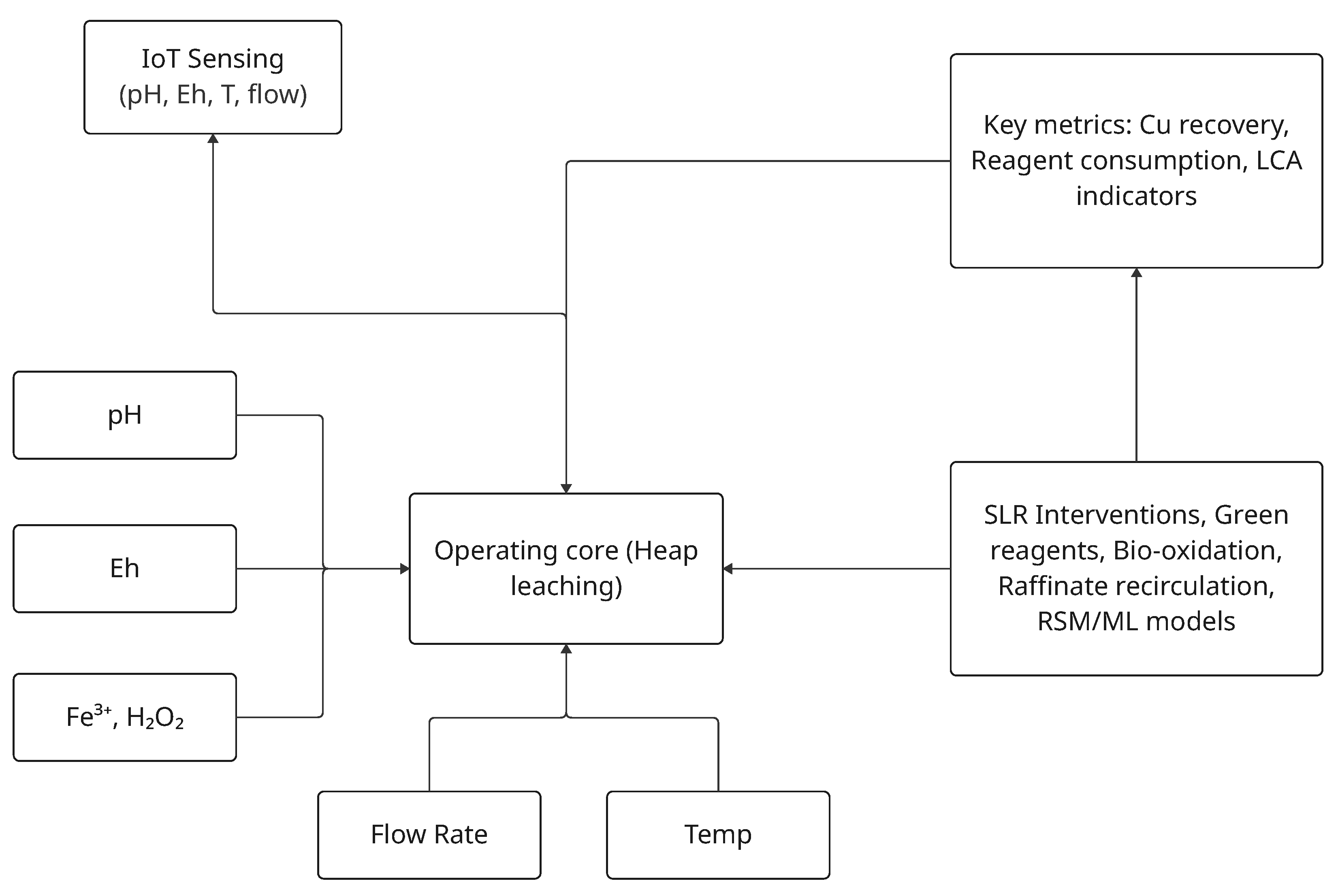

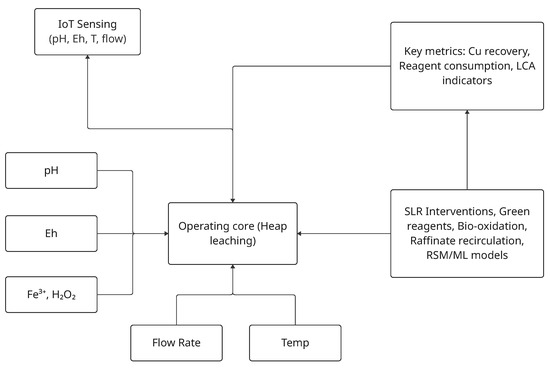

Heap leaching of copper is faced with a complex set of challenges, including mineral heterogeneity, the formation of passivating species, and the need to regulate critical variables such as pH, redox potential (Eh), oxidant concentration, and irrigation rate. If these factors are not properly managed, copper recovery is reduced, and significant environmental impacts may be generated, highlighting the urgency for systematic and sustainable approaches. To address this challenge, a systematic literature review (SLR) was conducted, screening 2344 documents and selecting 106 primary sources to analyze operational drivers and environmental considerations. Statistical methodologies (factorial designs, response surface methodology), multiscale modeling, and laboratory column tests were used to validate key variables, including pH (1.5–2.0), Eh (600–), temperature (25–55 °C), irrigation rate (5–), acid concentration (0.5–), and emerging “green” reagents (e.g., glycine, organic surfactants). Precise control of these factors was found to reduce passivation, minimize fine-particle migration, and improve copper extraction up to 90%. The incorporation of oxidizing agents (e.g., Fe3+, H2O2) further accelerated mineral dissolution while preventing unwanted precipitates. In parallel, bioleaching strategies maintained high recoveries with lower chemical demand. Reviews of pilot studies confirmed the scalability of these optimized conditions, emphasizing both sustainability and cost-effectiveness.

1. Introduction

Copper heap leaching is a widespread and significant mining practice due to its capacity to process large volumes of ore at relatively low cost and with a smaller environmental footprint compared to other hydrometallurgical or pyrometallurgical methods [1,2]. Industrial-scale heap leaching plants are now operating in every major copper region—South America (Chile and Peru), North America (United States and Mexico), East Asia (China), Central Asia (Kazakhstan), and Oceania (Australia). Together, they supply roughly one-fifth of the world’s refined copper, or about 4 Mt in 2023, and are a key source of export income and employment for producing countries (e.g., heap-leached cathodes account for 40% of Chilean copper exports). Forecasts by the International Energy Agency indicate that the global roll-out of electric vehicles, solar photovoltaics, and wind power could raise annual copper demand by 4–5 Mt by 2030. Because it combines low capital intensity with a relatively small environmental footprint, heap leaching is expected to play a central role in meeting this additional demand while supporting the economic resilience of mining regions [3,4].

Nevertheless, achieving optimal performance and stability necessitates meticulous control over factors: pH, redox potential (Eh), oxidizing agent concentration (Fe3+, H2O2), irrigation rate, and temperature [5,6,7]. Consequently, industrial design and optimization face substantial challenges, especially due to mineralogical heterogeneity and the need for high-purity Pregnant Leach Solution (PLS).

1.1. Relevance and Knowledge Gap

Whilst studies cover copper dissolution kinetics using diverse models [8,9], significant gaps remain regarding the holistic integration of operational factors. This is particularly true when integrating green agents (e.g., glycine) and emerging techniques like bioleaching into standard heap leaching [10,11]. Furthermore, the need to minimize environmental impact and reagent costs drives the development of methodologies balancing metallurgical efficiency with process sustainability.

1.2. Problem Statement

Owing to mineral heterogeneity and complex redox thermodynamics, managing critical variables (e.g., pH, Eh, temperature, irrigation rate) presents a highly multivariable challenge [2,5]. In practice, for instance, incorrect Fe3+ use risks jarosite formation, whilst excessive irrigation can lead to saturation, fine migration, and heap clogging [12,13]. These operational uncertainties therefore demand a systematic scientific approach, integrating literature reviews, expert validation, and experimentation, to delineate optimal operating ranges.

1.3. Research Objectives

Based on these considerations, the following general and specific objectives were defined:

- General Objective: Develop and validate a methodological framework that integrates systematic literature review, kinetic modeling, and experimental assays for the optimization of copper heap leaching under dynamic conditions.

- Specific Objectives:

- (a)

- Obj O.1: Identify the most influential operational variables (pH, Eh, Fe3+, etc.) and their optimal ranges according to the scientific literature and the authors’ own experimentation.

- (b)

- Obj O.2: Develop a multivariable mathematical model that incorporates the effects of acidity, oxidant concentration, and reaction kinetics to predict copper recovery under different operating conditions.

- (c)

- Obj O.3: Assess the practical applicability of this model and compare it with pilot-scale data, validating its robustness in scenarios involving mineral heterogeneity and dynamic irrigation configurations.

- (d)

- Obj O.4: Propose criteria for the industrial implementation of advanced control and monitoring methodologies in heaps, focusing on maximizing metallurgical efficiency and minimizing operational costs.

1.4. Research Questions

Based on the problem statement and the objectives outlined, the following research questions were formulated to guide the analysis and discussion (Section 3, Section 4 and Section 5):

- P.1

- Which are the most decisive parameters in copper heap leaching (pH, Eh, temperature, irrigation rate, concentrations of H2SO4 and/or Fe3+), and how do they interact to influence copper recovery?

- P.2

- To what extent can a multivariable mathematical model describe the kinetics of copper dissolution under dynamic operating conditions and mineral heterogeneity?

- P.3

- What findings help delineate optimal operating and industrial upscaling routes, considering the possible inclusion of “green” agents (glycine, eco-friendly surfactants) and bioleaching techniques?

1.5. Manuscript Structure and Methodological Approach

To address the research questions, our robust methodology merges literature review (detailed in Section 2) with experimentation. This yields a classified corpus of 12 thematic clusters (Section 3), encompassing topics such as waste electronics leaching, bioleaching, and deep eutectic solvents [10,11,14]. Subsequently, Table 1 outlines key results alongside the formulated copper leaching mathematical model. These findings are then analyzed and contextualized against prior work and industrial practice within Section 4. Finally, Section 5 highlights significant contributions and future research pathways, emphasising the vital theory–practice nexus for advancing mining efficiency and sustainability.

Table 1.

Discussion Synthesis Table: Key Factors and Recommendations for Copper Heap Leaching.

1.6. Justification and Scope

Relevant to both academia and industry, this research tackles the strategic priority of optimizing heap leaching, particularly in copper-producing nations. It contributes an integral analytical method to the body of knowledge whilst providing practical guidelines for implementing novel operational and environmental practices. Our integrated approach—combining rigorous search, scientific validation, and empirical testing—yields a holistic perspective, covering physicochemical understanding of copper dissolution through to industrial planning and cost management. Accordingly, this Section 1 sets the stage by outlining the study’s context and motivations, leading into the detailed methodological and technical discussions presented hereafter.

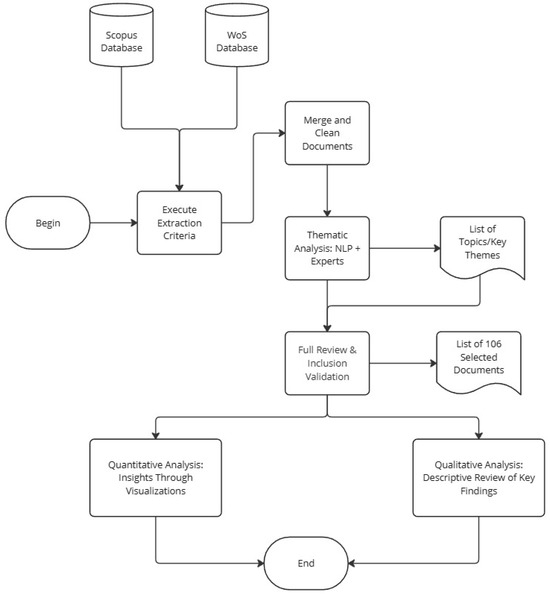

2. Systematic Analysis Methodology

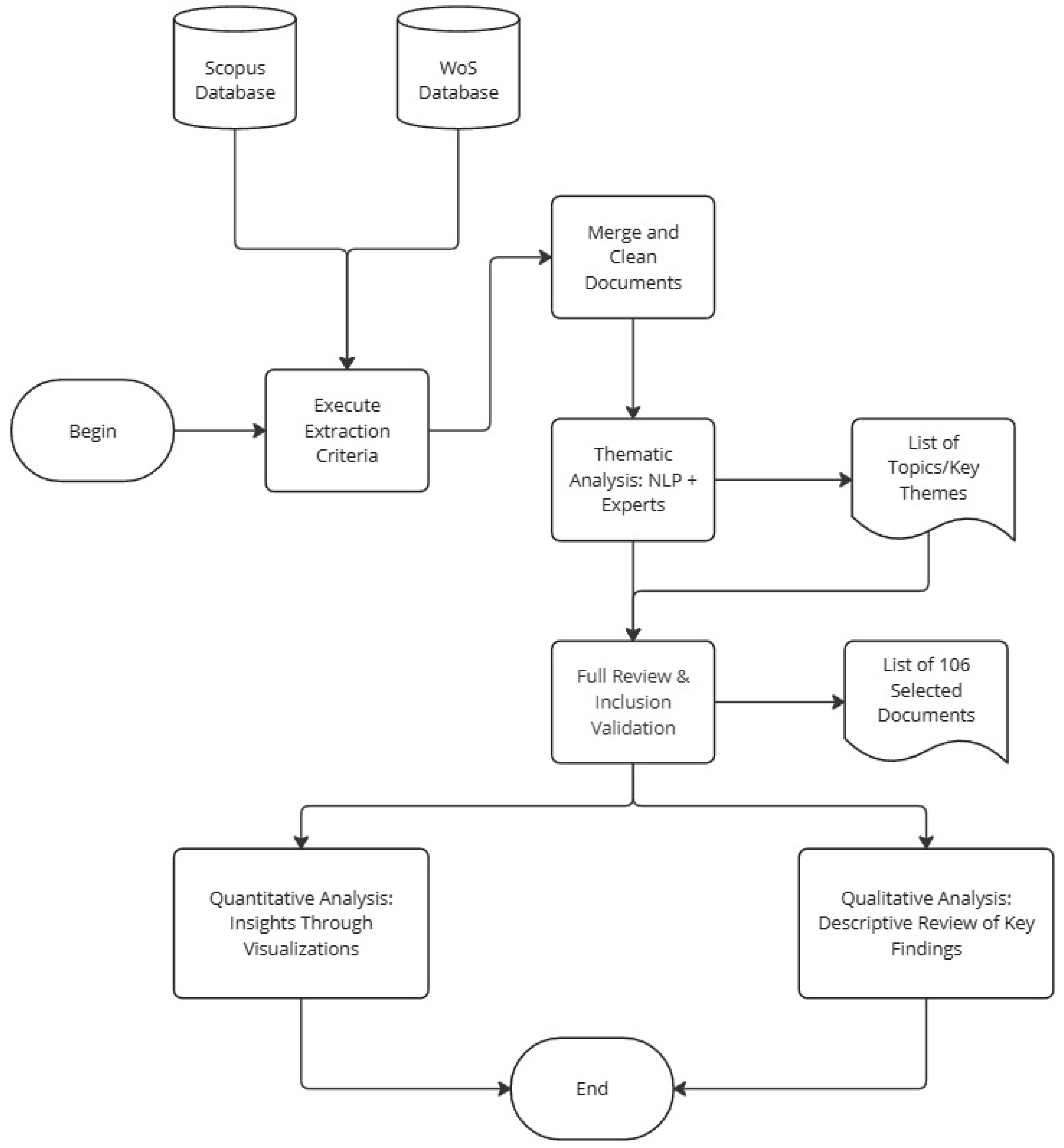

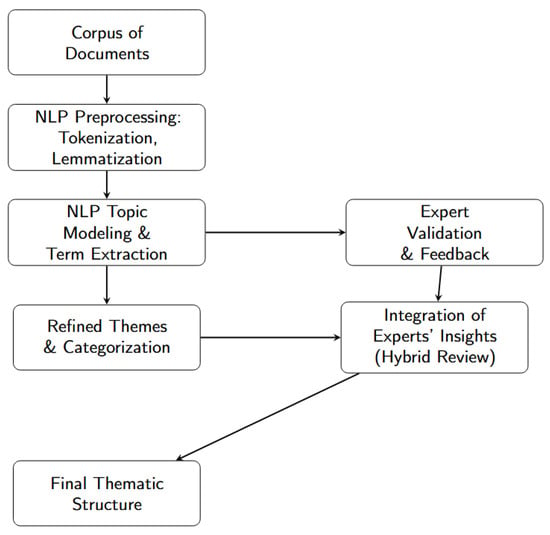

This section describes in detail the methodology adopted to conduct a systematic analysis, integrating both bibliographic search and filtering criteria as well as advanced Natural Language Processing (NLP) techniques and expert validation. The data were extracted and refined before subsequently being classified into thematic clusters, following a sequence of steps outlined below. Figure 1 provides an overview of the workflow.

Figure 1.

General workflow for the systematic analysis, integrating procedures for data extraction, cleaning, thematic identification via NLP, and expert validation.

2.1. Document Extraction and Search Criteria

A systematic literature search was conducted using the Scopus database (Elsevier, Amsterdam, The Netherlands) and the Web of Science Core Collection (Clarivate Analytics, Philadelphia, PA, USA), selected for their quality and indexing breadth.The Scopus and Web of Science (WoS) databases were last searched on 15 April 2025. The search strategy employed combined key terms related to copper leaching, influencing factors, operational variables, and optimization approaches, guided by specific criteria:

| Key Queries: | |

| Document Types: | Research articles, reviews, conference proceedings, and indexed book chapters. |

| Time Range: | 2015–2025, focusing on recent and high-impact contributions. |

Following duplicate removal and initial screening (year/quality criteria; see Section 3), 1721 documents remained from an initial 2344. A semantic filter (semantic filter) was then applied, using a relevance threshold (e.g., 0.96) based on similarity to core topics (leaching kinetics, critical variables), yielding 116 documents (score ≥ 2.0). After final cleaning and meticulous cross-checking (DOI, title, author) to prevent redundancy, 106 documents were selected. Exclusion criteria included absent abstracts or low topical relevance, ensuring the study’s focus and consistency. Inclusion required alignment between automated language-based categorization and independent expert assessment. Data extraction was carried out without relying on author queries or software-based automation.

2.2. Merging and Cleaning Documents

The retrieved documents were consolidated into a single repository for normalization. In line with good practices for systematic review, column headers were harmonized (Merge and Clean Documents) between Scopus and WoS to ensure consistency in metadata such as Title, Authors, Year, Abstract, Keywords, and DOI. Next, inclusion and exclusion criteria were established.

2.2.1. Inclusion Criteria

- Articles and reviews with accessible and verified full text.

- Studies published in English or Spanish.

- Sources ranked at least Q2 in Scopus/WoS, indexed conferences, or journals with a high impact factor.

- Documents with five or more verified citations or, failing that, with a clear methodological contribution.

- Direct contribution to the optimization of copper leaching, key variables, and/or innovation in monitoring and control methodologies.

2.2.2. Exclusion Criteria

- Records lacking sufficient information (Title/Abstract).

- Publications in languages other than English or Spanish without an official translation.

- Duplicates between WoS and Scopus.

- Articles with restricted access that could not be verified.

- Conference abstracts without full peer-reviewed text.

Applying these criteria reduced the corpus to 108 high-quality relevant documents.

2.3. Refinements in NLP-Driven Analysis and Bias Mitigation

Greater Emphasis on NLP Methods and Tools: Our initial strategy combined conventional document filtering (Scopus/Web of Science) with machine-learning-based semantic analysis. However, we recognized the need for deeper scrutiny of potential biases and overlooked research. Consequently, the updated methodology (Section 2, final portion) compares our approach with recently proposed systematic-review frameworks [15,16], highlighting how transformer-based semantics (e.g., Sentence-BERT) can refine classification accuracy and expose thematic gaps [17].

Specifically, we evaluated whether restricting the corpus to Q2+ journals or imposing a high threshold for similarity () might systematically exclude emergent or cross-disciplinary studies. To mitigate this risk, we introduced a two-stage validation process:

(i) Contextual embedding and topic modelling. Abstracts were embedded with Sentence-BERT v0.4.0 (UKPLab, TU Darmstadt, Darmstadt, Germany) and processed with spaCy v3.7.2 (Explosion AI GmbH, Berlin, Germany). The embeddings fed an advanced topic-modelling workflow built on BERTopic v0.16.1 (open-source; https://github.com/MaartenGr/BERTopic, accessed on 9 April 2025). The resulting clusters were benchmarked against classical Latent Dirichlet Allocation (LDA) and TF–IDF pipelines implemented in Gensim v4.3.1 (RARE Technologies Ltd., Prague, Czech Republic) and keyword extraction with RAKE [18,19,20].

(ii) Expert review. A panel of three metallurgical specialists examined borderline documents, verifying their relevance to copper leaching and ensuring that niche but methodologically robust works were retained.

We also implemented an iterative feedback loop with domain experts to calibrate hyperparameters like the minimal cluster size and the embedding dimensionality [21]. This fine-tuning step notably improved the resolution in detecting subthemes (e.g., bio-assisted leaching, surfactant-enabled kinetics), reducing the risk of conflating diverse research fronts into a single cluster. Furthermore, by contrasting specialized sets of articles on, for instance, glycine-based approaches or deep eutectic solvents, the refined semantic thresholds unveiled additional synergies previously masked by simpler keyword-matching filters.

Overall, these enhancements represent a more holistic and adaptive NLP-driven strategy for large-scale bibliometric reviews. The integrated pipeline—merging advanced embeddings, domain-expert feedback, and multi-method cross-validation—enables us to capture both mainstream and emergent scholarship in the copper-leaching domain, thus reinforcing the methodological rigor and credibility of our systematic analysis.

2.4. Thematic Analysis: NLP + Expert Validation

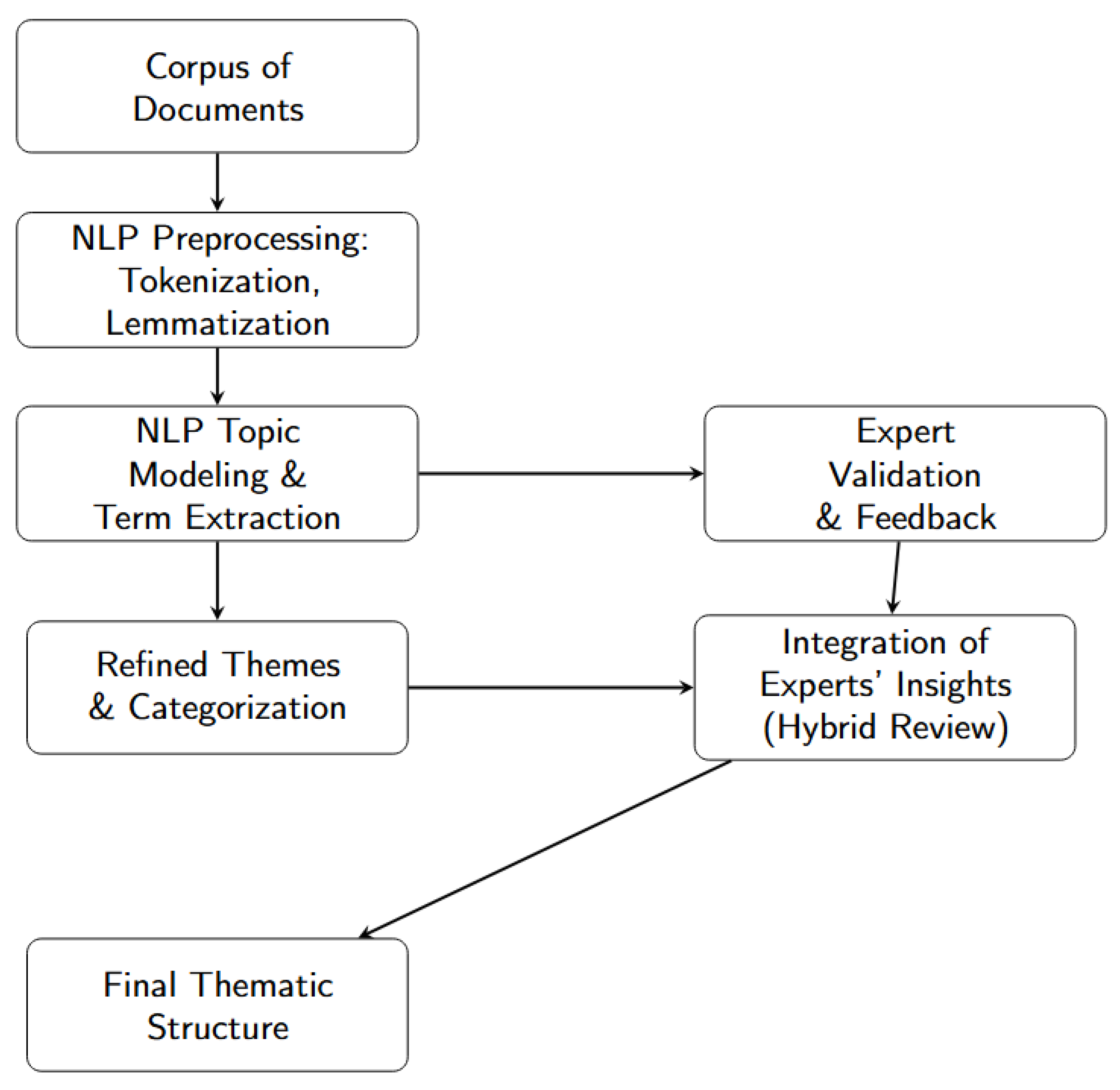

Once the pertinent documents were selected, we performed a thematic analysis that combined Natural Language Processing (NLP) with structured expert review. Following Garcia et al. [15], García et al. [16], we used standard algorithms for term extraction and unsupervised topic modeling to reveal semantic patterns; domain specialists then refined the output. Figure 2 summarizes the workflow.

Figure 2.

Workflow for topic identification and refinement: (1) NLP pre-processing, (2) topic modeling and term extraction, (3) expert validation, (4) refinement of themes, (5) hybrid integration of experts’ insights, and (6) final thematic structure.

The process comprised six sequential phases:

- Phase 1

- NLP pre-processing: tokenization, lemmatization and stop-word removal were applied to the titles, abstracts, and author keywords, producing a clean text corpus.

- Phase 2

- Topic modeling and term extraction: unsupervised methods (latent Dirichlet allocation and k-means) grouped documents by semantic similarity, while key terms for each provisional topic were extracted automatically.

- Phase 3

- Expert validation and feedback: three metallurgical specialists examined the provisional clusters, marking documents as coherent or mis-assigned and providing qualitative comments.

- Phase 4

- Refined themes and categorization: algorithmic labels were adjusted, overly small clusters were merged, and ambiguous documents were reassigned on the basis of the experts’ feedback.

- Phase 5

- Hybrid integration of experts’ insights: a second review round reconciled any remaining discrepancies and approved the revised set of themes.

- Phase 6

- Final thematic structure: the agreed-upon clusters—twelve in total—were adopted for the bibliographic synthesis reported in Section 3.

This hybrid approach leverages the scalability of automated NLP while retaining the contextual depth provided by expert judgement, yielding a robust and transparent thematic classification of the literature.

2.5. Comprehensive Review and Inclusion Validation

The curated subset (166 documents) was then subjected to a detailed inspection (Full Review and Inclusion Validation). Each article was evaluated manually and supported by automated ranking, confirming:

- Methodological Relevance: leaching processes, critical parameters, and reproducible outcomes.

- Scientific Quality: statistical rigor, robust experimental design, and/or sound theoretical modeling.

- Industrial Applicability: focus on copper leaching (oxide/sulfide), tailings management, or innovations in condition monitoring.

A total of 113 articles were selected as most closely aligned with the research question, in accordance with the validation methodologies outlined in [15] for systematic reviews.

2.6. Quantitative Analysis

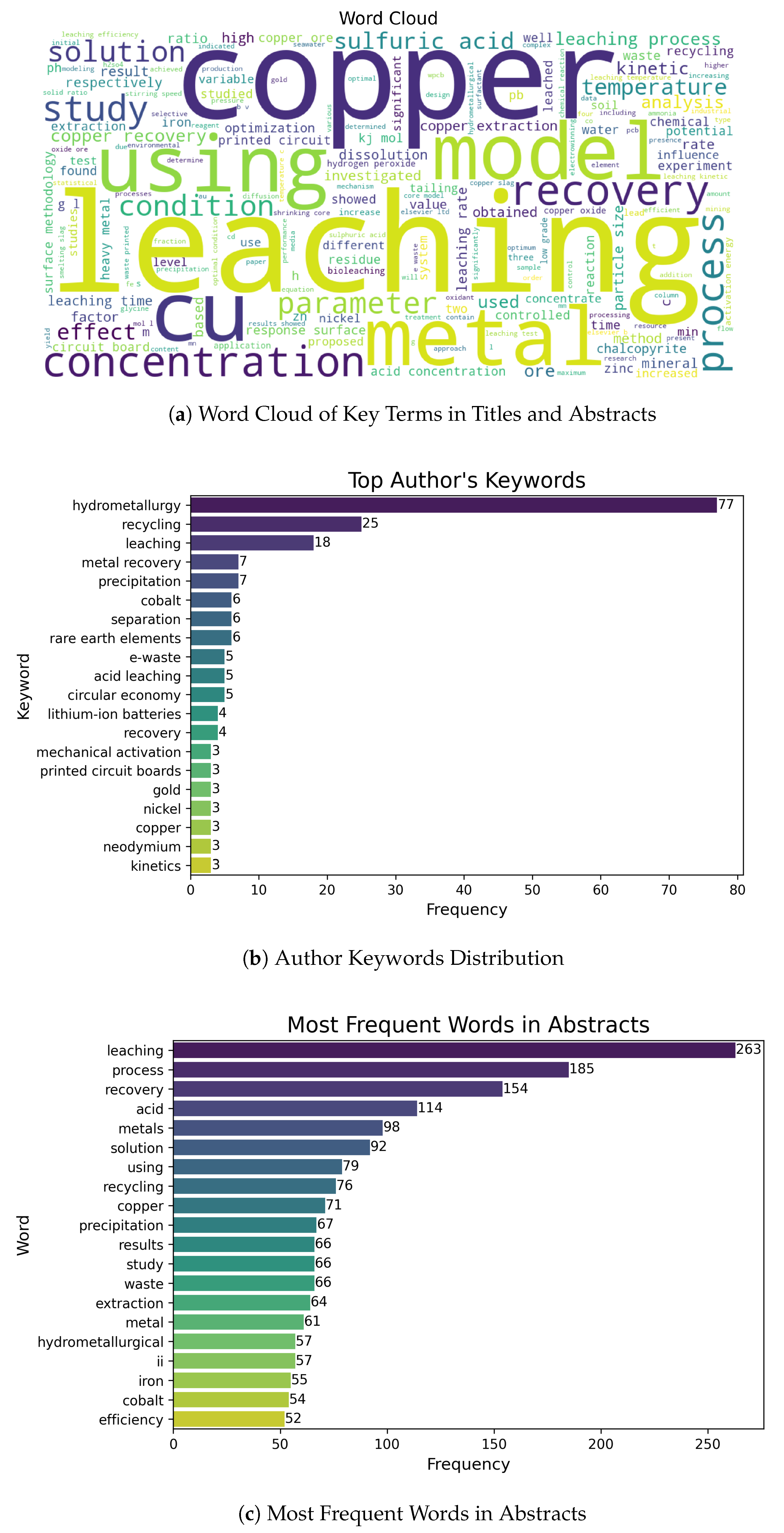

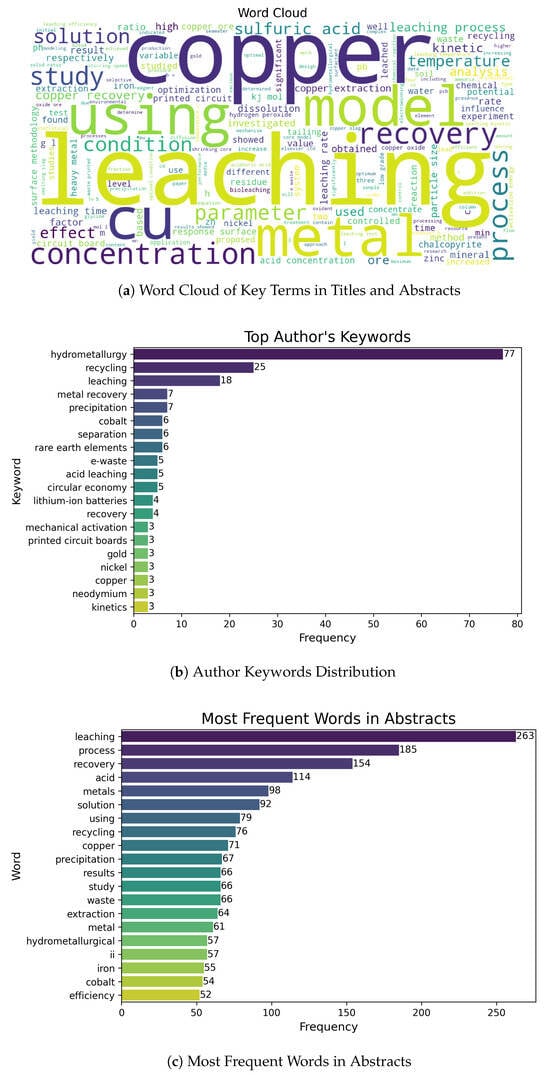

Using the final corpus, a Quantitative Analysis was performed to explore key bibliometric indicators (year of publication, document type, impact factor, countries of affiliation). Additionally, visualizations were generated to reveal trends and thematic relationships (e.g., co-occurrence networks, keyword histograms, and temporal evolution). As illustrated in Figure 3a, high frequency was detected in terms related to “copper leaching”, “kinetic models”, and “heap optimization”. These graphical representations provided a macroscopic view of dominant research lines and the multidisciplinary nature of the field, confirming the robustness of the selected body of literature.

Figure 3.

Comparative Terminology Visualization. (a) Word cloud highlighting frequent terms related to hydrometallurgy and process optimization. (b) Author keywords showing the coexistence of traditional and emerging concepts. (c) Term frequency from abstracts emphasizing both conventional and sustainable copper leaching strategies.

2.7. Qualitative Analysis: Descriptive Review of Key Findings

The key data items sought from each included study for the qualitative synthesis included (but were not limited to) (1) reported optimal ranges and effects of operational variables (pH, Eh, temperature, irrigation rate, oxidant concentration, etc.); (2) types and efficacy of conventional and ’green’ leaching reagents (e.g., glycine, organic acids, surfactants); (3) details of kinetic models or statistical methodologies applied and their predictive success; (4) information on bioleaching approaches and their performance; (5) discussed environmental impacts, sustainability strategies, and scalability. When studies reported multiple results or conditions, those highlighted by the original authors as most significant or optimal or those directly addressing the research questions of this SLR were prioritized for discussion within the thematic synthesis.

Where available, details on the copper source (e.g., specific ores, tailings, or e-waste), study scale (e.g., laboratory, pilot, or industrial), and employed methodologies (e.g., reactor type, column dimensions, analytical techniques) were recorded to contextualize the findings. Funding sources of the included studies were not a specific data item for extraction. If information on these contextual variables was unclear or missing in a primary study, the synthesis relied on the available details, and no assumptions were made to fill gaps; the focus remained on the reported findings.

Finally, a Qualitative Analysis was carried out on the most relevant findings from the prioritized documents (110 articles). Under a meta-synthesis criterion, notable contributions were grouped in relation to the following:

- Leaching Kinetics Modeling (shrinking-core equations, diffusional models, chemical reactions).

- Operational Control and In Situ Monitoring Practices (pH, Eh, irrigation rate, particle size).

- Impurity Management and Oxidizing Agents (Fe3+, H2O2, complexing agents).

- Emerging Trends such as “green” surfactants, bioleaching, and eutectic solvents.

The combination of quantitative and qualitative findings, alongside methodological evaluation, resulted in a robust thematic map presented in Section 3. This map comprehensively addresses the challenges and advances in optimizing heap leaching for copper, as well as perspectives on sustainability and future efficiency.

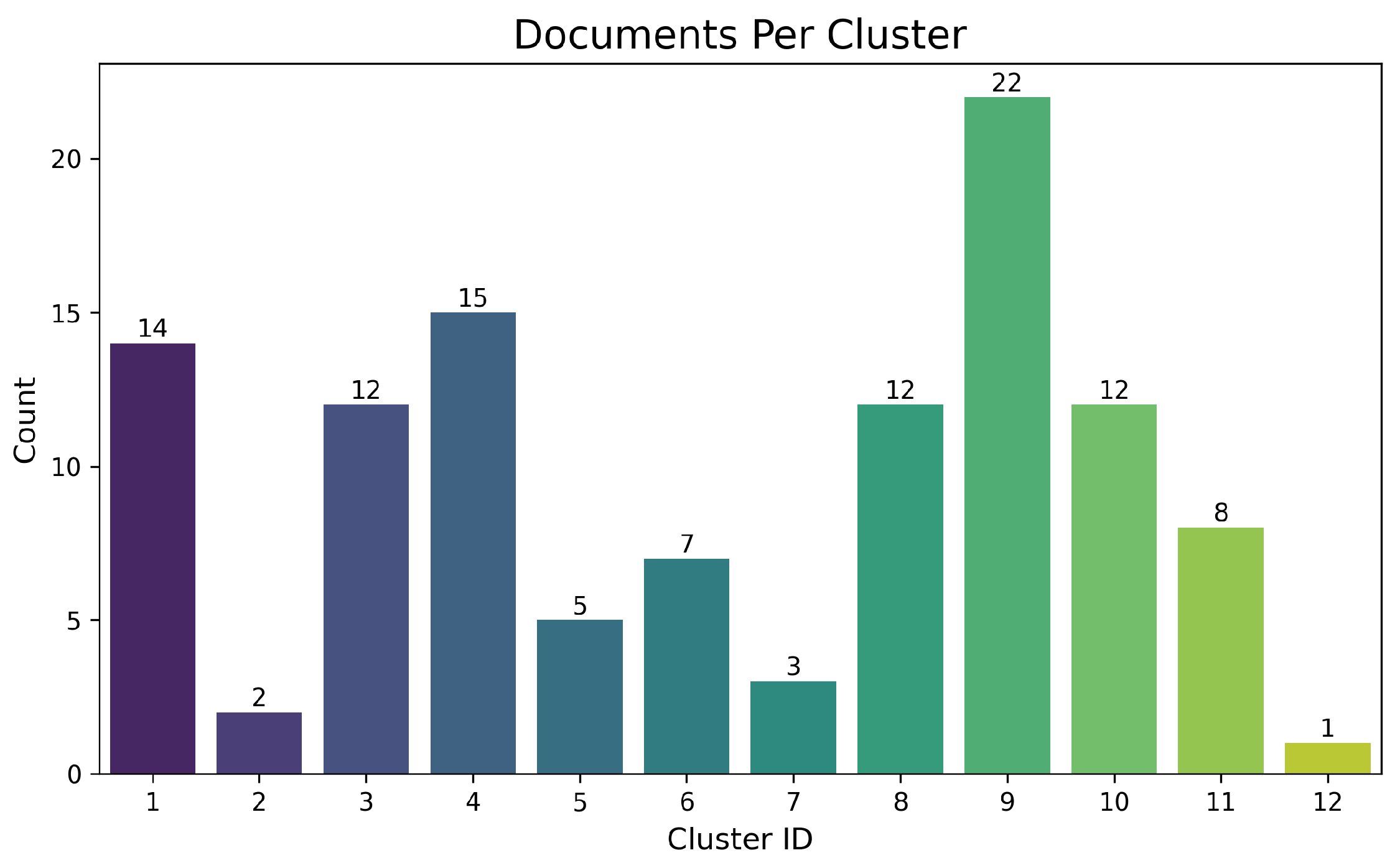

2.8. Quantitative Analysis and Results Visualization

This subsection presents various charts and histograms illustrating the distribution of selected documents in the present SLR (Systematic Literature Review), as well as the publication sources and associated thematic trends. Each figure enables a quantitative and bibliometric perspective on dominant research lines in copper leaching and the optimization of its key variables.

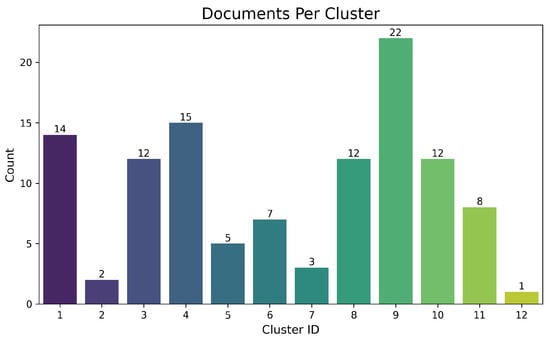

Figure 4: Document count per 12 clusters (defined via NLP/expert validation; Section 2). High-volume clusters (9, 8, 10, 4) emphasise slag leaching, variable optimization (pH, redox, surfactants), and complex/residual ore processing. Lower-volume clusters (e.g., 2, 12) cover specialized, high-specificity topics (e.g., Cu precipitation [cyanide], F fixation [tailings]).

Figure 4.

Distribution of documents by cluster. The horizontal axis denotes the numbering of the 12 thematic clusters, whereas the vertical axis shows the document count in each.

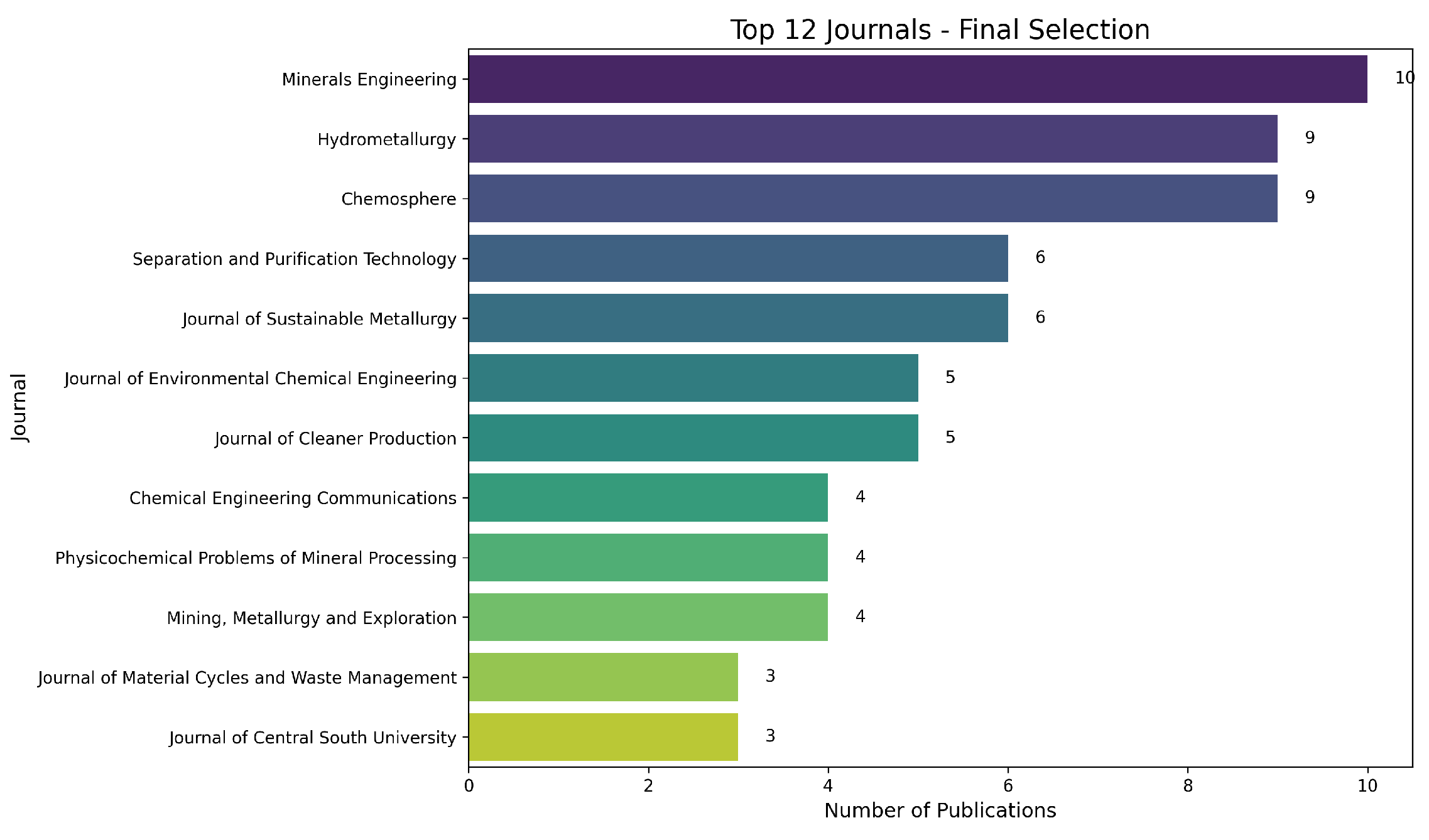

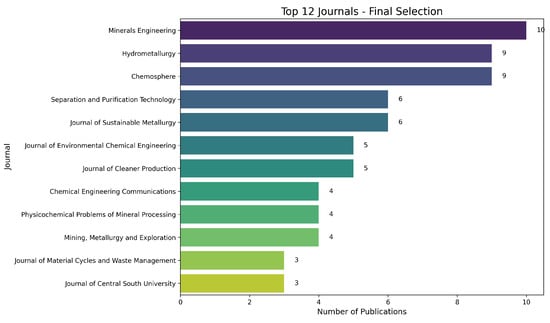

Figure 5 presents the 12 most representative publication sources in the final dataset. Minerals Engineering, Hydrometallurgy, and Chemosphere lead the list, confirming the multidisciplinary nature of the studies (extractive metallurgy, environmental chemistry, and process optimization). Collectively, these results indicate that the research on copper leaching and its critical variables is primarily found in high-impact (Q1/Q2) journals, with many articles specializing in process engineering, effluent treatment, and sustainability.

Figure 5.

Top 12 journals among the selected documents. The vertical axis lists the journals, and the horizontal axis shows the number of publications in each.

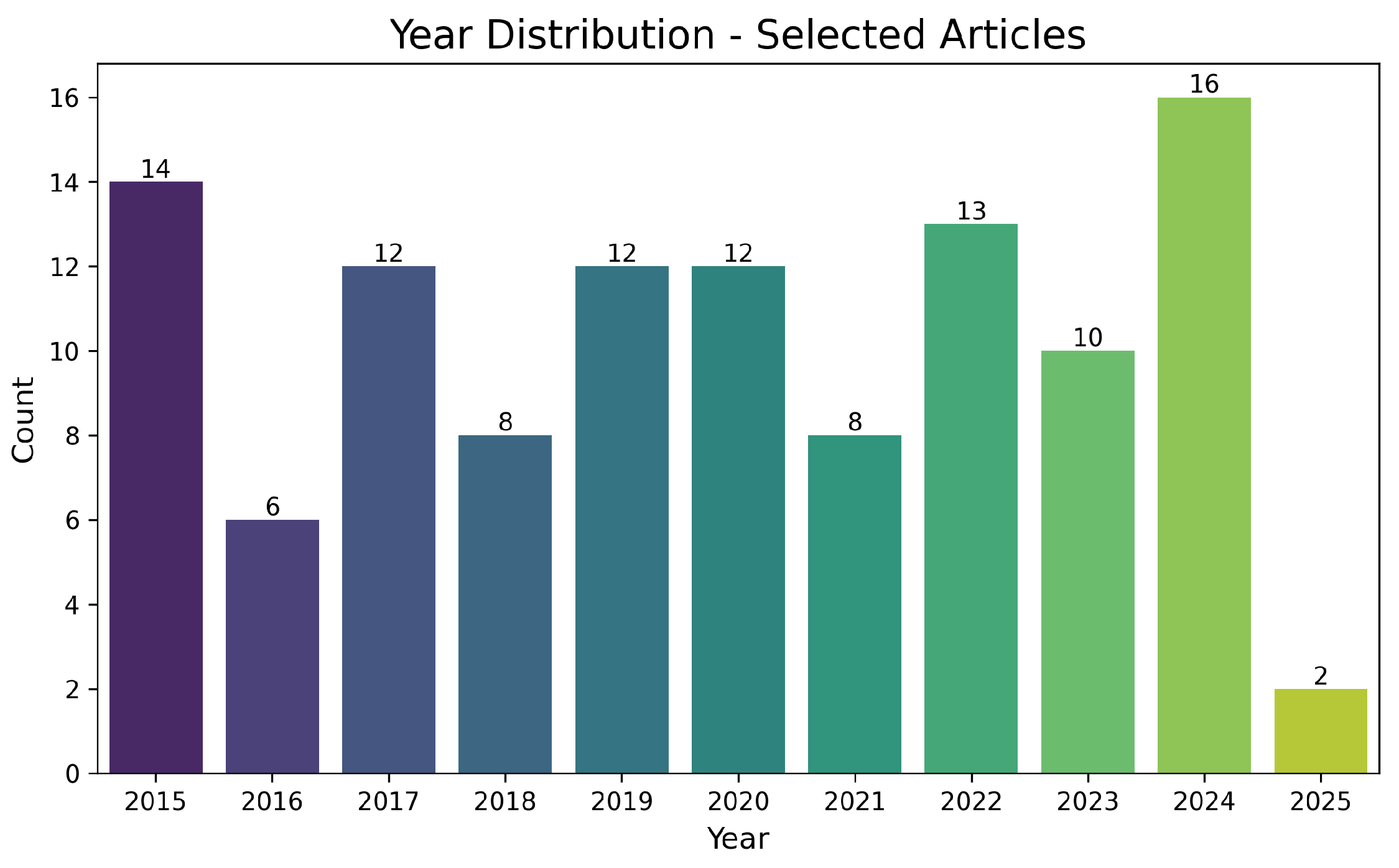

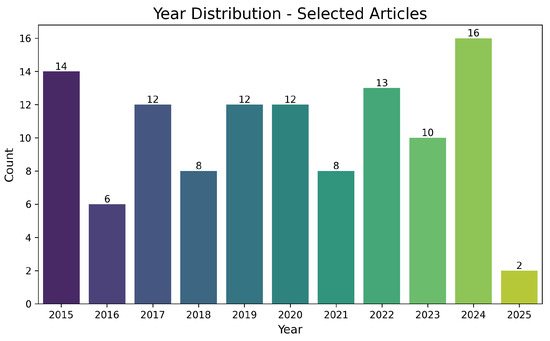

Figure 6 depicts the temporal evolution of selected publications, with a notable increase starting in 2020. This rise aligns with industrial interest in new intelligent mining technologies, process digitalization, and the quest for more sustainable methods of copper extraction. The expected peak in 2024 suggests that recent advances in leaching, complexing agents, and waste management continue to gain prominence, translating into a higher volume of publications.

Figure 6.

Distribution of selected articles by publication year (2015–2025). The vertical axis represents the number of documents, and the horizontal axis the year.

Quantitative Finding Overview

Our analysis indicates research on copper leaching (kinetics, conditions, optimisation) spans leading journals (e.g., Minerals Engineering, Hydrometallurgy) but clusters heavily. Furthermore, NLP identifies key dimensions like environmental aspects, surfactants/bioreactors, and kinetic/thermodynamic influences. Recent trends also highlight the industry’s drive towards enhancing copper production efficiency whilst minimizing its environmental impact.

2.9. Assessment of Publication Bias and Transformer-Based Semantics

To ensure internal validity, potential biases from database (Scopus/WoS)/criteria (Q2+)/semantic threshold combination were scrutinized. Firstly, retained/discarded articles were compared checking exclusion reasons (relevance vs. methodological limitations) [15,16]. Secondly, filter impact on emerging areas (e.g., eco-surfactants, extreme temp. bio-leaching) was assessed.

Advanced NLP refined classification/gap ID. Specifically, Sentence-BERT [17] provided accurate semantic similarity (surpassing TF-IDF/LDA) by capturing nuances [21]. An iterative expert review of ”borderline” cases (assessed on soundness/alignment with review question) strengthened this stage, enhancing recall and sub-theme detection [15,16].

Consequently, combining transformer semantics with expert input yielded refined classification and mitigated publication bias. This methodological refinement enhances literature representativeness and allows clearer thematic gap delineation in recent copper leaching approaches.

A formal risk of bias assessment was not conducted for each individual studies included in this systematic review. The review relied on the peer-review process and the quality indicators (journal ranking, citations as per Section 2.2.1) as an indirect measure of the robustness of the included studies.

3. Findings and Topic Synthesis

This section presents the detailed Findings and Topic Synthesis concerning the most significant variables in dynamic copper heap leaching, aiming to enhance the quality of the Pregnant Leach Solution (PLS). To this end, a range of scientific works were grouped into several thematic clusters, numbered 1 through 12. Each cluster synthesizes a particular problem or approach related to copper leaching, and the most noteworthy results and methodological contributions are discussed. An in-depth analysis of each cluster is provided below in successive order, emphasizing aspects relevant to leaching optimization, the characterization of critical parameters, and the achievement of a high-purity PLS.

3.1. Cluster 1: Copper Recovery from PCB Residues and New Hydrometallurgical Strategies

3.1.1. Cluster Overview

This initial group of studies investigates copper (Cu) recovery from waste printed circuit boards (PCBs), focusing on optimizing diverse hydrometallurgical pathways such as acidic/alkaline leaching, solvent extraction, and organic or ”green” methods. Emphasis is placed on alternative approaches aiming to enhance selectivity, purity, environmental sustainability, and the efficient utilisation of secondary resources. Furthermore, these studies evaluate various reagents (e.g., H2SO4-H2O2, ammoniacal solutions, ethylene glycol complexes) and solvents (e.g., M5640, D2EHPA, ammonium solutions) for extraction performance. Collectively, this research outlines the challenges and opportunities in PCB copper recovery, underscoring the importance of industrial scaling, kinetic modeling, and cost analysis.

3.1.2. Key Findings

“Clean” Leaching Pathways and Micro-Nano Copper Powders

In Li et al. [22], the feasibility of a so-called “clean” leaching process for extracting copper present in waste printed circuit boards (WPCBs) is analyzed. Through subsequent chemical reduction processes, these authors achieve the synthesis of micro-nano-scale copper powders, emphasizing the viability of producing high-value-added products from electronic waste.

Use of H2SO4 and H2O2 for Copper Extraction

The study by Ganji et al. [23] delves into the efficiency of the sulfuric acid–hydrogen peroxide (H2SO4-H2O2) combination for recovering Cu from PCBs. High recoveries (exceeding 90%) are reported, emphasizing both the operational simplicity of the method and the importance of properly controlling the redox potential to avoid unwanted byproduct formation.

Selective Leaching with Ammoniacal Systems

An alternative pathway is presented by Sun et al. [24] who employ an ammoniacal medium for the selective recovery of copper from complex mixtures of electronic waste. By using ammonia and ammonium carbonate solutions, they preferentially dissolve copper over other metals, thereby simplifying the subsequent separation and purification of the metal.

Role of Organic Agents in Enhanced Leaching

In He et al. [25], the addition of organic agents—specifically ethylene glycol—is assessed for its capacity to boost copper dissolution in an acidic medium, stabilizing H2O2 and enhancing the electrochemical behavior on the PCB surface. Such changes in leaching kinetics yield copper recovery efficiencies near 98%.

Physical Preconcentration and Ammonium-Based Leaching

Aiming to propose a “green” route with low reagent consumption, Shi et al. [26] outline a physical preconcentration strategy followed by ammoniacal leaching. This method achieves over 90% efficiency, underscoring the importance of combining physical (e.g., density or magnetic separation) and selective chemical steps to maximize extraction.

Solvent Extraction with Acorga M5640 and Solvent Reuse

According to Wang et al. [27], copper extraction from a leach solution can be enhanced by using specific extractants such as Acorga M5640. This solvent can be recycled more than ten times without significant loss of efficiency, implying cost savings and lower environmental impact.

Application of D2EHPA in the Hydrometallurgical Process

Following the solvent-extraction route for copper recovery, Correa et al. [28] describe the use of D2EHPA in a combined oxidizing leach and liquid–liquid extraction protocol. The process achieves notable copper purification while minimizing the entrainment of other metals, thereby consolidating a flow sheet with high scale-up potential.

Comparison of Hydrometallurgical Methods

In a review, Yousefzadeh et al. [29] carry out an analysis of hydrometallurgical techniques for Cu recovery, comparing them through modeling and multi-criteria methodologies (AHP-TOPSIS). They conclude that, although cyanide-based and strong-acid approaches achieve high efficiencies, alternative methods (e.g., organic acids or ammoniacal systems) may be more environmentally sustainable, depending on the specific operational conditions.

Chemical Leaching Modeling

Mathematical modeling plays a pivotal role in predicting copper recovery from PCBs. Becci et al. [30] propose a second-order equation integrating Fe3+ concentration, temperature, and the copper grade in the waste, enabling accurate estimation of leaching kinetics and metallic ion release.

Optimal Parameters for Chemical Leaching

To optimize the recovery of base metals from telecommunications and desktop-computer boards, Mizero et al. [31] employ experimental design (DOE) methods. Their findings highlight the significance of factors such as agitation rate, particle size, and H2SO4 concentration, aligning with other investigations that underscore the need for precise control of process variables.

Joint Recovery of Cu, Zn, and Ni

Some studies broaden the focus to include other valuable metals. Pinho et al. [32] explore the simultaneous dissolution of copper, zinc, and nickel from PCBs in an ammonia–ammonium sulfate system, demonstrating the flexibility of the ammoniacal medium for sequential separation of multiple metals and for producing high-grade products.

Bio-Metallurgical Aspects and Operational Parameters

In the bioleaching domain, Janyasuthiwong et al. [33] demonstrate the feasibility of recovering copper and other metals through microbial processes, contingent on well-established pH and redox potential conditions. Although the study primarily focuses on Ni and Pb, it underscores the potential of biological approaches, especially when combined with chemical methods.

Alkaline Fusion and Precious-Metal Leaching

Guo et al. [34] investigate a prior fusion of the material followed by leaching and separation steps to recover both Cu and other precious metals (Au, Ag). While the central focus is phase conversion, the study illustrates the versatility of the method in managing precious metals contained within the PCB matrix.

Sustainability and Industrial Scale-Up

Lastly, Dutta et al. [35] present a comprehensive assessment of the economic and environmental feasibility of recovering metals from PCBs, highlighting the optimization of hydrometallurgical stages and stressing the need for multivariable control to minimize hazardous waste production and maximize process profitability.

3.1.3. Contributions to Research

In summary, the assembled works provide a multidimensional view of copper and other metal recovery from PCB waste, covering the following:

- Novel reagents and leaching routes (H2SO4-H2O2 systems, ammoniacal media, alkaline fusion).

- Mathematical models and experimental designs for predicting and optimizing copper dissolution.

- Purification and solvent-extraction methods (Acorga M5640, D2EHPA) with potential reuse, reducing both costs and environmental impact.

- “Green” perspectives and industrial scale-up pathways, including the addition of organic agents or bioleaching.

These studies are fundamental for consolidating methodologies that deliver integrated solutions in metal recovery, with direct implications for managing electronic waste and optimizing hydrometallurgical processes in the mining industry. The diversity of approaches underlines the need to continue exploring technological synergies (e.g., physical and/or thermal pretreatments, deep eutectic solvents, advanced kinetic modeling) to ultimately bolster the development of sustainable and competitive industrial schemes.

3.2. Cluster 2: Complementary Studies on Copper Recovery and Leaching Risk

3.2.1. Cluster Overview

The second group of investigations, while not exclusively focused on copper heap leaching, complements the broader perspective on challenges and opportunities pertaining to copper recovery and metal management under various scenarios. On the one hand, the optimized recovery of copper from cyanidic solutions in gold–copper ore processing is discussed; on the other, the risks of copper mobilization and other metals in an electric-field-assisted phytoremediation setup are analyzed. These studies offer valuable insights into the management of Pregnant Leach Solutions (PLS) in gold mining and the mitigation of environmental risks in contaminated soils.

3.2.2. Key Findings

Optimizing Copper Recovery from Cyanidic Solutions

According to Kassymova et al. [36], copper present in the cyanidic solutions used to process gold–copper ores can be precipitated and recovered through a probabilistic–deterministic design, underscoring the complexity of adjusting variables like sulfidizer stoichiometry or the addition of neutralizing reagents. The authors employ a two-level full-factorial design () followed by a central composite response-surface model to screen three factors—pH, S dosage and temperature—and then refine their optimum. The model (adj. ) predicts that pH 11.2, 0.85 g S and 45 °C would raise Cu recovery from 78% to 86% while cutting reagent cost by 11%. This work proposes an experimental model that combines statistical analysis and empirical validation, striking a balance between metallurgical efficiency and the chemical stability of the post-leach solution. Such a multivariable approach aligns with the necessity for strict operational control in copper heap leaching [6,7], given the interplay of different reagents and conditions (pH, Eh, etc.).

Copper Mobilization Risk in Phytoremediation

Meanwhile, Luo et al. [37] address the risks of copper and lead leaching during soil phytoremediation using Noccaea caerulescens, under both traditional conditions and the application of an electric field. The study highlights how electric voltage can increase the mobility of metals not hyperaccumulated by the plant, thereby raising contamination risks for groundwater. Such findings underscore the importance of avoiding excessive dosing of reagents or over-intensifying processes (e.g., irrigation or electric power) to prevent undesired metal carry-over, a phenomenon similarly noted in copper heap leaching when excessively high irrigation rates are applied [12,13].

3.2.3. Practical Application of Statistical Design to Heap Leaching

Although Cluster 2 focuses on cyanidic solutions and phytoremediation, the statistical tools employed are directly transferable to heap-leach optimization. Full-factorial and response-surface methodologies such as those used by Kassymova et al. [36] are the same techniques successfully applied by Hosseinzadeh and Hosseini [6] (Taguchi ) and Yavari et al. [7] (Box–Behnken) to maximize oxide-ore extraction in column heaps. In those works, the most sensitive variables are the following:

- pH. Hosseinzadeh and Hosseini [6] reported that lowering solution pH from 2.5 to 1.8 increased Cu recovery from 74% to 82% (+8 pp) but raised acid consumption by 14 kg ore.

- Eh. In Yavari et al. [7], boosting redox potential from 540 mV to 670 mV (Ag/AgCl) with 5 g shortened the time to reach 80% extraction by 18%.

- Reagent concentration. Kassymova et al. [36] observed that S dosages above 1.0 g caused colloidal CuS formation and cut dissolved-Cu grade by 12%; factorial design identified 0.8–0.9 g as the economic optimum.

Applying these optimized conditions to pilot-scale heap columns reduced acid usage by 10–15 kg ore and lowered raffinate recycle volumes by 8%, yielding operating cost savings of USD 0.7– Cu [6,7].

3.2.4. Contributions to Research

The works included in this Cluster 2 provide complementary perspectives on the global understanding of Sustainable Leachate Recovery (SLR) by demonstrating

- Probabilistic–Deterministic Experimental Design: It is proposed by Kassymova et al. [36] to optimize copper recovery in cyanidic environments, illustrating the versatility of full-factorial and response-surface methodologies and their potential application in copper heap leaching, especially when handling mixed-metal solutions.

- Environmental Risk Management: The findings of Luo et al. [37] underscore the need to assess unintentional metal mobilisation during assisted remediation or extraction processes, an aspect that can be extrapolated to controlling redox potential and irrigation rate in heap leaching.

Hence, the optimization of hydrometallurgical processes is shown to aim not only at maximum copper recovery but also at minimizing the environmental risks associated with the release and transport of metals. The statistical design examples discussed above confirm that systematic experimentation—rather than one-factor-at-a-time trials—can simultaneously improve copper yield and reduce operating costs in heap operations. Integrating these designs with real-time monitoring of pH, Eh, and reagent dosing therefore represents the best practice for efficient and sustainable heap leaching.

3.3. Cluster 3: Optimization Methodologies in Copper Leaching and Processing Dynamics

3.3.1. Cluster Overview

This third cluster assembles research focused on the development and optimization of various copper leaching processes, emphasizing experimental design methodologies, the use of alternative water resources, and analyses of washout dynamics in heaps. The studies encompass approaches such as countercurrent leaching, the use of desalinated seawater in heap leaching, and the combination of statistical techniques (e.g., Taguchi, ANOVA, Response Surface Methodology, neural networks) to refine process efficiency.

3.3.2. Key Findings

Countercurrent Leaching and Raffinate Reuse

As reported by Movahhedi et al. [38], implementing a countercurrent leaching process offers an opportunity to reuse hydrometallurgical raffinate in treating low-grade ores. Through Response Surface Methodology (RSM), optimal operating conditions are determined, resulting in lower fresh-water requirements and greater copper selectivity.

Advanced Optimization Algorithms in Ammoniacal Systems

Combining RSM with evolutionary algorithms, such as a backpropagation neural network coupled with a genetic algorithm (GA-BPNN), allows for more accurate performance prediction in the leaching of copper oxides under ammoniacal conditions [39]. This approach simultaneously optimizes the ammonium concentration, pH, and temperature—crucial variables for preventing the formation of passivating species and achieving high copper recovery.

Experimental Design Methods for Concentrates and Tailing Leaching

Other authors, including Mbuya et al. [40], have employed Taguchi and ANOVA to optimize the leaching of tailings containing copper and cobalt, demonstrating that integrating these statistical tools facilitates identifying robust conditions against parameter fluctuations (temperature, time, concentrations, etc.). Similarly, Zandevakili et al. [41] apply the Taguchi method to fine-tune the leaching of Sarcheshmeh concentrate, whereas Borsynbayev et al. [42] propose an electrohydropulse discharge-based method to improve copper extraction from tailings. These studies underscore the importance of experimental planning in the mining industry, where mineralogical and operational variability pose an ongoing challenge [2,5].

Optimization and Modeling in Alkaline and Ammoniacal Systems

Process optimization in ammoniacal and alkaline solutions is also demonstrated by Nadirov et al. [43] who use mathematical models to identify optimal conditions for copper and zinc leaching from smelting slags. Their work confirms the critical role of carefully managing medium chemistry and the liquid–solid ratio, aspects of equal relevance to heap leaching [12].

Environmental Assessment and Water Resource Utilization

Access to water resources constitutes another essential factor. Goodboy and Missimer [44], for instance, compare the use of desalinated versus filtered seawater in copper extraction at mines located at high altitudes and in arid regions. While the study is not primarily focused on leaching kinetics, its findings complement the debate on water management and sustainability—critical elements in copper heap leaching, where the water balance is paramount [1].

Innovations in Heap Leaching Techniques

The deep well rinsing methodology proposed by Rucker [13] demonstrates the feasibility of injecting leaching solutions into deep wells to enhance copper extraction rates in oxidized ores. This approach becomes especially relevant when the heap exhibits structural heterogeneity or when surface drainage is hindered.

Leaching Dynamics and Metallurgical Efficiency

Studies such as Yuan et al. [45] highlight the importance of kinetic characterization and dynamic testing for recovering copper and silver from tailings, emphasizing the synergy between leaching parameters (chemical agent, temperature) and the overall profitability of the process. Additionally, Estay and Díaz-Quezada [46] “deconstruct” the so-called leaching ratio, a widely used industrial-scale simplification, pointing out that adopting more detailed kinetic models could enhance predictions of copper extraction and enrich heap leaching planning.

Application of Advanced Materials for Metal Containment

Regarding impact mitigation, Mazarji et al. [47] work with metal–organic frameworks (MIL-101) and biocarbons as amendments in contaminated soils, demonstrating their ability to immobilize copper (among other contaminants). Although the primary focus is the retention of metals in soils, such encapsulation strategies can be extrapolated to stabilize tailings or reduce metal migration in discontinued heap leaching systems.

3.3.3. Contributions to Research

Overall, the studies in Cluster 3 reinforce several key aspects in Sustainable Leachate Recovery (SLR):

- Statistical and Computational Models: Using RSM, Taguchi, ANOVA, and GA-BPNN (among others) refines parameters and detects nonlinear relationships in copper leaching, bolstering the robustness and repeatability of the process.

- Closed-Loop Approaches and New Technologies: Countercurrent leaching, raffinate reuse, and the injection of leachants into deep wells exemplify operational innovation aimed at metallurgical efficiency and optimized water consumption.

- Water Management and Environmental Factors: The adoption of desalinated or filtered water and the application of advanced materials for contaminant containment underscore the significance of environmental considerations, aligning with the sustainability mandate prevalent in the industry.

- Industrial Scale-Up Considerations: Studies by Movahhedi et al. [38], Goodboy and Missimer [44], and Rucker [13] reveal the complexities of scaling up, highlighting the need for pilot-scale tests and the adaptation of operations to local conditions (altitude, arid climate, mineral characteristics).

From the viewpoint of copper heap leaching, these contributions help consolidate methodologies for controlling and optimizing irrigation rate, temperature, and chemical reagent concentrations, while opening the door to alternative water strategies and more precise, reliable statistical models. In line with the holistic perspective of this research, they underscore the importance of comprehensive, multivariable control to achieve higher recovery levels and minimize the environmental impacts inherent to mining activities.

3.4. Cluster 4: Advances in Leaching of Oxidized and Complex Copper Ores

3.4.1. Cluster Overview

This fourth cluster encompasses a range of studies on copper extraction from oxidized and complex ores, highlighting a variety of reagents and methodologies—organic acids, ammoniacal solutions, surfactants, etc.—as well as their integration with flotation processes and kinetic-control strategies. Overall, these works underscore the importance of selectively adjusting operational parameters (pH, leaching agent, temperature, additives) to increase the copper dissolution rate and reduce costs, aspects equally relevant in large-scale heap leaching [12,48,49].

3.4.2. Key Findings

Organic Acids in Leaching Oxidized Copper Ores

Yaras and Arslanoglu [50] demonstrate that formic acid is effective in dissolving low-grade copper (malachite). Their study highlights the possibility of extending this route to other similar species (e.g., cuprite), provided that physicochemical parameters such as proton activity and formate concentration are carefully managed. This “organic” leaching proposal aligns with the growing trend of exploring “green” and eco-friendly reagents [10,11] to mitigate the environmental risks associated with using strong mineral acids.

Ammoniacal Systems and Specific Chelating Agents

Xiao et al. [14] examine the behavior of an oxidized copper ore with high gangue alkalinity when EDTA · 2Na is employed, emphasizing the preferential complexation of copper and the mitigation of side reactions with alkaline components. The use of chelators or complexing agents emerges as an alternative in cases where the presence of carbonated or silicate gangues hinders copper extraction using conventional acids. Similarly, Han et al. [51] confirm that activation with NH4HF2 in an ammoniacal medium (NH3-NH4Cl) enhances the dissolution of low-grade complex ores.

Leaching of Refractory Oxides and Copper Loss in Tailings

From another viewpoint, Wang et al. [52] investigate the behavior of refractory oxidized ores from the Yulong region (Tibet), placing emphasis on agitation and the need to optimize costs and recovery efficiency. Likewise, Aghazadeh et al. [8] and Ambo et al. [53] demonstrate the feasibility of combining leaching processes with pre-flotation or physical preconcentration methods (e.g., near-infrared sensors) to increase copper grade and reduce inert gangue before the main dissolution stage.

Kinetic Contributions and Leaching Models

Robertson [12] delves into the significance of an integrated flow-and-mineral-leaching model, addressing the solution transport dynamics in large heaps. This approach aligns with the case studies of Hosseinzadeh et al. [54] and Shi et al. [55], who assess leaching kinetics in low-grade ores and smelting slags, respectively. Both adopt the shrinking-core model or other kinetic variants to describe copper extraction and distinguish the controlling step (surface chemical reaction vs. diffusion through the product layer).

Acidification and Reagent Support in Ore and Slag Dissolution

In line with these findings, Deng et al. [56] explore the action of lactic acid in leaching oxidized ores, observing that temperature and reagent concentration strongly influence dissolution kinetics. Additionally, Wang et al. [2] describe a complementary method combining sulfide ore flotation with acid leaching of tailings to optimize overall copper recovery. Meanwhile, Yingwei et al. [57] focus on recovering tellurium from a copper–tellurium material, underscoring the versatility of H2O2 as an oxidant in acidic systems.

Synergy with Electrometallurgical Techniques and Surfactants

El-Okazy et al. [58] demonstrate copper recovery by electrodeposition from an acidic leach liquor, underscoring the importance of integrating hydro- and electrometallurgical techniques to produce a high-purity product. In parallel, Ai et al. [48] and Ai et al. [49] highlight the accelerated copper leaching achieved with surfactants, reducing surface tension and improving particle wettability. This aspect can be critical in large-scale heaps, where permeability and uniform irrigation are vital [13].

Methods, Effective Reagents, and Influence of Key Variables

Studies using organic acids report high copper extractions when both acidity and temperature are controlled. For example, Yaras and Arslanoglu [50] and Deng et al. [56] leach malachite and other oxidized ores with 1.0 mol formic acid at 60 °C and 0.8 mol lactic acid at 65–70 °C, obtaining 85–95% Cu while keeping the pH < 2. In ammoniacal media, Xiao et al. [14] reach about 92% recovery by adding 0.15 mol EDTA·2Na (pH 9–10, 45 °C), showing that selective complexation can overcome gangue alkalinity. Activation with 0.10 mol in Cl, as tested by Han et al. [51], raised copper dissolution from 48% to 83% at 50 °C through removal of silicate coatings. Low-dose surfactants (0.05–0.10 g SDS) reduced surface tension and improved diffusion, giving an extra 10–12% Cu at ambient temperature [48,49]. Finally, kinetic tests on refractory Yulong ores show that increasing the temperature from 25 °C to 70 °C roughly doubles the rate constant, although energy costs and impurity precipitation rise markedly above 60 °C [52]. Overall, the evidence identifies practical operating windows—pH < 2 for organic acids, pH 9–10 for ammoniacal systems, and 40–70 °C for temperature—and confirms that maximising copper recovery depends on matching each reagent system with tight control of pH and temperature.

3.4.3. Contributions to Research

The works compiled in this Cluster 4 complement Sustainable Leachate Recovery (SLR) with proposals centered on

- New Reagents and Operating Conditions: Use of organic acids [50,56], complexing agents such as EDTA [14], and surfactants [48,49] to optimize dissolution kinetics and reduce passivating byproducts.

- Kinetic Control and Advanced Modeling: Assessing the controlling mechanisms in leaching (chemical interface vs. diffusion), developing integrated mineral flow models [12], and validating them experimentally in different mineral matrices [54,55].

- Utilizing Tailings and Slags: Combining flotation–leaching strategies [2], treating slags with H2SO4 [55], or addressing complex ores [51] to maximize copper recovery and make use of residues normally discarded.

- Integration with Electrometallurgical Stages: Cases where leaching is followed by electrodeposition to obtain higher-purity copper, thereby extending the value chain [58].

Overall, these studies support the premise that optimizing copper leaching—whether in heaps or agitated reactors—depends on a blend of approaches: rigorous control of operational variables, careful reagent selection, and the application of suitable kinetic models to predict extraction rates and the formation of detrimental species (jarosites, passivating compounds, etc.). From the SLR perspective, adopting organic reagents, chelating agents, and “eco-friendly” surfactants appears promising for improving both performance and environmental sustainability of the process, provided that the leaching process and potential environmental impacts are managed in a comprehensive manner.

3.5. Cluster 5: “Green” Applications and Innovative Oxidants for Copper and Other Metal Recovery

3.5.1. Cluster Overview

This fifth cluster compiles research on more ecological (green) methods for recovering copper and other metals, with special attention to alternative reagents such as glycine and to kinetic strategies involving novel oxidants. The unifying theme across these studies is the pursuit of a balance between metallurgical efficiency and environmental sustainability, in line with the notion of Sustainable Leachate Recovery (SLR).

3.5.2. Key Findings

Glycine as a Selective and Eco-Friendly Agent

Barragán-Mantilla et al. [10] investigate the use of glycine for recovering copper from mining residues and less conventional ores, emphasizing its low environmental impact and the possibility of implementing a closed circuit to reduce effluent generation. This approach aligns with trends favoring “green” agents and minimizing aggressive reagent addition in copper heap leaching [11,23].

Application of Glycine in Smelting Slags

Huang et al. [11] develop a method for copper leaching from copper smelting slags using an alkaline glycine solution. High selectivity in copper extraction is observed, facilitating subsequent separation of other metals. This underscores the potential of glycine-based complexing leaching in alkaline conditions, where pH control and metal–ligand coordination play a pivotal role.

Recovery in Sediments and E-Waste with Environmental Metrics

Li et al. [59] address copper recovery in acidified sediments containing cupric thiocyanate (CuSCN) from the gold industry, demonstrating the feasibility of a “green” method that reduces hazardous chemicals and toxic effluents. Separately, Rezaee et al. [60] examine a staged glycine–permanganate leaching process for the valorization of base and precious metals (Au, Ag) in printed circuit boards (PCBs). Their study includes a life-cycle assessment (LCA), illustrating the reduced environmental footprint compared to conventional hydrometallurgical routes.

Oxidant-Based Approaches and Synergy with Other Additives

Though primarily focused on molybdenite, Shoghian-Alanaghi et al. [61] underscore the importance of employing specialized oxidants (H2O2, MnO2, or even Cu2+) where an intensified dissolution rate is desired. Moreover, the effect of adding ethylene glycol and oxygen is evaluated, increasing surface reactivity. This type of “combined” strategy can be extrapolated to copper heap leaching when co-oxidants and surfactants are used to improve infiltration and leaching kinetics [5,48].

3.5.3. Contributions to Research

The works included in Cluster 5 highlight the importance of

- Promoting mild and eco-friendly reagents, such as glycine, to reduce process toxicity and meet stricter environmental regulations.

- Designing staged leaching sequences, employing permanganate or co-oxidants, which facilitate precious-metal extraction and e-waste management Rezaee et al. [60].

- Assessing the synergy between leaching agents and oxidants (as in the use of ethylene glycol combined with H2O2 and O2), a way to enhance dissolution rate and lower operating costs Shoghian-Alanaghi et al. [61].

- Incorporating environmental indicators and life-cycle modeling (LCA) to objectively compare “green” pathways against conventional methods.

In the context of copper heap leaching, these advances suggest adopting combined strategies—glycine, “mild” oxidants, multistage leaching sequences—that could boost overall recovery and reduce the load of contaminants in the Pregnant Leach Solution (PLS). This approach aligns with the Sustainable Leachate Recovery (SLR) framework, in which metallurgical efficiency and environmental sustainability constitute a dual objective that is crucial for twenty-first-century copper mining.

3.6. Cluster 6: Leaching and Metal Recovery from E-Waste, Anode Slimes, and Industrial Residues

3.6.1. Cluster Overview

The sixth cluster covers studies focusing on metal extraction and recovery—chiefly copper, gold, and other valuable elements—from complex secondary sources such as integrated circuits, waste electrical and electronic equipment (WEEE), anode slimes, and NMC-type battery residues. These investigations highlight diverse reagents (including bromotrihalide ionic liquids, Na2S2O8, and strong acids) and the implementation of pressure-leaching and electro-generation techniques to optimize leaching kinetics and selectivity. Additionally, statistical modeling strategies and the feasibility of catalytic electrodeposition technologies are discussed to promote more sustainable metal utilization.

3.6.2. Key Findings

Novel Ionic Liquids for Gold and Copper Recovery

With a view to exploiting precious and base metals from circuit boards, Yin et al. [62] propose bromotrihalide-based ionic liquids capable of selectively dissolving gold and copper via a redox mechanism. They emphasize low toxicity and high extraction efficiency, both factors aligning with the quest for “green” and cost-effective routes. Although this approach targets e-waste, it resonates with the need for similar strategies in copper heap leaching (SLR) when dealing with complex ores.

Statistical Assessment of WEEE Leaching with Na2S2O8

Popescu et al. [63] employ statistical methods to unravel the factors influencing the dissolution of copper, zinc, and brass from electronic devices in a sodium persulfate (Na2S2O8) solution. Their work underscores the roles of temperature, contact time, and oxidant concentration, findings consistent with studies on sulfide or oxidized ores where adding oxidants (e.g., H2O2, Fe3+) can accelerate leaching kinetics [5,7].

Anode Slime Treatment and Pressure Leaching

An emerging field involves the treatment of anode slimes generated during copper electrorefining. Li et al. [64] propose an alkaline fusion followed by leaching to recover both copper-bearing and precious metals, whereas Seisko et al. [65] emphasize pressurized leaching of decopperized anode slimes, attaining high recoveries under strongly acidic conditions. This underscores both the significance of pressure leaching as a complement to heap leaching and the necessity for stringent pH and Eh control to maximize yield [12].

Electrochemistry and E-Waste-Related Technologies

Electrochemical techniques figure prominently in Li et al. [66] and Fathima et al. [67], which describe recovering copper and gold from memory modules and other electronic components. While Li et al. [66] couple electrooxidation in an HCl-H2O2 medium to simultaneously dissolve and recover metals, Fathima et al. [67] provide a critical review of catalytic electrodeposition for optimizing copper extraction from e-waste. In both cases, electrochemical control—whether by voltage or current—enhances selectivity and avoids passivating by-product formation, a principle also transferable to heap-leaching operations with subsequent electrolytic refining.

Battery Residues and Statistical Modeling

Partinen et al. [68] broaden the scope to “black mass” derived from lithium-ion batteries, containing metals such as Ni, Mn, and Co. They use experimental tests combined with regression modeling to understand leaching kinetics. Although their research focuses on the battery industry, the methodological approach—combining experiments with statistical modeling—aligns with optimizing copper heap leaching, where predicting kinetic behavior under varying acidity and irrigation conditions is crucial [6,46].

3.6.3. Contributions to Research

The works in Cluster 6 advance Sustainable Leachate Recovery (SLR) by

- Broadening the boundaries of leaching operations to include complex industrial byproducts (anode slimes, e-waste, spent batteries) with high copper or gold content.

- Integrating chemical and electrochemical leaching methods, particularly where rapid dissolution and simultaneous electrolytic metal recovery are sought.

- Employing advanced statistical and modeling techniques (e.g., design of experiments, multivariable regression) to elucidate how different operational factors interact in the leaching kinetics.

- Proposing ionic liquids and oxidants with lower environmental impact, paralleling the exploration of glycine and “green” surfactants for primary minerals.

Overall, these contributions highlight the need for a holistic perspective in the mining and recycling industries, where heap leaching could be complemented by electrolytic refining and innovative reagents to unlock the value of post-consumer waste and metallurgical byproducts. This approach aligns with the circular-mining trend and with reducing the environmental footprint associated with copper and precious-metal production.

3.7. Cluster 7: Biohydrometallurgy and Hybrid Methods for Copper Recovery from Electronic Waste

3.7.1. Cluster Overview

This seventh cluster brings together studies focusing on copper recovery from electronic waste and electric cables, emphasizing biohydrometallurgical methods and hybrid approaches that combine chemical, biological, and/or physical separation stages. The primary objective is to exploit the capacity of microorganisms (e.g., Acidithiobacillus ferrooxidans) to catalyze leaching, reducing reliance on harsh reagents and fostering more environmentally benign processes. These techniques can in part be extrapolated to heap leaching when bioleaching is introduced as an alternative or complement to conventional chemistry [5].

3.7.2. Key Findings

Copper Recovery from Electrical Cables by Bioleaching

Lambert et al. [69] examine copper leaching from discarded electrical cables, comparing purely chemical leaching to Acidithiobacillus-catalyzed leaching in terms of kinetics and reagent needs. A higher efficiency in copper dissolution emerges under well-controlled redox conditions, aided by biologically regenerated ferric iron. Controlling Eh, pH, and temperature—comparable to requirements in heap leaching of copper ore [6,7]—proves crucial for optimizing recovery rates.

Bio-Assisted Leaching of Pyrolyzed Circuit Boards

Building on this trend, Arinanda et al. [5] investigate copper recovery from pyrolyzed printed circuit boards (PCBs), examining how different operational parameters (e.g., agitation, ferric/ferrous concentration, dissolved oxygen) affect the dissolution of metallic copper. The process merges bio-oxidation of iron with subsequent copper dissolution, underscoring the role of microorganisms in continuously regenerating ferric species and enhancing selectivity, in accordance with bioleaching approaches for sulfide or oxide ores [10].

Hybrid Approaches and Copper Reuse

Conversely, Sinha et al. [70] propose a hybrid methodology for recovering and reusing copper from e-waste, integrating chemical leaching stages and low-cost biomaterials. The study highlights the feasibility of reintroducing recovered copper into industrial processes, thus closing the value loop and curbing the need for primary extraction. Such a circular-economy model aligns with the Sustainable Leachate Recovery (SLR) paradigm by prioritizing both metallurgical efficiency and waste minimization.

3.7.3. Contributions to Research

From a sustainable leaching perspective, the articles in Cluster 7 offer

- Bio-Assistance and Ferric Regeneration: Whether in electronic waste (cables or PCBs), bacteria like Acidithiobacillus can facilitate Fe3+ generation and speed up extraction kinetics, reducing large-scale oxidant requirements.

- Synergy between Chemical and Biological Processes: Integrating thermal pretreatment (pyrolysis), chemical leaching, and biological catalysis helps to optimize copper recovery, an approach with potential adaptation to heap leaching of difficult ores or byproducts.

- Use of Biomaterials and Circular Economy: Direct reuse of extracted copper, as in Sinha et al. [70], reinforces the circular-economy principle, where recovered metal is reinserted as a raw material—potentially extending to heap leaching circuits directly supplying electrowinning processes.

Overall, these approaches reaffirm the versatility of biohydrometallurgy and combined methods for optimizing copper recovery in a sustainable context, broadening the scope beyond primary mineral extraction and effectively applying these strategies to e-waste valorization. Under SLR, incorporating microorganisms and hybrid methodologies represents a promising path toward greater efficiency and reduced environmental impact in copper leaching.

3.8. Cluster 8: Modeling, Statistical Analysis, and Process Design for Copper Leaching

3.8.1. Cluster Overview

This eighth cluster groups studies that highlight the significance of statistical, mathematical, and computational modeling in copper leaching, spanning various approaches—from chemometric methods, response surface methodology, and experimental design, to machine-learning tools and multiscale models for predicting metal recovery. The common denominator is the pursuit of optimal conditions—tuning parameters such as leaching-agent concentration, column height, temperature, or irrigation rate—and the validation of these models under conditions of mineral heterogeneity.

3.8.2. Key Findings

Chemometrics and Chlorides in Sulfide Leaching

In Sokić et al. [71], a chemometric approach is employed to study the dissolution kinetics of chalcopyrite concentrate using sodium nitrate (NaNO3) in a H2SO4 medium, confirming that controlling variables such as the NaNO3:H2SO4 ratio and temperature significantly affects copper extraction rate. Similarly, Saldaña et al. [72] develop an analytical model for secondary sulfide leaching in chloridic media, underscoring the importance of chloride chemistry in enhancing copper recovery and proposing industrial alternatives when traditional sulfate environments fail to provide the desired kinetics.

Optimization via Response Surface Methodology and Experimental Design Models

Response Surface Methodology (RSM) appears in multiple studies. For instance, Yu et al. [73] use RSM to extract copper from refractory oxidized ores, whereas Hayati et al. [74] integrate it with Monte Carlo simulations to estimate copper leaching from e-waste under uncertainty. Likewise, Harichandan and Mandre [75] (in two successive publications) and Hernández et al. [76] demonstrate how to design and operate leaching systems (in both reactors and heaps) through statistical optimization techniques. These works underscore the relevance of variable interactions (pH, Eh, acid concentration, particle size, column height, etc.) in achieving optimal copper recovery.

Multiscale Models and Flow Simulations

From a more computational perspective, Ortega-Tong et al. [77] apply a reactive-transport model to identify the mineralogical controls governing in situ copper recovery. Similarly, Paspureddi et al. [78] propose a multiscale reactive-flow model in porous microstructures, a highly pertinent approach for predicting large-scale heap behavior by accounting for textural variability and the geo-chemical complexity of the ore [2,5].

Machine Learning and Neural Networks for Recovery Prediction

Machine learning has also found application in leaching. Flores and Leiva [79] compare various supervised learning algorithms to forecast copper recovery based on operational parameters. With a similar perspective, Harichandan and Mandre [75] evaluate both statistical models and artificial neural networks, highlighting the latter’s ability to capture nonlinear interactions and improve metallurgical performance predictions.

Modeling and Validation in Columns and Pilot Operations

Studies such as Wang et al. [80] (ISR in Kapunda, Australia) and Hoseinian et al. [81] (column leaching model for oxides) emphasize the importance of empirically validating models at the pilot or semi-pilot scale. Their findings demonstrate how intermediate-scale experimentation can validate—or refine—theoretical frameworks, thereby enabling scalability to industrial applications.

3.8.3. Contributions to Research

The works compiled in Cluster 8 are fundamental to Sustainable Leachate Recovery (SLR) by

- Enhancing predictive capabilities in copper leaching, integrating statistical methods (RSM, DOE), machine learning, and multiscale reactive-flow models.

- Demonstrating the usefulness of simulations to anticipate heap behavior under different conditions (height, particle size distribution, acid vs. chloride media, etc.), reducing costly trial-and-error testing.

- Underscoring the importance of variable interactions (pH, Eh, oxidant dosage, temperature) in dissolution kinetics, validating their relevance for the efficient and robust design and operation of leaching heaps.

- Highlighting methodological versatility, such as leaching in chloride media Saldaña et al. [72] or modeling with AI Flores and Leiva [79], providing new pathways for more stringent process control.

In conclusion, Cluster 8 accentuates the demand for analytical and computational tools to tackle the complexity of copper heap leaching, especially where mineralogical heterogeneity and large-scale flow dynamics complicate operational planning. Through these contributions, global optimization (metallurgical, economic, and environmental) becomes more attainable, bolstering SLR principles in the mining industry.

3.9. Cluster 9: Novel Approaches and Leaching Alternatives for Copper Complex Ores and Byproducts

3.9.1. Cluster Overview

This ninth cluster encompasses studies focused on copper extraction (and other valuable metals) from diverse sources: smelting slags, secondary sulfides in chloride media, tailings, and byproducts such as plant residues (CPR), as well as hybrid (bio-chemical) and solvometallurgical methods. These works highlight both the variety of reagents and environments (organic acids, deep eutectic solvents, pressurized media, chloride solutions, etc.) and the need to optimize leaching kinetics while anticipating environmental impacts.

3.9.2. Key Findings

Copper Slag Treatment and Kinetic Models

Sun et al. [82] delve into the kinetics of copper leaching from smelting slag using H2SO4 under atmospheric-pressure oxidation. Their findings suggest that control is governed by diffusion through the product layer, enabling up to 90% copper extraction under optimal conditions. Meanwhile, Topçu et al. [83] propose a deep eutectic solvent (based on choline chloride) to recover copper from slag; this “green” route reduces dependence on strong mineral acids and includes a predictive extraction model. Consistently, Gargul et al. [84] investigate the application of citric acid for leaching lead and copper from flash slags, confirming the feasibility of organic acids as an environmentally friendly alternative.

Bio-, Reactor, and Column Testing in Low-Grade Resources

In a comparative study, Panda et al. [85] combine reactor and column tests for two low-grade resources, finding that the combination of flotation and leaching significantly enhances recovery. Likewise, Wang et al. [2] describe controlled bioextraction of low-grade sulfide ores in columns using microorganisms and well-defined conditions (pre-leaching, temperature, irrigation distribution). This “well-controlled” design suggests adaptability to industrial heap leaching, where irrigation homogeneity is crucial [5].

Pressure Technologies and Advanced Processes

Green et al. [86] present a decade of experience in pressure leaching of copper concentrates at Morenci (U.S.), demonstrating high extractions and less impact compared to traditional pyrometallurgical methods. In turn, Mohamed et al. [87] detail the simultaneous recovery of copper and nickel from Egyptian ores via a “pug leaching” technique at moderate temperatures, underscoring the importance of optimizing variables (H2SO4/ore ratio, contact time, etc.). Combined agitation or pressurized conditions can boost the leaching rate and reduce costs.

Chloride Solutions, Tailings, and Byproducts

Schueler et al. [88] investigate the recovery of Cu, Zn, and Pb from sulfide tailings in a H2SO4/Cl− medium, revealing kinetic advantages and a more selective dissolution compared to the sulfate-only approach. Meanwhile, Turan et al. [89] employ ammonium salts for the selective extraction of copper from tailings, demonstrating that ammoniacal complexation at certain concentrations can favor copper transfer without requiring large volumes of acid. The recovery of lead from plant residues (CPR) is discussed by Li et al. [66], integrating a brine leaching process with precipitation and calcination—a method potentially applicable to copper recovery from byproducts in saline mixtures.

Comparative Appraisal of Alternative Leaching Media and Their Sustainability Trade-Offs

Recent studies allow a quantitative comparison of the main “non-conventional” lixiviants applied to complex ores and by-products. Acidic oxidation with H2SO4 remains the kinetic benchmark, reaching ~90% Cu recovery from smelting slag at 80 °C (10 g acid, 120 min) but generates sulfate-rich effluents that demand costly [82]. Citric acid, a biodegradable organic reagent, delivered 55–72% dissolution of flash-smelter slag at pH 2–3 and ambient temperature while lowering acute-toxicity indicators, although its high COD must be managed [84]. A choline-chloride/ethylene-glycol deep-eutectic solvent (DES) extracted up to ~85% Cu after 2 h at 90 °C, and the spent DES was recycled for five successive cycles with <5% efficiency loss, evidencing good circularity; its higher viscosity, however, may limit percolation in large heaps [83]. Finally, column bioleaching of low-grade sulfide tailings achieved 60–68% Cu after 35 days with minimal reagent input, although longer residence times and strict aeration control are required [2]. These data confirm that reagent selection involves a performance–environment balance whereby DES and organic acids reduce hazardous discharge, whereas bio-routes offer the lowest chemical footprint at the expense of slower kinetics.

Innovative Applications and Pilot-Scale Testing

Smolinski et al. [90] report on the utility of nuclear techniques (radiotracers with 64Cu) to track leaching kinetics and clarify extraction pathways, whereas Atta Mends et al. [91] address nickel and copper recovery from sulfide flotation tailings, reiterating the relevance of controlled leaching methodologies. Ambo et al. [92] describe the “selective leaching” of copper in infrared sensor–preconcentrated ores, illustrating the synergy between preconcentration techniques and leaching to improve feed grade and reduce contaminants. Finally, Kamariah et al. [93] introduce a solvometallurgical process using monoethanolamine to extract copper from chrysocolla, achieving high recovery at elevated temperatures and demonstrating the possibility of recycling the leachant.

Bioleaching and Toxicity in Metallurgical Residues

Potysz et al. [94] examine the bioleaching of slags and the residual toxicity of byproducts, demonstrating the complexities of managing metallurgical wastes. Such environmental implications resonate with previous heap-leaching studies, where the Pregnant Leach Solution (PLS) must meet purity standards for subsequent processing [11,95]. Likewise, Praburaman et al. [96] assess copper bioleaching in contaminated soils using an organic formulation (panchakavya), confirming that certain natural amendments can positively influence metal solubilization.

3.9.3. Contributions to Research

The works in Cluster 9 advance Sustainable Leachate Recovery (SLR) by

- Expanding the range of resources and byproducts (slag, tailings, contaminated soils, metallurgical residues) that can serve as feedstock for copper leaching under environmentally acceptable conditions.

- Showcasing various extraction pathways (leaching with organic acids, pressure processes, deep eutectic solvents, ammoniacal complexation, etc.), each offering distinct advantages depending on mineralogy and gangue composition.

- Highlighting methodological integration (column tests, reagent reuse, preconcentration via infrared sensors, radiotracers) to enhance recovery rates and reduce environmental footprints.

- Addressing toxicity and byproduct management, an essential aspect of the SLR philosophy, given that copper recovery must be coupled with the proper handling of undesirable metals and final residue.

In summary, the reviewed literature in this cluster demonstrates that copper leaching extends beyond conventional ores and acidic technologies, instead exploring novel reactive pathways and sustainable approaches capable of maximizing recovered value while minimizing environmental impact. This diversification reinforces the relevance of SLR as a strategy for contemporary mining, wherein technological innovation and sustainability criteria jointly define competitiveness and social acceptance of the sector.

3.10. Cluster 10: Metal Extraction and Environmental Effects of Minerometallurgical Wastes in the Context of Copper Leaching

3.10.1. Cluster Overview

The tenth cluster concentrates on investigations involving recovery of copper (and other metals) from metallurgical wastes (e.g., from zinc, brass, or spent catalysts) and the characterization of heavy-metal release in soils and environments impacted by mining. It also includes several studies that explore the potential use of copper tailings in geotechnical applications and the effects of different leachants on the release of contaminant metals. All of this aligns with the quest for more sustainable leaching methodologies and impact mitigation under Sustainable Leachate Recovery (SLR).

3.10.2. Key Findings

Copper Integration in Valuable-Element Extraction

Zhang et al. [97] (first reference in the cluster) and Zhang et al. [97] (third reference, same authors in another study) propose adding or involving copper powder in metal extraction from zinc-leaching residues and zinc ferrite, respectively. These investigations underscore the possible reuse of copper as a reducing or dissolution-promoting agent for other metals, emphasizing copper’s versatility in hydrometallurgical circuits and reinforcing the circular economy. Moreover, Sharma et al. [98] apply the Taguchi design to optimize copper and zinc leaching from spent CuO/ZnO/Al2O3 catalysts, illustrating the potential to recover copper from refining or chemical-processing industries.

Recovery from Tailings and Industrial Wastes